The Effects of Hybridization on the Flexural Performances of Carbon/Glass Interlayer and Intralayer Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

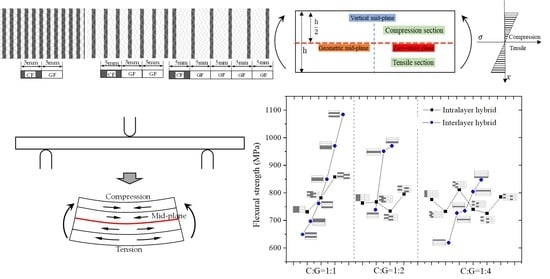

2.2. Layer Structure Schemes of Interlayer and Intralayer Hybrid Structures

2.3. Experiments

2.4. Theoretical Analysis Method

3. Results and Discussions

3.1. Flexural Properties of Interlayer Hybrid Composites

3.2. Flexural Properties of Intralayer Hybrid Composites

3.3. Comparison of Flexural Properties between Interlayer and Intralayer Hybrid Composites

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Markussen, C.M.; Andersen, T.L.; Madsen, B.; Prabhakaran, R.T.D.; Nielsen, M.W.; Lilholt, H. Improved compression strength of carbon/glass/epoxy hybrid composites. In Proceedings of the 19th International Conference on Composite Materials, Montreal, QC, Canada, 28 July–2 August 2013. [Google Scholar]

- Ikbal, H.; Wang, Q.; Azzam, A.; Li, W. GF/CF hybrid laminates made through intra-tow hybridization for automobile applications. Fiber Polym. 2016, 17, 1505–1521. [Google Scholar] [CrossRef]

- Oya, N.; Hamada, H. Effects of Reinforcing Fibre Properties on Various Mechanical Behaviors of Unidirectional Carbon/Epoxy Laminates. Sci. Eng. Compos. Mater. 1996, 5, 105–130. [Google Scholar] [CrossRef]

- Davies, I.J. Flexural Failure of Unidirectional Hybrid Fibre-Reinforced Polymer (Frp) Composites Containing Different Grades of Glass Fibre. Adv. Mater. Res. 2008, 41, 357–362. [Google Scholar]

- Ikbal, M.H.; Li, W. Effect of proportion of carbon fiber content and the dispersion of two fiber types on tensile and compressive properties of intra-layer hybrid composites. Text. Res. J. 2017, 87, 305–328. [Google Scholar] [CrossRef]

- Ikbal, M.H.; Ahmed, A.; Wang, Q.; Zeng, S.; Li, W. Hybrid composites made of unidirectional T600S carbon and E-glass fabrics under quasi-static loading. J. Ind. Text. 2017, 46, 1511–1535. [Google Scholar] [CrossRef]

- Manders, P.W.; Bader, M.G. The Strength of Hybrid Glass/Carbon Fibre Composites. J. Mater. Sci. 1981, 16, 2233–2245. [Google Scholar] [CrossRef]

- Zweben, C. Tensile Strength of Hybrid Composites. J. Mater. Sci. 1977, 12, 1325–1337. [Google Scholar] [CrossRef]

- Kretsis, G. A Review of the Tensile, Compressive, Flexural and Shear Properties of Hybrid Fibre-Reinforced Plastics. Composites 1987, 18, 13–23. [Google Scholar] [CrossRef]

- Reis, P.N.B.; Ferreira, J.A.M.; Antunes, F.V.; Costa, J.D.M. Flexural behaviour of hybrid laminated composites. Compos. Part A 2007, 38, 1612–1620. [Google Scholar] [CrossRef]

- Subagia, I.A.; Kim, Y.; Tijing, L.D.; Kim, C.S.; Shon, H.K. Effect of stacking sequence on the flexural properties of hybrid composites reinforced with carbon and basalt fibers. Compos. Part B 2014, 58, 251–258. [Google Scholar] [CrossRef]

- Jesthi, D.K.; Mandal, P.; Rout, A.K.; Nayak, R.K. Effect of carbon/glass fiber symmetric inter-ply sequence on mechanical properties of polymer matrix composites. Procedia Manuf. 2018, 20, 530–535. [Google Scholar] [CrossRef]

- Prusty, R.K.; Rathore, D.K.; Singh, B.P.; Mohanty, S.C.; Mahato, K.K.; Ray, B.C. Experimental optimization of flexural behaviour through inter-ply fibre hybridization in FRP composite. Constr. Build. Mater. 2016, 118, 327–336. [Google Scholar] [CrossRef]

- Dong, C.; Davies, I.J. Optimal design for the flexural behaviour of glass and carbon fibre reinforced polymer hybrid composites. Mater. Des. 2012, 37, 450–457. [Google Scholar] [CrossRef]

- Dong, C.; Ranaweera-Jayawardena, H.A.; Davies, I.J. Flexural properties of hybrid composites reinforced by S-2 glass and T700S carbon fibres. Compos. Part B 2012, 43, 573–581. [Google Scholar] [CrossRef]

- Dong, C.; Davies, I.J. Flexural and tensile strengths of unidirectional hybrid epoxy composites reinforced by S-2 glass and T700S carbon fibres. Mater. Des. 2014, 54, 955–966. [Google Scholar] [CrossRef]

- Dong, C.; Davies, I.J. Flexural and tensile moduli of unidirectional hybrid epoxy composites reinforced by S-2 glass and T700S carbon fibres. Mater. Des. 2014, 54, 893–899. [Google Scholar] [CrossRef]

- Sudarisman, D.S.M.B.; Davies, I. The effect of partial substitution of E-glass fibre for carbon fibre on the mechanical properties of CFRP composites. In Proceedings of the International Conference on Materials and Metallurgical Technology, Surabaya, Indonesia, 24–25 June 2009. [Google Scholar]

- Zhang, J.; Chaisombat, K.; He, S.; Wang, C.H. Hybrid composite laminates reinforced with glass/carbon woven fabrics for lightweight load bearing structures. Mater. Des. 2012, 36, 75–80. [Google Scholar] [CrossRef]

- Ikbal, M.H.; Wang, Q.; Li, W. Effect of Glass/Carbon Ratios and Laminate Geometry on Flexural Properties of Glass/Carbon Fiber Hybrid Composites. In Proceedings of the International Conference on Materials Chemistry and Environmental Protection, Sanya, China, 19–25 December 2015. [Google Scholar]

- Kalnin, I. Evaluation of unidirectional glass-graphite fiber/epoxy resin composites. Compos. Mater. Test. Des. 1972. [Google Scholar] [CrossRef]

- Kalantari, M.; Dong, C.; Davies, I.J. Numerical investigation of the hybridisation mechanism in fibre reinforced hybrid composites subjected to flexural load. Compos. Part B 2016, 102, 100–111. [Google Scholar] [CrossRef]

- Jones, R.M. Apparent Flexural Modulus and Strength of Multimodulus Materials. J. Compos. Mater. 1976, 10, 342–354. [Google Scholar] [CrossRef]

| Fabric type | Areal density (g/m2) | Ratio of C/G | |

|---|---|---|---|

| Carbon fiber | Glass fiber | ||

| Carbon | 728.3 | 0 | 1:0 |

| Glass | 0 | 944.9 | 0:1 |

| C-G | 364.2 | 472.4 | 1:1 |

| C-G-G | 242.8 | 629.9 | 1:2 |

| C-G-G-G-G | 145.7 | 755.9 | 1:4 |

| Material | Tensile strength (MPa) | Tensile modulus (GPa) |

|---|---|---|

| CPIC ECT469L-2400 Glass Fiber | 2366 | 78.7 |

| TORAY T620SC-24K-50C Carbon Fiber | 4175 | 234 |

| SWANCOR 2511-1A/BS Epoxy Resin | 73.5 | 3.1 |

| C/G Hybrid ratios | Stacking sequences | |||||

|---|---|---|---|---|---|---|

| C:G=1:1 |  |  |  |  |  |  |

| [G/G/C/C] | [C/C/G/G] | [G/C/C/G] | [C/G/G/C] | [C/G/C/G] | [G/C/G/C] | |

| C:G=1:2 |  |  |  | |||

| [G/G/C] | [C/G/G] | [G/C/G] | ||||

| C:G=1:3 |  |  |  |  | ||

| [G/G/G/C] | [G/G/C/G] | [G/C/G/G] | [C/G/G/G] | |||

| C:G=1:4 |  |  |  |  |  | |

| [G/G/G/G/C] | [G/G/G/C/G] | [G/G/C/G/G] | [G/C/G/G/G] | [C/G/G/G/G] | ||

| C/G Hybrid ratios | Ply sequences | |||||

|---|---|---|---|---|---|---|

| C-G C:G=1:1 |  |  |  | |||

| [C-G]-0 | [C-G]-1 | [C-G]-0.5 | ||||

| C-G-G C:G=1:2 |  |  |  |  | ||

| [C-G-G]-0 | [C-G-G]-1 | [C-G-G]-0.5 | [C-G-G]-1.5 | |||

| C-G-G-G-G C:G=1:4 |  |  |  | |||

| [C-G-G-G-G]-0 | [C-G-G-G-G]-1 | [C-G-G-G-G]-2 | ||||

|  |  | ||||

| [C-G-G-G-G]-0.5 | [C-G-G-G-G]-1.5 | [C-G-G-G-G]-2.5 | ||||

| Laminate structures | C/G Hybrid ratios | Layers | Laminate thickness/mm | Width/mm | Span/mm |

|---|---|---|---|---|---|

| Pure carbon fabric | 1:0 | 4 | 3.2 | 13 | 64 |

| Pure glass fabric | 0:1 | 4 | 3.2 | 13 | 64 |

| Interlayer laminate | 1:1 | 4 | 3.2 | 13 | 64 |

| 1:2 | 3 | 2.4 | 13 | 48 | |

| 1:3 | 4 | 3.2 | 13 | 64 | |

| 1:4 | 5 | 4 | 13 | 80 | |

| Intralayer laminate | 1:1 | 4 | 3.2 | 20 | 64 |

| 1:2 | 4 | 3.2 | 15 | 64 | |

| 1:4 | 4 | 3.2 | 25 | 64 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, W.; Wang, Q.; Ichenihi, A.; Shen, Y.; Li, W. The Effects of Hybridization on the Flexural Performances of Carbon/Glass Interlayer and Intralayer Composites. Polymers 2018, 10, 549. https://doi.org/10.3390/polym10050549

Wu W, Wang Q, Ichenihi A, Shen Y, Li W. The Effects of Hybridization on the Flexural Performances of Carbon/Glass Interlayer and Intralayer Composites. Polymers. 2018; 10(5):549. https://doi.org/10.3390/polym10050549

Chicago/Turabian StyleWu, Weili, Qingtao Wang, Amos Ichenihi, Yongmao Shen, and Wei Li. 2018. "The Effects of Hybridization on the Flexural Performances of Carbon/Glass Interlayer and Intralayer Composites" Polymers 10, no. 5: 549. https://doi.org/10.3390/polym10050549