Heteroepitaxy, an Amazing Contribution of Crystal Growth to the World of Optics and Electronics

Abstract

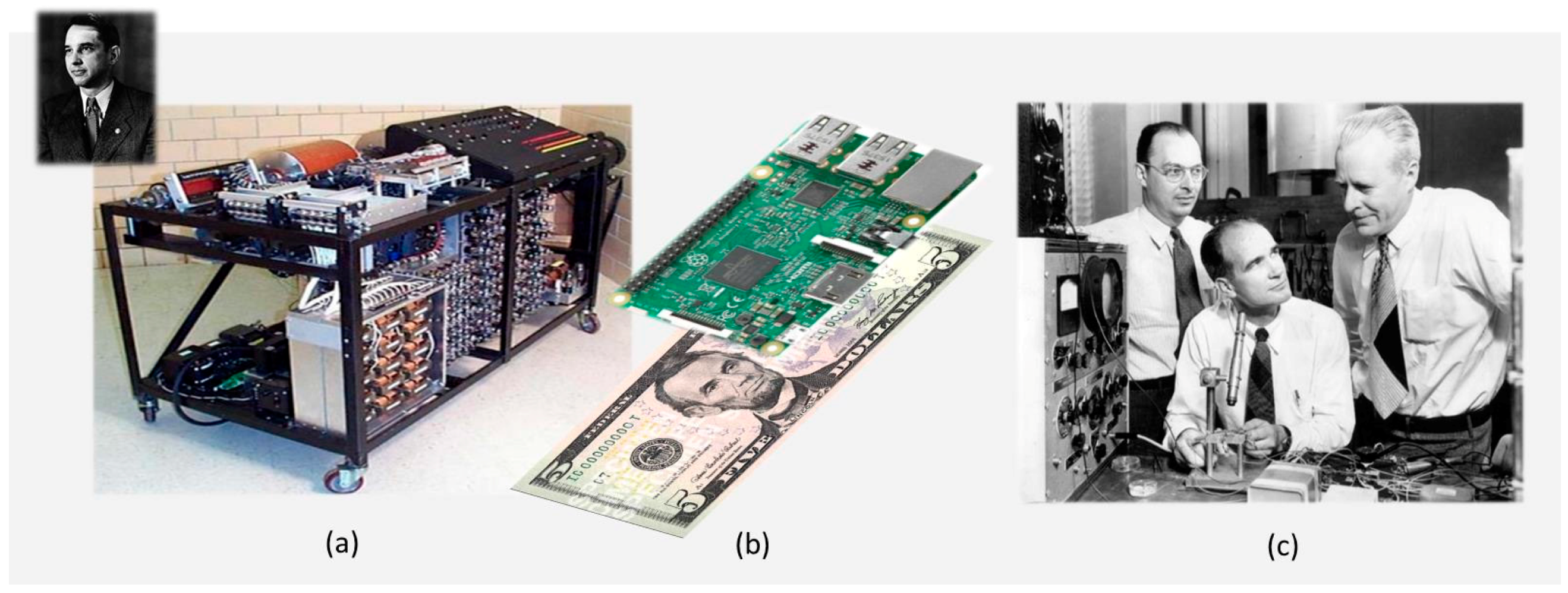

:1. Introduction

“... One cold winter night, frustrated after so many discouraging events, John got into his car and started driving without any destination. 200 miles later, he pulled onto a roadside somewhere in the state of Illinois. Here, he continued thinking about the creation of the machine and, as the rumor says, he had a drink of bourbon. No longer nervous and tense, he realized that his thoughts were coming together clearly”.[1]

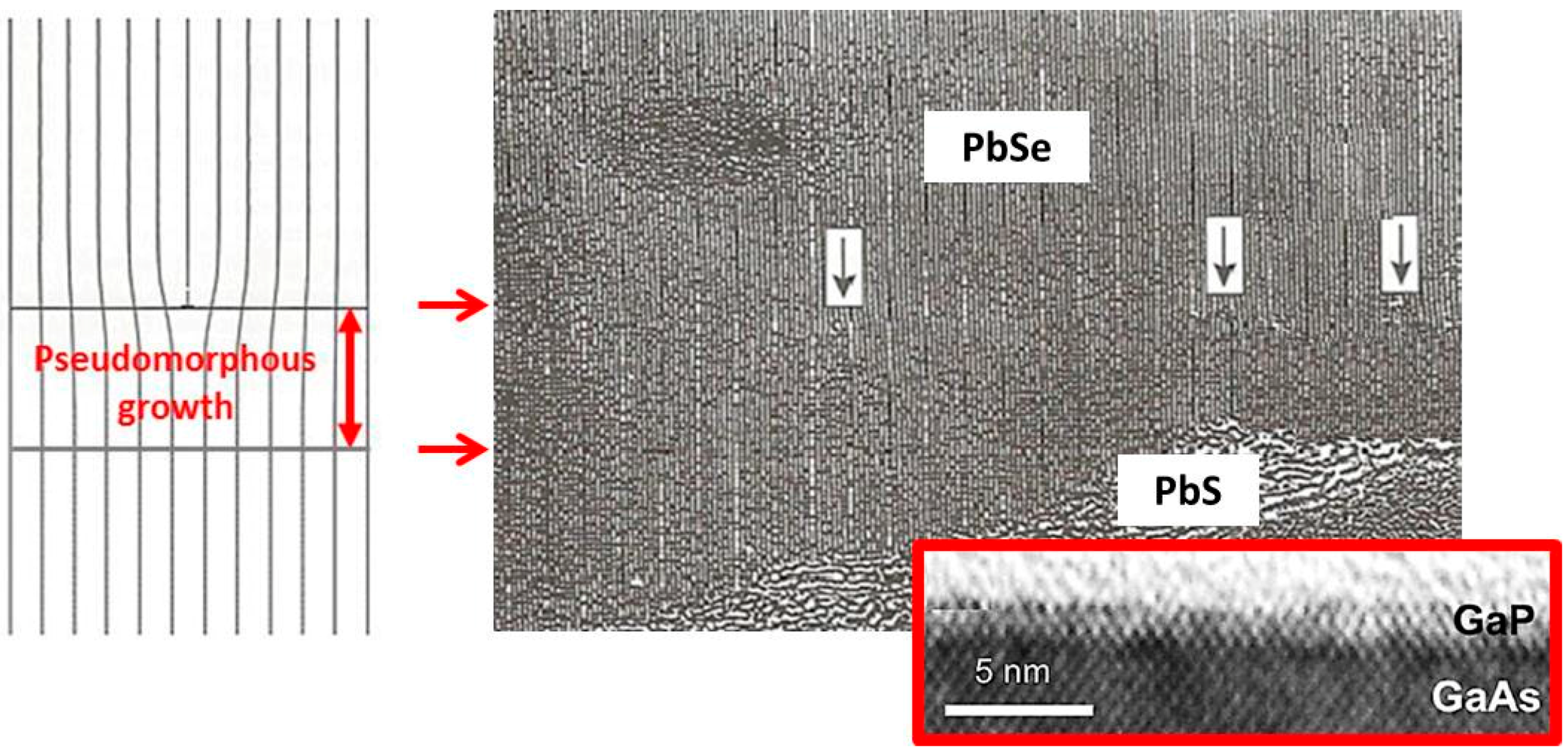

2. The Growth Modes of Heteroepitaxy

3. III-Nitrides

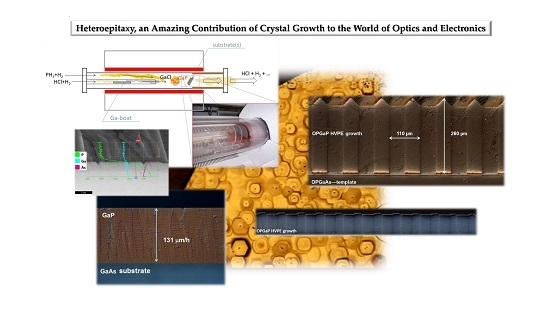

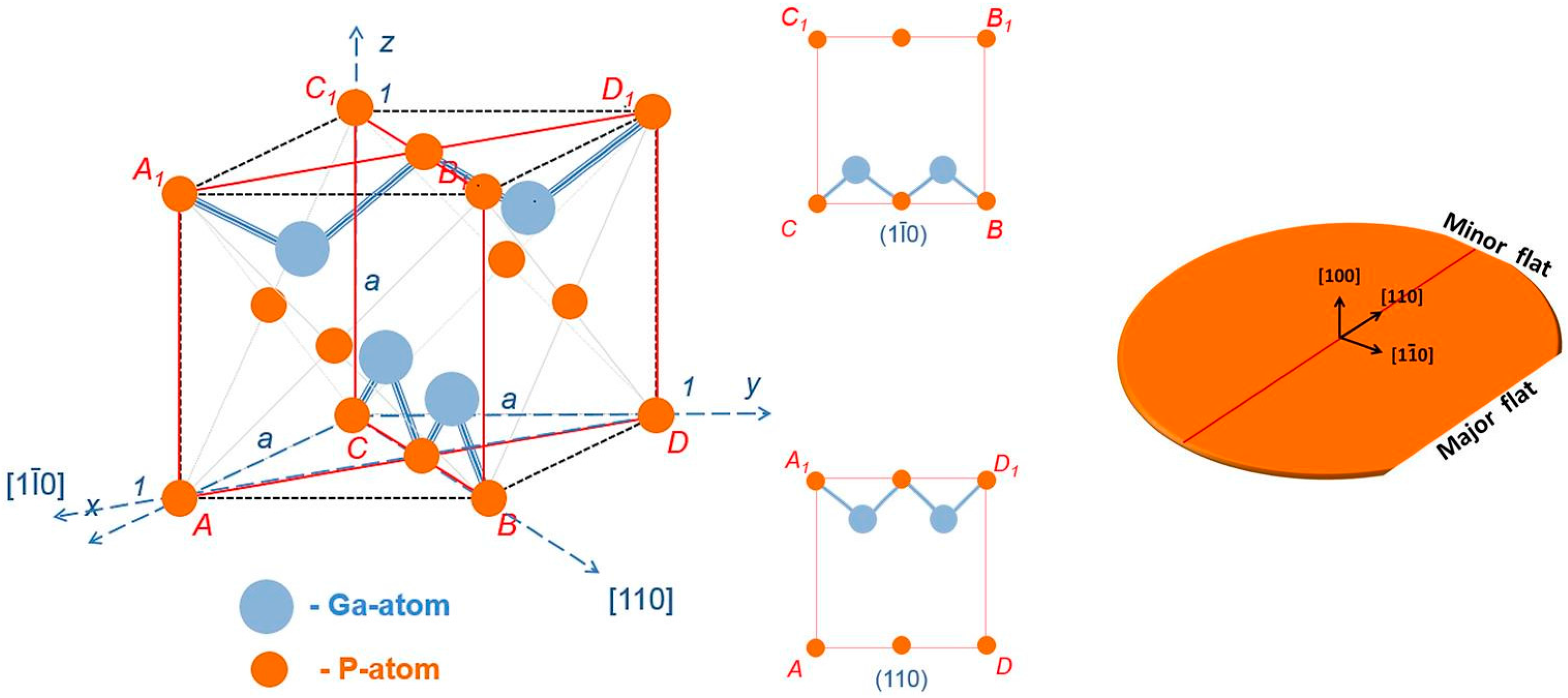

3.1. Heteroepitaxy of III-Nitrides

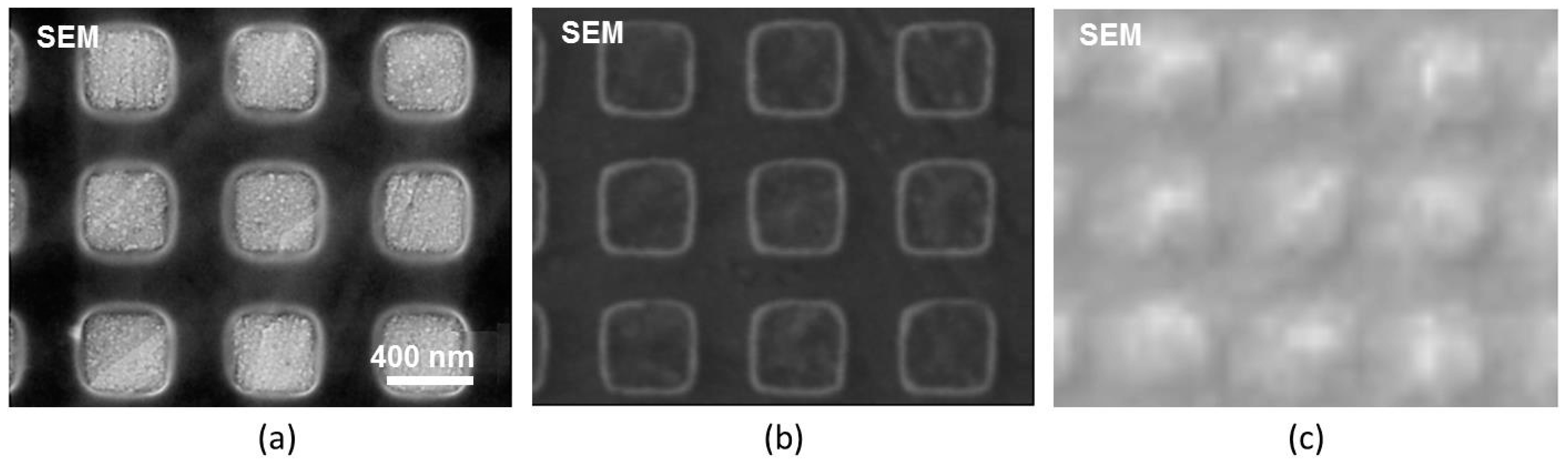

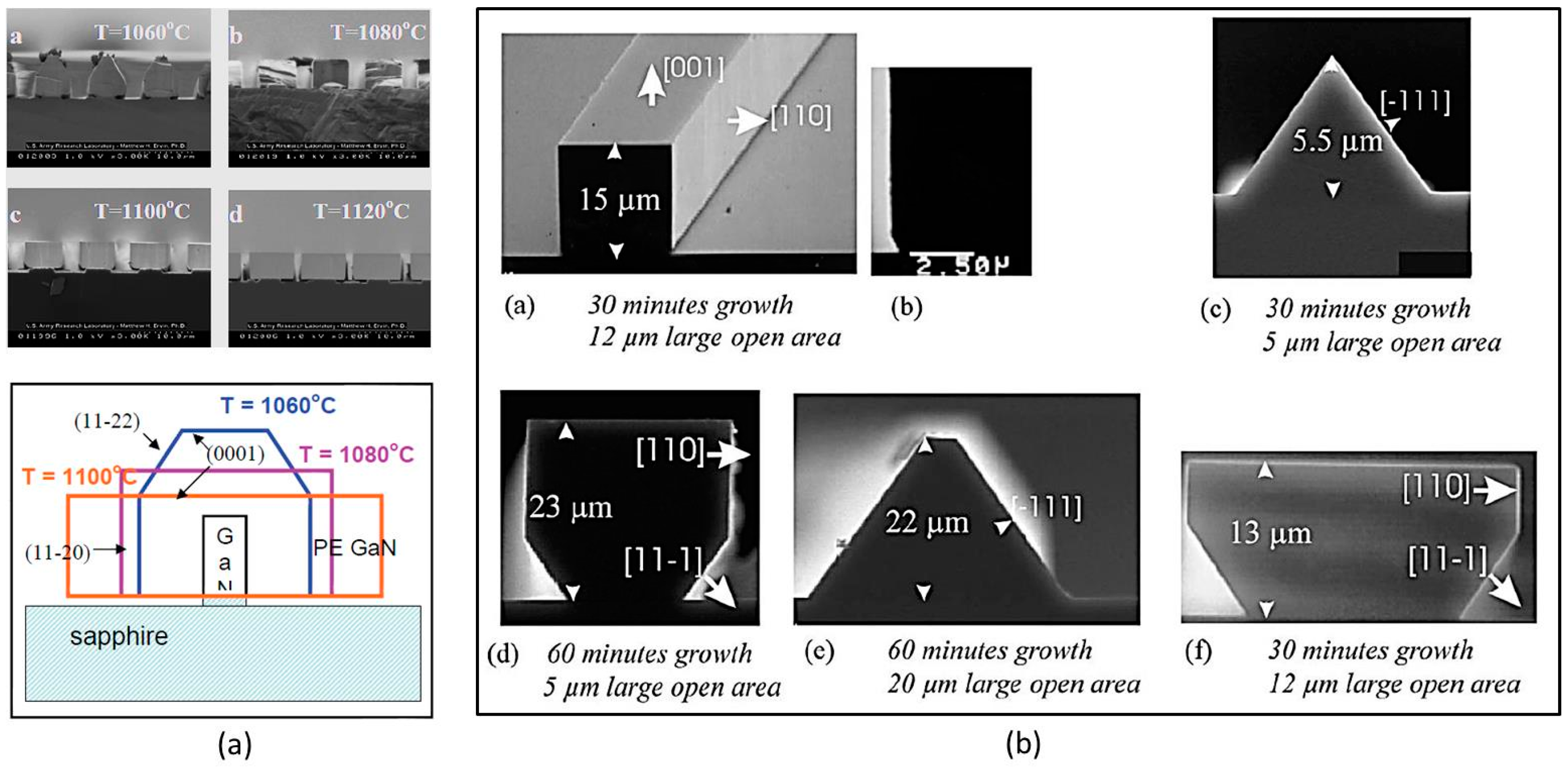

3.2. Nano- and Micro-Heteroepitaxy

3.3. Combinations of Different Growth Techniques

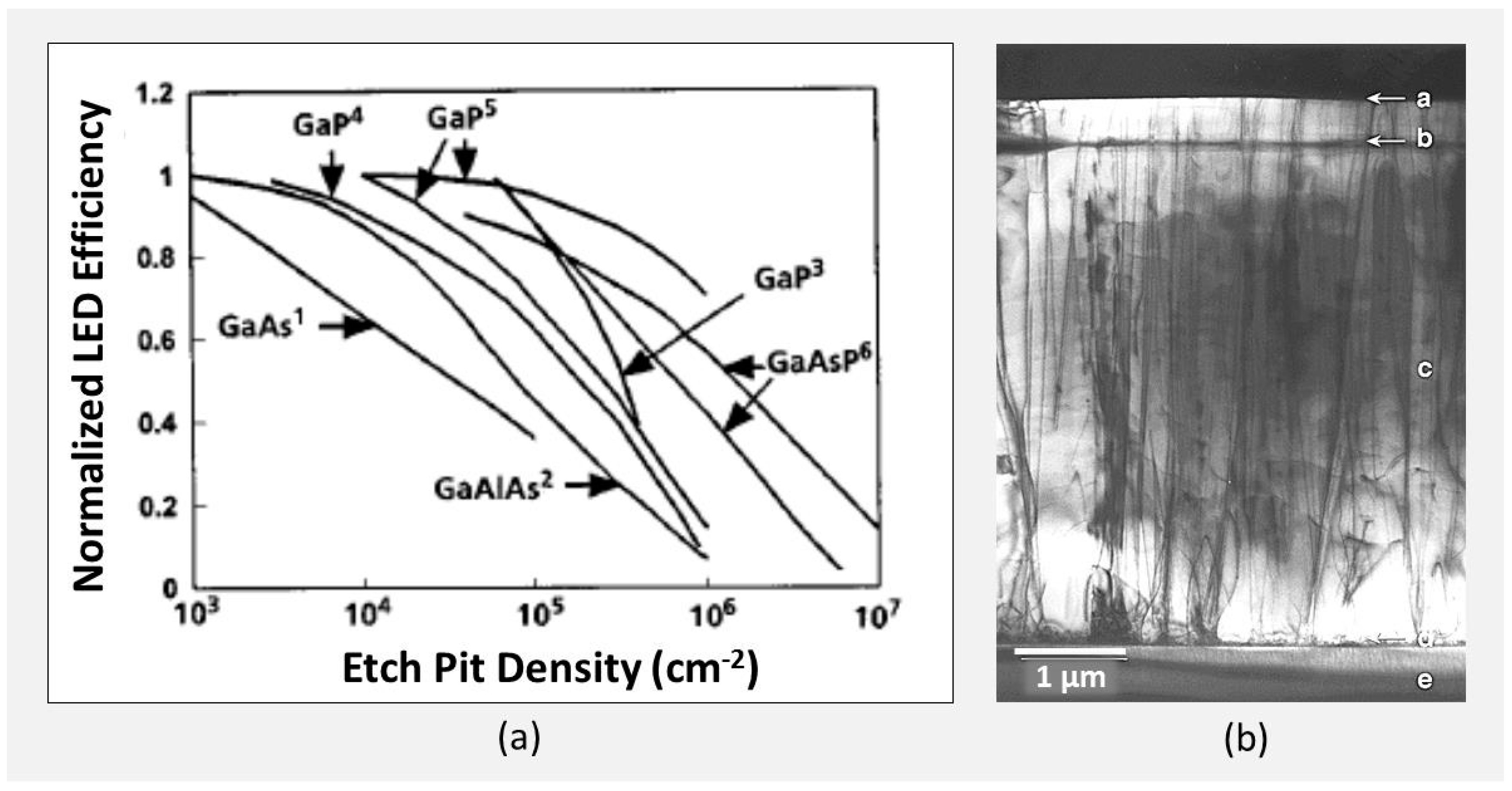

3.4. Crystal Defects in III-Nitrides and Other III-V Compound Semiconductors

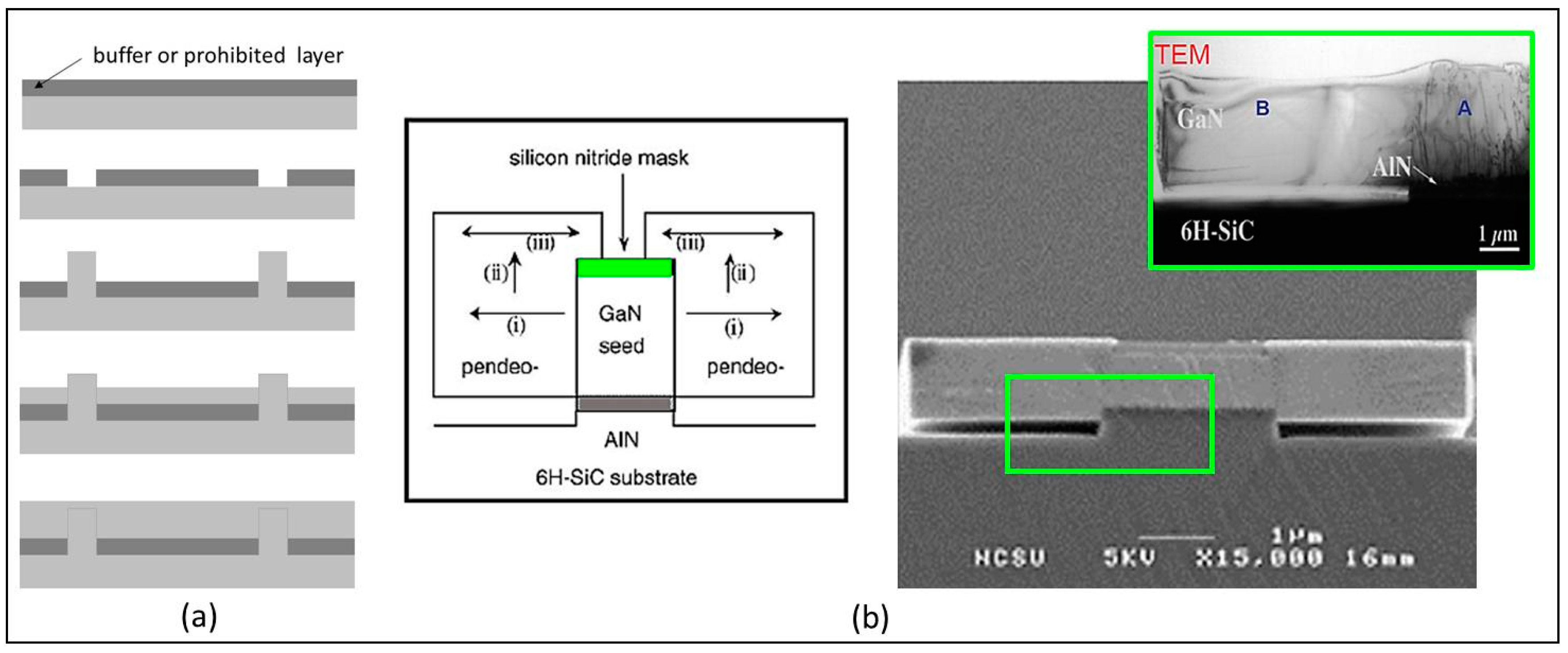

3.5. PENDEO and ELO Epitaxy

4. Other Matching Techniques

5. Triumphs and Defeats of the Direct Laser Sources

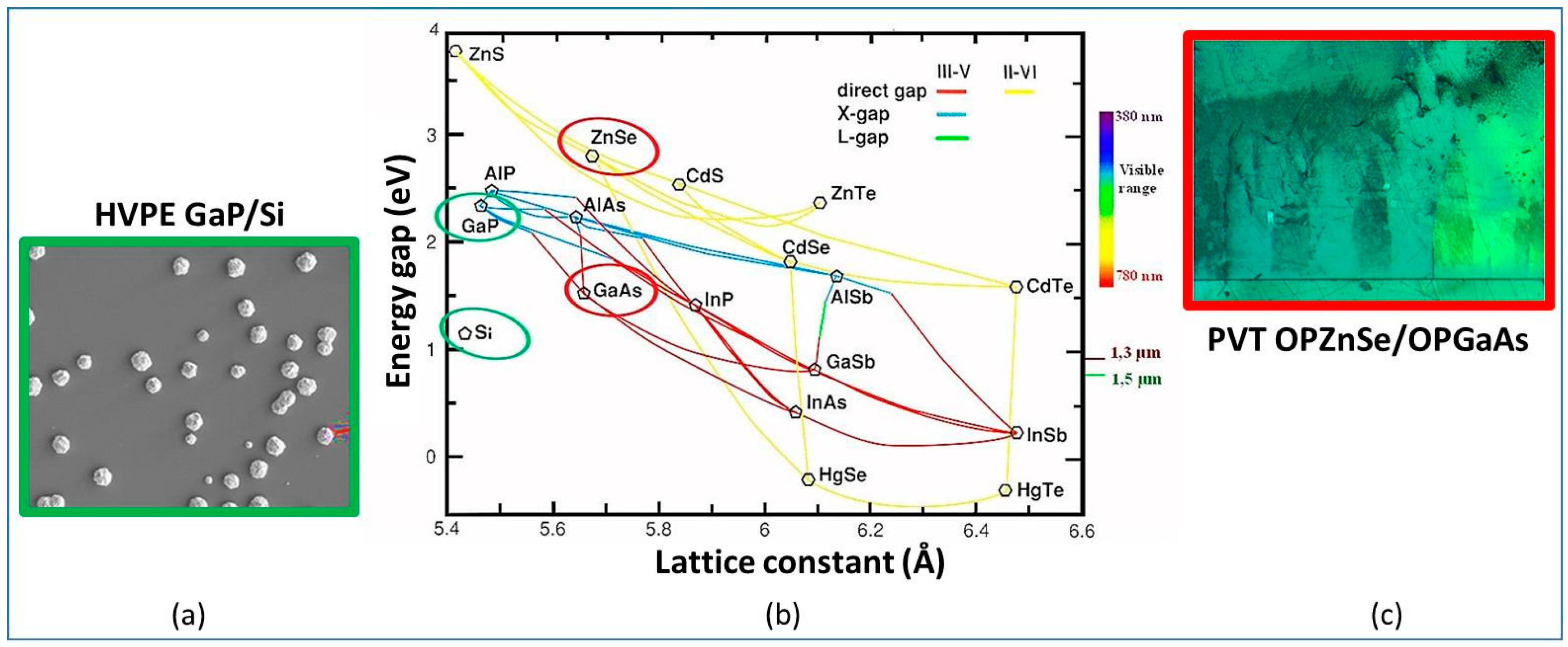

6. Engineering of Materials for Frequency Conversion in the IR and THz Region

6.1. Material Aspects in Retrospect

6.2. First Disappointments with OPGaP

6.2.1. Additional Absorption Band

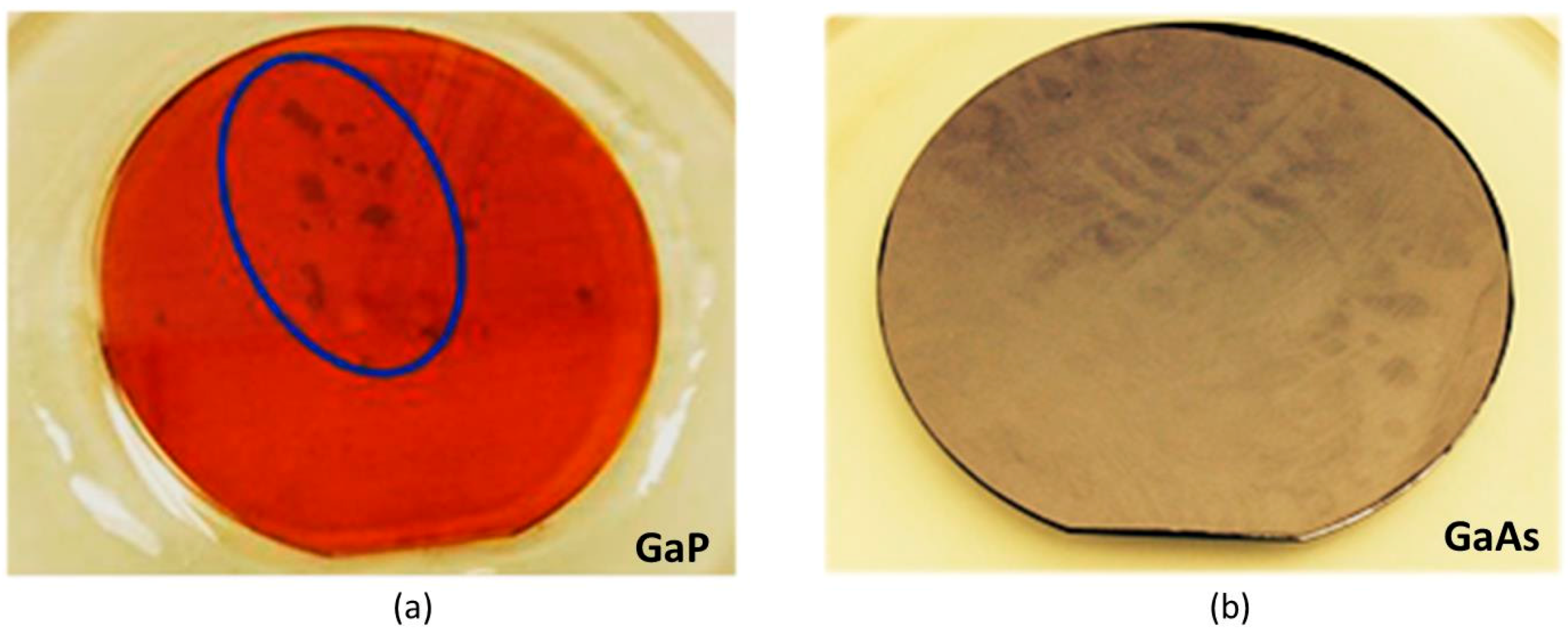

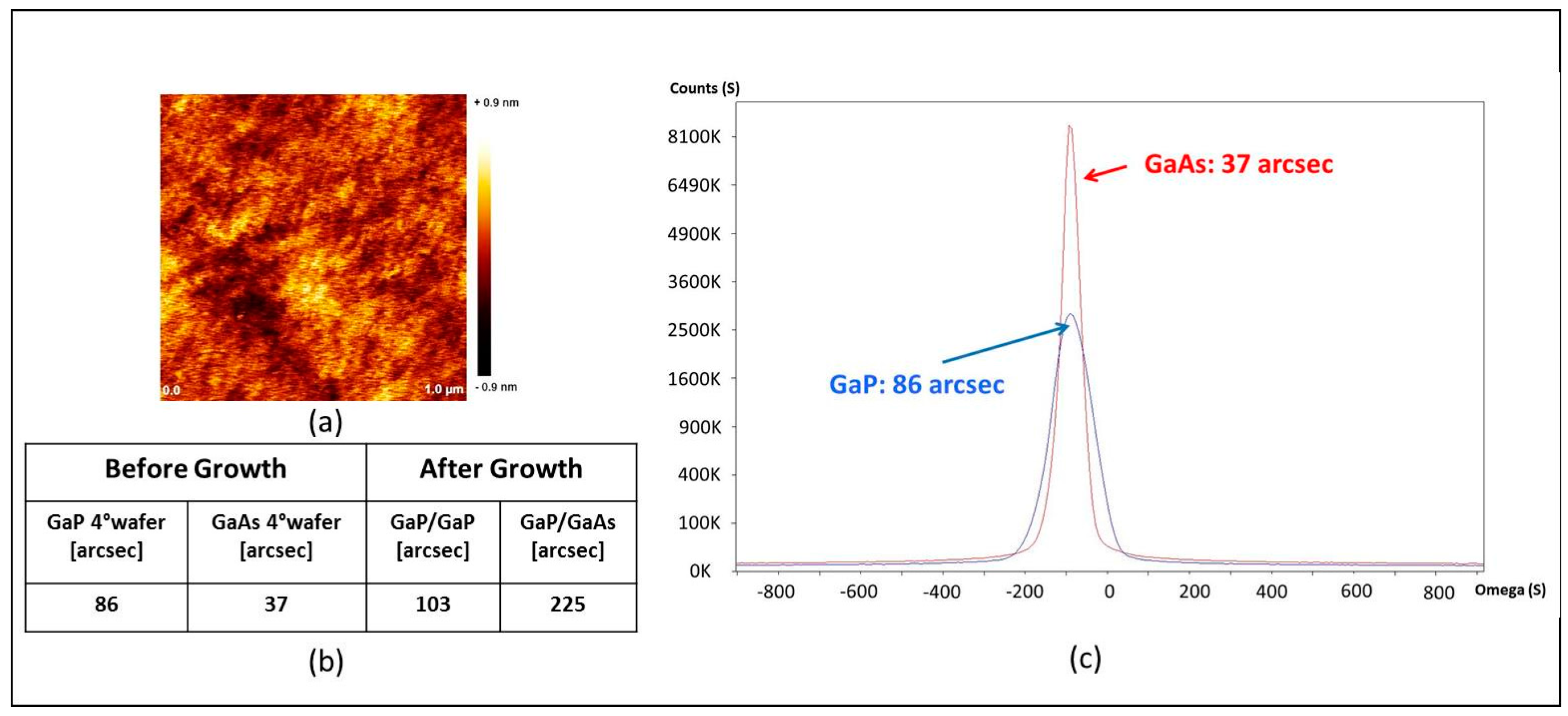

6.2.2. Expensive but Low Quality Commercial GaP

6.3. Alternative Substrate Materials

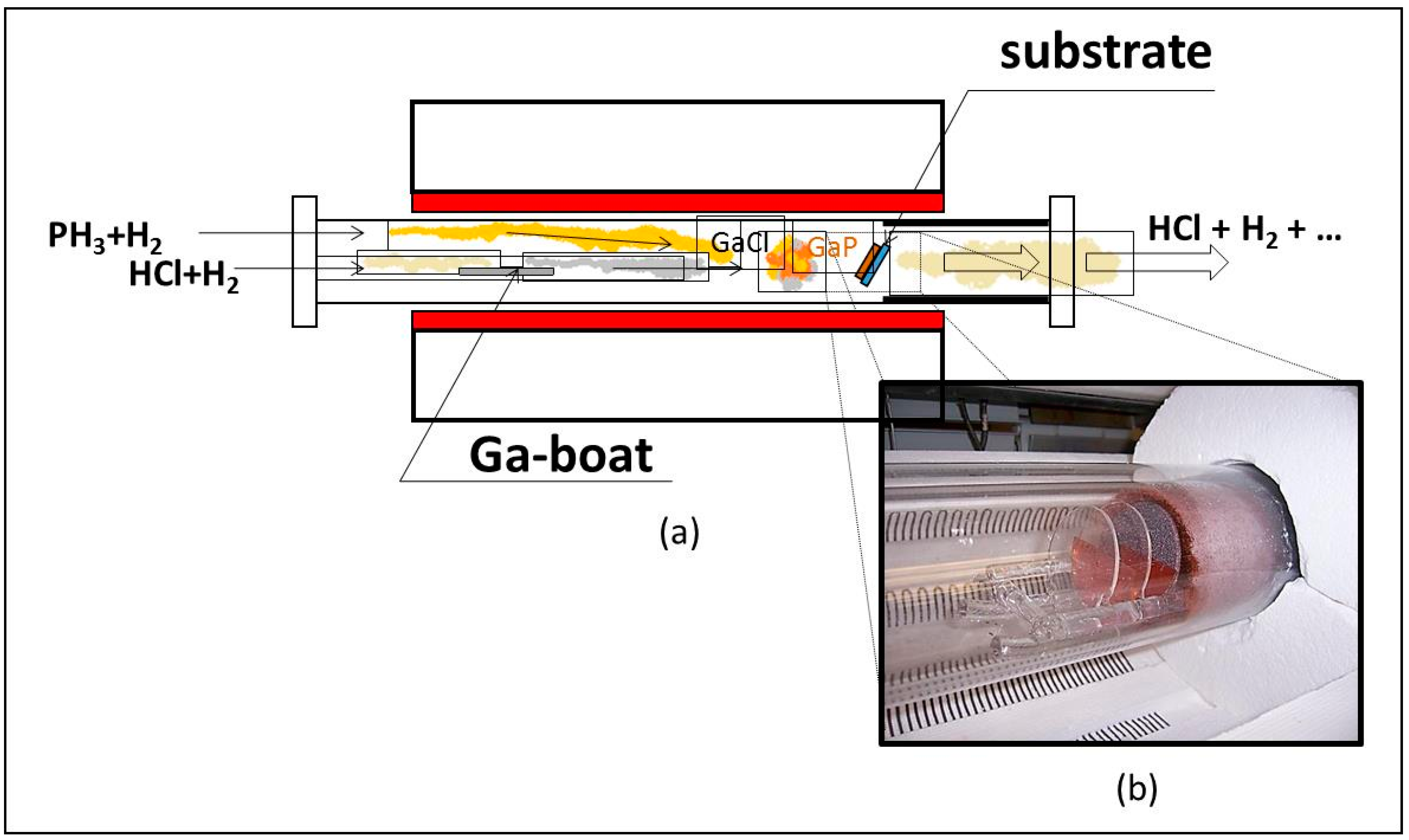

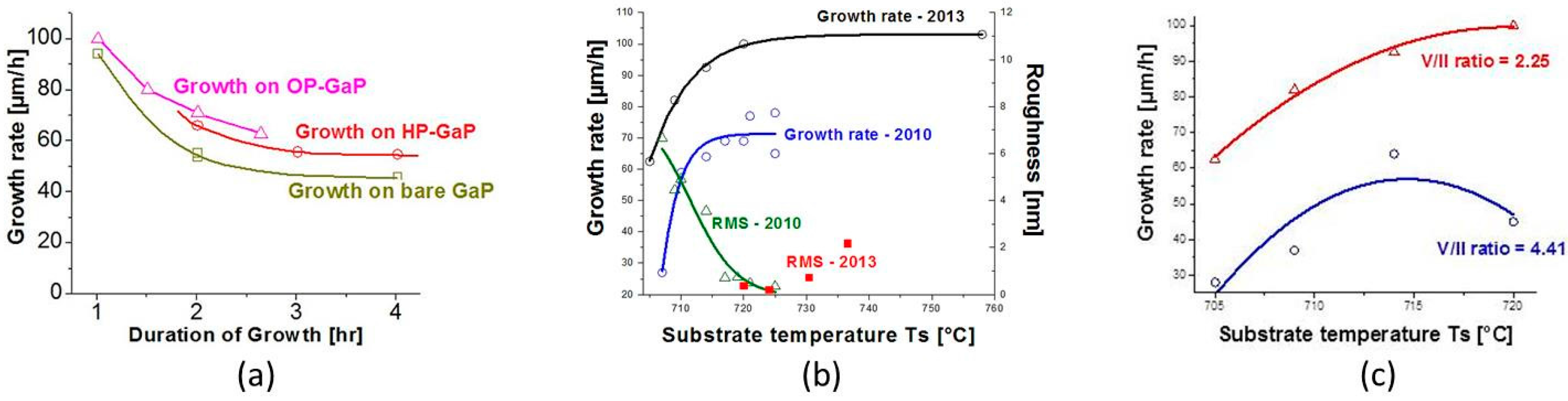

6.4. The HVPE Growth Process

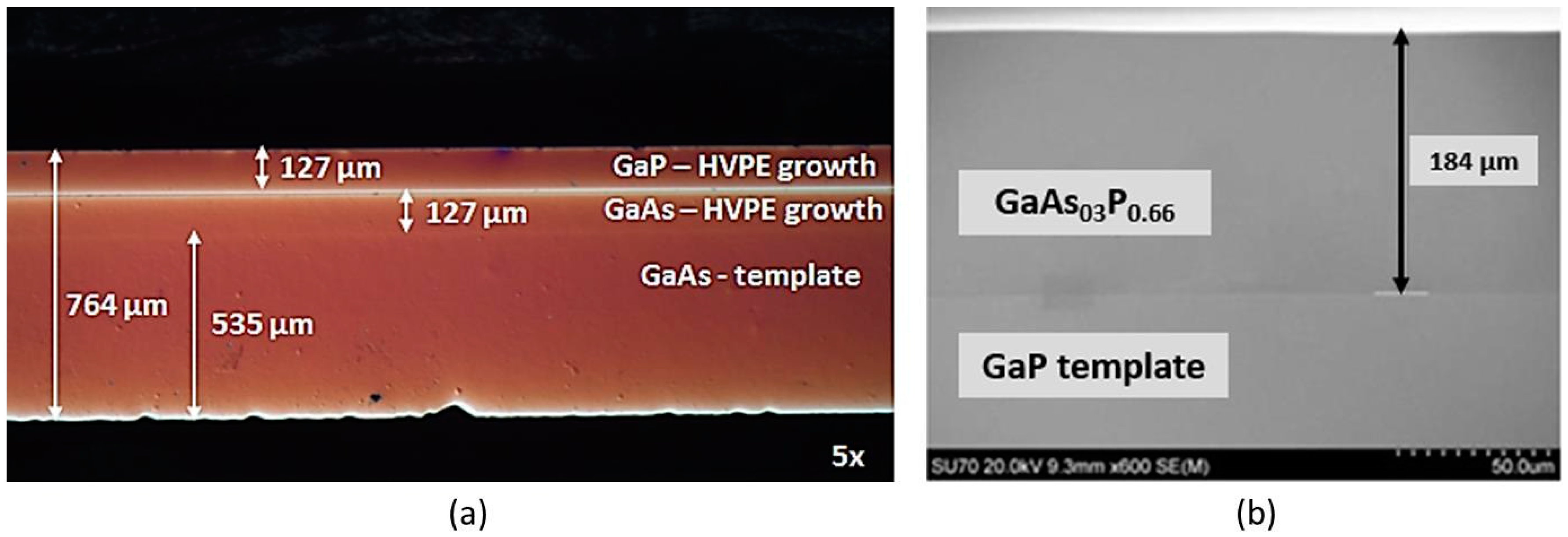

6.5. Combining Two Growth Approaches

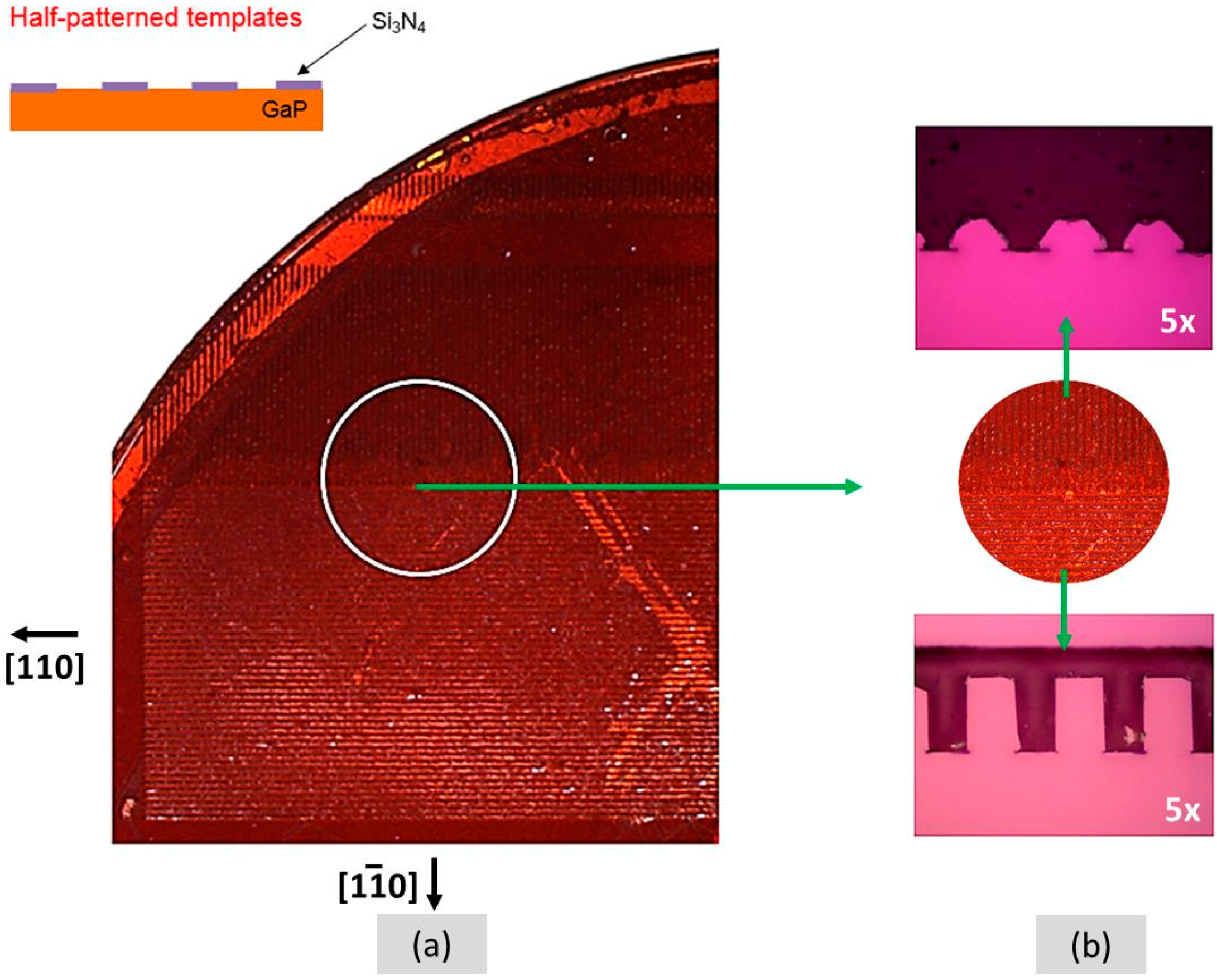

6.6. Purpose, Preparation and Growth on Half-Patterned Templates

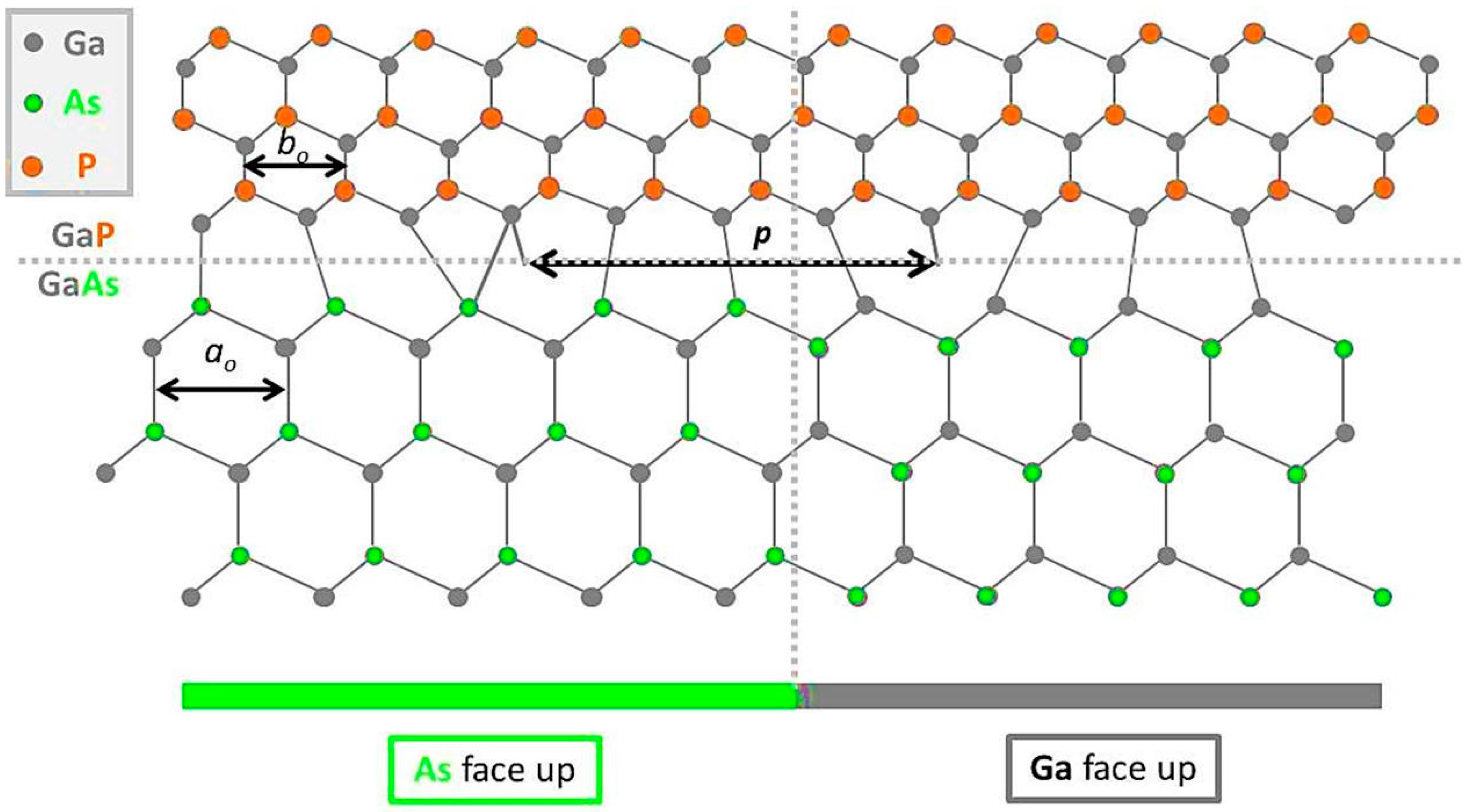

6.7. Preparation and Growth on Orientation-Patterned Templates

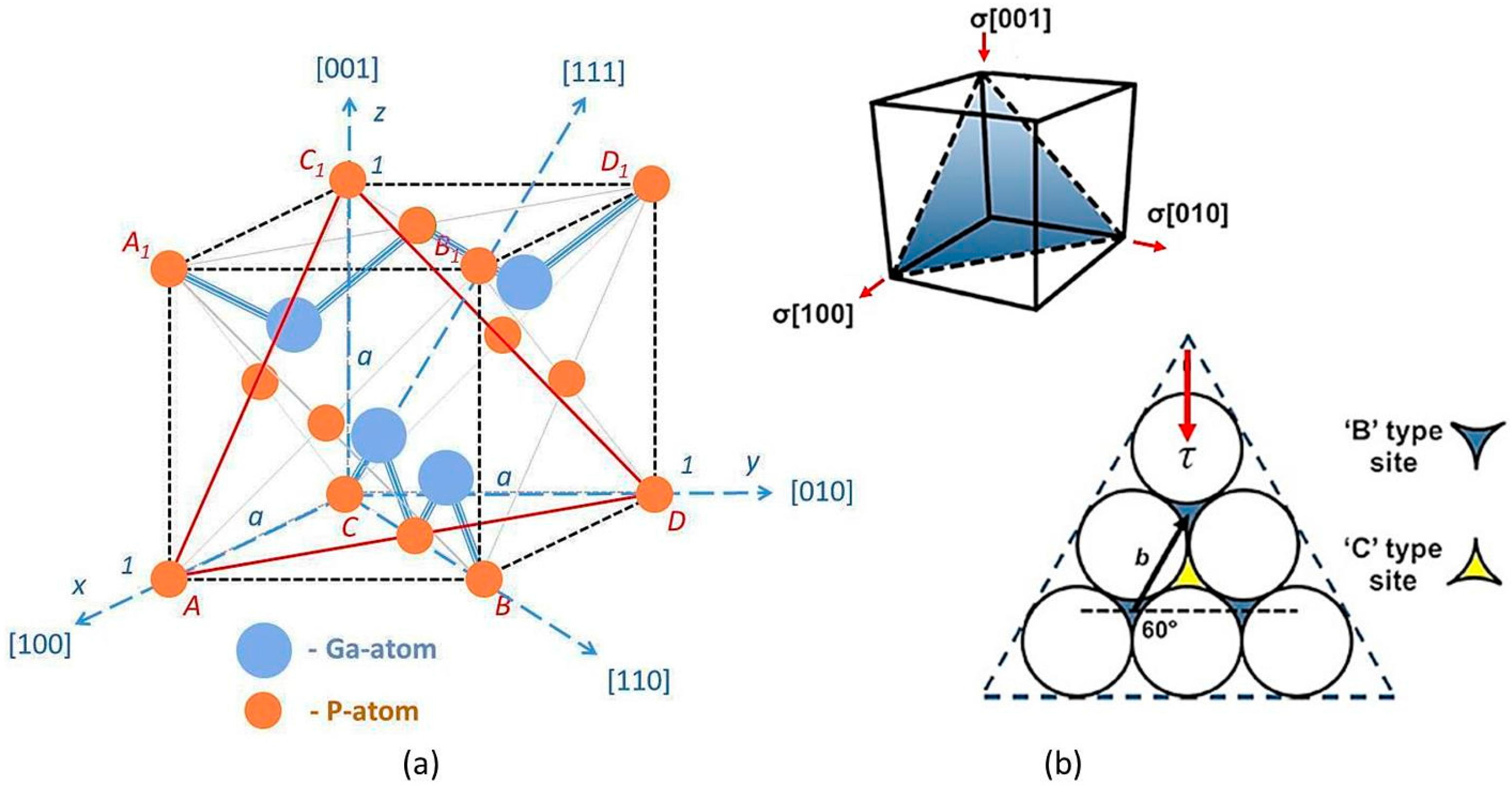

6.7.1. Preparation of OP Templates

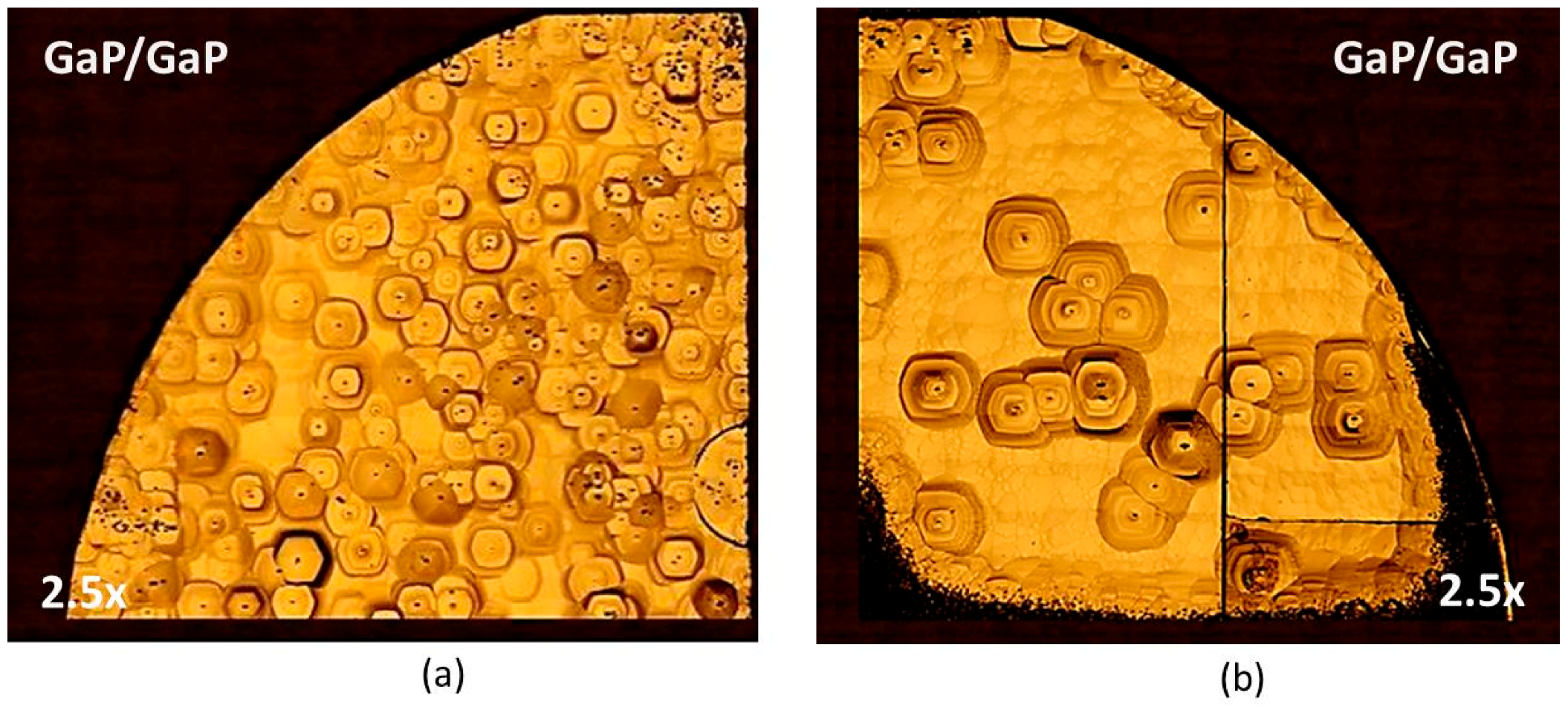

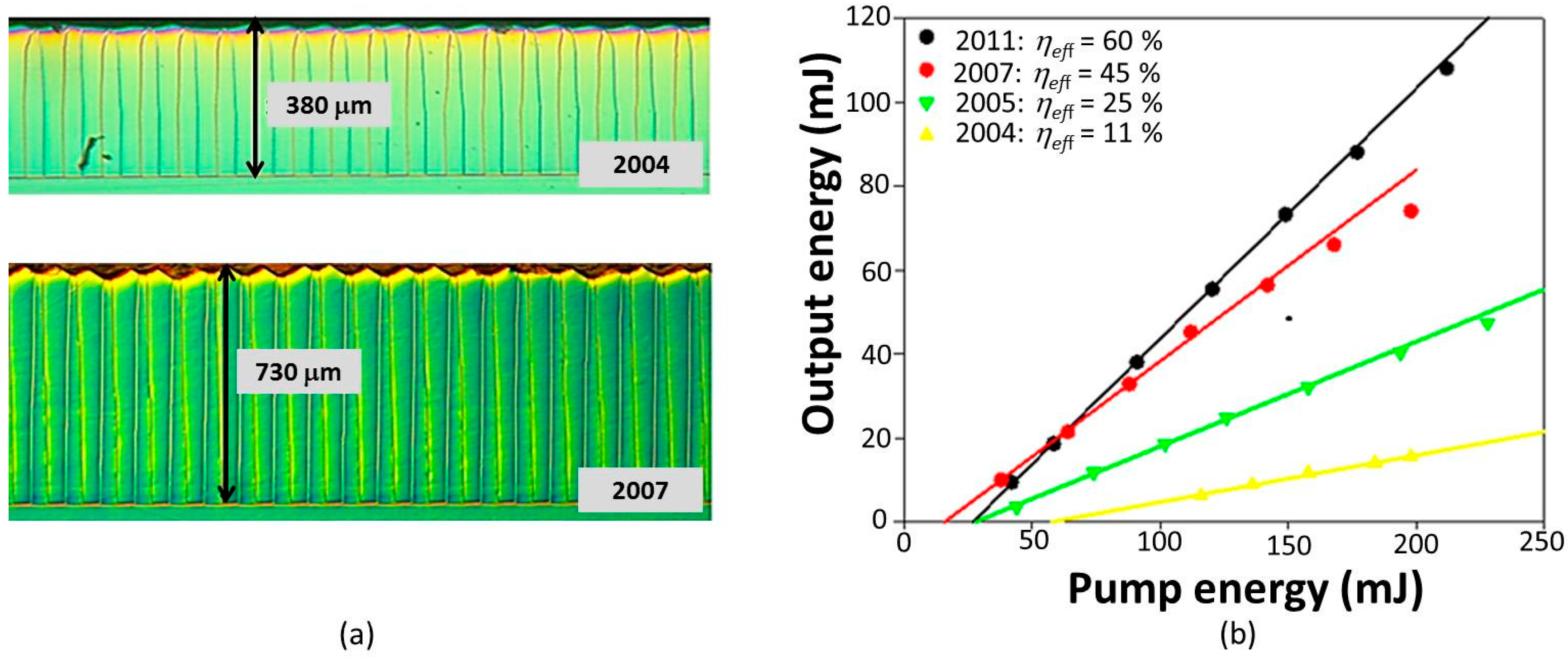

6.7.2. Homoepitaxy of OPGaP on OPGaP Templates

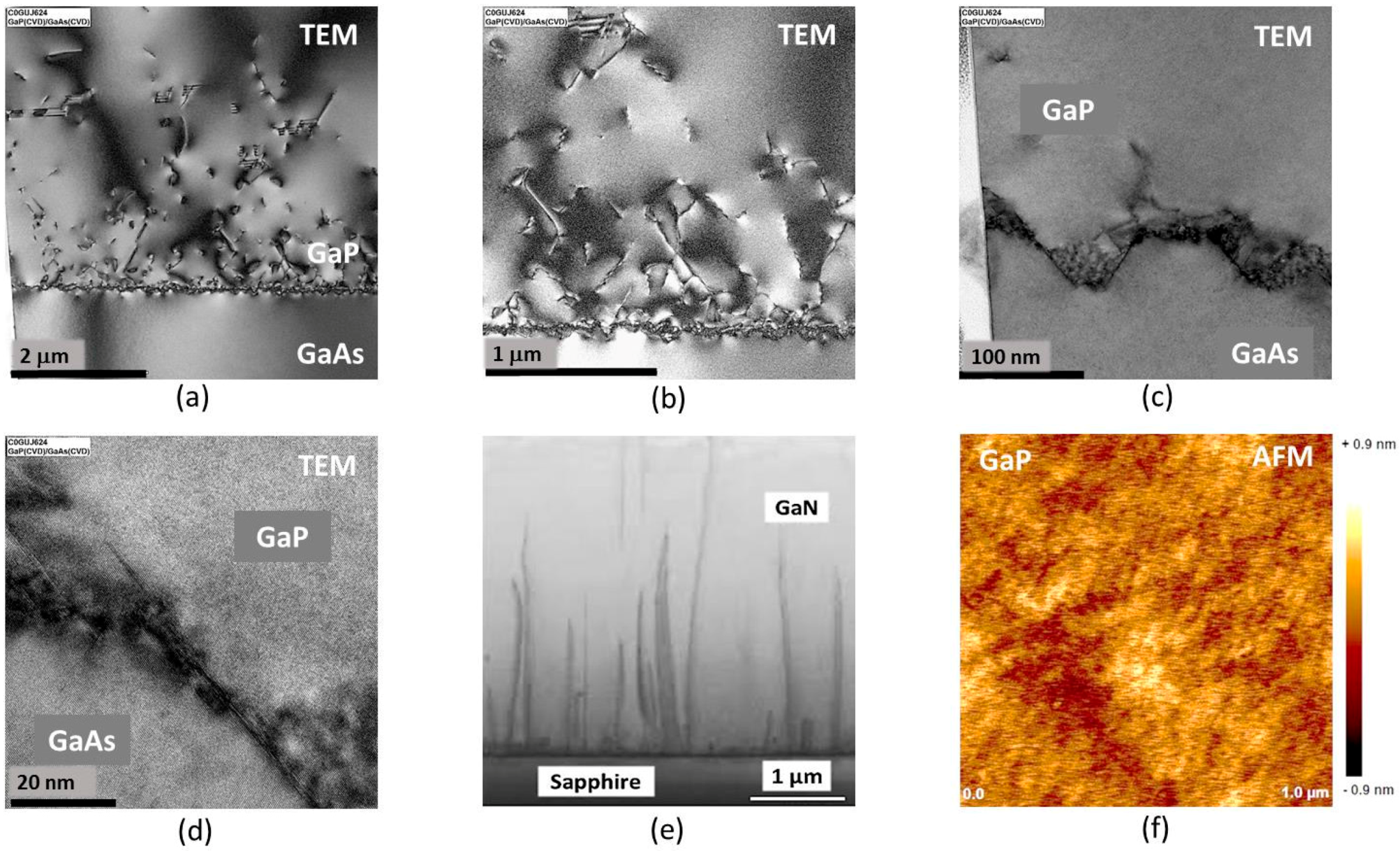

6.7.3. Heteroepitaxy of OPGaP on OPGaAs Templates

7. Discussion

7.1. Impact of the Parasitic Nucleation on the HVPE Growth

- To produce thicker OPGaP layers some crystal growers (Figure 28b) interrupt the growth after several hours, clean the reactor tube, slightly polish, if necessary, the already grown layer surface, and perform a second growth on the same sample to gain some more thickness.

- Instead of losing years in optimizing growth condition and reactor configuration the layer thickness (optical aperture) can be increased by precise face-to-face bonding at higher temperature for two device-sized pieces cut from one already grown OP-sample. For this purpose the triangular parts of the top domain surfaces (Figure 32a), if there are any, must be polished off first. Than the pieces must be faced to each other as attempts to align the same orientation domains must be made, although from the optical point of view this is not that critical for quasi-phase-matching (Figure 32b,c). Then the pieces should be pressed and kept in this way for several hours at higher temperature to allow mutual diffusion.

7.2. Some Considerations on Heteroepitaxy of OP Nonlinear Optical Materials

8. Conclusions

Acknowledgments

Conflicts of Interest

References

- John Vincent Atanasoff Biography. Available online: http://jva.cs.iastate.edu/jvabio.php (accessed on 18 April 2017).

- Raspberry PI Zero: The 5$ Computer. Available online: http://www.raspberry-pi-zero (accessed on 12 June 2017).

- Who Invented the Transistor? Available online: http:/www.computerhistory.org/atchm/who-invented-the-transistor/ (accessed on 18 April 2017).

- Markov, I.V. Crystal Growth for Beginners: Fundamentals of Nucleation, Crystal Growth and Epitaxy, 2nd ed.; World Scientific: Singapore; New York, NY, USA, 2003; p. 43. [Google Scholar]

- Wang, L.G.; Kratzer, P.; Schefller, M.; Moll, N. Formation and stability of self-assembled coherent islands in highly mismatched heteroepitaxy. Phys. Rev. Lett. 1999, 82, 4042–4045. [Google Scholar] [CrossRef]

- Brehm, M.; Montalenti, F.; Grydlik, M.; Vastola, G.; Lichtenberger, H.; Hrauda, N.; Beck, M.J.; Fromherz, T.; Schäffler, F.; Miglio, L.; et al. Key role of the wetting layer in revealing the hidden path of Ge/Si(001) Stranski-Krastanow growth onset. Phys. Rev. 2009, B80, 20FF5321. [Google Scholar] [CrossRef]

- Stranski, I.; Krastanov, L. Über die kristallisation von alkalihalogenidkristallen auf fluorit. Akad. Wiss. Lit. Mainz 1939, 146, 797. [Google Scholar]

- Bauer, E. Phänomenologische Theorie der Kristallabscheidung an Oberflächen. Kristallografiya 1958, 110, 372. [Google Scholar] [CrossRef]

- Wang, X.H.; Jia, H.Q.; Guo, L.W.; Xing, Z.G.; Wang, Y.; Pei, X.J.; Zhou, J.M.; Chen, H. White light-emitting diodes based on a single InGaN emission layer. Appl. Phys. Lett. 2007, 91, 161912. [Google Scholar] [CrossRef]

- Bhattacharyya, A.; Moustakas, T.D.; Zhou, L.; Smith, D.J.; Hug, W. Deep ultraviolet emitting AlGaN quantum wells with high internal quantum efficiency. Appl. Phys. Lett. 2009, 94, 181907. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, Y.; Zhou, G.; Tang, G.; Wang, Z. Wetting layer evolution and its temperature dependence during self-assembly of InAs/GaAs quantum dots. Nanoscale Res. Lett. 2012. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Edgar, J.H. Substrates for gallium nitride epitaxy. Mater. Sci. Eng. 2002, 37, 61–127. [Google Scholar] [CrossRef]

- Hellman, E.S. Properties, Processing and Applications of Gallium Nitride and Related Semiconductors: Alternative Oxide Substrates for GaN Heteroepitaxy; IEE, INSPEC: London, UK, 1999. [Google Scholar]

- Trampert, A.; Brandt, O.; Ploog, K.H. Crystal structure of Group III Nitrides. Semicond. Semimet. 1997, 50, 167–192. [Google Scholar] [CrossRef]

- Amano, H. Metalorganic vapor phase epitaxial growth of a high quality GaN film using an AlN buffer layer. Appl. Phys. Lett. 1986, 48, 353–355. [Google Scholar] [CrossRef]

- Amano, H.; Takeuchi, T.; Yamaguchi, S.; Wetzel, C.; Akasaki, I. Characterization of the crystalline quality on GaN on sapphire and ternary allows. Electr. Commun. Jpn. Part 2 1998, 81, 65–71. [Google Scholar]

- Nakamura, S. GaN growth using GaN buffer layer. Jpn. J. Appl. Phys. 1991, 30, L1705–L1707. [Google Scholar] [CrossRef]

- Park, H.; Chan, H.M. A novel process for the generation of pristine sapphire surfaces. Thin Solid Films 2002, 422, 135–140. [Google Scholar] [CrossRef]

- Park, H.; Chan, H.M.; Vinci, R.P. Patterning of sapphire substrates via a solid state conversion process. J. Mater. Res. 2005, 20, 417–423. [Google Scholar] [CrossRef]

- Falub, C.V.; Kanel, H.; Isa, F.; Bergamashini, R.; Marzegalli, A.; Chrastina, D. Scaling hetero-epitaxy from layers to three-dimensional crystals. Science 2012, 335, 1330–1334. [Google Scholar] [CrossRef] [PubMed]

- Isa, F.; Salvalaglio, M.; Dasilva, Y.; Meduna, M.; Barget, M.; Jung, A.; Kreliger, T.; Isella, G.; Emi, R.; Pezzoli, F.; et al. Highly mismatched, dislocation-free SiGe/Si heterostructures. Adv. Mater. 2016, 28, 884–888. [Google Scholar] [CrossRef] [PubMed]

- Zubia, D.; Hersee, S.D. Nanoheteroepitaxy: The application of nonostructuring and substrate compliance to the heteroepitaxy of mismatched semiconductor materials. J. Appl. Phys. 1999, 85, 6492–6496. [Google Scholar] [CrossRef]

- Lester, S.D.; Ponce, F.A.; Craford, M.G.; Steigerwald, D.A. High dislocation densities in high efficiency GaN-based light-emitting diodes. Appl. Phys. Lett. 1995, 66, 1249–1251. [Google Scholar] [CrossRef]

- Ponce, F.A.; Bour, D.P. Nitride-based semiconductors for blue and green light-emitting devices. Nature 1997, 386, 351–359. [Google Scholar] [CrossRef]

- Moustakas, T.D. The role of extended defects on the performance of optoelectronic devices in nitride semiconductors. Phys. Status Solidi 2013, 210, 169–174. [Google Scholar] [CrossRef]

- Zytkiewicz, Z.R. Laterally overgrown structures as substrates for lattice mismatched epitaxy. Thin Solid Films 2002, 412, 64–75. [Google Scholar] [CrossRef]

- Tadatomo, K.; Okagawa, H.; Ohuchi, Y.; Tsunekawa, T.; Imada, Y.; Kato, M.; Taguchi, T. High output power InGaN ultraviolet light-emitting diodes fabricated on patterned substrates using metalorganic vapor phase epitaxy. Jpn. J. Appl. Phys. 2001, 40, L583. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, S.; Lin, Z.; Hong, X.; Li, G. Enhanced light emitting diode light extraction efficiency by an optimized spherical cap-shaped patterned sapphire substrates. Jpn. J. Appl. Phys. 2013, 52, 092101. [Google Scholar] [CrossRef]

- Davis, R.F.; Bishop, S.M.; Mita, S.; Collazo, R.; Reitmeier, Z.J.; Sitar, Z. Epitaxial growth of gallium nitride. AIP Conf. Proc. 2007, 916, 520. [Google Scholar] [CrossRef]

- Zheleva, T.S.; Ashmawy, W.M.; Jones, K.A. Pendeo-Epitaxy versus Lateral Epitaxial Overgrowth of GaN: A Comparative Study via Finite Element Analysis. Phys. Status Solidi 1999, 176, 545–551. [Google Scholar] [CrossRef]

- Davis, R.F.; Gehrke, T.; Linthicum, K.J.; Zheleva, T.S.; Preble, E.A.; Rajagopal, P.; Zorman, C.A.; Mehregany, M. Pendeo-epitaxial growth of thin films of gallium nitride and related materials and their characterization. J. Cryst. Growth 2001, 225, 134–140. [Google Scholar] [CrossRef]

- Detchprohm, T.; Hiramatsu, K.; Itoh, K.; Akasaki, I. Relaxation Process of the Thermal Strain in the GaN/α-Al2O3 Heterostructure and Determination of the Intrinsic Lattice Constants of GaN Free from the Strain. Jpn. J. Appl. Phys. 1992, 31, L1454. [Google Scholar] [CrossRef]

- Tsuchiy, H.; Hasegawa, F.; Okukura, H.; Yoshida, S. Comparison of Hydride Vapor Phase Epitaxy of GaN layers on cubic GaN/(100) GaAs and hexagonal Ga/(111) GaAs substrates. Jpn. J. Appl. Phys. 1994, 33, 6448–6453. [Google Scholar] [CrossRef]

- List of Laser Types. Available online: https://en-wikipedia.org/wiki/List_of_laser_types (accessed on 12 June 2017).

- Maiman, T. Stimulated Radiation in Ruby. Nature 1960, 187, 493–494. [Google Scholar] [CrossRef]

- Tacke, M. Lead Laser Sources. Philos. Trans. R. Soc. Lond. 2001, A359, 547–566. [Google Scholar] [CrossRef]

- Ruby Laser. Available online: https://en-wikipedia.org/wiki/Ruby_laser (accessed on 12 June 2017).

- Infrared Lasers. Available online: https://en.wikipedia.org/wiki/Infrared_lasers (accessed on 14 June 2017).

- Kildaland, H.; Mikkelsen, J.C. The nonlinear coefficient phase matching and optical damage in the chalcopyrite AgGaSe2. Opt. Commun. 1973, 9, 315–318. [Google Scholar] [CrossRef]

- Myers, L.E.; Bosenberg, W.R. Periodically poled lithium niobate and quasi-phase-matched optical parametric oscillators. IEEE J. Quantum Electron. 1997, 33, 1663–1672. [Google Scholar] [CrossRef]

- Wu, Y.C.S.; Feigelson, R.S.; Route, R.K.; Zheng, D.; Gordon, L.A.; Fejer, M.M.; Byer, R.L. Low Optical Loss Wafer Bonded GaAs Structures for Quasi-Phase-Matched Second Harmonic Generation. Mater. Res. Soc. Symp. Proc. 1998, 484, 481–485. [Google Scholar] [CrossRef]

- Grisard, A.; Lallier, E.; Gérard, B. Quasi-phase-matched gallium arsenide for versatile mid-infrared frequency conversion. Opt. Mater. Express 2012, 2, 1021. [Google Scholar] [CrossRef]

- Schunemann, P.G.; Zetzler, S.D. Future directions in quasi-phasematched semiconductors for mid-infrared lasers. Proc. SPIE 2011, 7917, 79171F-1. [Google Scholar] [CrossRef]

- Hurlbut, W.; Lee, Y.; Vodopyanov, K.; Kuo, P.; Fejer, M. Multi-photon absorption and nonlinear refraction of GaAs in the mid-infrared. Opt. Lett. 2007, 32, 668–670. [Google Scholar] [CrossRef] [PubMed]

- Skauli, T.; Kuo, P.S.; Vodopyanov, K.L.; Pinguet, T.J.; Levi, O.; Eyres, L.A.; Harris, J.S.; Fejer, M.M.; Gerard, B.; Becouarn, L.; et al. Improved dispersion relations for GaAs and applications to nonlinear optics. J. Appl. Phys. 2003, 94, 6447. [Google Scholar] [CrossRef]

- Madarasz, F.L.; Dimmock, J.O.; Dietz, N.; Bachmann, K.J. Sellmeier parameters for ZnGaP2, ZnGaP2 and GaP. J. Appl. Phys. 2000, 87, 1564. [Google Scholar] [CrossRef]

- Tomita, I. Fabrication and characterization of a quasi-phase-matched GaP optical device for terahertz-wave generation. Opt. Mater. 2009, 32, 323–328. [Google Scholar] [CrossRef]

- Matsushita, T.; Ohta, I.; Kondo, T. Quasi-Phase-Matched Parametric Fluorescence in a Periodically Inverted GaP Waveguide. Appl. Phys. Exp. 2009, 2, 0611011–0611013. [Google Scholar] [CrossRef]

- Schunemann, P.G.; Pomeranz, L.A.; Magarrell, D.J. Optical parametric oscillation in quasi-phase-matched GaP. Proc. SPIE 2015, 9347. [Google Scholar] [CrossRef]

- Pomeranz, L.A.; Schunemann, P.G.; Magarrell, D.J.; McCarthy, J.C.; Zawilski, K.T.; Zelmon, D.E. 1-µm-pumped OPO based on orientation-patterned GaP. Proc. SPIE 2015, 9347. [Google Scholar] [CrossRef]

- Peterson, R.; Bliss, D.; Lynch, C.; Tomich, D. Progress in orientation-patterned GaAs for next-generation nonlinear optical devices. Proc. SPIE 2008, 6875. [Google Scholar] [CrossRef]

- Insero, G.; Clivati, C.; D’Ambrosio, D.; De Natale, P.; Santambrogio, S.; Schunemann, P.G.; Zondy, J.J.; Borri, S. Difference frequency generation in the mid-infrared with orientation-patterned gallium phosphide crystals. Opt. Lett. 2016, 41, 5114–5117. [Google Scholar] [CrossRef] [PubMed]

- Levine, B.F.; Bethea, C.G. Nonlinear Susceptibility of GaP: Relative Measurement and Use of Measured Values to Determine a Better Absolute Value. Appl. Phys. Lett. 1972, 20, 272. [Google Scholar] [CrossRef]

- Hu, X.P.; Xu, P.; Zhu, S.N. Engineered quasi-phase-matching for laser techniques. Photonics Res. 2013, 1, 171–185. [Google Scholar] [CrossRef]

- Spitzer, W.G.; Gershenzon, M.; Frosch, C.J.; Gibbs, D.F. Optical absorption in n-type gallium phosphide. J. Phys. Chem. Sol. 1959, 11, 339–341. [Google Scholar] [CrossRef]

- Yasakov, D.A.; Pikhtin, A.N.; Ulyanov, V.I. Optical properties of gallium phosphide grown by floating zone. Mater. Res. Bull. 1969, 4, 839–848. [Google Scholar] [CrossRef]

- Tassev, V.; Bliss, D.; Snure, M.; Bryant, G.; Peterson, R.; Bedford, R.; Yapp, C.; Goodhue, W.; Termkoa, K. HVPE growth and characterization of GaP on different substrates and patterned templates for frequency conversion devices. J. Eur. Opt. Soc. 2011, 6, 110171–110177. [Google Scholar] [CrossRef]

- Tassev, V.; Snure, M.; Peterson, R.; Schepler, K.L.; Bedford, R.; Manna, J.M.; Vangala, S.; Goodhue, W.; Lin, A.; Harris, J.; et al. Progress in orientation-patterned GaP for next-generation nonlinear optical devices. Proc. SPIE 2013, 8604. [Google Scholar] [CrossRef]

- Tassev, V.L.; Vangala, S.R.; Peterson, R.D.; Kimani, M.M.; Snure, M.; Stites, R.W.; Guha, S.; Slagle, J.E.; Ensley, T.R.; Syed, A.A.; et al. Heteroepitaxial growth of OPGaP on OPGaAs for frequency conversion in the IR and THz. Opt. Mater. Express 2016, 6, 1724–1737. [Google Scholar] [CrossRef]

- Lallier, E.; Brevignon, M.; Leho, J. Efficient second-harmonic generation of a CO2 laser with a quasi-phase-matched GaAs crystal. Opt. Lett. 1998, 23, 1511–1513. [Google Scholar] [CrossRef] [PubMed]

- Lin, A.; Fenner, D.B.; Termkoa, K.; Allen, M.; Moulton, P.; Lynch, C.; Bliss, D.F.; Goodhue, W.D. Wafer bonding of GaP, Wafer-fused orientation-patterned GaAs. Proc. SPIE 2008, 6875. [Google Scholar] [CrossRef]

- Kuzmenko, P.J.; Little, S.L.; Ikeda, Y.; Kobayashi, N. Fabrication and testing of diamond-machined gratings in ZnSe, GaP, and bismuth germanate for the near infrared and visible. Proc. SPIE 2008, 7018. [Google Scholar] [CrossRef]

- Tassev, V.; Snure, M.; Vangala, S.; Kimani, M.; Peterson, R.; Schunemann, P. Growth and study of nonlinear optical materials for frequency conversion devices with applications in defense and security. Proc. SPIE 2014, 9253. [Google Scholar] [CrossRef]

- Singh, N.B.; Kanner, G.S.; Berghmans, A.; Kahler, D.; Lin, A.; Wagner, B.; Kelley, S.P.; Knuteson, D.J.; Holmstrom, R.; Schepler, K.L.; et al. Characteristics of thick ZnSe films on quasi-phase-matched (QPM) GaAs substrates. J. Cryst. Growth 2010, 312, 1142–1145. [Google Scholar] [CrossRef]

- III-V Semiconductors. Available online: html://www.tf.uni-kiel.de/matwis/amat/semitech_en/kap_2/backbone/r2_3_1.html (accessed on 12 June 2017).

- Gil, E.; André, Y.; Cadoret, R.; Trassoudaine, A. Handbook of Crystal Growth: Hydride Vapor Phase Epitaxy for Current III–V and Nitride Semiconductor Compound Issues; Elsevier: Amsterdam, The Netherlands, 2015; pp. 51–93. [Google Scholar]

- Derenge, M.A.; Zheleva, T.S.; Jones, K.A.; Shah, P.B.; Ewing, D.; Molstad, J.; Lee, U.; Ervin, M.H.; Stepp, D.N. Pendeo-Epitaxy Process Optimization of GaN for Novel Devices Applications; ARL-TR-4426; Army Research Lab.: Adelphi, MD, USA, 2008; pp. 20783–21197. [Google Scholar]

- Gil-Lafon, E.; Napierala, J.; Castelluci, D.; Pimpinelli, A.; Cadoret, R.; Gerard, B. Selective growth of GaAs by HVPE: Keys for accurate control of the growth morphologies. J. Cryst. Growth 2001, 222, 482–496. [Google Scholar] [CrossRef]

- Tassev, V.L.; Vangala, S.; Peterson, R.; Kimani, M.; Snure, M.; Markov, I. Homo and heteroepitaxial growth and study of orientation-patterned GaP for nonlinear frequency conversion devices. Proc. SPIE 2016, 9731. [Google Scholar] [CrossRef]

- Bliss, D.F.; Lynch, C.; Weyburne, D.; O’Hearn, K.; Bailey, J.S. Epitaxial growth of thick GaAs on orientation-patterned wafers for nonlinear optical applications. J. Cryst. Growth 2006, 287, 673–678. [Google Scholar] [CrossRef]

- Eyres, L.A.; Tourreau, P.J.; Pinguet, T.J.; Ebert, C.B.; Harris, J.S.; Fejer, M.M.; Gerald, B.; Lallier, E. All-epitaxial fabrication of thick, orientation-patterned GaAs films for nonlinear optical frequency conversion. Appl. Phys. Lett. 2001, 79, 904–906. [Google Scholar] [CrossRef]

- Peterson, R.; Whelan, D.; Bliss, D.; Lynch, C. Improved material quality and OPO performance in orientation-patterned GaAs. Proc. SPIE 2009, 7197. [Google Scholar] [CrossRef]

- Faye, D.; Grisard, A.; Lallier, E.; Gérard, B.; Kieleck, C.; Hirth, A. Orientation-patterned gallium arsenide: Engineered materials for infrared sources. SPIE Newsroom 2008. [Google Scholar] [CrossRef]

- Ebert, C.B.; Eyres, L.A.; Fejer, M.M.; Harris, J.S. MBE growth of antiphase GaAs films using GaAs/Ge/GaAs heteroepitaxy. J. Cryst. Growth 1999, 201, 187. [Google Scholar] [CrossRef]

- Schunemann, P.G.; Setzler, S.D.; Mohnkern, L.; Pollak, T.M.; Bliss, D.F.; Weyburne, D.; O’Hearn, K. 2.05-µm-Laser-Pumped Orientation-Patterned Gallium Arsenide (OPGaAs) OPO. In Proceedings of the Conference on Lasers and Electro-Optics 2005, Baltimore, MD, USA, 22 May 2005. [Google Scholar]

- Lynch, C.; Bliss, D.F.; Zens, T.; Lin, A.; Harris, J.S.; Kuo, P.S.; Fejer, M.M. Growth of mm-thick orientation-patterned GaAs for IR and THZ generation. J. Cryst. Growth 2008, 310, 5241–5247. [Google Scholar] [CrossRef]

- Tassev, V.; Snure, M.; Peterson, R.; Bedford, R.; Bliss, D.; Bryant, G.; Mann, J.M.; Goodhue, W.; Vangala, S.; Termkoa, K.; et al. Epitaxial growth of quasi-phase-matched GaP for nonlinear applications: Systematic process improvements. J. Cryst. Growth 2012, 352, 72–77. [Google Scholar] [CrossRef]

- Schunemann, P.G.; Mohnkern, L.; Vera, A.; Yang, X.S.; Lin, A.C.; Harris, J.S.; Tassev, V.; Snure, M. All-Epitaxial Growth of Orientation-Patterned Gallium Phosphide (OPGaP). In Proceedings of the Advances in Optical Materials 2012, San Diego, CA, USA, 1–3 February 2012. [Google Scholar]

- Vangala, S.R.; Tassev, V.L.; Kimani, M.; Snure, M.; Peterson, R. Development of Thick Orientation Patterned GaP for Frequency Conversion in the Mid IR and THz Region. In Proceedings of the 2014 39th International Conference on Infrared, Millimeter, and Terahertz waves (IRMMW-THz), Tucson, AZ, USA, 14–19 September 2014. [Google Scholar]

- Joyce, B.A.; Vvedensky, D.D. Self-organized growth on GaAs surfaces. Mater. Sci. Eng. 2014, 46, 127–176. [Google Scholar] [CrossRef]

- Pierre-Louis, O.; D’Orsogna, M.R.; Einstein, T.L. Edge Diffusion during Growth: The Kink Ehrlich-Schwoebel Effect and Resulting Instabilities. Phys. Rev. Lett. 1999, 82, 3661–3664. [Google Scholar] [CrossRef]

- Leal, F.F.; Ferreira, S.O.; Ferreira, S.C. Modelling of epitaxial film growth with an Ehrlich-Schwoebel barrier dependent on the step height. J. Phys. Condense Matter 2011, 23, 292201. [Google Scholar] [CrossRef] [PubMed]

- Ayers, J.E.; Kujofsa, T.; Rago, P.; Raphael, J.E. Heteroepitaxy of Semiconductors: Theory, Growth and Characterization, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2017; pp. 154–165. [Google Scholar]

- Holt, D.B. Misfit dislocations in semiconductors. J. Phys. Chem. Solids 1966, 27, 1053–1067. [Google Scholar] [CrossRef]

- Simmonds, P.J.; Lee, M.L. Tensile-strained growth on low-index GaAs. Appl. Phys. Lett. 2011, 99, 123111. [Google Scholar] [CrossRef]

- Markov, I.; Milchev, A. The effect of anharmonicity in epitaxial interfaces: Equilibrium structure of thin epitaxial films. Surf. Sci. 1984, 136, 519–531. [Google Scholar] [CrossRef]

- Zangwill, A. Physics at Surfaces; Cambridge University Press: New York, NY, USA, 1988. [Google Scholar]

- Walther, M.; Biehl, M.; Kinzel, Y. Formation and consequences of misfit dislocations in heteroepitaxial growth. Phys. Status Solidi 1997, 4, 3210–3220. [Google Scholar] [CrossRef]

- Simmonds, P.J.; Lee, M.L. Self-assembly on (111)-oriented III-V surfaces. Appl. Phys. Lett. 2010, 97, 153101. [Google Scholar] [CrossRef]

- Simmonds, P.J.; Lee, M.L. Tensile GaAs (111) quantum dashes with tunable luminescence below the bulk bandgap. J. Appl. Phys. 2012, 112, 054313. [Google Scholar] [CrossRef]

- Pachinger, D.; Groiss, H.; Lichtenberger, H.; Stangl, J.; Hesser, G.; Schaffler, F. Stranski-Krastanov growth of tensile strained Si islands on Ge (001). Appl. Phys. Lett. 2007, 91, 233106. [Google Scholar] [CrossRef]

- Simon, J.; Tomasulo, S.; Simmonds, P.J.; Romero, M.; Lee, M.L. Metamorphic GaAsP buffers for growth of wide-bandgap InGaP solar cells. J. Appl. Phys. 2011, 109, 013708. [Google Scholar] [CrossRef]

- Leonard, D.; Krishnamurthy, M.; Reaves, C.M.; Denbaars, S.P.; Petroff, P.M. Direct formation of quantum-sized dots from uniform coherent islands of InGaAs on GaAs surfaces. Appl. Phys. Lett. 1993, 63, 3203. [Google Scholar] [CrossRef]

- Eaglesham, D.J.; Cerullo, M. Dislocation-free Stranski-Krastanov growth of Ge on Si (100). Phys. Rev. Lett. 1990, 64, 1943. [Google Scholar] [CrossRef] [PubMed]

- Kvam, E.P.; Hull, R. Surface orientation and stacking fault generation in strained epitaxial growth. J. Appl. Phys. 1993, 73, 7407. [Google Scholar] [CrossRef]

- Sheu, J.K.; Loe, M.L.; Lai, W.C. Effect of low-temperature grown GaP layer on reduced leakage current of GaN Schottky diodes. Appl. Phys. Lett. 2005, 86, 052103. [Google Scholar] [CrossRef]

- Szilagyi, A.; Hordvik, A.; Schlossberg, H. A quasi-phase-matching technique for efficient optical mixing and frequency doubling. J. Appl. Phys. 1976, 47, 2025–2932. [Google Scholar] [CrossRef]

- Vangala, S.; Peterson, R.; Snure, M.; Tassev, V. Development of orientation-patterned GaP grown on foreign substrates for QPM frequency conversion devices. Proc. SPIE 2017, 10088. [Google Scholar] [CrossRef]

- Vangala, S.; Kimani, M.; Peterson, R.; Sites, R.; Snure, M.; Tassev, V. Thick orientation-patterned growth of GaP on wafer-fused GaAs templates by hydride vapor phase epitaxy for frequency conversion. Opt. Mater. 2016, 60, 62–66. [Google Scholar] [CrossRef]

- Tassev, V.L.; Peterson, R.D. Heteroepitaxial Growth of Orientation-Patterned Materials on Orientation-Patterned Substrates. U.S. Patent 9,647,156, 9 May 2017. [Google Scholar]

- Paskova, T.; Tungasmita, S.; Valcheva, E.; Svedberg, E.B.; Arnaudov, B.; Evtimova, S.; Persson, P.A.; Henry, A.; Beccard, R.; Heuken, M.; et al. Hydride Vapour Phase Homoepitaxial Growth of GaN on MOCVD-Grown ‘Templates’. Mater. Res. Soc. Int. J. Nitride Semicond. Res. 2000, 5, 131–137. [Google Scholar] [CrossRef]

| Properties | GaAs | GaP |

|---|---|---|

| Transmission window [μm] | 1–16 | 0.55–12 |

| Nonlinear optical coefficient d14 [pm·V−1] | 94 | 71 |

| Index of refraction n | 3.34 | 3.03 |

| Thermal conductivity [W·m−1·K−1] | 55 | 110 |

| Thermal expansion coefficient [10−6·K−1] | 5.7 | 4.6 |

| 2PA coefficient [cm/G−1·W−1] at 1.06 μm | 28 | 0.02 |

| Characteristics/Wafer Material | GaP | GaAs |

|---|---|---|

| Price [USD] | 585–685 | 87–90 |

| EPD [etch pits/cm2] | 80,000–100,000 | 1500–5000 1 |

© 2017 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tassev, V.L. Heteroepitaxy, an Amazing Contribution of Crystal Growth to the World of Optics and Electronics. Crystals 2017, 7, 178. https://doi.org/10.3390/cryst7060178

Tassev VL. Heteroepitaxy, an Amazing Contribution of Crystal Growth to the World of Optics and Electronics. Crystals. 2017; 7(6):178. https://doi.org/10.3390/cryst7060178

Chicago/Turabian StyleTassev, Vladimir L. 2017. "Heteroepitaxy, an Amazing Contribution of Crystal Growth to the World of Optics and Electronics" Crystals 7, no. 6: 178. https://doi.org/10.3390/cryst7060178