Fused Deposition Modeling of ABS-Barium Titanate Composites: A Simple Route towards Tailored Dielectric Devices

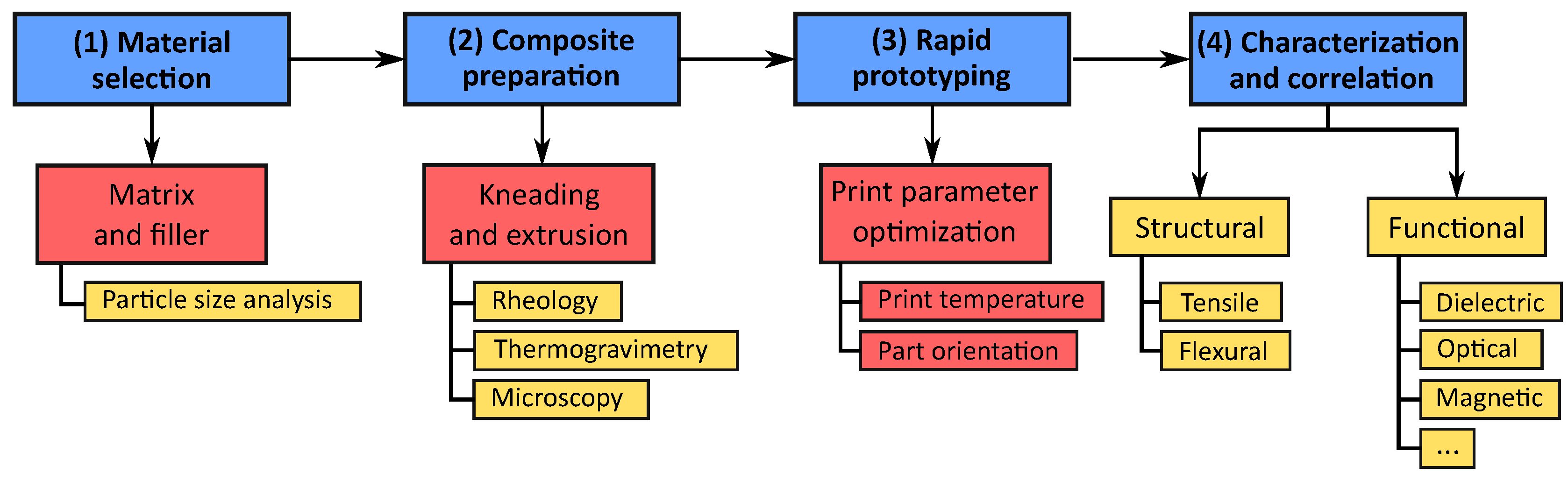

Abstract

:1. Introduction

2. Material Preparation

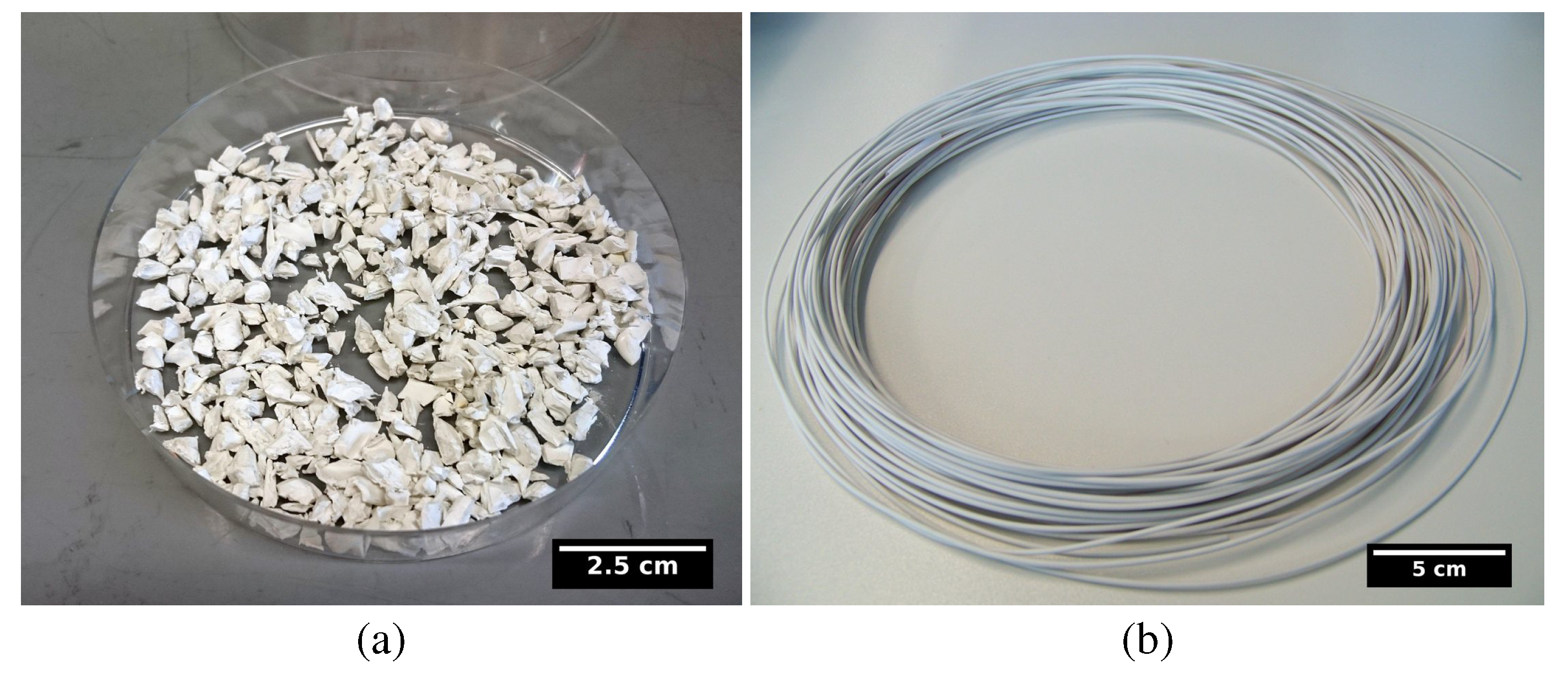

2.1. Feedstock Preparation

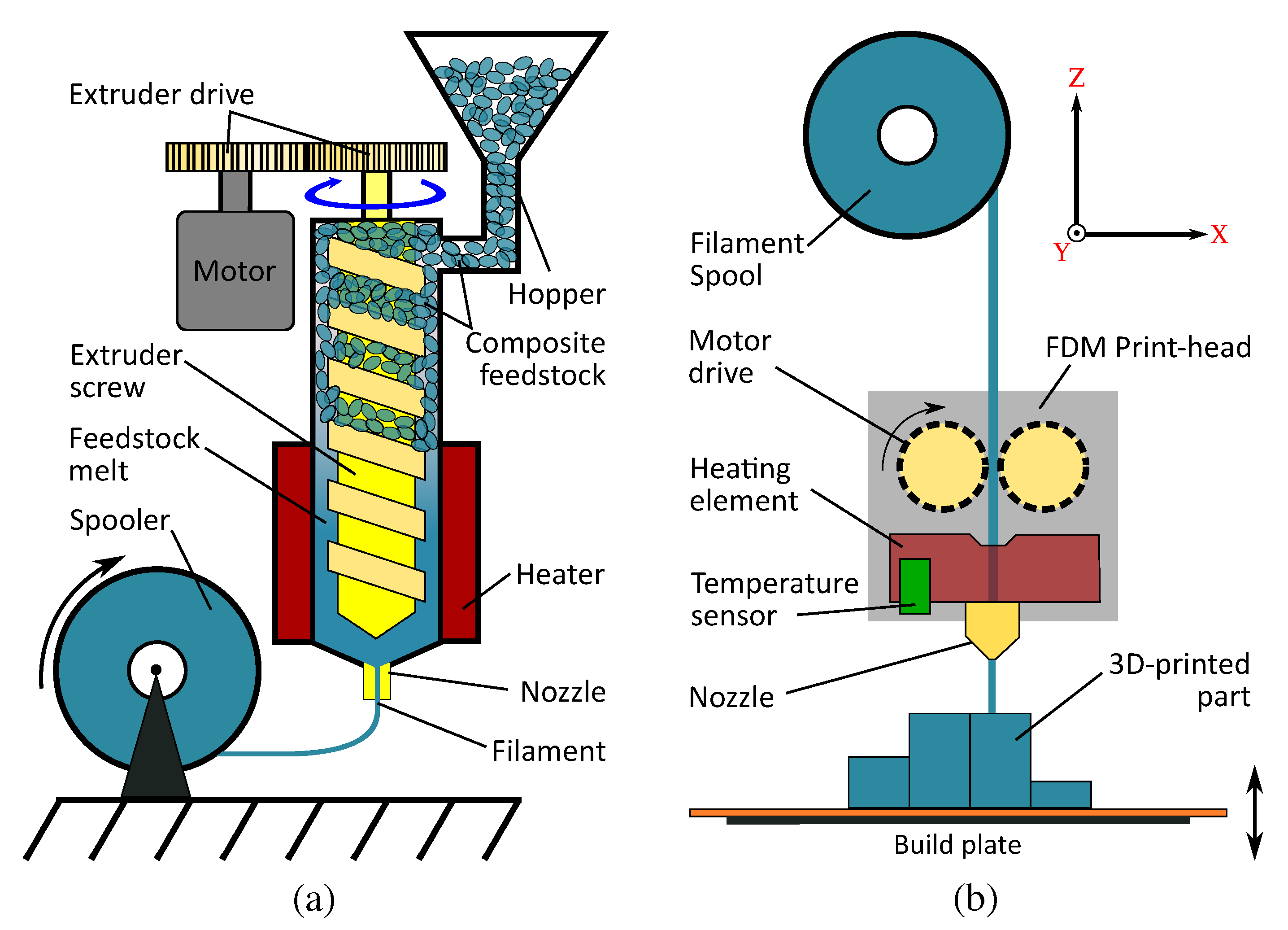

Filament Extrusion

2.2. 3D Printing

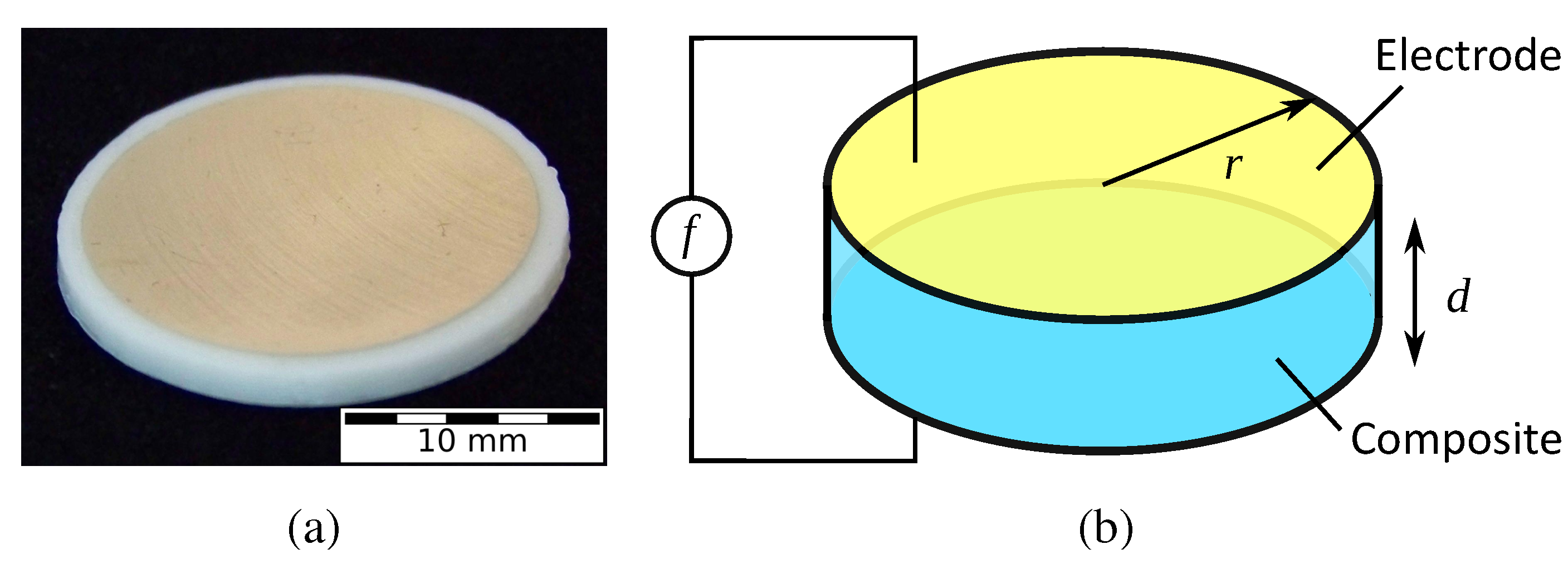

3. Sample Design and Characterization

3.1. Structural Characterization

3.1.1. Tensile

3.1.2. Flexural

3.2. Functional Characterization

4. Material Characterization

4.1. Particle Size Distribution

4.2. Feedstock Preparation

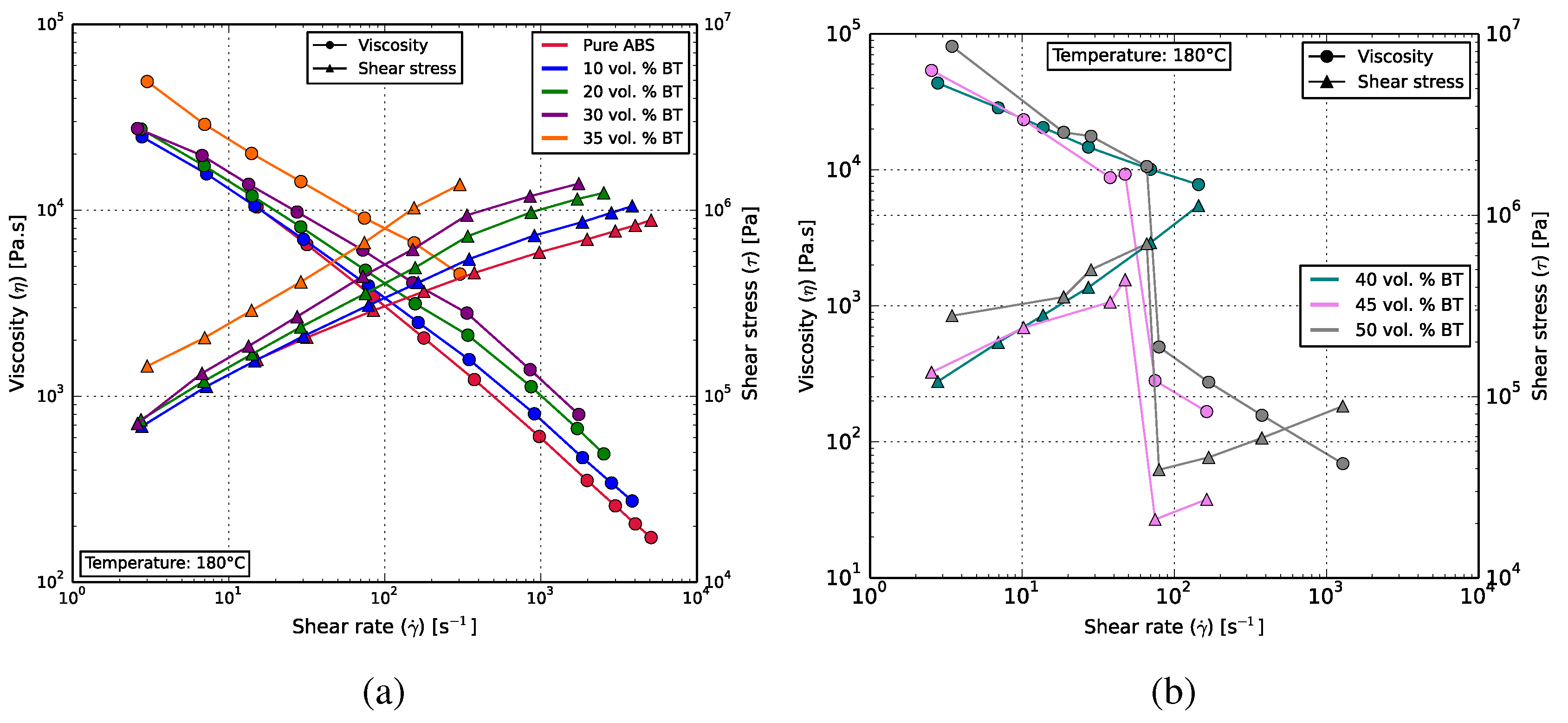

4.3. Rheology

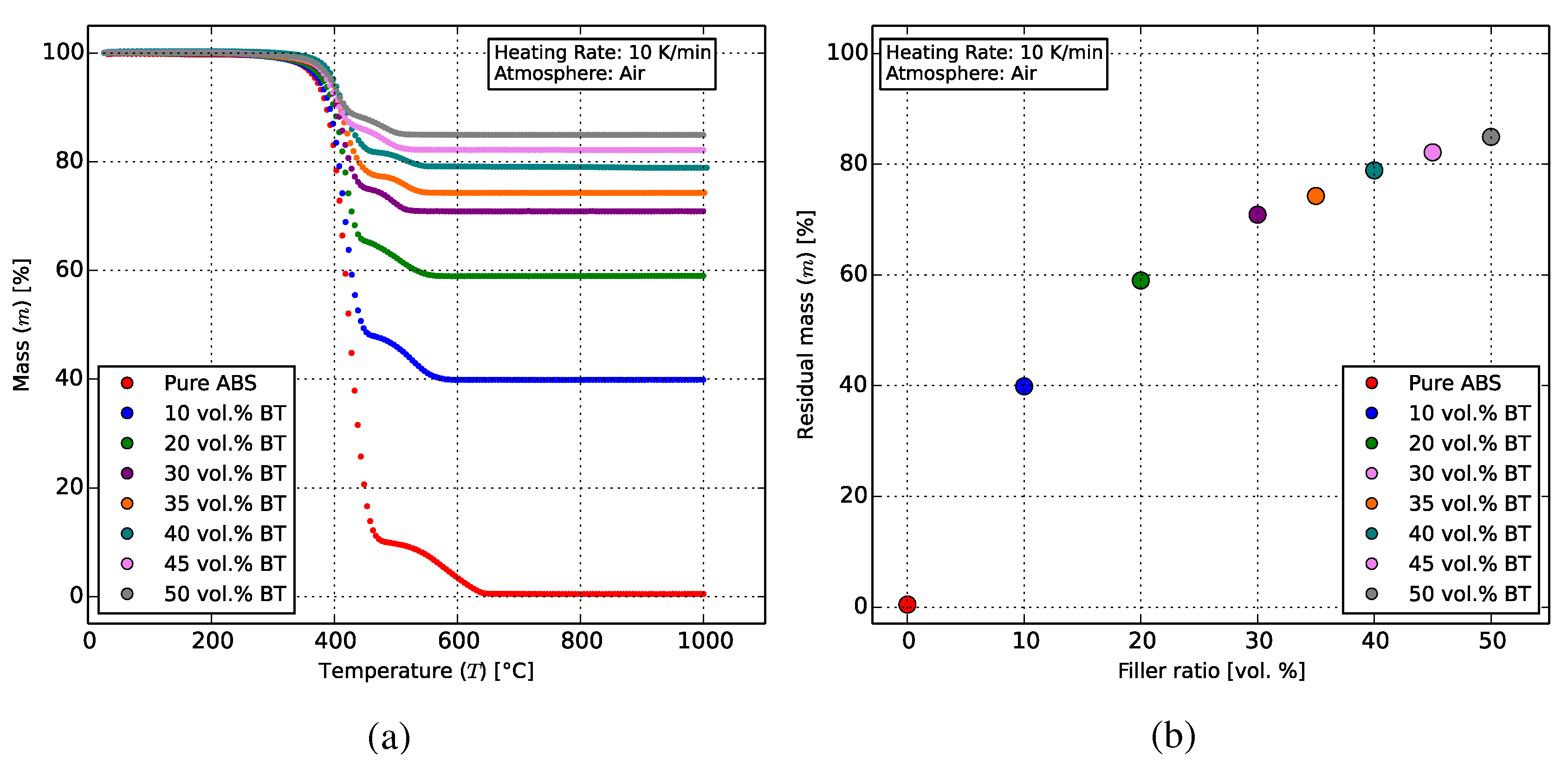

4.4. Thermogravimetry

5. Structural Characterization

5.1. Print Parameter Optimization

5.1.1. Part Orientation

5.1.2. Print Temperature

5.2. Microscopy

5.3. Tensile Characterization

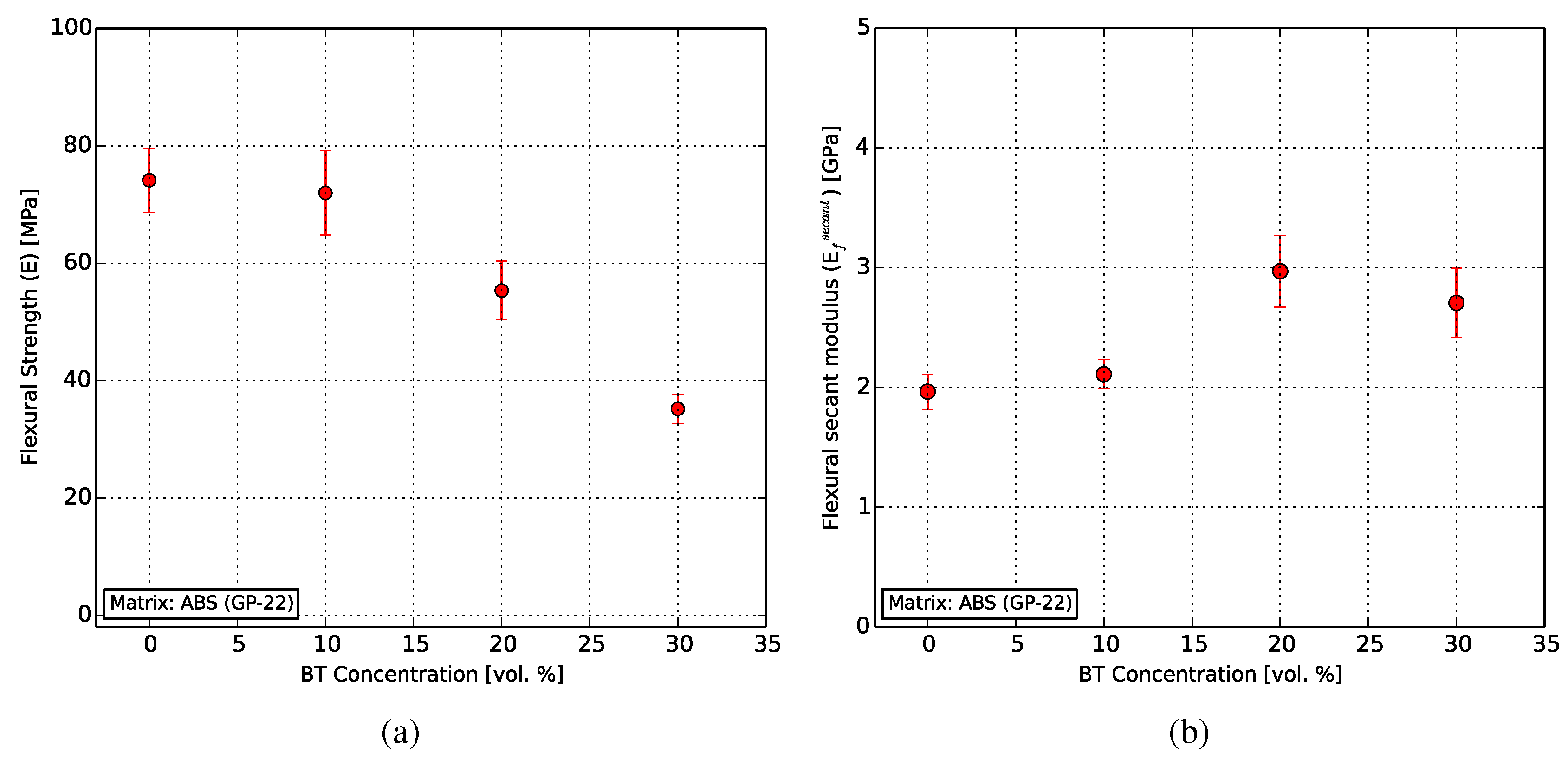

5.4. Flexural Characterization

6. Functional Characterization

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ARP | Additive rapid prototyping |

| RP | Rapid prototyping |

| SL | Stereolithography |

| SLS | Selective laser sintering |

| PJM | Polyjet modeling |

| FDM | Fused deposition modeling |

| FFF | Fused filament fabrication |

| ABS | Acrylonitrile butadiene styrene |

| BT | Barium titanate |

| UTS | Ultimate tensile strength |

| MG | Maxwell-Garnett |

| JS | Jayasundere-Smith |

References

- Wong, K.V.; Hernandez, A. A Review of Additive Manufacturing. ISRN Mech. Eng. 2012, 2012, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.W.; Chua, C.K.; Cheah, C.M.; Tan, L.H.; Feng, C. Rapid investment casting: Direct and indirect approaches via fused deposition modelling. Int. J. Adv. Manuf. Technol. 2004, 23, 93–101. [Google Scholar] [CrossRef]

- Zein, I.; Hutmacher, D.W.; Tan, K.C.; Teoh, S.H. Fused deposition modeling of novel scaffold architectures for tissue engineering applications. Biomaterials 2002, 23, 1169–1185. [Google Scholar] [CrossRef]

- Hutmacher, D.W. Scaffolds in tissue engineering bone and cartilage. Biomaterials 2000, 21, 2529–2543. [Google Scholar] [CrossRef]

- Thavornyutikarn, B.; Chantarapanich, N.; Sitthiseripratip, K.; Thouas, G.A.; Chen, Q. Bone tissue engineering scaffolding: Computer-aided scaffolding techniques. Prog. Biomater. 2014, 3, 61–102. [Google Scholar] [CrossRef] [PubMed]

- Kang, H.W.; Lee, S.J.; Ko, I.K.; Kengla, C.; Yoo, J.J.; Atala, A. A 3D bioprinting system to produce human-scale tissue constructs with structural integrity. Nat. Biotechnol. 2016, 34, 312–319. [Google Scholar] [CrossRef] [PubMed]

- Willis, K.; Brockmeyer, E.; Hudson, S.; Poupyrev, I. Printed optics: 3D printing of embedded optical elements for interactive devices. In Proceedings of the 25th Annual ACM Symposium on User Interface Software and Technology (ACM UIST) 2012—UIST’12, Cambridge, MA, USA, 7–10 October 2012; pp. 589–598. [Google Scholar] [CrossRef]

- Busch, S.F.; Weidenbach, M.; Fey, M.; Schäfer, F.; Probst, T.; Koch, M. Optical Properties of 3D Printable Plastics in the THz Regime and their Application for 3D Printed THz Optics. J. Infrared Millim. Terahertz Waves 2014, 35, 993–997. [Google Scholar] [CrossRef]

- Lee, K.G.; Park, K.J.; Seok, S.; Shin, S.; Kim, D.H.; Park, J.Y.; Heo, Y.S.; Lee, S.J.; Lee, T.J. 3D printed modules for integrated microfluidic devices. RSC Adv. 2014, 4, 32876–32880. [Google Scholar] [CrossRef]

- Lous, G.M.; Cornejo, I.A.; McNulty, T.F.; Safari, A.; Danfortha, S.C. Fabrication of Piezoelectric Ceramic/Polymer Composite Transducers using Fused Deposition of Ceramics. J. Am. Ceram. Soc. 2000, 83, 124–128. [Google Scholar] [CrossRef]

- Castles, F.; Isakov, D.; Lui, A.; Lei, Q.; Dancer, C.E.J.; Wang, Y.; Janurudin, J.M.; Speller, S.C.; Grovenor, C.R.M.; Grant, P.S. Microwave dielectric characterisation of 3D-printed BaTiO3/ABS polymer composites. Sci. Rep. 2016, 6, 22714. [Google Scholar] [CrossRef] [PubMed]

- Hao, L.; Mellor, S.; Seaman, O.; Henderson, J.; Sewell, N.; Sloan, M. Material characterisation and process development for chocolate additive layer manufacturing. Virtual Phys. Prototyp. 2010, 5, 57–64. [Google Scholar] [CrossRef]

- Kim, H.W.; Bae, H.; Park, H.J. Classification of the printability of selected food for 3D printing: Development of an assessment method using hydrocolloids as reference material. J. Food Eng. 2017, 215, 23–32. [Google Scholar] [CrossRef]

- Flowers, P.F.; Reyes, C.; Ye, S.; Kim, M.J.; Wiley, B.J. 3D printing electronic components and circuits with conductive thermoplastic filament. Addit. Manuf. 2017, 18, 156–163. [Google Scholar] [CrossRef]

- Kwok, S.W.; Goh, K.H.H.; Tan, Z.D.; Tan, S.T.M.; Tjiu, W.W.; Soh, J.Y.; Ng, Z.J.G.; Chan, Y.Z.; Hui, H.K.; Goh, K.E.J. Electrically conductive filament for 3D-printed circuits and sensors. Appl. Mater. Today 2017, 9, 167–175. [Google Scholar] [CrossRef]

- Licciulli, A.; Corcione, C.E.; Greco, A.; Amicarelli, V.; Maffezzoli, A. Laser stereolithography of ZrO2 toughened Al2O3. J. Eur. Ceram. Soc. 2005, 25, 1581–1589. [Google Scholar] [CrossRef]

- Lee, J.H.; Prud’Homme, R.K.; Aksay, I.A. Processing of Organic/Inorganic Composites by Stereolithography. Mater. Res. Soc. Symp. Proc. 2000, 625, 165–172. [Google Scholar] [CrossRef]

- Bertsch, A.; Jiguet, S.; Renaud, P. Microfabrication of ceramic components by microstereolithography. J. Micromech. Microeng. 2003, 14, 197–203. [Google Scholar] [CrossRef]

- Lopes, A.J.; MacDonald, E.; Wicker, R.B. Integrating stereolithography and direct print technologies for 3D structural electronics fabrication. Rapid Prototyp. J. 2012, 18, 129–143. [Google Scholar] [CrossRef]

- Chen, W.; Kirihara, S.; Miyamoto, Y. Fabrication and Characterization of Three-Dimensional ZrO2-Toughened Al2O3 Ceramic Microdevices. Int. J. Appl. Ceram. Technol. 2008, 5, 353–359. [Google Scholar] [CrossRef]

- Hinczewski, C.; Corbel, S.; Chartier, T. Ceramic suspensions suitable for stereolithography. J. Eur. Ceram. Soc. 1998, 18, 583–590. [Google Scholar] [CrossRef]

- Dufaud, O.; Corbel, S. Oxygen diffusion in ceramic suspensions for stereolithography. Chem. Eng. J. 2003, 92, 55–62. [Google Scholar] [CrossRef]

- Abouliatim, Y.; Chartier, T.; Abelard, P.; Chaput, C.; Delage, C. Optical characterization of stereolithography alumina suspensions using the Kubelka-Munk model. J. Eur. Ceram. Soc. 2009, 29, 919–924. [Google Scholar] [CrossRef]

- Kotz, F.; Arnold, K.; Bauer, W.; Schild, D.; Keller, N.; Sachsenheimer, K.; Nargang, T.M.; Richter, C.; Helmer, D.; Rapp, B.E. Three-dimensional printing of transparent fused silica glass. Nature 2017, 544, 337–339. [Google Scholar] [CrossRef] [PubMed]

- Leigh, S.J.; Purssell, C.P.; Bowen, J.; Hutchins, D.A.; Covington, J.A.; Billson, D.R. A miniature flow sensor fabricated by micro-stereolithography employing a magnetite/acrylic nanocomposite resin. Sens. Actuators A Phys. 2011, 168, 66–71. [Google Scholar] [CrossRef]

- Kalsoom, U.; Nesterenko, P.N.; Paull, B. Recent developments in 3D printable composite materials. RSC Adv. 2016, 6, 60355–60371. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Mohan, N.; Senthil, P.; Vinodh, S.; Jayanth, N. A review on composite materials and process parameters optimisation for the fused deposition modelling process. Virtual Phys. Prototyp. 2017, 12, 47–59. [Google Scholar] [CrossRef]

- Anitha, R.; Arunachalam, S.; Radhakrishnan, P. Critical parameters infuencing the quality of prototypes in fused deposition modelling. J. Mater. Process. Technol. 2001, 118, 2–5. [Google Scholar] [CrossRef]

- Ahn, S.H.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef] [Green Version]

- Cantrell, J.; Rohde, S.; Damiani, D.; Gurnani, R.; Disandro, L.; Anton, J.; Young, A.; Jerez, A.; Steinbach, D.; Kroese, C.; et al. Experimental Characterization of the Mechanical Properties of 3D-Printed ABS and Polycarbonate Parts. In Advancement of Optical Methods in Experimental Mechanics; Springer: Cham, Switzerland, 2016; pp. 89–105. [Google Scholar]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. Part B 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Kalsoom, U.; Peristyy, A.; Nesterenko, P.N.; Paull, B. A 3D printable diamond polymer composite: A novel material for fabrication of low cost thermally conducting devices. RSC Adv. 2016, 6, 38140–38147. [Google Scholar] [CrossRef]

- Shemelya, C.M.; Rivera, A.; Perez, A.T.; Rocha, C.; Liang, M.I.N.; Yu, X.; Kief, C.; Alexander, D.; Stegeman, J.; Xin, H.A.O.; et al. Mechanical, Electromagnetic, and X-ray Shielding Characterization of a 3D Printable Tungsten–Polycarbonate Polymer Matrix Composite for Space-Based Applications. J. Electron. Mater. 2015, 44, 2598–2607. [Google Scholar] [CrossRef]

- Sa’ude, N.; Masood, S.H.; Nikzad, M.; Ibrahim, M. Dynamic Mechanical Properties of Copper-ABS Composites for FDM Feedstock. Int. J. Eng. Res. Appl. 2013, 3, 1257–1263. [Google Scholar]

- Nikzad, M.; Masood, S.H.; Sbarski, I. Thermo-mechanical properties of a highly filled polymeric composites for Fused Deposition Modeling. Mater. Des. 2011, 32, 3448–3456. [Google Scholar] [CrossRef]

- Masood, S.H.; Song, W.Q. Development of new metal/polymer materials for rapid tooling using Fused deposition modelling. Mater. Des. 2004, 25, 587–594. [Google Scholar] [CrossRef]

- Hwang, S.; Reyes, E.I.; Moon, K.s.; Rumpf, R.C.; Kim, N.S. Thermo-mechanical Characterization of Metal/Polymer Composite Filaments and Printing Parameter Study for Fused Deposition Modeling in the 3D Printing Process. J. Electron. Mater. 2014, 44, 771–777. [Google Scholar] [CrossRef]

- Khatri, B.; Lappe, K.; Noetzel, D.; Pursche, K.; Hanemann, T. A 3D-Printable Polymer-Metal Soft-Magnetic Functional Composite—Development and Characterization. Materials 2018, 11, 189. [Google Scholar] [CrossRef] [PubMed]

- Arbaoui, Y.; Agaciak, P.; Chevalier, A.; Laur, V.; Maalouf, A.; Ville, J.; Roquefort, P.; Aubry, T.; Queffelec, P. 3D printed ferromagnetic composites for microwave applications. J. Mater. Sci. 2017. [Google Scholar] [CrossRef]

- Kalita, S.J.; Bose, S.; Hosick, H.L.; Bandyopadhyay, A. Development of controlled porosity polymer-ceramic composite scaffolds via fused deposition modeling. Mater. Sci. Eng. C 2003, 23, 611–620. [Google Scholar] [CrossRef]

- Isakov, D.V.; Lei, Q.; Castles, F.; Stevens, C.J.; Grant, P.S. 3D printed anisotropic dielectric composite with meta-material features. Mater. Des. 2016, 93, 423–430. [Google Scholar] [CrossRef]

- Moulart, A.; Marrett, C.; Colton, J. Polymeric composites for use in electronic and microwave devices. Polym. Eng. Sci. 2004, 44, 588–597. [Google Scholar] [CrossRef]

- Wu, Y.; Isakov, D.; Grant, P.S. Fabrication of composite filaments with high dielectric permittivity for fused deposition 3D printing. Materials 2017, 10, 1218. [Google Scholar] [CrossRef] [PubMed]

- Hopkinson, N.; Dicknes, P. Analysis of rapid manufacturing using layer manufacturing processes for production. Proc. Inst. Mech. Eng. Part C 2003, 217, 31–39. [Google Scholar] [CrossRef]

- Bak, D. Rapid prototyping or rapid production? 3D printing processes move industry towards the latter. Assem. Autom. 2003, 23, 340–345. [Google Scholar] [CrossRef]

- Khatri, B.; Lappe, K.; Habedank, M.; Mueller, T.; Megnin, C.; Hanemann, T. Development and characterization of functional polymer-ceramic composite structures using fused deposition modeling. In Proceedings of the 4M/IWMF2016 Conference, Lyngby, Denmark, 13–15 September 2016; pp. 251–254. [Google Scholar] [CrossRef]

- Garnett, J.M. Colous in Metal Glasses, in Metallic Films and in Metallic Solutions. II. Philos. Trans. R. Soc. A 1904, 205, 384–420. [Google Scholar] [CrossRef]

- Jayasundere, N.; Smith, B.V. Dielectric constant for binary piezoelectric 0-3 composites. J. Appl. Phys. 1993, 73, 2462–2466. [Google Scholar] [CrossRef]

- Sihvola, A.H.; Kong, J.A. Effective permittivity of dielectric mixtures. IEEE Trans. Geosci. Remote Sens. 1988, 26, 420–429. [Google Scholar] [CrossRef]

- Ogitani, S.; Bidstrup-Allen, S.A.; Kohl, P.A. Factors Influencing the Permittivity of Polymer/Ceramic Composites for Embedded Capacitors. IEEE Trans. Adv. Packag. 2000, 23, 313–322. [Google Scholar] [CrossRef]

- Cho, S.D.; Lee, S.Y.; Hyun, J.G.; Paik, K.W. Comparison of theoretical predictions and experimental values of the dielectric constant of epoxy/BaTiO3 composite embedded capacitor films. J. Mater. Sci. Mater. Electron. 2005, 16, 77–84. [Google Scholar] [CrossRef]

- Kinoshita, K. Grain-size effects on dielectric properties in barium titanate ceramics. J. Appl. Phys. 1976, 47, 371. [Google Scholar] [CrossRef]

- Arlt, G.; Hennings, D.; de With, G. Dielectric properties of fine-grained barium titanate ceramics. J. Appl. Phys. 1985, 58, 1619–1625. [Google Scholar] [CrossRef] [Green Version]

- Wu, L.; Chure, M.C.; Wu, K.K.; Chang, W.C.; Yang, M.J.; Liu, W.K.; Wu, M.J. Dielectric properties of barium titanate ceramics with different materials powder size. Ceram. Int. 2009, 35, 957–960. [Google Scholar] [CrossRef]

- Schumacher, B.; Gesswein, H.; Hausselt, J.; Hanemann, T. Permittivity of BaTiO3 polymer composite with differing particle size distribution. In Proceedings of the NSTI-NanoTech Conference, Houston TX, USA, 3–7 May 2009; Volume 2, pp. 546–549. [Google Scholar]

- McNeal, M.P.; Jang, S.J.; Newnham, R.E. The effect of grain and particle size on the microwave properties of barium titanate (BaTiO3). J. Appl. Phys. 1998, 83, 3288–3297. [Google Scholar] [CrossRef]

- Onwubolu, G.C.; Rayegani, F. Characterization and Optimization of Mechanical Properties of ABS Parts Manufactured by the Fused Deposition Modelling Process. Int. J. Manuf. Eng. 2014, 2014. [Google Scholar] [CrossRef]

- Bellini, A.; Güçeri, S. Mechanical characterization of parts fabricated using fused deposition modeling. Rapid Prototyp. J. 2003, 9, 252–264. [Google Scholar] [CrossRef]

| BT Ratio (vol %) | End Torque (N·m) |

|---|---|

| 0 | 24.0 |

| 10 | 26.0 |

| 20 | 27.1 |

| 30 | 28.6 |

| 35 * | 15.7 * |

| 40 | 32.4 |

| 45 | 34.9 |

| 50 | 37.7 |

| BT Ratio (vol %) | Theoretical (wt %) | Measured (wt %) | Back-Calculated (vol %) |

|---|---|---|---|

| 0 | 0 | 0.47 | |

| 10 | 38.4 | 39.9 | 10.5 |

| 20 | 58.5 | 59.0 | 20.3 |

| 30 | 70.8 | 70.8 | 30.2 |

| 35 | 75.2 | 74.2 | 33.9 |

| 40 | 79.0 | 79.0 | 40.0 |

| 45 | 82.2 | 82.1 | 44.9 |

| 50 | 85.0 | 84.9 | 50.0 |

| Number of Shells | Nozzle Diameter (μm) | Raster Angle (°) | Raster Width (μm) | Infill (%) | Build-Table Temperature (°C) |

|---|---|---|---|---|---|

| 3 | 400 | 45 | 200 | 100 | 110 |

| BT Ratio (vol %) | Voids (vol %) | MG Reduction (%) | JS Reduction (%) |

|---|---|---|---|

| 0 | 2.1 | 1.7 | 1.7 |

| 10 | 4.4 | 3.8 | 3.6 |

| 20 | 6.5 | 5.3 | 5.2 |

| 30 | 7.8 | 6.6 | 6.2 |

| 35 | 11.9 | 10.0 | 9.0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khatri, B.; Lappe, K.; Habedank, M.; Mueller, T.; Megnin, C.; Hanemann, T. Fused Deposition Modeling of ABS-Barium Titanate Composites: A Simple Route towards Tailored Dielectric Devices. Polymers 2018, 10, 666. https://doi.org/10.3390/polym10060666

Khatri B, Lappe K, Habedank M, Mueller T, Megnin C, Hanemann T. Fused Deposition Modeling of ABS-Barium Titanate Composites: A Simple Route towards Tailored Dielectric Devices. Polymers. 2018; 10(6):666. https://doi.org/10.3390/polym10060666

Chicago/Turabian StyleKhatri, Bilal, Karl Lappe, Mathis Habedank, Tobias Mueller, Christof Megnin, and Thomas Hanemann. 2018. "Fused Deposition Modeling of ABS-Barium Titanate Composites: A Simple Route towards Tailored Dielectric Devices" Polymers 10, no. 6: 666. https://doi.org/10.3390/polym10060666