1. Introduction

Urbanization leads to more impervious surface areas such as rooftops, roads, driveways and car parks [

1,

2,

3]. This can result in increased stormwater runoff and pollution, as well as increased risk of downstream flooding [

4]. More impervious pavement area also increases urban heat island effects [

5].

Over the last few decades, the management and treatment of stormwater runoff from urban areas has become a priority issue for those responsible for planning, construction and maintenance of urban developments. A variety of water management strategies have emerged globally in response to the need to address water and stormwater issues related to urban developments including Sustainable Urban Drainage Systems (SUDS) in Europe, Water Sensitive Urban Design (WSUD) in Australia, and Low Impact Development (LID) in the USA. These urban water management strategies integrate urban planning and management practices to protect and conserve the urban water cycle, and to ensure that urban developments are sensitive to natural hydrological and ecological processes [

6,

7].

Permeable pavements are one type of SUDS treatment device that are becoming increasingly popular globally due to the many stormwater management and environmental benefits they provide. Permeable pavements have been in commercial use now for around three decades and they are often used as an alternative to conventional impervious hard surfaces, such as roads, car parks, footpaths and pedestrian areas [

8]. Permeable pavements have considerably different design objectives and requirements to conventional pavements as they allow stormwater to infiltrate through the paving surface where it is filtered through the various layers. Stormwater quality can be substantially improved through the various filtering, chemical and biological treatments that occur within the permeable pavement structure. The filtered stormwater is then either harvested for later reuse or released slowly into the underlying soil or stormwater drainage system. This results in many stormwater management and environmental benefits.

The most common type of permeable pavement is the permeable interlocking concrete paving (PICP) system [

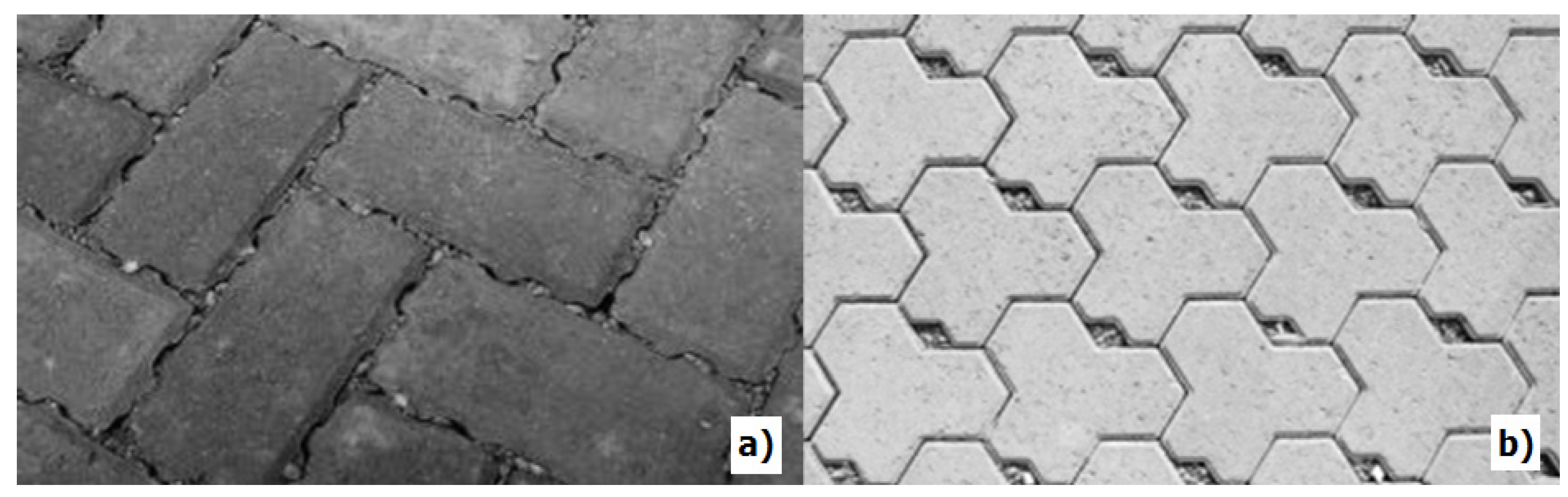

9]. PICPs are generally designed so that there is sufficient open space between the individual pavers to allow water to infiltrate into the pavement structure. This is either achieved with slots or spacing lugs that are cast into the perimeter of the pavers to keep them apart (

Figure 1a), or by way of specially designed paving shapes that include small apertures in the paving surface (

Figure 1b). The joints or spaces between PICPs are not filled with sand or other binders as they are with conventional pavers. Instead, when the joints are wide enough, the open spaces between the pavers are often filled with the same 2 to 5 mm aggregate that is used for the paving bedding layer.

Figure 1.

Permeable interlocking concrete pavements (PICPs) with Wide Joints (a) and Apertures (b).

Figure 1.

Permeable interlocking concrete pavements (PICPs) with Wide Joints (a) and Apertures (b).

Permeable pavements can remove sediment, total suspended solids (TSS) and other pollutants from stormwater runoff during the filtration processes that occur within the pavement structure. Over time, this can lead to a reduction of the infiltration capacity of the PICP system and clogging [

10,

11,

12]. Clogging is a result of fines, organic matter and traffic-caused abraded particles, blocking the gaps and surfaces of PICPs due to physical, biological and chemical processes [

13]. This clogging decreases the porosity/permeability of the paving surface and hence the infiltration rate of a system. The degree that particle deposition onto pavement surfaces impacts on the performance of a system depends on the particle size distribution of the material and the pore structure or permeability of the system [

14]. Street tree litter can also block permeable pavements. However, one advantage of decomposing leaves is the elevated nutrient levels which can stimulate microbial activity resulting in accelerated hydrocarbon breakdown [

15].

There is a perception that pervious pavements will block quickly when used as a stormwater source control, resulting in high maintenance and replacement costs [

16]. However, some manufacturers claim that when regularly inspected and maintained, PICPs should last between 20 and 25 years [

15,

16,

17]. Various studies have investigated the clogging processes that occur in pervious pavements and the pollutant distribution within paving structures [

9,

10,

16,

18,

19,

20,

21,

22]. Other research investigated the effects of maintenance on clogging, infiltration performance and the effective lifespans of pervious pavements [

8,

11,

12,

23,

24,

25]

Lucke and Beecham [

9] undertook a forensic investigation of a clogged eight year old PICP system to determine how sediment had accumulated within the pavement structure. They found that most of the sediment was either trapped in the gaps between the paving blocks, or on top of the bedding aggregate directly below the gaps. The sediment accumulation pattern that took place on the bedding aggregate beneath pavers is shown

Figure 2. This clearly demonstrates the effectiveness of the bedding aggregate as a filter medium to remove sediment from stormwater runoff.

Figure 2.

Sediment Accumulation Pattern on Bedding Aggregate [

9].

Figure 2.

Sediment Accumulation Pattern on Bedding Aggregate [

9].

It is also clear from

Figure 2 that sediment was mostly deposited on the bedding aggregate directly below the paving joints. The rest of the bedding aggregate was effectively “as new” and had performed no sediment removal function at all. This suggests that the PICP design was not fully utilizing the filter medium properties of the bedding aggregate. Therefore, this led to the hypothesis that there may be a more effective PICP design that makes greater use of the bedding aggregate area to filter more sediment from stormwater runoff.

This paper describes a proof of concept study that was undertaken at the University of the Sunshine Coast in Australia to investigate more efficient use of the bedding aggregate used in PICP systems. Lateral drainage channels (slots) were cut into the underside of PICP blocks to allow sediment-laden stormwater to access, and be treated by, a greater surface area of bedding aggregate. Eight different slot designs were trialed in the study. Specially fabricated PICP models were tested in the laboratory using semi-synthetic stormwater [

26,

27] to determine which of the slot designs made the most efficient use of the bedding aggregate to filter the sediment from the stormwater.

2. Materials and Methods

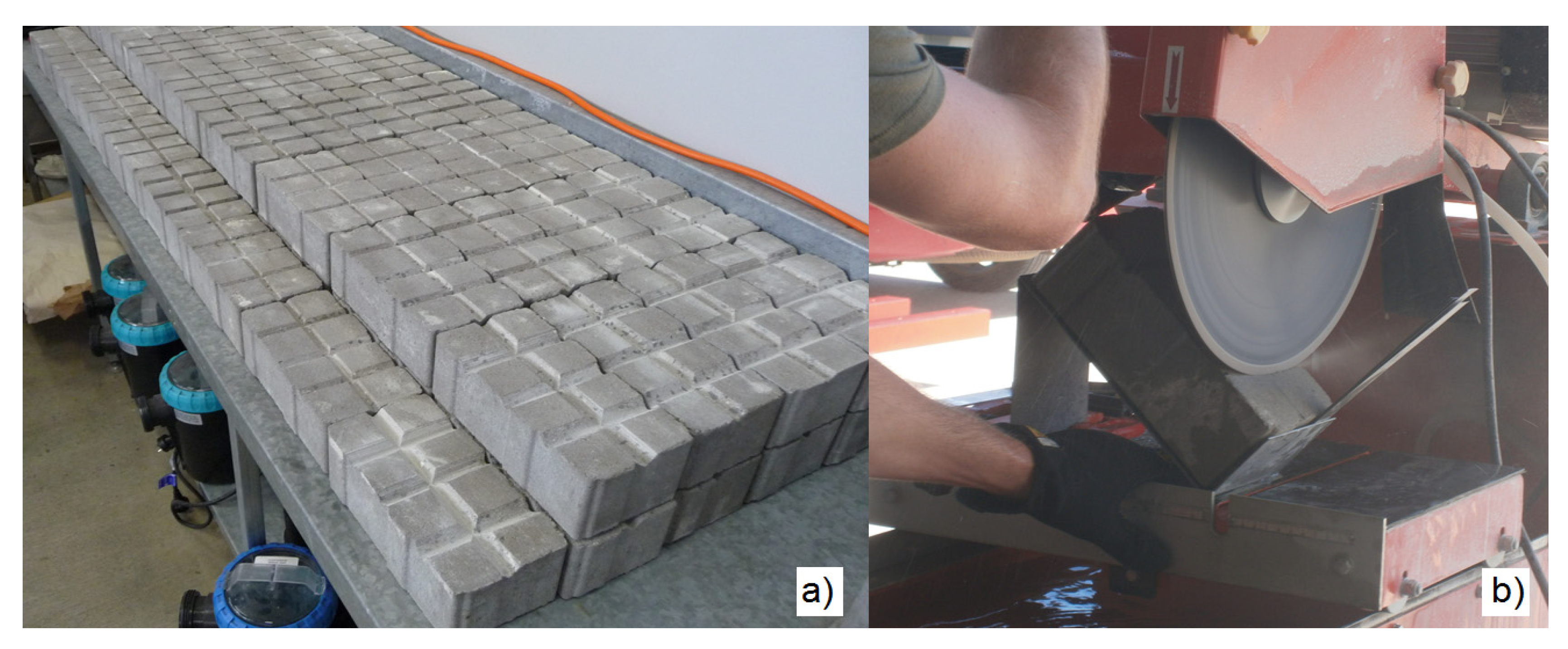

A variety of drainage slot patterns were considered for the underside of the pavers used in the study including different combinations of rectangular, diamond and square patterns. A square pattern dividing the paver into eight equally sized segments was eventually chosen due to the difficulty in cutting the slots into the base of the pavers (

Figure 3a). A brick saw with a 300 mm diameter diamond blade was used to cut the slots (

Figure 3b). Introducing slots into the base of the pavers will obviously affect their flexural strength and these effects would need to be properly evaluated before production.

Figure 3.

Cutting slots in base of pavers. (a) Variety of slots; (b) Brick saw cutting.

Figure 3.

Cutting slots in base of pavers. (a) Variety of slots; (b) Brick saw cutting.

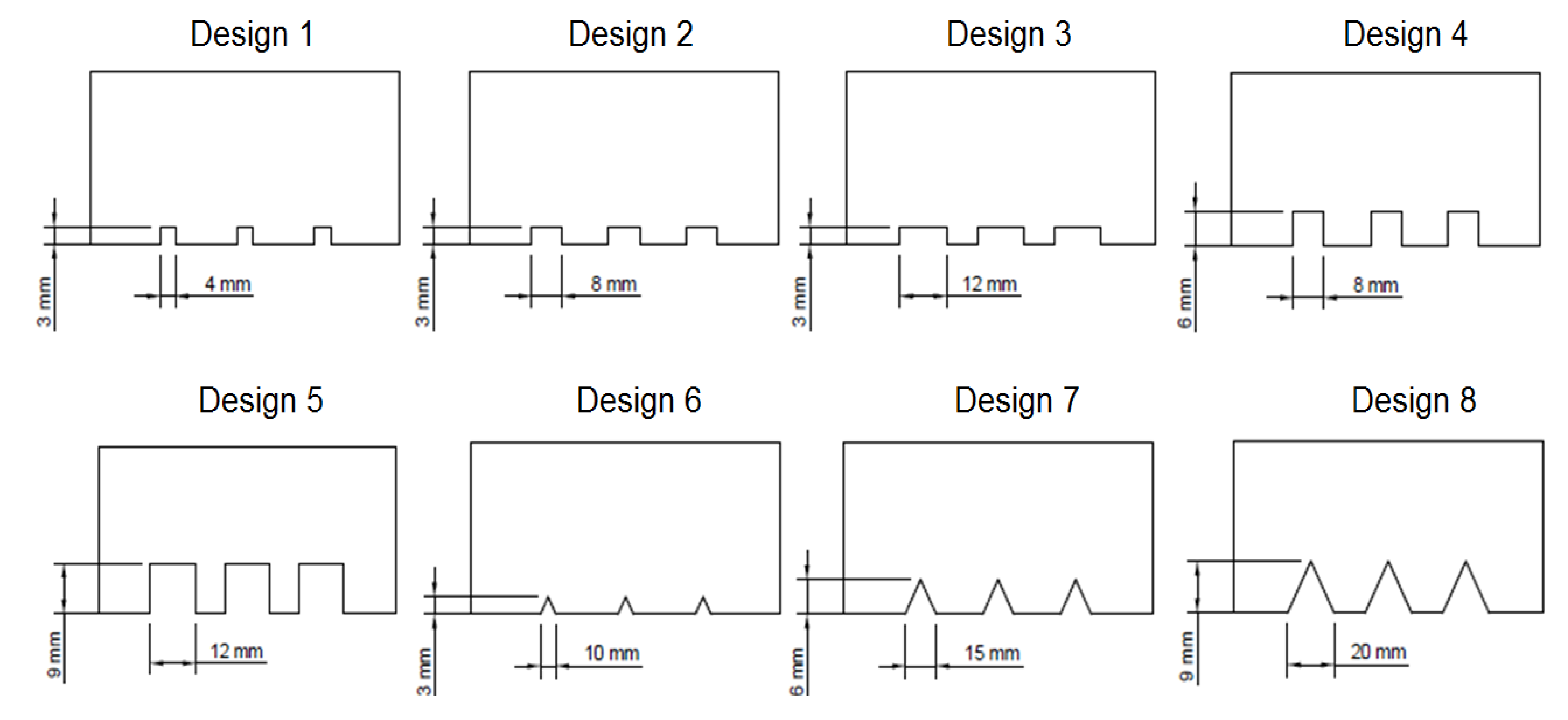

Eight drainage slot designs of different sizes and shapes (square, rectangular and triangular) were tested in the study (

Figure 4). To ensure the structural integrity of the pavers was not too heavily compromised, the maximum slot depth was restricted to 9 mm. The maximum slot width trialled was 20 mm. The patterns of the sediment deposited beneath each of the eight different slot designs were compared to the typical sediment pattern beneath unmodified pavers (

Figure 2).

Nine specially constructed PICP models were tested in the laboratory using accelerated stormwater simulation techniques [

26,

27,

28]. The stormwater used in the simulation experiments was termed “semi-synthetic” stormwater as it consisted of real sediment that was mixed with potable water. The use of the semi-synthetic stormwater mixture minimized variations in inflow concentrations whilst still maintaining a realistic composition [

28]. Over 10 kg (dry weight) of real stormwater sediment was collected from a variety of stormwater pits and drains located on the Sunshine Coast. Litter and large organic material was first removed from the collected sediment and then it was placed in an oven at 104 °C to dry. The dried sediment was then passed through a 1.18 mm sieve to remove larger stones and organic particles that may have interfered with the testing procedure. The sediment was added to the water in carefully controlled proportions to replicate sediment loads found in typical Australian stormwater runoff [

29].

Figure 4.

Eight Different Drainage Slot Designs Trialed in Study (not to scale).

Figure 4.

Eight Different Drainage Slot Designs Trialed in Study (not to scale).

The dimensions of the nine PICP models (eight different slot patterns and one control) were 440 mm long and 330 mm wide, providing a test surface area of 0.145 m

2 each. Hydrapave™ pavers (80 mm thick) were used in the models and these were laid in a standard herringbone configuration on a 50 mm thick layer of 2/5 mm bedding aggregate. The bedding aggregate was held in place by a

Bidim® A19 geofabric laid on a galvanized steel mesh set inside a welded angle frame base. The bedding aggregate was thoroughly pre-washed using a drum mixer prior to its use in the PICP models. The test pavers were confined within transparent acrylic sheeting and sealed internally around the perimeter using plumbers’ putty (

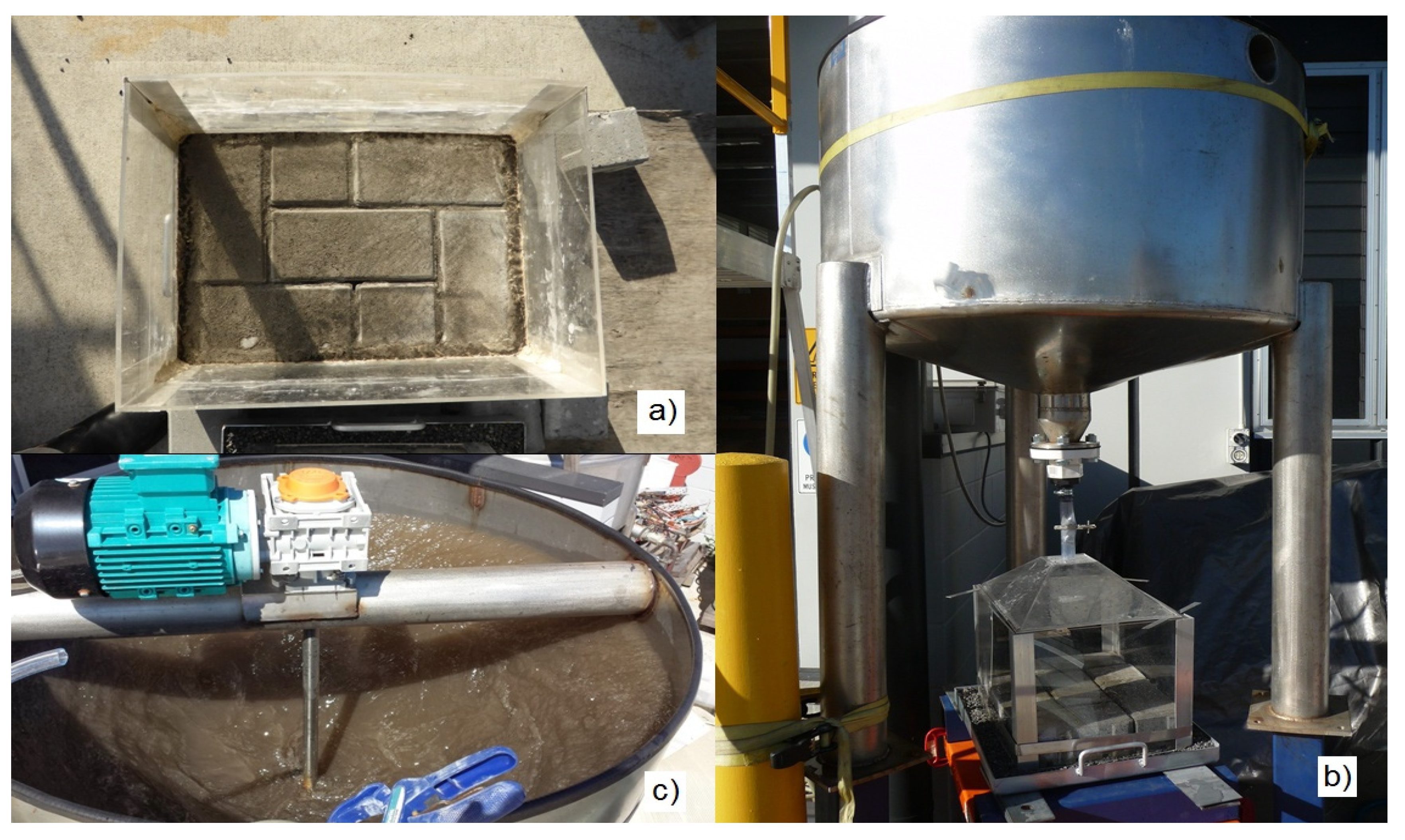

Figure 5a).

The average annual rainfall on the Sunshine Coast is approximately 1620 mm per year. A volume of 235 liters (1620 × 0.145 m

2) was required to deliver the equivalent of one year’s rainfall to the test models. Duncan [

29] proposed that the average concentration of total suspended sediment (TSS) in Australian urban runoff is 150 mg/L and this value was used to prepare the semi-synthetic stormwater used in this experimental study. This equated to 35.3 g of sediment being added to each 235 L test volume (one year’s rainfall and runoff sediment load). Each model received the equivalent of 10 years’ worth of semi-synthetic stormwater (total sediment weight per model = 353 g) during the study. To simulate drying time effects, the models were allowed to dry in the sunshine for at least one full day before the next year’s stormwater was applied. A purpose-built testing rig (

Figure 5b) was used to perform the accelerated stormwater simulations. The test rig comprised a 500 L, circular tank equipped with a variable-speed stirring mechanism. The stirring system was used to keep the added sediment in homogenous suspension (

Figure 5c) and to ensure the models received consistent sediment concentrations during the simulation tests. A specially designed sprinkler head was connected to the tank outlet to distribute the stormwater equally over the surface of the models (

Figure 5b).

Figure 5.

Accelerated stormwater simulation testing setup. (a) Paver test model; (b) Test rig; (c) Tank stirrer.

Figure 5.

Accelerated stormwater simulation testing setup. (a) Paver test model; (b) Test rig; (c) Tank stirrer.

After 10 years’ worth of semi-synthetic stormwater was applied to each of the nine models, they were allowed to completely dry out in the sunshine before being disassembled. The sides of the models were first removed and then each of the individual pavers was carefully removed one at a time until only the deposited sediment patterns remained on the bedding aggregate. The sediment pattern results clearly demonstrated that the slots had been effective in spreading the sediment over more of the bedding aggregate surface (

Figure 6a). However, the results also showed that it would be very difficult to accurately quantify the amounts of sediment deposited on the bedding aggregate beneath each of the different slot patterns. In addition, allowing the models to completely dry out before dismantling them turned out to be a mistake as it was not possible to stop the dried sediment trapped in the joints between the pavers (Sediment Line—

Figure 6b) from slumping onto the bedding aggregate as the pavers were removed (

Figure 6b). This further complicated attempts to accurately quantify the sediment distribution performance of the different slot patterns.

Figure 6.

Sediment deposits on bedding aggregate. (a) Sediment pattern; (b) Sediment line.

Figure 6.

Sediment deposits on bedding aggregate. (a) Sediment pattern; (b) Sediment line.

Due to the difficulty in quantifying the amount of sediment deposited beneath the pavers on the bedding aggregate in the initial tests, it was decided to repeat the accelerated stormwater simulation testing procedure outlined above. However, in order to be able to determine the sediment distribution performance of the different slot patterns more accurately, the models used in the second test series contained no bedding aggregate and the pavers were laid directly on the geofabric layer.

3. Results and Discussion

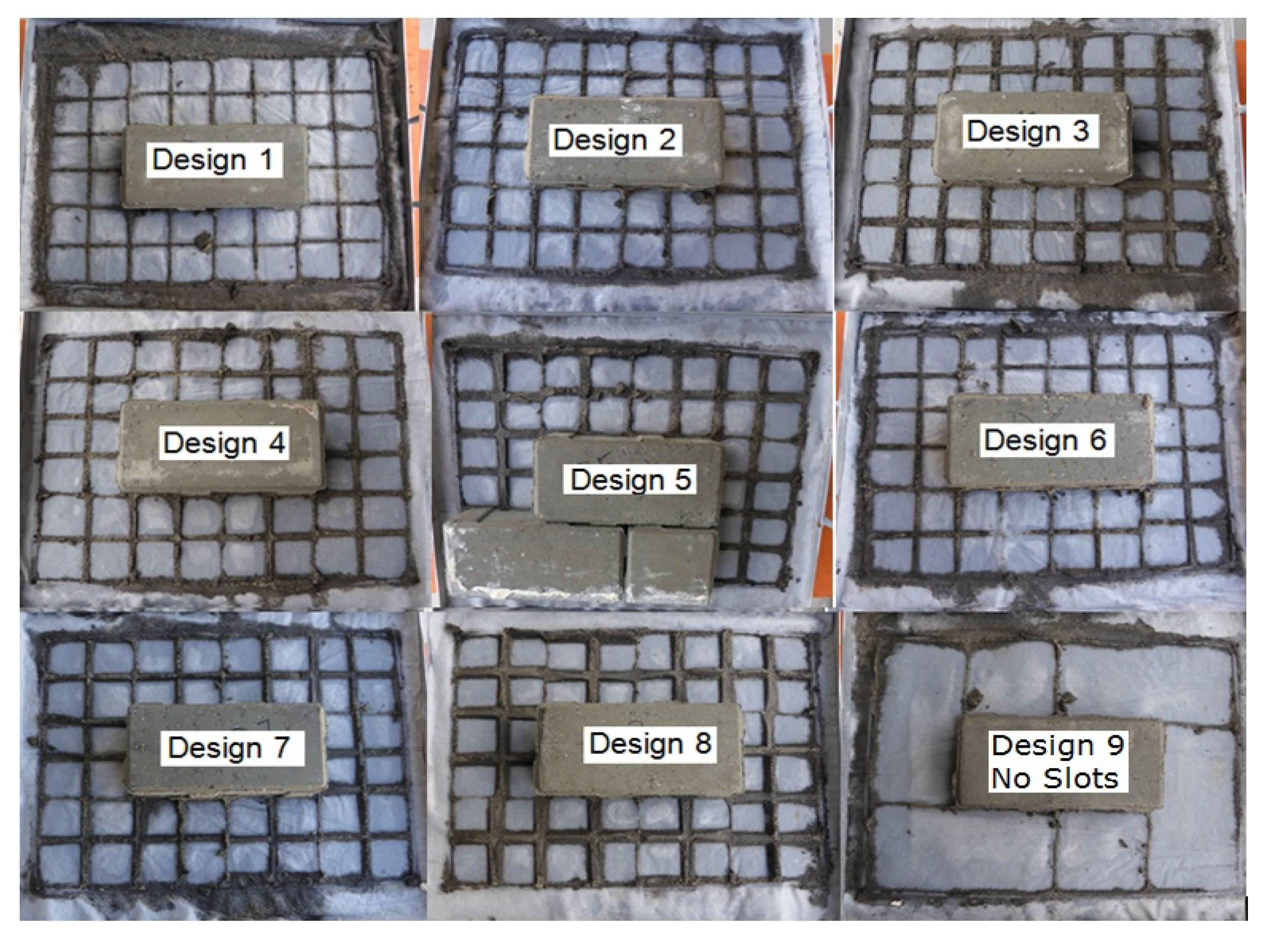

The second series of tests undertaken on the models without the bedding aggregate produced much better sedimentation results. In these tests, the models were not completely dried out before they were dismantled and this allowed a more reliable and accurate determination of the sediment distribution performance of the different drainage slot patterns. The sediment distribution patterns for the eight different slot patterns are shown in

Figure 7 (Designs 1–8). The sediment distribution pattern of the control pavers (Design 9—no drainage slots) is also shown in

Figure 7.

Figure 7.

Sediment Distribution Patterns of Geofabric Tests.

Figure 7.

Sediment Distribution Patterns of Geofabric Tests.

The results shown in

Figure 7 clearly indicate that the drainage slots in the base of the pavers of Designs 1 to 8 spread the sediment over a much greater area of geofabric than the control (Design 9) pavers. However, there were still a few problems quantifying which of the slot designs was the most effective. These included moist sediment sticking inside the slots and being removed with the pavers, sediment trapped within the paving joints falling onto the geofabric, and sediment leaching out around the perimeter of some of the models (

Figure 7). These problems increased the difficulty of measuring the amount of sediment that was retained on each of the geofabric samples with any certainty.

In order to enable a more accurate comparison of the amount of sediment deposited on the geofabrics by each slot design, the perimeters of all the geofabrics were trimmed to exactly the same size to remove any leached sediment around the edges (

Figure 8a). Any sediment from the paving joints that had fallen onto the geofabric was also removed during this process. The nine identically-sized geofabric samples containing the deposited sediment were then allowed to dry out completely for a period of one week (

Figure 8b). The dry weights of the geofabrics including sediment were then recorded and these are listed in order of increasing weight in

Table 1.

Figure 8.

Trimming and drying sediment-laden geofabric for weighing.

Figure 8.

Trimming and drying sediment-laden geofabric for weighing.

Table 1.

Dry weights of sediment-laden geofabrics.

Table 1.

Dry weights of sediment-laden geofabrics.

| Dry Weight (g) | Design Number | % Increase on Control |

|---|

| 43.9 | 9 | 0% |

| 54.9 | 1 | 25% |

| 67.9 | 6 | 55% |

| 89.8 | 4 | 105% |

| 92.8 | 2 | 111% |

| 117.2 | 5 | 167% |

| 119.3 | 3 | 172% |

| 131.1 | 7 | 199% |

| 204.4 | 8 | 366% |

As can be seen in

Table 1, all of the drainage slot designs deposited more sediment on the geofabric than the control pavement (Design 9). This varied from 25% more sediment for slot Design 1, through to 366% more sediment for slot Design 8. The results suggest that triangular shaped slots may be the most effective for spreading sediment beneath pavers. However, further research, including field studies, would be required to verify this. Although there were a number of possible errors in the sediment measurement techniques used in the study, the results in

Table 1 suggest that PICPs using pavers with drainage slots cast into the underside of the paver should theoretically take longer to clog than pavers without slots. These results may be considered to be proof for the concept of this study.

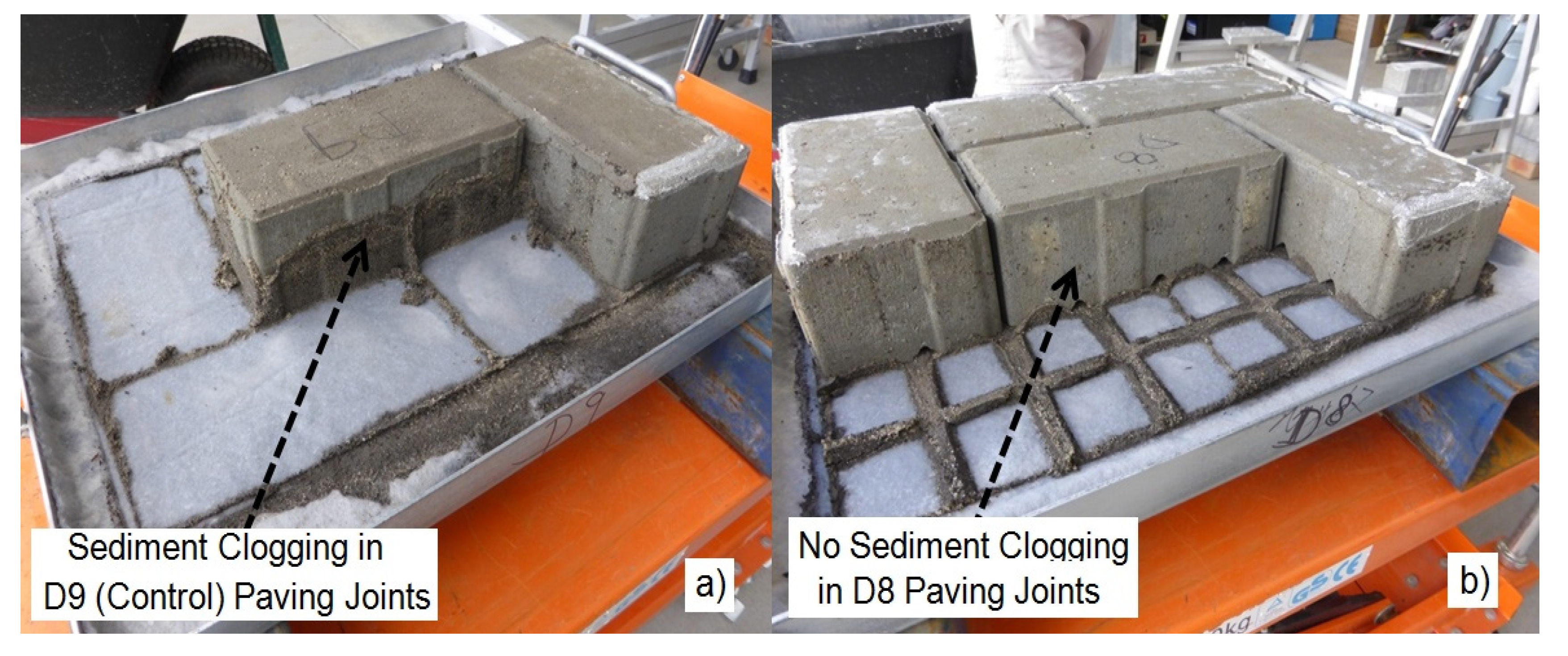

Figure 9a clearly shows the high level of sediment build-up in the joints of the unmodified, control paving blocks (Design 9). In contrast,

Figure 9b shows that there was no sediment build-up at all in the joints between the drainage slot Design 8 (D8) pavers.

Figure 9b also shows that a substantial amount of sediment build-up occurred beneath the drainage slots of the Design 8 pavers. However, there was no sediment build-up evident beneath the base of the control (D9) pavers. These results clearly demonstrate that the Design 8 drainage slots were more effective in spreading the sediment over a greater area beneath the pavers than the control pavement (D9). This again suggests that PICP systems with drainage slots cast into their bases would take much longer to clog (delay clogging effects) than unmodified pavers, once more proving the concept of this study.

Figure 9.

Comparison of sediment blockage in paving joints. (a) Clogging in joints; (b) No joint clogging.

Figure 9.

Comparison of sediment blockage in paving joints. (a) Clogging in joints; (b) No joint clogging.