Electrospun PVA Polymer Embedded with Ceria Nanoparticles as Silicon Solar Cells Rear Surface Coaters for Efficiency Improvement

Abstract

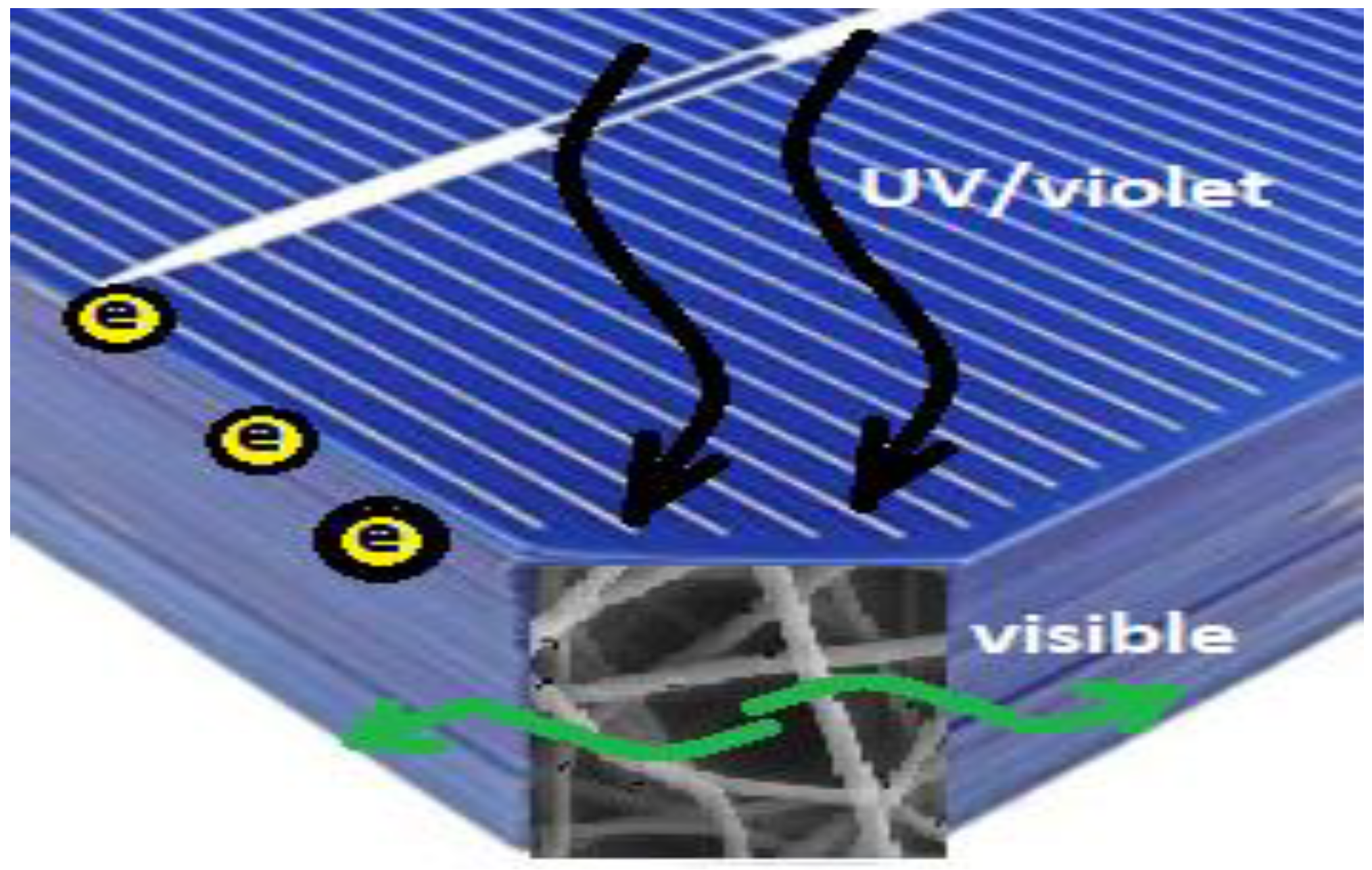

:1. Introduction

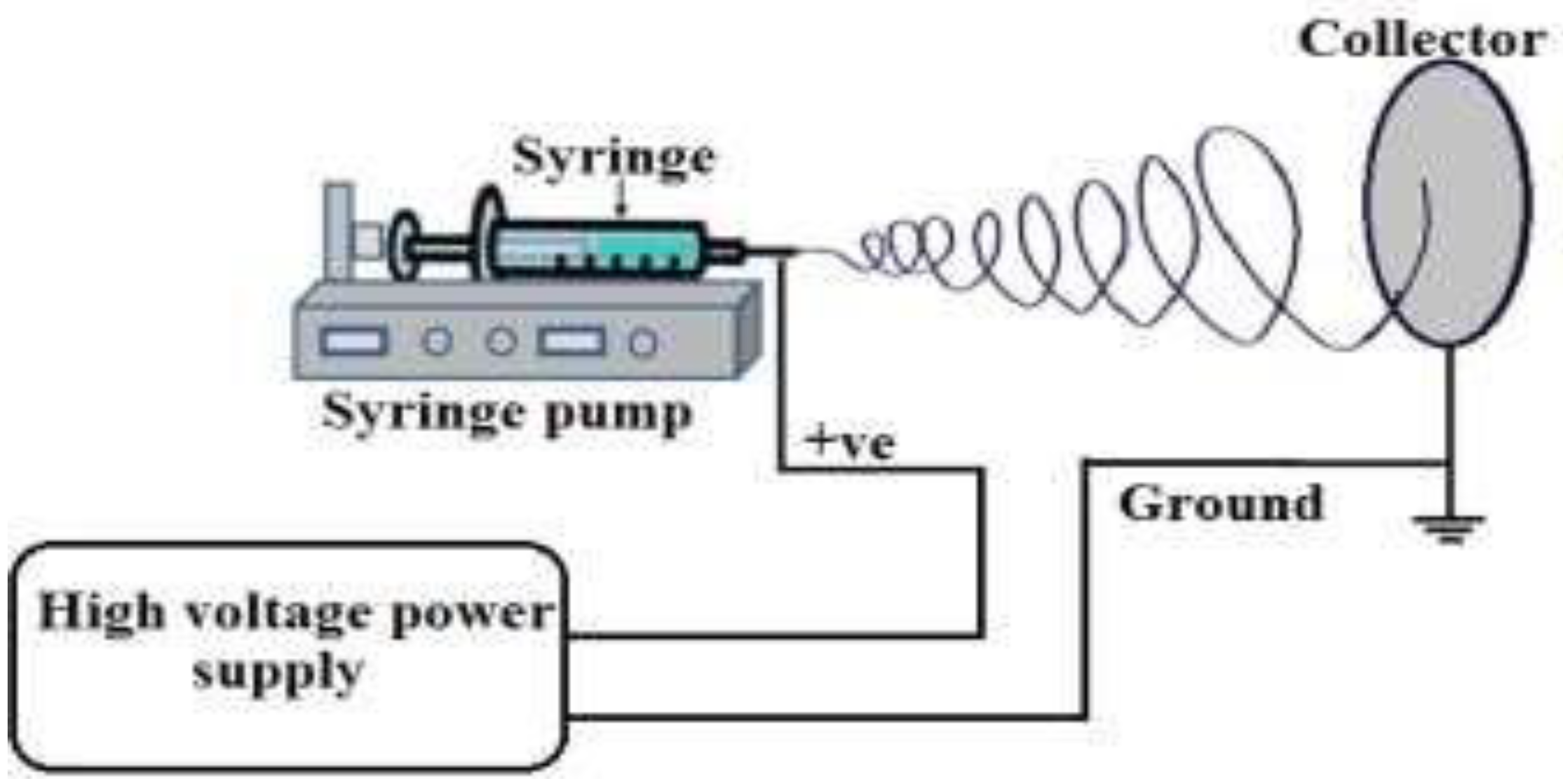

2. Materials and Methods

3. Results& Discussion

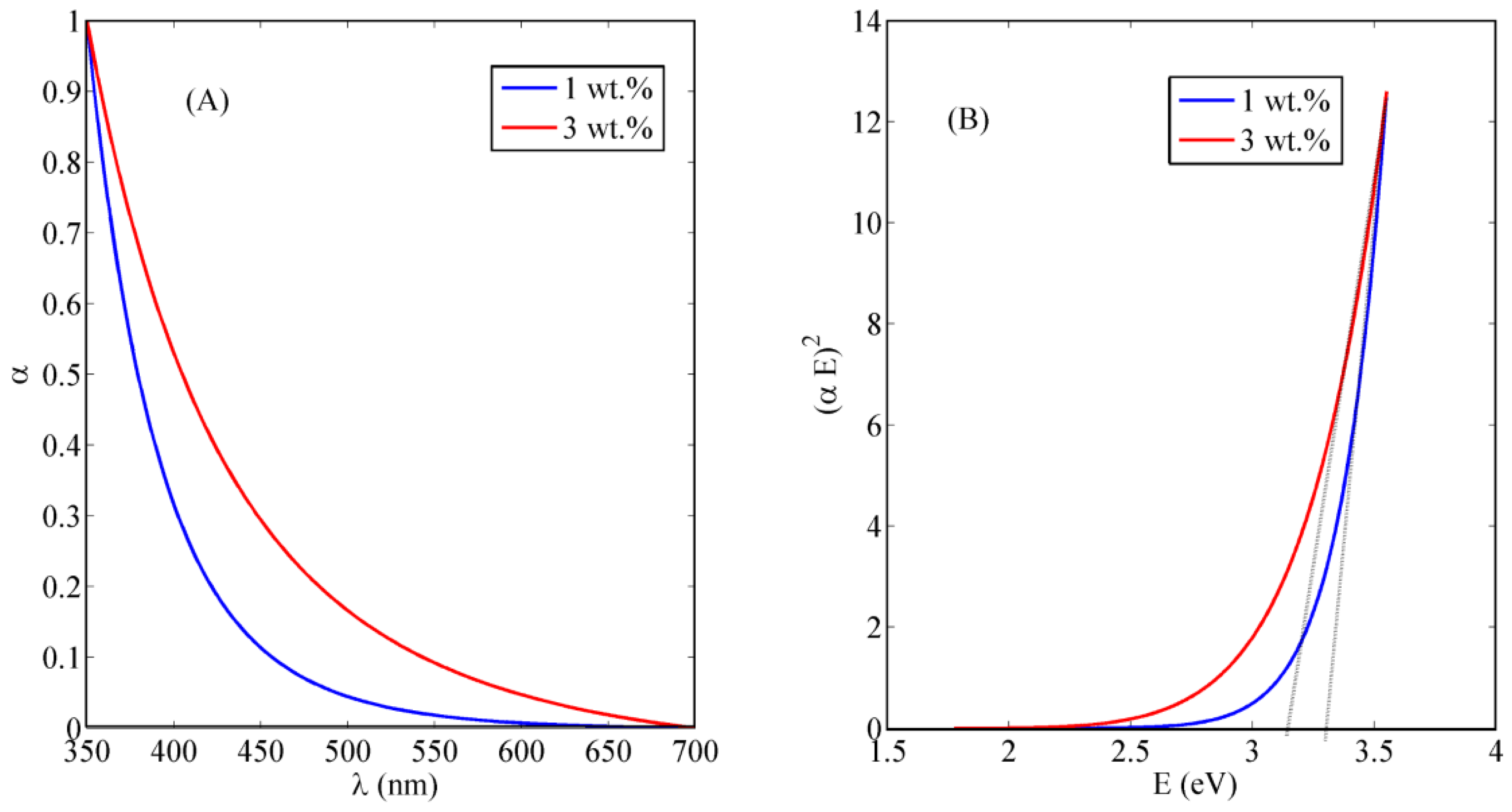

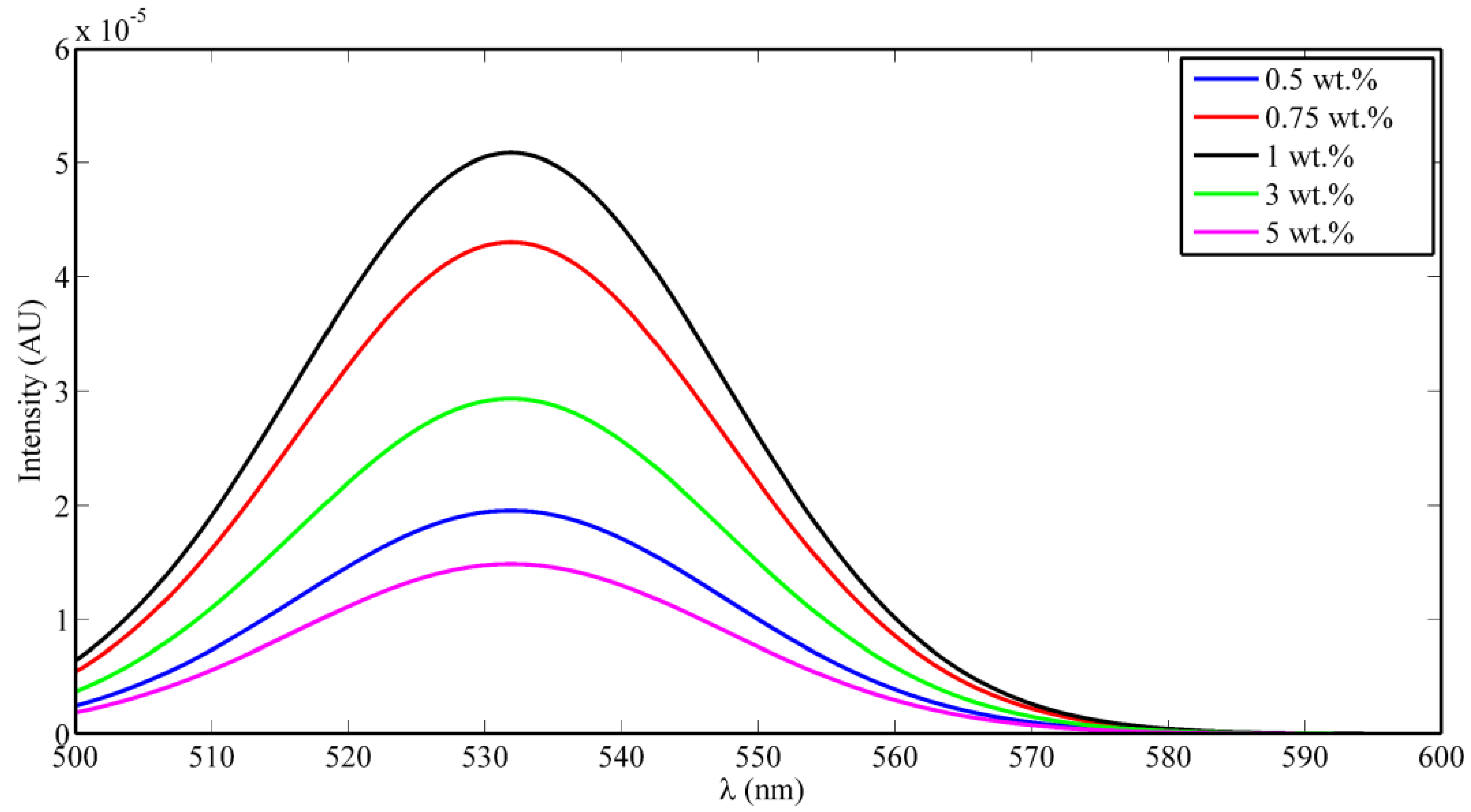

3.1. Optical Characterization of the Electrospun Nanocomposite Nanofibers

3.2. Electrospun the Nanocomposite onto the Rear Side of Silicon Solar Cells

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ivaturi, A.; Macdougall, S.K.; Martín-Rodríguez, R.; Quintanilla, M.; Marques-Hueso, J.; Krämer, K.W.; Richards, B.S. Optimizing infrared to near infraredupconversion quantum yield of β-NaYF4:Er3 in fluoropolymer matrix for photovoltaic devices. J. Appl. Phys. 2013, 114, 013505. [Google Scholar] [CrossRef] [Green Version]

- Rüdiger, M.; Fischer, S.; Frank, J.; Ivaturi, A.; Richards, B.S.; Krämer, K.W.; Goldschmidt, J.C. Bifacial n-type silicon solar cells for upconversion applications. Sol. Energy Mater. Sol. Cells 2014, 128, 57–68. [Google Scholar] [CrossRef]

- Fischer, S.; Favilla, E.; Tonelli, M.; Goldschmidt, J.C. Record efficient upconverter solar cell devices with optimized bifacial silicon solar cells and monocrystalline BaY2F8:30%Er3+ upconverter. Sol. Energy Mater. Sol. Cells 2015, 136, 127–134. [Google Scholar] [CrossRef]

- Trupke, T.; Green, M.A.; Würfel, P. Improving solar cell efficiencies by up-conversion of sub-band-gap light. J. Appl. Phys. 2002, 92, 4117. [Google Scholar] [CrossRef]

- Gibart, P.; Auzel, F.; Guillaume, J.; Zahraman, K. Below Band-Gap IR Response of Substrate-Free GaAs Solar Cells Using Two-Photon Up-Conversion. Jpn. J. Appl. Phys. 1996, 35 Pt 1, 4401–4402. [Google Scholar] [CrossRef]

- Strümpel, C.; Mccann, M.; Beaucarne, G.; Arkhipov, V.; Slaoui, A.; Švrček, V.; Tobias, I. Modifying the solar spectrum to enhance silicon solar cell efficiency—An overview of available materials. Sol. Energy Mater. Sol. Cells 2007, 91, 238–249. [Google Scholar] [CrossRef]

- Dyk, E.V.; Meyer, E. Analysis of the effect of parasitic resistances on the performance of photovoltaic modules. Renew. Energy 2004, 29, 333–344. [Google Scholar]

- Shehata, N.; Clavel, M.; Meehan, K.; Samir, E.; Gaballah, S.; Salah, M. Enhanced erbium-doped ceria nanostructure coating to improve solar cell performance. Materials 2015, 8, 7663–7672. [Google Scholar] [CrossRef] [PubMed]

- Quaranta, M.; Borisov, S.M.; Klimant, I. Indicators for optical oxygen sensors. Bioanal. Rev. 2012, 4, 115–157. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rzigalinski, B.A.; Meehan, K.; Davis, R.M.; Xu, Y.; Miles, W.C.; Cohen, C.A. Radical nanomedicine. Nanomedicine 2006, 1, 399–412. [Google Scholar] [CrossRef] [PubMed]

- Shehata, N.; Azab, M.; Kandas, I.; Meehan, K. Nano-Enriched and Autonomous Sensing Framework for Dissolved Oxygen. Sensors 2015, 15, 20193–20203. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, H.-I.; Chang, H.-Y. Homogeneous precipitation of cerium dioxide nanoparticles in alcohol/water mixed solvents. Coll. Surf. APhysicochem. Eng. Asp. 2004, 242, 61–69. [Google Scholar] [CrossRef]

- Pankove, J.I. Optical Processes in Semiconductors, 1st ed.; Dover Publications Inc.: New York, NY, USA, 1971. [Google Scholar]

- Shehata, N.; Meehan, K.; Hassounah, I.; Hudait, M.; Jain, N.; Clavel, M.; Elhelw, S.; Madi, N. Reduced erbium-doped ceria nanoparticles: One nano-host applicable for simultaneous optical down- and up-conversions. Nanoscale Res. Lett. 2014, 9, 231. [Google Scholar] [CrossRef] [PubMed]

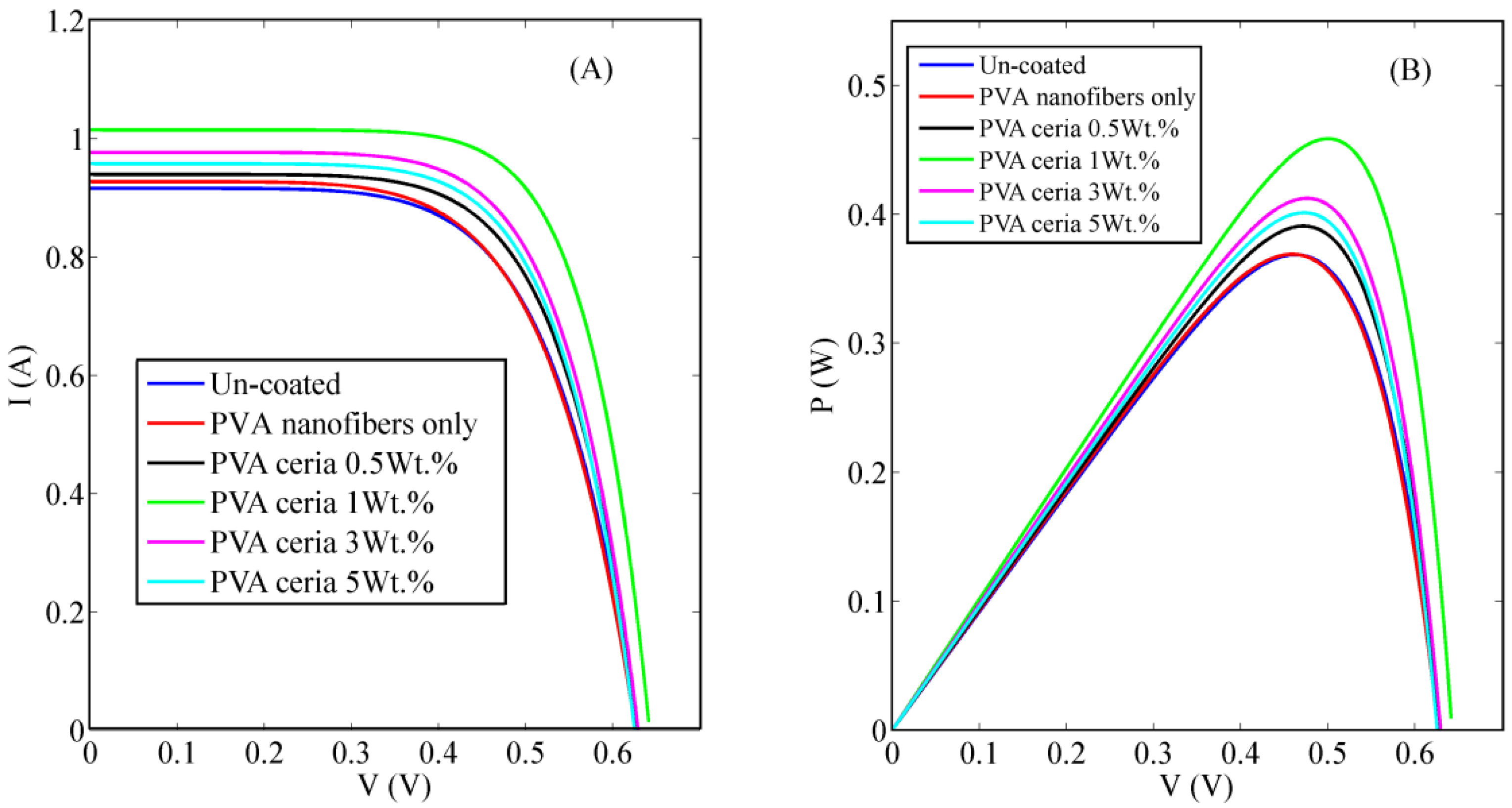

| Condition | Concentration (mg/mL) | VOC(V) | ISC (A) | F.F. | JSC (A/m2) | Efficiency (η%) |

|---|---|---|---|---|---|---|

| Uncoated Solar cell | Uncoated | 0.6320 | 0.9165 | 0.6620 | 366.6 | 14.74 |

| Nanocomposite coated solar cell | PVA only | 0.6282 | 0.9279 | 0.6313 | 371.2 | 14.75 |

| 0.5 wt % | 0.6308 | 0.9400 | 0.6667 | 376.0 | 15.63 | |

| 1 wt % | 0.6414 | 1.0153 | 0.7079 | 406.1 | 18.34 | |

| 3 wt % | 0.6320 | 0.9774 | 0.6760 | 390.9 | 16.49 | |

| 5 wt % | 0.6270 | 0.9581 | 0.6792 | 383.2 | 16.04 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samir, E.; Salah, M.; Hajjiah, A.; Shehata, N.; Fathy, M.; Hamed, A. Electrospun PVA Polymer Embedded with Ceria Nanoparticles as Silicon Solar Cells Rear Surface Coaters for Efficiency Improvement. Polymers 2018, 10, 609. https://doi.org/10.3390/polym10060609

Samir E, Salah M, Hajjiah A, Shehata N, Fathy M, Hamed A. Electrospun PVA Polymer Embedded with Ceria Nanoparticles as Silicon Solar Cells Rear Surface Coaters for Efficiency Improvement. Polymers. 2018; 10(6):609. https://doi.org/10.3390/polym10060609

Chicago/Turabian StyleSamir, Effat, Mohamed Salah, Ali Hajjiah, Nader Shehata, Marwa Fathy, and Aya Hamed. 2018. "Electrospun PVA Polymer Embedded with Ceria Nanoparticles as Silicon Solar Cells Rear Surface Coaters for Efficiency Improvement" Polymers 10, no. 6: 609. https://doi.org/10.3390/polym10060609