1. Introduction

Unsteady flow in rivers can be caused by natural or man-made floods, such as hydropower peaking operations. The unsteadiness of the flow [

1] ranges from gentle increase or decrease of flow depth and discharge over time, to more extreme events like flash floods or even dam break scenarios. Depending on the hydrograph, such discharge variations can affect the riverbed, banks and hydraulic structures differently than steady conditions do. Unsteady flow triggers processes like upwelling and downwelling, which govern the pressure gradient and pore water exchange in the hyporheic zone [

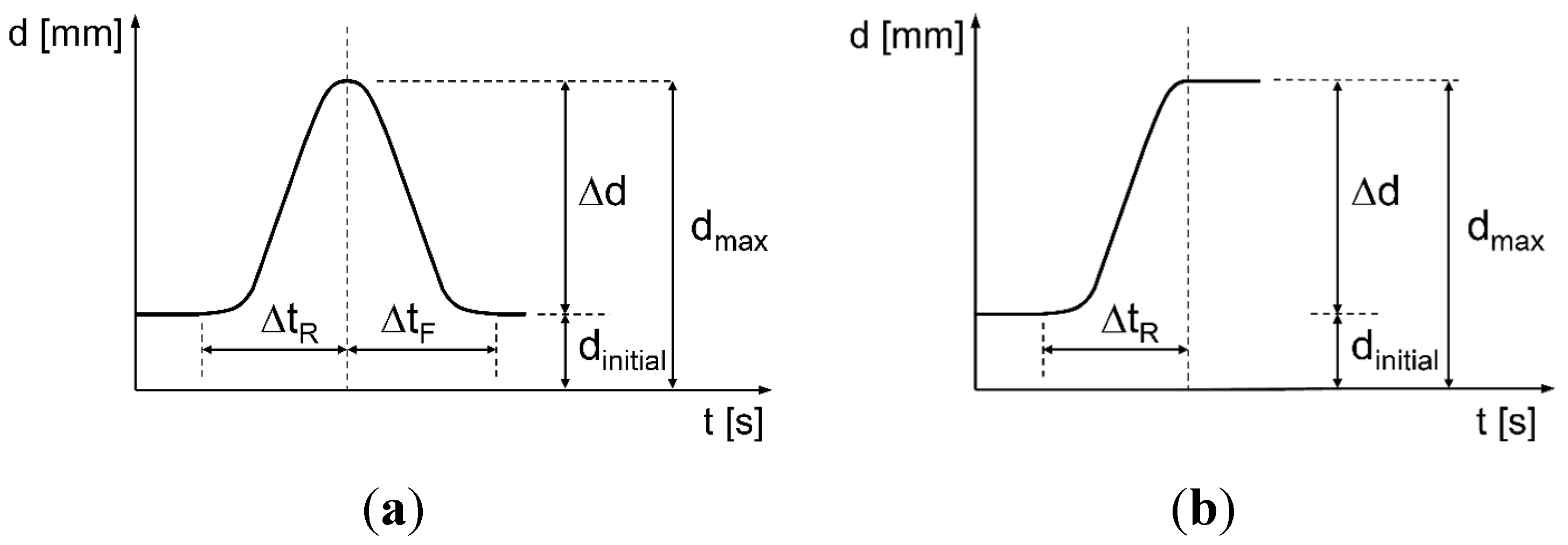

2]. In experimental investigations of unsteady flow, hydrographs for both increasing and decreasing discharge typically follow a curve such as schematically presented in

Figure 1a. Hysteresis effects are neglected in the present study. Symmetric hydrographs consist of a rising and a falling branch (

Figure 1a), in contrary to a one-sided hydrograph that exclusively consists of one branch: in case of

Figure 1b, a rising branch. Both hydrographs are characterized by the initial flow depth

, maximum flow depth

, the total depth increase or decrease

and the time duration for the rising branch

and falling branch

. The ramping rates,

and

, respectively, define the steepness of each branch. Graf and Suszka [

1] introduced an unsteadiness parameter

, which is used to combine the characteristics of a symmetric hydrograph in one factor:

where

represents the shear velocity of the initial uniform flow condition,

the initial bed shear stress,

the water density,

the local gravitational acceleration,

the flow depth and

is the bed slope. Furthermore,

denotes the total duration of the rising and falling branch of the hydrograph. A high unsteadiness parameter implies therefore a rapid or very strong flow variation.

Figure 1.

(a) Symmetric hydrograph; (b) One sided hydrograph.

Figure 1.

(a) Symmetric hydrograph; (b) One sided hydrograph.

Song and Graf [

3] performed an experimental study with unsteadiness parameters in the range of

. They state that most of the analyzed hydrographs in their study did not show significant effects of unsteadiness compared to quasi-steady assumptions, both regarding the horizontal velocity profiles and turbulence intensity. Only for the largest unsteadiness parameters in the experimental range, they reported minor differences in the velocity profiles and turbulence intensities for the rising and falling branch.

Bed shear stress and lift are key factors when it comes to estimating the incipient motion of particles and therefore to evaluate the effect of the water flow on the riverbed. While shear stress is widely accepted to describe the threshold of particle motion, the influence of lift is often underestimated [

4]. In fact, this has been a matter of debate over decades. Chepil [

5] concludes that both lift and drag must be considered to describe the threshold of soil grain movement due to fluid motion. Chi-Hai [

6] studied two thresholds for the incipient motion of particles: the rolling threshold and the lifting threshold, suggesting to apply both thresholds for sediment transport studies instead of using one combined “critical” parameter. This implies that lift should be regarded independently. More recently, Vollmer and Kleinhans [

7] point out the importance of “vertical pressure gradients in the upper sediment layer”, which are directly connected to a certain lift force acting on the bed surface. Further studies investigate the pressure fluctuations in and above gravel beds and link their results to incipient motion of single particles [

8,

9]. In addition numerical investigations such as Derksen and Larsen [

10] report strong lift forces, while others [

11] still argue that lift forces can be neglected. While those studies are all based on steady flow, limited research has been performed to investigate the effect of unsteadiness in free surface flows. Some unsteady flow experiments focus on velocity measurements, sediment transport behavior or studied the river as an ecosystem [

3,

12,

13,

14,

15,

16,

17]. Others address different types of flows, like gravity currents [

18,

19]. However, none addressed the direct influence of unsteadiness on bed shear stress and lift.

In the case of up- and downwelling, the pressure difference between surface water and ground water table causes surface water to infiltrate into the hyporheic zone or vice versa. Especially in armored gravel beds, where the armor layer has a porosity as low as 6% [

20], the pressure gradient can be expected to be very high, resulting in a significant pressure difference from directly above to directly below the armor layer. The armor layer can be regarded as a kind of barrier between surface and subsurface water. Logically, this strong pressure gradient exerts a vertical stress or lift on the bed surface in up- or downward direction. Up- and downwelling are slow processes and can be explained from a hydrostatic perspective. Thus, they can be described as quasi-steady effects and contribute to the static lift on an armor layer. However, it is still to be investigated whether the unsteadiness of the surface flow above the armor layer accounts for an additional dynamic lift on the surface particles.

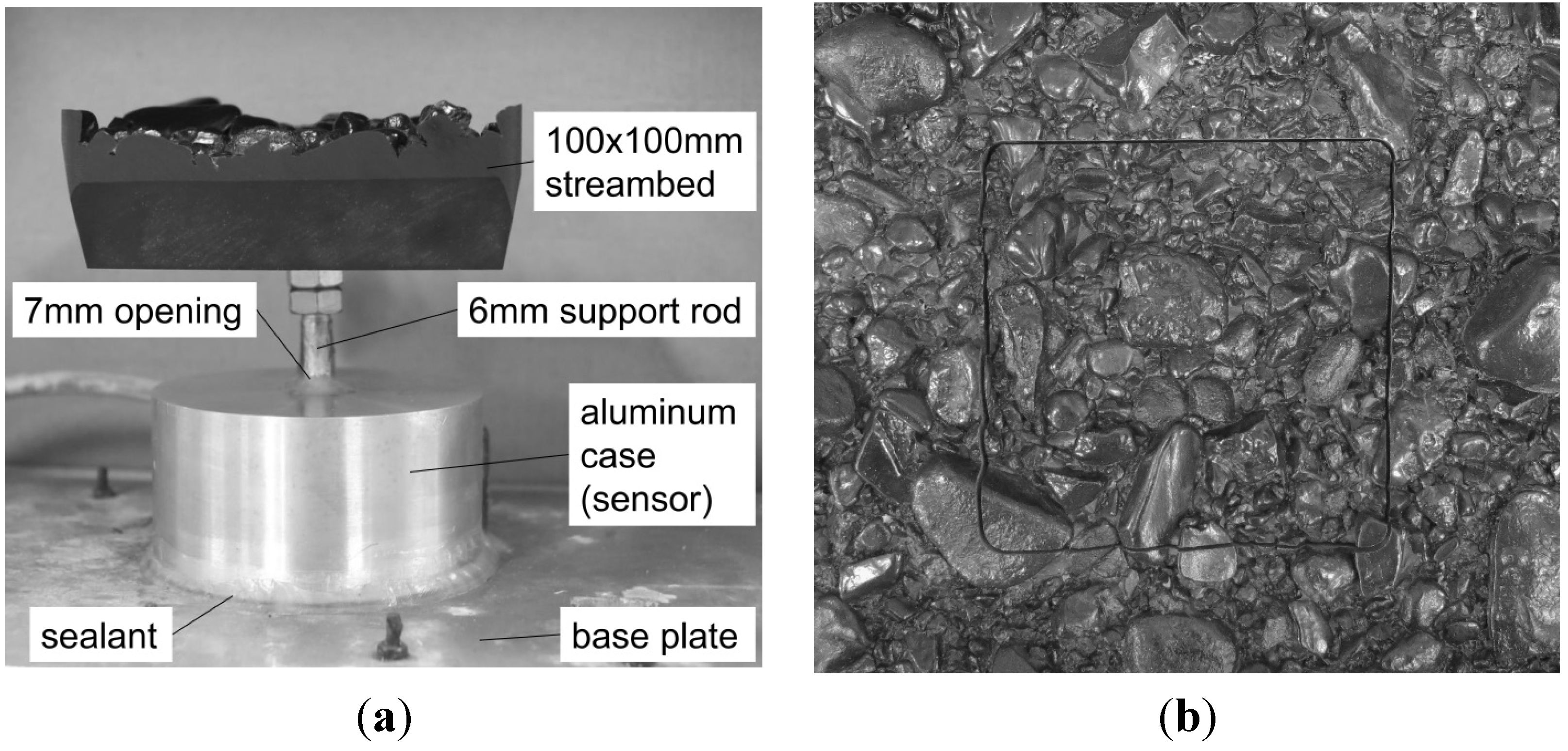

A direct measurement of shear stress and lift on a certain area of the riverbed is technically difficult because of its granular structure. In addition, granular bed surfaces, even in the form of static armor layers [

21,

22], are movable and therefore alter its surface arrangement over time. A single experiment rearranges the surface structure and changes the initial conditions for the subsequent experiment. Thus, the prerequisite conditions for a series of experiments are similar but not identical.

To overcome those problems, fixed beds or mixed forms of movable and fixed beds are reported in the literature. Previous studies partly included the use of pressure, drag or lift sensors [

23,

24,

25,

26]. A fixed or artificial streambed provides a persistent bed-surface structure for a series of experiments. Such beds often model a natural streambed artificially, with a well-defined, equally distributed roughness, using for example spherical obstacles [

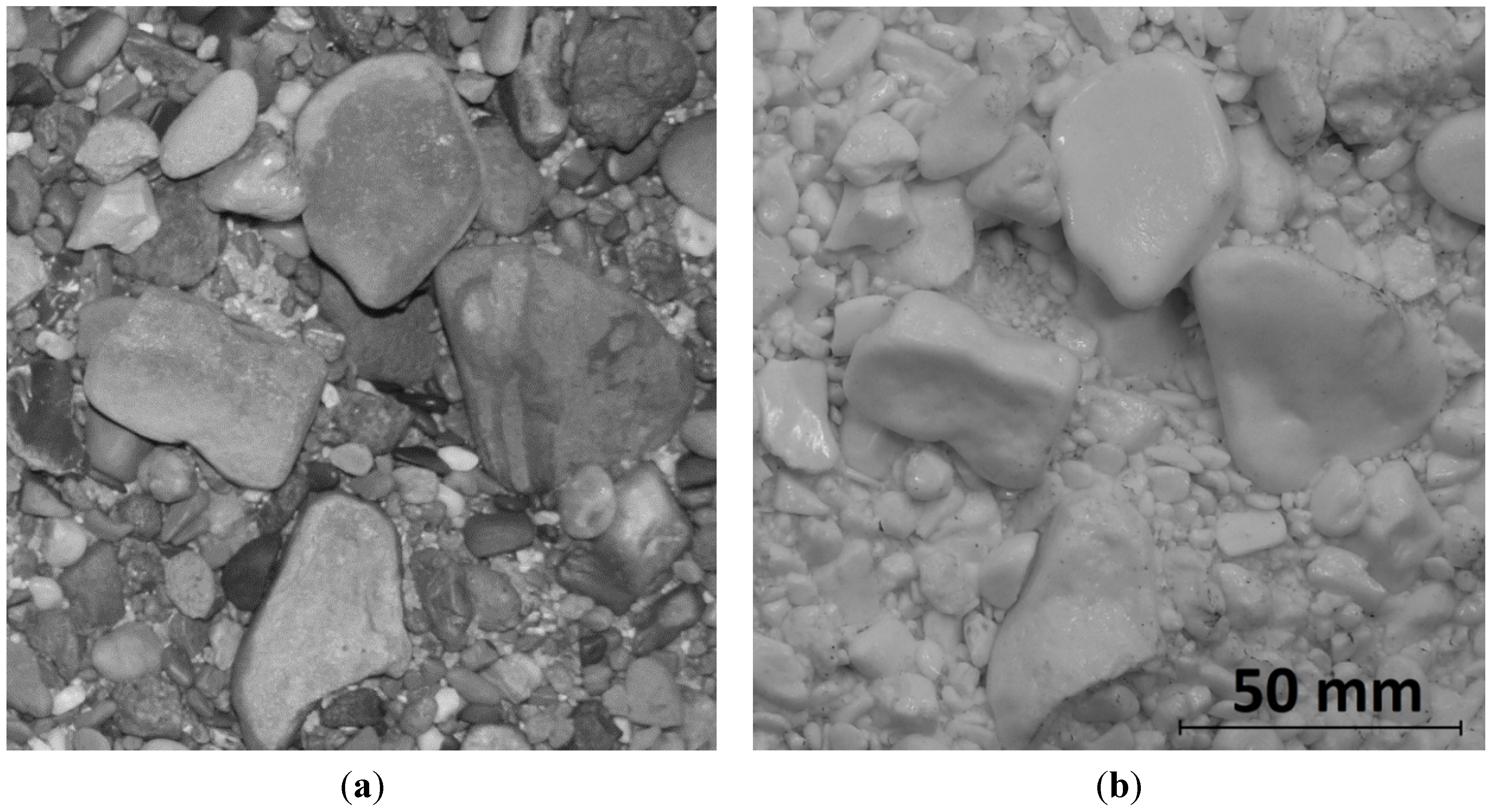

24]. The conditions for a series of experiments therefore represent an idealized model of a water-worked surface. To achieve a riverbed model closer to an original armor layer, Spiller

et al. [

27] present a technique to mold the surface structure of an actual gravel bed, which results in an artificial copy of a static armor layer. It models both exposed and hidden particles in great detail, including protruded surface grains and undercuts, and can produce multiple copies of the same surface structure. However, it does not model the subsurface porosity.

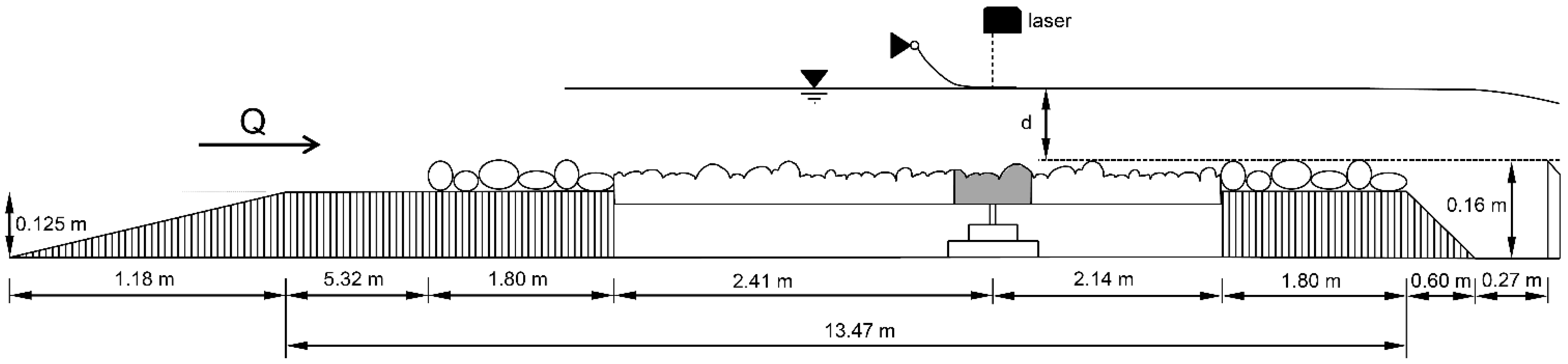

The present study provides results of direct lift measurements, using the aforementioned technique, for a large variety of flow variations. It focuses exclusively on increasing flow. Firstly, the experimental setup and all measurement devices are described in detail, followed by the experimental procedure. Secondly, the results of the experimental study are presented with focus on the influence of , , and the armor layer porosity. Herewith, is termed ramping duration. Thirdly, a discussion provides the perspective to link the experimental model to natural rivers. Finally, the key findings of this study are summarized in a conclusion.

4. Discussions

4.1. Model vs. Reality

The obtained data show a significant influence of single hydrograph characteristics on the dynamic lift. Two major simplifications were performed in the present study to model a natural gravel bed. The surface material, i.e., the static armor layer, was represented by a non-porous artificial streambed and the pore water, which is usually distributed within the granular structure of the subsurface material, was modeled by a non-moving, clear water body below the artificial streambed. This offers a unique opportunity to directly measure the total lift force on a streambed patch.

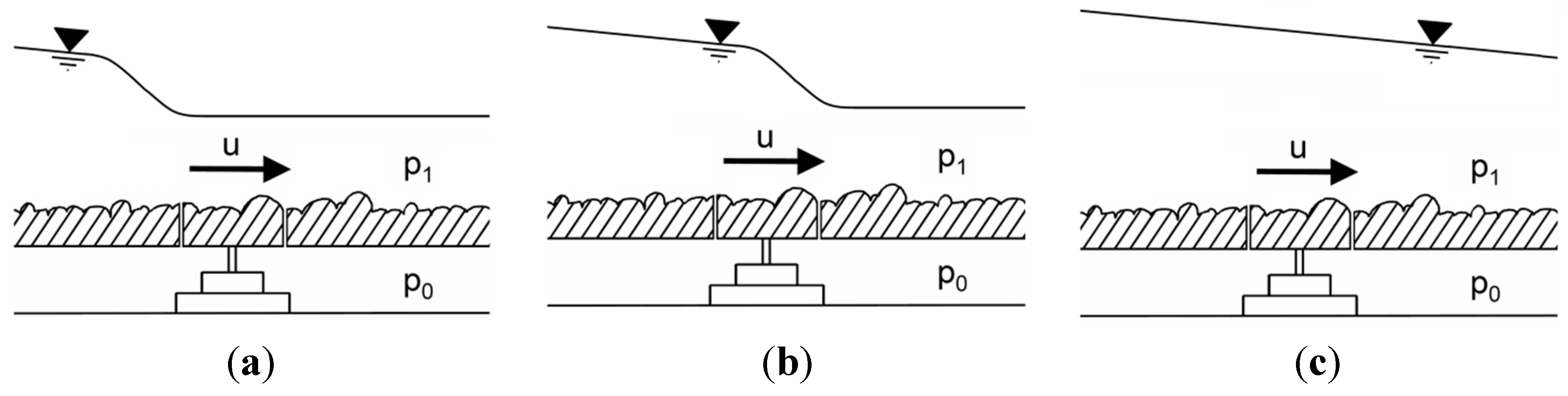

Figure 4 shows how the physical model of the present study compares to a real streambed. The model consists of a solid artificial armor layer, where the gap around the target piece is the only connection of surface and subsurface water in the vicinity of the sensor. However, a real armor layer is certainly a very close-grained structure, but still offers porosity. It therefore provides a well-distributed network of connections between surface and subsurface water. Hence, the pressure above the armor layer and the pore pressure in the subsurface material might communicate in a different way as they do in the model. Investigations [

20] have shown that the porosity of armor layers is much smaller (

compared to the subsurface material (

. The armor layer is comparable to an almost solid layer that divides the surface water from the underlying pore system, which is very close to the conditions in the model.

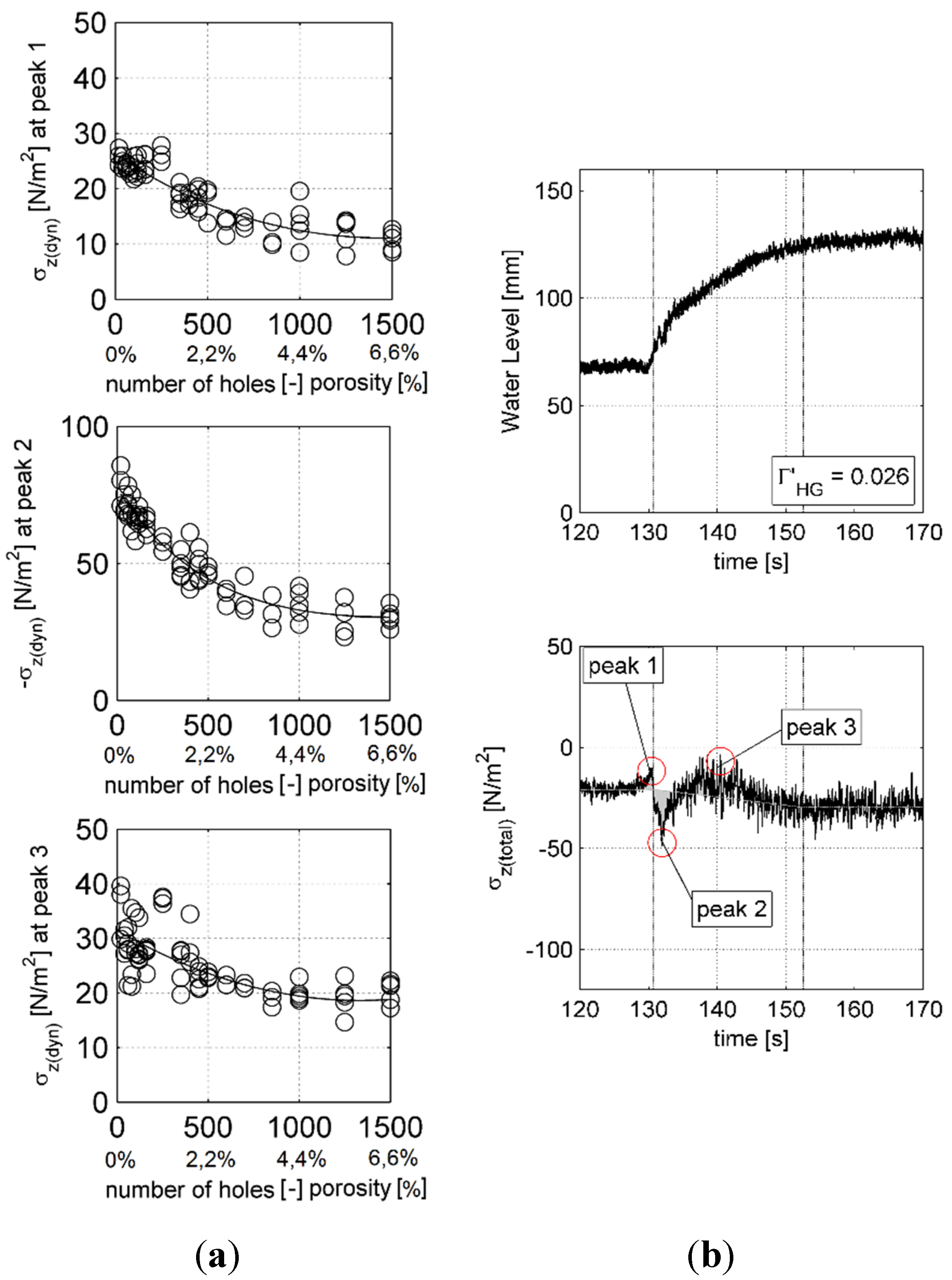

The present study further investigates the influence of the armor layer porosity by modifying the solid streambed and connecting the subsurface and surface water column via a number of randomly distributed holes. Accordingly, the natural armor layer porosity was underestimated by the solid bed (0 holes; ) and slightly overestimated by the most porous bed (1500 holes; = 6.6%). Both the upper and lower limit in porosity showed qualitatively similar results, so that comparable dynamic lift peaks can be expected in a natural gravel bed. Quantitatively however, expected values in a real armor layer might be estimated lower than the values from the solid bed results and slightly higher than the values of the most-porous bed results in this study.

It remains unclear whether the granular structure of real subsurface material implicates a general dampening or time lag of pressure exchanges between the surface- and subsurface water, compared to the clear water body in the model. It is, furthermore, uncertain what influence such a dampening would have on the observed dynamic lift peaks. An adjusted model, including a granular subsurface material below the porous streambed, might be applicable for future investigations regarding the influence of the subsurface material, which should also include pressure measurements above and below the armor layer.

4.2. Range of Unsteadiness Parameters

Unsteady flow in rivers has various origins such as natural floods, hydropower peaking or even dam break scenarios. The unsteadiness of the flow in such examples can range from mild flow variations, to very rapid fluctuations. To cover most of this variety, the present study included hydrographs with a wide range of unsteadiness parameters,

. As a practical example: Recent field studies on hydropower peaking have shown that unsteadiness parameters of

and higher, also occur in real gravel bed streams. Applying Equation (2) to the raw data of a field study at River Lundesokna in Norway [

2], a hydrograph with an unsteadiness parameter of

could be observed downstream a hydropower plant on 30 January 2012. In comparison, the largest unsteadiness parameter in the study of [

3] is

, resulting in hardly recognizable significant unsteady effects for this measurement range (

Figure 7). Song and Graf [

3] used a slightly wider but comparable channel to the one in the present study. The maximum specific discharges used in both studies were also in a similar range. The present study, however, covered lower initial depths, as well as higher ramping rates.

4.3. Negative Lift during Steady Flow

During steady flow, negative lift was experienced in the present study. Einstein and El-Samni [

4] stated the lift on a rough surface during steady open channel flow to be generally positive in upward direction. A possible explanation for the contrary observations in the present study could be the individual shape of the streambed in the target piece area. The target piece area was carefully chosen to represent the entire streambed in order to draw general conclusions (see

Section 2.3). However, some areas of the riverbed are formed differently than others, so that the vertical stress on the bed is not equally distributed. Depending on the surface structure and the orientation in which single grains are exposed to the flow, it is only reasonable that some areas experience a slight lift. Others must be affected in the opposite way with a slight downward pressure. The integral of the vertical stress over a large area is still slightly positive in upward direction, according to [

4].

In fact, Friedrich

et al. [

30] performed velocity measurements during steady flow over the exact same artificial surface as the present study. The measurements show that an exposed grain upstream the target piece causes a downward velocity component in the target piece area. This downward velocity exerts a downward force or negative lift on the target piece. Higher discharges cause higher downward velocities and therefore a higher negative static lift in this area.

For the present study, a neutral section of the streambed would be preferred for lift measurements, since the static lift would be negligible and the measured total lift would directly represent the dynamic lift. However, it is difficult to identify which part of the bed surface acts in that way. Even though the chosen segment for force measurements was representative for the entire streambed in terms of shape and grain size distribution, it turned out to be subject to a negative static lift force. This tendency increases with the discharge and is persistent throughout all experimental runs.

To adjust the results for general conclusions, the static lift was subtracted from the total lift by relating all lift peaks to a quasi-steady reference line. In a neutral section of the riverbed, where neither lift nor downward pressure occurs during steady flow, this reference line would be constant at = 0. Any significant deviation of the force measurement from this reference line was regarded as dynamic lift, or in other words, an unsteady effect that is not describable with a quasi-steady approach. Thus, the dynamic lift, which is the core parameter of this investigation, is regarded to be representative for the entire flume, so that general conclusions can be drawn from this investigation.

4.4. The Cause of the Dynamic Lift Peaks

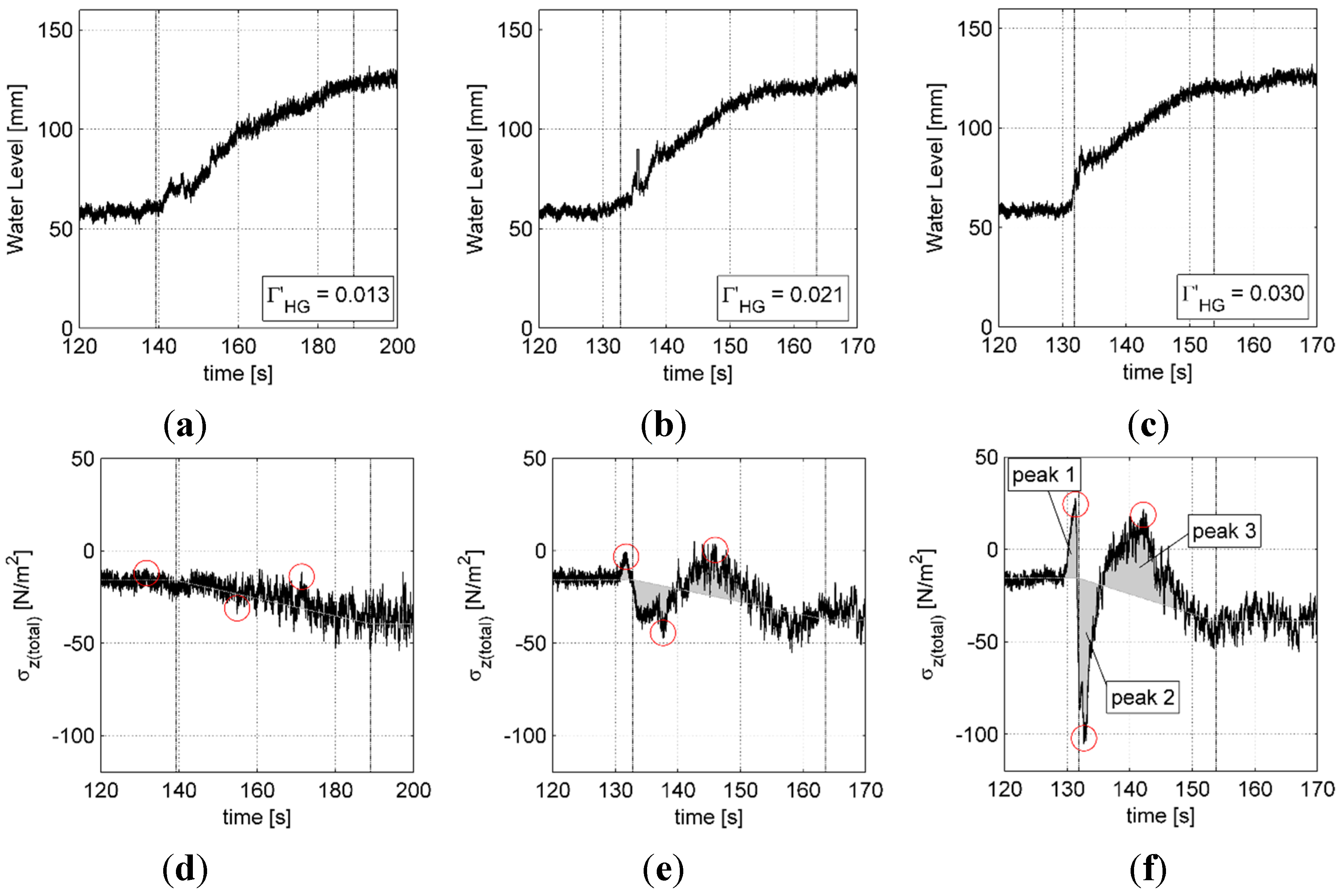

The first peak occurs a few seconds before the tip of the increasing water flow reaches the target piece.

Figure 11a shows the water level during Peak 1. A rather steep depth increase is approaching the test section. The main part of the measured lift in this case results from a pressure difference below and above the bed surface,

p0 and

p1, respectively. Peak 1 corresponds to a positive dynamic lift in upward direction,

p0 must therefore be larger than

p1. Assuming hydrostatic pressure above the target piece,

p1 correlates with the initial flow depth. On the other hand, below the target piece,

p0 seems to be partly influenced by the elevated flow depth further upstream. Through small gaps at the upstream end of the artificial bed as well as through the de-aeration holes in the PVC bars besides the artificial bed,

p0 could already build up to an increased level before the free surface wave above the bed reached the target piece. Hence, the target piece experiences a positive dynamic lift. In an actual riverbed, this translates to a situation where through a breach in the clogged armor layer, pressure builds up in the porous subsurface material and causes lift on the armor layer further downstream.

The beginning of the second peak coincides with the rather steep wave front arriving at the target piece (

Figure 11b). At a certain moment, the hydrostatic pressure above the bed surface increases significantly. At this stage, the subsurface pressure still depends partly on the increased pressure from upstream and the initial pressure from downstream, so that

p1 even exceeds

p0 for a moment causing negative lift. Peak 2 ends after a few seconds when

p0 adjusts to

p1.

Figure 11.

Schematic water level above the test section during the occurrence of the dynamic lift peaks: (a) Peak 1; (b) Peak 2; and (c) Peak 3.

Figure 11.

Schematic water level above the test section during the occurrence of the dynamic lift peaks: (a) Peak 1; (b) Peak 2; and (c) Peak 3.

The steep tip of the approaching flow increase is followed by a consistent increase in flow depth, lasting for a much longer time than Peaks 1 and 2. In a similar way to Peak 1,

p0 is possibly affected by the further depth increase approaching from upstream and causes positive dynamic lift,

i.e., Peak 3. Depending on the water surface slope, which directly correlates to the ramping rate, a larger difference between

p0 and

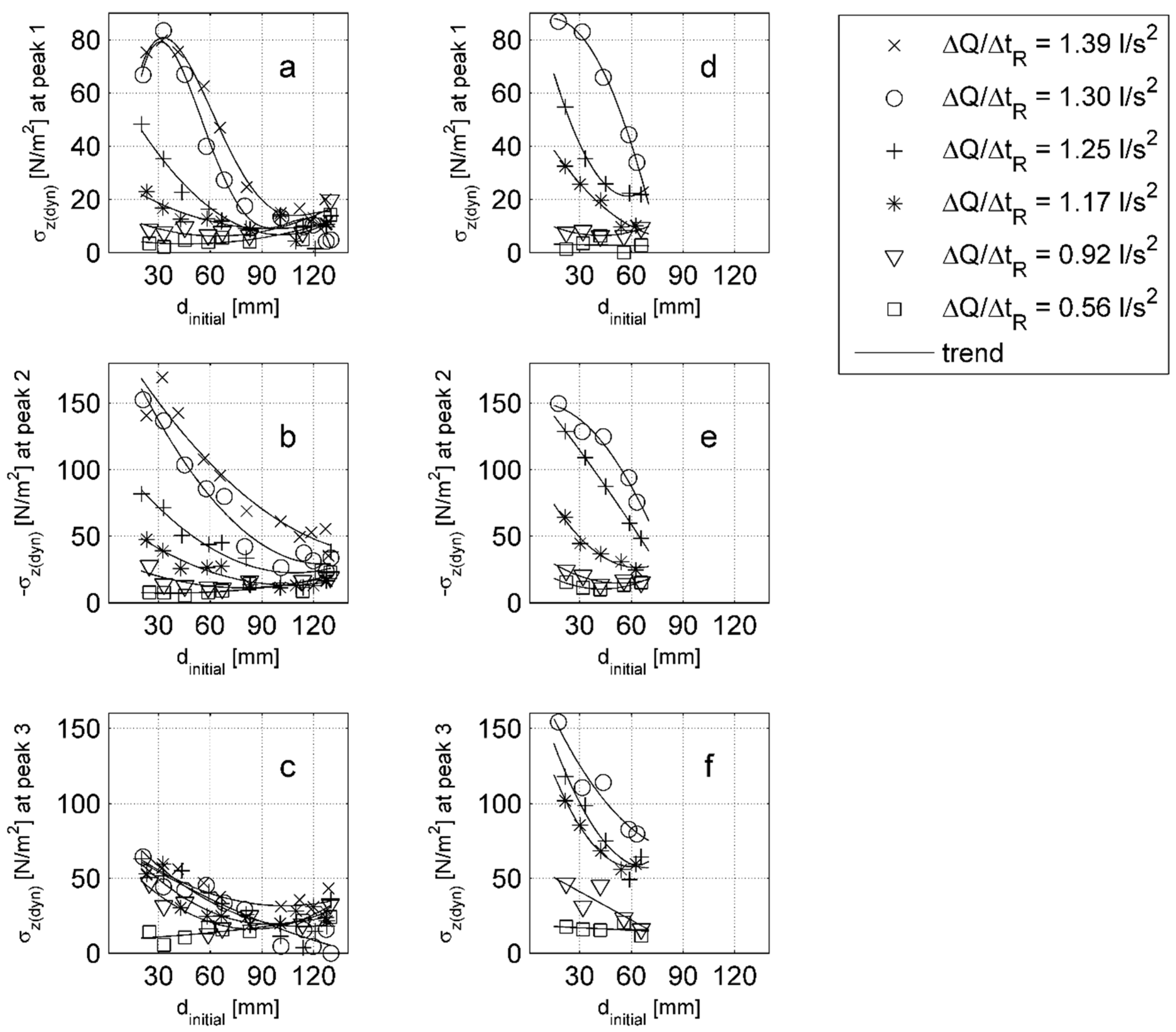

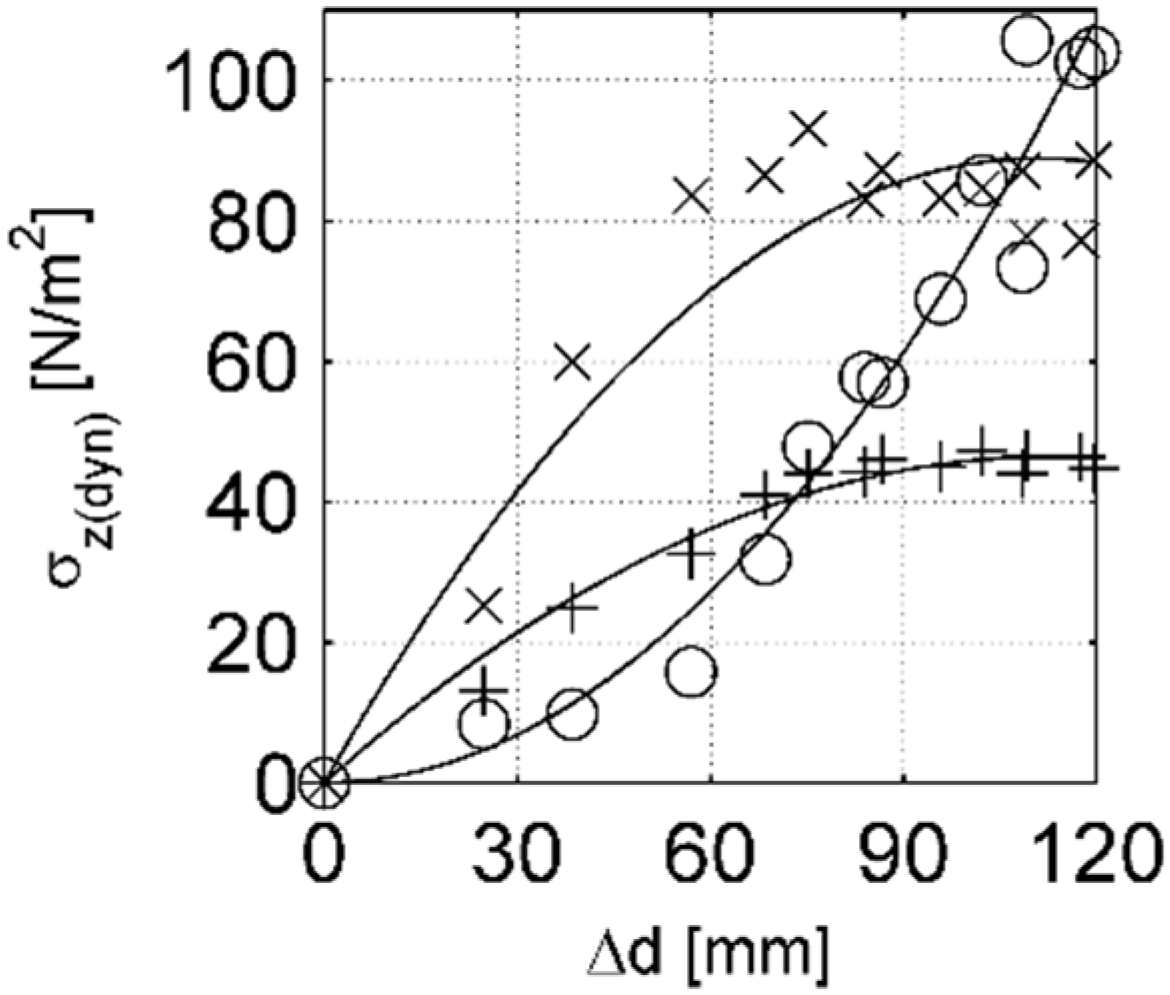

p1 could be expected. This explains why higher ramping rates lead to larger dynamic lift in Peak 3 (

Figure 6). It does not explain why stronger dynamic lift was recorded for higher

values, with a constant ramping rate (

Figure 9). It seems that additional, hydrodynamic effects enhance the dynamic lift in Peak 3. Investigations regarding the velocity field above the streambed during unsteady flow are suggested to provide further conclusions.

5. Conclusions

The lift on a 100 mm × 100 mm piece of artificial streambed was directly measured during unsteady flow in a physical experiment. Increasing the flow from a lower to a higher discharge, a wide spectrum of unsteadiness parameters and porosities was tested during 190 experimental runs. In general, three major dynamic lift peaks were recorded for experiments with unsteadiness parameters of . Comparing the maximum dynamic lift during the observed peaks, the influence of single hydrograph characteristics could be isolated and evaluated. Initial flow depth, duration and extent of the flow increase are therefore the key factors influencing dynamic lift during highly unsteady flow.

The observed unsteady effects in form of dynamic lift peaks were increasing with: (1) decreasing initial flow depth ; (2) increasing ramping rate and therefore decreasing ramping duration ; (3) increasing flow variation or at a constant ramping rate, especially regarding Peak 3; and, finally, (4) increasing unsteadiness parameter .

Additional experiments showed a major influence of the armor layer porosity on the observed dynamic lift peaks. Increasing armor layer porosity reduced the dynamic lift, but could not make it disappear entirely.

The present study shows that lift, which is compared to the shear stress and is often neglected during steady flow, plays a vital role in the interaction between unsteady flow and the streambed.