Electronic and Optical Properties of Dislocations in Silicon

Abstract

:1. Introduction

2. Dislocations in Silicon

2.1. General Aspects

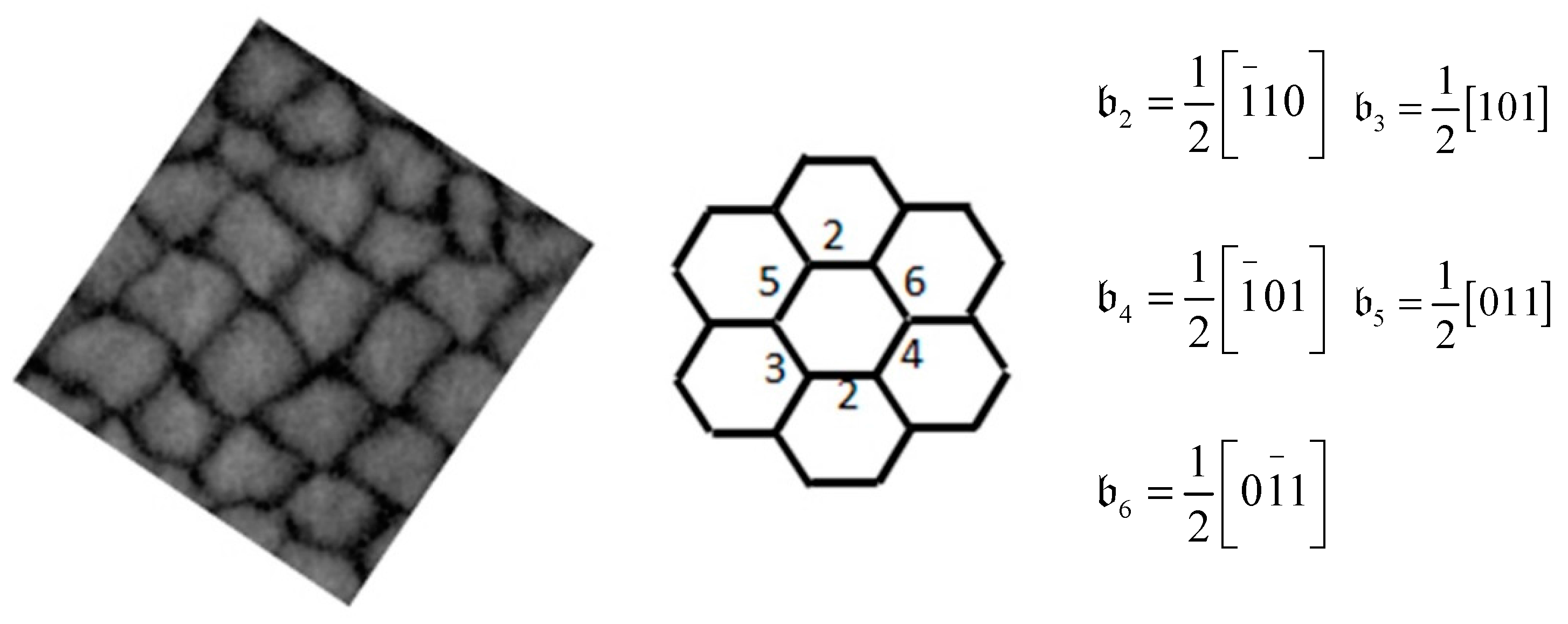

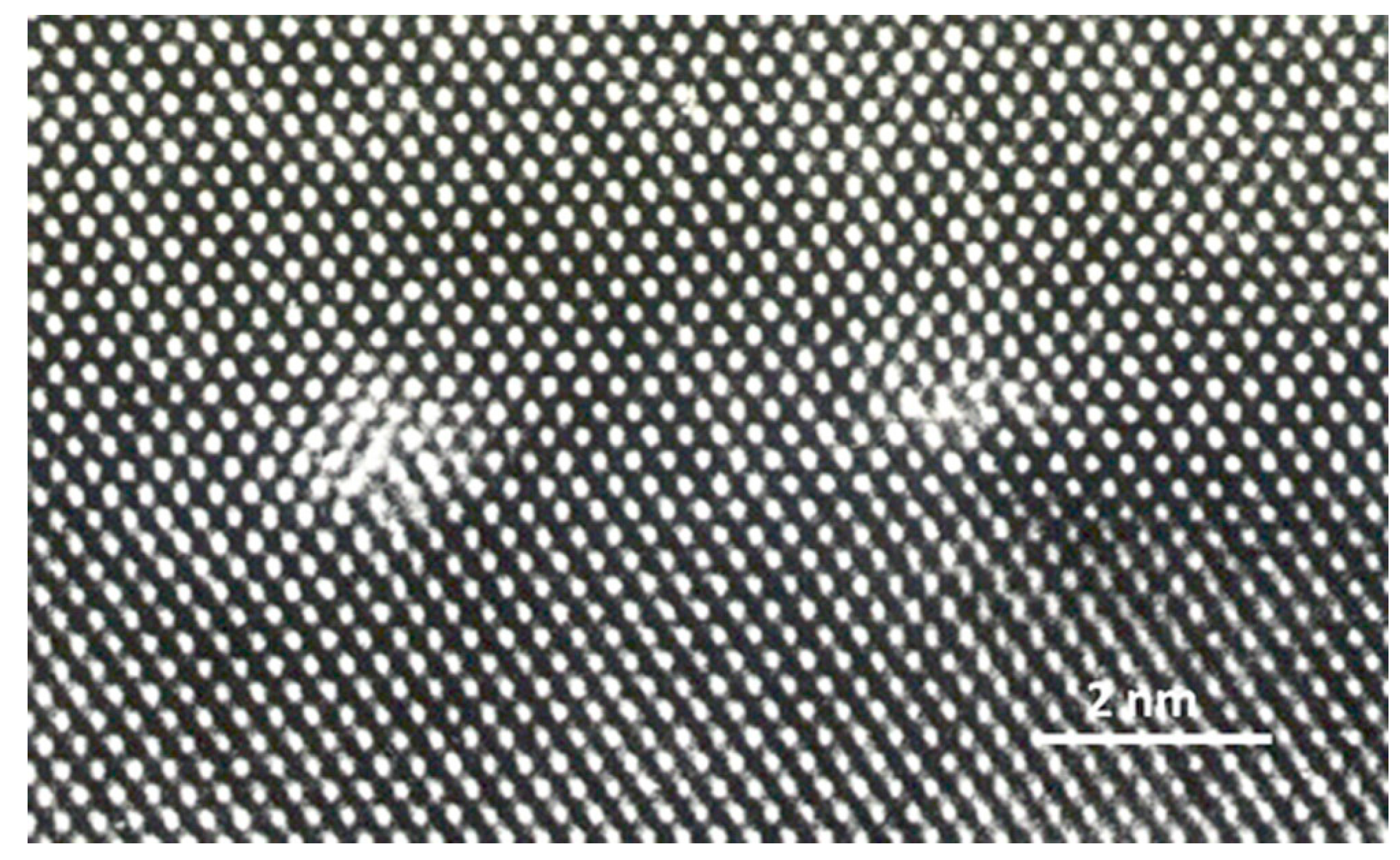

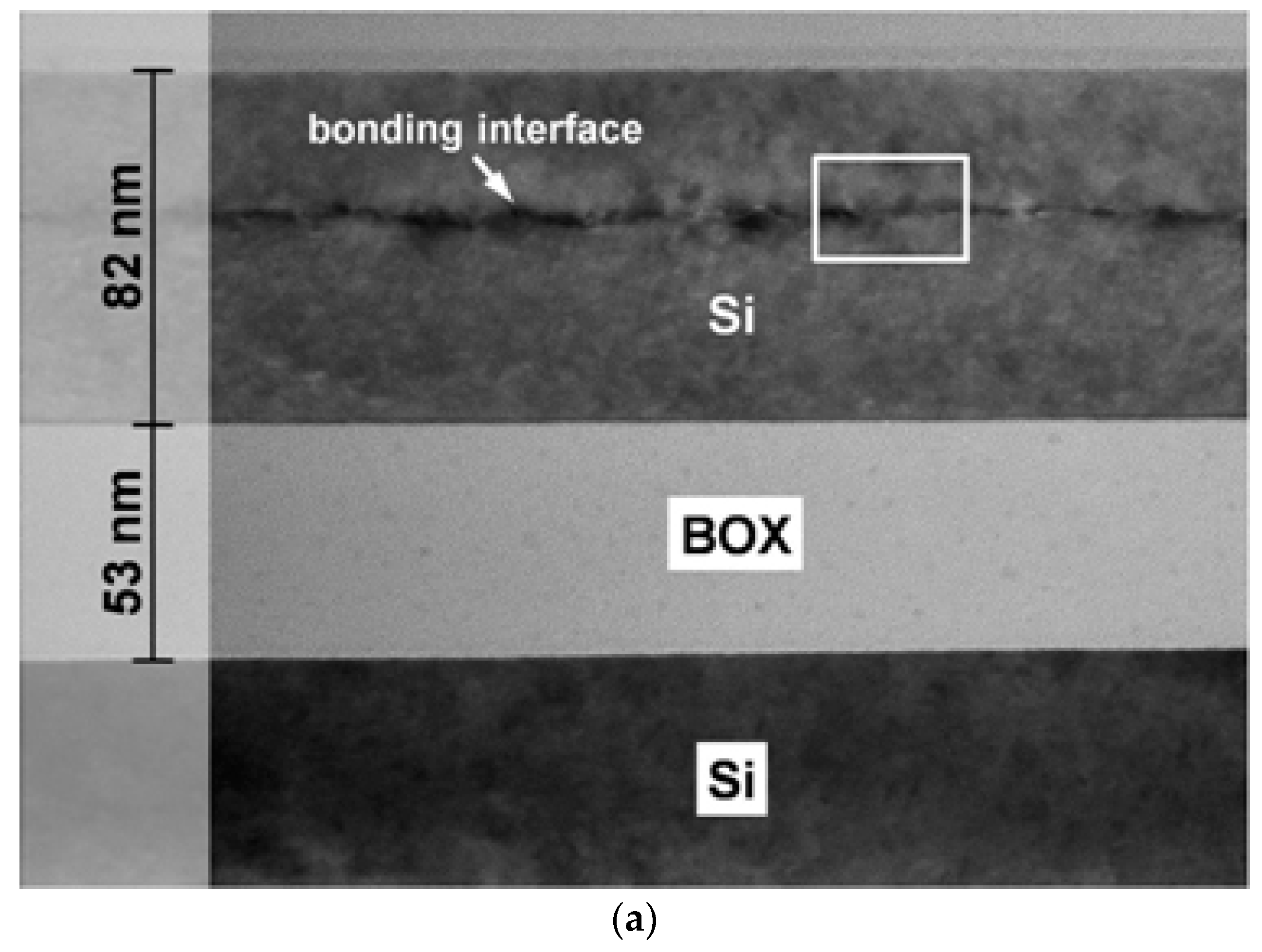

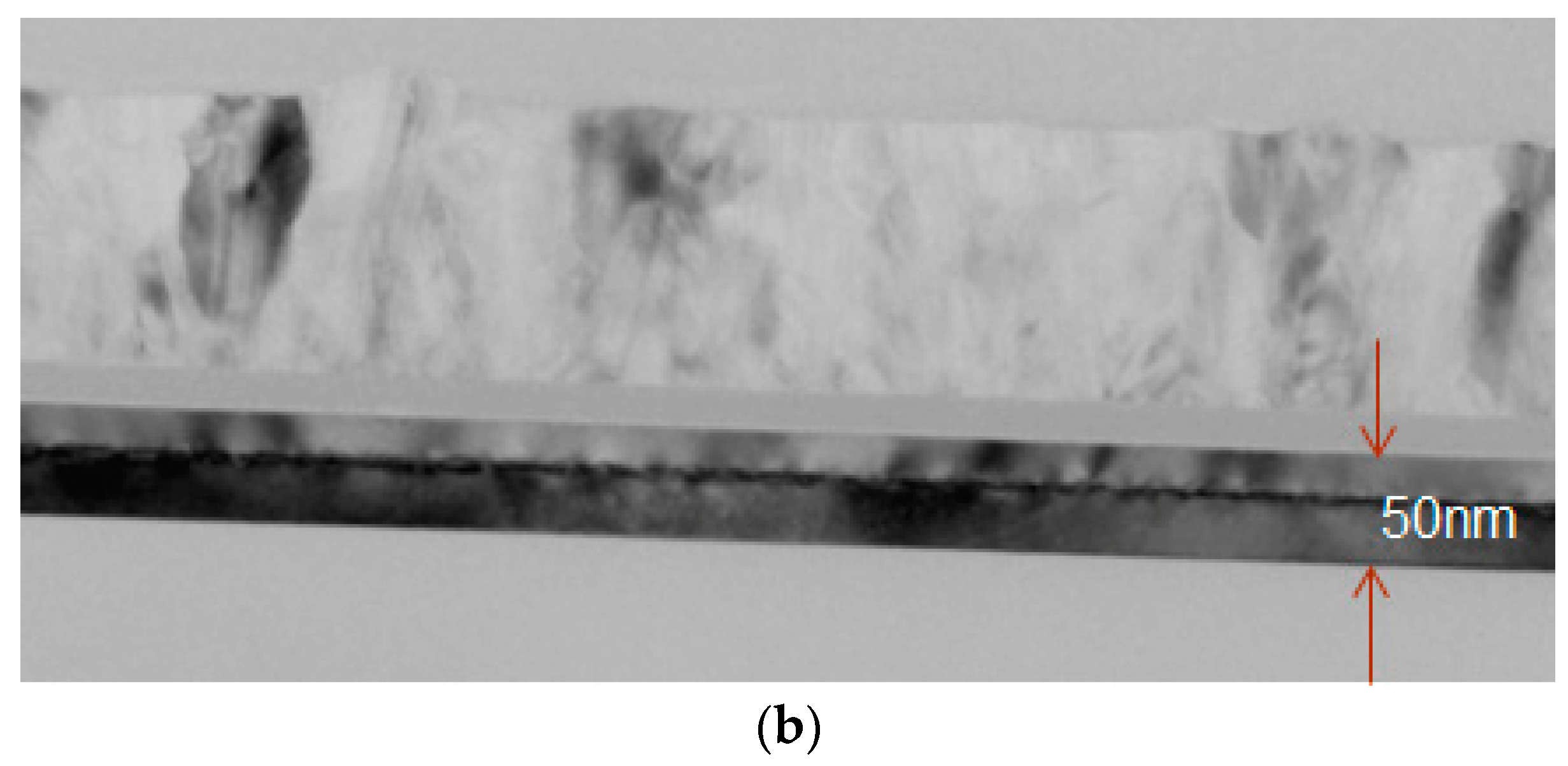

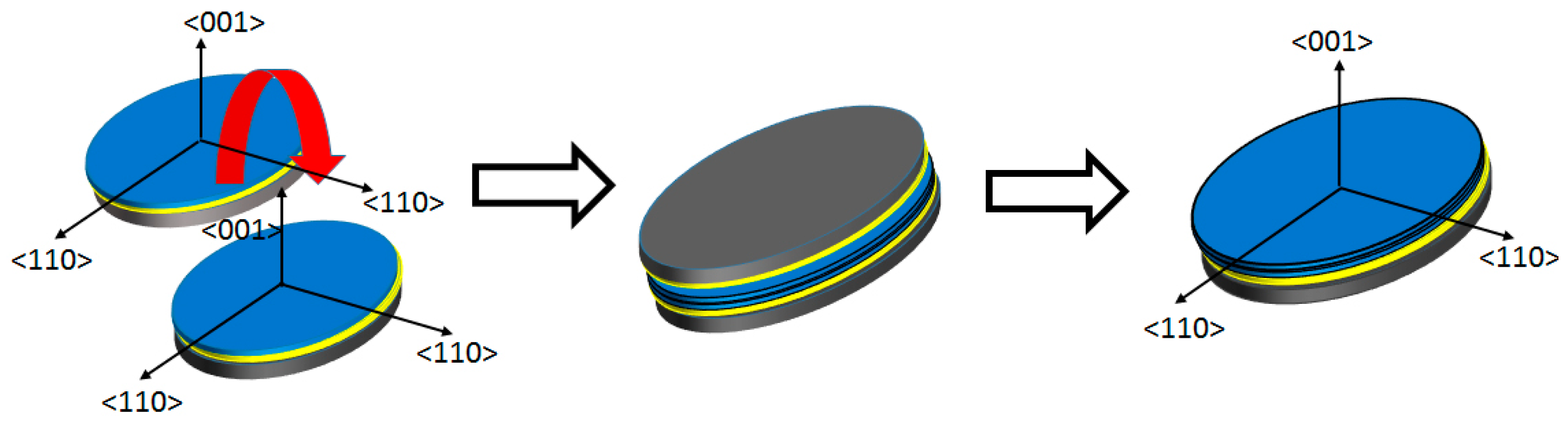

2.2. Two-Dimensional Dislocation Networks

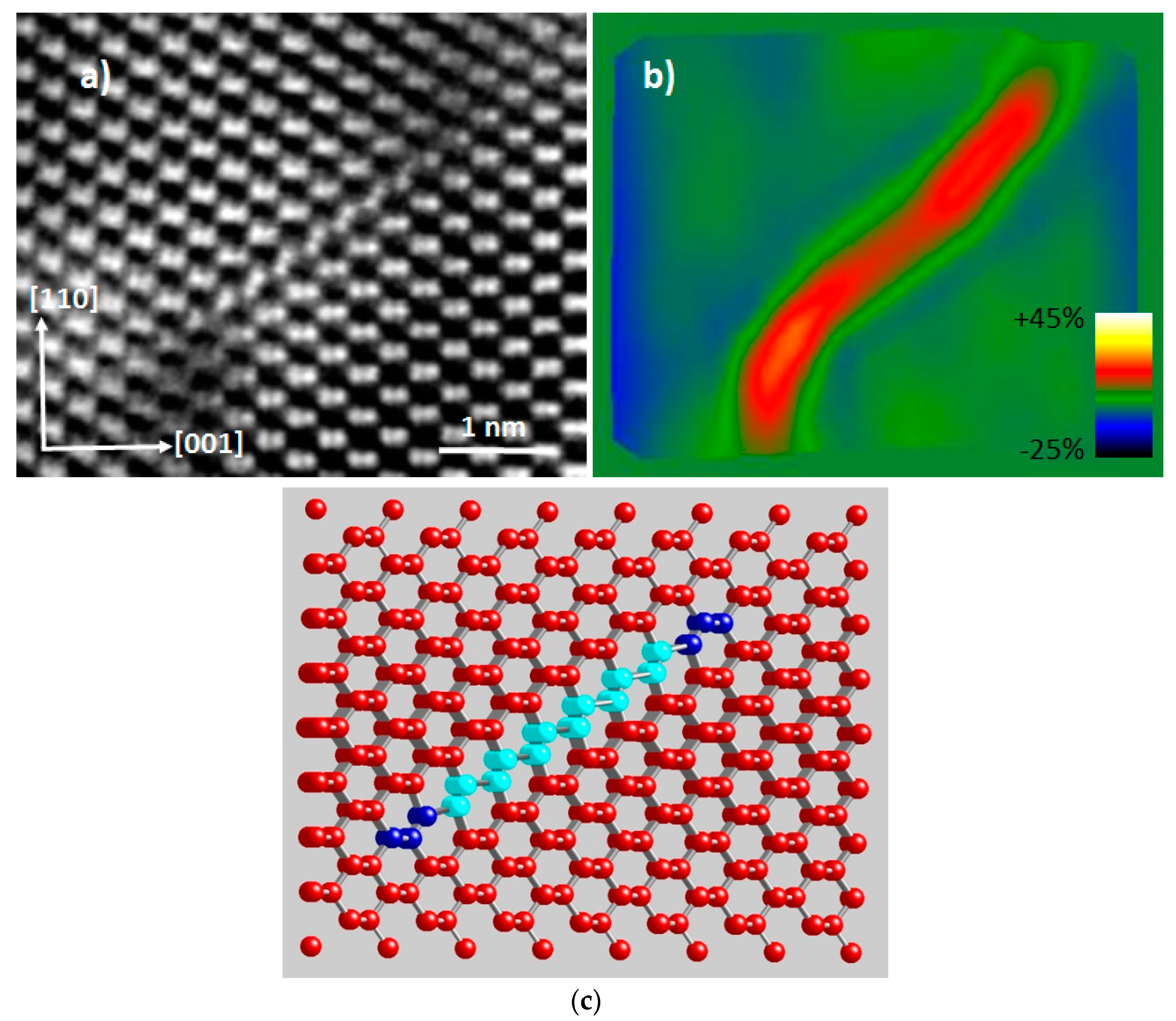

2.3. Structure of Individual Dislocations

3. Electronic and Optical Properties of Dislocations in Silicon

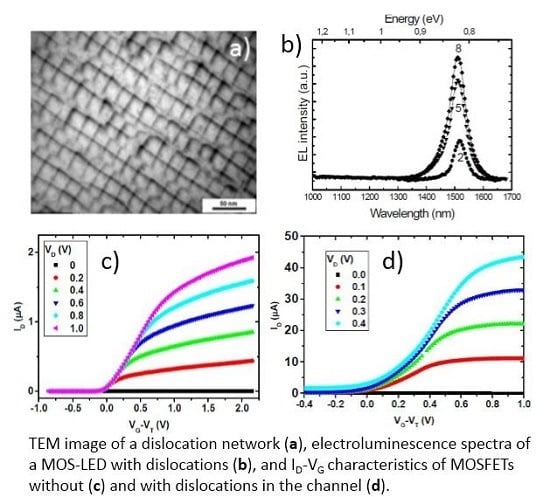

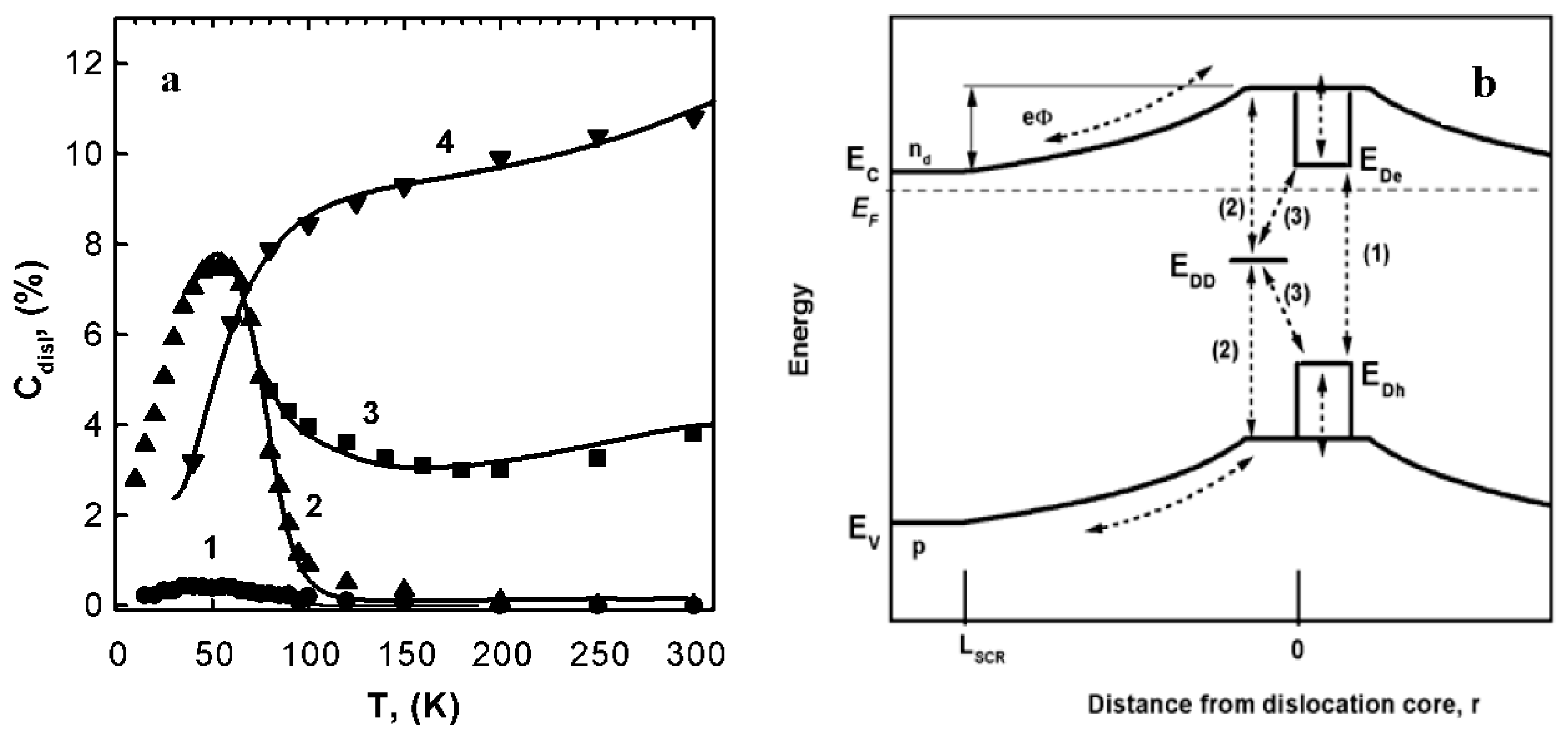

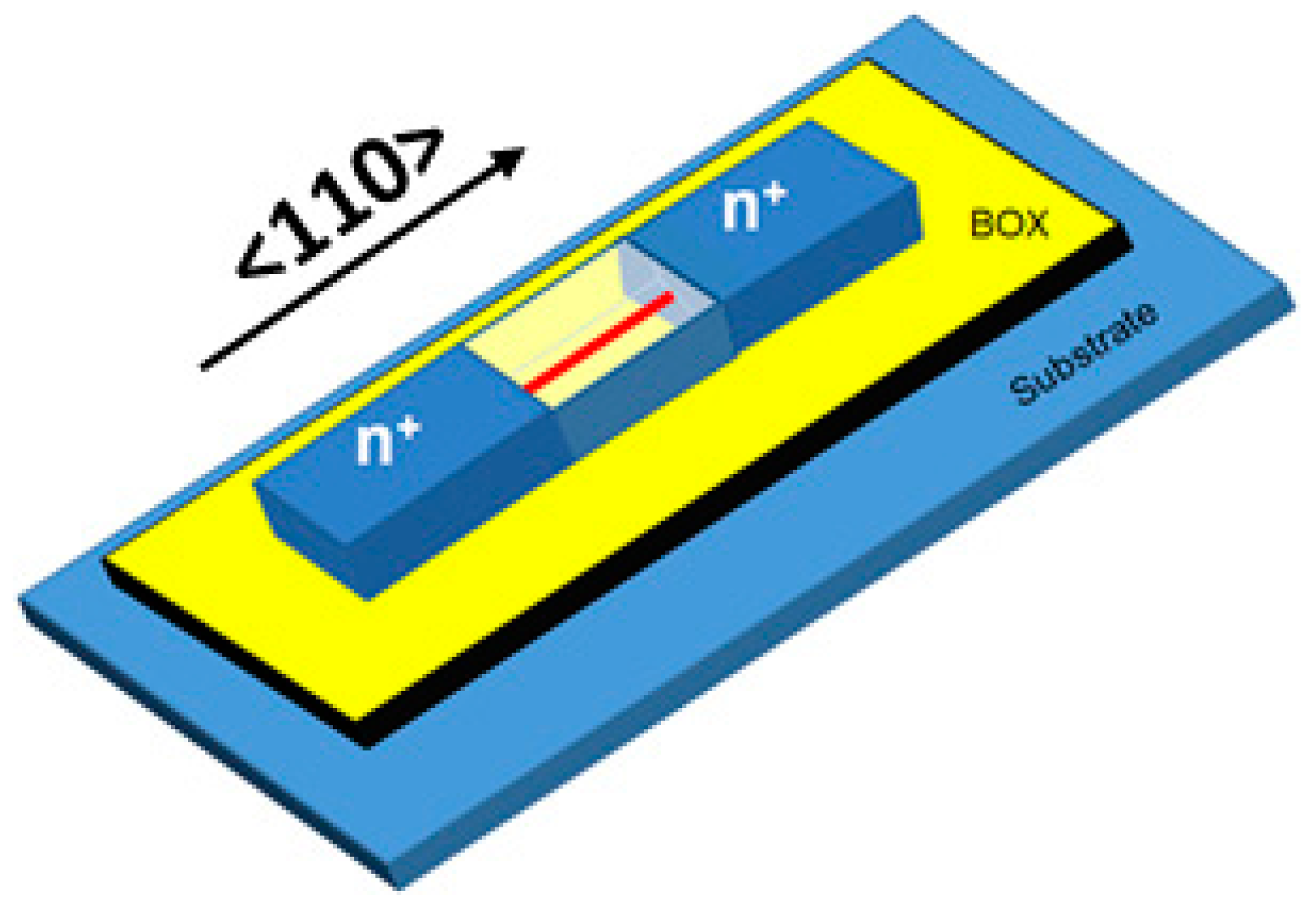

3.1. Electrical Measurements on Dislocations

3.2. Comparison with Theory

- (i.)

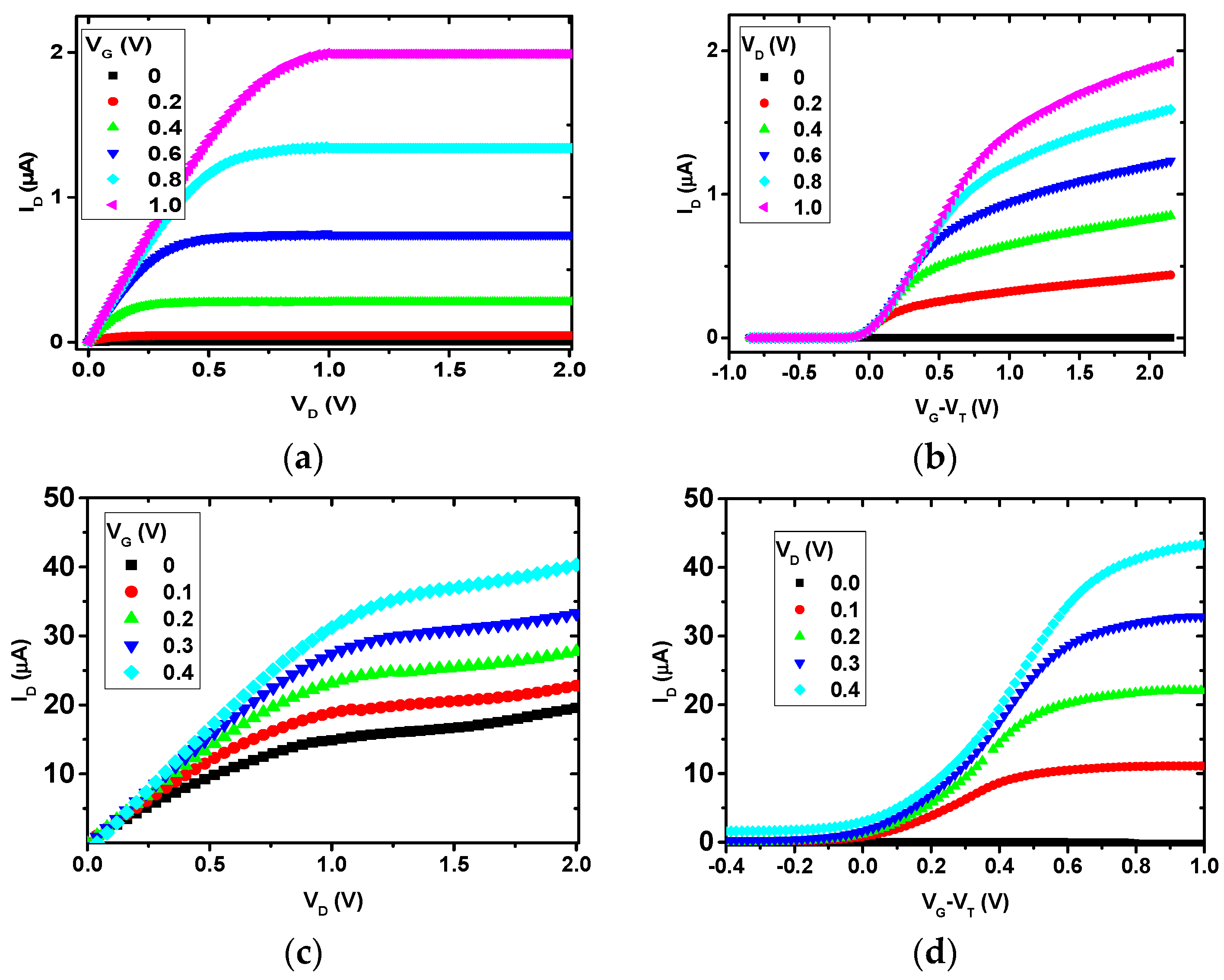

- An increase in the drain current for nMOSFETs results from an increased electron transport along dislocations in the device channel. Note that the channel material is p-type silicon for nMOSFETs.

- (ii.)

- An increase in the drain current also exists for pMOSFETs, where holes are involved in the carrier transport. The channel material here is n-type silicon.

- (iii.)

- There are dislocations (mixed dislocations) that may transport electrons and holes in the same time.

- (iv.)

- Measurements at very low temperatures (T < 1 K) proved the functionality of MOSFETs having dislocations in the channel. Ionized impurity atoms in the surrounding cylinder screening the line charge of the dislocation core, would be completely froze out at this extremely low temperatures. Then, according to the models of Read and Schröter and Labusch, only a line charge of the same type as the bulk material remains. Note that reference devices without dislocations in the channel do not operate at such temperatures.

- (v.)

- It would be also conceivable that, supposing the charges on the dislocation core are bounded to atoms, they are increasingly immobile at very low temperatures. This, however, is in contrast to the obvious facts of the MOSFET functionality at T < 1 K and the supermetallic behavior at higher temperatures.

- (i.)

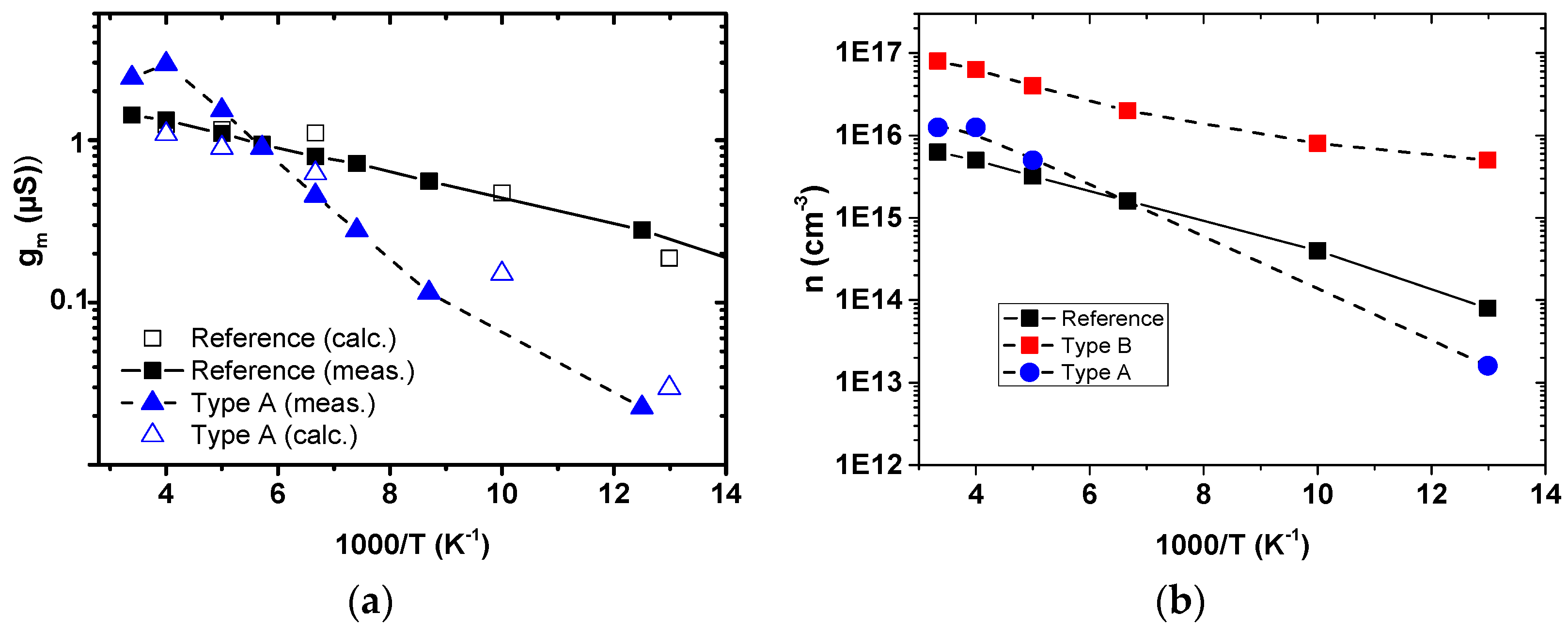

- Dislocations are characterized by dimensions of a few nanometers in diameter and up to a few micrometers in length. This means that dislocations are native nanostructures embedded in a crystalline matrix and therefore quantum mechanical effects play an important role for interpretation of their electronic properties.

- (ii.)

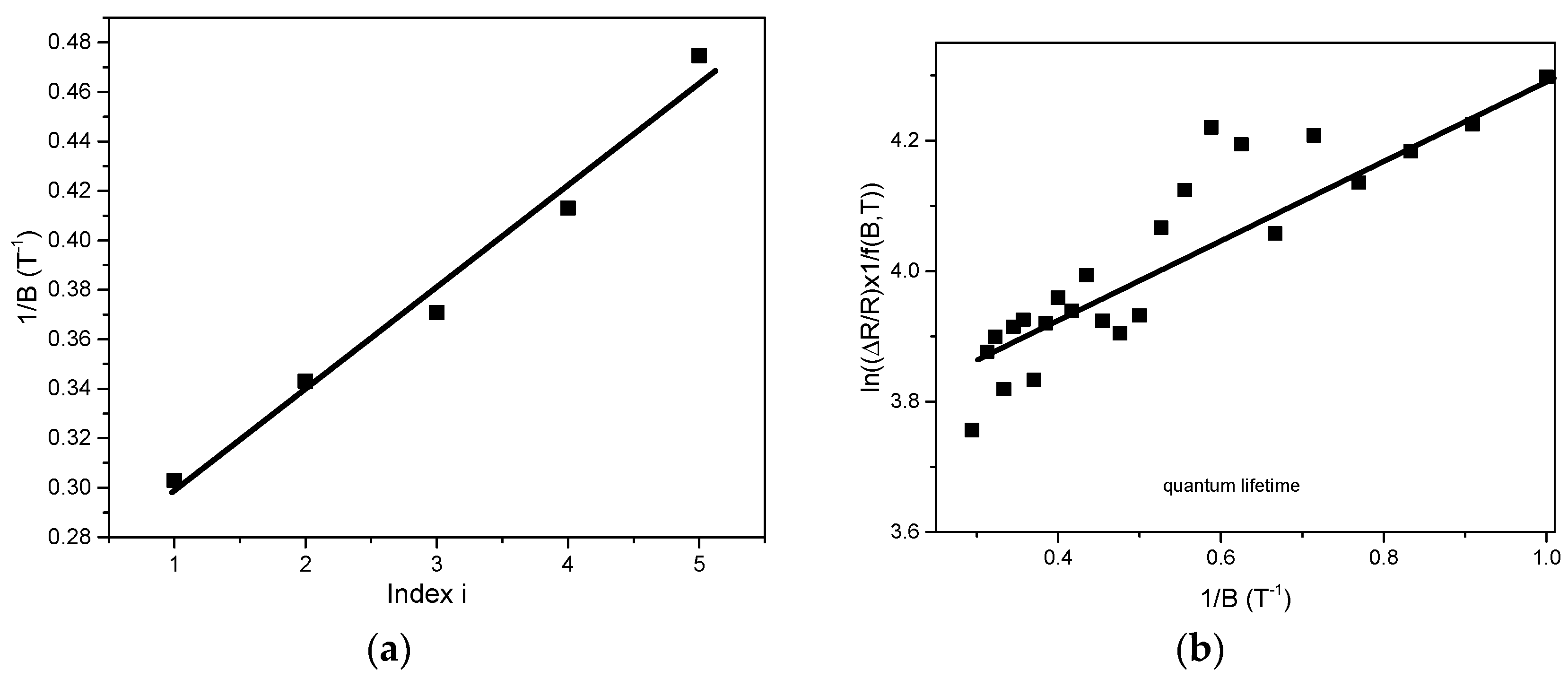

- Low-temperature measurements proved a two-dimensional electron gas (2DEG) for samples containing a dislocation network. The 2DEG of the network consists of a number of one-dimensional electron gases (1DEGs) on individual dislocations.

- (iii.)

- The electron gas is the reason for the supermetallic behavior and makes it possible that MOSFETs operate at extremely low temperatures.

- (iv.)

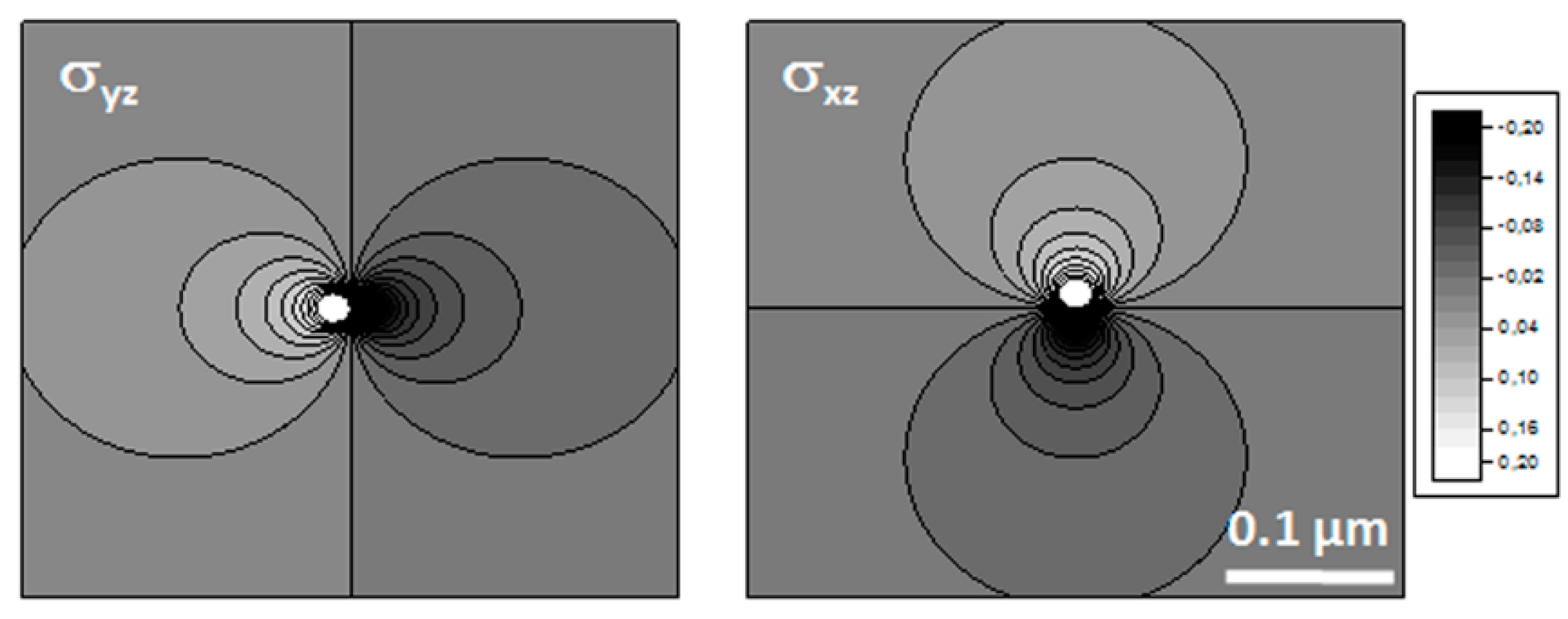

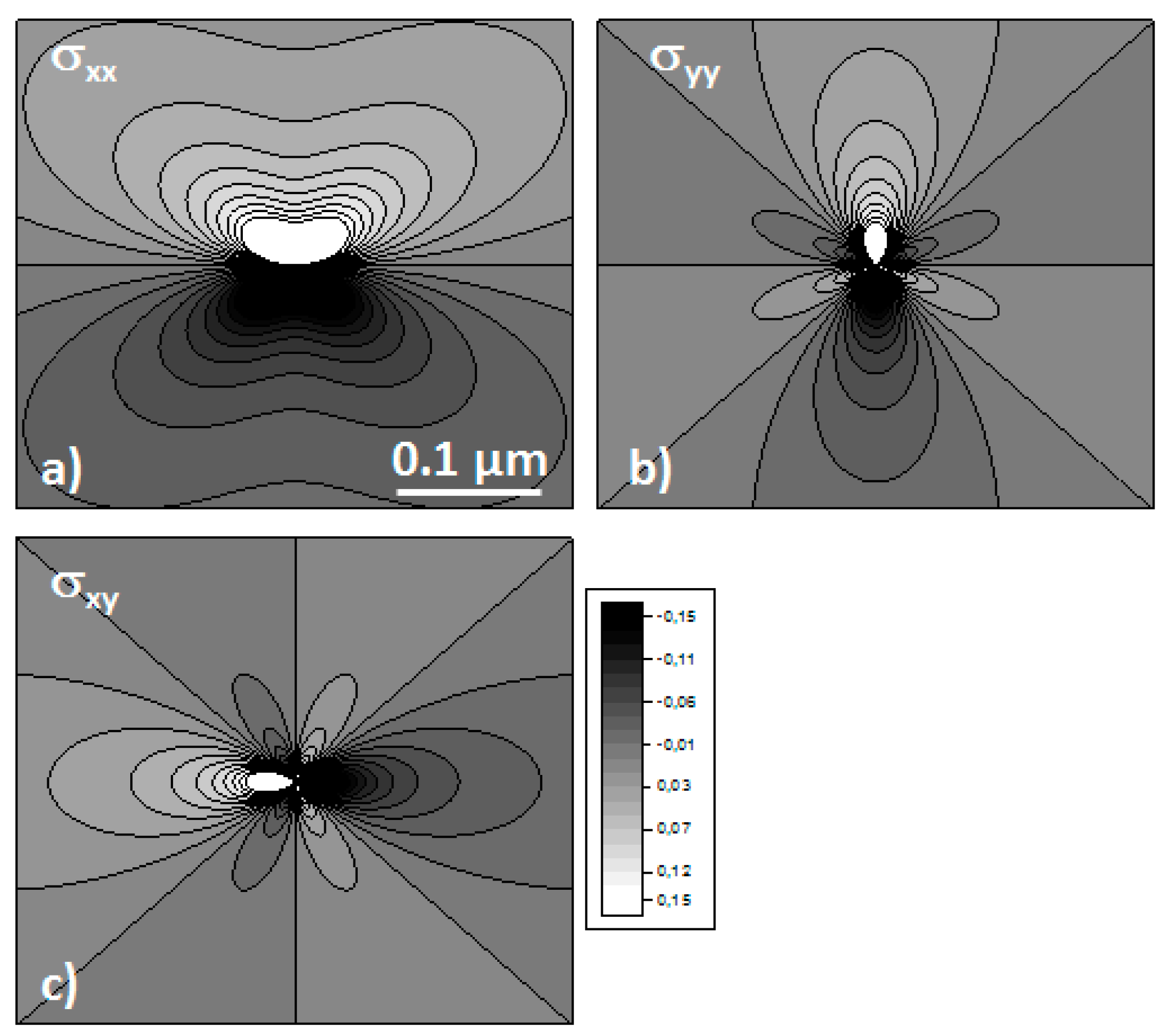

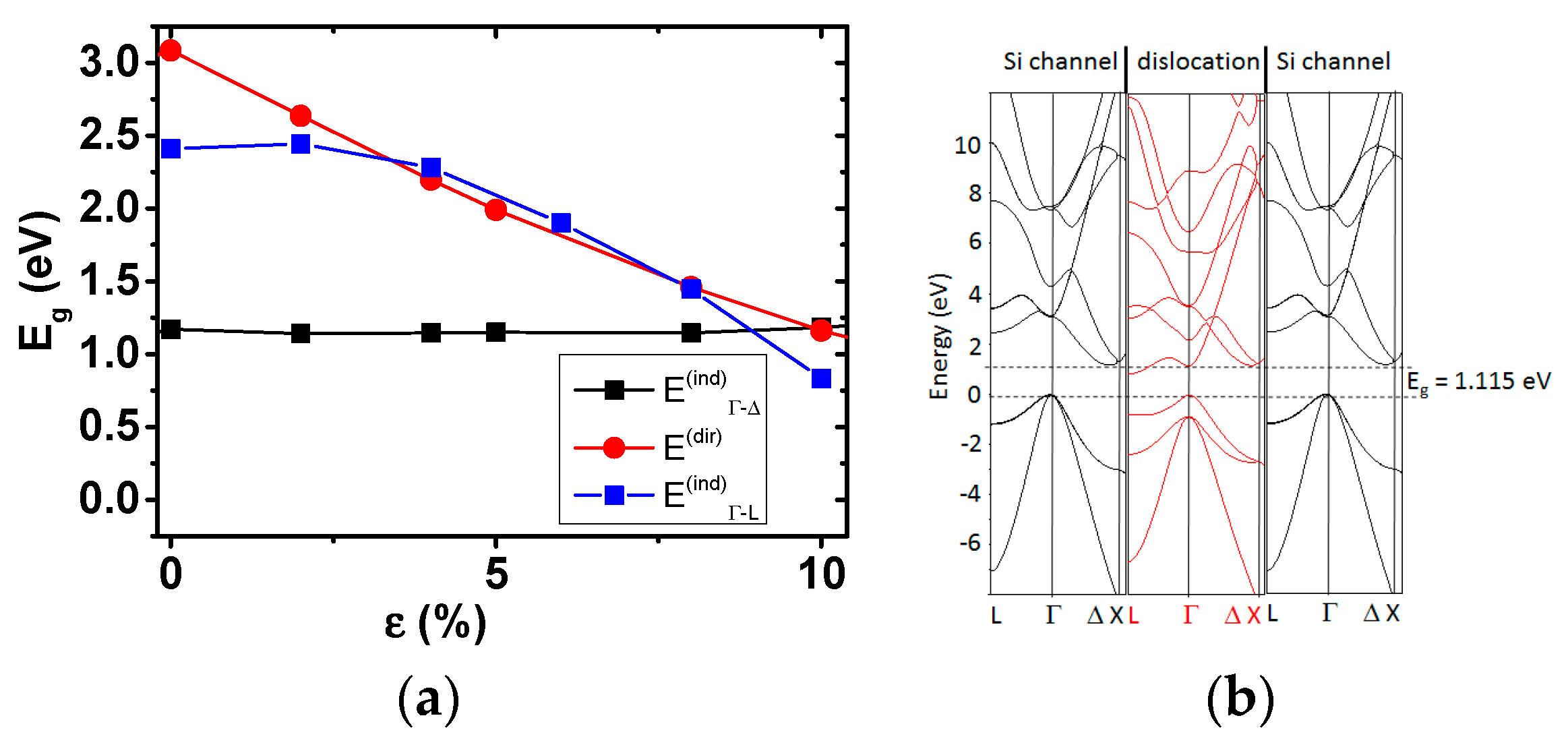

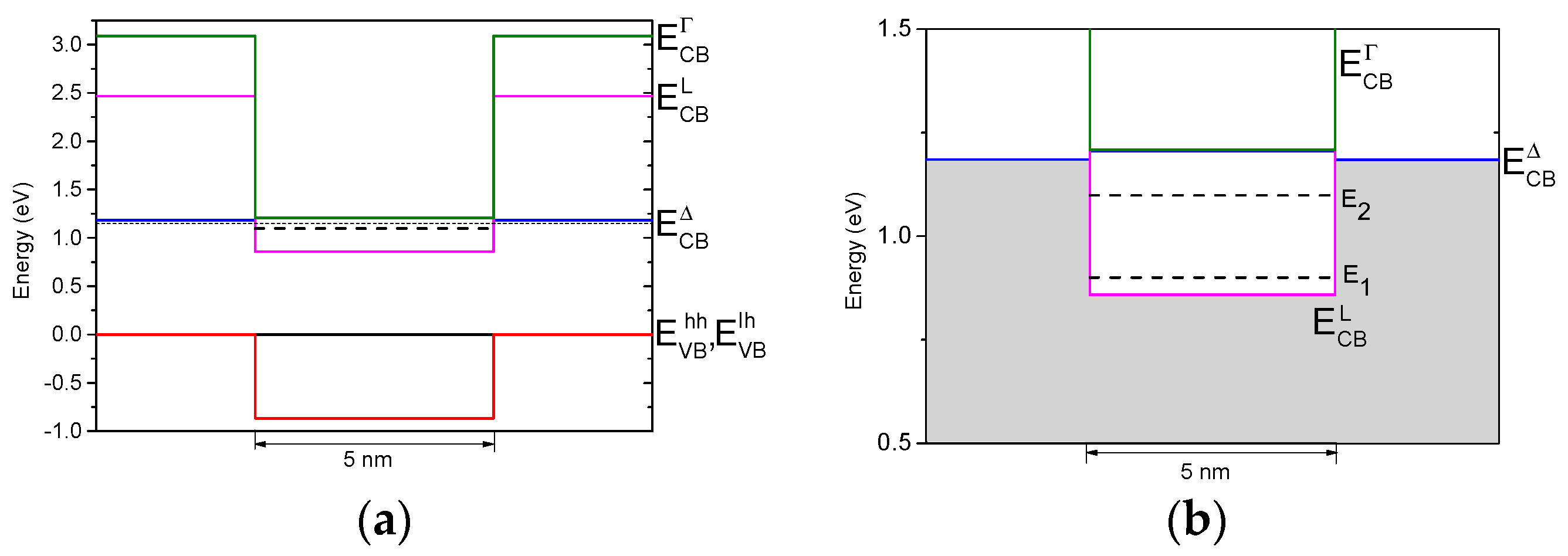

- Electron microscopy proved high strain levels on the core of dislocations. The strain is in the order of 10% (ε ≅ 0.1) corresponding to a stress of σ ≅ 16 GPa. Such values are about two orders of magnitude higher than in the long-range stress field around the defect. The stress is uniaxial tensile in the case of screw dislocations and compressive for edge dislocations.

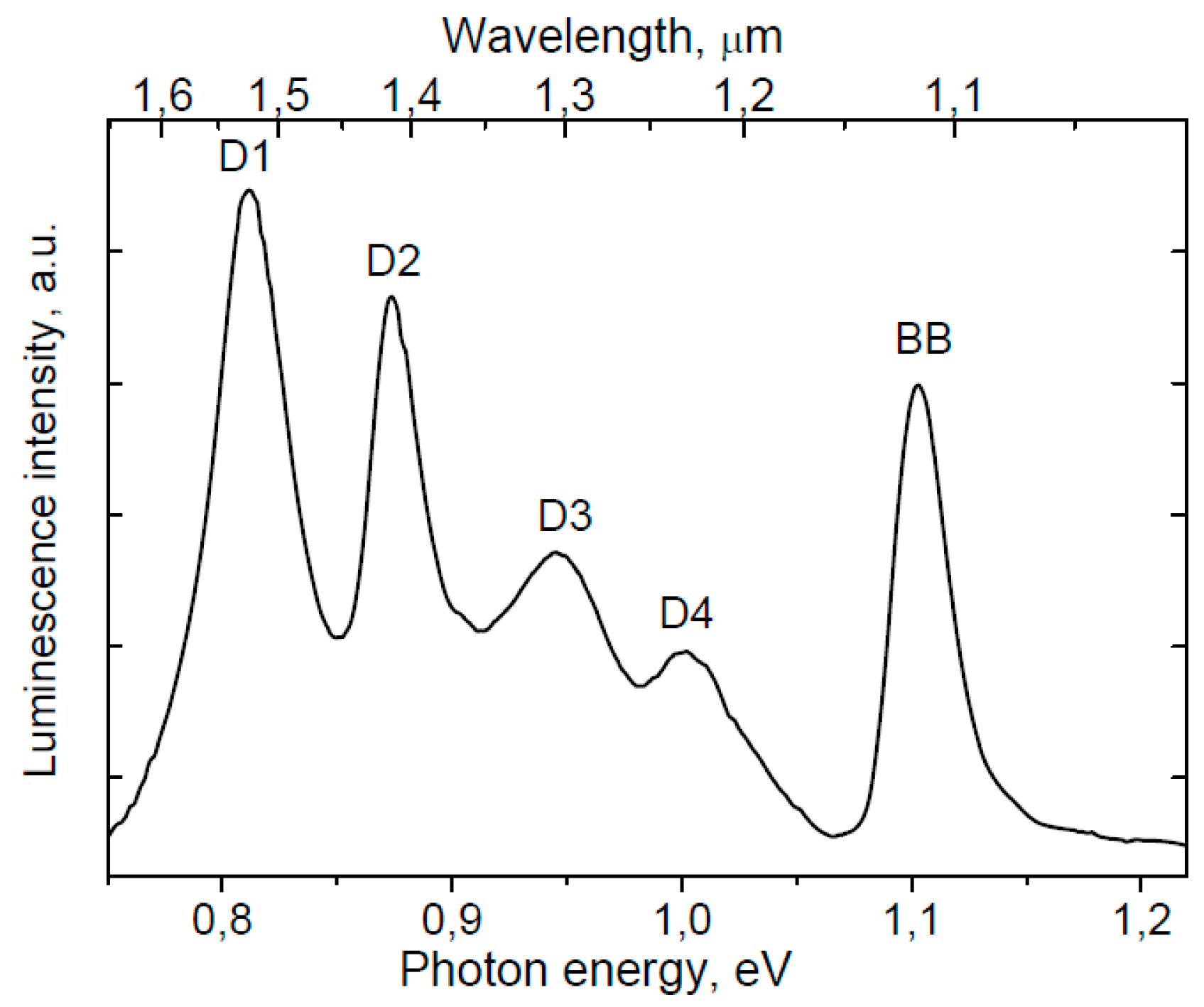

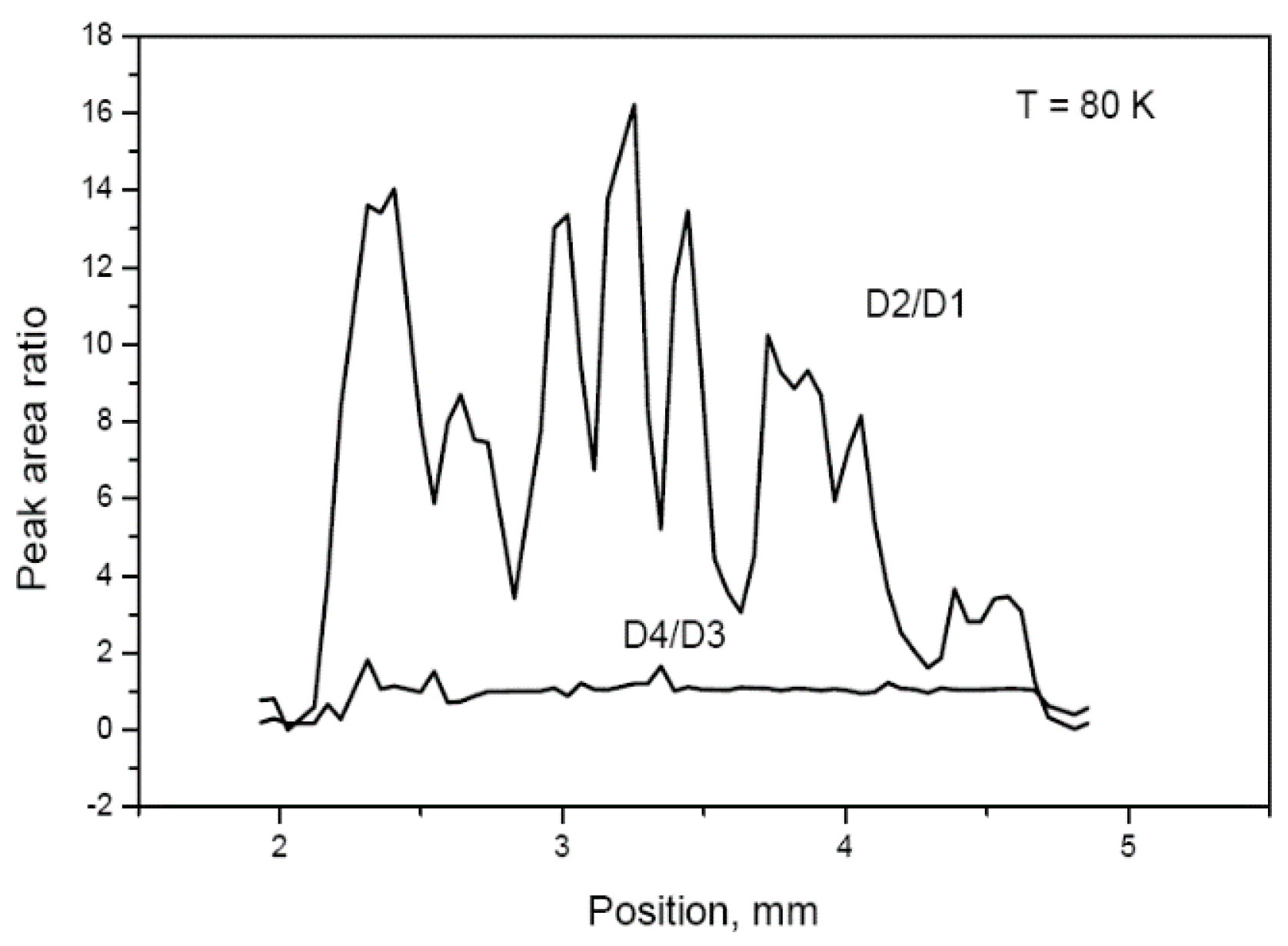

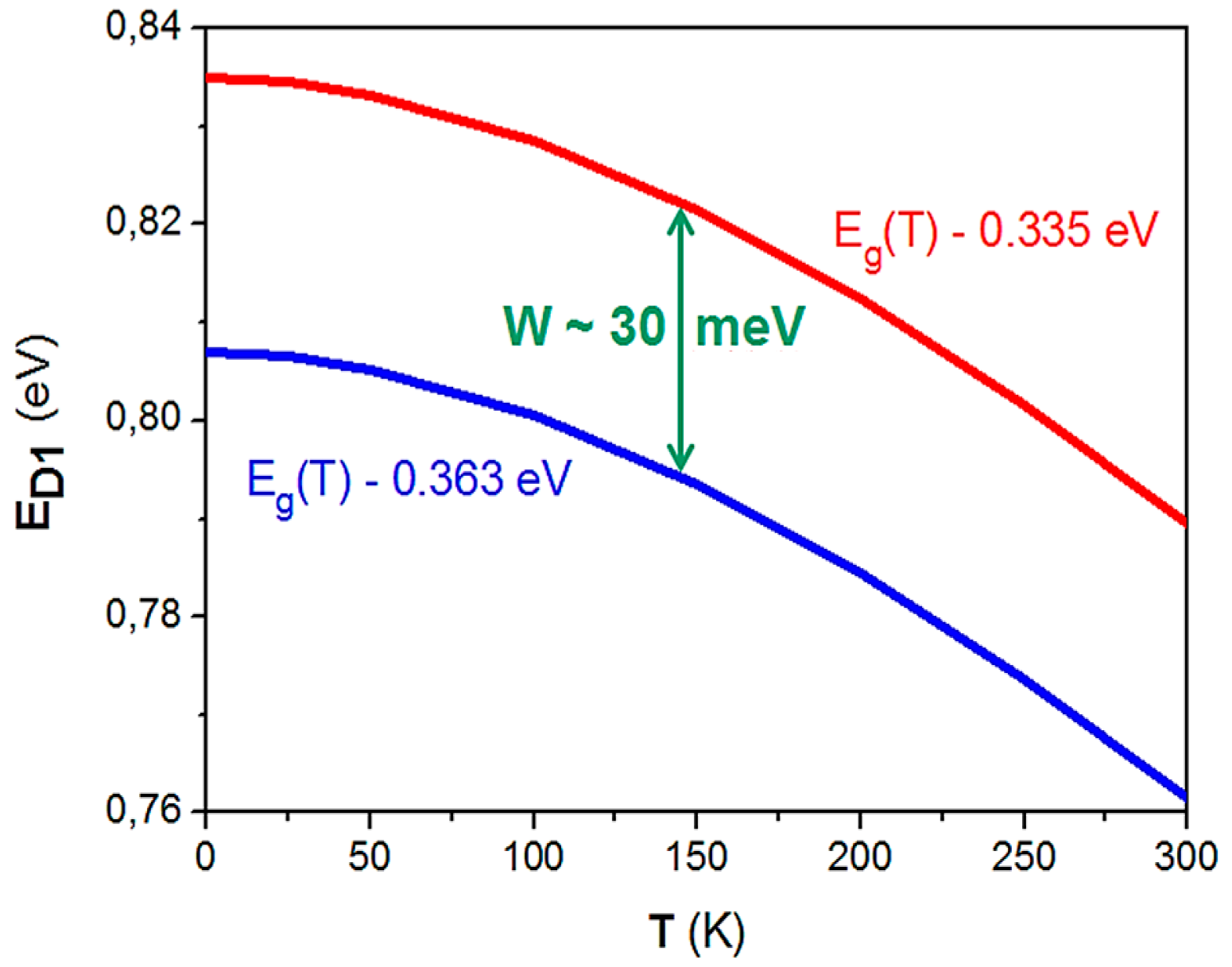

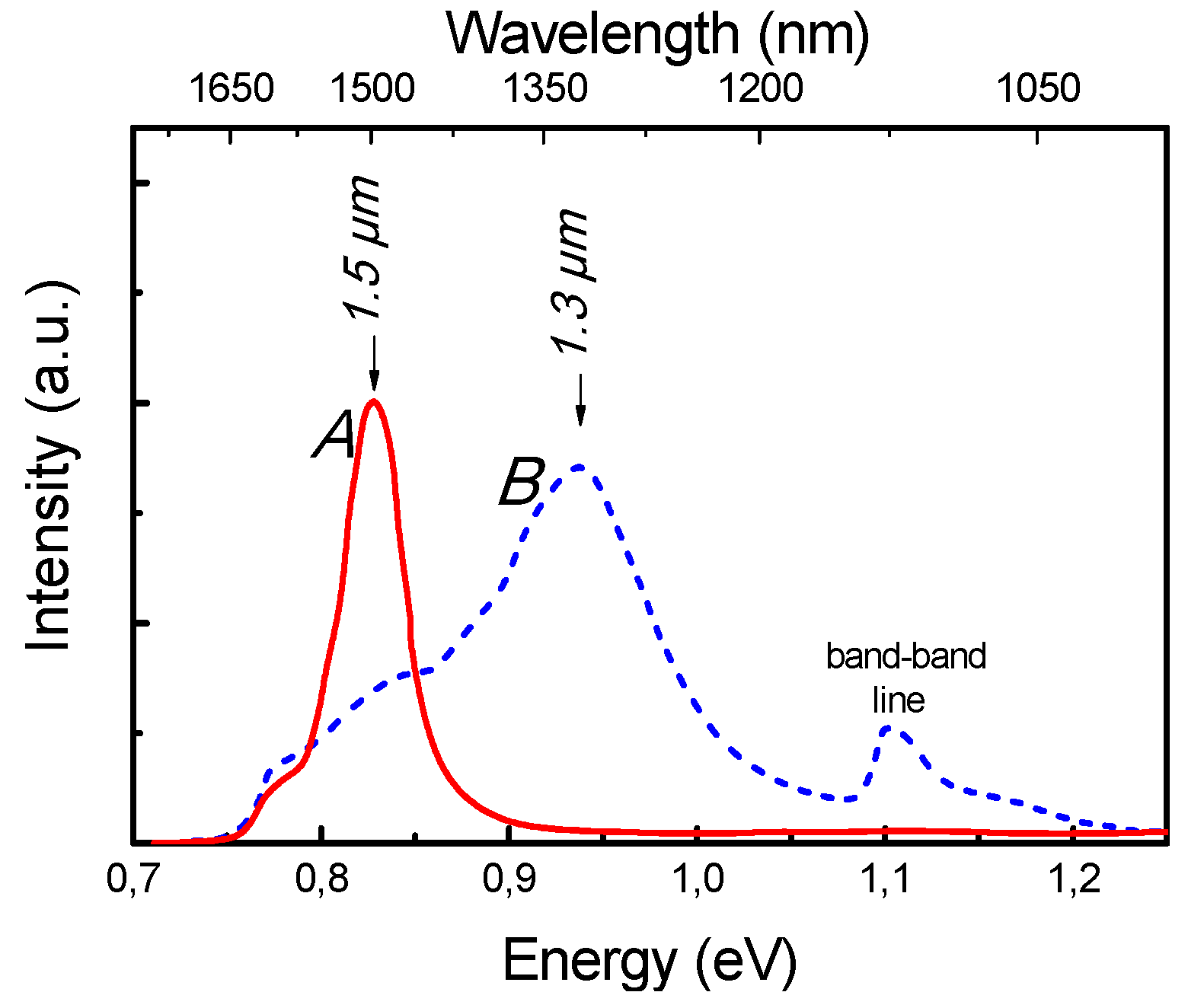

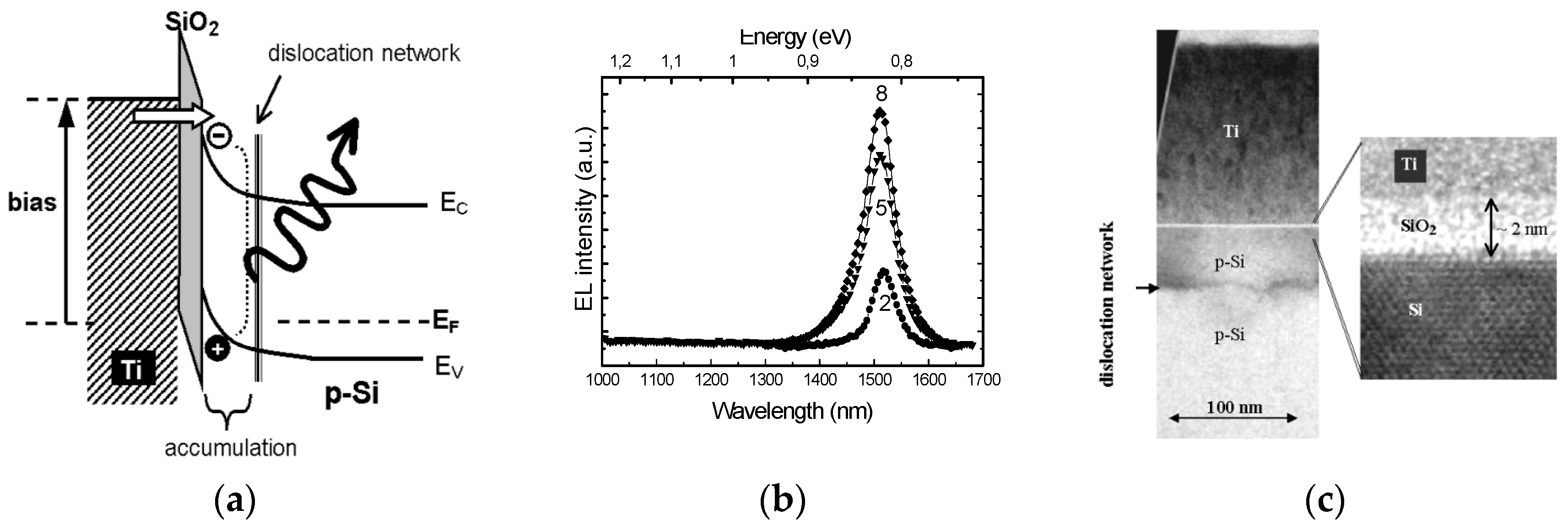

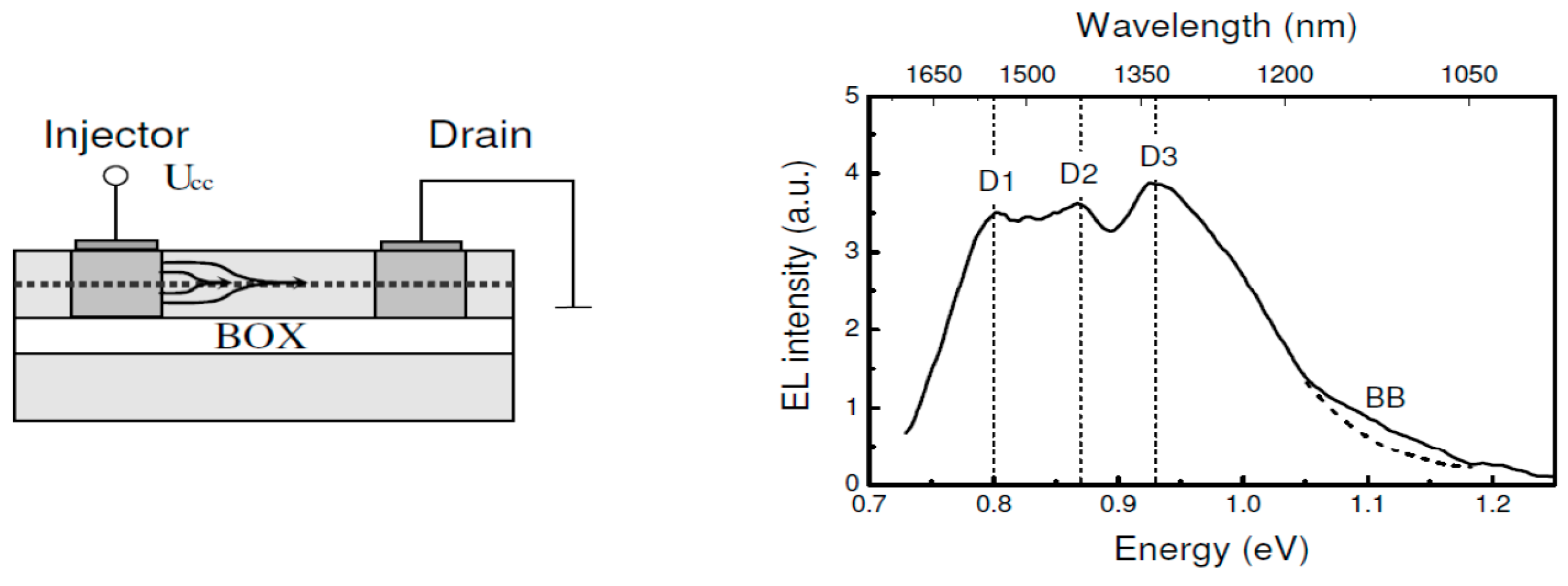

3.3. Optical Properties of Dislocations—Electron-Hole Recombination at Dislocations

4. Materials and Methods

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Vainshtein, B.K.; Fridkin, V.M.; Indenbom, V.L. Modern Crystallography 2: Structure of Crystals; Springer: Berlin, Germany, 2000; pp. 330–399. [Google Scholar]

- Weingarten, G. Sulle superficie di discontinuitá nella teoria della elasticitá dei corpi solidi. Rend. Reale Accad dei Lincei Classe di Sci. Fis. Mater. Nat. Ser. 5 1901, 10, 57–60. [Google Scholar]

- Michell, J.H. On the direct determination of stress in an elastic solid, with application to the theory of plates. Proc. Lond. Math. Soc. 1899, 31, 100–124. [Google Scholar] [CrossRef]

- Timpe, A. Probleme der Spannungsverteilung in ebenen Systemen, einfach gelöst mit Hilfe der Airyschen Funktion. Z. Math. Phys. 1905, 52, 348–383. [Google Scholar]

- Volterra, V. Sur l′équilibre des corps élastiques multiplement connexes. Ann. Scientif. Éc. Norm. Sup. 3e Sér. 1907, 24, 401–517. [Google Scholar]

- Love, A.E.H. A Treatise on the Mathematical Theory of Elasticity; Cambridge University Press: Cambridge, UK, 1927; pp. 221–228. [Google Scholar]

- Orowan, E. Zur Kristallplastizität III. Z. Phys. 1934, 89, 634–659. [Google Scholar] [CrossRef]

- Polanyi, M. Über eine art gitterstörung, die einen Kristall plastisch machen könnte. Z. Phys. 1934, 89, 660–664. [Google Scholar] [CrossRef]

- Taylor, G.I. The mechanism of plastic deformation of crystals. Part I.—Theoretical. Proc. R. Soc. Lond. 1934, 145, 362–387. [Google Scholar] [CrossRef]

- Taylor, G.I. The mechanism of plastic deformation of crystals. Part II.—Comparison with observations. Proc. R. Soc. Lond. 1934, 145, 388–404. [Google Scholar] [CrossRef]

- Frank, F.C.I. Liquid crystals—On the theory of liquid crystals. Discuss. Faraday Soc. 1958, 25, 19–28. [Google Scholar] [CrossRef]

- Dewit, R. Theory of disclinations: II. Continuous and discrete dislclinations in anisotropic elasticity. J. Res. Nat. Bur. Stand. A Phys. Chem. 1973, 77, 49–100. [Google Scholar] [CrossRef]

- Kröner, E.; Anthony, K.-H. Dislocations and disclinations in material structures: The basic topological concepts. Annu. Rev. Mater. Sci. 1975, 5, 43–72. [Google Scholar] [CrossRef]

- Hirth, J.P. A brief history of dislocation theory. Metall. Trans. A 1985, 16, 2085–2090. [Google Scholar] [CrossRef]

- Volmer, M. Kinetik der Phasenbildung; Steinkopff: Dresden, Leipzig, Germany, 1939. [Google Scholar]

- Volmer, M.; Schultze, W. Kondensation an Kristallen. Z. Physik. Chem. 1931, 156, 1–22. [Google Scholar]

- Frank, F.C. The influence of dislocations on crystal growth. Discuss. Faraday Soc. 1949, 5, 48–54. [Google Scholar] [CrossRef]

- Frenkel, J. Zur theorie der elastizitätsgrenze und der festigkeit kristallinischer körper. Z. Phys. 1926, 37, 572–609. [Google Scholar] [CrossRef]

- Hirth, J.P.; Lothe, J. Theory of Dislocations; Wiley: New York, NY, USA, 1982. [Google Scholar]

- Hull, D.; Bacon, D.J. Introduction to Dislocations; Butterworth & Heinemann: Oxford, UK, 2010. [Google Scholar]

- Amelinckx, S. The Direct Observation of Dislocations; Academic Press: New York, NY, USA, 1965. [Google Scholar]

- Hirsch, P.B.; Horne, R.W.; Whelan, M.J. Direct observation of the arrangement and motion of dislocations in Aluminium. Philos. Mag. 1956, 1, 677–684. [Google Scholar] [CrossRef]

- Bollmann, W. Interference effects in the electron microscopy of thin crystal foils. Phys. Rev. 1956, 103, 1588–1589. [Google Scholar] [CrossRef]

- Dash, W.C. Copper precipitation on dislocations in silicon. J. Appl. Phys. 1956, 27, 1193–1195. [Google Scholar] [CrossRef]

- Ravi, K.V. Imperfections and Impurities in Semiconductor Silicon; Wiley: New York, NY, USA, 1981. [Google Scholar]

- Schröter, W.; Labusch, R. Electrical properties of dislocations in Ge and Si. Phys. Stat. Sol. 1969, 36, 539–550. [Google Scholar] [CrossRef]

- Alexander, H.; Teichler, H. Dislocations. In Materials Science and Technology, Vol. 4, Electronic Structure and Properties of Semiconductors; Schröter, W., Ed.; VCH: Weinheim, Germany, 1991; pp. 249–319. [Google Scholar]

- Drozdov, N.A.; Patrin, A.A.; Tkachev, V.D. Recombination radiation on dislocations in silicon (in russisch). Pisma Zh. Eksp. Teor. Fiz. 1976, 23, 651–653. [Google Scholar]

- Drozdov, N.A.; Patrin, A.A.; Tkachev, V.D. Recombination radiation on dislocations in silicon. Sov. Phys. JETP Lett. 1976, 23, 597–599. [Google Scholar]

- Drozdov, N.A.; Patrin, A.A.; Tkachev, V.D. On the nature of the dislocation luminescence in silicon. Phys. Stat. Sol. B 1977, 83, K137–K139. [Google Scholar] [CrossRef]

- Thibault-Desseaux, J.; Putaux, J.-L.; Bourret, A.; Kirchner, H.O.K. Dislocations stopped by the S = 9(122) grain boundary in Si. An HREM study of thermal activation. J. Phys. 1989, 50, 2525–2540. [Google Scholar] [CrossRef]

- Aubert, J.J.; Bacmann, J.J. Czochralski growth of silicon bicrystals. Rev. Phys. Appl. 1987, 22, 515–518. [Google Scholar] [CrossRef]

- Reiche, M.; Kittler, M. Structure and properties. In Crystalline Silicon—Properties and Uses; Basu, S., Ed.; Intech: Rijeka, Croatia, 2011; pp. 57–80. [Google Scholar]

- Reiche, M. Direct wafer bonding. In Handbook of Wafer Bonding; Ramm, P., Lu, J.-Q., Taklo, M.V., Eds.; Wiley-VCH: Weinheim, Germany, 2012; pp. 81–100. [Google Scholar]

- Hornstra, J. Dislocations in the diamond lattice. J. Phys. Chem. Solids 1958, 5, 129–141. [Google Scholar] [CrossRef]

- Seitz, F. The plasticity of silicon and germanium. Phys. Rev. 1952, 88, 722–724. [Google Scholar] [CrossRef]

- Amelinckx, S. Dislocations in particular structures. In Dislocations in Solids; Nabarro, F.R.N., Ed.; North-Holland: Amsterdam, The Netherlands, 1982; pp. 67–460. [Google Scholar]

- Gomez, A.; Hirsch, P.B. On the mobility of dislocations in germanium and silicon. Philos. Mag. 1977, 36, 169–179. [Google Scholar] [CrossRef]

- Ray, I.L.F.; Cockayne, D.J.H. The dissociation of dislocations in silicon. Proc. R. Soc. Lond. A 1971, 325, 543–554. [Google Scholar] [CrossRef]

- Alexander, H. Dislocations in covalent crystals. In Dislocations in Solids; Nabarro, F.R.N., Ed.; North-Holland: Amsterdam, The Netherlands, 1986; pp. 113–234. [Google Scholar]

- Duesbery, M.S.; Joós, B. Dislocation motion in silicon: The shuffle-glide controversy. Philos. Mag. Lett. 1996, 74, 253–258. [Google Scholar] [CrossRef]

- Marklund, S. Electron states associated with partial dislocations in silicon. Phys. Stat. Sol. B 1979, 92, 83–89. [Google Scholar] [CrossRef]

- Bulatov, V.V.; Cai, W. Computer Simulation of Dislocations; Oxford University Press: Oxford, UK, 2006. [Google Scholar]

- 4Smallman, R.E.; Ngan, A.H.W. Introduction to dislocations. In Modern Physical Metallurgy; Elsevier: Boston, MA, USA, 2014. [Google Scholar]

- Bourdelle, K.K.; Rayssac, O.; Lambert, A.; Fournel, F.; Hebras, X.; Allibert, F.; Figuet, C.; Boussagol, A.; Berne, C.; Tsyganenko, K.; et al. Fabrication of directly bonded Si substrates with hybrid crystal orientation for advanced bulk CMOS technology. ECS Trans. 2006, 3, 409–415. [Google Scholar]

- Toyoda, E.; Sakai, A.; Nakatsuka, O.; Isogai, H.; Senda, T.; Izunome, K.; Ogawa, M.; Zaima, S. Characterization of bonding structures of directly bonded hybrid crystal orientation substrates. Thin Solid Films 2008, 517, 323–326. [Google Scholar] [CrossRef]

- Reiche, M. Dislocation networks formed by silicon wafer direct bonding. Mater. Sci. Forum 2008, 590, 57–78. [Google Scholar] [CrossRef]

- Goodhew, P.J.; Darby, T.P.; Balluffi, R.W. On the dislocation structure of low angle (110) twist boundaries and its relationship to the O-lattice. Scr. Metall. 1976, 10, 495–499. [Google Scholar] [CrossRef]

- Reiche, M.; Kittler, M.; Uebensee, H.; Pippel, E.; Hopfe, S. Dislocations as native nanostructures-electronic properties. Adv. Nano Res. 2014, 2, 1–14. [Google Scholar] [CrossRef]

- Belov, A.Y.; Scholz, R.; Scheerschmidt, K. Dissociation of screw dislocations on (001) low-angle twist boundaries: A source of the 30° partial dislocations in silicon. Philos. Mag. Lett. 1999, 79, 531–538. [Google Scholar] [CrossRef]

- Galindo, P.L.; Krel, S.; Sanchez, A.M.; Laval, J.-Y.; Sanez, A.; Pizarro, J.; Guerrero, E.; Ben, T.; Molina, S.I. The peak pairs algorithm for strain mapping from HRTEM images. Ultramicroscopy 2007, 107, 1186–1193. [Google Scholar] [CrossRef] [PubMed]

- Alexander, H.; Gottschalk, H.; Kisielowski-Kemmerich, C. New Results on the Core of Dislocations in Silicon by EPR and TEM, in Dislocations in Solids; Suzuki, H., Ninomiya, T., Sumino, K., Takeuchi, S., Eds.; University of Tokyo Press: Tokyo, Japan, 1985; pp. 337–342. [Google Scholar]

- Blumenau, A.T. The Modelling of Dislocations in Semiconductor Crystals. Ph.D. Thesis, University of Paderborn, Paderborn, Germany, 2002. [Google Scholar]

- Zhao, C.W.; Xing, Y.M. Nanoscale strain analysis of an edge dislocation. Proc. SPIE 2008. [Google Scholar] [CrossRef]

- Kittler, M.; Yu, X.; Mchedlidze, T.; Arguirov, T.; Vyvenko, O.F.; Seifert, W.; Reiche, M.; Wilhelm, T.; Seibt, M.; Voß, O.; et al. Regular dislocation networks in silicon as a tool for nanostructure devices used in optics, biology, and electronics. Small 2007, 3, 964–973. [Google Scholar] [CrossRef] [PubMed]

- Reiche, M.; Kittler, M.; Pippel, E.; Erfurth, W.; Haehnel, A.; Uebensee, H. Strain and carrier transport along dislocations. Phys. Stat. Sol. C 2015, 12, 1071–1076. [Google Scholar] [CrossRef]

- Ishikawa, Y.; Yamamoto, C.; Tabe, M. Single-electron tunneling in a silicon-on-insulator layer embedding an artificial dislocation network. Appl. Phys. Lett. 2006, 88, 0731121–0731123. [Google Scholar] [CrossRef]

- Reiche, M.; Kittler, M.; Scholz, R.; Hähnel, A.; Arguirov, T. Structure and properties of dislocations in interfaces of bonded silicon wafers. J. Phys. Conf. Ser. 2011. [Google Scholar] [CrossRef]

- Reiche, M.; Kittler, M.; Erfurth, W.; Pippel, E.; Sklarek, K. On the electronic properties of a single dislocation. J. Appl. Phys. 2014. [Google Scholar] [CrossRef]

- Liu, Z.-H.; Hu, C.; Huang, J.-H.; Chan, T.-Y.; Jeng, M.-C.; Ko, P.K.; Cheng, Y.C. Threshold voltage model for deep-submicrometer MOSFETs. IEEE Trans. Electron Dev. 1993, 40, 86–94. [Google Scholar] [CrossRef]

- Rauly, E.; Potavin, O.; Balestra, F.; Raynaud, C. On the subthreshold swing and short channel effects in singl and double gate deep submicron SOI-MOSFETs. Solid State Electron. 1999, 43, 2033–2037. [Google Scholar] [CrossRef]

- Reiche, M.; Kittler, M.; Krause, M.; Uebensee, H. Electrons on dislocations. Phys. Stat. Sol. C 2013, 10, 40–43. [Google Scholar] [CrossRef]

- Kittler, M.; Kveder, V. Dislocations in silicon and D-band luminescence for infrared light emitters. Mater. Sci. Forum 2008, 590, 29–56. [Google Scholar]

- Labusch, R.; Schröter, W. Electrical properties of dislocations in semiconductors. In Dislocations in Solids; Nabarro, F.R.N., Ed.; North-Holland: Amsterdam, The Netherlands, 1980; pp. 127–191. [Google Scholar]

- Reiche, M.; Kittler, M.; Uebensee, H.; Pippel, E. A novel SOI-based MOSFET with ultra-low subthreshold swing for cryogenic applications. In Proceedings of the 2013 Symposium on Microelectronics Technology and Devices (SBMicro), Curitiba, Brasil, 2–6 September 2013; pp. 1–3.

- Klaassen, D.B.M. A unified mobility model for device simulation—I. Model equations and concentration dependence. Solid State Electron. 1992, 35, 953–959. [Google Scholar] [CrossRef]

- Reiche, M.; Kittler, M.; Schmelz, M.; Stolz, R.; Pippel, E.; Uebensee, H.; Kermann, M.; Ortlepp, T. Single-electron transitions in one-dimensional native nanostructures. J. Phys. Conf. Ser. 2014, 568, 052024. [Google Scholar] [CrossRef]

- Ando, T.; Fowler, A.B.; Stern, F. Electronic properties of two-dimensional systems. Rev. Mod. Phys. 1982, 54, 437–672. [Google Scholar] [CrossRef]

- Ihn, T. Semiconductor Nanostructures: Quantum States and Electronic Transport; Oxford University Press: New York, NY, USA, 2010. [Google Scholar]

- Kouwenhoven, L.P.; Marcus, C.M.; McEuen, P.L.; Tarucha, S.; Westervelt, R.M.; Wingreen, N.S. Electron transport in quantum dots. In Mesoscopic Electron Transport; Sohn, L.L., Kouwenhoven, L.P., Schön, G., Eds.; Kluwer: Dordrecht, The Netherlands, 1997. [Google Scholar]

- Tilke, A.T.; Simmel, F.C.; Blick, R.H.; Lorenz, H.; Kotthaus, J.P. Coulomb blockade in silicon nanostructures. Progr. Quant. Electron. 2001, 25, 97–138. [Google Scholar] [CrossRef]

- Zhong, Z.; Fang, Y.; Lu, W.; Lieber, C.M. Coherent single charge transport in molecular-scale silicon nanowires. Nano Lett. 2005, 5, 1143–1146. [Google Scholar] [CrossRef] [PubMed]

- Gallagher, C.J. Plastic deformation of germanium and silicon. Phys. Rev. 1952, 88, 721–722. [Google Scholar] [CrossRef]

- Pearson, G.L.; Read, W.T.; Morin, F.J. Dislocations in plastically deformed germanium. Phys. Rev. 1954, 93, 666–667. [Google Scholar] [CrossRef]

- Read, W.T. Theory of dislocations in germanium. Philos. Mag. 1954, 45, 775–796. [Google Scholar] [CrossRef]

- Read, W.T. Statistics of the occupation of dislocation acceptor centres. Philos. Mag. 1954, 45, 1119–1128. [Google Scholar] [CrossRef]

- Schröter, W. Trägerbeweglichkeit in verformtem Germanium. Phys. Stat. Sol. 1969, 31, 177–186. [Google Scholar] [CrossRef]

- Weber, H.; Schröter, W.; Haasen, P. Elektronenzustände an Versetzungen in Silizium. Helv. Phys. Acta 1968, 41, 1255–1258. [Google Scholar]

- Veth, H.; Lannoo, M. The electronic properties of charged dislocations in semiconductors. Philos. Mag. B 1984, 50, 93–102. [Google Scholar] [CrossRef]

- Reiche, M.; Kittler, M.; Uebensee, H.; Pippel, E.; Haehnel, A.; Birner, S. Electronic properties of dislocations. Appl. Phys. A 2016, 122, 389. [Google Scholar] [CrossRef]

- Fischetti, M.V.; Ren, Z.; Solomon, P.M.; Yang, M.; Rim, K. Six-band k.p calculation of the hole mobility in silicon inversion layers: Dependence on surface orientation, strain, and silicon thickness. J. Appl. Phys. 2003, 94, 1079–1095. [Google Scholar] [CrossRef]

- Sverdlov, V. Strain-Induced Effects in Advanced MOSFETs. Computational Microelectronics; Selberherr, S., Ed.; Springer: Wien, Austria, 2011. [Google Scholar]

- Maegawa, T.; Yamauchi, T.; Hara, T.; Tsuchiya, H.; Ogawa, M. Strain effects on electronic bandstructures in nanoscaled silicon: From bulk to nanowire. IEEE Trans. Electron. Dev. 2009, 56, 553–559. [Google Scholar] [CrossRef]

- Ungersboeck, E.; Dhar, S.; Karlowatz, G.; Sverdlov, V.; Kosina, H.; Selberherr, S. The effect of general strain on the band structure and electron mobility of silicon. IEEE Trans. Electron. Dev. 2007, 54, 2183–2190. [Google Scholar] [CrossRef]

- Shiri, D.; Kong, Y.; Buin, A.; Anantram, M.P. Strain induced change of bandgap and effective mass in silicon nanowires. Appl. Phys. Lett. 2008. [Google Scholar] [CrossRef]

- Karazhanov, S.Z.; Davletova, A.; Ulyashin, A. Strain-induced modulation of band structure of silicon. J. Appl. Phys. 2008, 104, 024501. [Google Scholar] [CrossRef]

- Birner, S.; Zibold, T.; Andlauer, T.; Kubis, T.; Sabathil, M.; Trellakis, A.; Vogl, P. Nextnano: General purpose 3-D simulations. IEEE Trans. Electron Dev. 2007, 54, 2137–2142. [Google Scholar] [CrossRef]

- Jancu, J.-M.; Scholz, R.; Beltram, F.; Bassani, F. Empirical spds* tight-binding calculation for cubic semiconductors: General method and material parameters. Phys. Rev. B 1998, 57, 6493–6507. [Google Scholar] [CrossRef]

- Cohen, M.L.; Chelikowsky, J. Electronic Structure and Optical Properties of Semiconductors; Springer: Berlin, Germany, 1989. [Google Scholar]

- Ungersboeck, E. Numerische Berechnung der Bandstruktur von Halbleitern. Master’s Thesis, Vienna University of Technology, Wien, Austria, 2002. [Google Scholar]

- Ungersboeck, E.; Dhar, S.; Karlowatz, G.; Kosina, H.; Selberherr, S. Physical modeling of electron mobility enhancement for arbitrarily strained silicon. J. Comput. Electron. 2007, 6, 55–58. [Google Scholar] [CrossRef]

- Kittler, M.; Reiche, M.; Krause, M. Charge carrier transport along grain boundaries in silicon. Solid State 2013. [Google Scholar] [CrossRef]

- Reiche, M.; Kittler, M.; Krause, M.; Uebensee, H. Carrier transport on dislocations in silicon. AIP Conf. Proc. 2014, 1583, 33–36. [Google Scholar]

- Schröter, W.; Cerva, H. Interaction of point defects with dislocations in silicon and germanium: Electrical and optical effects. Solid State Phenom. 2002, 85–86, 67–144. [Google Scholar] [CrossRef]

- Bondarenko, A.; Vyvenko, O.F.; Isakov, I. Electron levels and luminescence of dislocation networks formed by the hydrophilic bonding of silicon wafers. Semiconductors 2013, 47, 223–227. [Google Scholar] [CrossRef]

- Knobloch, K.; Seifert, W.; Kittler, M. Application of scanning deep level transient spectroscopy for characterisation of multicrystalline silicon. Mater. Sci. Eng. 1996, 42, 254–259. [Google Scholar] [CrossRef]

- Donolato, C. Quantitative characterization of semiconductor defects by electron beam induced currents. In Point and Extended Defects in Semiconductors; Benedek, G., Cavallini, A., Schröter, W., Eds.; Plenum Press: New York, NY, USA, 1989; pp. 225–242. [Google Scholar]

- Kittler, M.; Ulhaq-Bouillet, C.; Higgs, V. Influence of copper contamination on recombination activity of misfit dislocations in SiGe/Si epilayers: Temperature dependence of activity as a marker characterizing the contamination level. J. Appl. Phys. 1995, 78, 4573–4583. [Google Scholar] [CrossRef]

- Kittler, M.; Seifert, W. Two classes of defect recombination behavior in silicon as studied by SEM-EBIC. Scan. Microsc. 1993, 15, 316–321. [Google Scholar]

- Kittler, M.; Seifert, W.; Higgs, V. Recombination activity of misfit dislocations in silicon. Phys. Stat. Sol. A 1993, 137, 327–335. [Google Scholar] [CrossRef]

- Knobloch, K.; Kittler, M.; Seifert, W.; Simon, J.J.; Périchaud, I. Impact of phosphorous diffusion on the contamination level of dislocations in deformed float zone silicon as studied by beam injection techniques. Solid State Phenom. 1998, 63–64, 105–114. [Google Scholar] [CrossRef]

- Kusanagi, S.; Sekiguchi, T.; Shen, B.; Sumino, K. Electrical activity of extended defects and gettering of metallic impurities in silicon. Mater. Sci. Technol. 1995, 11, 685–690. [Google Scholar]

- Shen, B.; Sekiguchi, T.; Zhang, R.; Shi, Y.; Shi, H.; Yang, K.; Zheng, Y.; Sumino, K. Precipitation of Cu and Fe in dislocated floating-zone-grown silicon. Jpn. J. Appl. Phys. 1996, 35, 3301–3305. [Google Scholar] [CrossRef]

- Kveder, V.; Kittler, M.; Schröter, W. Recombination activity of contaminated dislocations in silicon: A model describing electron-beam-induced current contrast behavior. Phys. Rev. B 2001. [Google Scholar] [CrossRef]

- Wilshaw, P.R.; Booker, G.R. New results and an interpretation for SEM EBIC contrast arising from individual dislocations in silicon. Inst. Phys. Conf. Ser. 1985, 76, 329–336. [Google Scholar]

- Knobloch, K.; Kittler, M.; Seifert, W. Influence of contamination on the dislocation-related deep level C1 line observed in deep-level-transient spectroscopy of n-type silicon: A comparison with the technique of electron-beam-induced current. J. Appl. Phys. 2003, 93, 1069–1074. [Google Scholar] [CrossRef]

- Kittler, M.; Seifert, W. Estimation of the upper limit of the minority-carrier diffusion length in multicrystalline silicon: Limitation of the action of gettering and passivation on dislocations. Solid State Phenom. 2004, 95–96, 197–204. [Google Scholar] [CrossRef]

- Kittler, M.; Mchedlidze, T.; Arguirov, T.; Seifert, W.; Reiche, M.; Wilhelm, T. Silicon based IR light emitters. Phys. Stat. Sol. C 2009, 6, 707–715. [Google Scholar] [CrossRef]

- Mchedlidze, T.; Kittler, M. Investigation of defect states in heavily dislocated thin silicon films. J. Appl. Phys. 2012, 111, 053706. [Google Scholar] [CrossRef]

- Arguirov, T. Electro-Optical Properties of Dislocations in Silicon and Their Posssible Application for Light Emitters. Ph.D. Thesis, Brandenburg Technology University, Cottbus, Germany, 2007. [Google Scholar]

- Mchedlidze, T.; Arguirov, T.; Kittler, M.; Hoang, T.; Holleman, J.; Schmitz, J. Influence of electric field on spectral positions of dislocation-related luminescence peaks in silicon: Stark effect. Appl. Phys. Lett. 2007, 91, 201113. [Google Scholar] [CrossRef]

- Sauer, R.; Weber, J.; Stolz, J.; Weber, E.R.; Küsters, K.-H.; Alexander, H. Dislocation-related photoluminescence in silicon. Appl. Phys. A 1985, 36, 1–13. [Google Scholar] [CrossRef]

- Kittler, M.; Arguirov, T.; Reiche, M.; Krause, M.; Mankovics, D. About dislocation and oxygen related luminescence of Si around 0.8 eV. Phys. Stat. Sol. C 2015, 12, 1077–1080. [Google Scholar] [CrossRef]

- Higgs, V.; Goulding, M.; Brinklow, A.; Kighthley, P. Characterization of epitaxial and oxygen-induced stacking faults in silicon: The influence of transition-metal contamination. Appl. Phys. Lett. 1992, 60, 1369–1371. [Google Scholar] [CrossRef]

- Mchedlidze, T.; Wilhelm, T.; Arguirov, T.; Trushin, M.; Reiche, M.; Kittler, M. Correlation of electrical and luminescence properties of dislocation networkswith its microscopic structure. Phys. Stat. Sol. C 2009, 6, 1817–1822. [Google Scholar] [CrossRef]

- Yu, X.; Seifert, W.; Vyvenko, O.F.; Kittler, M.; Wilhelm, T.; Reiche, M. A pure 1.5 µm electroluminescence from metal-oxide-silicon tunneling diode using dislocation network. Appl. Phys. Lett. 2008, 93, 041108. [Google Scholar] [CrossRef]

- Kittler, M.; Reiche, M.; Yu, X.; Arguirov, T.; Seifert, W.; Vyvenko, O.F. 1.5 µm emission from a silicon MOS-LED based on a dislocation network. IEDM Technol. Dig. 2006, 845–848. [Google Scholar] [CrossRef]

- Kittler, M.; Reiche, M.; Arguirov, T. 1.55 µm light emitter based on dislocation D1-emission in silicon. In Proceedings of the 2013 Symposium on Microelectronics Technology and Devices (SBMicro), Curitiba, Brasil, 2–6 September 2013.

- Tong, Q.-Y.; Gösele, U. Semiconductor Wafer Bonding: Science and Technology; Wiley: New York, NY, USA, 1999. [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reiche, M.; Kittler, M. Electronic and Optical Properties of Dislocations in Silicon. Crystals 2016, 6, 74. https://doi.org/10.3390/cryst6070074

Reiche M, Kittler M. Electronic and Optical Properties of Dislocations in Silicon. Crystals. 2016; 6(7):74. https://doi.org/10.3390/cryst6070074

Chicago/Turabian StyleReiche, Manfred, and Martin Kittler. 2016. "Electronic and Optical Properties of Dislocations in Silicon" Crystals 6, no. 7: 74. https://doi.org/10.3390/cryst6070074