Fabrication of Nerve Growth Factor Encapsulated Aligned Poly(ε-Caprolactone) Nanofibers and Their Assessment as a Potential Neural Tissue Engineering Scaffold

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

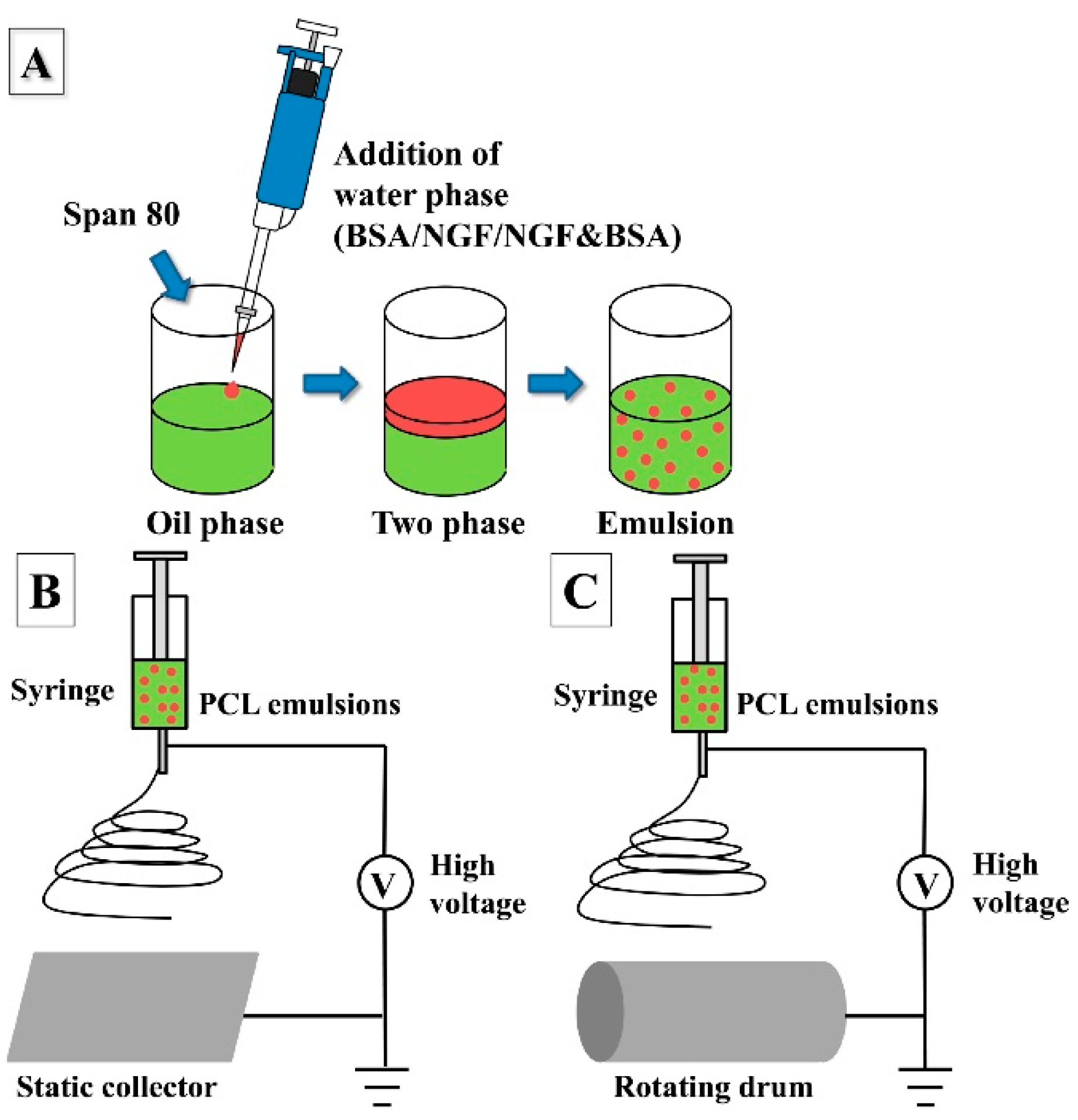

2.2. Scaffolds Fabrication

2.3. Characterization of Scaffolds

2.3.1. Observation of Field Emission Scanning Electron Microscope (FESEM)

2.3.2. Observation of Transmission Electron Microscopy (TEM)

2.3.3. Measurement of Water Contact Angle

2.4. Encapsulation Efficiency and In vitro Protein Release Study

2.5. Cell Culture and In vitro Cytotoxicity Study

2.6. Differentiation Study of PC12 Cells

2.6.1. Morphology Study of Differentiated PC12 Cells by SEM

2.6.2. Immunofluorescence Staining

2.7. Statistical Analysis

3. Results and Discussion

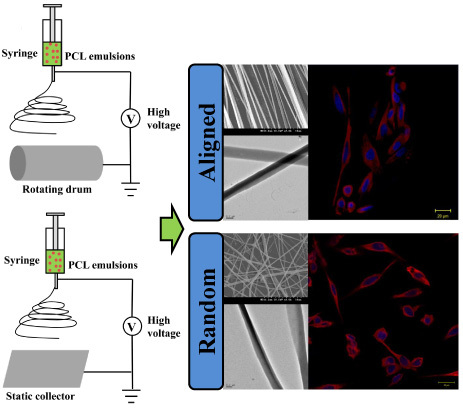

3.1. Formation of Emulsion Electrospun Nanofibrous Scaffolds

3.2. Characterization of Nanofibrous Scaffolds

3.2.1. Morphology Analysis of Nanofibrous Mats

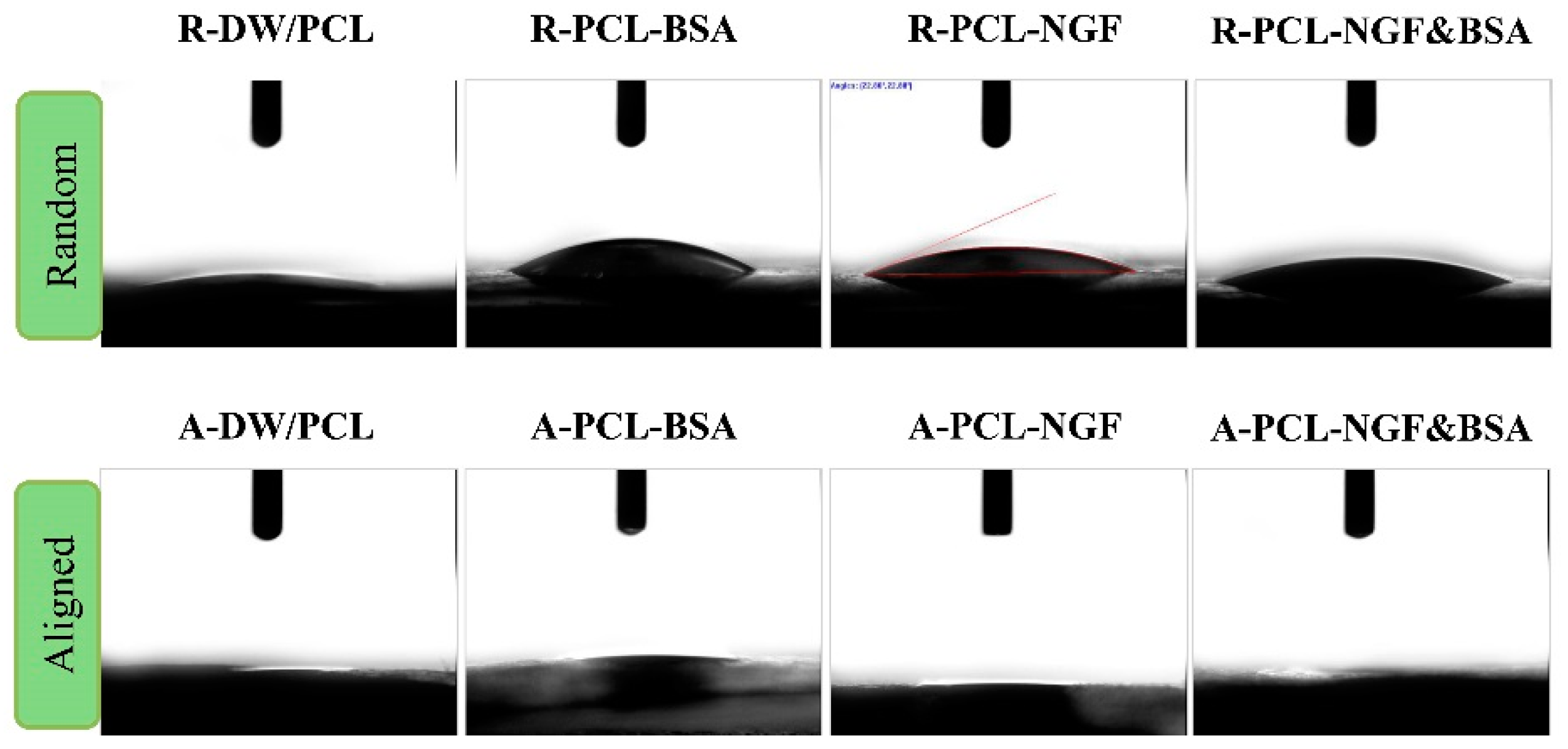

3.2.2. Analysis of Surface Hydrophilicity

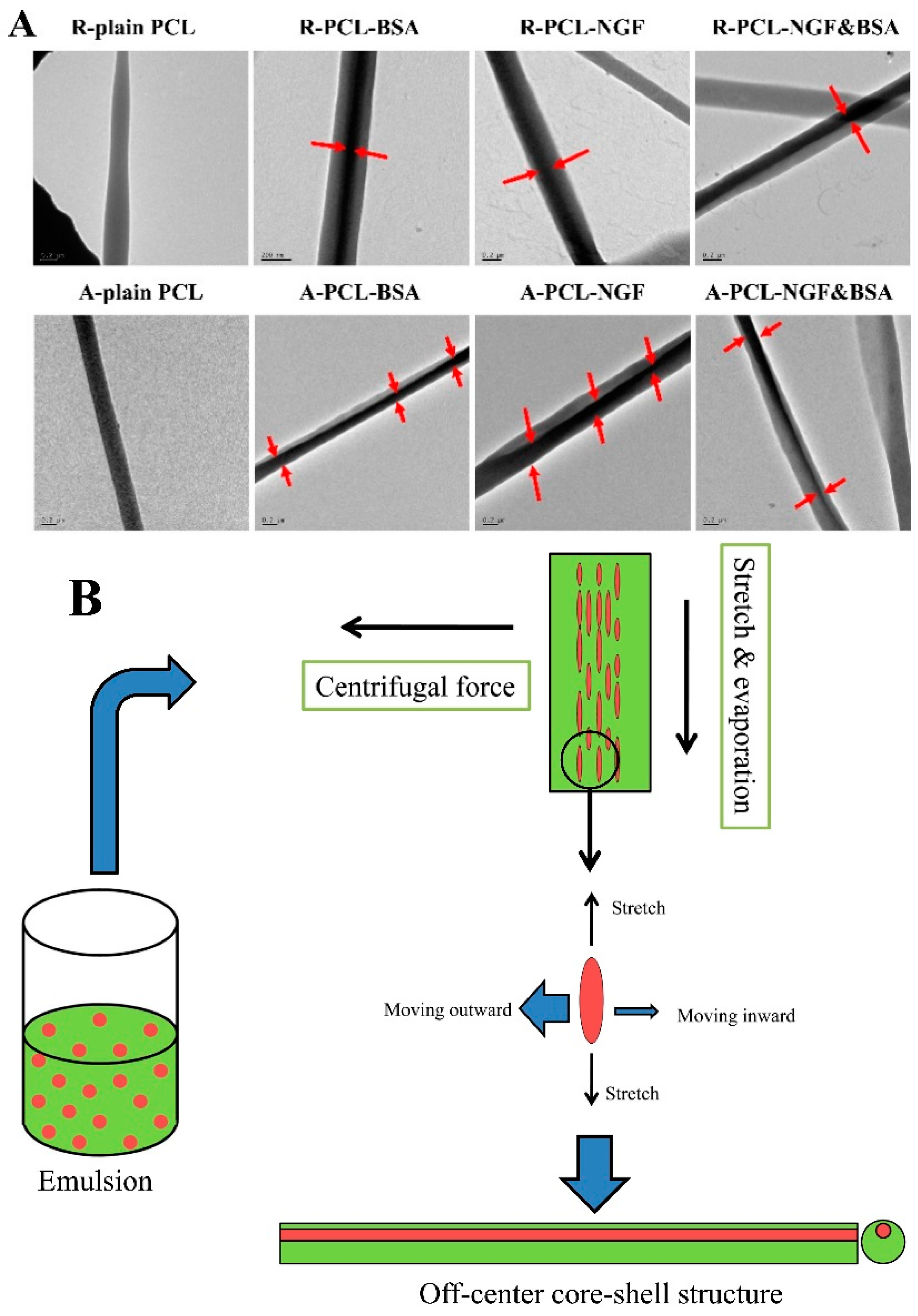

3.2.3. Study on the Internal Structure of Core-Shell Nanofibers

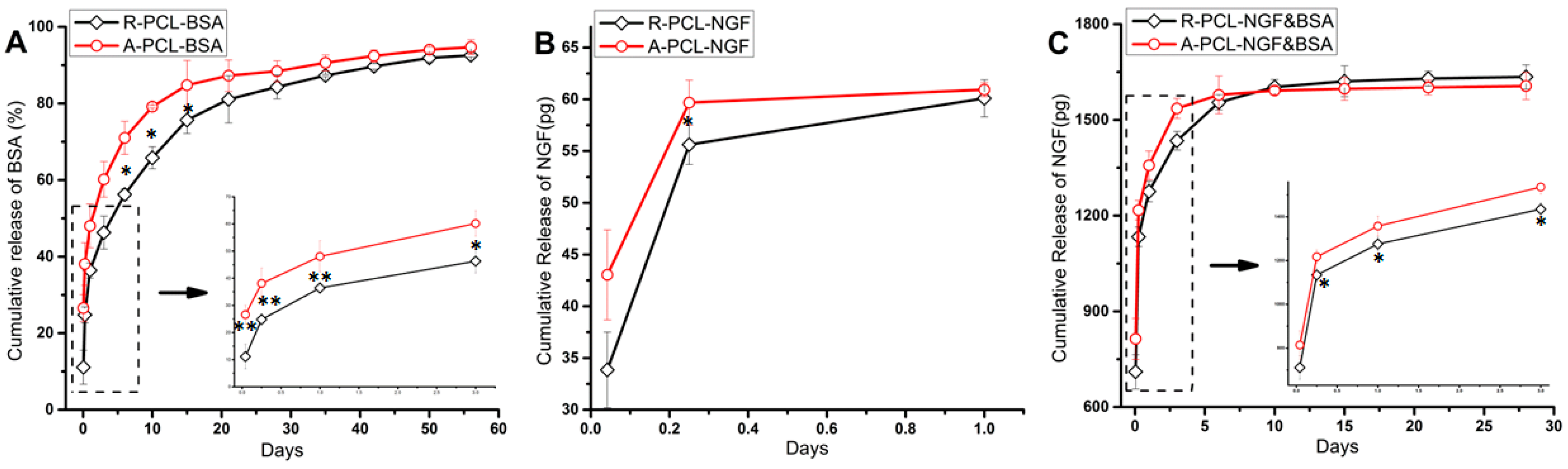

3.3. Encapsulation Efficiency and In vitro Protein Release Analysis of BSA

3.4. In vitro Release Study of NGF

3.5. In vitro Cytotoxicity Study of Emulsion Electrospun Nanofibers

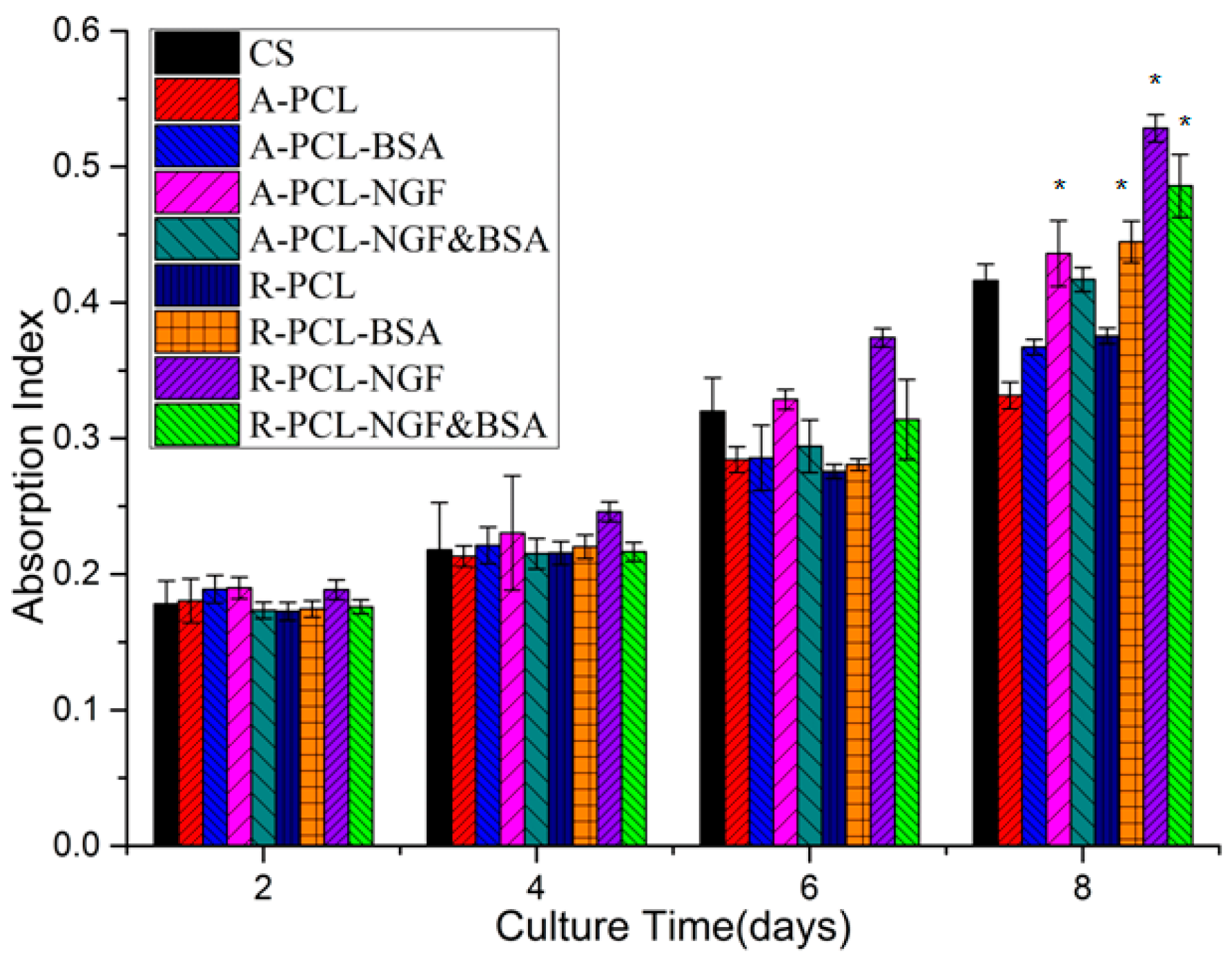

3.6. Differentiation Study of PC12 Cells

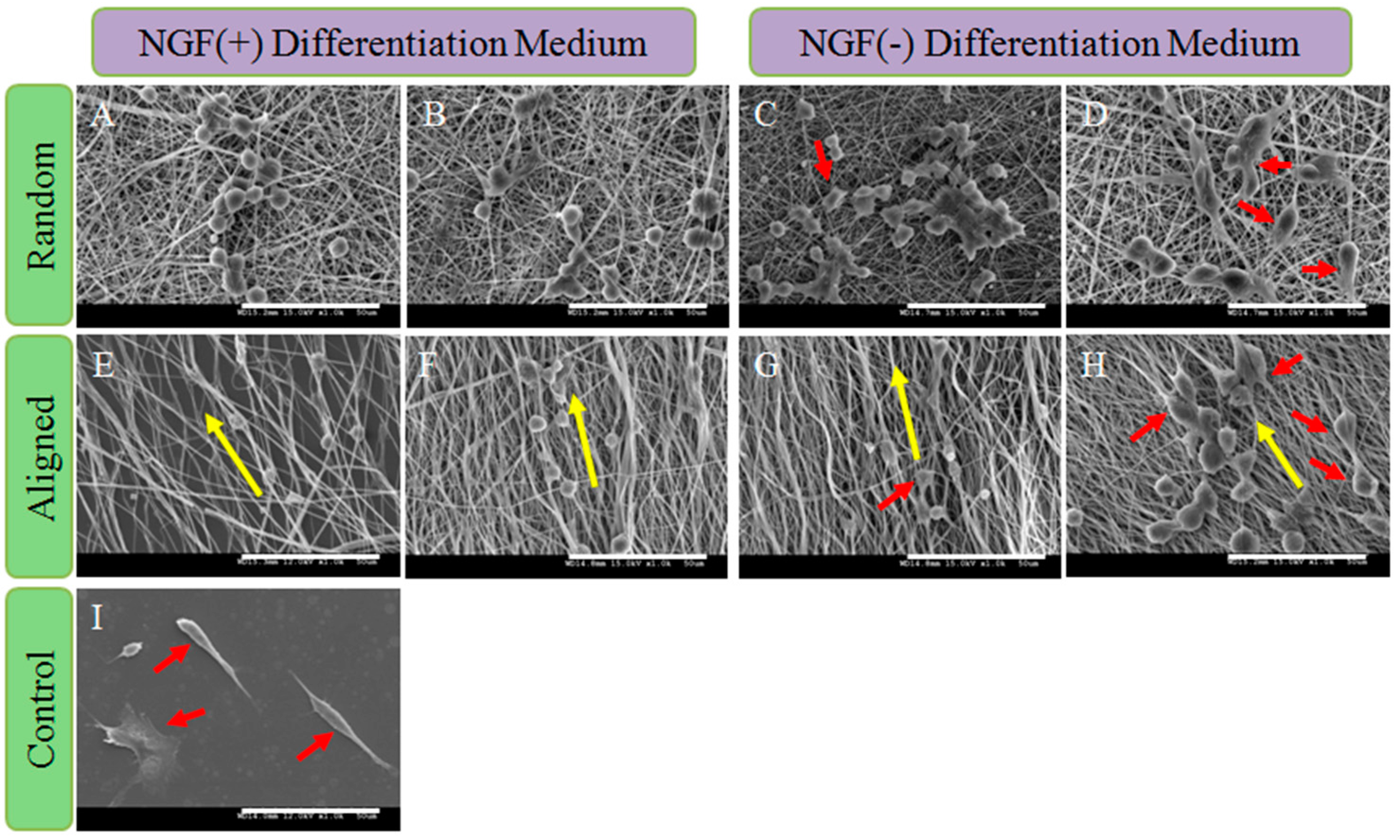

3.6.1. Morphology Analysis of Differentiated PC12 Cells

3.6.2. Analysis of the Expression of -Tubulin

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Dinis, T.M.; Elia, R.; Vidal, G.; Auffret, A.; Kaplan, D.L.; Egles, C. Method to form a fiber/growth factor dual-gradient along electrospun silk for nerve regeneration. ACS Appl. Mater. Interfaces 2014, 6, 16817–16826. [Google Scholar] [CrossRef] [PubMed]

- GhoshMitra, S.; Diercks, D.R.; Mills, N.C.; Hynds, D.L.; Ghosh, S. Role of engineered nanocarriers for axon regeneration and guidance: Current status and future trends. Adv. Drug Deliv. Rev. 2012, 64, 110–125. [Google Scholar] [CrossRef] [PubMed]

- Min, B.M.; You, Y.; Kim, J.M.; Lee, S.J.; Park, W.H. Formation of nanostructured poly(lactic-co-glycolic acid)/chitin matrix and its cellular response to normal human keratinocytes and fibroblasts. Carbohydr. Polym. 2004, 57, 285–292. [Google Scholar] [CrossRef]

- Stevens, M.M.; George, J.H. Exploring and engineering the cell surface interface. Science 2005, 310, 1135–1138. [Google Scholar] [CrossRef] [PubMed]

- Al-Omair, M. Synthesis of antibacterial silver–poly(ε-caprolactone)-methacrylic acid graft copolymer nanofibers and their evaluation as potential wound dressing. Polymers 2015, 7, 1464–1475. [Google Scholar] [CrossRef]

- Yan, S.; Xiaoqiang, L.; Lianjiang, T.; Chen, H.; Xiumei, M. Poly(l-lactide-co-ε-caprolactone) electrospun nanofibers for encapsulating and sustained releasing proteins. Polymer 2009, 50, 4212–4219. [Google Scholar] [CrossRef]

- Tian, L.; Prabhakaran, M.P.; Hu, J.; Chen, M.; Besenbacher, F.; Ramakrishna, S. Coaxial electrospun poly (lactic acid)/silk fibroin nanofibers incorporated with nerve growth factor support the differentiation of neuronal stem cells. RSC Adv. 2015, 5, 49838–49848. [Google Scholar] [CrossRef]

- Zhu, W.; Masood, F.; O’Brien, J.; Zhang, L.G. Highly aligned nanocomposite scaffolds by electrospinning and electrospraying for neural tissue regeneration. Nanomedicine 2015, 11, 693–704. [Google Scholar] [CrossRef] [PubMed]

- Kuihua, Z.; Chunyang, W.; Cunyi, F.; Xiumei, M. Aligned SF/P(LLA-CL)-blended nanofibers encapsulating nerve growth factor for peripheral nerve regeneration. J. Biomed. Mater. Res. A 2014, 102, 2680–2691. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Qiu, K.; Sun, B.; Fang, J.; Zhang, K.; Ei-Hamshary, H.; Al-Deyab, S.S.; Mo, X. The aligned core-sheath nanofibers with electrical conductivity for neural tissue engineering. J. Mater. Chem. B 2014, 2, 7945–7954. [Google Scholar] [CrossRef]

- Lorentz, A.; Hoppe, J.; Worthmann, H.; Gebhardt, T.; Hesse, U.; Bienenstock, J.; Bischoff, S.C. Neurotrophin-3, but not nerve growth factor, promotes survival of human intestinal mast cells. Neurogastroenterol. Motil. 2007, 19, 301–308. [Google Scholar] [CrossRef] [PubMed]

- Pfister, L.A.; Alther, E.; Papaloïzos, M.; Merkle, H.P.; Gander, B. Controlled nerve growth factor release from multi-ply alginate/chitosan-based nerve conduits. Eur. J. Pharm. Biopharm. 2008, 69, 563–572. [Google Scholar] [CrossRef] [PubMed]

- Pfister, L.A.; Papaloïzos, M.; Merkle, H.P.; Gander, B. Nerve conduits and growth factor delivery in peripheral nerve repair. J. Peripher. Nerv. Syst. 2007, 12, 65–82. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Liu, J.; Ma, J.; Xiang, L. Local delivery of controlled released nerve growth factor promotes sciatic nerve regeneration after crush injury. Neurosci. Lett. 2014, 566, 177–181. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H.; Wang, L.; Zhu, K. Coaxial electrospinning for encapsulation and controlled release of fragile water-soluble bioactive agents. J. Control. Release 2014, 193, 296–303. [Google Scholar] [CrossRef] [PubMed]

- Tian, L.; Prabhakaran, M.; Ding, X.; Kai, D.; Ramakrishna, S. Emulsion electrospun nanofibers as substrates for cardiomyogenic differentiation of mesenchymal stem cells. J. Mater. Sci. Mater. Med. 2013, 24, 2577–2587. [Google Scholar] [CrossRef] [PubMed]

- Briggs, T.; Arinzeh, T.L. Examining the formulation of emulsion electrospinning for improving the release of bioactive proteins from electrospun fibers. J. Biomed. Mater. Res. A 2014, 102, 674–684. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Prabhakaran, M.P.; Tian, L.; Ding, X.; Ramakrishna, S. Drug-loaded emulsion electrospun nanofibers: Characterization, drug release and in vitro biocompatibility. RSC Adv. 2015, 5, 100256–100267. [Google Scholar] [CrossRef]

- Xue, J.; He, M.; Niu, Y.; Liu, H.; Crawford, A.; Coates, P.; Chen, D.; Shi, R.; Zhang, L. Preparation and in vivo efficient anti-infection property of GTR/GBR implant made by metronidazole loaded electrospun polycaprolactone nanofiber membrane. Int. J. Pharm. 2014, 475, 566–577. [Google Scholar] [CrossRef] [PubMed]

- Valmikinathan, C.M.; Defroda, S.; Yu, X. Polycaprolactone and bovine serum albumin based nanofibers for controlled release of nerve growth factor. Biomacromolecules 2009, 10, 1084–1089. [Google Scholar] [CrossRef] [PubMed]

- Zeng, W.; Rong, M.; Hu, X.; Xiao, W.; Qi, F.; Huang, J.; Luo, Z. Incorporation of chitosan microspheres into collagen-chitosan scaffolds for the controlled release of nerve growth factor. PLoS ONE 2014, 9, e101300. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.Y.; Liu, J.J.; Fan, C.Y.; Mo, X.M.; Ruan, H.J.; Li, F.F. The effect of aligned core-shell nanofibres delivering NGF on the promotion of sciatic nerve regeneration. J. Biomater. Sci. Polym. Ed. 2012, 23, 167–184. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.-J.; Wang, C.-Y.; Wang, J.-G.; Ruan, H.-J.; Fan, C.-Y. Peripheral nerve regeneration using composite poly(lactic acid-caprolactone)/nerve growth factor conduits prepared by coaxial electrospinning. J. Biomed. Mater. Res. A 2011, 96A, 13–20. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.H.; Wang, C.H.; Tong, Y.W. In vitro characterization of hepatocyte growth factor release from PHBV/PLGA microsphere scaffold. J. Biomed. Mater. Res. A 2009, 89, 411–423. [Google Scholar] [CrossRef] [PubMed]

- Chou, D.K.; Krishnamurthy, R.; Randolph, T.W.; Carpenter, J.F.; Manning, M.C. Effects of tween 20® and tween 80® on the stability of albutropin during agitation. J. Pharm. Sci. 2005, 94, 1368–1381. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.J.; McAuley, A.; Schilke, K.F.; McGuire, J. Molecular origins of surfactant-mediated stabilization of protein drugs. Adv. Drug Deliv. Rev. 2011, 63, 1160–1171. [Google Scholar] [CrossRef] [PubMed]

- Serno, T.; Geidobler, R.; Winter, G. Protein stabilization by cyclodextrins in the liquid and dried state. Adv. Drug Deliv. Rev. 2011, 63, 1086–1106. [Google Scholar] [CrossRef] [PubMed]

- Cappelletti, G.; Maggioni, M.G.; Tedeschi, G.; Maci, R. Protein tyrosine nitration is triggered by nerve growth factor during neuronal differentiation of PC12 cells. Exp. Cell Res. 2003, 288, 9–20. [Google Scholar] [CrossRef]

- Cappelletti, G.; Maggioni, M.G.; Ronchi, C.; Maci, R.; Tedeschi, G. Protein tyrosine nitration is associated with cold- and drug-resistant microtubules in neuronal-like PC12 cells. Neurosci. Lett. 2006, 401, 159–164. [Google Scholar] [CrossRef] [PubMed]

- Zander, N.; Orlicki, J.; Rawlett, A.; Beebe, T. Surface-modified nanofibrous biomaterial bridge for the enhancement and control of neurite outgrowth. Biointerphases 2010, 5, 149–158. [Google Scholar] [CrossRef] [PubMed]

- Yan, S.; Xiaoqiang, L.; Shuiping, L.; Xiumei, M.; Ramakrishna, S. Controlled release of dual drugs from emulsion electrospun nanofibrous mats. Colloids Surf. B Biointerfaces 2009, 73, 376–381. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.L.; Chen, X.S.; Wang, Z.F.; Jing, X.B. Ultrafine PEG-PLA fibers loaded with both paclitaxel and doxorubicin hydrochloride and their in vitro cytotoxicity. Eur. J. Pharm. Biopharm. 2009, 72, 18–25. [Google Scholar] [CrossRef] [PubMed]

- Tian, L.; Prabhakaran, M.P.; Ding, X.; Kai, D.; Ramakrishna, S. Emulsion electrospun vascular endothelial growth factor encapsulated poly(l-lactic acid-co-ε-caprolactone) nanofibers for sustained release in cardiac tissue engineering. J. Mater. Sci. 2011, 47, 3272–3281. [Google Scholar] [CrossRef]

- Xu, X.L.; Chen, X.S.; Ma, P.A.; Wang, X.R.; Jing, X.B. The release behavior of doxorubicin hydrochloride from medicated fibers prepared by emulsion-electrospinning. Eur. J. Pharm. Biopharm. 2008, 70, 165–170. [Google Scholar] [CrossRef] [PubMed]

- De Boer, R.; Knight, A.M.; Spinner, R.J.; Malessy, M.J.; Yaszemski, M.J.; Windebank, A.J. In vitro and in vivo release of nerve growth factor from biodegradable poly-lactic-co-glycolic-acid microspheres. J. Biomed. Mater. Res. A 2010, 95, 1067–1073. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Zhou, Y.; Chen, S.; Bu, M.; Xin, J.; Li, S. Current sustained delivery strategies for the design of local neurotrophic factors in treatment of neurological disorders. Asian J. Pharm. Sci. 2013, 8, 269–277. [Google Scholar] [CrossRef]

- Han, N.; Johnson, J.; Lannutti, J.J.; Winter, J.O. Hydrogel–electrospun fiber composite materials for hydrophilic protein release. J. Control. Release 2012, 158, 165–170. [Google Scholar] [CrossRef] [PubMed]

- Dinis, T.; Elia, R.; Vidal, G.; Dermigny, Q.; Denoeud, C.; Kaplan, D.; Egles, C.; Marin, F. 3D multi-channel bi-functionalized silk electrospun conduits for peripheral nerve regeneration. J. Mech. Behav. Biomed. Mater. 2015, 41, 43–55. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.; Xu, F.; Guo, D.; Liu, G. In vitro evaluation of the effects of various additives and polymers on nerve growth factor microspheres. Drug Dev. Ind. Pharm. 2014, 40, 452–457. [Google Scholar] [CrossRef] [PubMed]

- Kijeńska, E.; Prabhakaran, M.P.; Swieszkowski, W.; Kurzydlowski, K.J.; Ramakrishna, S. Interaction of schwann cells with laminin encapsulated plcl core–shell nanofibers for nerve tissue engineering. Eur. Polym. J. 2014, 50, 30–38. [Google Scholar] [CrossRef]

- Bhang, S.H.; Lee, T.-J.; Lim, J.M.; Lim, J.S.; Han, A.M.; Choi, C.Y.; Kim Kwon, Y.H.; Kim, B.-S. The effect of the controlled release of nerve growth factor from collagen gel on the efficiency of neural cell culture. Biomaterials 2009, 30, 126–132. [Google Scholar] [CrossRef] [PubMed]

| Scaffolds (8% PCL) | W/O | Diameter (nm/n = 100) | Contact angle (°/n = 3) | Scaffolds (9% PCL) | W/O | Diameter (nm/n = 100) | Contact angle (°/n = 3) |

|---|---|---|---|---|---|---|---|

| R-PCL | DW-PCL | 343 ± 113 | 0 | A-PCL | DW-PCL | 354 ± 91 | 0 |

| R-PCL-BSA | BSA-PCL | 301 ± 76 | 24.7 ± 1.2 | A-PCL-BSA | BSA-PCL | 302 ± 70 | 6.7 ± 2.5 |

| R-PCL-NGF | NGF-PCL | 371 ± 95 | 22.8 ± 2.9 | A-PCL-NGF | NGF-PCL | 333 ± 90 | 0 |

| R-PCL-NGF&BSA | NGF&BSA-PCL | 320 ± 97 | 21.4 ± 1.7 | A-PCL-NGF&BSA | NGF&BSA-PCL | 320 ± 87 | 0 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, J.; Tian, L.; Prabhakaran, M.P.; Ding, X.; Ramakrishna, S. Fabrication of Nerve Growth Factor Encapsulated Aligned Poly(ε-Caprolactone) Nanofibers and Their Assessment as a Potential Neural Tissue Engineering Scaffold. Polymers 2016, 8, 54. https://doi.org/10.3390/polym8020054

Hu J, Tian L, Prabhakaran MP, Ding X, Ramakrishna S. Fabrication of Nerve Growth Factor Encapsulated Aligned Poly(ε-Caprolactone) Nanofibers and Their Assessment as a Potential Neural Tissue Engineering Scaffold. Polymers. 2016; 8(2):54. https://doi.org/10.3390/polym8020054

Chicago/Turabian StyleHu, Jue, Lingling Tian, Molamma P. Prabhakaran, Xin Ding, and Seeram Ramakrishna. 2016. "Fabrication of Nerve Growth Factor Encapsulated Aligned Poly(ε-Caprolactone) Nanofibers and Their Assessment as a Potential Neural Tissue Engineering Scaffold" Polymers 8, no. 2: 54. https://doi.org/10.3390/polym8020054