Photoautotrophic Microalgae Screening for Tertiary Treatment of Livestock Wastewater and Bioresource Recovery

Abstract

:1. Introduction

2. Materials and Methods

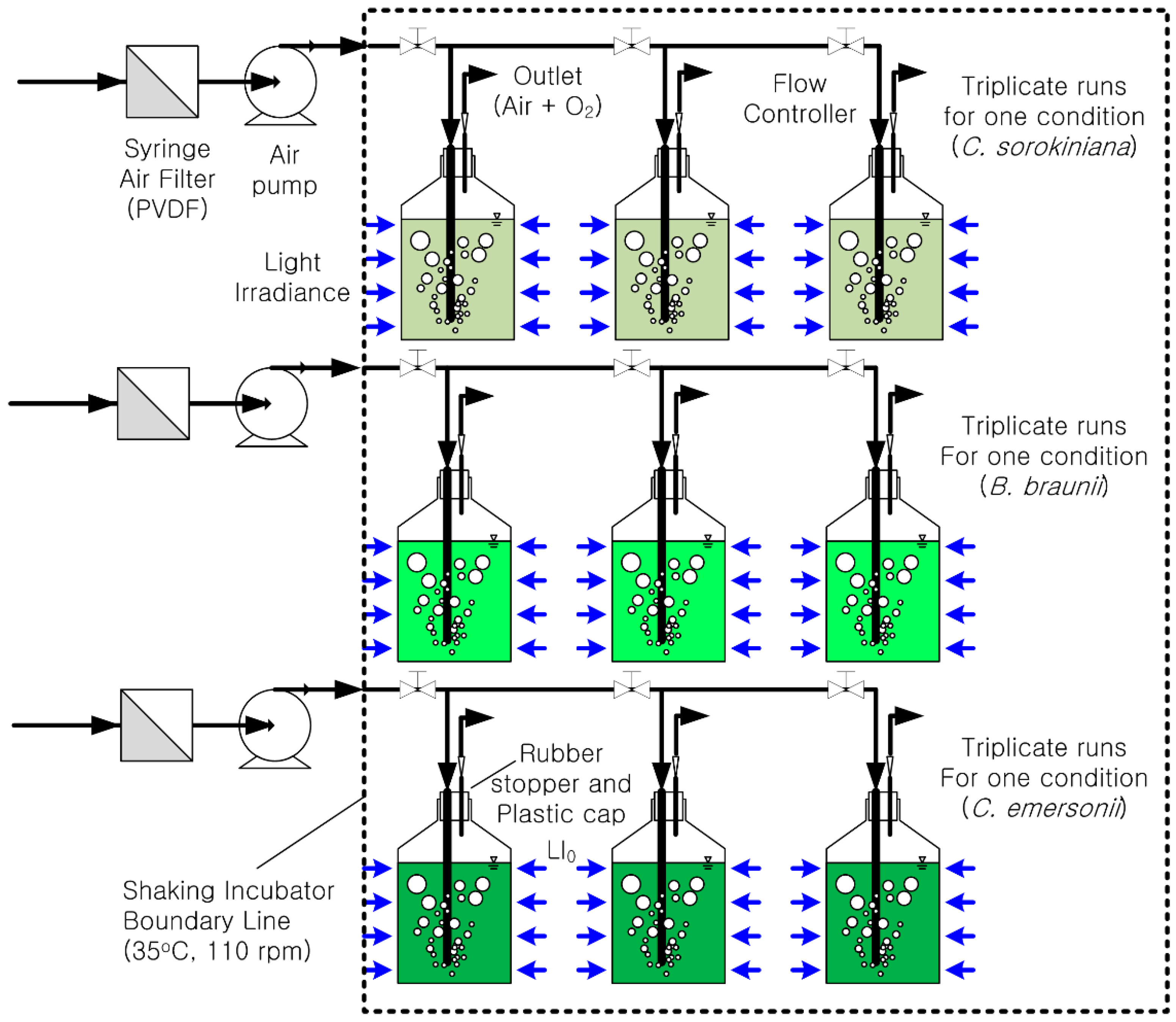

2.1. Experimental Set-up of the PBRs (Photobioreactors)

2.2. Inoculum and Culture Media

2.3. Regression and Statistical Analysis

2.4. Sampling and Analytical Methods

3. Results

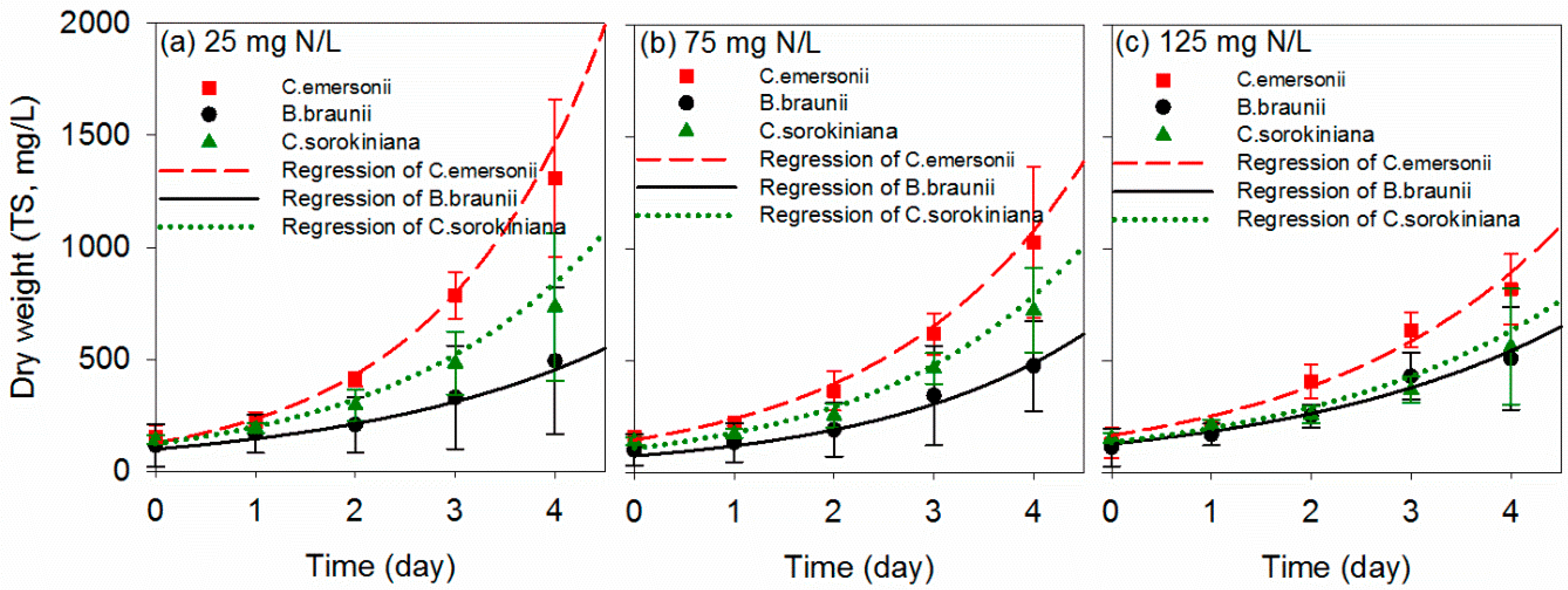

3.1. Photoautotrophic Growth Dynamics of Tested Microalgae

3.2. Growth Kinetics

3.3. TIC Removal

3.4. TN Removal

4. Discussion

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lee, S.; Maniquiz-Redillas, M.C.; Choi, J.; Kim, L.-H. Nitrogen mass balance in a constructed wetland treating piggery wastewater effluent. J. Environ. Sci. 2014, 26, 1260–1266. [Google Scholar] [CrossRef]

- Posadas, E.; Bochon, S.; Coca, M.; García-González, M.C.; García-Encina, P.A.; Muñoz, R. Microalgae-based agro-industrial wastewater treatment: A preliminary screening of biodegradability. J. Appl. Phycol. 2014, 26, 2335–2345. [Google Scholar] [CrossRef]

- Kim, H.W.; Vannela, R.; Zhou, C.; Harto, C.; Rittmann, B.E. Photoautotrophic nutrient utilization and limitation during semi-continuous growth of synechocystis sp pcc6803. Biotechnol. Bioeng. 2010, 106, 553–563. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.K.; Singh, M.P. Importance of algae as a potential source of biofuel. Cell. Mol. Biol. 2014, 60, 106–109. [Google Scholar] [PubMed]

- Wijffels, R.H.; Barbosa, M.J. An outlook on microalgal biofuels. Science 2010, 329, 796–799. [Google Scholar] [CrossRef] [PubMed]

- Tabernero, A.; Martin del Valle, E.M.; Galan, M.A. Evaluating the industrial potential of biodiesel from a microalgae heterotrophic culture: Scale-up and economics. Biochem. Eng. J. 2012, 63, 104–115. [Google Scholar] [CrossRef]

- González-Garcinuño, Á.; Tabernero, A.; Sánchez-Álvarez, J.M.; Martin del Valle, E.M.; Galán, M.A. Effect of nitrogen source on growth and lipid accumulation in scenedesmus abundans and chlorella ellipsoidea. Bioresour. Technol. 2014, 173, 334–341. [Google Scholar] [CrossRef] [PubMed]

- Ji, M.K.; Kim, H.C.; Sapireddy, V.R.; Yun, H.S.; Abou-Shanab, R.A.I.; Choi, J.; Lee, W.; Timmes, T.C.; Inamuddin; Jeon, B.H. Simultaneous nutrient removal and lipid production from pretreated piggery wastewater by chlorella vulgaris ysw-04. Appl. Microbiol. Biotechnol. 2013, 97, 2701–2710. [Google Scholar] [CrossRef] [PubMed]

- Takeshita, T.; Ota, S.; Yamazaki, T.; Hirata, A.; Zachleder, V.; Kawano, S. Starch and lipid accumulation in eight strains of six chlorella species under comparatively high light intensity and aeration culture conditions. Bioresour. Technol. 2014, 158, 127–134. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Yuan, W.; Pei, Z.; Mao, E. Culture of microalga botryococcus in livestock wastewater. In Transactions of the ASABE; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2008; Volume 51, pp. 1395–1400. [Google Scholar]

- Kim, H.-C.; Choi, W.J.; Ryu, J.H.; Maeng, S.K.; Kim, H.S.; Lee, B.-C.; Song, K.G. Optimizing cultivation strategies for robust algal growth and consequent removal of inorganic nutrients in pretreated livestock effluent. Appl. Biochem. Biotechnol. 2014, 174, 1668–1682. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.L.; Huang, C.C.; Ho, K.C.; Hsiao, P.X.; Wu, M.S.; Chang, J.S. Biodiesel production from wet microalgae feedstock using sequential wet extraction/transesterification and direct transesterification processes. Bioresour. Technol. 2015, 194, 179–186. [Google Scholar] [CrossRef] [PubMed]

- Sathish, A.; Marlar, T.; Sims, R.C. Optimization of a wet microalgal lipid extraction procedure for improved lipid recovery for biofuel and bioproduct production. Bioresour. Technol. 2015, 193, 15–24. [Google Scholar] [CrossRef] [PubMed]

- Kuo, C.M.; Chen, T.Y.; Lin, T.H.; Kao, C.Y.; Lai, J.T.; Chang, J.S.; Lin, C.S. Cultivation of chlorella sp gd using piggery wastewater for biomass and lipid production. Bioresour. Technol. 2015, 194, 326–333. [Google Scholar] [CrossRef] [PubMed]

- Shriwastav, A.; Gupta, S.K.; Ansari, F.A.; Rawat, I.; Bux, F. Adaptability of growth and nutrient uptake potential of chlorella sorokiniana with variable nutrient loading. Bioresour. Technol. 2014, 174, 60–66. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.-W.; Park, S.; Rittmann, B.E. Multi-component kinetics for the growth of the Cyanobacterium synechocystis sp. Pcc6803. Environ. Eng. Res. 2015, 20, 347–355. [Google Scholar] [CrossRef]

- Madigan, M.T.; Martinko, J.M.; Stahl, D.A.; Clark, D.P.; Brock, T.D. Brock Biology of Microorganisms; Pearson: Upper Saddle River, NJ, USA, 2012. [Google Scholar]

- Eaton, A.D.; Clesceri, L.S.; Rice, E.W.; Greenberg, A.E.; Franson, M.A.H. Standard Methods for the Examination of Water and Wastewater, 22nd ed.; American Public Health Association: Washington, DC, USA; American Water Works Association: Denver, CO, USA; Water Environment Federation: Alexandria, VA, USA, 2014. [Google Scholar]

- Wang, Y.; Ho, S.-H.; Cheng, C.-L.; Guo, W.-Q.; Nagarajan, D.; Ren, N.-Q.; Lee, D.-J.; Chang, J.-S. Perspectives on the feasibility of using microalgae for industrial wastewater treatment. Bioresour. Technol. 2016, 222, 485–497. [Google Scholar] [CrossRef] [PubMed]

- Eustance, E.; Gardner, R.D.; Moll, K.M.; Menicucci, J.; Gerlach, R.; Peyton, B.M. Growth, nitrogen utilization and biodiesel potential for two chlorophytes grown on ammonium, nitrate or urea. J. Appl. Phycol. 2013, 25, 1663–1677. [Google Scholar] [CrossRef]

- Zhu, L.; Wang, Z.; Takala, J.; Hiltunen, E.; Qin, L.; Xu, Z.; Qin, X.; Yuan, Z. Scale-up potential of cultivating chlorella zofingiensis in piggery wastewater for biodiesel production. Bioresour. Technol. 2013, 137, 318–325. [Google Scholar] [CrossRef] [PubMed]

- Illman, A.M.; Scragg, A.H.; Shales, S.W. Increase in chlorella strains calorific values when grown in low nitrogen medium. Enzym. Microb. Technol. 2000, 27, 631–635. [Google Scholar] [CrossRef]

- Borkenstein, C.G.; Knoblechner, J.; Fruehwirth, H.; Schagerl, M. Cultivation of chlorella emersonii with flue gas derived from a cement plant. J. Appl. Phycol. 2011, 23, 131–135. [Google Scholar] [CrossRef]

- Scragg, A.H.; Illman, A.M.; Carden, A.; Shales, S.W. Growth of microalgae with increased calorific values in a tubular bioreactor. Biomass Bioenerg 2002, 23, 67–73. [Google Scholar] [CrossRef]

- An, J.Y.; Sim, S.J.; Lee, J.S.; Kim, B.W. Hydrocarbon production from secondarily treated piggery wastewater by the green alga botryococcus braunii. J. Appl. Phycol. 2003, 15, 185–191. [Google Scholar] [CrossRef]

- Li, T.; Zheng, Y.; Yu, L.; Chen, S. Mixotrophic cultivation of a chlorella sorokiniana strain for enhanced biomass and lipid production. Biomass Bioenergy 2014, 66, 204–213. [Google Scholar] [CrossRef]

| Characteristics | Unit | Content |

|---|---|---|

| CODCr | mg·COD/L | 111.9 ± 16.7 |

| TN | mg·N/L | 15.4 ± 0.3 |

| TNH3 | mg·N/L | 13.4 ± 0.5 |

| TP | mg·P/L | 0.7 ± 0.0 |

| DOC | mg·C/L | 15.6 ± 0.4 |

| TIC | mg·Ci/L | 28.3 ± 0.6 |

| pH | - | 9.7 ± 0.1 |

| Initial Nitrogen (mg/L) | Specific Growth Rate (Day−1) | Doubling Time (Day) | ||||

|---|---|---|---|---|---|---|

| C. emersonii | B. braunii | C. sorokiniana | C. emersonii | B. braunii | C. sorokiniana | |

| 25 | 0.61 | 0.39 | 0.34 | 1.2 | 1.8 | 1.4 |

| 75 | 0.53 | 0.44 | 0.45 | 1.4 | 1.7 | 1.4 |

| 125 | 0.51 | 0.43 | 0.33 | 1.7 | 1.9 | 1.8 |

| Initial Nitrogen (mg/L) | TN removal Efficiency (%) | TN Removal Rate (Day−1) | ||||

|---|---|---|---|---|---|---|

| C. emersonii | B. braunii | C. sorokiniana | C. emersonii | B. braunii | C. sorokiniana | |

| 25 | 49.4 | 46.2 | 36.9 | 0.170 | 0.166 | 0.123 |

| 75 | 46.9 | 58.2 | 44.7 | 0.178 | 0.226 | 0.151 |

| 125 | 44.4 | 29.9 | 34.0 | 0.182 | 0.110 | 0.133 |

| Reference | Strain | Light Irradiance (µmol·E/s·m2) | Temperature (°C) | Nitrogen Concentration (mg/L) | Final Biomass Concentration (mg·DW/L) | Nitrogen Removal Efficiency (%) | Specific Growth Rate (Day−1) |

|---|---|---|---|---|---|---|---|

| This study | C. emersonii | 160 | 35 | 25 | 1461 | 53.7 | 0.55 |

| 160 | 35 | 75 | 1071 | 45.1 | 0.49 | ||

| 160 | 35 | 125 | 857 | 49.1 | 0.48 | ||

| [23] | 200 | 25 | N.A | 2060 | - | 0.10 | |

| [24] | 130 | 25 | 203 | 468 | - | 0.38 | |

| This study | B. braunii | 160 | 35 | 25 | 453 | 46.2 | 0.37 |

| 160 | 35 | 75 | 486 | 60.9 | 0.41 | ||

| 160 | 35 | 125 | 500 | 34.4 | 0.31 | ||

| [10] | 150–190 | 22 | 25 | - | 25.0 | - | |

| 150–190 | 22 | 75 | - | 46.7 | - | ||

| [11] | 75 | 25 | 110 | 1250 | 90.9 | - | |

| [25] | 100 | 25 | 204 | 2500 | 90.0 | 0.82 | |

| This study | C. sorokiniana | 160 | 35 | 25 | 557 | 41.5 | 0.42 |

| 160 | 35 | 75 | 786 | 41.5 | 0.43 | ||

| 160 | 35 | 125 | 657 | 35.3 | 0.39 | ||

| [26] | 100 | 25 | 160 | 680 | - | 0.63 | |

| 100 | 37 | 160 | 270 | - | 0.40 | ||

| [15] | 80 | 22 | 25 | 117 | 75.4 | 0.28 | |

| [14] | Chlorella sp. | 300 | 26 | 20 | >1500 | - | 0.47 |

| [11] | S. accuminatus | 75 | 25 | 163 | - | - | 0.57 |

| [21] | C. zofingiensis | 230 | 25 | 148 | 2860 | 82.7 | 0.34 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-Y.; Kim, H.-W. Photoautotrophic Microalgae Screening for Tertiary Treatment of Livestock Wastewater and Bioresource Recovery. Water 2017, 9, 192. https://doi.org/10.3390/w9030192

Kim J-Y, Kim H-W. Photoautotrophic Microalgae Screening for Tertiary Treatment of Livestock Wastewater and Bioresource Recovery. Water. 2017; 9(3):192. https://doi.org/10.3390/w9030192

Chicago/Turabian StyleKim, Ji-Yeon, and Hyun-Woo Kim. 2017. "Photoautotrophic Microalgae Screening for Tertiary Treatment of Livestock Wastewater and Bioresource Recovery" Water 9, no. 3: 192. https://doi.org/10.3390/w9030192