Enhanced Optoelectronic Properties of PFO/Fluorol 7GA Hybrid Light Emitting Diodes via Additions of TiO2 Nanoparticles

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Materials

2.2. Samples Preparation and OLEDs Fabrication

2.3. Samples Characterization

3. Results and Discussion

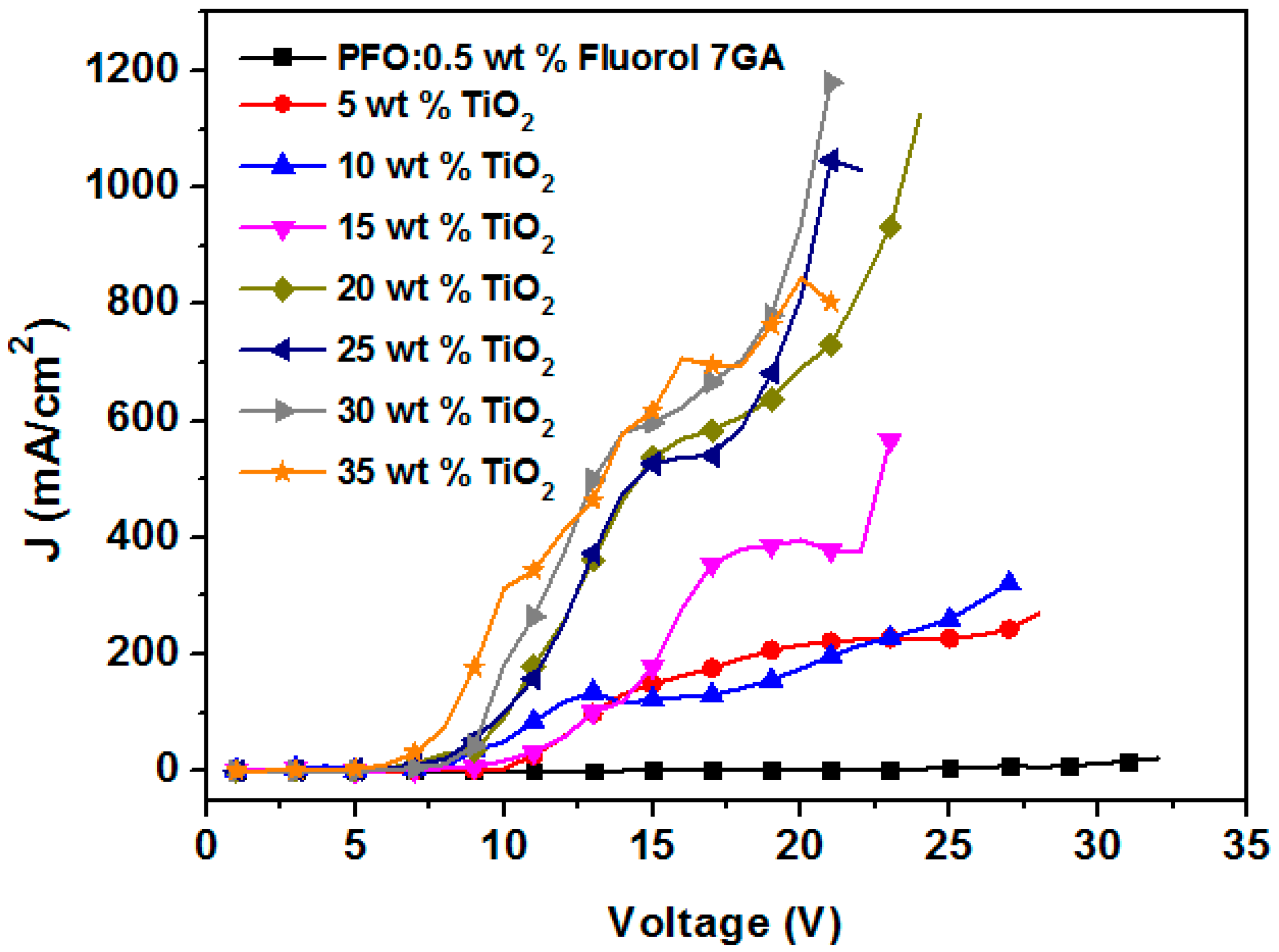

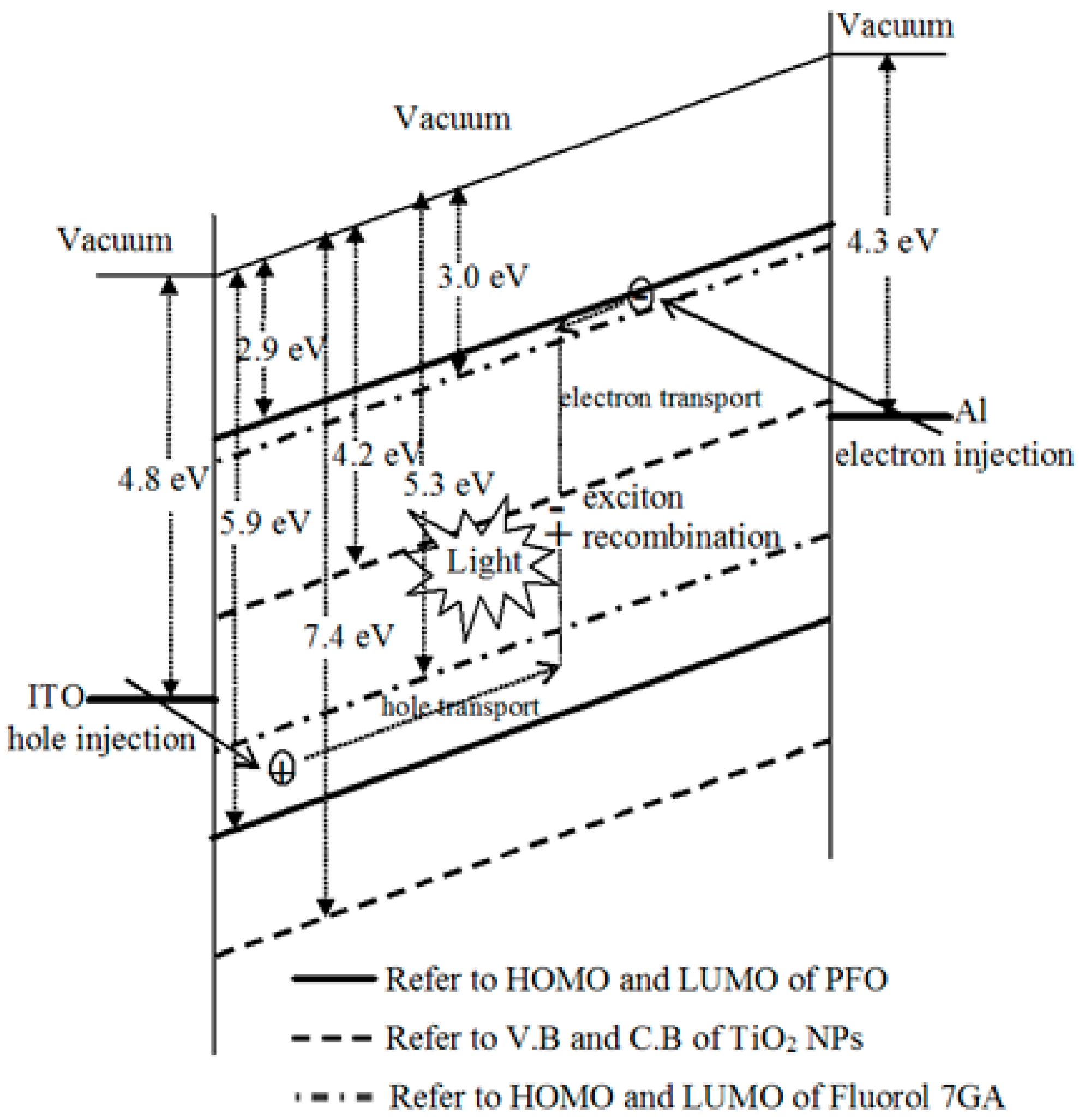

3.1. Current Density–Voltage Measurements

3.2. Electroluminescence Spectra

3.3. Luminance (cd/cm2) and Luminance Efficiency (cd/A)

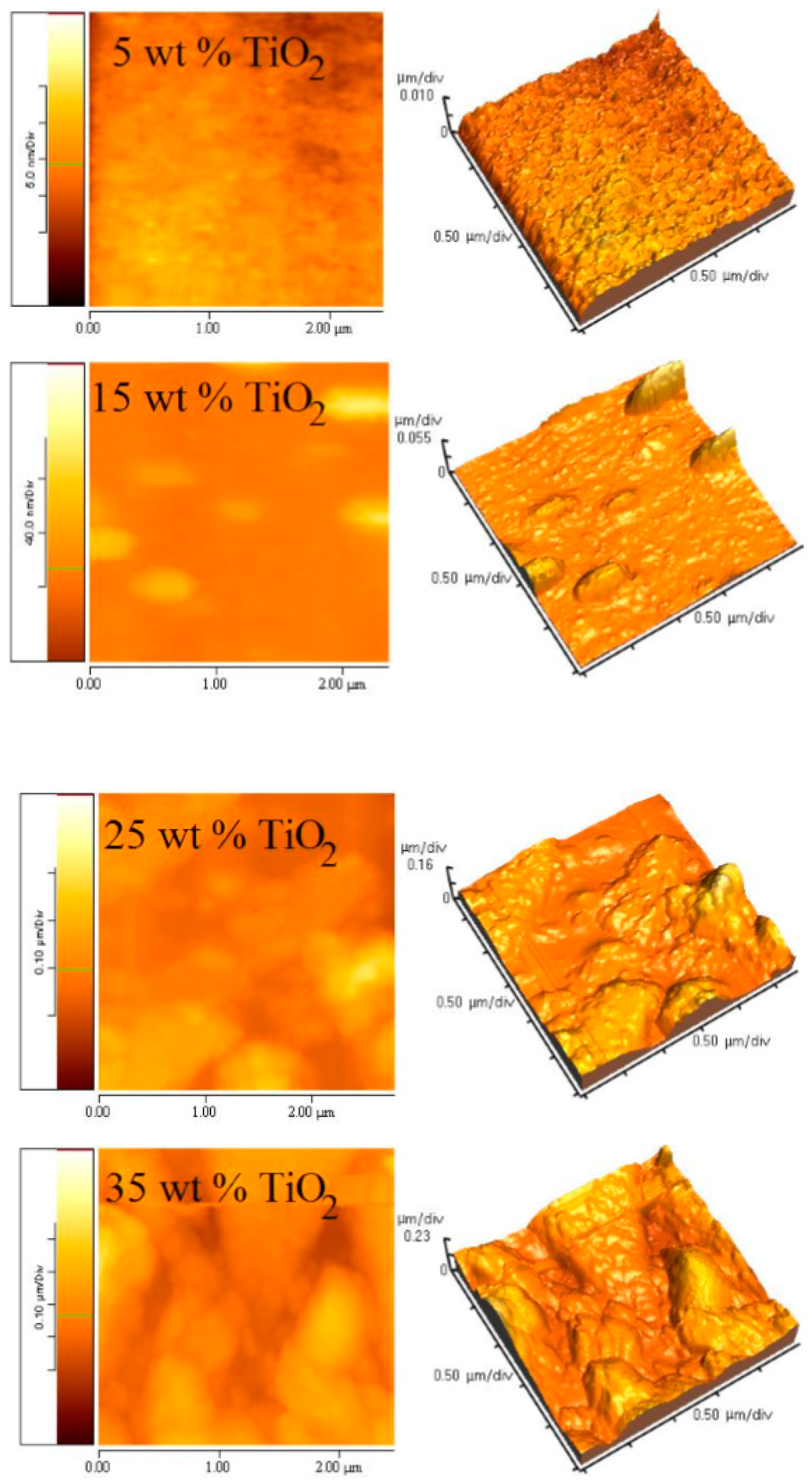

3.4. Morphology of (PFO/Fluorol 7GA)/TiO2 Nanocomposite Films

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Jameel, D.A.; Felix, J.F.; Aziz, M.; Al Saqri, N.; Taylor, D.; De Azevedo, W.M.; Da Silva, E.F., Jr.; Albalawi, H.; Alghamdi, H.; Al Mashary, F.; et al. High-performance organic/inorganic hybrid heterojunction based on gallium arsenide (gaas) substrates and a conjugated polymer. Appl. Surf. Sci. 2015, 357, 2189–2197. [Google Scholar] [CrossRef]

- Stanculescu, F.; Rasoga, O.; Catargiu, A.M.; Vacareanu, L.; Socol, M.; Breazu, C.; Preda, N.; Socol, G.; Stanculescu, A. Maple prepared heterostructures with arylene based polymer active layer for photovoltaic applications. Appl. Surf. Sci. 2015, 336, 240–248. [Google Scholar] [CrossRef]

- Gupta, N.; Grover, R.; Mehta, D.S.; Saxena, K. Efficiency enhancement in blue organic light emitting diodes with a composite hole transport layer based on poly(ethylenedioxythiophene): Poly(styrenesulfonate) doped with TiO2 nanoparticles. Displays 2015, 39, 104–108. [Google Scholar] [CrossRef]

- Yin, Y.; Deng, Z.; Lü, Z.; Li, X.; Li, M.; Liu, B.; Wang, Y.; Teng, F. Electroluminescent properties of poly[N,N′-bis(4-butylphenyl)-N,N′-bis(phenyl)benzidine] doped with 1,3,5-Tris(1-phenyl-1H-benzimidazol-2-yl)benzene. Displays 2015, 38, 32–37. [Google Scholar] [CrossRef]

- Romero-Servin, S.; Lozano-Hernández, L.-A.; Maldonado, J.-L.; Carriles, R.; Ramos-Ortíz, G.; Pérez-Gutiérrez, E.; Scherf, U.; Zolotukhin, M. Light emission properties of a cross-conjugated fluorene polymer: Demonstration of its use in electro-luminescence and lasing devices. Polymers 2016, 8, 43. [Google Scholar] [CrossRef]

- Bernardo, G.; Charas, A.; Morgado, J. Luminescence properties of poly(9,9-dioctylfluorene)/polyvinylcarbazole blends: Role of composition on the emission colour stability and electroluminescence efficiency. J. Phys. Chem. Solids 2010, 71, 340–345. [Google Scholar] [CrossRef]

- Lu, J.; Tao, Y.; D′Iorio, M.; Li, Y.; Ding, J.; Day, M. Pure deep blue light-emitting diodes from alternating fluorene/carbazole copolymers by using suitable hole-blocking materials. Macromolecules 2004, 37, 2442–2449. [Google Scholar] [CrossRef]

- Al-Asbahi, B.A.; Jumali, M.H.H.; Yap, C.C.; Salleh, M.M.; AlSalhi, M.S. Inhibition of dark quenching by TiO2 nanoparticles content in novel PFO/fluorol 7GA hybrid: A new role to improve OLED performance. Chem. Phys. Lett. 2013, 570, 109–112. [Google Scholar] [CrossRef]

- Willander, M.; Nur, O.; Zaman, S.; Zainelabdin, A.; Bano, N.; Hussain, I. Zinc oxide nanorods/polymer hybrid heterojunctions for white light emitting diodes. J. Phys. D Appl. Phys. 2011, 44, 224017–224023. [Google Scholar] [CrossRef]

- Jumali, M.H.H.; Al-Asbahi, B.A.; Yap, C.C.; Salleh, M.M.; Alsalhi, M.S. Optoelectronic property enhancement of conjugated polymer in poly(9,9′-di-n-octylfluorenyl-2.7-diyl)/titania nanocomposites. Thin Solid Films 2012, 524, 257–262. [Google Scholar] [CrossRef]

- Al-Asbahi, B.A.; Jumali, M.H.H.; Yap, C.C.; Salleh, M.M. Influence of TiO2 nanoparticles on enhancement of optoelectronic properties of PFO-based light emitting diode. J. Nanomater. 2013, 2013, 130. [Google Scholar] [CrossRef]

- Camurlu, P.; Giovanella, U.; Bolognesi, A.; Botta, C.; Cik, G.; Végh, Z. Polythiophene–polyoxyethylene copolymer in polyfluorene-based polymer blends for light-emitting devices. Synth. Met. 2009, 159, 41–44. [Google Scholar] [CrossRef]

- De Deus, J.F.; Faria, G.C.; Iamazaki, E.T.; Faria, R.M.; Atvars, T.D.Z.; Akcelrud, L. Polyfluorene based blends for white light emission. Org. Electron. 2011, 12, 1493–1504. [Google Scholar] [CrossRef] [Green Version]

- Al-Asbahi, B.A.; Jumali, M.H.H.; Yap, C.C.; Flaifel, M.H.; Salleh, M.M. Photophysical properties and energy transfer mechanism of PFO/Fluorol 7GA hybrid thin films. J. Lumin. 2013, 142, 57–65. [Google Scholar] [CrossRef]

- Al-Asbahi, B.A.; Jumali, H.; Hafizuddin, M.; Yap, C.C.; Salleh, M.M. Enhancement of poly (9,9′-di-n-octylfluorenyl-2.7-diyl) optoelectronic properties in novel conjugated polymer/laser dye hybrid OLEDs. Mater. Sci. Forum 2013, 756, 281–288. [Google Scholar] [CrossRef]

- Park, T.J.; Jeon, W.S.; Park, J.J.; Kim, S.Y.; Lee, Y.K.; Jang, J.; Kwon, J.H. Driving voltage reduction and efficiency increase by narrow bandgap host materials in phosphorescent organic light-emitting diodes. Thin Solid Films 2008, 517, 896–900. [Google Scholar] [CrossRef]

- Wang, R.; Shi, Z.; Zhang, C.; Zhang, A.; Chen, J.; Guo, W.; Sun, Z. Facile synthesis and controllable bromination of asymmetrical intermediates of perylene monoanhydride/monoimide diester. Dyes Pigm. 2013, 98, 450–458. [Google Scholar] [CrossRef]

- Bajpai, M.; Srivastava, R.; Kamalasanan, M.N.; Tiwari, R.S.; Chand, S. Charge transport and microstructure in PFO: MEH-PPV polymer blend thin films. Synth. Met. 2010, 160, 1740–1744. [Google Scholar] [CrossRef]

- Chang, C.-C.; Hsieh, M.-T.; Chen, J.-F.; Hwang, S.-W.; Chen, C.H. Highly power efficient organic light-emitting diodes with a p-doping layer. Appl. Phys. Lett. 2006, 89, 253504. [Google Scholar] [CrossRef]

- Madhwal, D.; Singh, I.; Kumar, J.; Bhatia, C.S.; Bhatnagar, P.K.; Mathur, P.C. Increasing the luminous efficiency of an MEH-PPV based pled using salmon DNA and single walled carbon nanotube. J. Lumin. 2011, 131, 1264–1266. [Google Scholar] [CrossRef]

- Rao, M.M.; Su, Y.; Huang, T.; Yeh, C.-H.; Tu, M.-L. Electroluminescent characteristics of DBPPV–ZnO nanocomposite polymer light emitting devices. Nanoscale Res. Lett. 2009, 4, 485–490. [Google Scholar]

- Zou, J.P.; Le Rendu, P.; Musa, I.; Yang, S.H.; Dan, Y.; That, C.T.; Nguyen, T.P. Investigation of the optical properties of polyfluorene/ZnO nanocomposites. Thin Solid Films 2011, 519, 3997–4003. [Google Scholar] [CrossRef]

- Hung, H.-W.; Yokoyama, N.; Yahiro, M.; Adachi, C. Low driving voltage organic light emitting diode using phenanthrene oligomers as electron transport layer. Thin Solid Films 2008, 516, 8717–8720. [Google Scholar] [CrossRef]

- Li, F.; Tang, H.; Shinar, J.; Resto, O.; Weisz, S.Z. Effects of aquaregia treatment of indium–tin–oxide substrates on the behavior of double layered organic light-emitting diodes. Appl. Surf. Sci. 1997, 70, 2741–2743. [Google Scholar] [CrossRef]

| Emissive layer | Max. luminance (cd/m2) | Luminance efficiency (a) (cd/A) | Turn-on voltage (b) (V) | Current density (a) (mA/cm2) |

|---|---|---|---|---|

| 5 wt % TiO2 | 40.7 at 29 V | 0.014 | 20 | 280.0 |

| 10 wt % TiO2 | 139 at 26 V | 0.048 | 16.5 | 290.6 |

| 15 wt % TiO2 | 198 at 21 V | 0.052 | 15 | 378.7 |

| 20 wt % TiO2 | 223 at 20 V | 0.024 | 12 | 937.7 |

| 25 wt % TiO2 | 238 at 20 V | 0.029 | 12.5 | 813.0 |

| 30 wt % TiO2 | 80.5 at 24 V | 0.007 | 15 | 1124.1 |

| 35 wt % TiO2 | 65.3 at 19 V | 0.009 | 12 | 764.2 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Asbahi, B.A.; Haji Jumali, M.H.; AlSalhi, M.S. Enhanced Optoelectronic Properties of PFO/Fluorol 7GA Hybrid Light Emitting Diodes via Additions of TiO2 Nanoparticles. Polymers 2016, 8, 334. https://doi.org/10.3390/polym8090334

Al-Asbahi BA, Haji Jumali MH, AlSalhi MS. Enhanced Optoelectronic Properties of PFO/Fluorol 7GA Hybrid Light Emitting Diodes via Additions of TiO2 Nanoparticles. Polymers. 2016; 8(9):334. https://doi.org/10.3390/polym8090334

Chicago/Turabian StyleAl-Asbahi, Bandar Ali, Mohammad Hafizuddin Haji Jumali, and Mohamad Saleh AlSalhi. 2016. "Enhanced Optoelectronic Properties of PFO/Fluorol 7GA Hybrid Light Emitting Diodes via Additions of TiO2 Nanoparticles" Polymers 8, no. 9: 334. https://doi.org/10.3390/polym8090334