3D Printing Technologies for Flexible Tactile Sensors toward Wearable Electronics and Electronic Skin

Abstract

:1. Introduction

2. A Brief Overview of Tactile Sensors

2.1. Functional Requirements of Tactile Sensors

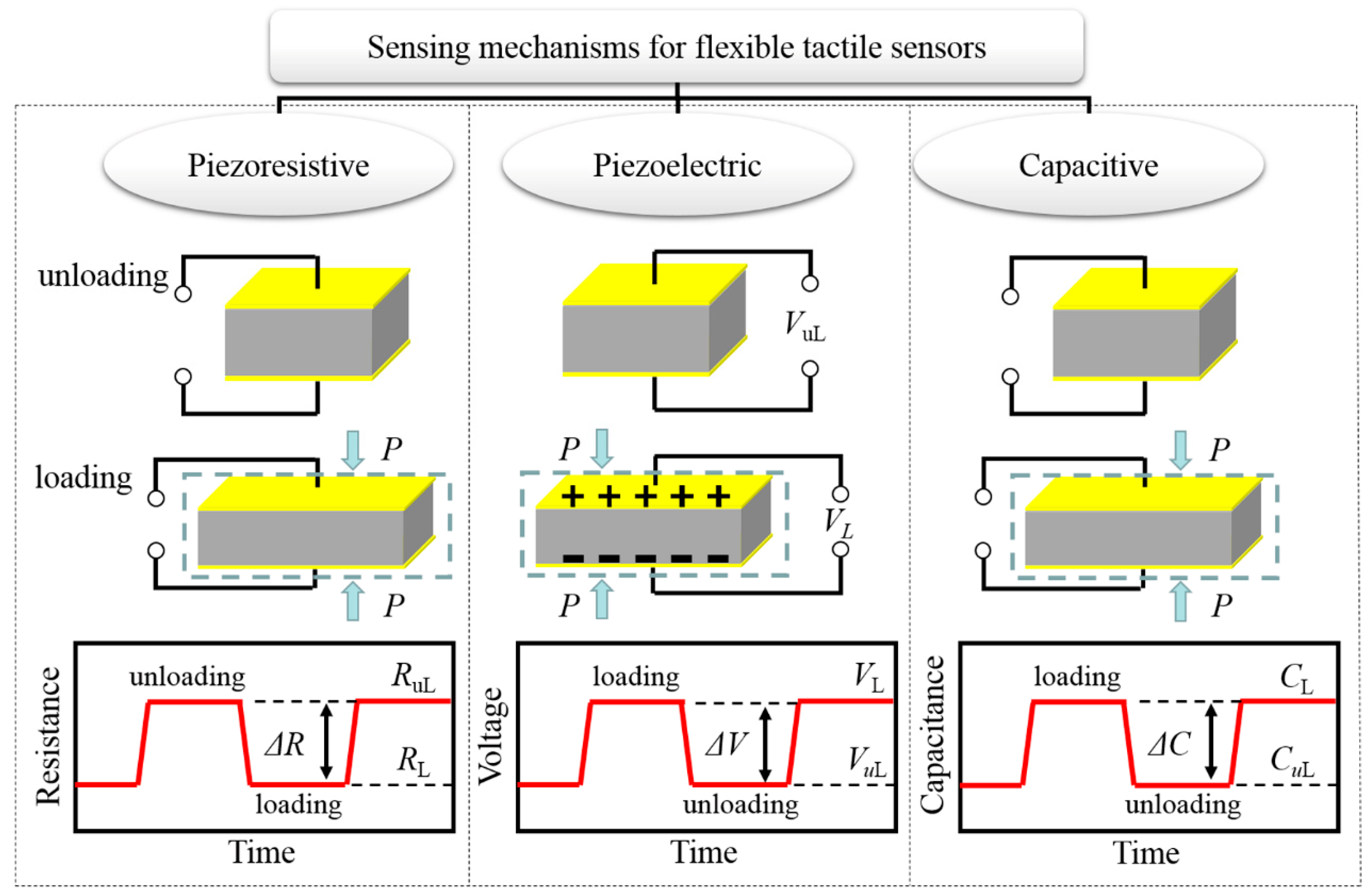

2.2. Sensing Mechanism of Flexible Tactile Sensors

2.2.1. Piezoresistive Sensing

2.2.2. Piezoelectric Sensing

2.2.3. Capacitive Sensing

3. 3D printing Applications in Tactile Sensors

3.1. A Brief Overview of 3D Printing

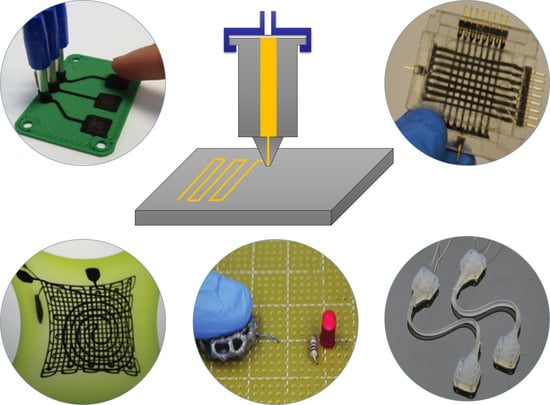

3.2. A Brief Overview of 3D Printing Applications in Tactile Sensors

3.3. Photopolymerization-Based 3D Printing for Tactile Sensors

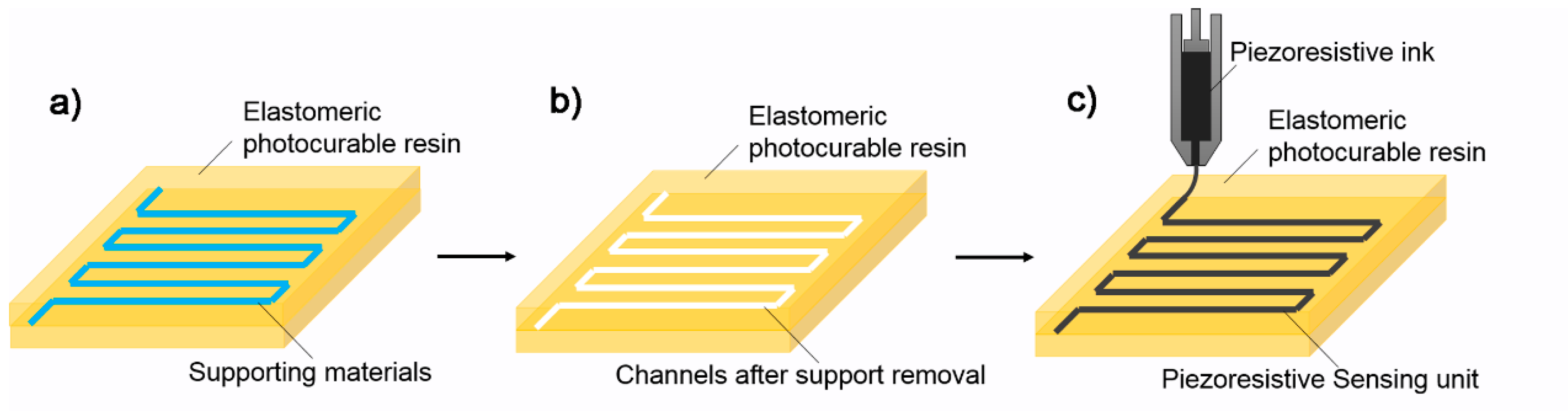

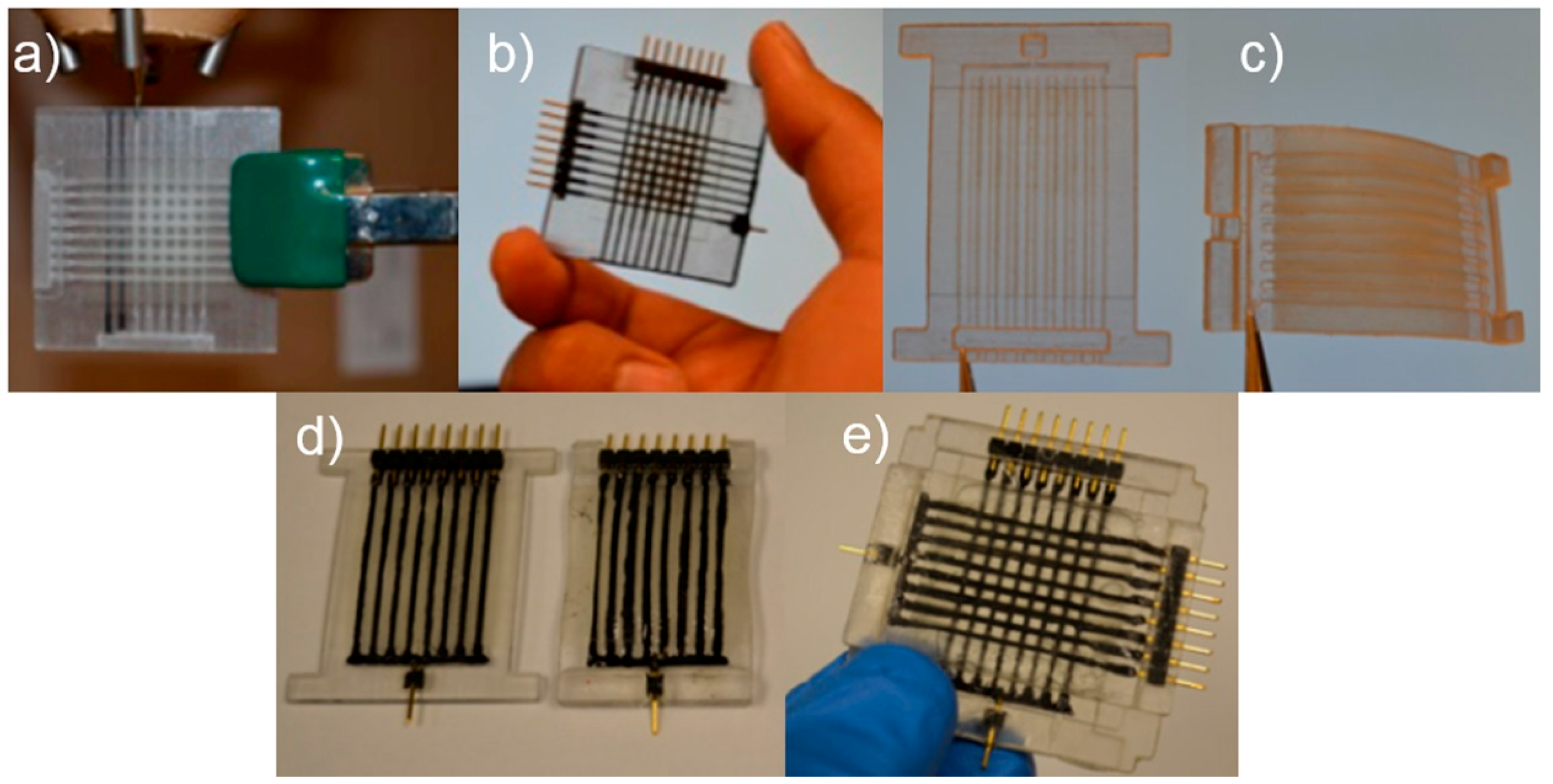

3.4. Materials Extrusion-Based 3D Printing for Tactile Sensors

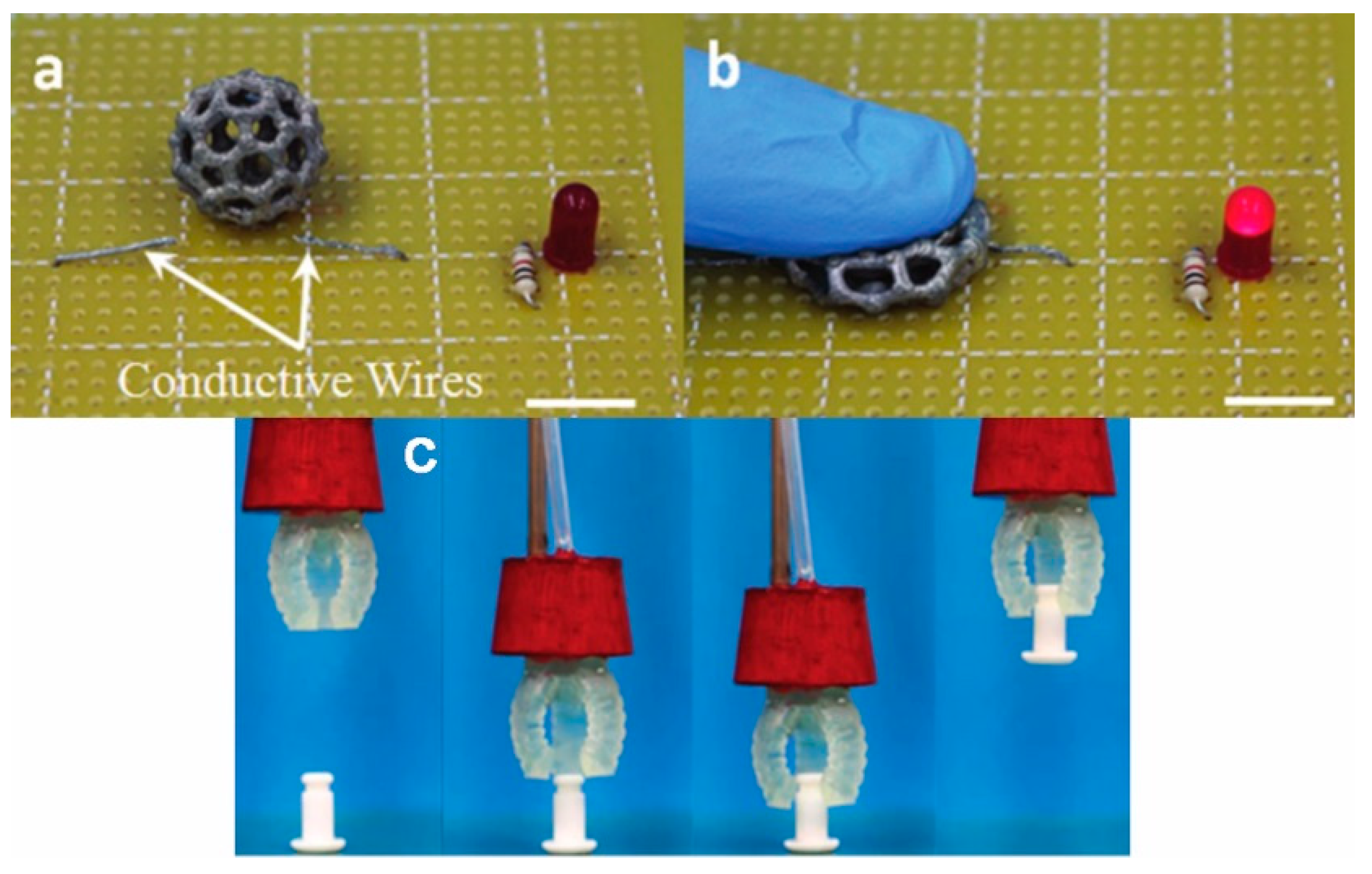

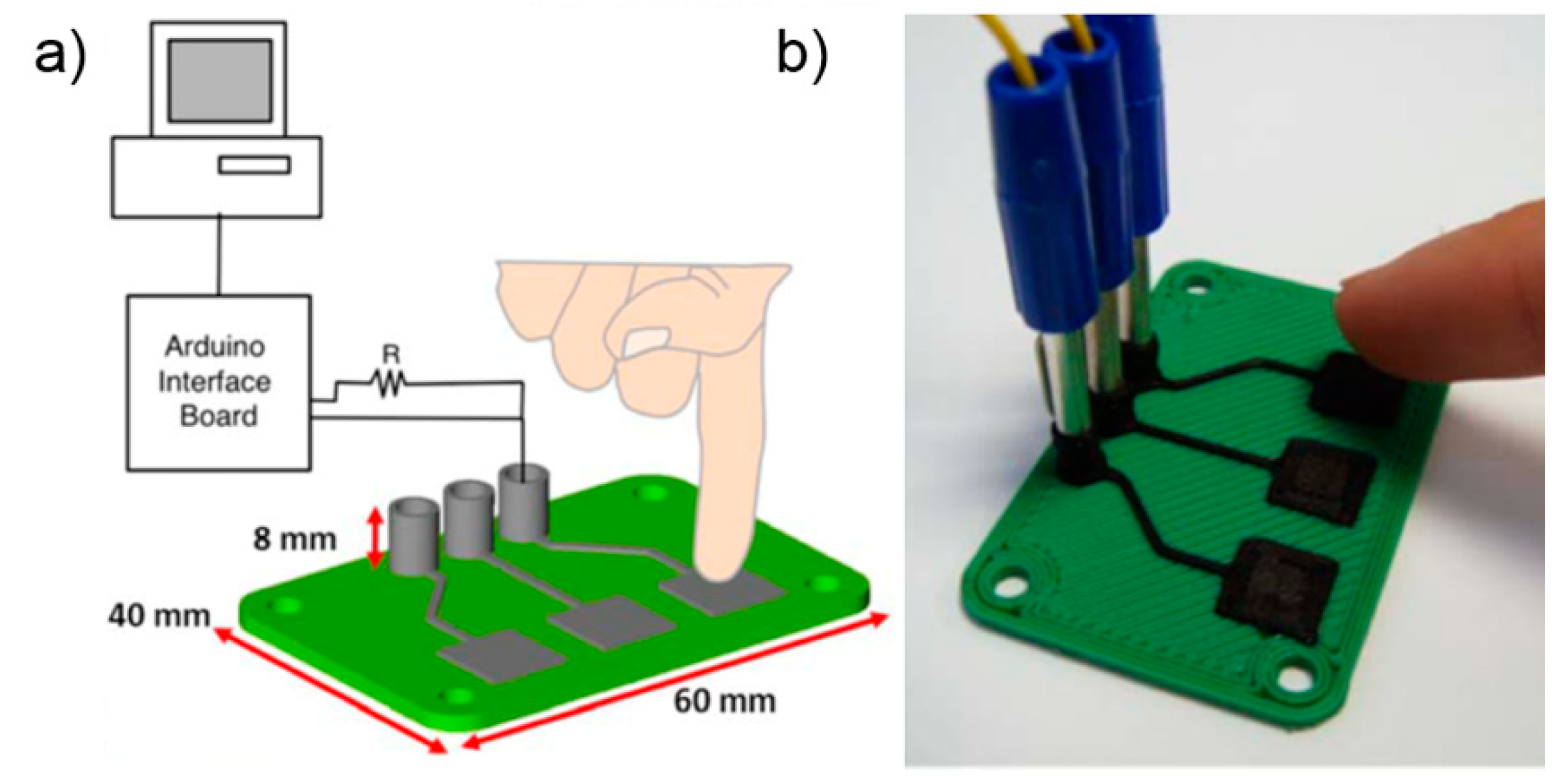

3.4.1. FDM Process for Tactile Sensors

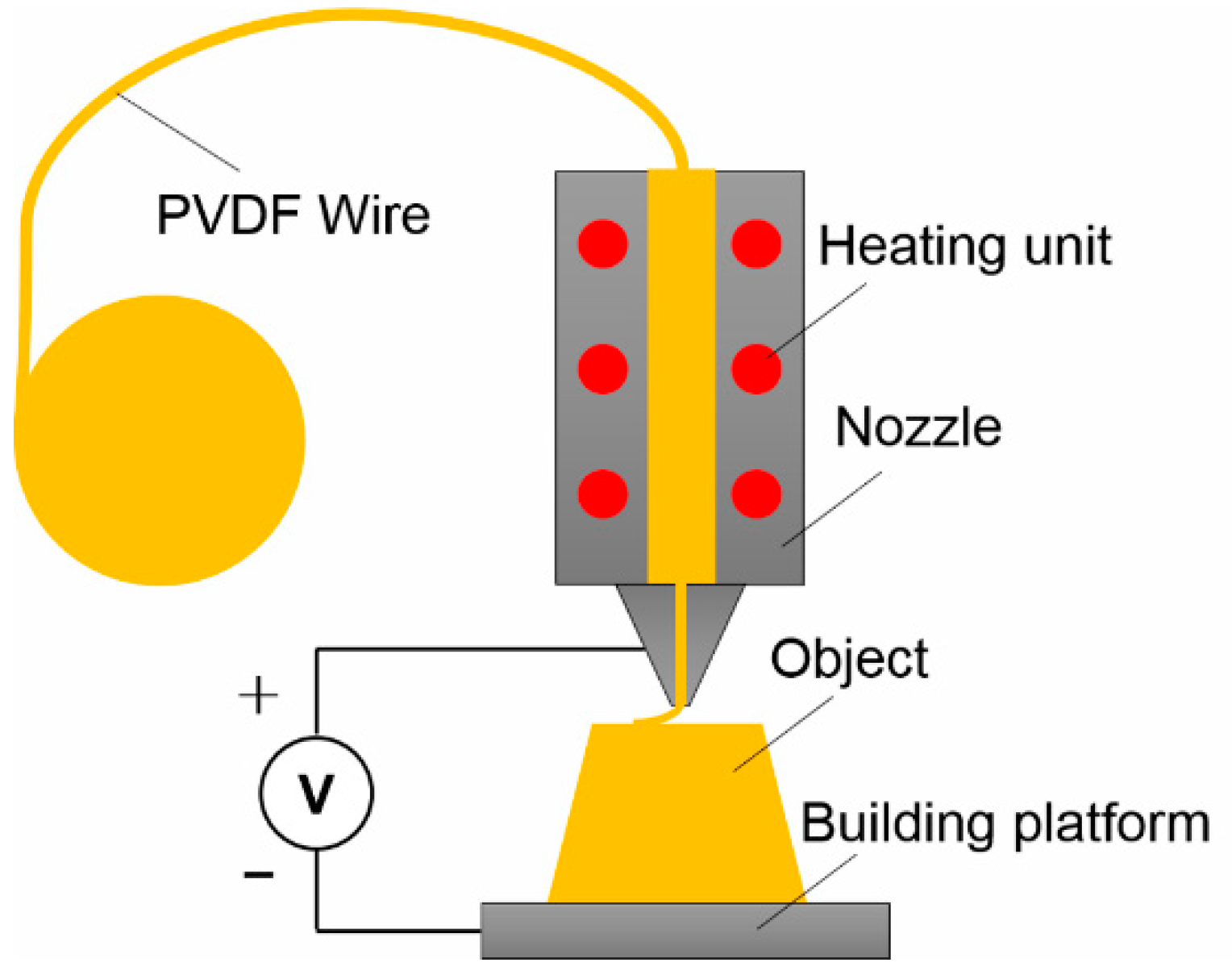

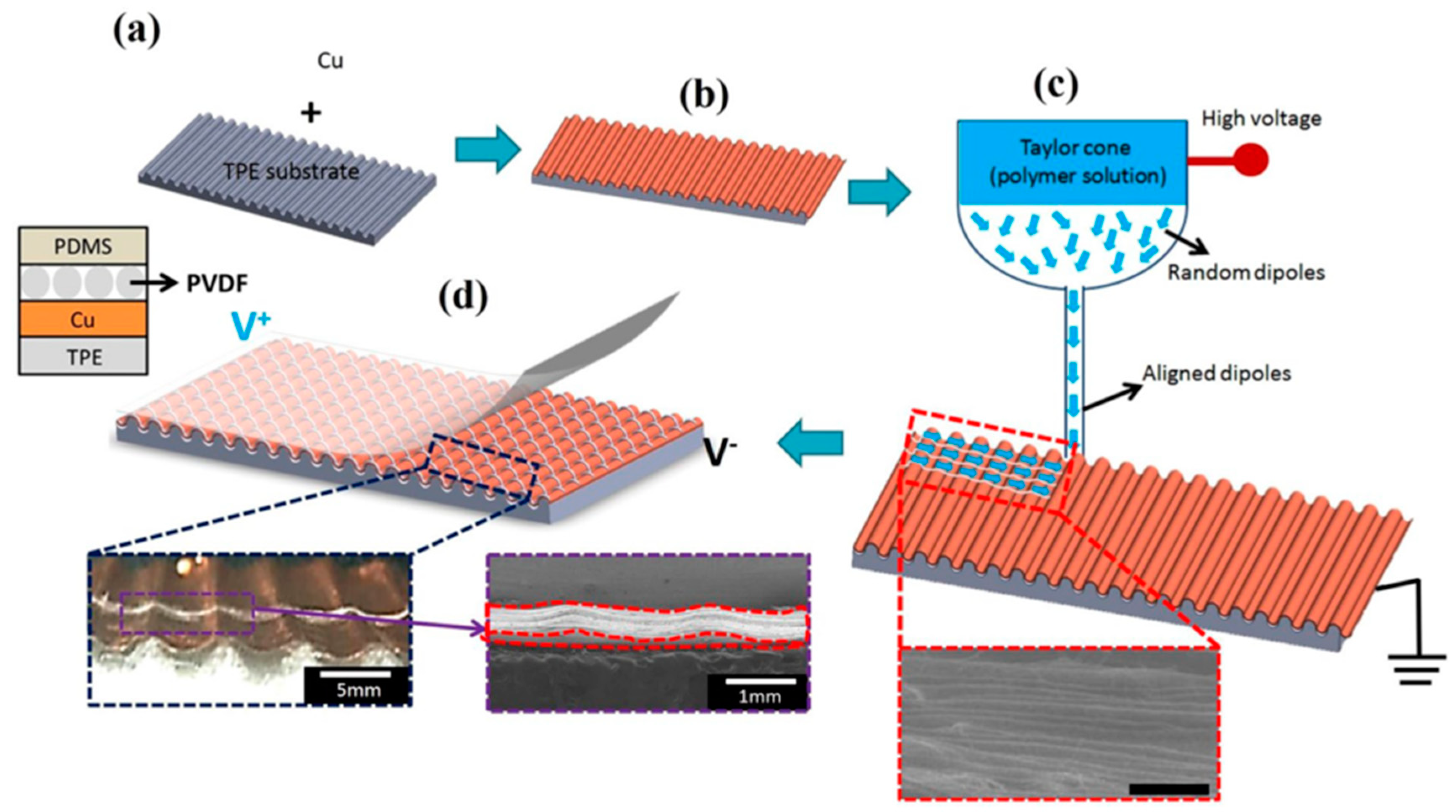

3.4.2. Electric Poling-Assisted FDM Process for Tactile Sensors

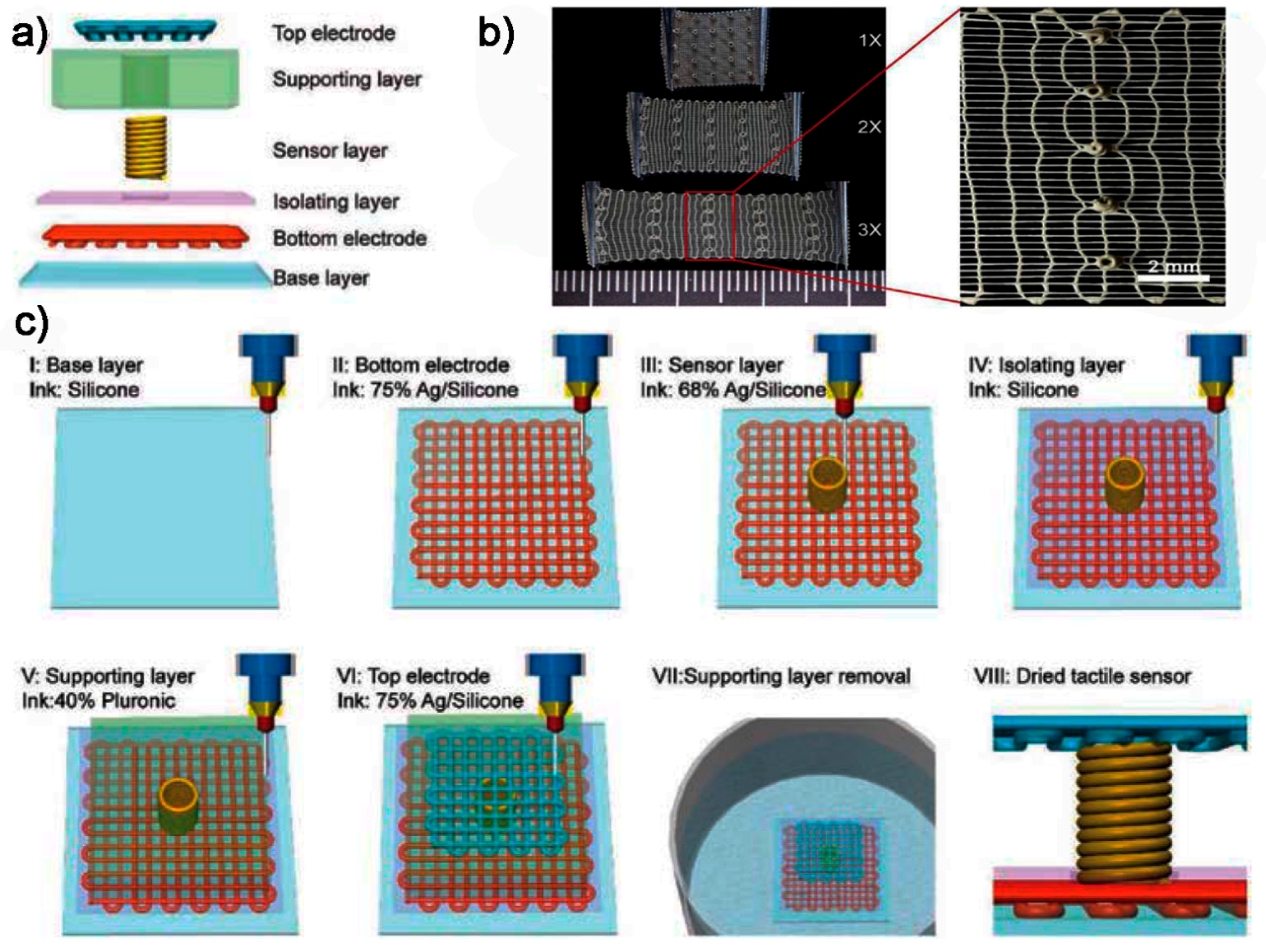

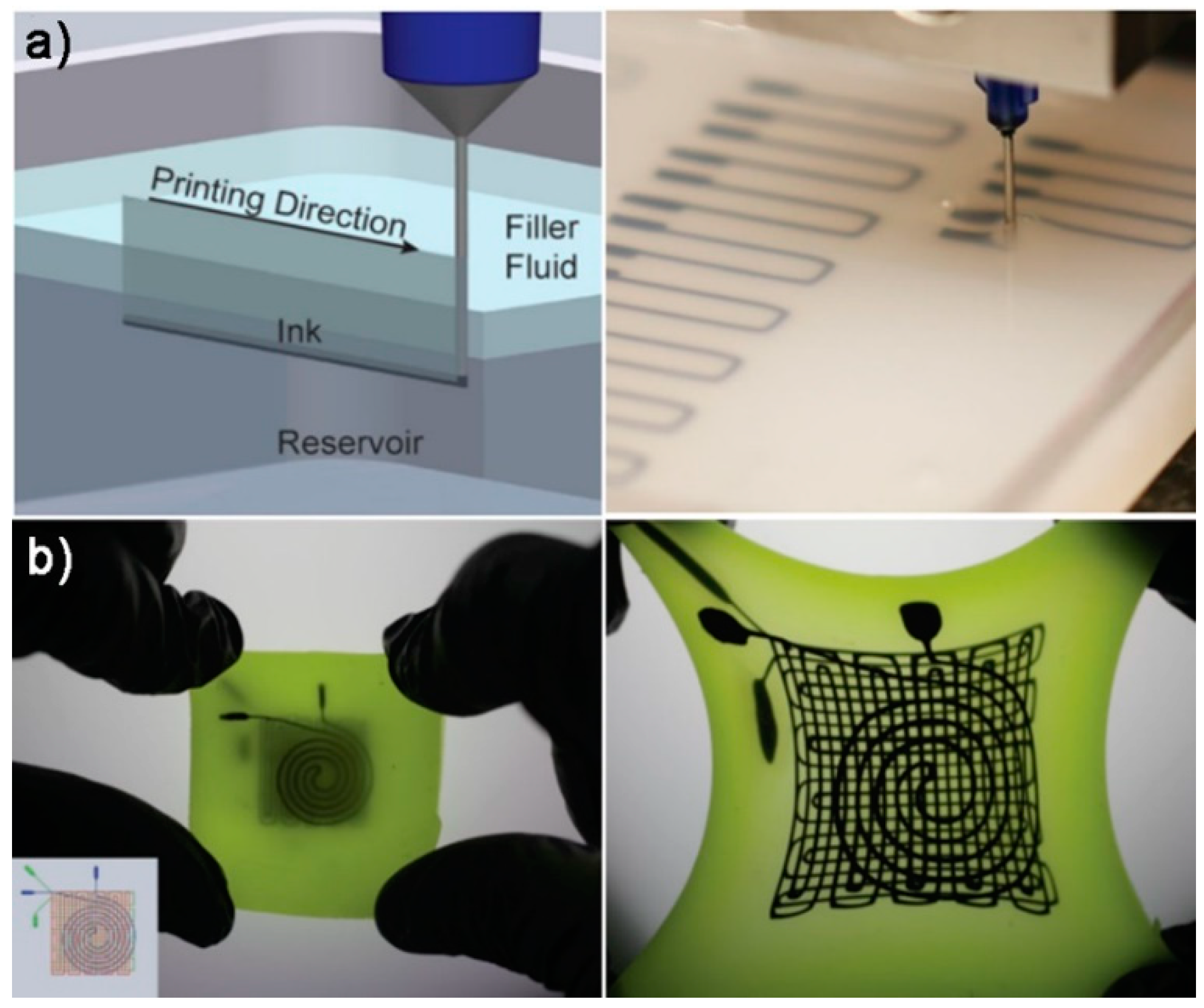

3.4.3. Direct Ink Writing for Tactile Sensors

3.5. Electrohydrodynamic 3D Printing for Piezoelectric Tactile Sensors

3.6. Comparison of Different 3D Printing Technologies for Tactile Sensors

4. Conclusions and Outlook

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Kim, D.H.; Lu, N.S.; Ma, R.; Kim, Y.S.; Kim, R.H.; Wang, S.D.; Wu, J.; Won, S.M.; Tao, H.; Islam, A.; et al. Epidermal electronics. Science 2011, 333, 838–843. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.D.; Li, M.; Wu, J.; Kim, D.H.; Lu, N.S.; Su, Y.W.; Kang, Z.; Huang, Y.G.; Rogers, J.A. Mechanics of epidermal electronics. J. Appl. Mech. Trans. ASME 2012, 79, 031022. [Google Scholar] [CrossRef]

- Yeo, W.H.; Kim, Y.S.; Lee, J.; Ameen, A.; Shi, L.K.; Li, M.; Wang, S.D.; Ma, R.; Jin, S.H.; Kang, Z.; et al. Multifunctional epidermal electronics printed directly onto the skin. Adv. Mater. 2013, 25, 2773–2778. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.D.; Dong, L.; Zhang, H.L.; Yu, R.M.; Pan, C.F.; Wang, Z.L. Recent progress in electronic skin. Adv. Sci. 2015, 2, 1500169. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.; Lee, H.; Ghaffari, R.; Hyeon, T.; Kim, D.H. Recent advances in flexible and stretchable bio-electronic devices integrated with nanomaterials. Adv. Mater. 2016, 28, 4203–4218. [Google Scholar] [CrossRef] [PubMed]

- Chortos, A.; Liu, J.; Bao, Z.A. Pursuing prosthetic electronic skin. Nat. Mater. 2016, 15, 937–950. [Google Scholar] [CrossRef] [PubMed]

- Rim, Y.S.; Bae, S.H.; Chen, H.J.; De Marco, N.; Yang, Y. Recent progress in materials and devices toward printable and flexible Sensors. Adv. Mater. 2016, 28, 4415–4440. [Google Scholar] [CrossRef] [PubMed]

- Han, S.T.; Peng, H.Y.; Sun, Q.J.; Venkatesh, S.; Chung, K.S.; Lau, S.C.; Zhou, Y.; Roy, V.A.L. An overview of the development of flexible sensors. Adv. Mater. 2017, 29, 1700375. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.W.; Liu, Z.; Zhang, T. Flexible sensing electronics for wearable/attachable health monitoring. Small 2017, 13, 1602790. [Google Scholar] [CrossRef] [PubMed]

- Yang, T.T.; Xie, D.; Li, Z.H.; Zhu, H.W. Recent advances in wearable tactile sensors: Materials, sensing mechanisms, and device performance. Mater. Sci. Eng. R 2017, 115, 1–37. [Google Scholar] [CrossRef]

- Chen, S.; Jiang, K.; Lou, Z.; Chen, D.; Shen, G.Z. Recent developments in graphene-based tactile sensors and e-skins. Adv. Mater. Technol. 2018, 3, 1700248. [Google Scholar] [CrossRef]

- Zou, Z.N.; Zhu, C.P.; Li, Y.; Lei, X.F.; Zhang, W.; Xiao, J.L. Rehealable, fully recyclable, and malleable electronic skin enabled by dynamic covalent thermoset nanocomposite. Sci. Adv. 2018, 4, eaaq0508. [Google Scholar] [CrossRef] [PubMed]

- Amjadi, M.; Kyung, K.U.; Park, I.; Sitti, M. Stretchable, skin-mountable, and wearable strain sensors and their potential applications: A review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Heikenfeld, J.; Jajack, A.; Rogers, J.; Gutruf, P.; Tian, L.; Pan, T.; Li, R.; Khine, M.; Kim, J.; Wang, J.; et al. Wearable sensors: Modalities, challenges, and prospects. Lab Chip 2018, 18, 217–248. [Google Scholar] [CrossRef] [PubMed]

- Yao, S.S.; Swetha, P.; Zhu, Y. Nanomaterial-enabled wearable sensors for healthcare. Adv. Healthc. Mater. 2018, 7, 1700889. [Google Scholar] [CrossRef] [PubMed]

- Pang, C.; Lee, G.Y.; Kim, T.I.; Kim, S.M.; Kim, H.N.; Ahn, S.H.; Suh, K.Y. A flexible and highly sensitive strain-gauge sensor using reversible interlocking of nanofibres. Nat. Mater. 2012, 11, 795–801. [Google Scholar] [CrossRef] [PubMed]

- Obitayo, W.; Liu, T. A Review: Carbon nanotube-based piezoresistive strain sensors. J. Sens. 2012, 2012, 652438. [Google Scholar] [CrossRef]

- Yamada, T.; Hayamizu, Y.; Yamamoto, Y.; Yomogida, Y.; Izadi-Najafabadi, A.; Futaba, D.N.; Hata, K. A stretchable carbon nanotube strain sensor for human-motion detection. Nat. Nanotechnol. 2011, 6, 296–301. [Google Scholar] [CrossRef] [PubMed]

- Hu, N.; Fukunaga, H.; Atobe, S.; Liu, Y.; Li, J. Piezoresistive strain sensors made from carbon nanotubes based polymer nanocomposites. Sensors 2011, 11, 10691–10723. [Google Scholar]

- Eswaraiah, V.; Balasubramaniam, K.; Ramaprabhu, S. Functionalized graphene reinforced thermoplastic nanocomposites as strain sensors in structural health monitoring. J. Mater. Chem. 2011, 21, 12626. [Google Scholar] [CrossRef]

- Li, X.; Zhang, R.J.; Yu, W.J.; Wang, K.L.; Wei, J.Q.; Wu, D.H.; Cao, A.Y.; Li, Z.H.; Cheng, Y.; Zheng, Q.H.; et al. Stretchable and highly sensitive graphene-on-polymer strain sensors. Sci. Rep. 2012, 2, 870. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yao, H.B.; Ge, J.; Wang, C.F.; Wang, X.; Hu, W.; Zheng, Z.J.; Ni, Y.; Yu, S.H. A flexible and highly pressure-sensitive graphene-polyurethane sponge based on fractured microstructure design. Adv. Mater. 2013, 25, 6692–6698. [Google Scholar] [CrossRef] [PubMed]

- Amjadi, M.; Pichitpajongkit, A.; Lee, S.; Ryu, S.; Park, I. Highly stretchable and sensitive strain sensor based on silver nanowire-elastomer nanocomposite. ACS Nano 2014, 8, 5154–5163. [Google Scholar] [CrossRef] [PubMed]

- Choong, C.L.; Shim, M.B.; Lee, B.S.; Jeon, S.; Ko, D.S.; Kang, T.H.; Bae, J.; Lee, S.H.; Byun, K.E.; Im, J.; et al. Highly stretchable resistive pressure sensors using a conductive elastomeric composite on a micropyramid array. Adv. Mater. 2014, 26, 3451–3458. [Google Scholar] [CrossRef] [PubMed]

- Chun, S.; Kim, Y.; Jin, H.; Choi, E.; Lee, S.-B.; Park, W. A graphene force sensor with pressure-amplifying structure. Carbon 2014, 78, 601–608. [Google Scholar] [CrossRef]

- Gong, S.; Schwalb, W.; Wang, Y.W.; Chen, Y.; Tang, Y.; Si, J.; Shirinzadeh, B.; Cheng, W.L. A wearable and highly sensitive pressure sensor with ultrathin gold nanowires. Nat. Commun. 2014, 5, 3132. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hou, C.; Wang, H.; Zhang, Q.; Li, Y.; Zhu, M. Highly conductive, flexible, and compressible all-graphene passive electronic skin for sensing human touch. Adv. Mater. 2014, 26, 5018–5024. [Google Scholar] [CrossRef] [PubMed]

- Park, Y.J.; Lee, S.K.; Kim, M.S.; Kim, H.; Ahn, J.H. Graphene-based conformal devices. ACS Nano 2014, 8, 7655–7662. [Google Scholar] [CrossRef] [PubMed]

- Viry, L.; Levi, A.; Totaro, M.; Mondini, A.; Mattoli, V.; Mazzolai, B.; Beccai, L. Flexible three-axial force sensor for soft and highly sensitive artificial touch. Adv. Mater. 2014, 26, 2659–2664. [Google Scholar] [CrossRef] [PubMed]

- Yan, C.; Wang, J.; Kang, W.; Cui, M.; Wang, X.; Foo, C.Y.; Chee, K.J.; Lee, P.S. Highly stretchable piezoresistive graphene-nanocellulose nanopaper for strain sensors. Adv. Mater. 2014, 26, 2022–2027. [Google Scholar] [CrossRef] [PubMed]

- Yang, T.T.; Wang, Y.; Li, X.M.; Zhang, Y.Y.; Li, X.; Wang, K.L.; Wu, D.H.; Jin, H.; Li, Z.H.; Zhu, H.W. Torsion sensors of high sensitivity and wide dynamic range based on a graphene woven structure. Nanoscale 2014, 6, 13053–13059. [Google Scholar] [CrossRef] [PubMed]

- Chun, S.; Kim, Y.; Oh, H.S.; Bae, G.; Park, W. A highly sensitive pressure sensor using a double-layered graphene structure for tactile sensing. Nanoscale 2015, 7, 11652–11659. [Google Scholar] [CrossRef] [PubMed]

- He, Z.F.; Chen, W.J.; Liang, B.H.; Liu, C.Y.; Yang, L.L.; Lu, D.W.; Mo, Z.C.; Zhu, H.; Tang, Z.K.; Gui, X.C. Capacitive pressure sensor with high sensitivity and fast response to dynamic interaction based on graphene and porous nylon networks. ACS Appl. Mater. Inter. 2018, 10, 12816–12823. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Lee, M.S.; Jeon, S.; Kim, M.; Kim, S.; Kim, K.; Bien, F.; Hong, S.Y.; Park, J.U. Highly transparent and stretchable field-effect transistor sensors using graphene-nanowire hybrid nanostructures. Adv. Mater. 2015, 27, 3292–3297. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.Y.; Park, S.; Park, H.W.; Park, D.H.; Jeong, Y.; Kim, D.H. Highly sensitive and multimodal all-carbon skin sensors capable of simultaneously detecting tactile and biological stimuli. Adv. Mater. 2015, 27, 4178–4185. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Zhang, M.; Huang, L.; Li, Y.R.; Chen, J.; Li, C.; Shi, G.Q. High-quality graphene ribbons prepared from graphene xxide hydrogels and their application for strain sensors. ACS Nano 2015, 9, 12320–12326. [Google Scholar] [CrossRef] [PubMed]

- Rahimi, R.; Ochoa, M.; Yu, W.Y.; Ziaie, B. Highly stretchable and sensitive unidirectional strain sensor via laser carbonization. ACS Appl. Mater. Interfaces 2015, 7, 4463–4470. [Google Scholar] [CrossRef] [PubMed]

- Tian, H.; Shu, Y.; Wang, X.F.; Mohammad, M.A.; Bie, Z.; Xie, Q.Y.; Li, C.; Mi, W.T.; Yang, Y.; Ren, T.L. A graphene-based resistive pressure sensor with record-high sensitivity in a wide pressure range. Sci. Rep. 2015, 5, 8603. [Google Scholar] [CrossRef] [PubMed]

- Yang, T.T.; Wang, W.; Zhang, H.Z.; Li, X.M.; Shi, J.D.; He, Y.J.; Zheng, Q.S.; Li, Z.H.; Zhu, H.W. Tactile sensing system based on arrays of graphene woven microfabrics: Electromechanical behavior and electronic skin application. ACS Nano 2015, 9, 10867–10875. [Google Scholar] [CrossRef] [PubMed]

- Lai, Y.C.; Ye, B.W.; Lu, C.F.; Chen, C.T.; Jao, M.H.; Su, W.F.; Hung, W.Y.; Lin, T.Y.; Chen, Y.F. Extraordinarily sensitive and low-voltage operational cloth-based electronic skin for wearable sensing and multifunctional integration uses: A tactile-induced insulating-to-conducting transition. Adv. Funct. Mater. 2016, 26, 1286–1295. [Google Scholar] [CrossRef]

- Li, J.H.; Zhao, S.F.; Zeng, X.L.; Huang, W.P.; Gong, Z.Y.; Zhang, G.P.; Sun, R.; Wong, C.P. Highly stretchable and sensitive strain sensor based on facilely prepared three-dimensional graphene foam composite. ACS Appl. Mater. Interfaces 2016, 8, 18954–18961. [Google Scholar] [CrossRef] [PubMed]

- Lou, Z.; Chen, S.; Wang, L.; Jiang, K.; Shen, G. An ultra-sensitive and rapid response speed graphene pressure sensors for electronic skin and health monitoring. Nano Energy 2016, 23, 7–14. [Google Scholar] [CrossRef]

- Shi, G.; Zhao, Z.H.; Pai, J.H.; Lee, I.; Zhang, L.Q.; Stevenson, C.; Ishara, K.; Zhang, R.J.; Zhu, H.W.; Ma, J. Highly sensitive, wearable, durable strain sensors and stretchable conductors using graphene/silicon rubber composites. Adv. Funct. Mater. 2016, 26, 7614–7625. [Google Scholar] [CrossRef]

- Shi, J.; Li, X.; Cheng, H.; Liu, Z.; Zhao, L.; Yang, T.; Dai, Z.H.; Cheng, Z.G.; Shi, E.Z.; Yang, L.; et al. Graphene reinforced carbon nanotube networks for wearable strain sensors. Adv. Funct. Mater. 2016, 26, 2078–2084. [Google Scholar] [CrossRef]

- Chen, Q.; Xu, R.; He, Z.; Zhao, K.; Pan, L. Printing 3D gel polymer electrolyte in lithium-ion microbattery using stereolithography. J. Electrochem. Soc. 2017, 164, A1852–A1857. [Google Scholar] [CrossRef]

- Foster, C.W.; Down, M.P.; Zhang, Y.; Ji, X.; Rowley-Neale, S.J.; Smith, G.C.; Kelly, P.J.; Banks, C.E. 3D printed graphene based energy storage devices. Sci. Rep. 2017, 7, 42233. [Google Scholar] [CrossRef] [PubMed]

- Fu, K.; Wang, Y.B.; Yan, C.Y.; Yao, Y.G.; Chen, Y.A.; Dai, J.Q.; Lacey, S.; Wang, Y.B.; Wan, J.Y.; Li, T.; et al. Graphene oxide-based electrode inks for 3D-printed lithium-ion batteries. Adv. Mater. 2016, 28, 2587–2594. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.T.; Jiang, Y.; Cui, S.H.; Duan, Y.D.; Liu, T.C.; Guo, H.; Lin, L.P.; Lin, Y.; Zheng, J.X.; Amine, K.; et al. 3D-printed cathodes of LiMn1−xFexPO4 nanocrystals achieve both ultrahigh rate and high capacity for advanced lithium-ion battery. Adv. Energy Mater. 2016, 6, 1600856. [Google Scholar] [CrossRef]

- Kohlmeyer, R.R.; Blake, A.J.; Hardin, J.O.; Carmona, E.A.; Carpena-Nunez, J.; Maruyama, B.; Berrigan, J.D.; Huang, H.; Durstock, M.F. Composite batteries: A simple yet universal approach to 3D printable lithium-ion battery electrodes. J. Mater. Chem. A 2016, 4, 16856–16864. [Google Scholar] [CrossRef]

- Li, J.; Leu, M.C.; Panat, R.; Park, J. A hybrid three-dimensionally structured electrode for lithium-ion batteries via 3D printing. Mater. Des. 2017, 119, 417–424. [Google Scholar] [CrossRef]

- Liu, C.; Cheng, X.; Li, B.; Chen, Z.; Mi, S.; Lao, C. Fabrication and characterization of 3D-printed highly-porous 3D LiFePO4 electrodes by low temperature direct writing process. Materials 2017, 10, 934. [Google Scholar] [CrossRef] [PubMed]

- Rocha, V.G.; Garcia-Tunon, E.; Botas, C.; Markoulidis, F.; Feilden, E.; D’Elia, E.; Ni, N.; Shaffer, M.; Saiz, E. Multimaterial 3D printing of graphene-based electrodes for electrochemical energy storage using thermoresponsive inks. ACS Appl. Mater. Interfaces 2017, 9, 37136–37145. [Google Scholar] [CrossRef] [PubMed]

- Sun, K.; Wei, T.S.; Ahn, B.Y.; Seo, J.Y.; Dillon, S.J.; Lewis, J.A. 3D printing of interdigitated Li-ion microbattery architectures. Adv. Mater. 2013, 25, 4539–4543. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Chen, C.; Xie, H.; Gao, T.; Yao, Y.; Pastel, G.; Han, X.G.; Li, Y.J.; Zhao, J.P.; Fu, K.K.; et al. 3D-printed all-fiber Li-ion battery toward wearable energy storage. Adv. Funct. Mater. 2017, 27, 1703140. [Google Scholar] [CrossRef]

- Areir, M.; Xu, Y.M.; Harrison, D.; Fyson, J. 3D printing of highly flexible supercapacitor designed for wearable energy storage. Mater. Sci. Eng. B 2017, 226, 29–38. [Google Scholar] [CrossRef]

- Huang, W.H.; Finnerty, C.; Sharp, R.; Wang, K.; Balili, B. High-performance 3D printed microtubular solid oxide fuel cells. Adv. Mater. Technol. 2017, 2, 1600258. [Google Scholar] [CrossRef]

- Philamore, H.; Rossiter, J.; Walters, P.; Winfield, J.; Ieropoulos, I. Cast and 3D printed ion exchange membranes for monolithic microbial fuel cell fabrication. J. Power Sources 2015, 289, 91–99. [Google Scholar] [CrossRef]

- Wang, Q.; Yu, Y.; Yang, J.; Liu, J. Fast fabrication of flexible functional circuits based on liquid metal dual-trans printing. Adv. Mater. 2015, 27, 7109–7116. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.Y.; Yang, C.; Hsu, W.; Lin, L. 3D-printed microelectronics for integrated circuitry and passive wireless sensors. Microsyst. Nanoeng. 2015, 1, 15013–15021. [Google Scholar] [CrossRef]

- Zheng, Y.; He, Z.; Gao, Y.; Liu, J. Direct desktop printed-circuits-on-paper flexible electronics. Sci. Rep. 2013, 3, 1786. [Google Scholar] [CrossRef]

- Liu, C.Y.; Li, Y.; Zhang, L.; Mi, S.L.; Xu, Y.Y.; Sun, W. Development of a novel low-temperature deposition machine using screw extrusion to fabricate poly(l-lactide-co-glycolide) acid scaffolds. Proc. Inst. Mech. Eng. H 2014, 228, 593–606. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.Y.; Guo, X.; Yang, S.T.; Li, L.; Zhang, P.; Sun, W.; Liu, C.Y.; Mi, S.L. Construction of bionic tissue engineering cartilage scaffold based on three-dimensional printing and oriented frozen technology. J. Biomed. Mater. Res. A 2018, 106, 1664–1676. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.J.; Su, X.; Xu, Y.Y.; Kong, B.; Sun, W.; Mi, S.L. Bioprinting three-dimensional cell-laden tissue constructs with controllable degradation. Sci. Rep. 2016, 6, 24474. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kong, B.; Sun, W.; Chen, G.S.; Tang, S.; Li, M.; Shao, Z.W.; Mi, S.L. Tissue-engineered cornea constructed with compressed collagen and laser-perforated electrospun mat. Sci. Rep. 2017, 7, 970. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.Y.; Wu, X.Y.; Guo, X.; Kong, B.; Zhang, M.; Qian, X.; Mi, S.L.; Sun, W. The boom in 3D-printed sensor technology. Sensors 2017, 17, 1166. [Google Scholar] [CrossRef] [PubMed]

- Chun, S.; Hong, A.; Choi, Y.; Ha, C.; Park, W. A tactile sensor using a conductive graphene-sponge composite. Nanoscale 2016, 8, 9185–9192. [Google Scholar] [CrossRef] [PubMed]

- Someya, T.; Sekitani, T.; Iba, S.; Kato, Y.; Kawaguchi, H.; Sakurai, T. A large-area, flexible pressure sensor matrix with organic field-effect transistors for artificial skin applications. Proc. Natl. Acad. Sci. USA 2004, 101, 9966–9970. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tok, J.B.H.; Bao, Z.A. Recent advances in flexible and stretchable electronics, sensors and power sources. Sci. China Chem. 2012, 55, 718–725. [Google Scholar] [CrossRef]

- Chortos, A.; Bao, Z.N. Skin-inspired electronic devices. Mater. Today 2014, 17, 321–331. [Google Scholar] [CrossRef]

- Lee, Y.; Oh, J.Y.; Kim, T.R.; Gu, X.D.; Kim, Y.; Wang, G.J.N.; Wu, H.-C.; Pfattner, R.; To, J.W.F.; Katsumata, T.; et al. Deformable organic nanowire field-effect transistors. Adv. Mater. 2018, 30, 1704401. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.J.N.; Gasperini, A.; Bao, Z.A. Stretchable polymer semiconductors for plastic electronics. Adv. Electron. Mater. 2018, 4, 1700429. [Google Scholar] [CrossRef]

- Wang, S.H.; Xu, J.; Wang, W.C.; Wang, G.J.N.; Rastak, R.; Molina-Lopez, F.; Chung, J.W.; Niu, S.M.; Feig, V.R.; Lopez, J.; et al. Skin electronics from scalable fabrication of an intrinsically stretchable transistor array. Nature 2018, 555, 83–88. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.K.; Hong, S.; Cho, H.M.; Lee, J.; Suh, Y.D.; Ham, J.; Ko, S.H. Highly sensitive and stretchable multidimensional strain sensor with prestrained anisotropic metal nanowire percolation networks. Nano Lett. 2015, 15, 5240–5247. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.J.; Zhang, H.L.; Yao, G.; Liao, F.Y.; Gao, M.; Huang, Z.L.; Li, K.Y.; Lin, Y. Highly stretchable, sensitive, and flexible strain sensors based on silver nanoparticles/carbon nanotubes composites. J. Alloy. Compd. 2015, 652, 48–54. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, S.; Wang, M.; Yu, J.; Khan, Q.; Shang, J.; Ba, L. Continuous graphene and carbon nanotube based high flexible and transparent pressure sensor arrays. Nanotechnology 2015, 26, 115501. [Google Scholar] [CrossRef] [PubMed]

- Yu, G.H.; Hu, J.D.; Tan, J.P.; Gao, Y.; Lu, Y.F.; Xuan, F.Z. A wearable pressure sensor based on ultraviolet/ozone microstructured carbon nanotube/polydimethylsiloxane arrays for electronic skins. Nanotechnology 2018, 29, 115502. [Google Scholar] [CrossRef] [PubMed]

- Amjadi, M.; Yoon, Y.J.; Park, I. Ultra-stretchable and skin-mountable strain sensors using carbon nanotubes-Ecoflex nanocomposites. Nanotechnology 2015, 26, 375501. [Google Scholar] [CrossRef] [PubMed]

- Cho, D.; Park, J.; Kim, J.; Kim, T.; Kim, J.; Park, I.; Jeon, S. Three-dimensional continuous conductive nanostructure for highly sensitive and stretchable strain sensor. ACS Appl. Mater. Interfaces 2017, 9, 17370–17379. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Lim, M.; Yoon, J.; Kim, M.S.; Choi, B.; Kim, D.M.; Kim, D.H.; Park, I.; Choi, S. Transparent, flexible strain sensor based on a solution-processed carbon nanotube network. ACS Appl. Mater. Interfaces 2017, 9, 26279–26285. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Vosguerichian, M.; Bao, Z.A. A review of fabrication and applications of carbon nanotube film-based flexible electronics. Nanoscale 2013, 5, 1727–1752. [Google Scholar] [CrossRef] [PubMed]

- Pan, L.J.; Chortos, A.; Yu, G.H.; Wang, Y.Q.; Isaacson, S.; Allen, R.; Shi, Y.; Dauskardt, R.; Bao, Z.N. An ultra-sensitive resistive pressure sensor based on hollow-sphere microstructure induced elasticity in conducting polymer film. Nat. Commun. 2014, 5, 3002. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, Z.; Wang, D.Y.; Pang, Y.; Li, Y.X.; Wang, Q.; Zhang, T.Y.; Wang, J.B.; Liu, X.; Yang, Y.Y.; Jian, J.M.; et al. Simultaneously detecting subtle and intensive human motions based on a silver nanoparticles bridged graphene strain sensor. ACS Appl. Mater. Interfaces 2018, 10, 3948–3954. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Kim, S.; Lee, J.; Yang, D.; Park, B.C.; Ryu, S.; Park, I. A stretchable strain sensor based on a metal nanoparticle thin film for human motion detection. Nanoscale 2014, 6, 11932–11939. [Google Scholar] [CrossRef] [PubMed]

- Tee, B.C.K.; Wang, C.; Allen, R.; Bao, Z.N. An electrically and mechanically self-healing composite with pressure- and flexion-sensitive properties for electronic skin applications. Nat. Nanotechnol. 2012, 7, 825–832. [Google Scholar] [CrossRef] [PubMed]

- Bae, S.-H.; Lee, Y.; Sharma, B.K.; Lee, H.-J.; Kim, J.-H.; Ahn, J.-H. Graphene-based transparent strain sensor. Carbon 2013, 51, 236–242. [Google Scholar] [CrossRef]

- Kwon, O.K.; Lee, J.H.; Kim, K.-S.; Kang, J.W. Developing ultrasensitive pressure sensor based on graphene nanoribbon: Molecular dynamics simulation. Phys. E Low-Dimens. Syst. Nanostruct. 2013, 47, 6–11. [Google Scholar] [CrossRef]

- Zhu, S.-E.; Krishna Ghatkesar, M.; Zhang, C.; Janssen, G.C.A.M. Graphene based piezoresistive pressure sensor. Appl. Phys. Lett. 2013, 102, 161904. [Google Scholar] [CrossRef] [Green Version]

- Gonçalves, V.; Brandão, L.; Mendes, A. Development of porous polymer pressure sensors incorporating graphene platelets. Polym. Test. 2014, 37, 129–137. [Google Scholar] [CrossRef] [Green Version]

- Jeong, Y.R.; Park, H.; Jin, S.W.; Hong, S.Y.; Lee, S.-S.; Ha, J.S. Highly stretchable and sensitive strain sensors using fragmentized graphene foam. Adv. Funct. Mater. 2015, 25, 4228–4236. [Google Scholar] [CrossRef]

- Kazemzadeh, R.; Andersen, K.; Motha, L.; Kim, W.S. Highly sensitive pressure sensor array with photothermally reduced graphene oxide. IEEE Electron Device Lett. 2015, 36, 180–182. [Google Scholar] [CrossRef]

- Samad, Y.A.; Li, Y.Q.; Schiffer, A.; Alhassan, S.M.; Liao, K. Graphene foam developed with a novel two-step technique for low and high strains and pressure-sensing applications. Small 2015, 11, 2380–2385. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Yang, T.; Zhu, H.; Zheng, Q. Bio-inspired mechanics of highly sensitive stretchable graphene strain sensors. Appl. Phys. Lett. 2015, 106, 171903. [Google Scholar] [CrossRef]

- Yeo, J.C.; Yu, J.; Shang, M.; Loh, K.P.; Lim, C.T. Highly flexible graphene oxide nanosuspension liquid-based microfluidic tactile sensor. Small 2016, 12, 1593–1604. [Google Scholar]

- Lin, Y.; Liu, S.Q.; Chen, S.; Wei, Y.; Dong, X.C.; Liu, L. A highly stretchable and sensitive strain sensor based on graphene-elastomer composites with a novel double-interconnected network. J. Mater. Chem. C 2016, 4, 6345–6352. [Google Scholar] [CrossRef]

- Tadakaluru, S.; Kumpika, T.; Kantarak, E.; Sroila, W.; Panthawan, A.; Sanmuangmoon, P.; Thongsuwan, W.; Singjai, P. Highly stretchable and sensitive strain sensors using nano-graphene coated natural rubber. Plast. Rubber Compos. 2017, 46, 301–305. [Google Scholar] [CrossRef]

- Akdogan, E.K.; Allahverdi, M.; Safari, A. Piezoelectric composites for sensor and actuator applications. IEEE Ultrason. Ferroelectr. 2005, 52, 746–775. [Google Scholar] [CrossRef]

- Gullapalli, H.; Vemuru, V.S.M.; Kumar, A.; Botello-Mendez, A.; Vajtai, R.; Terrones, M.; Nagarajaiah, S.; Ajayan, P.M. Flexible piezoelectric ZnO-paper nanocomposite strain sensor. Small 2010, 6, 1641–1646. [Google Scholar] [CrossRef] [PubMed]

- Liang, R.J.; Wang, Q.M. High sensitivity piezoelectric sensors using flexible PZT thick-film for shock tube pressure testing. Sens. Actuators A Phys. 2015, 235, 317–327. [Google Scholar] [CrossRef]

- Chen, Z.F.; Wang, Z.; Li, X.M.; Lin, Y.X.; Luo, N.Q.; Long, M.Z.; Zhao, N.; Xu, J.B. Flexible piezoelectric-induced pressure sensors for static measurements based on nanowires/graphene heterostructures. ACS Nano 2017, 11, 4507–4513. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Zhang, S.; Jin, Y.M.; Ouyang, H.; Zou, Y.; Wang, X.X.; Xie, L.X.; Li, Z. Flexible piezoelectric nanogenerator in wearable self-powered active sensor for respiration and healthcare monitoring. Semicond. Sci. Technol. 2017, 32, 064004. [Google Scholar] [CrossRef]

- Chen, S.W.; Wu, N.; Ma, L.; Lin, S.Z.; Yuan, F.; Xu, Z.S.; Li, W.B.; Wang, B.; Zhou, J. Noncontact heartbeat and respiration monitoring based on a hollow microstructured self-powered pressure sensor. ACS Appl. Mater. Interfaces 2018, 10, 3660–3667. [Google Scholar] [CrossRef] [PubMed]

- Persano, L.; Dagdeviren, C.; Su, Y.W.; Zhang, Y.H.; Girardo, S.; Pisignano, D.; Huang, Y.G.; Rogers, J.A. High performance piezoelectric devices based on aligned arrays of nanofibers of poly(vinylidenefluoride-co-trifluoroethylene). Nat. Commun. 2013, 4, 1633. [Google Scholar] [CrossRef] [PubMed]

- Park, S.H.; Lee, H.B.; Yeon, S.M.; Park, J.; Lee, N.K. Flexible and stretchable piezoelectric sensor with thickness-tunable configuration of electrospun nanofiber mat and elastomeric substrates. ACS Appl. Mater. Interfaces 2016, 8, 24773–24781. [Google Scholar] [CrossRef] [PubMed]

- Xing, L.D.; Zhu, R.J.; Wang, Z.M.; Wang, F.X.; Kimura, H. Flexible tensile strain sensor based on lead-free 0.5Ba (Ti0.8Zr0.2) O3-0.5(Ba0.7Ca0.3) TiO3 piezoelectric nanofibers. Smart Mater. Struct. 2017, 26. [Google Scholar] [CrossRef]

- Deutz, D.B.; Mascarenhas, N.T.; Schelen, J.B.J.; de Leeuw, D.M.; van der Zwaag, S.; Groen, P. Flexible piezoelectric touch sensor by alignment of lead-free alkaline niobate microcubes in PDMS. Adv. Funct. Mater. 2017, 27, 1700728. [Google Scholar] [CrossRef]

- Mannsfeld, S.C.B.; Tee, B.C.K.; Stoltenberg, R.M.; Chen, C.V.H.H.; Barman, S.; Muir, B.V.O.; Sokolov, A.N.; Reese, C.; Bao, Z.N. Highly sensitive flexible pressure sensors with microstructured rubber dielectric layers. Nat. Mater. 2010, 9, 859–864. [Google Scholar] [CrossRef] [PubMed]

- Lipomi, D.J.; Vosgueritchian, M.; Tee, B.C.K.; Hellstrom, S.L.; Lee, J.A.; Fox, C.H.; Bao, Z.N. Skin-like pressure and strain sensors based on transparent elastic films of carbon nanotubes. Nat. Nanotechnol. 2011, 6, 788–792. [Google Scholar] [CrossRef] [PubMed]

- Cohen, D.J.; Mitra, D.; Peterson, K.; Maharbiz, M.M. A highly elastic, capacitive strain gauge based on percolating nanotube networks. Nano Lett. 2012, 12, 1821–1825. [Google Scholar] [CrossRef] [PubMed]

- Tee, B.C.K.; Chortos, A.; Dunn, R.R.; Schwartz, G.; Eason, E.; Bao, Z.A. Tunable flexible pressure sensors using microstructured elastomer geometries for intuitive electronics. Adv. Funct. Mater. 2014, 24, 5427–5434. [Google Scholar] [CrossRef]

- Kwon, D.; Lee, T.I.; Shim, J.; Ryu, S.; Kim, M.S.; Kim, S.; Kim, T.S.; Park, I. Highly sensitive, flexible, and wearable pressure sensor based on a giant piezocapacitive effect of three-dimensional microporous elastomeric dielectric layer. ACS Appl. Mater. Interfaces 2016, 8, 16922–16931. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Luo, H.; Qin, L.; Wang, X.W.; Xiong, Z.P.; Ding, H.Y.; Gu, Y.; Liu, Z.; Zhang, T. Flexible capacitive tactile sensor based on micropatterned dielectric layer. Small 2016, 12, 5042–5048. [Google Scholar] [CrossRef] [PubMed]

- Chhetry, A.; Yoon, H.; Park, J.Y. A flexible and highly sensitive capacitive pressure sensor based on conductive fibers with a microporous dielectric for wearable electronics. J. Mater. Chem. C 2017, 5, 10068–10076. [Google Scholar] [CrossRef]

- Kang, M.; Kim, J.; Jang, B.; Chae, Y.; Kim, J.H.; Ahn, J.H. Graphene-based three-dimensional capacitive touch sensor for wearable electronics. ACS Nano 2017, 11, 7950–7957. [Google Scholar] [CrossRef] [PubMed]

- Atalay, O.; Atalay, A.; Gafford, J.; Walsh, C. A highly sensitive capacitive-based soft pressure sensor based on a conductive fabric and a microporous dielectric layer. Adv. Mater. Technol. 2018, 3, 1700237. [Google Scholar] [CrossRef]

- Cheng, W.; Wang, J.; Ma, Z.; Yan, K.; Wang, Y.M.; Wang, H.T.; Li, S.; Li, Y.; Pan, L.J.; Shi, Y. Flexible pressure sensor with high sensitivity and low hysteresis based on a hierarchically microstructured electrode. IEEE Electron Device Lett. 2018, 39, 288–291. [Google Scholar] [CrossRef]

- Lin, M.F.; Xiong, J.Q.; Wang, J.X.; Parida, K.; Lee, P.S. Core-shell nanofiber mats for tactile pressure sensor and nanogenerator applications. Nano Energy 2018, 44, 248–255. [Google Scholar] [CrossRef]

- Park, S.; Kim, H.; Vosgueritchian, M.; Cheon, S.; Kim, H.; Koo, J.H.; Kim, T.R.; Lee, S.; Schwartz, G.; Chang, H.; et al. Stretchable energy-harvesting tactile electronic skin capable of differentiating multiple mechanical stimuli modes. Adv. Mater. 2014, 26, 7324–7332. [Google Scholar] [CrossRef] [PubMed]

- Boutry, C.M.; Nguyen, A.; Lawal, Q.O.; Chortos, A.; Rondeau-Gagne, S.; Bao, Z.N. A sensitive and biodegradable pressure sensor array for cardiovascular monitoring. Adv. Mater. 2015, 27, 6954–6961. [Google Scholar] [CrossRef] [PubMed]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Schmidt, M.; Merklein, M.; Bourell, D.; Dimitrov, D.; Hausotte, T.; Wegener, K.; Overmeyer, L.; Vollertsen, F.; Levy, G.N. Laser based additive manufacturing in industry and academia. CIRP Ann. 2017, 66, 561–583. [Google Scholar] [CrossRef]

- Durmus, N.G.; Tasoglu, S.; Demirci, U. Bioprinting functional droplet networks. Nat. Mater. 2013, 12, 478–479. [Google Scholar] [CrossRef] [PubMed]

- Mironov, V.; Prestwich, G.; Forgacs, G. Bioprinting living structures. J. Mater. Chem. 2007, 17, 2054–2060. [Google Scholar] [CrossRef]

- Norotte, C.; Marga, F.S.; Niklason, L.E.; Forgacs, G. Scaffold-free vascular tissue engineering using bioprinting. Biomaterials 2009, 30, 5910–5917. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rodriguez-Devora, J.I.; Zhang, B.M.; Reyna, D.; Shi, Z.D.; Xu, T. High throughput miniature drug-screening platform using bioprinting technology. Biofabrication 2012, 4, 035001. [Google Scholar] [CrossRef] [PubMed]

- Tasoglu, S.; Demirci, U. Bioprinting for stem cell research. Trends Biotechnol. 2013, 31, 10–19. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Au, A.K.; Huynh, W.; Horowitz, L.F.; Folch, A. 3D-printed microfluidics. Angew. Chem. Int. Ed. 2016, 55, 3862–3881. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharjee, N.; Urrios, A.; Kanga, S.; Folch, A. The upcoming 3D-printing revolution in microfluidics. Lab Chip 2016, 16, 1720–1742. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ho, C.M.B.; Ng, S.H.; Li, K.H.H.; Yoon, Y.J. 3D printed microfluidics for biological applications. Lab Chip 2015, 15, 3627–3637. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; He, J.K.; Li, X.; Xu, F.Y.; Li, D.C. Micro/nanoscale electrohydrodynamic printing: From 2D to 3D. Nanoscale 2016, 8, 15376–15388. [Google Scholar] [CrossRef] [PubMed]

- Vatani, M.; Lu, Y.; Engeberg, E.D.; Choi, J.-W. Combined 3D printing technologies and material for fabrication of tactile sensors. Int. J. Precis. Eng. Manuf. 2015, 16, 1375–1383. [Google Scholar] [CrossRef]

- Agarwala, S.; Goh, G.L.; Yap, Y.L.; Goh, G.D.; Yu, H.; Yeong, W.Y.; Tran, T. Development of bendable strain sensor with embedded microchannels using 3D printing. Sens. Actuators A Phys. 2017, 263, 593–599. [Google Scholar] [CrossRef]

- Patel, D.K.; Sakhaei, A.H.; Layani, M.; Zhang, B.; Ge, Q.; Magdassi, S. Highly stretchable and UV curable elastomers for digital light processing based 3D printing. Adv. Mater. 2017, 29, 1606000. [Google Scholar] [CrossRef] [PubMed]

- Leigh, S.J.; Bradley, R.J.; Purssell, C.P.; Billson, D.R.; Hutchins, D.A. A simple, low-cost conductive composite material for 3D printing of electronic sensors. PLoS ONE 2012, 7, e49365. [Google Scholar] [CrossRef] [PubMed]

- Saari, M.; Xia, B.; Cox, B.; Krueger, P.S.; Cohen, A.L.; Richer, E. Fabrication and analysis of a composite 3D printed capacitive force sensor. 3D Print. Add. Manuf. 2016, 3, 136–141. [Google Scholar] [CrossRef]

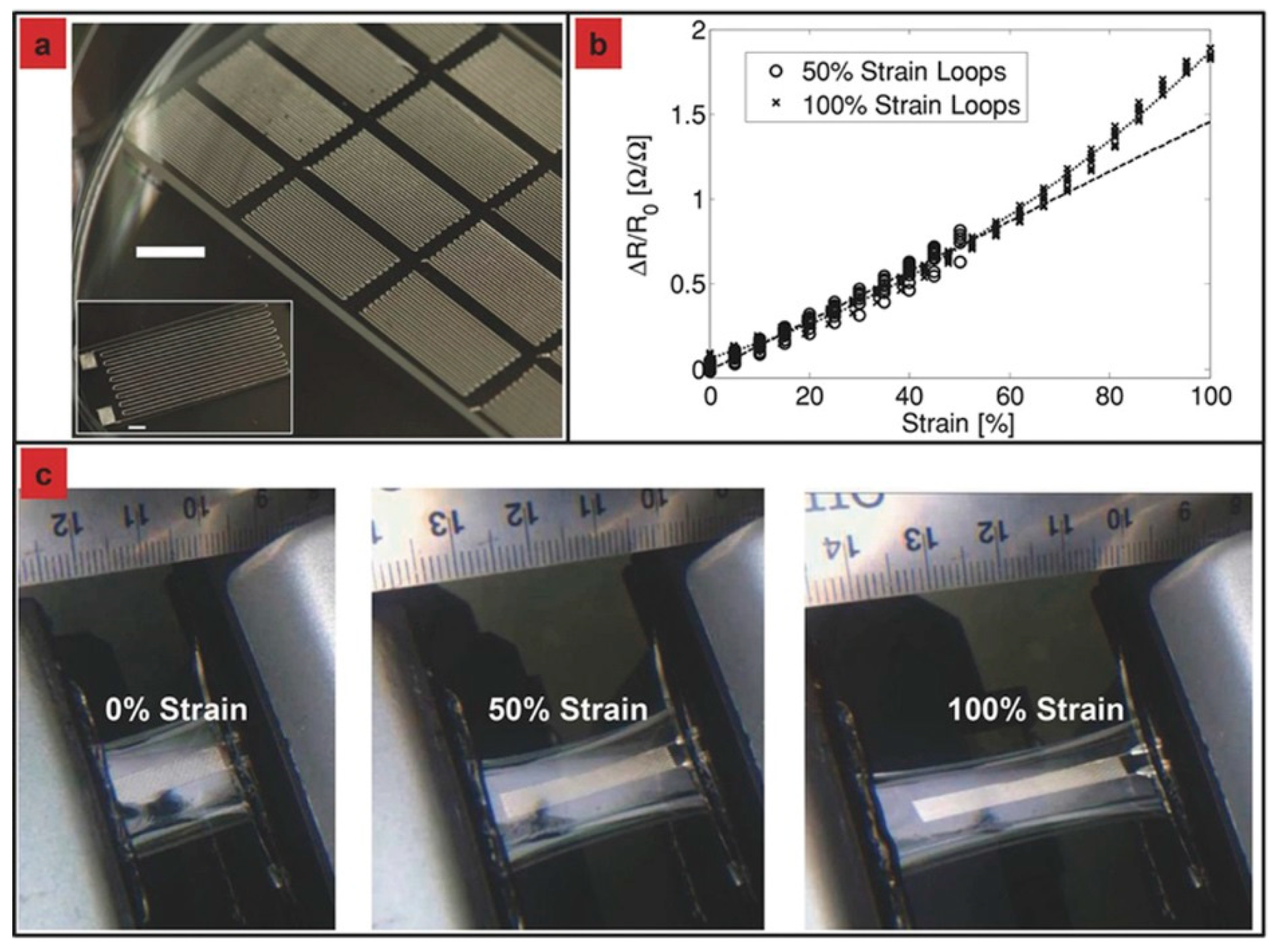

- Christ, J.F.; Aliheidari, N.; Ameli, A.; Potschke, P. 3D printed highly elastic strain sensors of multiwalled carbon nanotube/thermoplastic polyurethane nanocomposites. Mater. Des. 2017, 131, 394–401. [Google Scholar] [CrossRef]

- Kim, K.; Park, J.; Suh, J.H.; Kim, M.; Jeong, Y.; Park, I. 3D printing of multiaxial force sensors using carbon nanotube (CNT)/thermoplastic polyurethane (TPU) filaments. Sens. Actuators A Phys. 2017, 263, 493–500. [Google Scholar] [CrossRef]

- Zhuo, B.G.; Chen, S.J.; Zhao, M.M.; Guo, X.J. High sensitivity flexible capacitive pressure sensor using polydimethylsiloxane elastomer dielectric layer micro-structured by 3D printed mold. IEEE J. Electron Devices Soc. 2017, 5, 219–223. [Google Scholar] [CrossRef]

- Lee, C.; Tarbutton, J.A. Electric poling-assisted additive manufacturing process for PVDF polymer-based piezoelectric device applications. Smart Mater. Struct. 2014, 23, 095044. [Google Scholar] [CrossRef]

- Kim, H.; Torres, F.; Wu, Y.; Villagran, D.; Lin, Y.; Tseng, T.-L. Integrated 3D printing and corona poling process of PVDF piezoelectric films for pressure sensor application. Smart Mater. Struct. 2017, 26, 085027. [Google Scholar] [CrossRef]

- Guo, S.Z.; Qiu, K.Y.; Meng, F.B.; Park, S.H.; McAlpine, M.C. 3D printed stretchable tactile sensors. Adv. Mater. 2017, 29, 1701218. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.Y.; Ji, S.; Jung, S.; Ryu, B.H.; Kim, H.S.; Lee, S.S.; Choi, Y.; Jeong, S. 3D printable composite dough for stretchable, ultrasensitive and body-patchable strain sensors. Nanoscale 2017, 9, 11035–11046. [Google Scholar] [CrossRef] [PubMed]

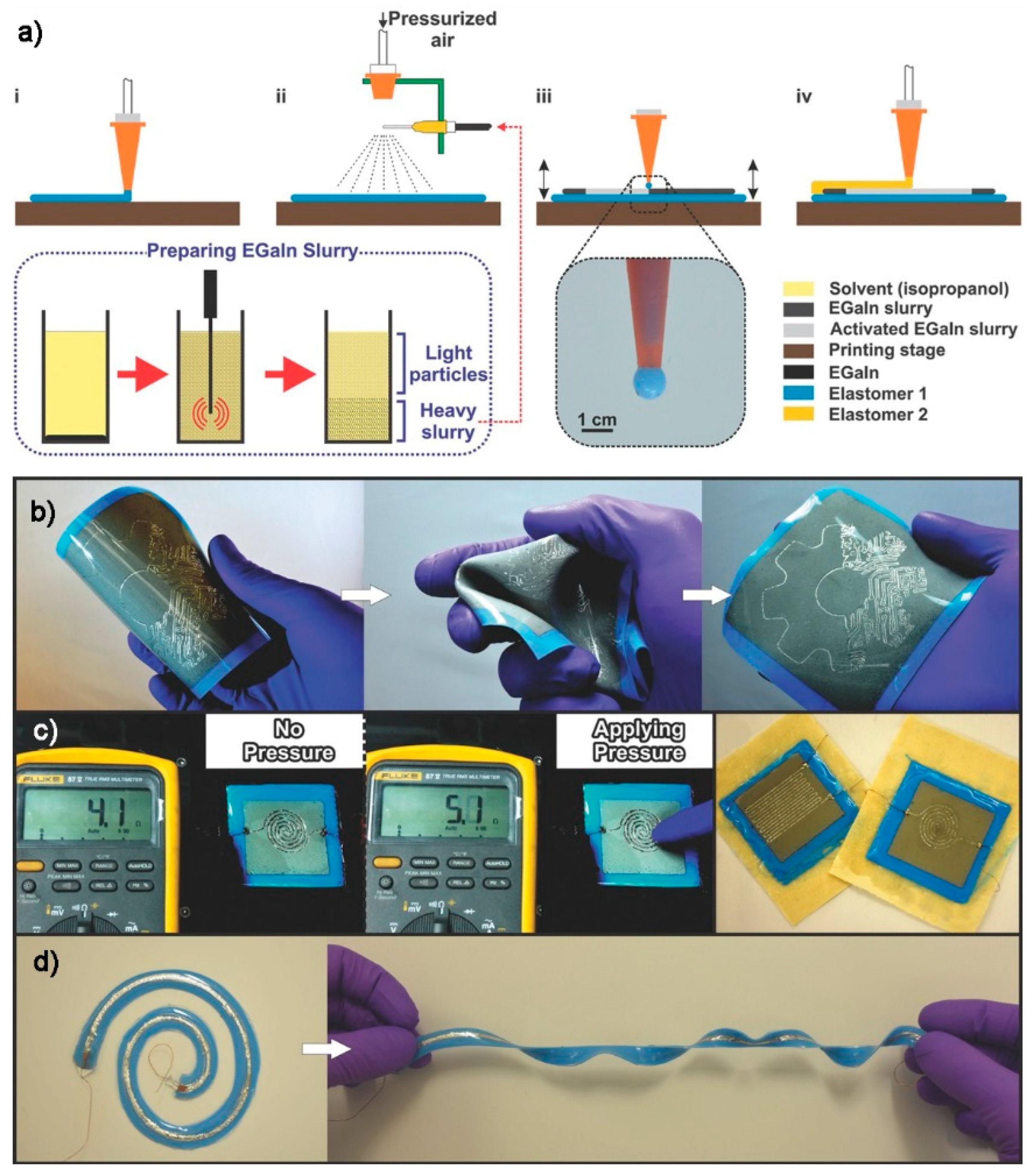

- Boley, J.W.; White, E.L.; Chiu, G.T.C.; Kramer, R.K. Direct writing of gallium-indium alloy for stretchable electronics. Adv. Funct. Mater. 2014, 24, 3501–3507. [Google Scholar] [CrossRef]

- Mohammed, M.G.; Kramer, R. All-printed flexible and stretchable electronics. Adv. Mater. 2017, 29, 1604965. [Google Scholar] [CrossRef] [PubMed]

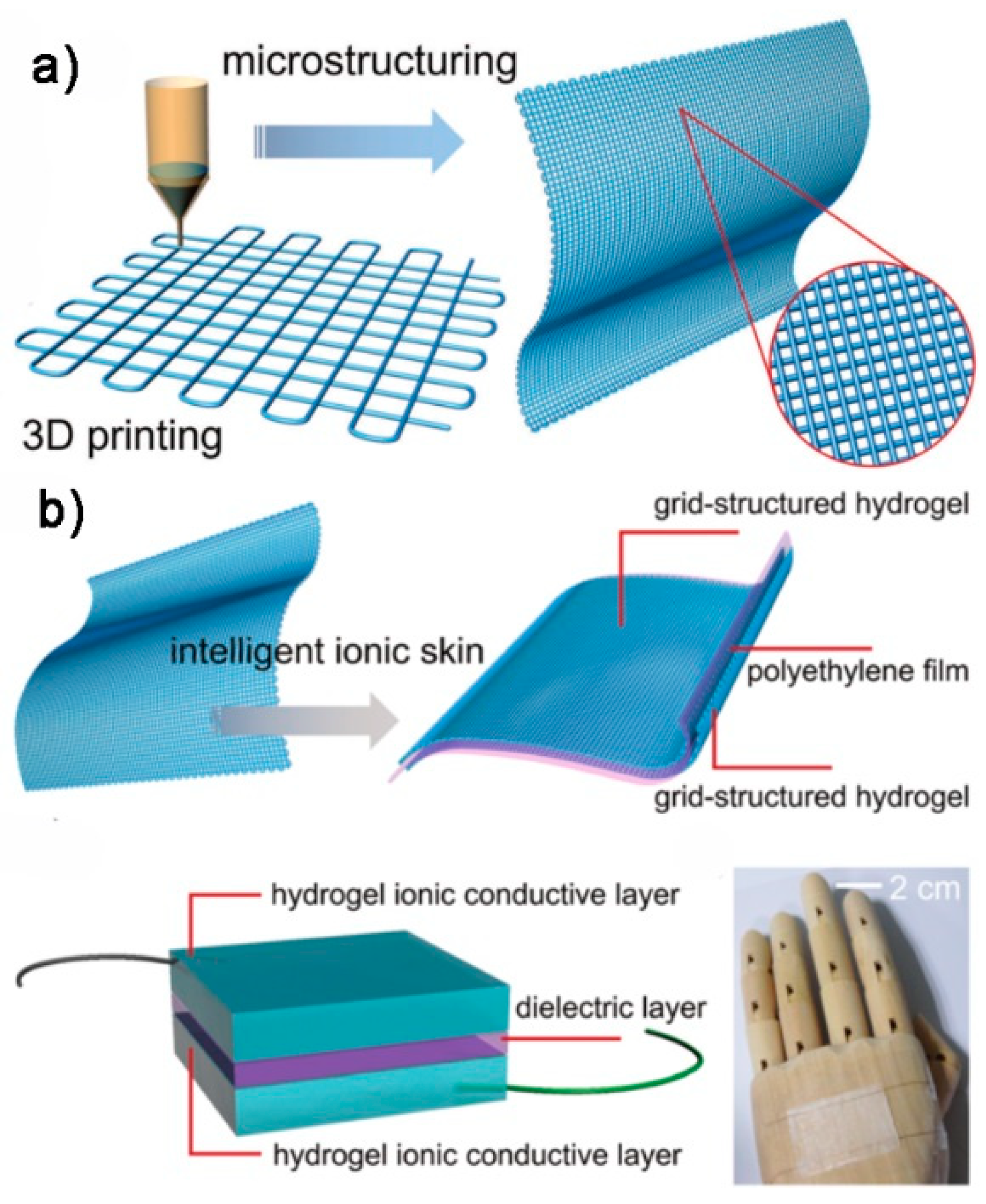

- Lei, Z.Y.; Wang, Q.K.; Wu, P.Y. A multifunctional skin-like sensor based on a 3D printed thermo-responsive hydrogel. Mater. Horiz. 2017, 4, 694–700. [Google Scholar] [CrossRef]

- Liu, S.J.; Li, L. Ultrastretchable and self-healing double-network hydrogel for 3D printing and strain sensor. ACS Appl. Mater. Interfaces 2017, 9, 26429–26437. [Google Scholar] [CrossRef] [PubMed]

- Song, J.H.; Kim, Y.T.; Cho, S.; Song, W.J.; Moon, S.; Park, C.G.; Park, S.; Myoung, J.M.; Jeong, U. Surface-embedded stretchable electrodes by direct printing and their uses to fabricate ultrathin vibration sensors and circuits for 3D structures. Adv. Mater. 2017, 29, 1702625. [Google Scholar] [CrossRef] [PubMed]

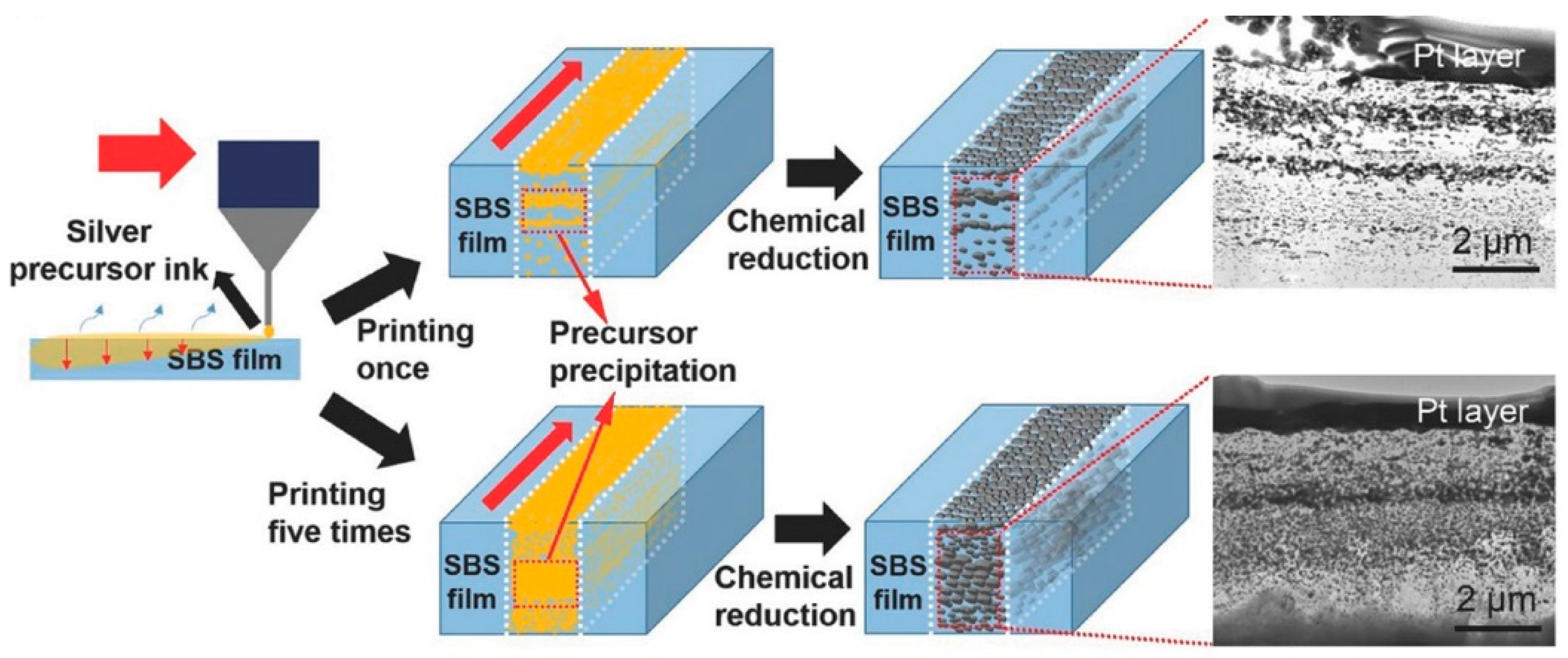

- Zhang, S.M.; Cai, L.; Li, W.; Miao, J.H.; Wang, T.Y.; Yeom, J.; Sepulveda, N.; Wang, C.A. Fully printed silver-nanoparticle-based strain gauges with record high sensitivity. Adv. Electron. Mater. 2017, 3, 1700067. [Google Scholar] [CrossRef]

- Cai, L.; Zhang, S.M.; Zhang, Y.H.; Li, J.Q.; Miao, J.S.; Wang, Q.F.; Yu, Z.B.; Wang, C. Direct printing for additive patterning of silver nanowires for stretchable sensor and display applications. Adv. Mater. Technol. 2018, 3, 1700232. [Google Scholar] [CrossRef]

- Wei, H.; Li, K.; Liu, W.G.; Meng, H.; Zhang, P.X.; Yan, C.Y. 3D printing of free-standing stretchable electrodes with tunable structure and stretchability. Adv. Eng. Mater. 2017, 19, 1700341. [Google Scholar] [CrossRef]

- Muth, J.T.; Vogt, D.M.; Truby, R.L.; Menguc, Y.; Kolesky, D.B.; Wood, R.J.; Lewis, J.A. Embedded 3D printing of strain sensors within highly stretchable elastomers. Adv. Mater. 2014, 26, 6307–6312. [Google Scholar] [CrossRef] [PubMed]

- Frutiger, A.; Muth, J.T.; Vogt, D.M.; Menguc, Y.; Campo, A.; Valentine, A.D.; Walsh, C.J.; Lewis, J.A. Capacitive soft strain sensors via multicore-shell fiber printing. Adv. Mater. 2015, 27, 2440–2446. [Google Scholar] [CrossRef] [PubMed]

- Fuh, Y.K.; Wang, B.S.; Tsai, C.Y. Self-Powered Pressure Sensor with fully encapsulated 3D printed wavy substrate and highly-aligned piezoelectric fibers array. Sci. Rep. 2017, 7, 6759. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Qin, H.T.; Cai, Y.; Dong, J.Y.; Lee, Y.S. Direct printing of capacitive touch sensors on flexible substrates by additive E-Jet printing with silver nanoinks. J. Manuf. Sci. Trans. ASME 2017, 139, 031011. [Google Scholar] [CrossRef]

| 3DP Technology | Sensing Mechanism | Loads | Printable Materials | Materials Shape | Printed Component | Ref. |

|---|---|---|---|---|---|---|

| PolyJet | Piezoresistive | Pressure | Photocurable TangoPlus | Photopolymer, photopolymer composites | Sensor body | [131] |

| Piezoresistive | Pressure | Conductive photocurable TangoPlus/MWCNTs composites | Sensing element | [131] | ||

| Piezoresistive | Pressure | Photocurable VisiJet composites | Sensor body | [132] | ||

| DLP | —— | —— | UV curable EAA/AUD stretchable elastomer | Substrate/Sensor body | [133] | |

| FDM | Piezoresistive | Pressure | Conductive PCL/CB composite | Filament | Sensing element | [134] |

| Piezoelectric | Pressure | Thermoplastic elastomer | Sensor wavy substrate | [153] | ||

| Piezoresistive | Tensile strain | Conductive TPU/MWCNTs nanocomposites | Sensing element | |||

| Capacitive | Pressure | Thermoplastic elastomer | Dielectric layer | [135] | ||

| Piezoresistive | Pressure | Supporting structure: TPUSensing element: TPU/MWCNTs composites | Supporting structure, sensing element | [137] | ||

| Capacitive | Pressure | ABS | Molds for microstructuring sensing element | [138] | ||

| Electric poling-assisted FDM | Piezoelectric | Tensile strain | Piezoelectric PVDF polymer | Filament | Sensing element | [139] |

| Piezoelectric | Pressure | Piezoelectric PVDF polymer | Filament | Sensing element | [140] | |

| Piezoelectric | Pressure | PVDF/BaTiO3 composites | Filament | Sensing element | [140] | |

| Direct ink writing | Piezoresistive | Pressure | Sensing layer: 68 wt % Ag/silicone ink Electrode layer: 75 wt % Ag/silicone ink Substrate layer: silicone elastomer Supporting layer: 40% pluronic ink | Inks | Fully 3D-printed tactile sensor | [141] |

| Piezoresistive | Tensile strain | Composite dough materials: NH2-MWCNTs/GO/SIS composites | Ink | Sensing element | [142] | |

| Piezoresistive | Tensile strain | Gallium-indium alloy | Ink | Sensing element | [143] | |

| Piezoresistive | Pressure, tensile strain | Elastomer, gallium-indium alloy | Ink | Fully 3D-printed tactile sensor | [144] | |

| Capacitive | Pressure, temperature | Thermo-responsive hydrogel | Inks | Ionically conductive layer | [145] | |

| Piezoresistive | Tensile strain | κ-carrageenan/PAAm double-network hydrogel | Inks | Sensing element | [146] | |

| Piezoresistive | Tensile strain | Silver precursor (silver trifluoroacetate) solution in alcohol or acetone | Inks | Stretchable electrodes, sensing element | [147] | |

| —— | Tensile strain | PDMS/MWCNTs composite | Inks | Stretchable electrodes | [150] | |

| Piezoresistive | Tensile strain | Silver nanoparticle-based inks | Inks | Sensing element | [148] | |

| Piezoresistive | Tensile strain, pressure | Silver nanowire-based inks | Inks | Sensing element, stretchable electrodes | [149] | |

| Embedded direct ink writing | Piezoresistive | Tensile strain | Suspensions of CB in silicone oil | Inks | Sensing element | [151] |

| Multicore-shell direct ink writing | Capacitive | Tensile strain | Conductive layer: ionically conductive ink composed of glycerol, NaCL, and PEG Dielectric/encapsulation layer: modified silicone elastomer | Inks | Fully 3D-printed tactile sensor | [152] |

| electrohydrodynamic printing | Piezoelectric | Pressure | Piezoelectric PVDF polymer | Polymer solution | Sensing element | [153] |

| Capacitive | Finger touch | 20 wt %–35 wt % Ag nanoparticles/triethylene glycol composite | Composite solution | Conductive electrode | [154] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Huang, N.; Xu, F.; Tong, J.; Chen, Z.; Gui, X.; Fu, Y.; Lao, C. 3D Printing Technologies for Flexible Tactile Sensors toward Wearable Electronics and Electronic Skin. Polymers 2018, 10, 629. https://doi.org/10.3390/polym10060629

Liu C, Huang N, Xu F, Tong J, Chen Z, Gui X, Fu Y, Lao C. 3D Printing Technologies for Flexible Tactile Sensors toward Wearable Electronics and Electronic Skin. Polymers. 2018; 10(6):629. https://doi.org/10.3390/polym10060629

Chicago/Turabian StyleLiu, Changyong, Ninggui Huang, Feng Xu, Junda Tong, Zhangwei Chen, Xuchun Gui, Yuelong Fu, and Changshi Lao. 2018. "3D Printing Technologies for Flexible Tactile Sensors toward Wearable Electronics and Electronic Skin" Polymers 10, no. 6: 629. https://doi.org/10.3390/polym10060629