Properties and Fabrication of PA66/Surface-Modified Multi-Walled Nanotubes Composite Fibers by Ball Milling and Melt-Spinning

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of MWNTs-SDBS

2.3. Fabrication of Composite Powders

2.4. Melt-Spinning of Composite Fibers

2.5. Characterization

3. Results and Discussion

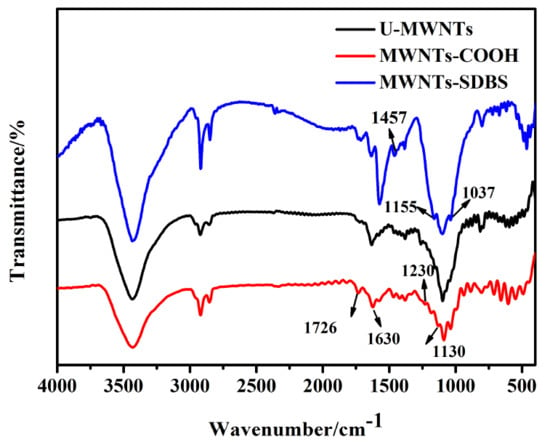

Morphology and Structural of MWNTs

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bellenger, V.; Tcharkhtchi, A.; Castaing, P. Thermal and mechanical fatigue of a PA66/glass fibers composite material. Int. J. Fatigue 2006, 28, 1348–1352. [Google Scholar] [CrossRef]

- Jin, J.; Zhang, L.; Chen, W.; Li, C.Z. Synthesis of glass fiber-multiwall carbon nanotube hybrid structures for high-performance conductive. Polym. Compos. 2013, 34, 1313–1320. [Google Scholar] [CrossRef]

- Chang, Q.X.; Zhao, H.J.; He, R.Q. The addition of clay on the mechanical properties of surface-treated CF-filled PA66 composites. Surf. Interface Anal. 2017, 49, 837–842. [Google Scholar] [CrossRef]

- Xu, X.M.; Li, B.J.; Lu, H.M.; Zhang, Z.J.; Wang, H.G. The interface structure of nano-SiO2/PA66 composite and its influence on material’s mechanical and thermal properties. Appl. Surf. Sci. 2007, 254, 1456–1462. [Google Scholar] [CrossRef]

- Sandler, J.K.W.; Pegel, S.; Cadek, M.; Gojny, F.; van Es, M.; Lohmar, J.; Blau, W.J.; Schulte, K.; Windle, A.H.; Shaffer, M.S.P. A comparative study of melt spun polyamide-12 fibers reinforced with carbon nanotubes and nanofiber. Polymer 2004, 45, 2001–2015. [Google Scholar] [CrossRef]

- Mai, F.; Pan, D.; Gao, X. Extrusion-induced mechanical reinforcement in melt-spun fibers of polyamide 66/multiwalled carbon nanotube composites. Polym. Int. 2011, 60, 1646–1654. [Google Scholar] [CrossRef]

- Meng, Q.J.; Wang, Z.M.; Zhang, X.X.; Wang, X.C.; Bai, S.H. Fabrication and properties of polyamide-6, 6-functionalized carboxylic multi-walled carbon nanotube composite fibers. High Perform. Polym. 2010, 22, 848–862. [Google Scholar] [CrossRef]

- Zhang, X.X.; Meng, Q.J.; Wang, X.C.; Bai, S.H. Poly(adipic acid-hexamethylene diamine)-functionalized multi-walled carbon nanotube nanocomposites. J. Mater. Sci. 2011, 46, 923–930. [Google Scholar] [CrossRef]

- Shojaei, A.; Nourbakhsh, P.; Faghihi, M. An investigation on the structural characteristics and reinforcement of melt processed polyamide 66/multiwalled carbon nanotube composites. Polym. Adv. Technol. 2014, 25, 406–417. [Google Scholar] [CrossRef]

- Tran, T.Q.; Fan, Z.; Mikhalchan, A.; Liu, P.; Duong, H.M. Post-treatments for multifunctional property enhancement of carbon nanotube fibers from the floating catalyst method. ACS Appl. Mater. Interfaces 2016, 8, 7948–7956. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.K.; Le, T.H.; Kim, S.; Park, G.S.; Yang, K.S.; Yoon, H.S. Single-walled carbon nanotube-in-binary-polymer nanofiber structures and their use as carbon precursors for electrochemical applications. J. Phys. Chem. C 2018, 122, 4189–4198. [Google Scholar] [CrossRef]

- Chen, T.; Wang, Y.Z.; Liu, H.H.; Zhang, X.X. Melt-spinning of carboxylated MWNTs reinforced polyamide 6 fibers with solid mixing nanocomposites. Polym. Compos. 2017. [Google Scholar] [CrossRef]

- Kim, J.W.; Oh, J.W.; Lee, K.Y.; Jung, I.; Park, M. Dispersion of graphene-based nanocarbon fillers in polyamide 66 by dry processing and its effect on mechanical properties. Comp. B Eng. 2017, 114, 445–456. [Google Scholar] [CrossRef]

- Yu, M.F.; Lourie, O.; Dyer, M.J.; Maloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Fu, Y.Q.; Liao, K.; Li, F.; Cheng, H.M. Fatigue failure mechanisms of single-walled carbon nanotube ropes embedded in epoxy. Appl. Phys. Lett. 2004, 84, 2811–2813. [Google Scholar] [CrossRef]

- Wang, Z.M.; Bai, S.H.; Zhang, X.X.; Wang, X.C. Preparation and characterization of carboxylic multi-walled carbon nanotubes/ PA66 composite by solution mixing process. Acta Mater. Compos. Sin. 2010, 27, 12–17. [Google Scholar]

- Mai, F.; Pan, D.D.; Gao, X.; Yao, M.J.; Deng, H.; Wang, K.; Chen, F.; Fu, Q. Extension-induced mechanical reinforcement in melt-spun fibers of polyamide 66/multiwalled carbon nanotube composites. Polym. Int. 2011, 60, 1646–1654. [Google Scholar] [CrossRef]

- Wang, Z.M.; Zhang, X.X.; Wang, X.C.; Bai, S.H.; Qiao, Z.J. Preparation and properties of melt-blended carboxyl multi-walled carbon nanotubes/ PA66 composite fibers. Acta Mater. Compos. Sin. 2011, 28, 16–21. [Google Scholar]

- Mahmood, N.; Islam, M.; Hameed, A.; Saeed, S.; Khan, A.N. Polyamide-6-based composites reinforced with pristine or functionalized multi-walled carbon nanotubes produced using melt extrusion technique. J. Compos. Mater. 2014, 48, 1197–1207. [Google Scholar] [CrossRef]

- Deng, Z.; Yu, H.J.; Wang, L.; Zhai, X.T. A novel ferrocene-containing polymer based dispersant for noncovalent dispersion of multi-walled carbon nanotubes in chloroform. J. Organomet. Chem. 2015, 791, 274–278. [Google Scholar] [CrossRef]

- Loyta, M.; Hernandez, Y.; King, P.J.; Smith, R.J.; Nicolosi, V.; Karlsson, L.S.; Blighe, F.M.; De, S.; Wang, Z.M.; McGovern, I.T.; et al. Liquid phase production of graphene by exfoliation of graphite in surfactant/water solutions. J. Am. Chem. Soc. 2009, 131, 3611–3620. [Google Scholar] [CrossRef] [PubMed]

- Choi, E.Y.; Roh, S.C.; Kim, C.K. Noncovalent functionalization of multi-walled carbon nanotubes with pyrene-linked nylon 66 for high performance nylon 66/multi-walled carbon nanotube composites. Carbon 2014, 72, 160–168. [Google Scholar] [CrossRef]

- Meng, H.; Sui, G.X.; Fang, P.F.; Yang, R. Effects of acid- and diamine-modified MWNTs on the mechanical properties and crystallization behavior of polyamide 6. Polymer 2008, 49, 610–620. [Google Scholar] [CrossRef]

- Shao, W.G.; Wang, Q.; Wang, F.; Chen, Y.H. The cutting of multi-walled carbon nanotubes and their strong interfacial interaction with polyamide 6 in the solid state. Carbon 2006, 44, 2708–2714. [Google Scholar] [CrossRef]

- Soares, O.S.G.P.; Rocha, R.P.; Goncalves, A.G.; Figueiredo, J.L.; Orfao, J.J.M.; Pereira, M.F.R. Highly active N-doped carbon nanotubes prepared by an easy ball milling method for advanced oxidation processes. Appl. Catal. B-Environ. 2016, 192, 296–303. [Google Scholar] [CrossRef]

| Sample | Tm/°C | ΔHm/J/g | Tc/°C | Xc/% |

|---|---|---|---|---|

| PA66 | 260.3 | 81.93 | 231.8 | 41.8 |

| PA66/U-MWNTs | 261.0 | 90.48 | 236.8 | 46.2 |

| PA66/MWNTs-SDBS | 260.8 | 93.49 | 236.7 | 47.7 |

| PA66/MWNTs-COOH | 262.0 | 88.76 | 236.6 | 45.3 |

| Sample | Ti/°C | △T/°C* | T10%/°C | Tmax/°C |

|---|---|---|---|---|

| PA66 | 408.9 | 0 | 403.3 | 440.9 |

| PA66/MWNTs | 414.4 | 5.5 | 408.1 | 443.1 |

| PA66/MWNTs-SDBS | 416.3 | 7.4 | 409.9 | 445.4 |

| PA66/MWNTs-COOH | 414.5 | 5.6 | 406.8 | 446.2 |

| Sample | MWNTs loading (%) | Young’s modulus/GPa (Increase ratio) | Tensile strength/MPa (Increase ratio) | Strain/% |

|---|---|---|---|---|

| PA66 | 0 | 0.23 | 73.60 | 33 |

| PA66/MWNTs-SDBS | 0.05 | 0.30(26%) | 82.40(11%) | 27 |

| 0.08 | 0.37(40%) | 90.00(18%) | 24 | |

| 0.1 | 0.33(32%) | 100.70(27%) | 30 | |

| 0.3 | 0.30(26%) | 86.70(15%) | 28 | |

| PA66/MWNTs-COOH | 0.05 | 0.37(39%) | 81.10(9%) | 22 |

| 0.08 | 0.38(40%) | 93.40(21%) | 25 | |

| 0.1 | 0.41(45%) | 96.20(24%) | 23 | |

| 0.3 | 0.47(52%) | 93.30(21%) | 20 | |

| PA66/U-MWNTs | 0.05 | 0.13(−68%) | 62.80(−17%) | 47 |

| 0.08 | 0.20(−13%) | 84.20(13%) | 42 | |

| 0.1 | 0.36(38%) | 94.10(22%) | 26 | |

| 0.3 | 0.27(15%) | 63.90(−15%) | 24 | |

| Ref 7(PA66/MWNT-COOH) | 0.5 | (65%) | (48%) | |

| Ref 16(PA66/MWNT-COOH) | 1 | (33%) | (49%) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, T.; Liu, H.; Wang, X.; Zhang, H.; Zhang, X. Properties and Fabrication of PA66/Surface-Modified Multi-Walled Nanotubes Composite Fibers by Ball Milling and Melt-Spinning. Polymers 2018, 10, 547. https://doi.org/10.3390/polym10050547

Chen T, Liu H, Wang X, Zhang H, Zhang X. Properties and Fabrication of PA66/Surface-Modified Multi-Walled Nanotubes Composite Fibers by Ball Milling and Melt-Spinning. Polymers. 2018; 10(5):547. https://doi.org/10.3390/polym10050547

Chicago/Turabian StyleChen, Tian, Haihui Liu, Xuechen Wang, Hua Zhang, and Xingxiang Zhang. 2018. "Properties and Fabrication of PA66/Surface-Modified Multi-Walled Nanotubes Composite Fibers by Ball Milling and Melt-Spinning" Polymers 10, no. 5: 547. https://doi.org/10.3390/polym10050547