1. Introduction

Molecular crystals are put to a variety of different uses, including some explosives, pharmaceuticals, and foods. Despite having very different practical applications, these materials often have similar molecular structures as well as physical and mechanical properties. Often, one type of molecular crystal is used to simulate or “mock” another type of crystal for a given test or scenario. Mock materials are commonly used when the simulant allows for increased safety, lower costs, or ease of handling compared to the original material. Recently, several materials were identified as new mocks for the explosive cyclotetramethylene-tetranitramine (HMX), in terms of density and thermal stability [

1]. However, the effectiveness of simulating mechanical properties with these new mocks has not been addressed. Typically, sucrose has been used to mock HMX mechanically [

2] but it has a lower density and melt point, limiting the scenarios that can be simulated. In other cases, such as with pharmaceuticals, the use of a model material allows for rapid or inexpensive assessment of some processing parameters [

3]. One possible way to identify materials with similar physical (elastic properties) and mechanical responses (for plastic flow and fracture) is to utilize nanoindentation to probe the properties of individual single crystals of these materials with little need for complex sample geometries.

Testing the mechanical properties of powders and small powder-like particles can be difficult both due to the small size of many of these materials in their as-formed state; testing can also be difficult with regard to forming or machining samples to meet standard mechanical test geometries. Nanoindentation resolves this limitation, as indentation can be performed on samples with lateral dimensions on the order of 10’s of μms or smaller. While it is possible to assess the properties of individual grains within metallic systems (where the grains are often identified by electron backscattered diffraction [

4]), it is also possible to use indentation to characterize molecular crystals such as cyclotrimethylene-trinitramine (RDX), HMX, 1,3,5-triamino-2,4,6-trinitrobenzene (TATB), sucrose, aspirin, and many more [

5,

6,

7,

8,

9,

10]. The small length scale of nanoindentation also enables the crystals to be tested without additional processing, whereas other techniques or larger mechanical tests (such as using a Vickers hardness test on RDX [

11]) might require growing large and pristine single crystals. Nanoindentation therefore allows molecular crystals to be tested in their as-received or as-used condition. This is critical for evaluating the actual properties of the materials in application, since common techniques to grow “better” samples can alter the measured properties. For example, individual crystal growth could be enhanced using solution adjuncts which minimize nucleation, so growth rates may greatly exceed nucleation rates, which could impact the defect density within the crystals [

12].

Instrumented indentation has been used to quantify a wide variety of mechanical properties including elastic modulus [

13,

14,

15], which may be crystal orientation-dependent [

16,

17], and hardness [

18,

19], which is often used as a surrogate for general plastic flow behavior. Additionally, yield points during initial loading can be indicative of the onset of dislocation nucleation [

20]. Finally, indentation-induced fracture [

21,

22,

23,

24,

25,

26] has been used by many researchers as a surrogate to quantify toughness in materials where meeting American Society for Testing and Materials (ASTM) standard specimen geometries would be challenging. Elastic modulus, hardness, and yield behavior are often measured using a Berkovich indenter probe, but more acute probes, such as the cube corner geometry, can be useful in initiating fracture.

Indentation fracture, often with a Vickers geometry and testing system [

27], conventionally uses post-indentation characterization to assess if cracks are present in the sample, and then relates cracking behavior to the stress fields which drove crack propagation. Experiments have demonstrated that in some cases cracking can occur during loading of the indenter, while in other cases the cracks initiate upon unloading, as shown by Cook and Pharr [

21]. Identifying a crack after the indentation is complete is typically done using optical, electron, or scanning probe microscopy, but a crack may also be identified by the load-depth curve of the indentation. Morris and co-workers showed that when a material is indented with two different indenter probes of varying acuteness, materials that have not cracked have superimposable unloading portions of the load-depth curves, whereas when the material has cracked the unloading curves will be nonsuperimposable [

28]. This method of detecting fracture allows cracks to be identified even when they cannot be seen optically, for more precise identification of the onset of fracture. The need to identify fracture behavior is important in assessing materials properties, not only in determining toughness, but if modulus or hardness of two different materials are being compared it is crucial to ensure that the systems are behaving similarly. It is not appropriate to compare hardness or modulus if, in one case, a crack had formed and in the other material it had not, as the conventionally used models used to extract properties such as hardness and modulus during nanoindentation were developed for bulk materials that exhibited uniform elastic-plastic deformation and do not consider fracture.

In this paper we assess the suitability of using idoxuridine to serve as a surrogate for the mechanical response of HMX using nanoindentation for granular solids in the sub-mm regime, taking into account possible differences in material fracture behavior when comparing mechanical properties. We use two different indenter tips to conduct unloading analysis to investigate cracking and supplement this with scanning probe microscopy. We also find that using the samples as-received is sufficient for accurate data collection.

2. Results and Discussion

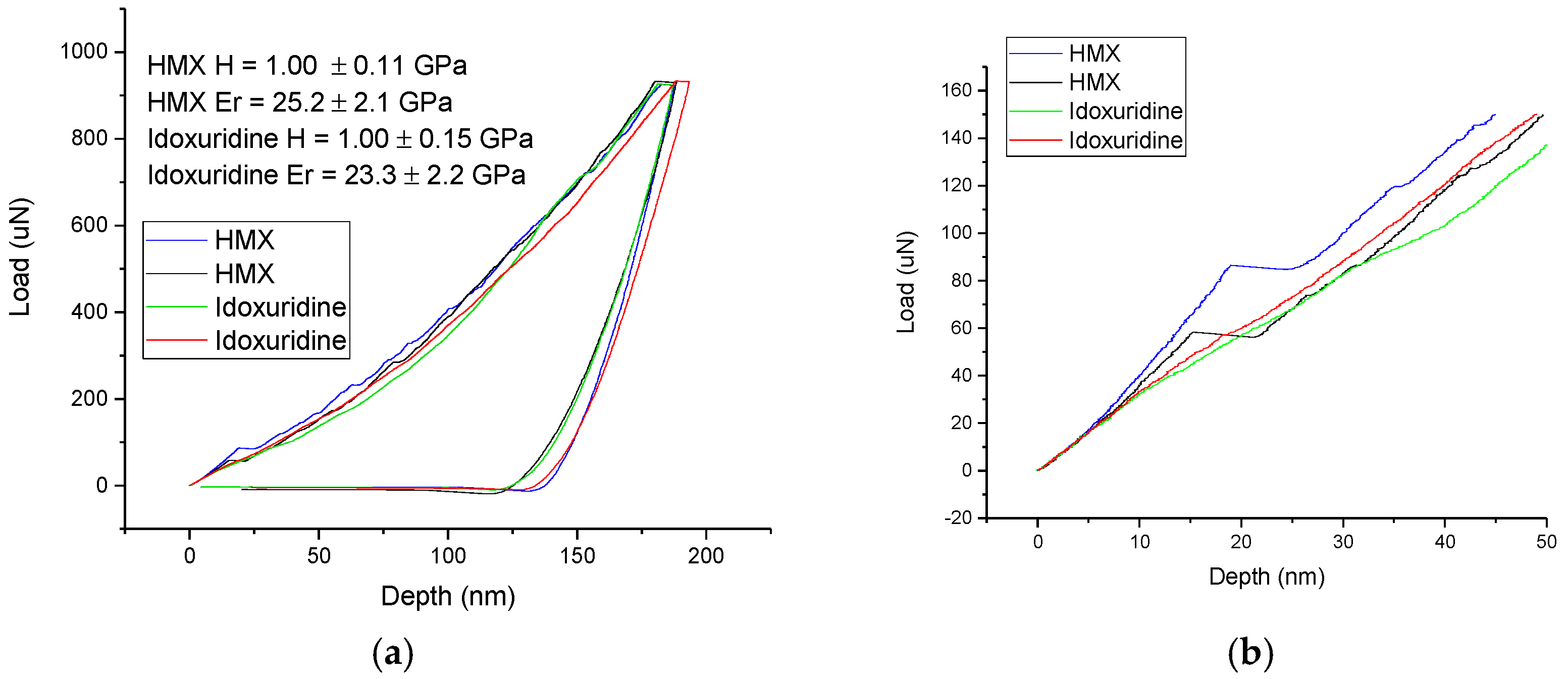

Hardness and elastic modulus measurements were taken using a Berkovich indenter probe at 1000 μN in both materials; the resulting load-displacement data is shown in

Figure 1.

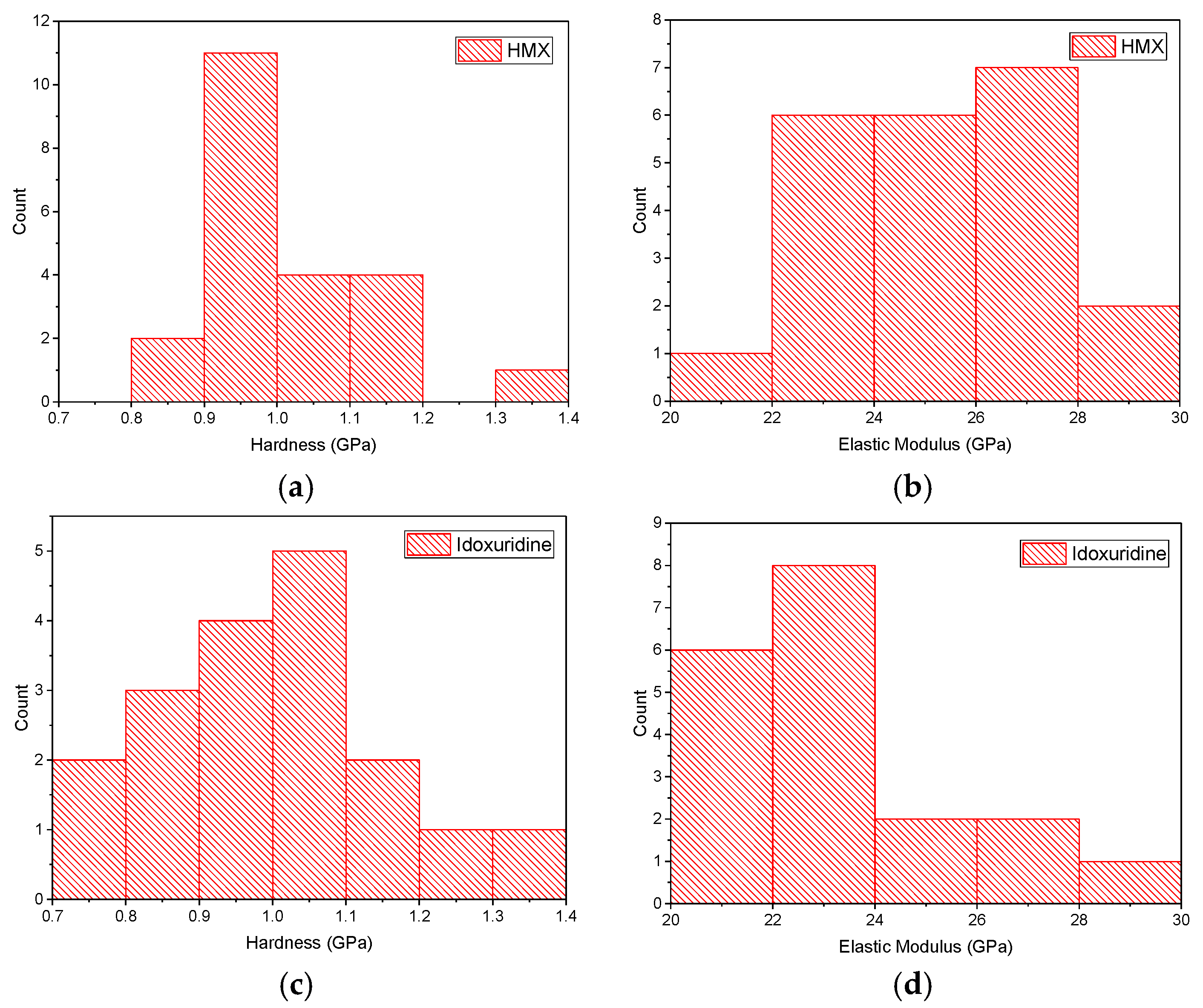

For HMX, 22 indents were done on approximately 10 different crystals. Some crystals were only measured once, while others were large enough to accommodate multiple indents; all indentations were spaced at least 10 times across the residual impression diameter to ensure the pristine material was being evaluated. The average hardness measured for HMX was 1.00 ± 0.11 GPa, and the average reduced elastic modulus measured for HMX was 25.2 ± 2.1 GPa. On idoxuridine, 19 indents were done on approximately 10 crystals, with an average hardness measurement of 1.00 ± 0.15 GPa, and an average reduced elastic modulus measurement of 23.3 ± 2.2 GPa. The distribution of these measurements is shown in

Figure 2. A Wilcoxon rank-sum test comparing the hardness of HMX to the hardness of idoxuridine gave a

p value of 0.9167, so the hardness of the two materials is not significantly different. For comparing elastic modulus, a Wilcoxon rank-sum test gave a

p value of 0.007, indicating that the elastic moduli of these materials are statistically different. However, because the elastic moduli of the two materials are within 10% of each other, they are likely similar enough to be considered “mocks” in many situations. For example, sucrose is considered a mechanical mock but has much higher elastic modulus, between 33 and 38 GPa depending on orientation [

6].

As noted in

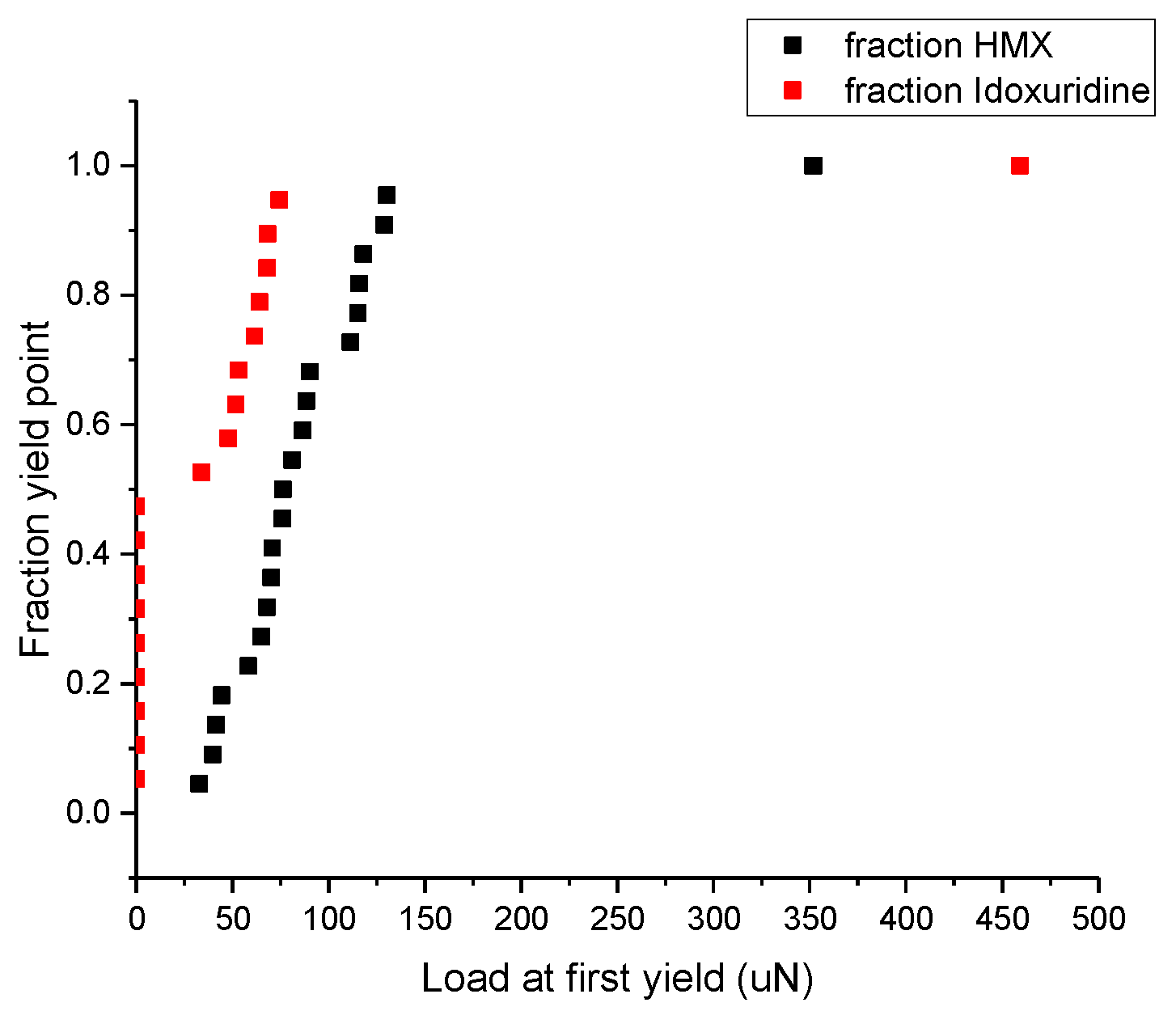

Figure 1, many indentations exhibited a “pop-in” or “excursion” in the load depth curve. This is commonly considered to be indicative of the transition from elastic to plastic deformation. Yield point behavior can be quantified by the load at yield (which is proportional to the maximum applied shear stress for materials with the same elastic modulus when a common tip with a fixed radius is used). In all indentations in HMX the indentation curve exhibited a yield point, while in the case of idoxuridine only half of the indents exhibited a yield point.

Figure 3 shows the difference in the distribution of load at the first yield point for all indentations performed in this study. Using a cumulative distribution plot is a convenient way to determine if different defect densities or mechanisms are being probed [

29], and the relative curvature and position are indicative of an activation energy to nucleate a dislocation when one compares the only the fraction that yielded (ignoring those that exhibit no yield point). In metallic systems, higher defect densities are linked to larger numbers of indentations that do not exhibit a yield point [

30], and surface preparation can shift (in load) or “tilt” in probability the cumulative fraction plot in RDX [

31]. The mean load at yield for indentations that did exhibit a yield pinot for idoxuridine was 98 μN and for HMX was 93 μN, (very similar results); the maximum load exhibited (which previous studies have considered to be linked to approaching the theoretical shear stress in the crystal) are also of a similar magnitude, as one might expect for materials with similar elastic modulus values. Finally, the median of the loads which caused yield are similar for these indentations, 78.5 μN for HMX and 62.8 μN for idoxuridine. The implication here is that while the average shear stress needed to nucleate dislocations in both materials is almost identical, suggesting the nucleation phenomena is based on the same mechanism in both these samples, and the maximum shear stress is of the same order, based on the similarity of the maximum observed value in yield point, the likelihood of probing a mechanical defect (such as a pre-existing dislocation) is much higher in the idoxuridine than in the HMX for the forms of the materials tested in this study.

One concern with assessing brittle molecular solids is the possibility of cracking. Critical loads beyond which there is fracture are often reported for many brittle materials such as RDX [

24] and glass [

23]. Identifying cracking in molecular crystals can be challenging. Two approaches to identifying indent-induced cracking are with post-indent microscopy and with unloading analysis [

28].

Figure 4 shows scanning probe images of indents on HMX and idoxuridine with both Berkovich and cube corner indenter probes, at loads of 500 μN and 5000 μN, where cracking could not be confirmed via microscopy in any of these cases.

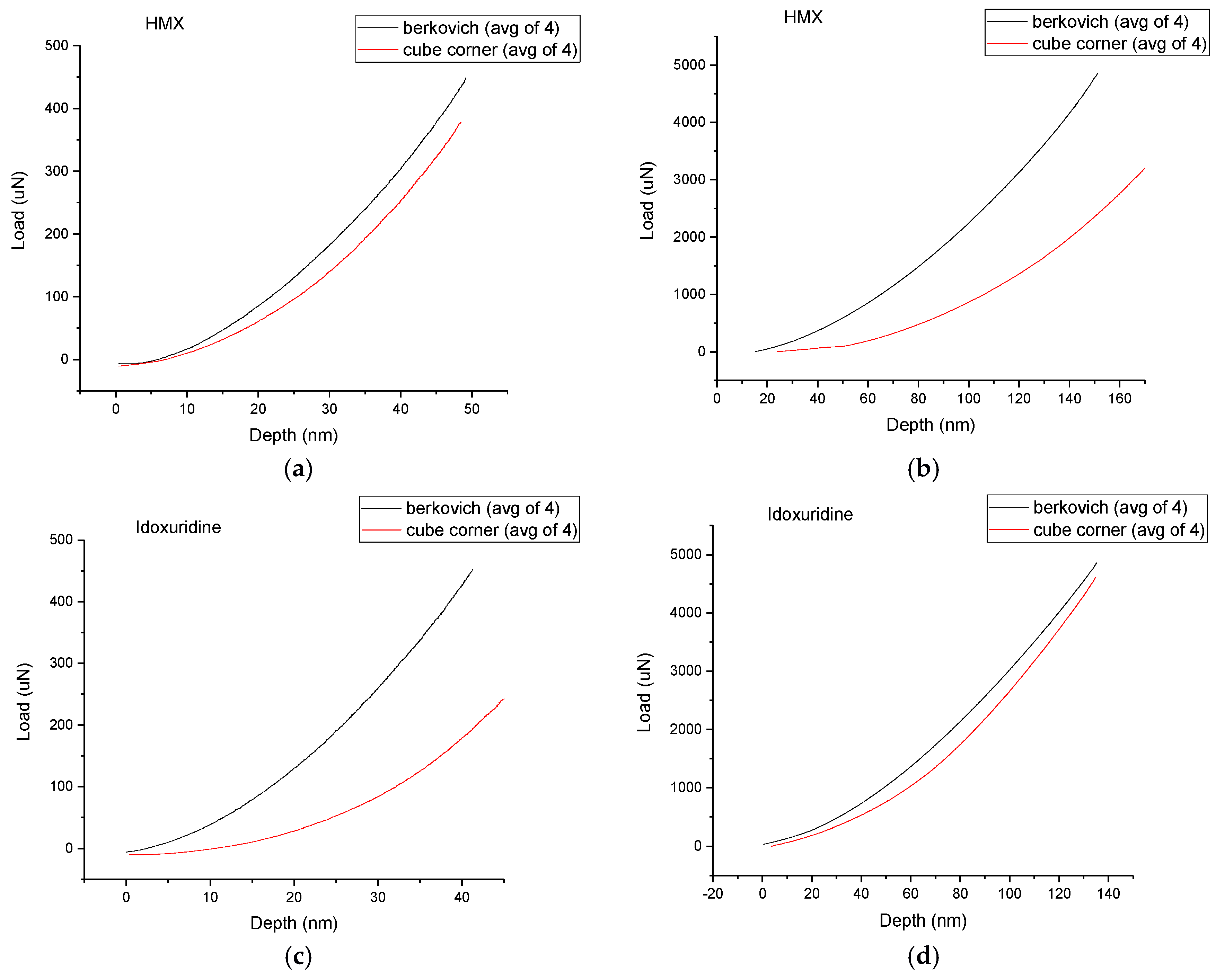

Though scanning probe images do not conclusively show surface cracks, there is still the possibility of subsurface cracking. To attempt to determine whether subsurface cracking occurred, the unloading analysis method of Morris and co-workers was used [

28]. For a specific load, in this case nominal loads of 500 μN and 5000 μN, each material was indented four times with a Berkovich probe and four times with a cube corner probe, and the unloading segment of these indents were averaged, as shown in

Figure 5.

These indentations were carried out on random crystals with no specific orientation. Morris et al. showed that when unloading curves from the same load, using tips of different acuity was superimposable and there was no evidence of cracking, and when the unloading curves were more compliant for the sharper tip this was indicative of cracking during the indentation. While it was not possible to exactly reproduce the conditions used by Morris and coworkers in this study, the general similarity, or lack thereof, was used in this study to indicate a propensity for indentation induced fracture. For some crystals (orientations), there is no significant evidence of cracking with acute probes (

Figure 5a,d show very similar unloading slopes), while other individual crystals exhibit evidence of cracking (

Figure 5b,c). In all cases, there has been no direct evidence of cracking caused by a Berkovich indenter using post indent microscopy. The range of unloading behavior suggest that there is a variation between crystal faces, crystal orientations, and probe orientations in the subsequent fracture behavior that is not present in the more uniformly distributed hardness and modulus measurements. In particular, for HMX there appears to be a cracking threshold (at loads above 1 mN we consistently observed a more compliant unloading curve, indicative of fracture), while for idoxuridine some indentations at low loads show fracture with the cube corner tip (

Figure 5c), while fracture doesn’t appear at higher loads (

Figure 5d). This variation in idoxuridine may be tied to the behavior noted in

Figure 3, which indicated that the crystal to crystal variation in defect density was more significant for idoxuridine than HMX. However, without the current ability to index the individual crystals that were tested, the supposition that it is orientation-dependent cracking, and not some other crystal to crystal variation, that is leading to the less reproducible behavior in compliance on unloading is only one possible explanation, and this area of inquiry requires further study.

3. Materials and Methods

HMX and idoxuridine, shown in

Figure 6, were provided by Los Alamos National Laboratory. HMX single crystals were recrystallized in acetone from Class 1 HMX produced by Holston. Idoxuridine was originally purchased from Chem-Impex International, Inc. and recrystallized in water.

All samples were mounted using the technique described by Maughan et al. [

32] for mounting small crystals. To briefly summarize, a flat face of a crystal was placed on an aluminum block, and a commercially available AFM “puck” (a 7 mm diameter steel disc) was suspended above the crystal by a magnet with an adhesive on the downward face of the disc. The disc was lowered such that the adhesive came in contact with the crystal, and upon inversion of the disc, the surface of the crystal was the flat face that had previously rested on the aluminum block and was therefore parallel to the AFM disc and normal to the indenter probe. Nanoindentation was performed using a Hysitron Triboindenter 950, with both Berkovich and cube corner indenter probes with tip radii of approximately 600 nm and 140 nm, respectively. All indents were quasistatic open-loop with 30 s loading, 5 s hold, and 5 s unload times; this loading profile was used in prior studies of RDX and some other organic molecular crystals [

5]. The unloading curves were analyzed using the Oliver and Pharr technique; the tip had been calibrated in fused quartz and aluminum prior to indentation accounting for

S (unloading stiffness),

P,

h, and

A being load, depth, and contact area, respectively, a geometric constant γ.

and modulus,

where

Er is the reduced modulus, accounting for the Young’s Modulus,

E and Poisson’s ratio,

υ, of the indenter tip (

i) and sample (

s). While

E and

υ of the diamond indenter tip are well known (1249 GPa and 0.07, respectively), we do not know for certain the Poisson’s ratio of these samples, and therefore this paper reports only

Er. Imaging (

Figure 4) was carried out using the Hysitron scanning probe mode, where the tip making the indentation is used to image as a fixed load (in this case 2 μN).