GainTKW: A Measurement System of Thousand Kernel Weight Based on the Android Platform

Abstract

:1. Introduction

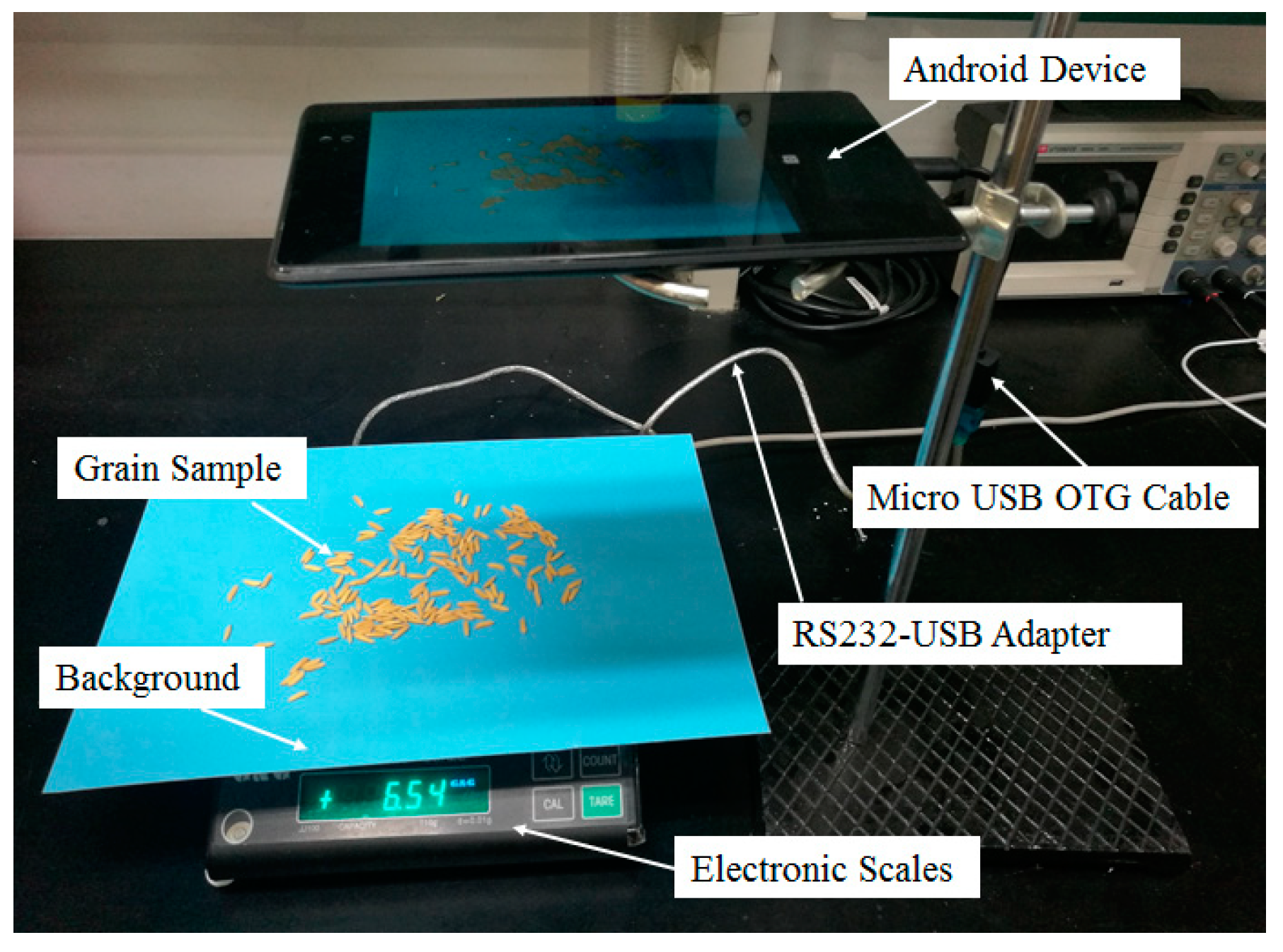

2. Materials and Methods

2.1. Materials Preparation

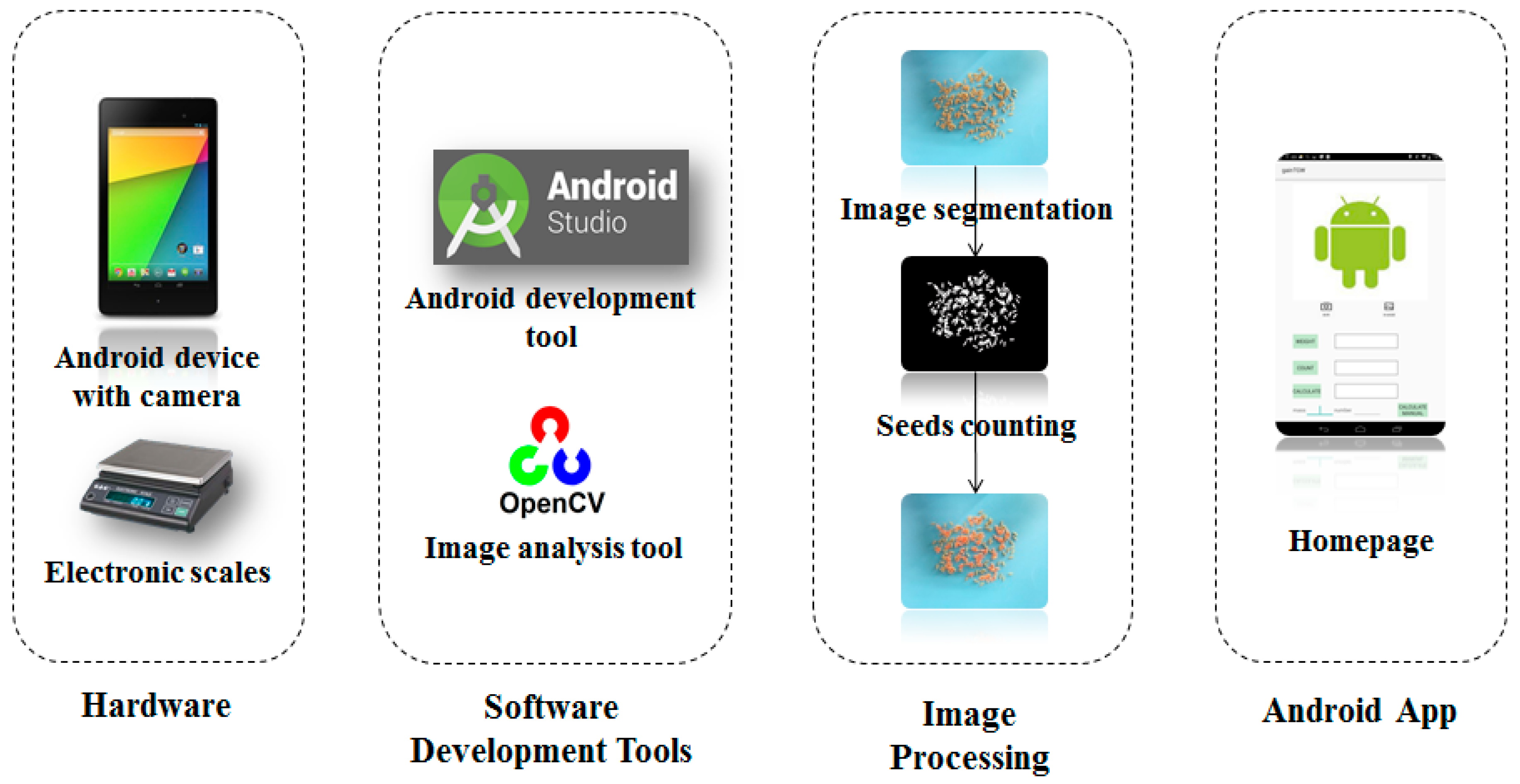

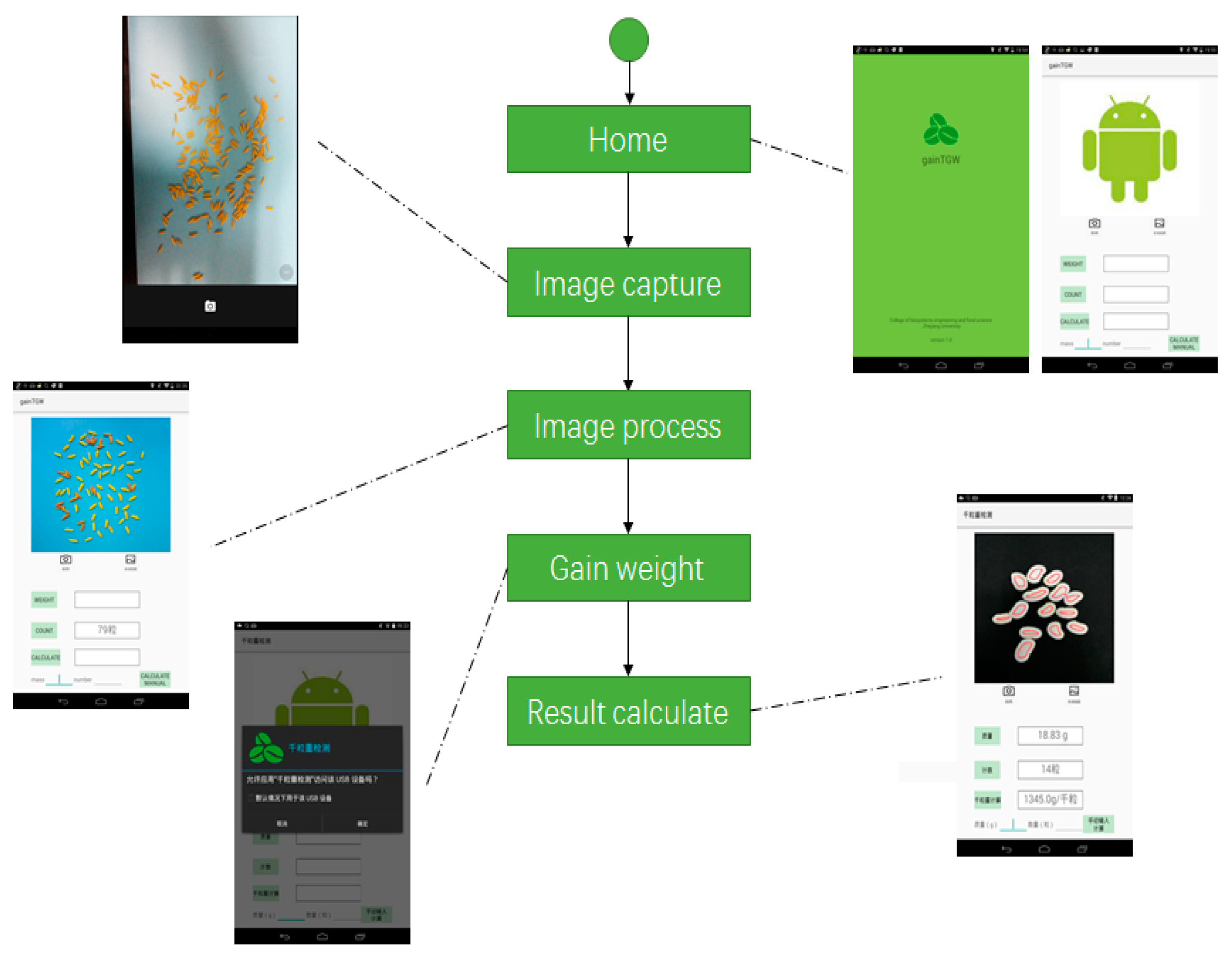

2.2. System Design

2.3. Development Tools

- Build Tools: Android Studio utilizes the fast growing Gradle build system. Eclipse, on the other hand uses Apache Ant as its main build system.

- Advanced Code Completion/Refactoring: Both IDEs feature the standard Java code auto completion but in the case of Android Studio, Google has baked in deeper support for specific Android code and refactoring. Android Studio can refactor your code in places where it’s just not possible using Eclipse and ADT.

- Project Organization: Both IDEs work differently in an effort to help you manage and organize your projects. When using Eclipse you must be familiar with the concept of workspaces, but Android Studio introduces the concept of modules.

- IDE Performance/Stability: Eclipse is a purely Java based software, and needs high amounts of Ram and CPU power to run reliably. Android Studio is a more stable and lightweight IDE.

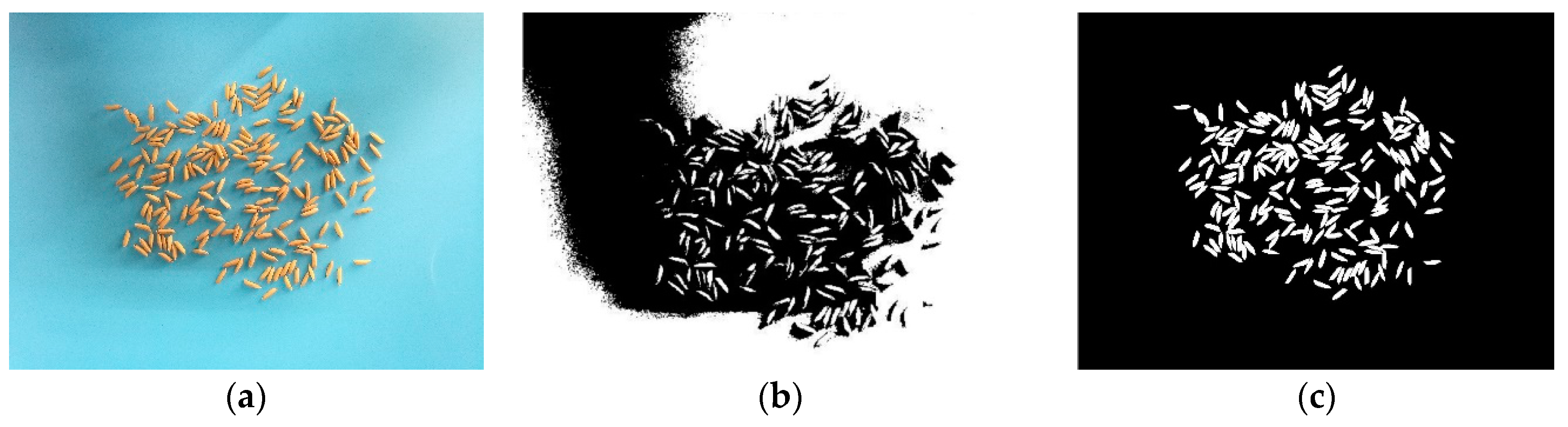

2.4. Image Processing

2.4.1. Kernels Segmentation

| Algorithm 1 K-means algorithm |

| Input: K (number of clusters), Training set x(1), x(2), …, x(m) |

| Randomly initialize K cluster centroids μ1, μ2, …, μK |

| repeat |

| // cluster assignment step: find closest centroid |

| for i = 1 to m data points do |

| c(i): = index of cluster centroid closest to x(i) |

| end for |

| // update centroid step: compute means based on assignment |

| for k = 1 to K centroid do |

| μ: = average(mean) of points assigned to cluster k |

| end for |

| until N iterations |

| Output: centroids assignments c(1), c(2), …, c(m), and learned centroids μ1, μ2, …, μK |

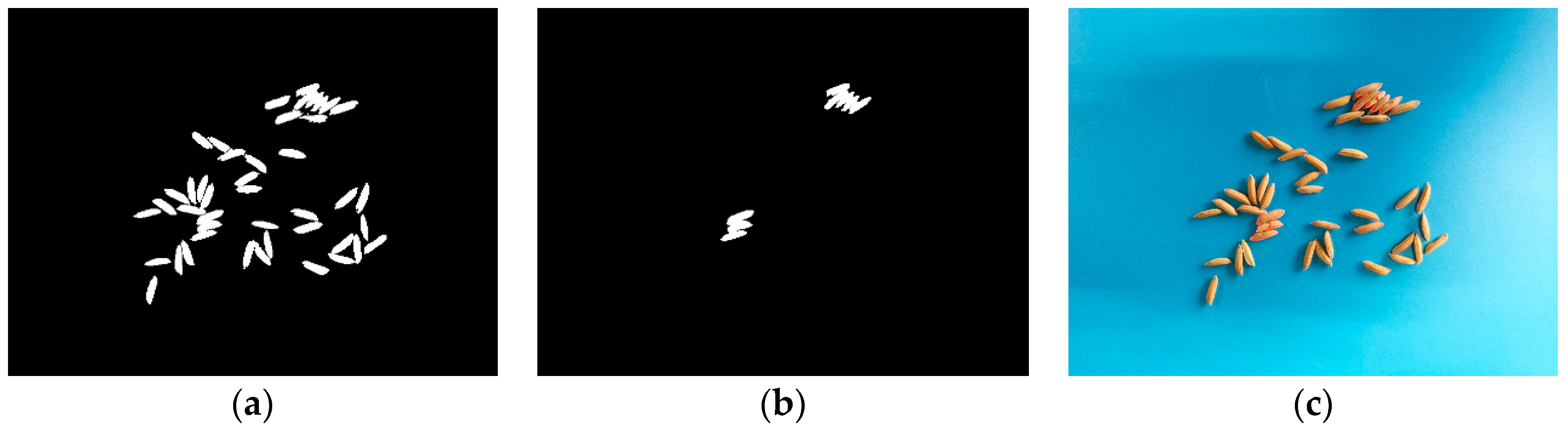

2.4.2. Counting Method

3. Results

3.1. Description of Application’s Performance

3.2. Evaluatio of Application’s Performance

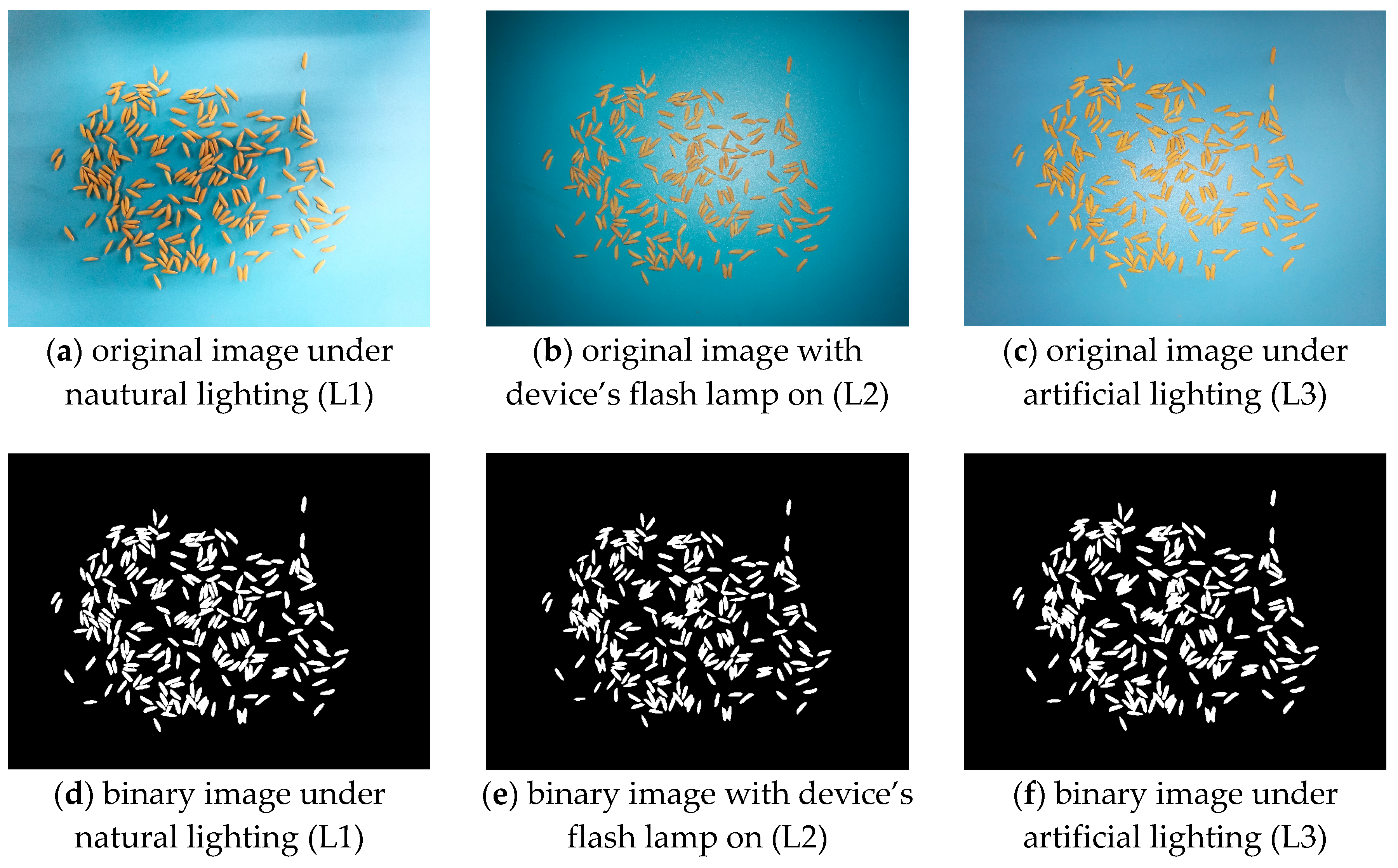

3.2.1. Performance Evaluation under Different Light Conditions

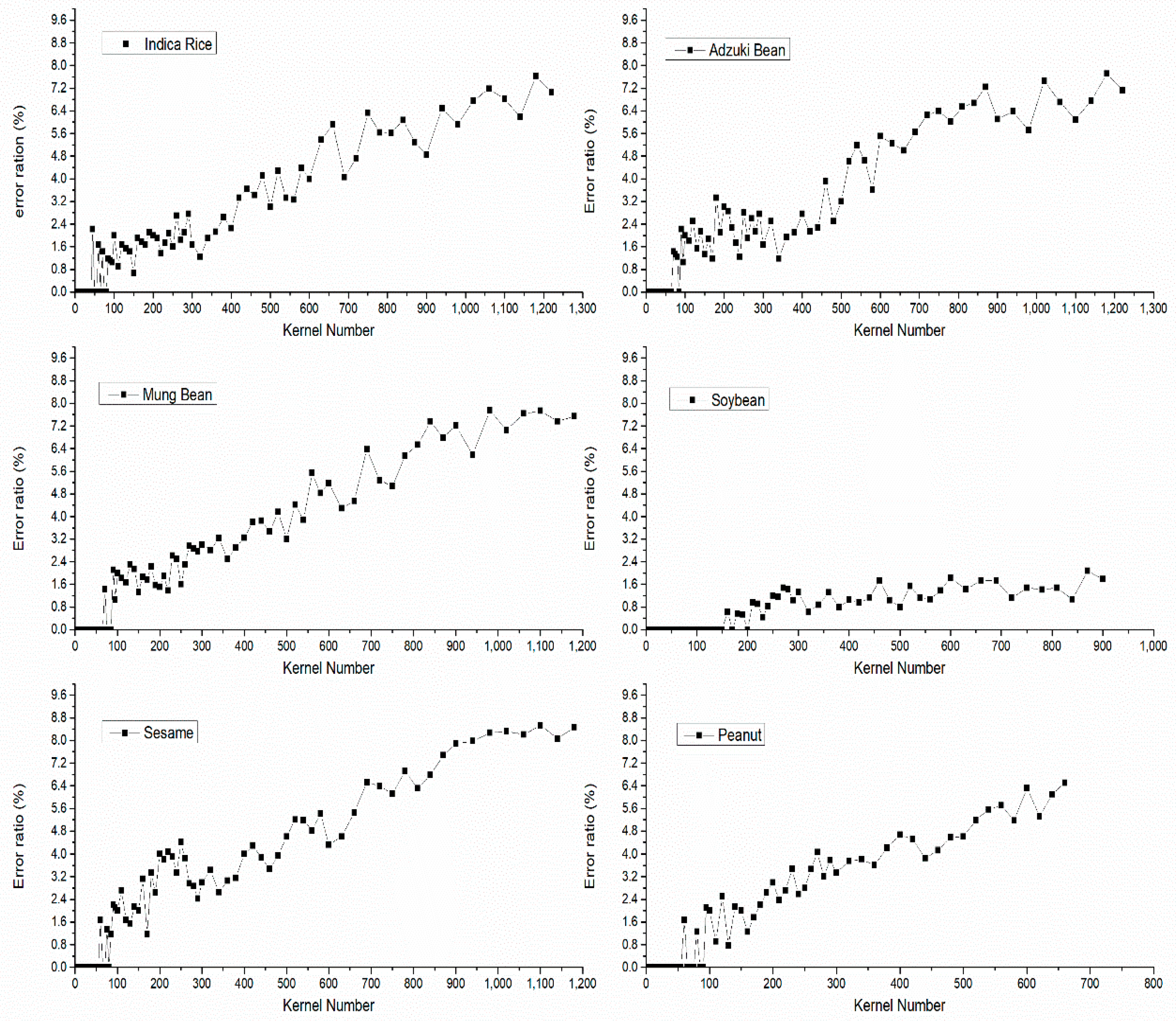

3.2.2. Performance Evaluation on Different Species of Kernels

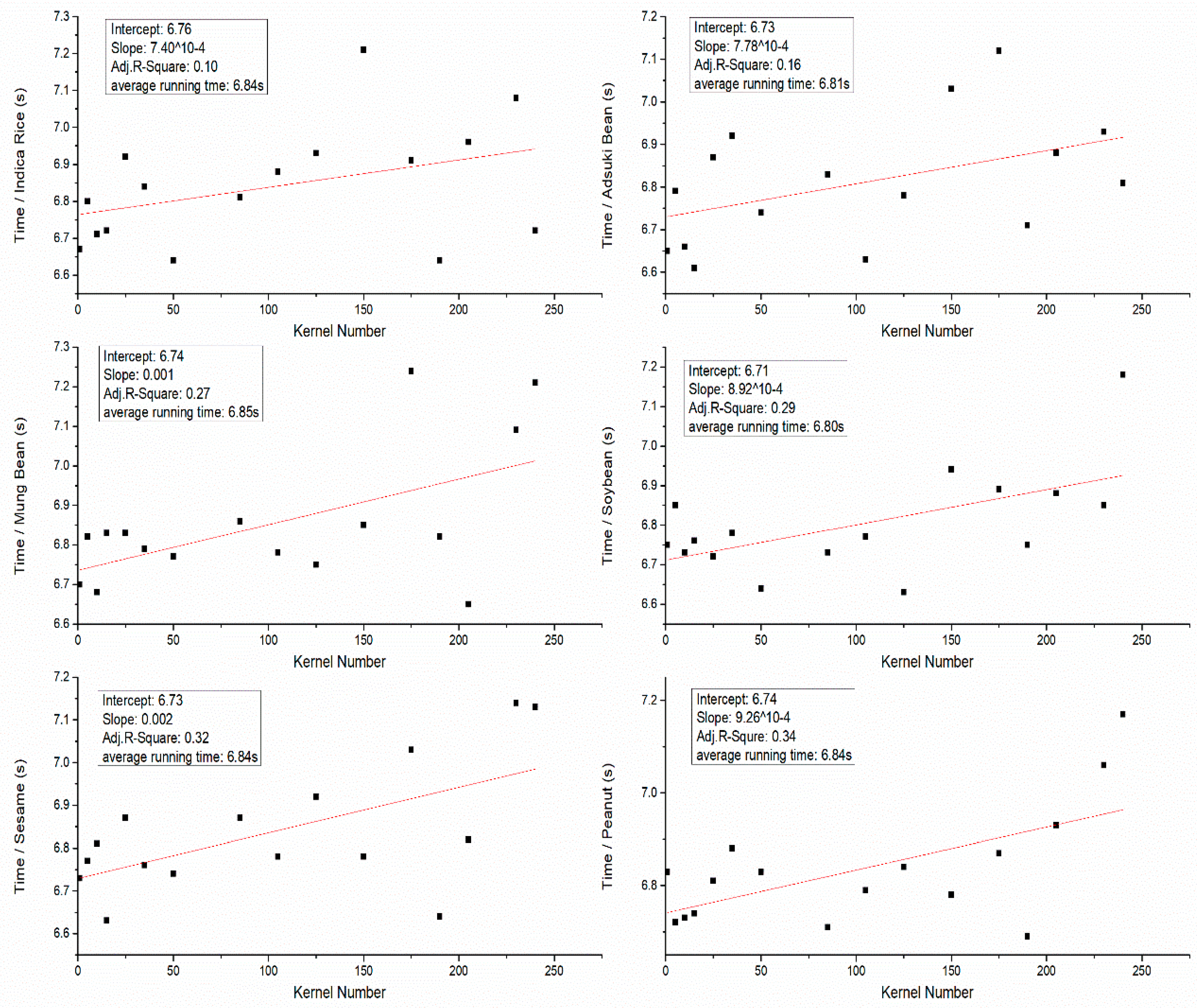

3.3. Application’s Computational Efficiency Study

- Closing all recent applications in the device.

- Re-starting the device.

- Selecting the flight mode.

- Waiting for 40 s for the operating system to completely load.

- Starting the “gainTKW” application.

- Running the tests 3 times.

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Botwright, T.L.; Condon, A.G.; Rebetzke, G.J.; Richards, R.A. Field evaluation of early vigour for genetic improvement of grain yield in wheat. Aust. J. Agric. Res. 2002, 53, 1137–1145. [Google Scholar] [CrossRef]

- Dholakia, B.B.; Ammiraju, J.S.S.; Singh, H.; Lagu, M.D.; Röder, M.S.; Rao, V.S.; Dhaliwal, H.S.; Ranjekar, P.K.; Gupta, V.S. Molecular marker analysis of kernel size and shape in bread wheat. Plant Breed. 2003, 122, 392–395. [Google Scholar] [CrossRef]

- Li, J.; Thomson, M.; McCouch, S.R. Fine mapping of a grain-weight quantitative trait locus in the pericentromeric region of rice chromosome 3. Genetics 2004, 168, 2187–2195. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Wu, W.; Chen, W.; Sun, C.; Chen, C.; Wang, R.; Zhu, X.; Guo, W. A shadow-based method to calculate the percentage of filled rice grains. Biosyst. Eng. 2016, 150, 79–88. [Google Scholar] [CrossRef]

- Mclaughlin, N.B.; Giesbrecht, J.; Bligh, D.F. Design and performance of an electronic seed counter. Can. J. Plant Sci. 1976, 56, 351–355. [Google Scholar] [CrossRef]

- Lin, P.; Chen, Y.M.; He, Y.; Hu, G.W. A novel matching algorithm for splitting touching rice kernels based on contour curvature analysis. Comput. Electron. Agric. 2014, 109, 124–133. [Google Scholar] [CrossRef]

- Otsu, N. A Threshold Selection Method from Gray-Level Histograms. IEEE Trans. Syst. Man. Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

- Nam, Y.; Hwang, E.; Kim, D. A similarity-based leaf image retrieval scheme: Joining shape and venation features. Comput. Vis. Image Underst. 2008, 110, 245–259. [Google Scholar] [CrossRef]

- Dubey, S.R.; Jalal, A.S. Apple disease classification using color, texture and shape features from images. Signal. Image Video Process. 2016, 10, 819–826. [Google Scholar] [CrossRef]

- Jayas, D.S.; Bulley, N.R. Digital image analysis for software separation and classification of touching grains: II. classification. Trans. ASAE 1995, 38, 645–649. [Google Scholar]

- Yan, L.; Park, C.-W.; Lee, S.-R.; Lee, C.-Y. New separation algorithm for touching grain kernels based on contour segments and ellipse fitting. J. Zhejiang Univ. Sci. C 2011, 12, 54–61. [Google Scholar] [CrossRef]

- Zhang, G.; Jayas, D.S.; White, N.D.G. Separation of touching grain kernels in an image by ellipse fitting algorithm. Biosyst. Eng. 2005, 92, 135–142. [Google Scholar] [CrossRef]

- Bai, X.; Sun, C.; Zhou, F. Splitting touching cells based on concave points and ellipse fitting. Pattern Recognit. 2009, 42, 2434–2446. [Google Scholar] [CrossRef]

- Visen, N.S.; Shashidhar, N.S.; Paliwal, J.; Jayas, D.S. Identification and segmentation of occluding groups of grain kernels in a grain sample image. J. Agric. Eng. Res. 2001, 79, 159–166. [Google Scholar] [CrossRef]

- Zhong, Q.; Zhou, P.; Yao, Q.; Mao, K. A novel segmentation algorithm for clustered slender-particles. Comput. Electron. Agric. 2009, 69, 118–127. [Google Scholar] [CrossRef]

- Wang, W.; Paliwal, J. Separation and identification of touching kernels and dockage components in digital images. Can. Biosyst. Eng. 2006, 48, 1–7. [Google Scholar]

- Mebatsion, H.K.; Paliwal, J. A Fourier analysis based algorithm to separate touching kernels in digital images. Biosyst. Eng. 2011, 108, 66–74. [Google Scholar] [CrossRef]

- Komyshev, E.; Genaev, M.; Afonnikov, D. Evaluation of the SeedCounter, A Mobile Application for Grain Phenotyping. Front. Plant Sci. 2017, 7. [Google Scholar] [CrossRef] [PubMed]

- Gong, A.; Yu, J.; He, Y.; Qiu, Z. Citrus yield estimation based on images processed by an Android mobile phone. Biosyst. Eng. 2013, 115, 162–170. [Google Scholar] [CrossRef]

- Zhao, Z.Q.; Ma, L.H.; Cheung, Y.M.; Wu, X.; Tang, Y.; Chen, C.L.P. ApLeaf: An efficient Android-based plant leaf identification system. Neurocomputing 2015, 151, 1112–1119. [Google Scholar] [CrossRef]

- Rahman, M.; Blackwell, B.; Banerjee, N.; Saraswat, D. Smartphone-based hierarchical crowdsourcing for weed identification. Comput. Electron. Agric. 2015, 113, 14–23. [Google Scholar] [CrossRef]

- Gómez-Robledo, L.; López-Ruiz, N.; Melgosa, M.; Palma, A.J.; Capitán-Vallvey, L.F.; Sánchez-Marañón, M. Using the mobile phone as munsell soil-colour sensor: An experiment under controlled illumination conditions. Comput. Electron. Agric. 2013, 99, 200–208. [Google Scholar] [CrossRef]

- Onyango, C.M.; Marchant, J.A. Segmentation of row crop plants from weeds using colour and morphology. Comput. Electron. Agric. 2003, 39, 141–155. [Google Scholar] [CrossRef]

- Lee, J.-S. Digital image smoothing and the sigma filter. Comput. Vis. Graph. Image Process. 1983, 24, 255–269. [Google Scholar] [CrossRef]

- Mizushima, A.; Lu, R. An image segmentation method for apple sorting and grading using support vector machine and Otsu’s method. Comput. Electron. Agric. 2013, 94, 29–37. [Google Scholar] [CrossRef]

- Montalvo, M.; Pajares, G.; Guerrero, J.M.; Romeo, J.; Guijarro, M.; Ribeiro, A.; Ruz, J.J.; Cruz, J.M. Automatic detection of crop rows in maize fields with high weeds pressure. Expert Syst. Appl. 2012, 39, 11889–11897. [Google Scholar] [CrossRef] [Green Version]

- McCracken, K.E.; Yoon, J.Y. Recent approaches for optical smartphone sensing in resource-limited settings: A brief review. Anal. Methods 2016, 8, 6591–6601. [Google Scholar] [CrossRef]

- Connolly, C.; Fliess, T. A study of efficiency and accuracy in the transformation from RGB to CIELAB color space. IEEE Trans. Image Process. 1997, 6, 1046–1048. [Google Scholar] [CrossRef] [PubMed]

- Parvati, K.; Prakasa Rao, B.S.; Mariya Das, M. Image segmentation using gray-scale morphology and marker-controlled watershed transformation. Discret. Dyn. Nat. Soc. 2008, 2008. [Google Scholar] [CrossRef]

- Tanabata, T.; Shibaya, T.; Hori, K.; Ebana, K.; Yano, M. SmartGrain: High-Throughput Phenotyping Software for Measuring Seed Shape through Image Analysis. Plant Physiol. 2012, 160, 1871–1880. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gong, L.; Lin, K.; Wang, T.; Liu, C.; Yuan, Z.; Zhang, D.; Hong, J. Image-Based On-Panicle Rice [Oryza sativa L.] Grain Counting with a Prior Edge Wavelet Correction Model. Agronomy 2018, 8, 91. [Google Scholar] [CrossRef]

- Liu, T.; Chen, W.; Wang, Y.; Wu, W.; Sun, C.; Ding, J.; Guo, W. Rice and wheat grain counting method and software development based on Android system. Comput. Electron. Agric. 2017, 141, 302–309. [Google Scholar] [CrossRef]

| Number | Lighting Facilities | Luminous Flux (Lux) |

|---|---|---|

| L1 | Daylight, sunny day, indoors | 105 |

| L2 | With the Android device’s flash lamp on | 350 |

| L3 | Artificial lighting under the Android device | 500 |

| Device | HUAWEI P9 | Nexus 7 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Seed Species | |||||||||

| Indica Rice | KN | Error Ratio (%) | KN | Error Ratio (%) | KN | Error Ratio (%) | KN | Error Ratio (%) | |

| 5 | 0.00 | 150 | 0.67 | 5 | 0.00 | 150 | 1.33 | ||

| 10 | 0.00 | 200 | 2.00 | 10 | 0.00 | 200 | 1.50 | ||

| 20 | 0.00 | 250 | 1.60 | 20 | 0.00 | 250 | 1.60 | ||

| 50 | 0.00 | 300 | 1.67 | 50 | 2.00 | 300 | 1.67 | ||

| 100 | 2.00 | 350 | 2.28 | 100 | 1.00 | 350 | 2.28 | ||

| Adzuki Bean | 5 | 0.00 | 150 | 1.33 | 5 | 0.00 | 150 | 1.33 | |

| 10 | 0.00 | 200 | 2.50 | 10 | 0.00 | 200 | 2.00 | ||

| 20 | 0.00 | 250 | 2.80 | 20 | 0.00 | 250 | 2.80 | ||

| 50 | 0.00 | 300 | 1.67 | 50 | 0.00 | 300 | 1.67 | ||

| 100 | 2.00 | 350 | 1.71 | 100 | 2.00 | 350 | 1.71 | ||

| Mung Bean | 5 | 0.00 | 150 | 1.33 | 5 | 0.00 | 150 | 1.33 | |

| 10 | 0.00 | 200 | 1.50 | 10 | 0.00 | 200 | 2.00 | ||

| 20 | 0.00 | 250 | 1.60 | 20 | 0.00 | 250 | 1.60 | ||

| 50 | 0.00 | 300 | 3.00 | 50 | 0.00 | 300 | 3.33 | ||

| 100 | 2.00 | 350 | 1.43 | 100 | 2.00 | 350 | 2.29 | ||

| Soybean | 5 | 0.00 | 150 | 0.00 | 5 | 0.00 | 150 | 0.00 | |

| 10 | 0.00 | 200 | 0.00 | 10 | 0.00 | 200 | 0.50 | ||

| 20 | 0.00 | 250 | 1.20 | 20 | 0.00 | 250 | 1.20 | ||

| 50 | 0.00 | 300 | 1.33 | 50 | 0.00 | 300 | 1.67 | ||

| 100 | 0.00 | 350 | 0.86 | 100 | 0.00 | 350 | 1.14 | ||

| Sesame | 5 | 0.00 | 150 | 2.00 | 5 | 0.00 | 150 | 2.00 | |

| 10 | 0.00 | 200 | 4.00 | 10 | 0.00 | 200 | 4.00 | ||

| 20 | 0.00 | 250 | 4.40 | 20 | 0.00 | 250 | 4.40 | ||

| 50 | 2.00 | 300 | 3.30 | 50 | 2.00 | 300 | 3.67 | ||

| 100 | 2.00 | 350 | 3.43 | 100 | 2.00 | 350 | 3.71 | ||

| Peanut | 5 | 0.00 | 150 | 0.67 | 5 | 0.00 | 150 | 1.33 | |

| 10 | 0.00 | 200 | 1.50 | 10 | 0.00 | 200 | 1.50 | ||

| 20 | 0.00 | 250 | 2.80 | 20 | 0.00 | 250 | 3.20 | ||

| 50 | 0.00 | 300 | 3.33 | 50 | 0.00 | 300 | 3.33 | ||

| 100 | 1.00 | 350 | 3.71 | 100 | 1.00 | 350 | 3.71 | ||

| Species | Indica Rice | Adzuki Bean | Mung Bean | Soybean | Sesame | Peanut |

|---|---|---|---|---|---|---|

| TKW (g) | 28.84 | 58.27 | 53.44 | 182.31 | 2.76 | 386.25 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, W.; Zhou, L.; Chen, J.; Qiu, Z.; He, Y. GainTKW: A Measurement System of Thousand Kernel Weight Based on the Android Platform. Agronomy 2018, 8, 178. https://doi.org/10.3390/agronomy8090178

Wu W, Zhou L, Chen J, Qiu Z, He Y. GainTKW: A Measurement System of Thousand Kernel Weight Based on the Android Platform. Agronomy. 2018; 8(9):178. https://doi.org/10.3390/agronomy8090178

Chicago/Turabian StyleWu, Wenhua, Lei Zhou, Jian Chen, Zhengjun Qiu, and Yong He. 2018. "GainTKW: A Measurement System of Thousand Kernel Weight Based on the Android Platform" Agronomy 8, no. 9: 178. https://doi.org/10.3390/agronomy8090178