Finite-Element Investigation of the Structural Behavior of Basalt Fiber Reinforced Polymer (BFRP)- Reinforced Self-Compacting Concrete (SCC) Decks Slabs in Thompson Bridge

Abstract

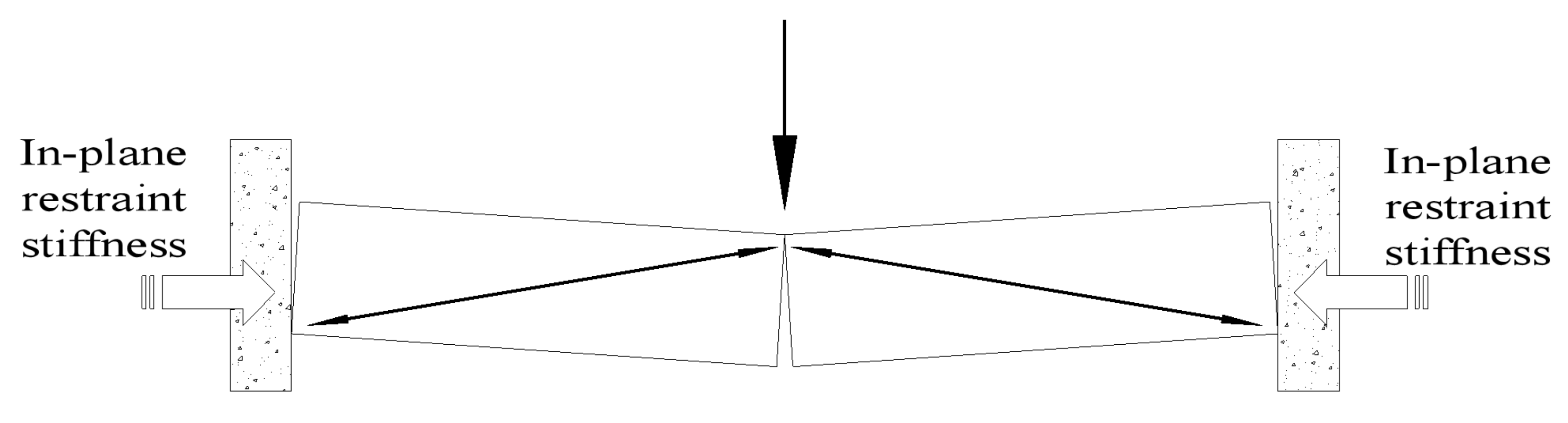

:1. Introduction

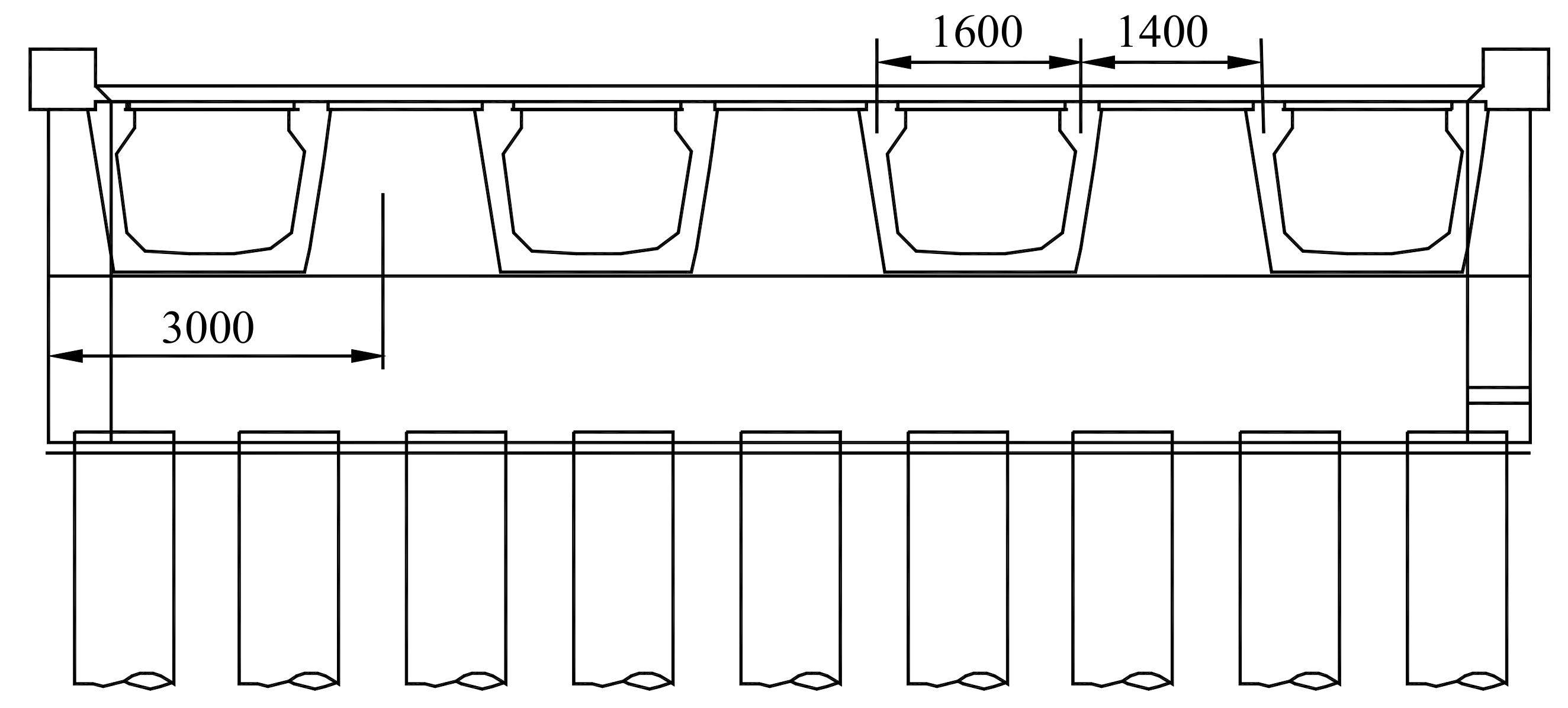

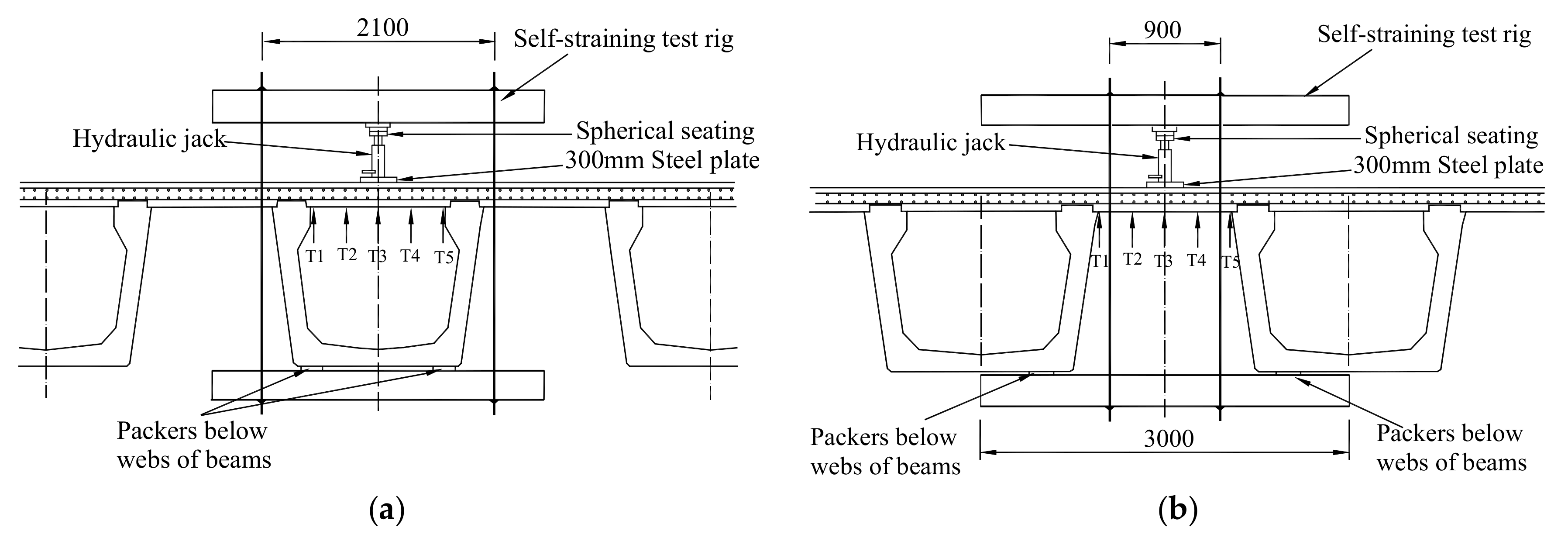

2. Experimental Program

2.1. Introduction of Thompson Bridge

2.2. Material Properties

2.3. Test Loading

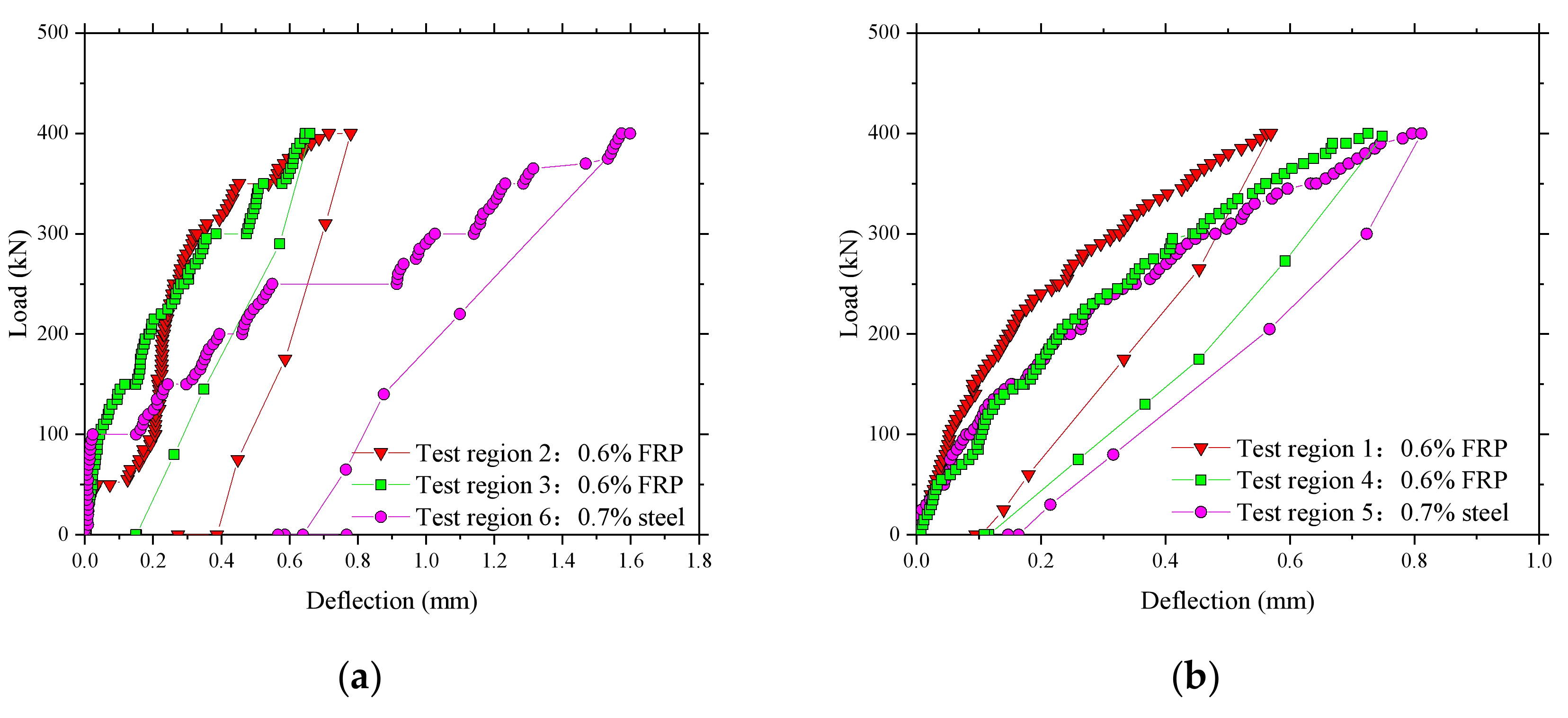

2.4. Test Results and Analysis

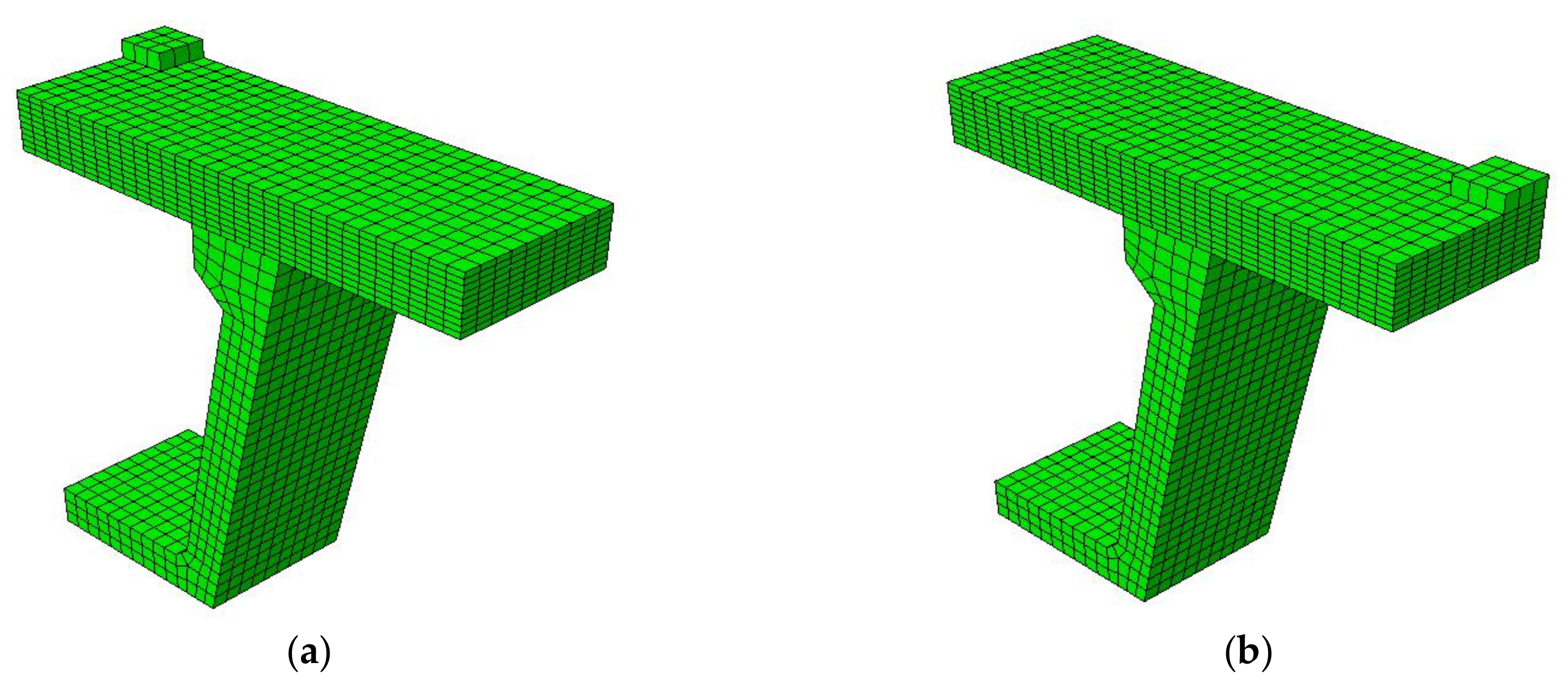

3. Numerical Investigation of the Local Bridge Model

3.1. Nonlinear Finite Element Model

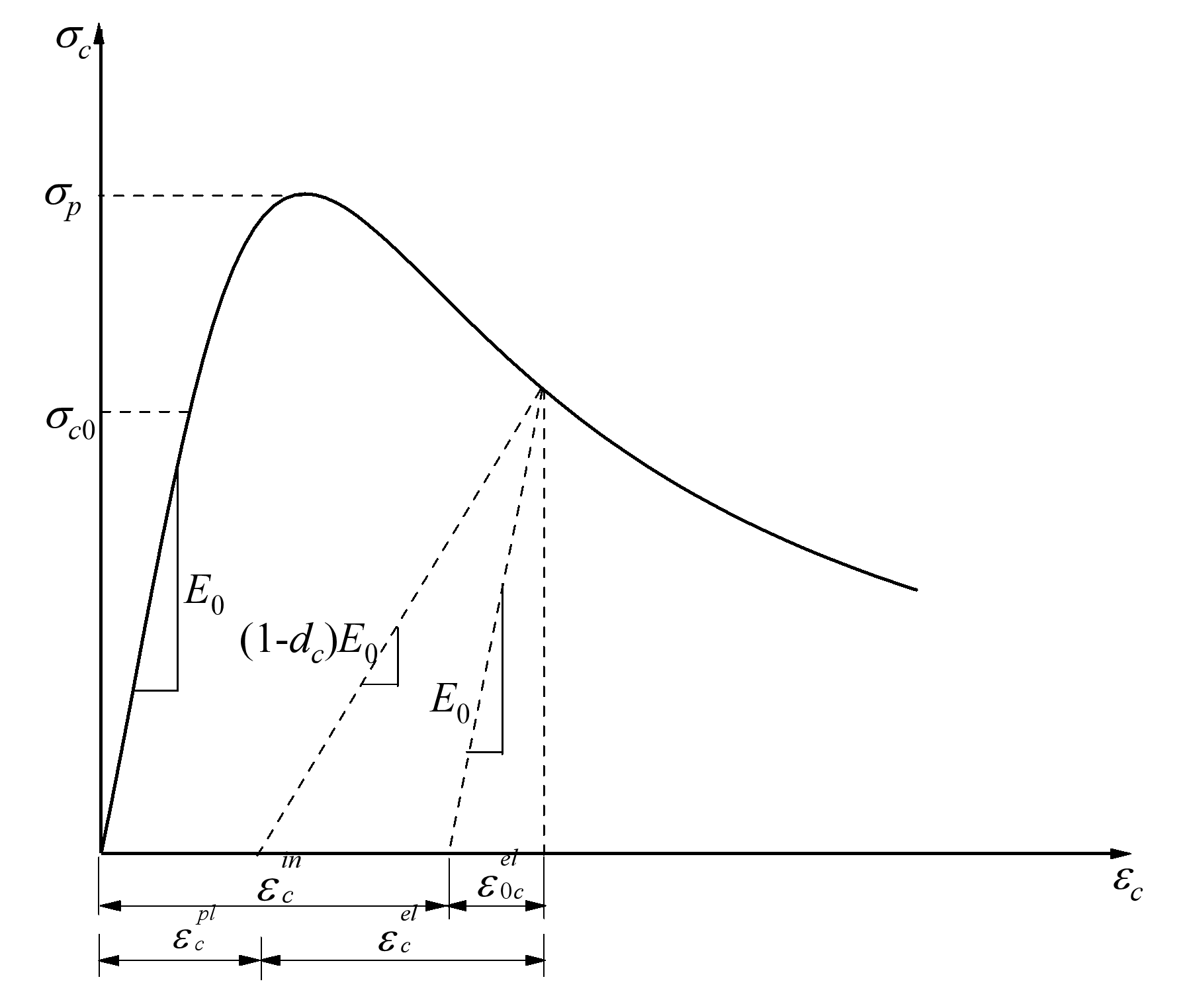

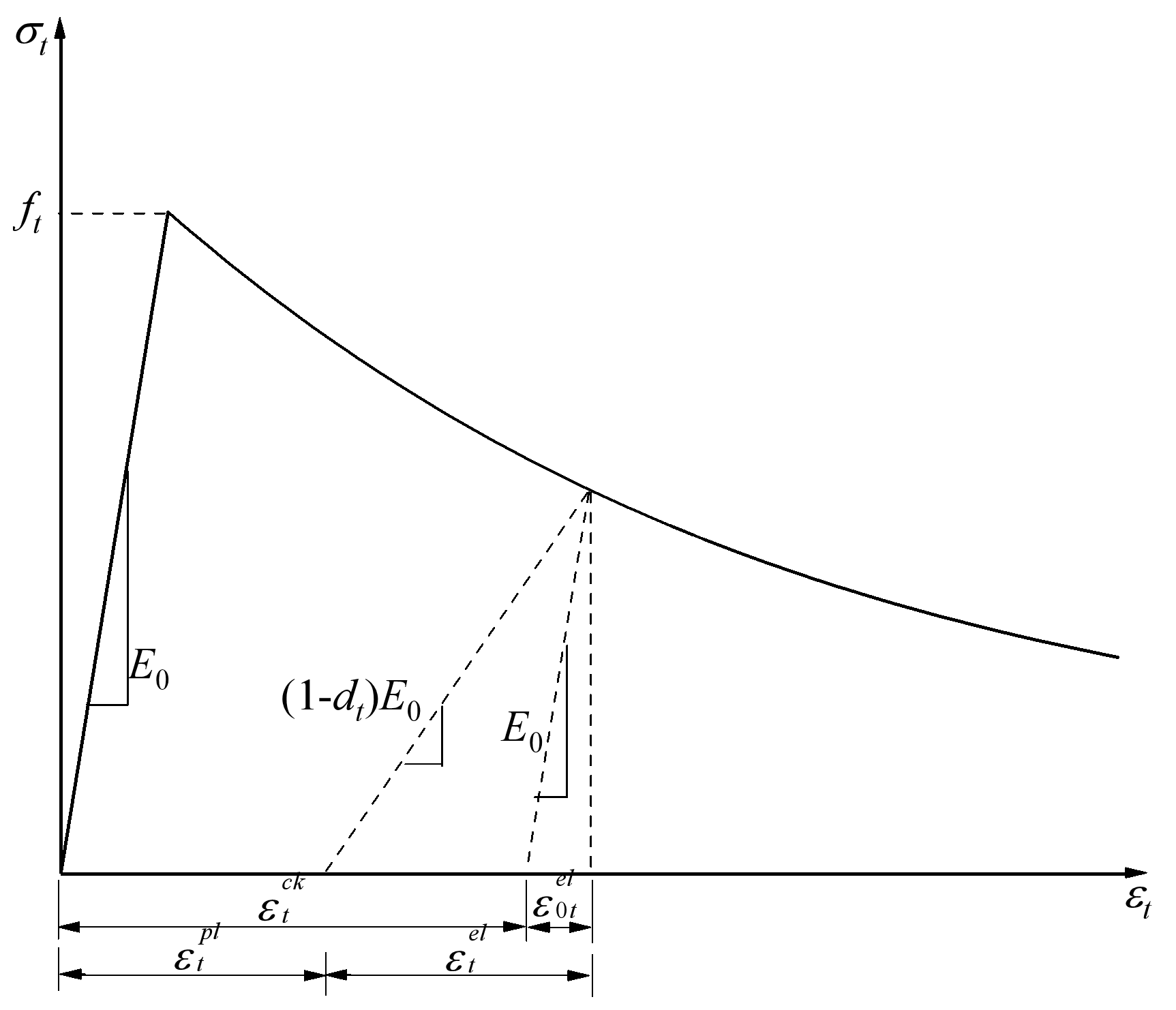

3.2. Constitutive Models

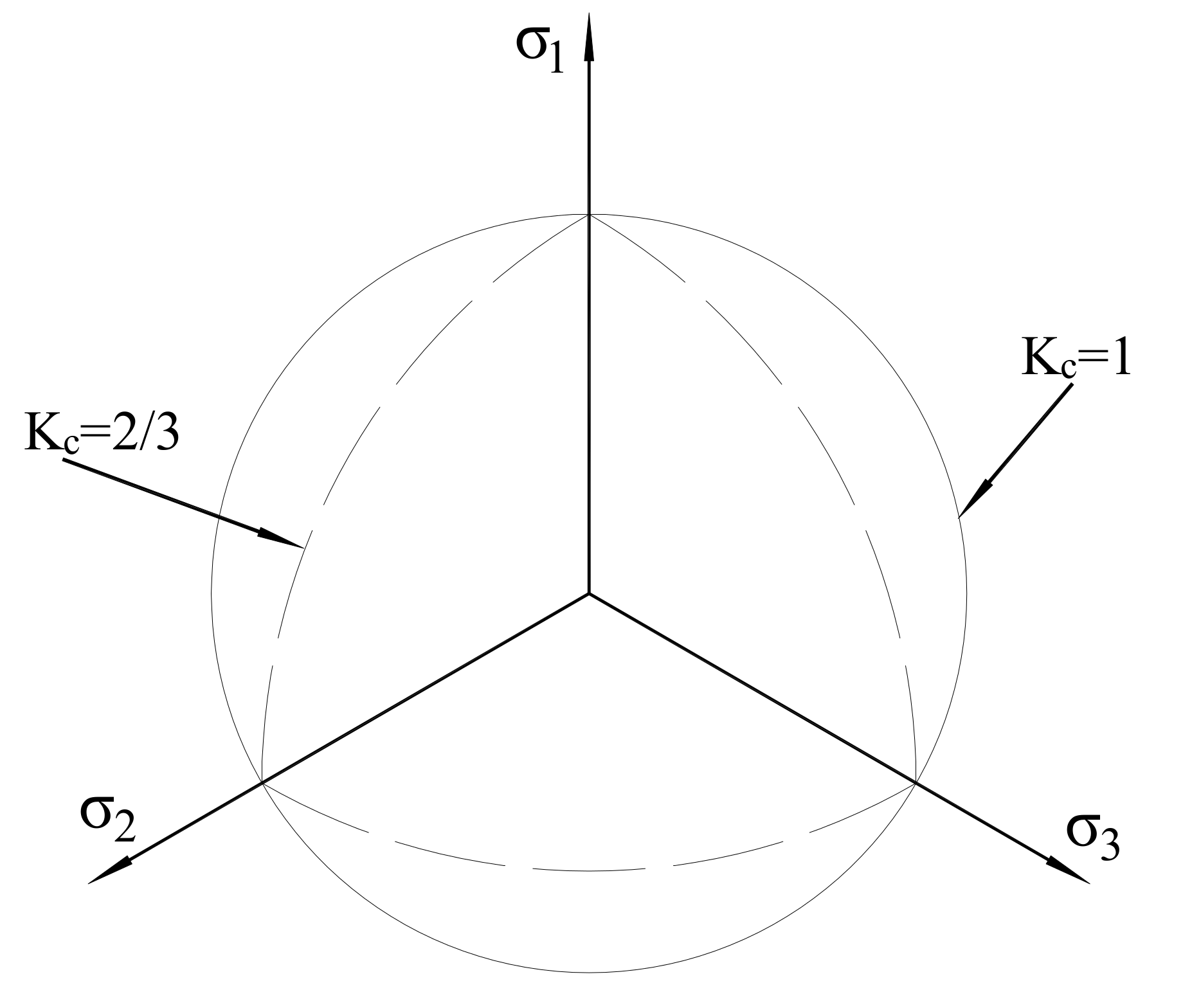

3.2.1. Damaged Plasticity Model

3.2.2. Constitutive Relationship of Concrete

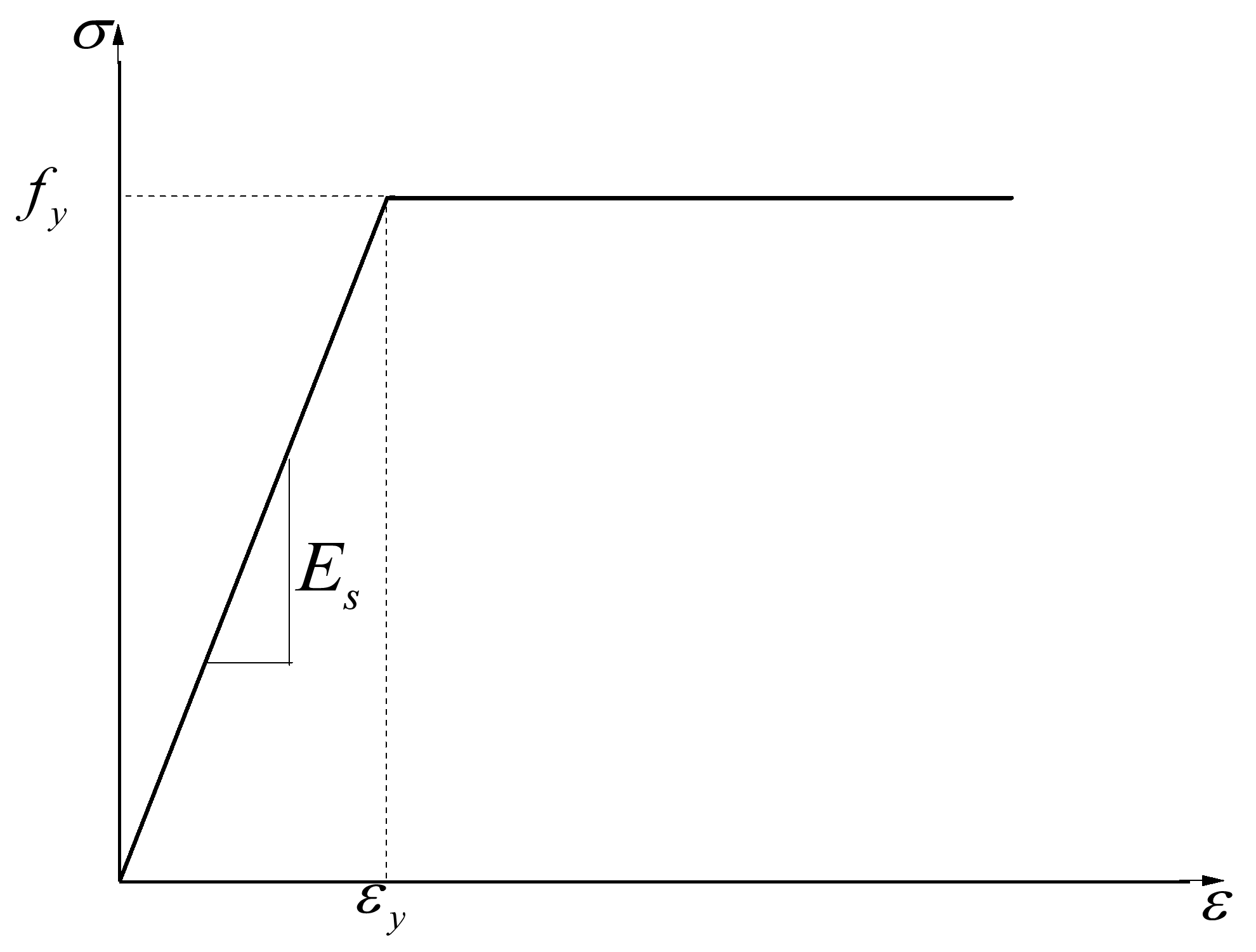

3.2.3. FRP and Steel Reinforcement

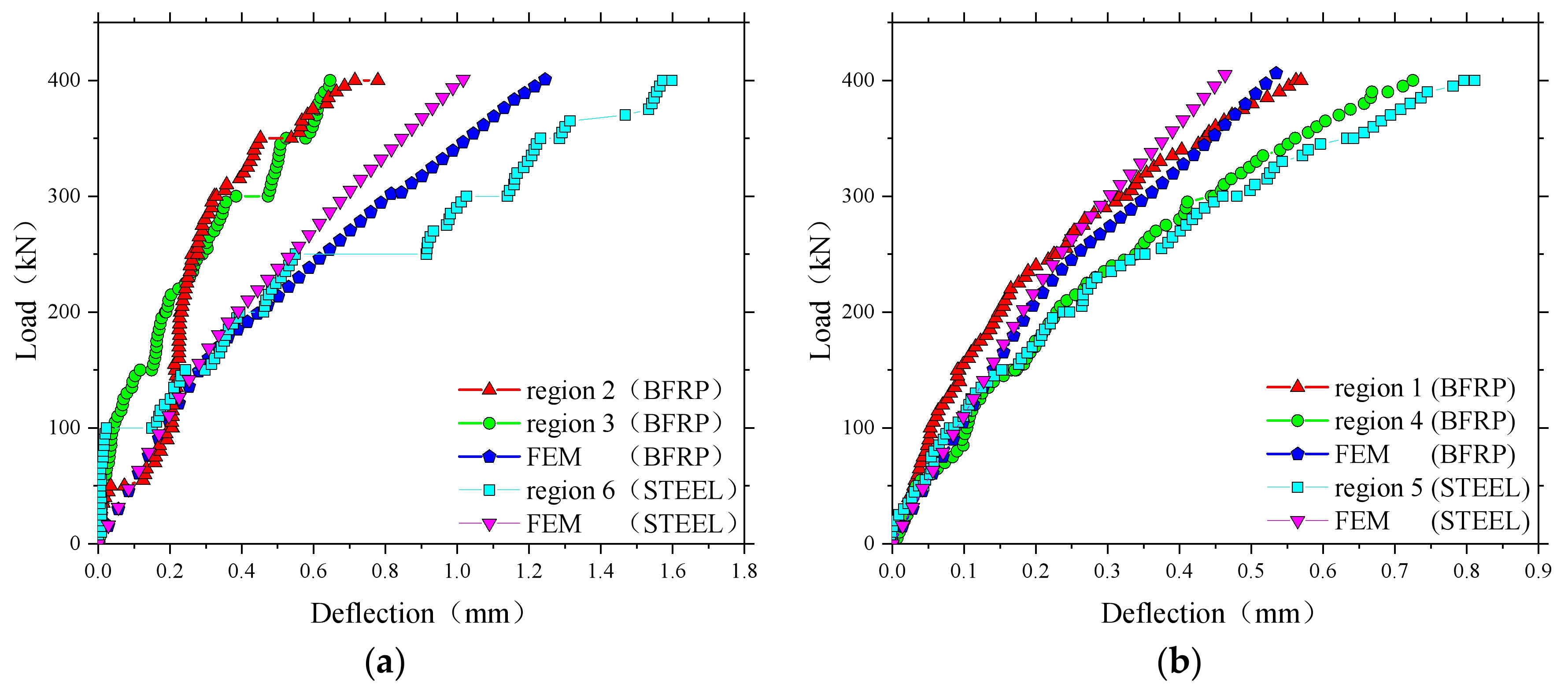

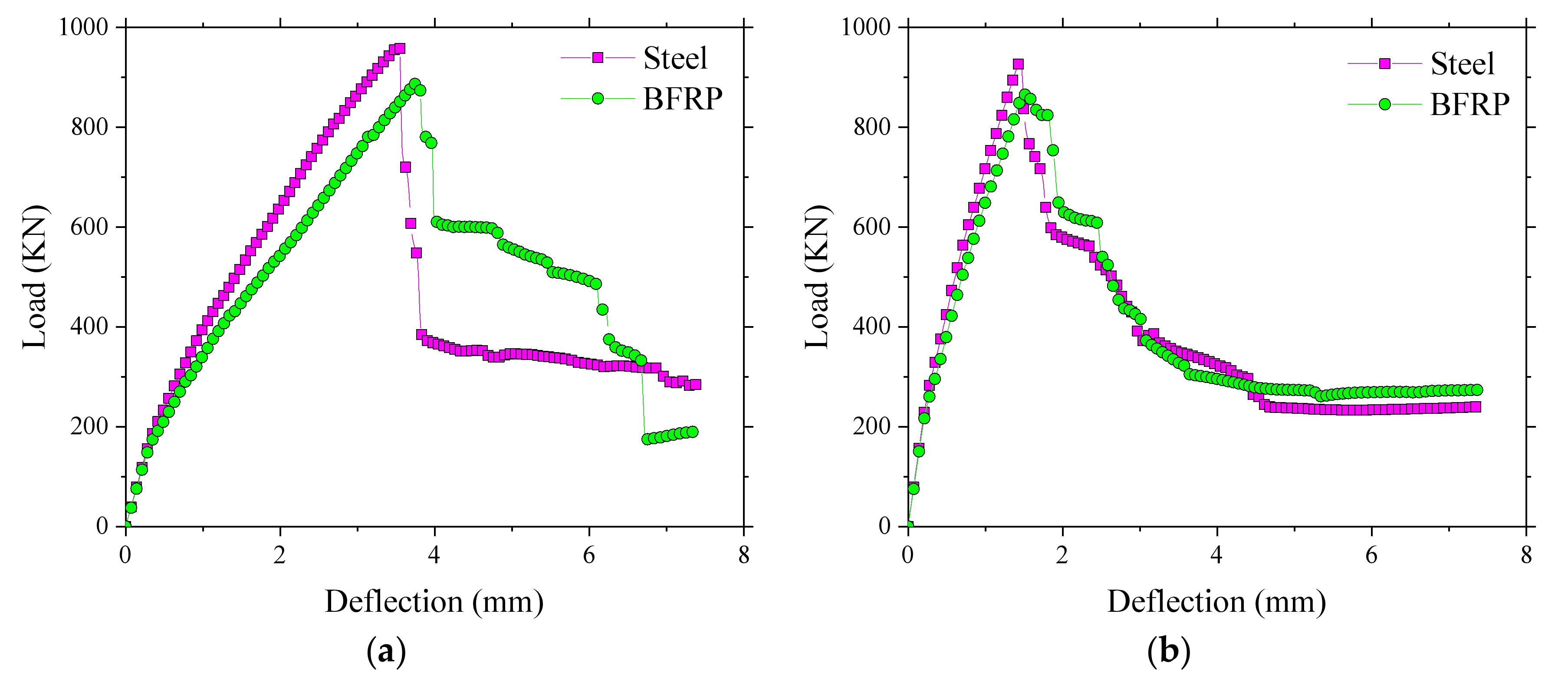

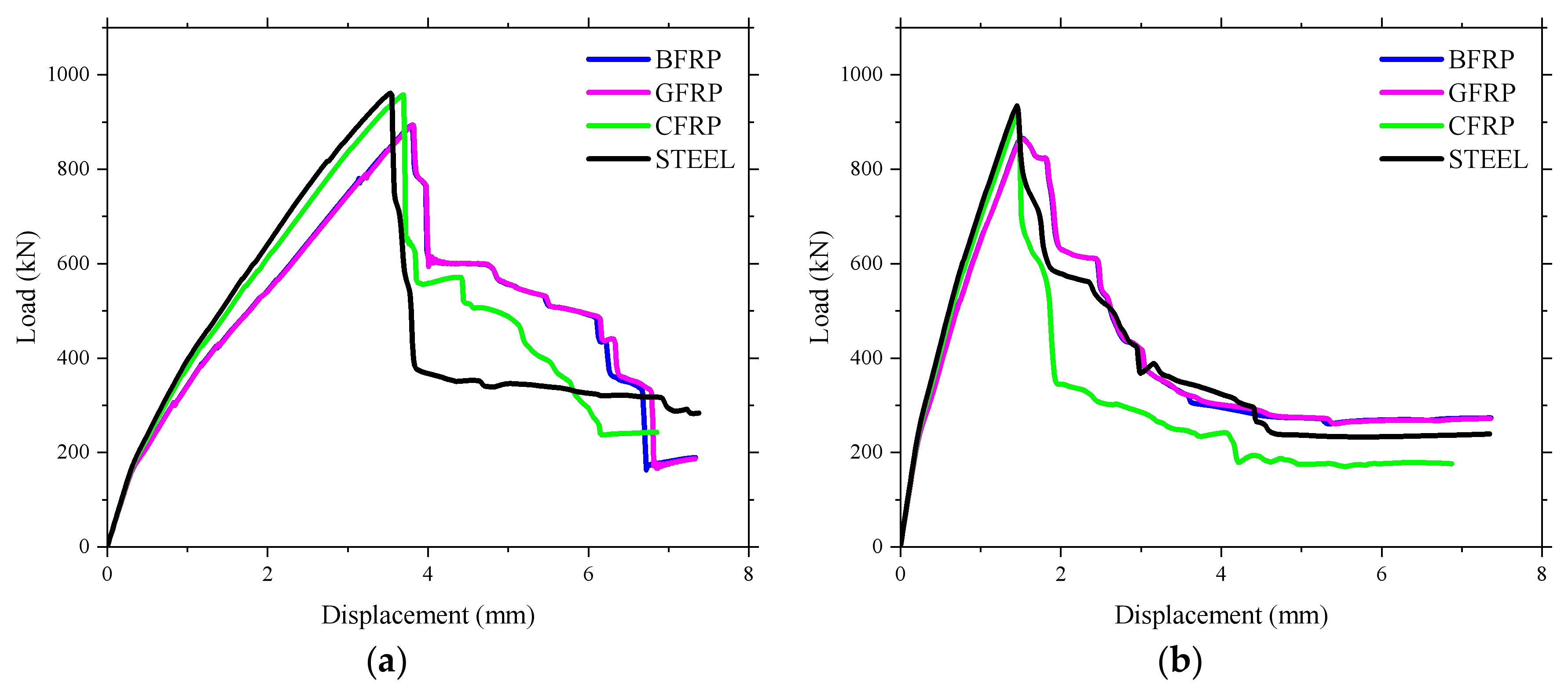

3.3. Validation of the Accuracy of the FE Analsysis

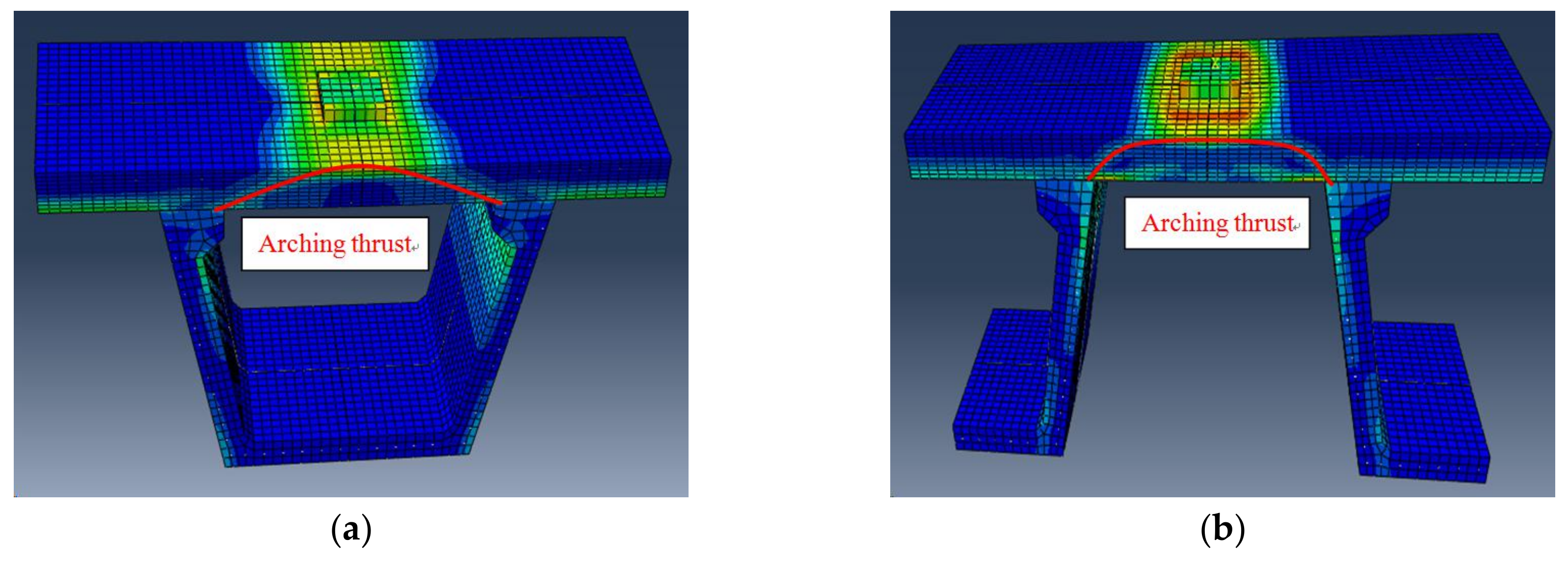

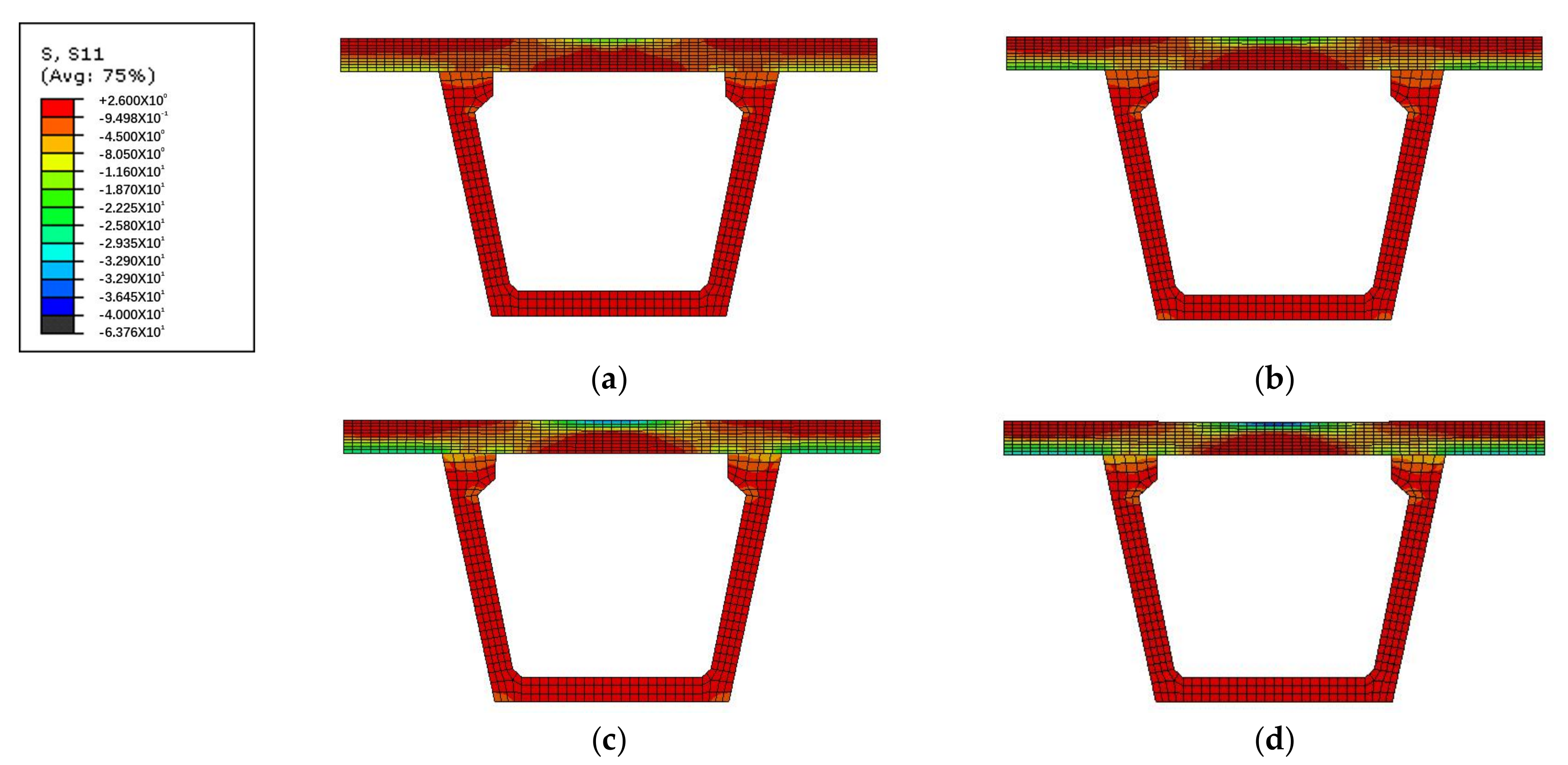

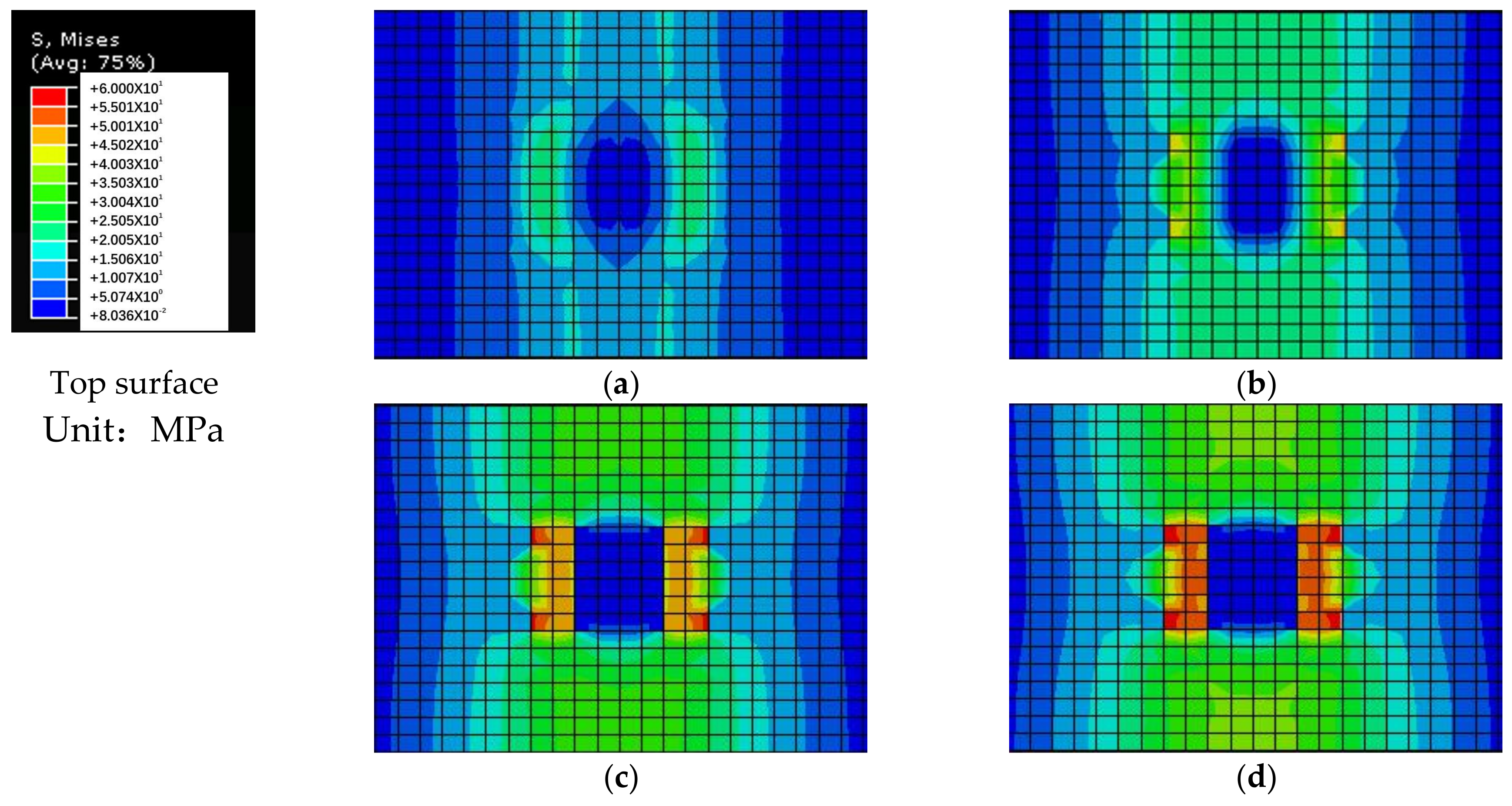

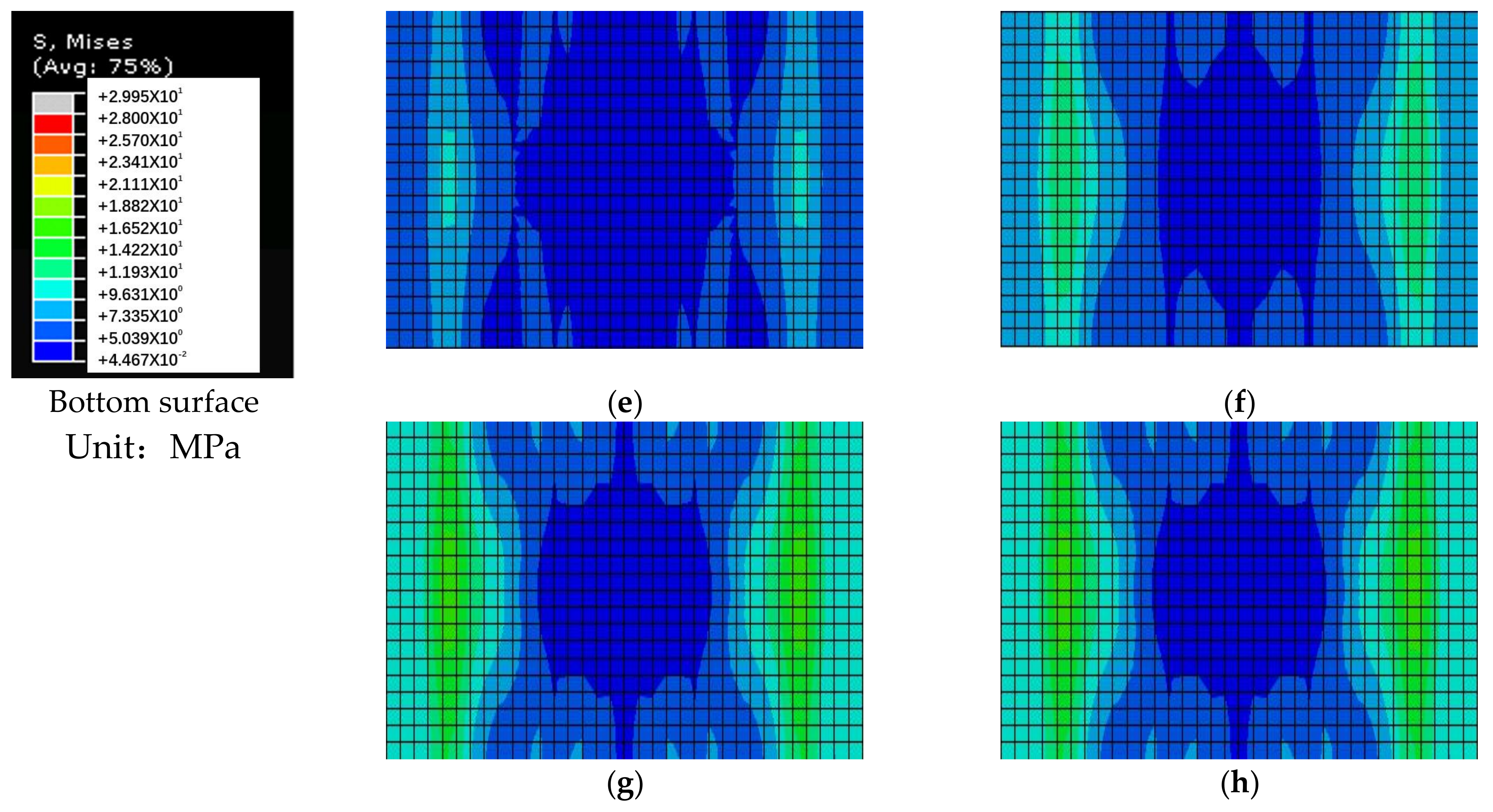

3.4. Discussion of the Stress Distribution

3.5. Prediction of the Ultimate Bearing Capacity and Failure Mechanism

4. Parameter Analysis of the Local Bridge Model

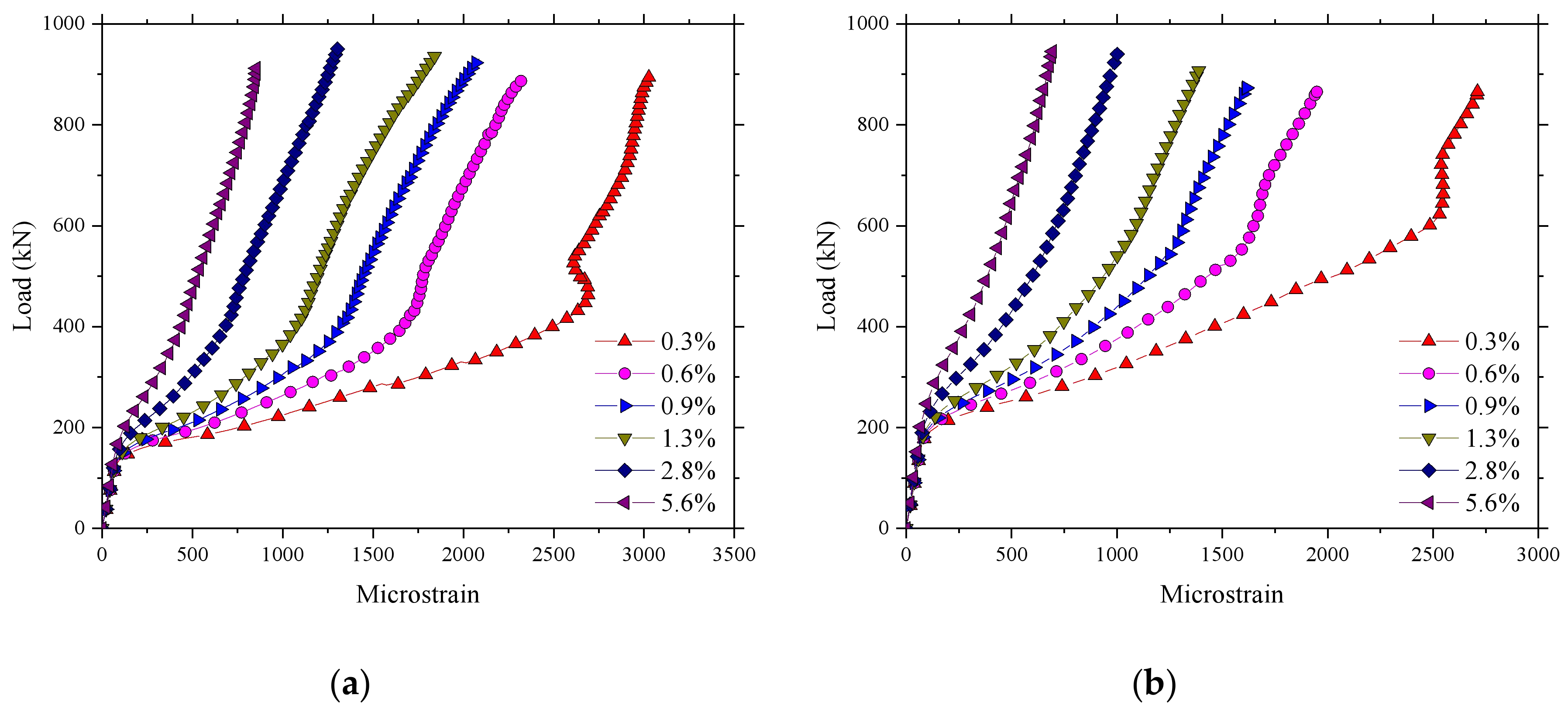

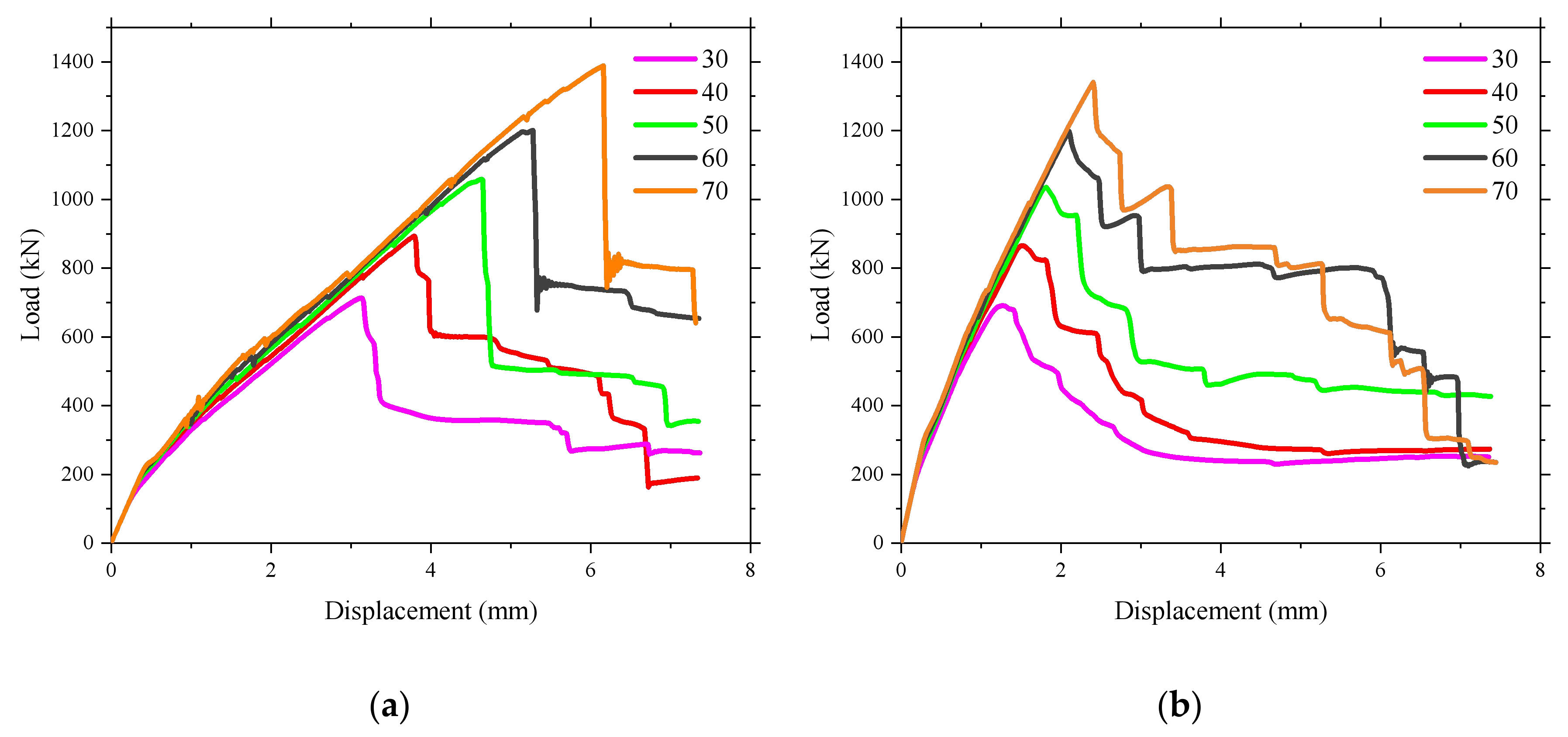

4.1. Effect of the Reinforcement Ratio

4.2. Effect of the Reinforcement Type

4.3. Effect of Concrete Compressive Strength

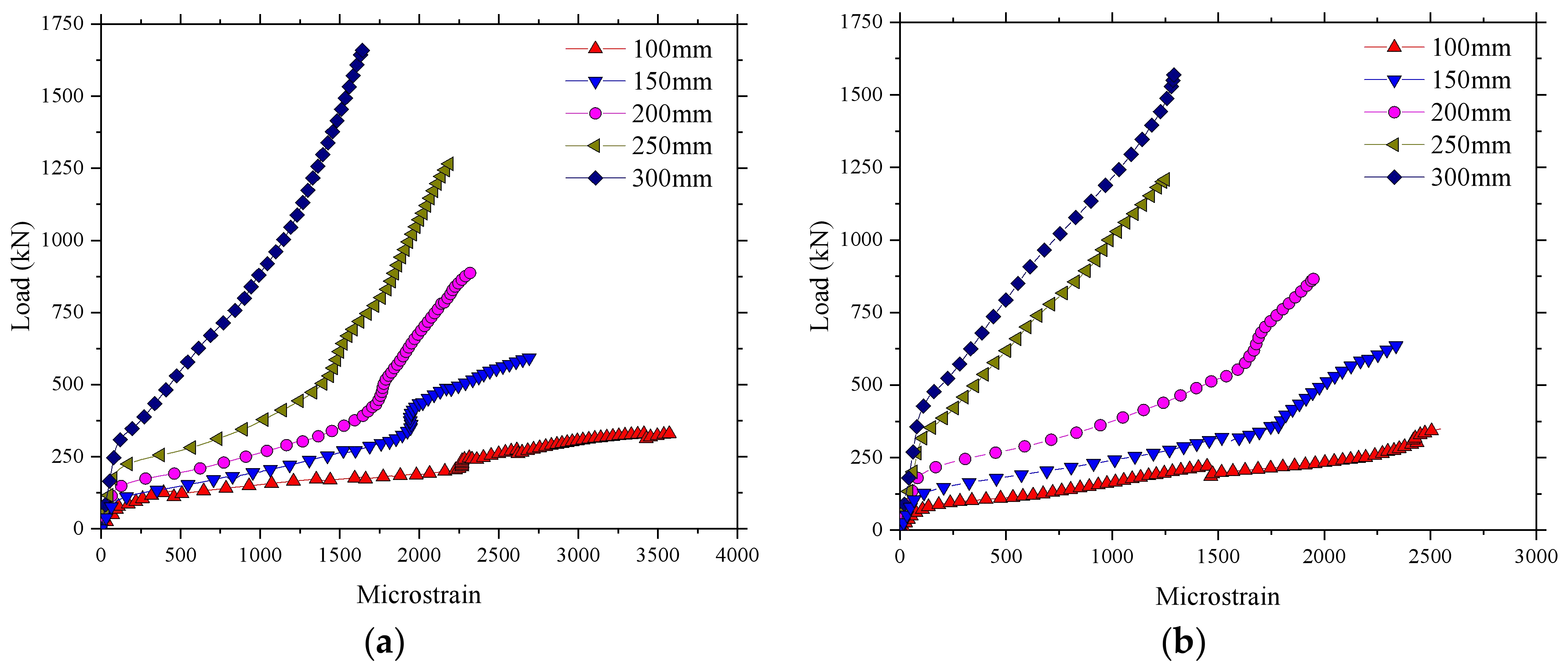

4.4. Effect of the Depth of the Bridge Deck Slab

5. Conclusions

- The results of the field test in Thompson Bridge showed that the deflections and strain values of BFRP-reinforced concrete deck slabs under a wheel load of 400 kN were within an acceptable service range. However, it is worth mentioning that BFRP-reinforced SCC deck slabs exhibited better structural behaviors that that is predicted by current design codes, due to the contribution of the compressive membrane action to the structural behaviors of restrained deck slabs.

- The results of the proposed FE model for BFRP-reinforced SCC deck slabs in Thompson Bridge showed good agreement with the field test results.

- The FE analysis results indicated that BFRP-reinforced SCC deck slabs used in Thompson Bridge exhibited Compressive Membrane Action (CMA), as clearly obtained in the FE analysis.

- The ultimate load-carrying capacity of the SCC deck slabs with BFRP-reinforced was predicted to be approximately 1000 kN by the FE model, which far exceeds the design ultimate loads. Because of the influence of CMA, the SCC deck slabs reinforced with BFRP bars had a similar reinforcement percentage as those reinforced with steel bars. In addition, the predicted failure mode of the SCC deck slabs reinforced with BFRP bars under wheel load was determined to be the punching failure by the FE model.

- The parametric analysis by the FE model demonstrated that the reinforcement ratio and reinforcement type have an insufficient effect on the structural behavior of the bridge deck slabs. This is attributed to the contribution of CMA inside the laterally restrained deck slabs. However, the concrete compressive strength and the depth of the bridge deck slabs play a significant role in the structural mechanical properties of the bridge deck slabs under ultimate and service state.

- The FE investigation results indicates that the BFRP-reinforced SCC deck slabs showed similar structural behavior as the steel-reinforced normal concrete (NC) deck slabs in terms of compressive membrane action. However, because of the use of a high volume of an industrial by-product (fly ash) in the SCC mixture of this study, the sustainability and durability of SCC can be improved compared to traditional NC. Additionally, using the benefits of the compressive membrane action it is possible to configure a very low reinforcement ratio of BFRP bars in concrete deck slabs. On the basis of the corrosion-free property of the BFRP bars, these findings indicate that the combination of the compressive membrane action, BFRP, and SCC can produce low-carbon footprint, durable, and economical infrastructures.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bossio, A.; Monetta, T.; Bellucci, F.; Lignola, G.P.; Prota, A. Modeling of concrete cracking due to corrosion process of reinforcement bars. Cem. Concr. Res. 2015, 71, 78–92. [Google Scholar] [CrossRef]

- Chernin, L.; Val, D.V. Prediction of corrosion-induced cover cracking in reinforced concrete structures. Constr. Build. Mater. 2011, 25, 1854–1869. [Google Scholar] [CrossRef]

- Zhao, J.; Cai, G.; Cui, L.; Larbi, A.S.; Tsavdaridis, K.D. Deterioration of basic properties of the materials in FRP-strengthening RC structures under ultraviolet exposure. Polymers 2017, 9, 402. [Google Scholar] [CrossRef]

- Taylor, S.E.; Mullin, B. Arching action in FRP reinforced concrete slabs. Constr. Build. Mater. 2006, 20, 71–80. [Google Scholar] [CrossRef]

- Adelzadeh, M.; Hajiloo, H.; Green, M.F. Numerical study of FRP reinforced concrete slabs at elevated temperature. Polymers 2014, 6, 408–422. [Google Scholar] [CrossRef]

- El-Salakawy, E.F.; Benmokrane, B.; El-Ragaby, A.; Nadeau, D. Field Investigation on the first bridge deck slab reinforced with glass FRP bars constructed in Canada. J. Compos. Constr. 2005, 9, 470–479. [Google Scholar] [CrossRef]

- Zhou, Y.; Hu, J.; Li, M.; Sui, L.; Xing, F. FRP-confined recycled coarse aggregate concrete: experimental investigation and model comparison. Polymers 2016, 8, 375. [Google Scholar] [CrossRef]

- Zheng, Y.; Fu, X.Y.; Lu, Z.Y.; Pan, Y.F. Investigation of structural behaviour of GFRP reinforced concrete deck slabs through NLFEA. Constr. Build. Mater. 2013, 45, 60–77. [Google Scholar] [CrossRef]

- Frigione, M.; Lettieri, M. Durability issues and challenges for material advancements in frp employed in the construction industry. Polymers 2018, 10, 247. [Google Scholar] [CrossRef]

- Zheng, Y.; Sun, C.; Deng, T.; Yang, J.B.; Lu, Z.Y. Arching action contribution to punching failure of GFRP-reinforced concrete bridge deck slabs. Arab. J. Sci. Eng. 2014, 39, 8609–8625. [Google Scholar] [CrossRef]

- Taylor, S.E. Compressive membrane action in high strength concrete bridge deck slabs. Inf. Med. Equip. 2000, 96, 12126–12131. [Google Scholar]

- Kirkpatrick, J.; Rankin, G.I.B.; Long, A.E. Influence of compressive membrane action on the serviceability of beam and slab bridge decks. In Structural Engineer Part B; Institution of Structural Engineers: London, UK, 1986; Volume 64b. [Google Scholar]

- Zheng, Y.; Robinson, D.J.; Taylor, S.E.; Cleland, D.J. Finite element investigation of the structural behaviour of deck slabs in composite bridges. Eng. Struct. 2009, 31, 1762–1776. [Google Scholar] [CrossRef]

- GarcãA-Taengua, E.; Sonebi, M.; Crossett, P.; Taylor, S.; Deegan, P.; Ferrara, L.; Pattarini, A. Performance of sustainable SCC mixes with mineral additions for use in precast concrete industry. J. Sustain. Cem.-Based Mater. 2016, 5, 157–175. [Google Scholar] [CrossRef]

- Chen, Y.Y.; Tuan, B.L.A.; Hwang, C.L. Effect of paste amount on the properties of self-consolidating concrete containing fly ash and slag. Constr. Build. Mater. 2013, 47, 340–346. [Google Scholar] [CrossRef]

- Khotbehsara, M.M.; Mohseni, E.; Yazdi, M.A.; Sarker, P.; Ranjbar, M.M. Effect of nano-CuO and fly ash on the properties of self-compacting mortar. Constr. Build. Mater. 2015, 94, 758–766. [Google Scholar] [CrossRef]

- Uysal, M.; Yilmaz, K. Effect of mineral admixtures on properties of self-compacting concrete. Cem. Concr. Compos. 2011, 33, 771–776. [Google Scholar] [CrossRef]

- Sonebi, M. Transport properties of self-consolidating concrete. ACI Mater. J. 2009, 106, 161–166. [Google Scholar]

- Zheng, Y.; Taylor, S.E.; Sonebi, M.; Robinson, D. The influence of arching action on BFRP reinforced SCC deck slabs in Thompson bridge. In Proceedings of the 24th Australasian Conference on the Mechanics of Structures and Materials, Perth, Australia, 6–9 December 2016. [Google Scholar]

- Zeng, J.J.; Guo, Y.C.; Li, L.J.; Chen, W.P. Behavior and three-dimensional finite element modeling of circular concrete columns partially wrapped with FRP strips. Polymers 2018, 10, 253. [Google Scholar] [CrossRef]

- Zheng, Y. Investigation of ultimate strength of deck slabs in steel-concrete bridges. ACI Mater. J. 2010, 107, 82–91. [Google Scholar]

- European Committee for Standardization (CEN). Eurocode 2: Design of concrete structures—Part 1-1: General Rules and Rules for Buildings; CEN: Brussels, Belgium, 2004; pp. 1–225. [Google Scholar]

- Yu, H.; Bai, Y.L.; Dai, J.G.; Gao, W.Y. Finite element modeling for debonding of FRP-to-concrete interfaces subjected to mixed-mode loading. Polymers 2017, 9, 438. [Google Scholar] [CrossRef]

- Lubliner, J.; Oliver, J.; Oller, S.; Oñate, E. A plastic-damage model for concrete. Int. J. Solids Struct. 1989, 25, 299–326. [Google Scholar] [CrossRef]

- Lee, J.; Fenves, G.L. Plastic-damage model for cyclic loading of concrete structures. J. Eng. Mech. 1998, 124, 892–900. [Google Scholar] [CrossRef]

- Saenz, L.P. Discussion of ‘Equation for the stress-strain curve of concrete’ by P. Desayi and S. Krishan. ACI J. 1964, 61, 1229–1235. [Google Scholar]

- Chen, W.F. Plasticity in Reinforced Concrete; McGraw-Hill: New York, NY, USA, 1982. [Google Scholar]

- Hordijk, D.A. Local Approach to Fatigue of Concrete. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 1991. [Google Scholar]

- Jendele, L.; Cervenka, J. Finite element modelling of reinforcement with bond. Comput. Struct. 2006, 84, 1780–1791. [Google Scholar] [CrossRef]

- Chen, G.M.; Teng, J.G.; Chen, J.F. Finite element modeling of intermediate crack debonding in frp-plated rc beams. J. Compos. Constr. 2011, 15, 339–353. [Google Scholar] [CrossRef]

- Birtel, V.; Mark, P. Parameterised finite element modelling of RC beam shear failure. In Proceedings of the 19th Annual International ABAQUS Users’ Conference, Boston, MA, USA, 23–25 May 2006; pp. 95–108. [Google Scholar]

- Benmokrane, B.; Elsalakawy, E. Serviceability of concrete bridge deck slabs reinforced with fiber-reinforced polymer composite bars. ACI Struct. J. 2004, 101, 727–736. [Google Scholar]

- Einsfeld Ricardo, A.; Martha Luiz, F.; Bitttenourt Tulio, N. Combination of smearedand discrete approaches with the use of interface elements. In Europeancongress on Computational Methods in Applied Sciences and Engineering; ECCOMAS: Barcelona, Spain, 2000. [Google Scholar]

- Einsfeld, R.A.; Elwi, A.E.; Bittencourt, T.N.; Martha, L.F. Numerical simulation of fracturing in concrete structures using a combination of smeared and discrete approaches. Int. J. Rock Mech. Min. Sci. 1997, 34, 189.e1–189.e11. [Google Scholar] [CrossRef]

- European Standard, BSI. BS EN 1992, British Standards Institute, Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules; European Standard, BSI: London, UK, 2004. [Google Scholar]

- Bakht, B.; Jaeger, L.G. Ultimate load tests on slabs on girder bridges. J. Struct. Eng. 1992, 118, 1608–1624. [Google Scholar] [CrossRef]

- Elgabbas, F.; Ahmed, E.A.; Benmokrane, B. Experimental testing of concrete bridge-deck slabs reinforced with Basalt-FRP reinforcing bars under concentrated loads. J. Bridge Eng. 2016, 21, 04016029. [Google Scholar] [CrossRef]

| Test | Slump Flow (mm) | V-Funnel (s) | J-Ring (mm) | Compressive Strength (MPa) |

|---|---|---|---|---|

| Test Result | 650 | 12 | 8 | 50.5 |

| Type | Tensile Strength (MPa) | Yield Strength (MPa) | Elastic Modulus (MPa) | Ultimate Strain (με) |

|---|---|---|---|---|

| BFRP bars | 920 | / | 54,000 | 17,037 |

| Steel bars | 750 | 520 | 210,000 | 10,000 |

| Type | Density (kg/m3) | Elastic Modulus (MPa) | Poisson’s Ratio | Tensile Strength (MPa) | Ultimate Strain (με) |

|---|---|---|---|---|---|

| BFRP Bar | 1900 | 54,000 | 0.2 | 920 | 17,037 |

| GFRP Bar | 2000 | 51,000 | 0.2 | 1610 | 31,000 |

| CFRP Bar | 1500 | 150,000 | 0.2 | 1700 | 11,000 |

| Steel Bar | 7800 | 210,000 | 0.3 | 520 (750) | 10,000 |

| Type | Cross Section of Bars (m2) | Elastic Modulus (MPa) | A*E (m2·MPa) | Tensile Strength (MPa) | A*f(m2·MPa) |

|---|---|---|---|---|---|

| BFRP Bar | A | 54,000 | 54,000 A | 920 | 920 A |

| GFRP Bar | A | 51,000 | 51,000 A | 1610 | 1510 A |

| CFRP Bar | A | 150,000 | 150,000 A | 1700 | 1700 A |

| Steel Bar | A | 210,000 | 210,000 A | 750 | 750 A |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, L.; Zheng, Y.; Taylor, S.E. Finite-Element Investigation of the Structural Behavior of Basalt Fiber Reinforced Polymer (BFRP)- Reinforced Self-Compacting Concrete (SCC) Decks Slabs in Thompson Bridge. Polymers 2018, 10, 678. https://doi.org/10.3390/polym10060678

Zhou L, Zheng Y, Taylor SE. Finite-Element Investigation of the Structural Behavior of Basalt Fiber Reinforced Polymer (BFRP)- Reinforced Self-Compacting Concrete (SCC) Decks Slabs in Thompson Bridge. Polymers. 2018; 10(6):678. https://doi.org/10.3390/polym10060678

Chicago/Turabian StyleZhou, Lingzhu, Yu Zheng, and Susan E. Taylor. 2018. "Finite-Element Investigation of the Structural Behavior of Basalt Fiber Reinforced Polymer (BFRP)- Reinforced Self-Compacting Concrete (SCC) Decks Slabs in Thompson Bridge" Polymers 10, no. 6: 678. https://doi.org/10.3390/polym10060678