Topological Insulator Film Growth by Molecular Beam Epitaxy: A Review

Abstract

:1. Introduction

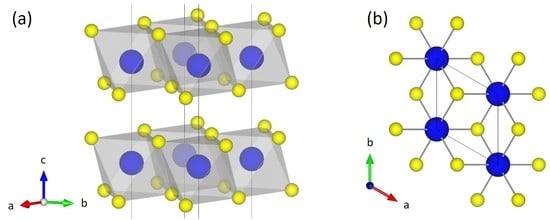

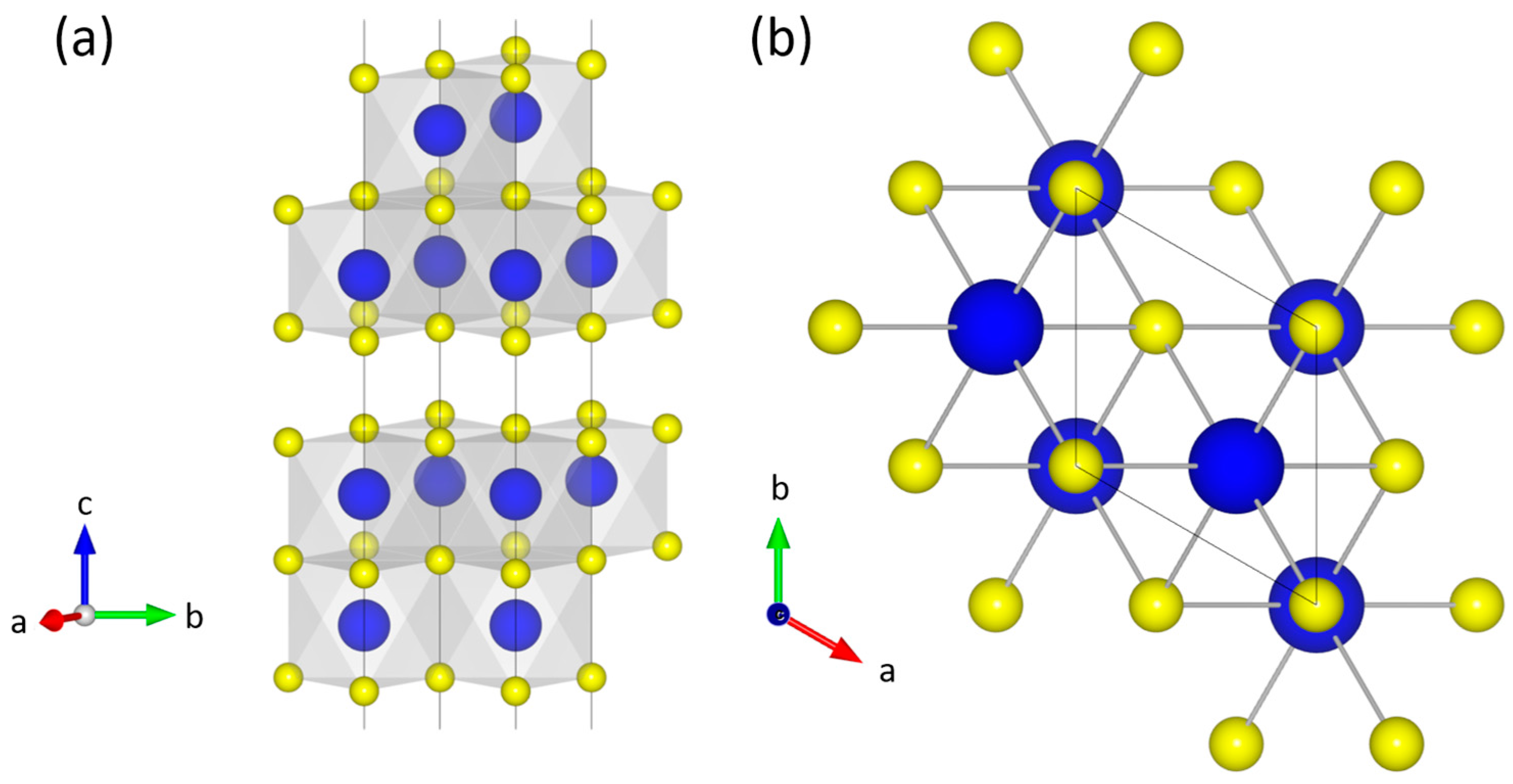

1.1. Crystal Structure

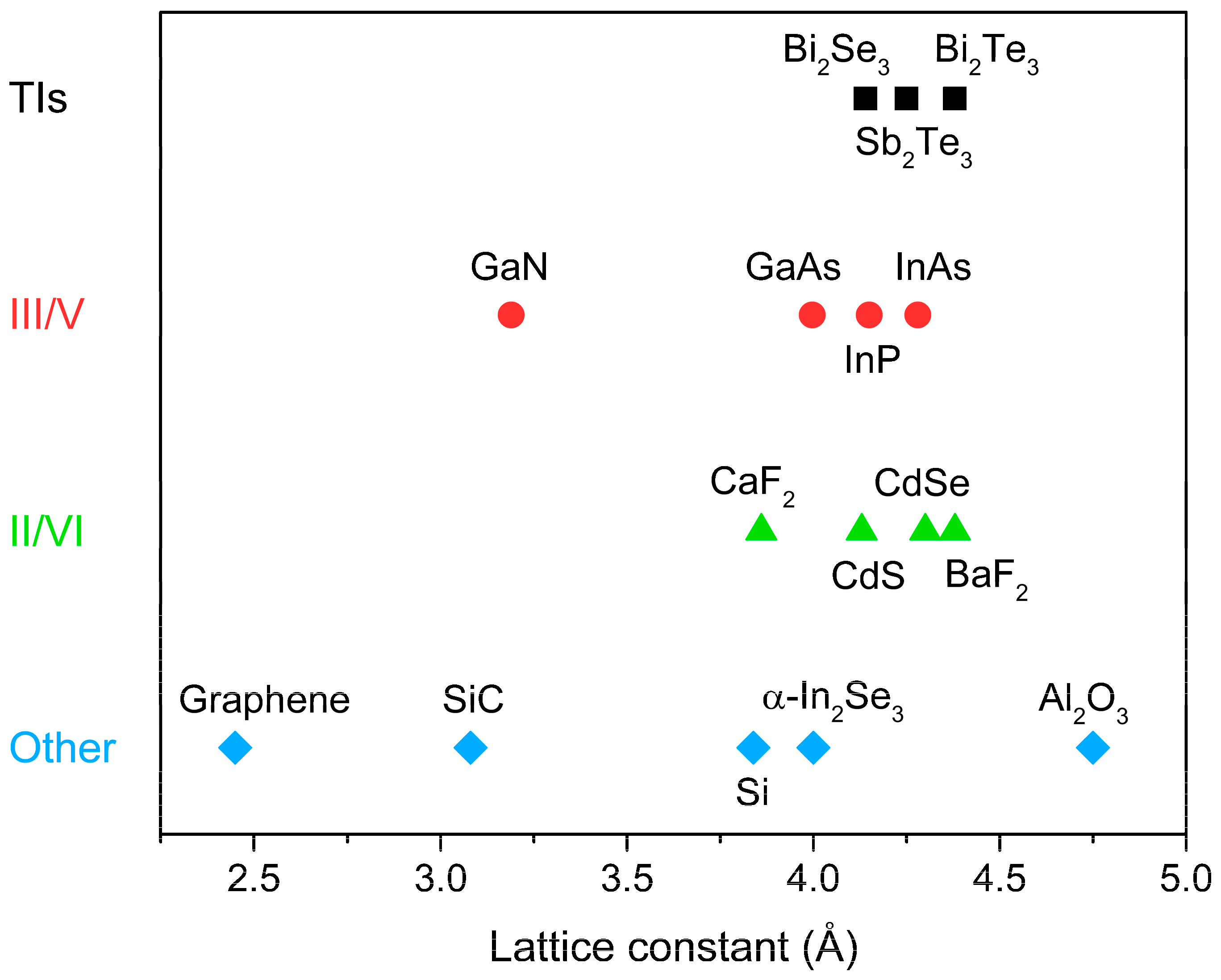

1.2. Substrate Choice

1.3. Aging Effects

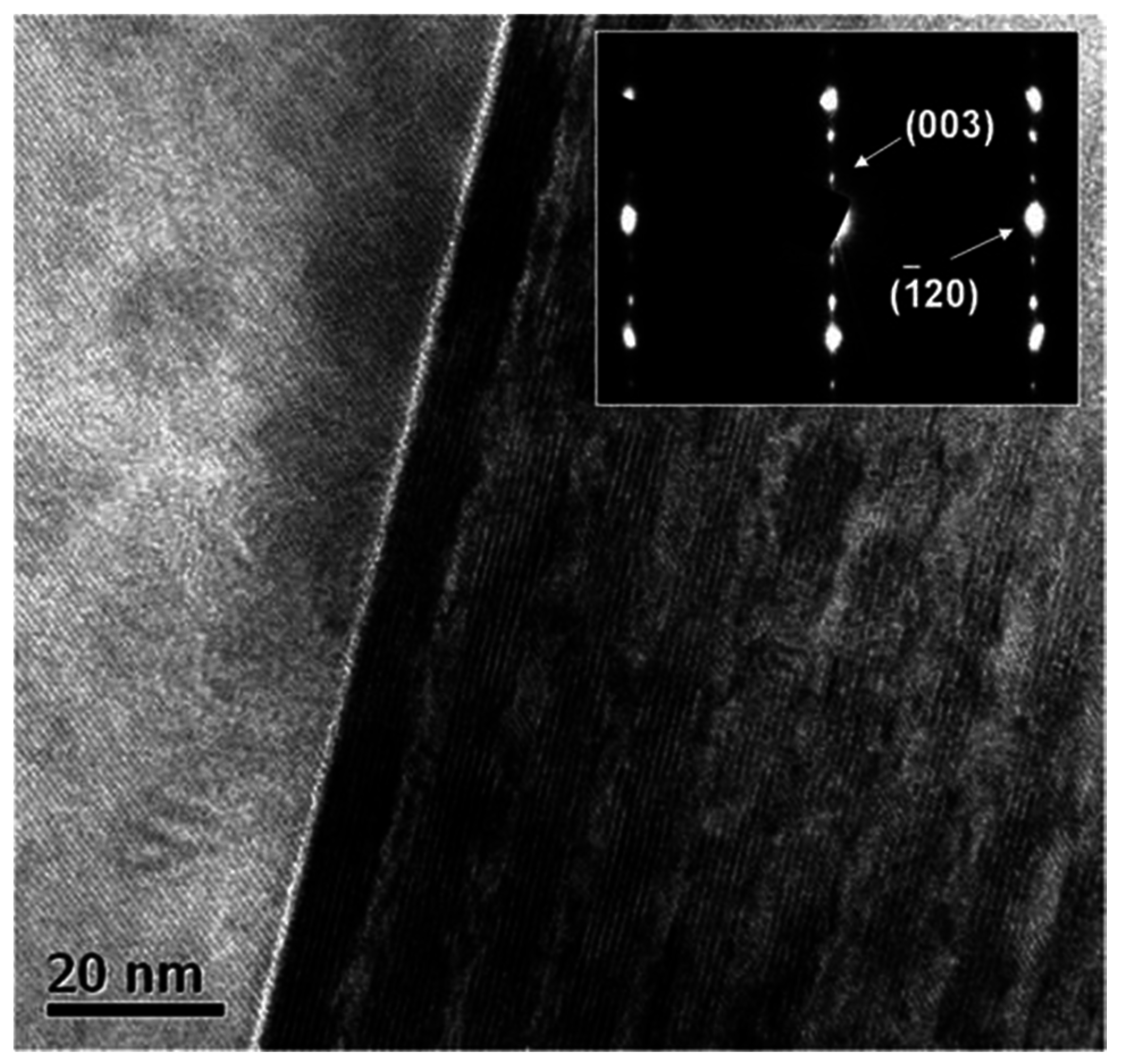

1.4. TI Film Structural Quality

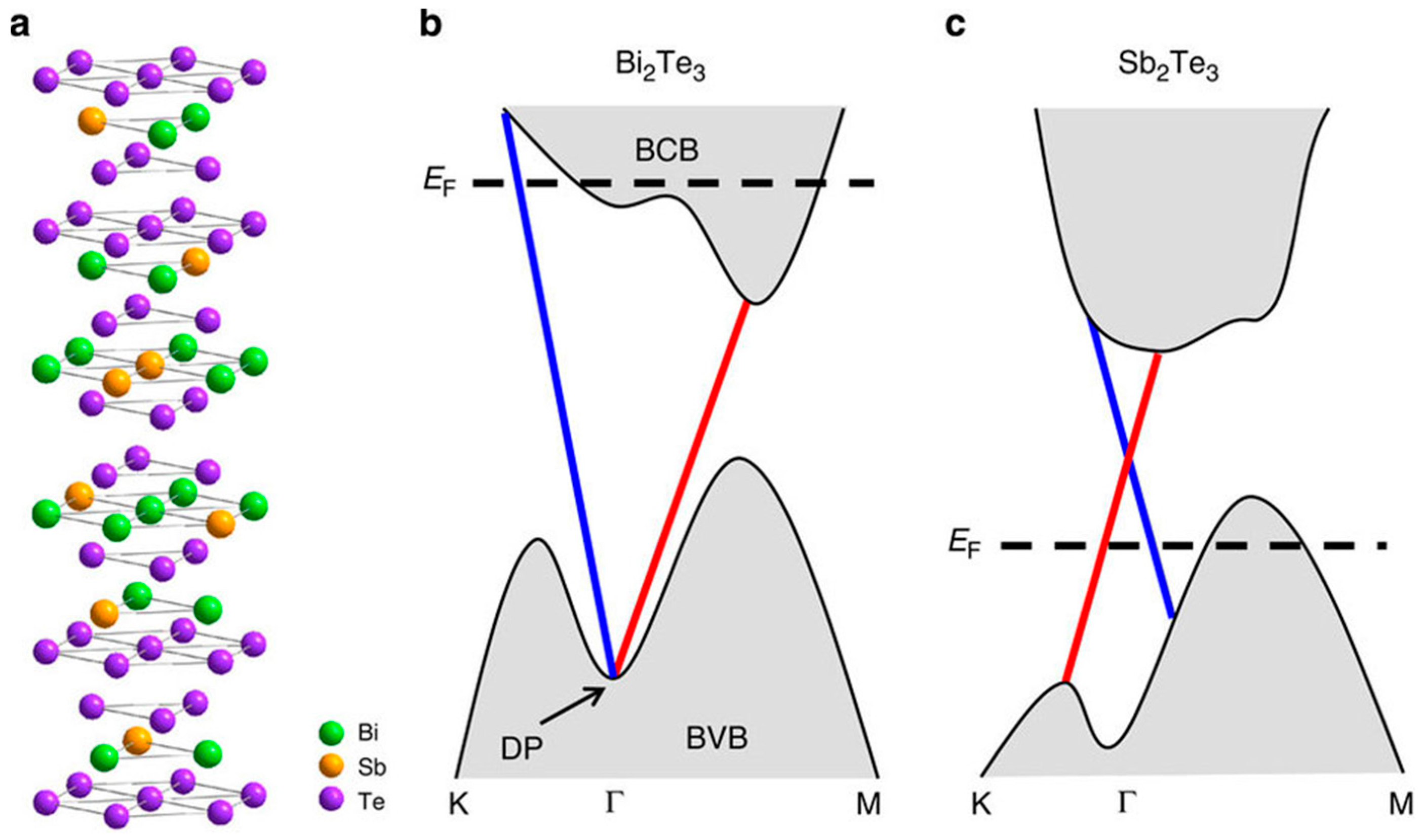

2. Binary Materials (E.G. Bi2Se3, Bi2Te3, Sb2Te3)

2.1. Bi2Se3

2.1.1. Standard Growth Parameters

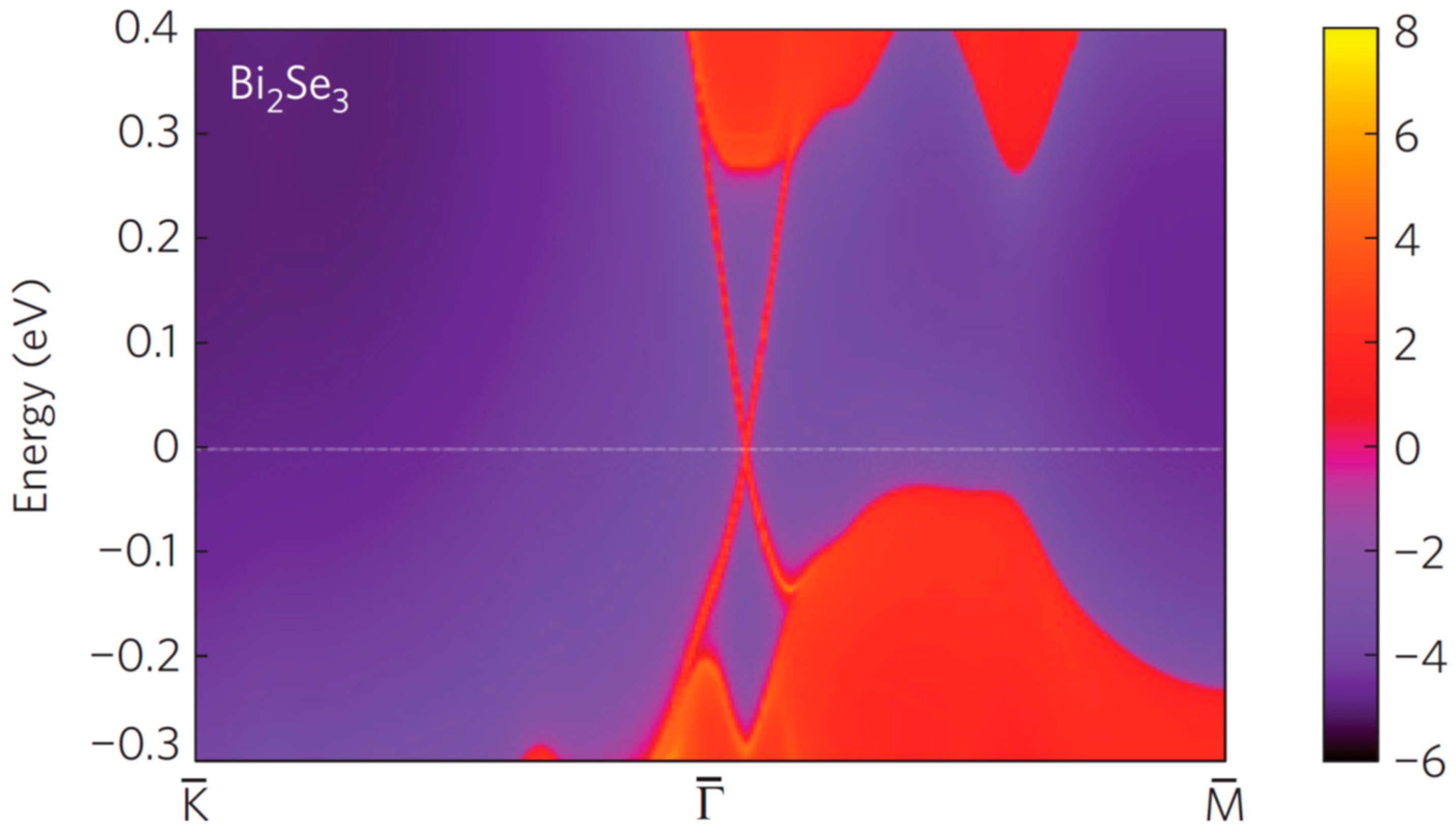

2.1.2. Electrical Properties/ARPES

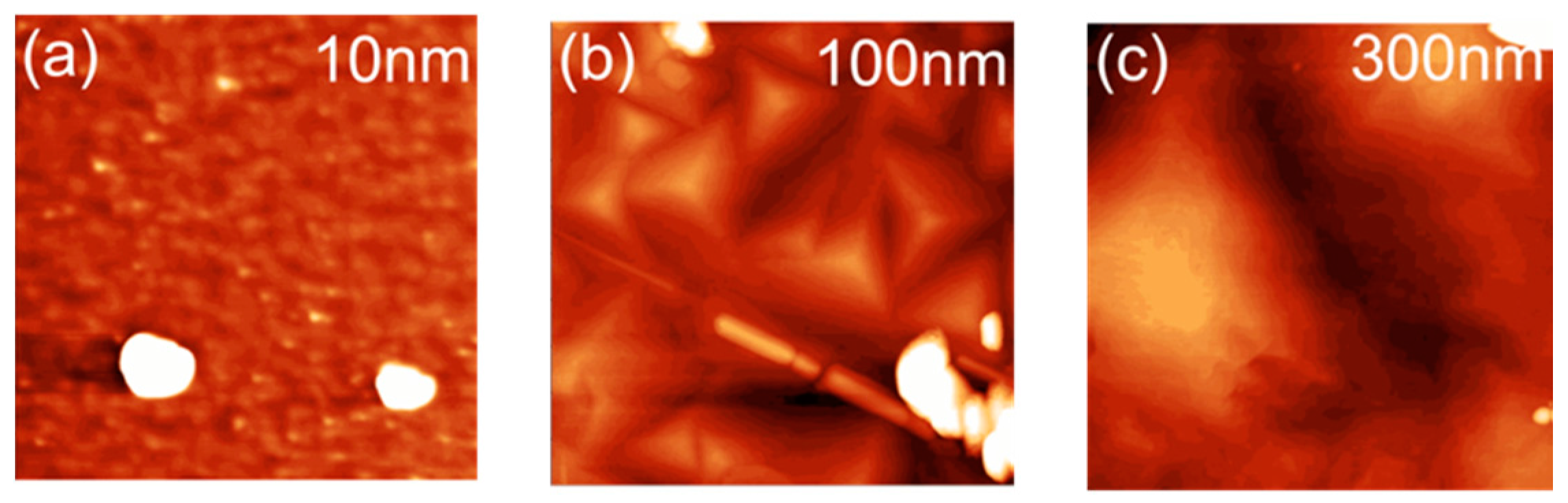

2.1.3. Atomic Force Microscopy

2.1.4. Substrate Choice

2.1.5. Cracking Source

2.2. Bi2Te3

2.3. Sb2Te3

2.4. A Discussion on Carrier Density Determination

3. Ternary Materials (E.G. Bi2(Se1–xTex)3, (BixSb1–x)2Te3)

4. Heterostructures and Superlattices

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chen, Y.L.; Analytis, J.G.; Chu, J.-H.; Liu, Z.K.; Mo, S.-K.; Qi, X.L.; Zhang, H.J.; Lu, D.H.; Dai, X.; Fang, Z.; et al. Experimental realization of a three-dimensional topological insulator, Bi2Te3. Science 2009, 325, 178–181. [Google Scholar] [CrossRef] [PubMed]

- Xia, Y.; Qian, D.; Hsieh, D.; Wray, L.; Pal, A.; Lin, H.; Bansil, A.; Grauer, D.; Hor, Y.S.; Cava, R.J.; et al. Observation of a large-gap topological-insulator class with a single Dirac cone on the surface. Nat. Phys. 2009, 5, 398–402. [Google Scholar] [CrossRef]

- Hsieh, D.; Xia, Y.; Qian, D.; Wray, L.; Dil, J.H.; Meier, F.; Osterwalder, J.; Patthey, L.; Checkelsky, J.G.; Ong, N.P.; et al. A tunable topological insulator in the spin helical Dirac transport regime. Nature 2009, 460, 1101–1105. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hsieh, D.; Xia, Y.; Qian, D.; Wray, L.; Dil, J.H.; Osterwalder, J.; Patthey, L.; Fedorov, A.V.; Lin, H.; Bansil, A.; et al. Observation of Time-Reversal-Protected Single-Dirac-Cone Topological-Insulator States. Phys. Rev. Lett. 2009, 103, 146401. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Liu, C.-X.; Qi, X.-L.; Dai, X.; Fang, Z.; Zhang, S.-C. Topological insulators in Bi2Se3, Bi2Te3 and Sb2Te3 with a single Dirac cone on the surface. Nat. Phys. 2009, 5, 438–442. [Google Scholar] [CrossRef]

- Zhu, X.; Santos, L.; Howard, C.; Sankar, R.; Chou, F.C.; Chamon, C.; El-Batanouny, M. Electron-Phonon Coupling on the Surface of the Topological Insulator Bi2Se3 Determined from Surface-Phonon Dispersion Measurements. Phys. Rev. Lett. 2012, 108, 185501. [Google Scholar] [CrossRef] [PubMed]

- Pan, Z.-H.; Fedorov, A.V.; Gardner, D.; Lee, Y.S.; Chu, S.; Valla, T. Measurement of an Exceptionally Weak Electron-Phonon Coupling on the Surface of the Topological Insulator Bi2Se3 Using Angle-Resolved Photoemission Spectroscopy. Phys. Rev. Lett. 2012, 108, 187001. [Google Scholar] [CrossRef] [PubMed]

- Nemec, P.; Novák, V.; Sinova, J.; Jungwirth, T. Spin Hall Effect Transistor. Science 2010, 330, 1801–1804. [Google Scholar]

- Appelbaum, I.; Drew, H.D.; Fuhrer, M.S.; Appelbaum, I.; Drew, H.D.; Fuhrer, M.S. Proposal for a topological plasmon spin rectifier. Appl. Phys. Lett. 2011, 98, 23103. [Google Scholar] [CrossRef]

- Fu, L.; Kane, C. Superconducting Proximity Effect and Majorana Fermions at the Surface of a Topological Insulator. Phys. Rev. Lett. 2008, 100, 96407. [Google Scholar] [CrossRef] [PubMed]

- Akhmerov, A.R.; Nilsson, J.; Beenakker, C.W.J. Electrically Detected Interferometry of Majorana Fermions in a Topological Insulator. Phys. Rev. Lett. 2009, 102, 216404. [Google Scholar] [CrossRef] [PubMed]

- Hasan, M.Z.; Kane, C.L. Colloquium: Topological insulators. Rev. Mod. Phys. 2010, 82, 3045–3067. [Google Scholar] [CrossRef]

- Bernevig, B.A.; Zhang, S. Quantum Spin Hall Effect. Phys. Rev. Lett. 2006, 96, 106802. [Google Scholar] [CrossRef] [PubMed]

- Bernevig, B.A.; Hughes, T.L.; Zhang, S.-C. Quantum spin hall effect and topological phase transition in HgTe quantum wells. Science 2006, 314, 1757–1761. [Google Scholar] [CrossRef] [PubMed]

- Fu, L.; Kane, C.L.; Mele, E.J. Topological Insulators in Three Dimensions. Phys. Rev. Lett. 2007, 98, 106803. [Google Scholar] [CrossRef] [PubMed]

- Moore, J.E.; Balents, L. Topological invariants of time-reversal-invariant band structures. Phys. Rev. B 2007, 75, 121306(R). [Google Scholar] [CrossRef]

- Roy, R. Topological phases and the quantum spin Hall effect in three dimensions. Phys. Rev. B 2009, 79, 195322. [Google Scholar] [CrossRef]

- Hsieh, D.; Qian, D.; Wray, L.; Xia, Y.; Hor, Y.S.; Cava, R.J.; Hasan, M.Z. A topological Dirac insulator in a quantum spin Hall phase. Nature 2008, 452, 970–974. [Google Scholar] [CrossRef] [PubMed]

- Hsieh, D.; Xia, Y.; Wray, L.; Qian, D.; Pal, A.; Dil, J.H.; Osterwalder, J.; Meier, F.; Bihlmayer, G.; Kane, C.L.; et al. Observation of Unconventional Quantum Spin Textures in Topological Insulators. Science 2009, 323, 919–922. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moore, J.E. The birth of topological insulators. Nature 2010, 464, 194–198. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Liu, Z.; Peng, H. A Roadmap for Controlled Production of Topological Insulator Nanostructures and Thin Films. Small 2015, 11, 3290–3305. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.; Zhang, J.; Feng, X.; Shen, J.; Zhang, Z.; Guo, M.; Li, K.; Ou, Y.; Wei, P.; Wang, L.; et al. Experimental Observation of the Quantum Anomalous Hall Effect in a Magnetic Topological Insulator. Science 2013, 340, 167–171. [Google Scholar] [CrossRef] [PubMed]

- Qi, S.; Qiao, Z.; Deng, X.; Cubuk, E.D.; Chen, H.; Zhu, W.; Kaxiras, E.; Zhang, S.B.; Xu, X.; Zhang, Z. High-Temperature Quantum Anomalous Hall Effect in n-p Codoped Topological Insulators. Phys. Rev. Lett. 2016, 117, 056804. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.Z.; Zhang, J.; Liu, M.; Zhang, Z.; Feng, X.; Li, K.; Wang, L.L.; Chen, X.; Dai, X.; Fang, Z.; et al. Thin films of magnetically doped topological insulator with carrier-independent long-range ferromagnetic order. Adv. Mater. 2013, 25, 1065–1070. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.-Z.; Zhao, W.; Kim, D.Y.; Zhang, H.; Assaf, B.A.; Heiman, D.; Zhang, S.-C.; Liu, C.; Chan, M.H.W.; Moodera, J.S. High-precision realization of robust quantum anomalous Hall state in a hard ferromagnetic topological insulator. Nat. Mater. 2015, 14, 473–477. [Google Scholar] [CrossRef] [PubMed]

- Kou, X.; Guo, S.T.; Fan, Y.; Pan, L.; Lang, M.; Jiang, Y.; Shao, Q.; Nie, T.; Murata, K.; Tang, J.; et al. Scale-invariant quantum anomalous hall effect in magnetic topological insulators beyond the two-dimensional limit. Phys. Rev. Lett. 2014, 113, 137201. [Google Scholar] [CrossRef] [PubMed]

- Checkelsky, J.G.; Yoshimi, R.; Tsukazaki, A.; Takahashi, K.S.; Kozuka, Y.; Falson, J.; Kawasaki, M.; Tokura, Y. Trajectory of the anomalous Hall effect towards the quantized state in a ferromagnetic topological insulator. Nat. Phys. 2014, 10, 731–736. [Google Scholar] [CrossRef]

- Chen, Z.; Zhao, L.; Park, K.; Garcia, T.A.; Tamargo, M.C.; Krusin-Elbaum, L. Robust Topological Interfaces and Charge Transfer in Epitaxial Bi2Se3/II-VI Semiconductor Superlattices. Nano Lett. 2015, 15, 6365–6370. [Google Scholar] [CrossRef] [PubMed]

- Bianchi, M.; Guan, D.; Bao, S.; Mi, J.; Iversen, B.B.; King, P.D.C.; Hofmann, P. Coexistence of the topological state and a two-dimensional electron gas on the surface of Bi2Se3. Nat. Commun. 2010, 1, 128. [Google Scholar] [CrossRef] [PubMed]

- Koma, A.; Sunouchi, K.; Miyajima, T. Fabrication and characterization of heterostructures with subnanometer thickness. Microelectron. Eng. 1984, 2, 129–136. [Google Scholar] [CrossRef]

- Koma, A. Van der Waals epitaxy—A new epitaxial growth method for a highly lattice-mismatched system. Thin Solid Films 1992, 216, 72–76. [Google Scholar] [CrossRef]

- Momma, K.; Izumi, F. VESTA 3 for three-dimensional visualization of crystal, volumetric and morphology data. J. Appl. Crystallogr. 2011, 44, 1272–1276. [Google Scholar] [CrossRef]

- Chang, C.-Z.; He, K.; Wang, L.-L.; Ma, X.-C.; Liu, M.-H.; Zhang, Z.-C.; Chen, X.; Wang, Y.-Y.; Xue, Q.-K. Growth of quantum well films of topological insulator Bi2Se3 on insulating substrate. SPIN 2011, 1, 21. [Google Scholar] [CrossRef]

- Tarakina, N.V.; Schreyeck, S.; Luysberg, M.; Grauer, S.; Schumacher, C.; Karczewski, G.; Brunner, K.; Gould, C.; Buhmann, H.; Dunin-Borkowski, R.E.; et al. Suppressing Twin Formation in Bi2Se3 Thin Films. Adv. Mater. Interfaces 2014, 1, 1400134. [Google Scholar] [CrossRef]

- Kampmeier, J.; Borisova, S.; Plucinski, L.; Luysberg, M.; Mussler, G.; Grutzmacher, D. Suppressing Twin Domains in Molecular Beam Epitaxy Grown Bi2Te3 Topological Insulator Thin Films. Cryst. Growth Des. 2015, 15, 390–394. [Google Scholar] [CrossRef]

- Richardella, A.; Zhang, D.M.; Lee, J.S.; Koser, A.; Rench, D.W.; Yeats, A.L.; Buckley, B.B.; Awschalom, D.D.; Samarth, N. Coherent heteroepitaxy of Bi2Se3 on GaAs (111)B. Appl. Phys. Lett. 2010, 97, 262104. [Google Scholar] [CrossRef]

- Schreyeck, S.; Tarakina, N.V.; Karczewski, G.; Schumacher, C.; Borzenko, T.; Brüne, C.; Buhmann, H.; Gould, C.; Brunner, K.; Molenkamp, L.W.; et al. Molecular beam epitaxy of high structural quality Bi2Se3 on lattice matched InP(111) substrates. Appl. Phys. Lett. 2013, 102, 041914. [Google Scholar] [CrossRef]

- Guo, X.; Xu, Z.J.; Liu, H.J.C.; Zhao, B.; Dai, X.Q.; He, H.T.; Wang, J.N.; Liu, H.J.C.; Ho, W.K.; Xie, M.H. Single domain Bi2Se3 films grown on InP(111)A by molecular-beam epitaxy. Appl. Phys. Lett. 2013, 102, 151604. [Google Scholar] [CrossRef]

- He, L.; Xiu, F.; Wang, Y.; Fedorov, A.V.; Huang, G.; Kou, X.; Lang, M.; Beyermann, W.P.; Zou, J.; Wang, K.L. Epitaxial growth of Bi2Se3 topological insulator thin films on Si(111). J. Appl. Phys. 2011, 109, 103702. [Google Scholar] [CrossRef]

- Bansal, N.; Kim, Y.S.; Edrey, E.; Brahlek, M.; Horibe, Y.; Iida, K.; Tanimura, M.; Li, G.-H.; Feng, T.; Lee, H.-D.; et al. Epitaxial growth of topological insulator Bi2Se3 film on Si(111) with atomically sharp interface. Thin Solid Films 2011, 520, 224–229. [Google Scholar] [CrossRef]

- Borisova, S.; Krumrain, J.; Luysberg, M.; Mussler, G.; Grützmacher, D. Mode of Growth of Ultrathin Topological Insulator Bi2Te3 Films on Si(111) Substrates. Cryst. Growth Des. 2012, 12, 6098–6103. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Li, H.D.; Guo, X.; Ho, W.K.; Xie, M.H. Growth characteristics of topological insulator Bi2Se3 films on different substrates. J. Cryst. Growth 2011, 334, 96–102. [Google Scholar] [CrossRef]

- Rathi, S.J.; Smith, D.J.; Drucker, J. Optimization of In2Se3/Si(111) Heteroepitaxy To Enable Bi2Se3/In2Se3 Bilayer Growth. Cryst. Growth Des. 2014, 14, 4617–4623. [Google Scholar] [CrossRef]

- Koirala, N.; Brahlek, M.; Salehi, M.; Wu, L.; Dai, J.; Waugh, J.; Nummy, T.; Han, M.-G.; Moon, J.; Zhu, Y.; et al. Record Surface State Mobility and Quantum Hall Effect in Topological Insulator Thin Films via Interface Engineering. Nano Lett. 2015, 15, 8245–8249. [Google Scholar] [CrossRef] [PubMed]

- Valdés Aguilar, R.; Wu, L.; Stier, A.V.; Bilbro, L.S.; Brahlek, M.; Bansal, N.; Oh, S.; Armitage, N.P. Aging and reduced bulk conductance in thin films of the topological insulator Bi2Se3. J. Appl. Phys. 2013, 113, 153702. [Google Scholar] [CrossRef]

- Bianchi, M.; Hatch, R.C.; Mi, J.; Iversen, B.B.; Hofmann, P. Simultaneous quantization of bulk conduction and valence states through adsorption of nonmagnetic impurities on Bi2Se3. Phys. Rev. Lett. 2011, 107, 086802. [Google Scholar] [CrossRef] [PubMed]

- King, P.D.C.; Hatch, R.C.; Bianchi, M.; Ovsyannikov, R.; Lupulescu, C.; Landolt, G.; Slomski, B.; Dil, J.H.; Guan, D.; Mi, J.L.; et al. Large Tunable Rashba Spin Splitting of a Two-Dimensional Electron Gas in Bi2Se3. Phys. Rev. Lett. 2011, 107, 096802. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; He, S.; Weng, H.; Zhang, W.; Zhao, L.; Liu, H.; Jia, X.; Mou, D.; Liu, S.; He, J.; et al. Robustness of topological order and formation of quantum well states in topological insulators exposed to ambient environment. Proc. Natl. Acad. Sci. USA 2012, 109, 3694–3698. [Google Scholar] [CrossRef] [PubMed]

- Benia, H.M.; Lin, C.; Kern, K.; Ast, C.R. Reactive Chemical Doping of the Bi2Se3 Topological Insulator. Phys. Rev. Lett. 2011, 107, 177602. [Google Scholar] [CrossRef] [PubMed]

- Bianchi, M.; Hatch, R.C.; Guan, D.; Planke, T.; Mi, J.; Iversen, B.B.; Hofmann, P. The electronic structure of clean and adsorbate-covered Bi2Se3: An angle-resolved photoemission study. Semicond. Sci. Technol. 2012, 27, 124001. [Google Scholar] [CrossRef]

- Hoefer, K.; Becker, C.; Rata, D.; Swanson, J.; Thalmeier, P.; Tjeng, L.H. Intrinsic conduction through topological surface states of insulating Bi2Te3 epitaxial thin films. Proc. Natl. Acad. Sci. USA 2014, 111, 14979–14984. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Zhu, X.; Wen, J.; Chen, X.; He, K.; Wang, L.; Ma, X.; Liu, Y.; Dai, X.; Fang, Z.; et al. Atomically smooth ultrathin films of topological insulator Sb2Te3. Nano Res. 2010, 3, 874–880. [Google Scholar] [CrossRef]

- Plucinski, L.; Herdt, A.; Fahrendorf, S.; Bihlmayer, G.; Mussler, G.; Döring, S.; Kampmeier, J.; Matthes, F.; Bürgler, D.E.; Grützmacher, D.; et al. Electronic structure, surface morphology, and topologically protected surface states of Sb2Te3 thin films grown on Si(111). J. Appl. Phys. 2013, 113, 053706. [Google Scholar] [CrossRef]

- Pauly, C.; Bihlmayer, G.; Liebmann, M.; Grob, M.; Georgi, A.; Subramaniam, D.; Scholz, M.R.; Sánchez-Barriga, J.; Varykhalov, A.; Blügel, S.; et al. Probing two topological surface bands of Sb2Te3 by spin-polarized photoemission spectroscopy. Phys. Rev. B Condens. Matter Mater. Phys. 2012, 86, 235106. [Google Scholar] [CrossRef]

- Seixas, L.; Abdalla, L.B.; Schmidt, T.M.; Fazzio, A.; Miwa, R.H. Topological states ruled by stacking faults in Bi2Se3 and Bi2Te3. J. Appl. Phys. 2013, 113, 023705. [Google Scholar] [CrossRef]

- Tarakina, N.V.; Schreyeck, S.; Borzenko, T.; Schumacher, C.; Karczewski, G.; Brunner, K.; Gould, C.; Buhmann, H.; Molenkamp, L.W. Comparative Study of the Microstructure of Bi2Se3 Thin Films Grown on Si(111) and InP(111) Substrates. Cryst. Growth Des. 2012, 12, 1913–1918. [Google Scholar] [CrossRef]

- Li, H.D.; Wang, Z.Y.; Kan, X.; Guo, X.; He, H.T.; Wang, Z.; Wang, J.N.; Wong, T.L.; Wang, N.; Xie, M.H. The van der Waals epitaxy of Bi2Se3 on the vicinal Si(111) surface: An approach for preparing high-quality thin films of a topological insulator. New J. Phys. 2010, 12, 103038. [Google Scholar] [CrossRef]

- Takagaki, Y.; Jenichen, B. Epitaxial growth of Bi2Se3 layers on InP substrates by hot wall epitaxy. Semicond. Sci. Technol. 2012, 27, 35015. [Google Scholar] [CrossRef]

- Alpichshev, Z.; Biswas, R.R.; Balatsky, A.V.; Analytis, J.G.; Chu, J.-H.; Fisher, I.R.; Kapitulnik, A. STM Imaging of Impurity Resonances on Bi2Se3. Phys. Rev. Lett. 2012, 108, 206402. [Google Scholar] [CrossRef] [PubMed]

- Analytis, J.G.; Chu, J.-H.; Chen, Y.; Corredor, F.; Mcdonald, R.D.; Shen, Z.X.; Fisher, I.R. Bulk Fermi surface coexistence with Dirac surface state in Bi2Se3: A comparison of photoemission and Shubnikov–de Haas measurements. Phys. Rev. B 2010, 81, 205407. [Google Scholar] [CrossRef]

- Berkowitz, J. Equilibrium Composition of Selenium Vapor; the Thermodynamics of the Vaporization of HgSe, CdSe, and SrSe. J. Chem. Phys. 1966, 45, 4289. [Google Scholar] [CrossRef]

- Ginley, T.P.; Law, S. Growth of Bi2Se3 topological insulator films using a selenium cracker source. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2016, 34, 02L105. [Google Scholar] [CrossRef]

- Liu, X.; Smith, D.J.; Fan, J.; Zhang, Y.-H.; Cao, H.; Chen, Y.P.; Leiner, J.; Kirby, B.J.; Dobrowolska, M.; Furdyna, J.K. Structural properties of Bi2Te3 and Bi2Se3 topological insulators grown by molecular beam epitaxy on GaAs(001) substrates. Appl. Phys. Lett. 2011, 99, 171903. [Google Scholar] [CrossRef]

- Liu, X.; Smith, D.J.; Cao, H.; Chen, Y.P.; Fan, J.; Zhang, Y.-H.; Pimpinella, R.E.; Dobrowolska, M.; Furdyna, J.K. Characterization of Bi2Te3 and Bi2Se3 topological insulators grown by MBE on (001) GaAs substrates. J. Vac. Sci. Technol. B 2012, 30, 02B103. [Google Scholar] [CrossRef]

- Kim, N.; Lee, P.; Kim, Y.Y.; Kim, J.S.; Kim, Y.Y.; Noh, D.Y.; Yu, S.U.; Chung, J.; Kim, K.S. Persistent Topological Surface State at the Interface of Bi2Se3 Film Grown on Patterned Graphene. ACS Nano 2014, 8, 1154–1160. [Google Scholar] [CrossRef] [PubMed]

- Song, C.-L.; Wang, Y.Y.-L.; Jiang, Y.-P.; Zhang, Y.; Chang, C.-Z.; Wang, L.; He, K.; Chen, X.; Jia, J.-F.; Wang, Y.Y.-L.; et al. Topological insulator Bi2Se3 thin films grown on double-layer graphene by molecular beam epitaxy. Appl. Phys. Lett. 2010, 97, 143118. [Google Scholar] [CrossRef]

- Xie, M.-H.; Guo, X.; Xu, Z.-J.; Ho, W.-K. Molecular-beam epitaxy of topological insulator Bi2Se3 (111) and (221) thin films. Chin. Phys. B 2013, 22, 68101. [Google Scholar] [CrossRef]

- Pashley, M.D.; Li, D. Control of the Fermi-level position on the GaAs(001) surface: Se passivation. J. Vac. Sci. Technol. A 1994, 12, 1848. [Google Scholar] [CrossRef]

- Emziane, M.; Marsillac, S.; Bernède, J.C. Preparation of highly oriented α-In2Se3 thin films by a simple technique. Mater. Chem. Phys. 2000, 62, 84–87. [Google Scholar] [CrossRef]

- Jing, Y.; Huang, S.; Zhang, K.; Wu, J.; Guo, Y.; Peng, H.; Liu, Z.; Xu, H.Q. Weak antilocalization and electron–electron interaction in coupled multiple-channel transport in a Bi2Se3 thin film. Nanoscale 2016, 8, 1879–1885. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; He, X.; Guan, T.; Liao, J.; Lin, C.; Wu, K.; Li, Y.; Zeng, C. Transport properties of topological insulator Bi2Se3 thin films in tilted magnetic fields. Physica E 2012, 46, 236–240. [Google Scholar] [CrossRef]

- Li, C.H.; van't Erve, O.M.J.; Robinson, J.T.; Liu, Y.; Li, L.; Jonker, B.T. Electrical detection of charge-current-induced spin polarization due to spin-momentum locking in Bi2Se3. Nat. Nanotechnol. 2014, 9, 218–224. [Google Scholar] [CrossRef] [PubMed]

- Jerng, S.-K.; Joo, K.; Kim, Y.S.Y.; Yoon, S.-M.; Lee, J.H.; Kim, M.; Kim, J.S.; Yoon, E.; Chun, S.-H.; Kim, Y.S.Y. Ordered growth of topological insulator Bi2Se3 thin films on dielectric amorphous SiO2 by MBE. Nanoscale 2013, 5, 10618. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.H.; Chong, C.W.; Jheng, J.L.; Huang, S.Y.M.; Huang, J.C.A.; Li, Z.; Qiu, H.; Huang, S.Y.M.; Marchenkov, V.V. Gate-tunable coherent transport in Se-capped Bi2Se3 grown on amorphous SiO2/Si. Appl. Phys. Lett. 2015, 107, 12106. [Google Scholar] [CrossRef]

- Tabor, P.; Keenan, C.; Urazhdin, S.; Lederman, D.; Urazdhin, S.; Lederman, D. Molecular beam epitaxy and characterization of thin Bi2Se3 films on Al2O3 (110). Appl. Phys. Lett. 2011, 99, 13111. [Google Scholar] [CrossRef]

- Glinka, Y.D.; Babakiray, S.; Lederman, D. Plasmon-enhanced electron-phonon coupling in Dirac surface states of the thin-film topological insulator Bi2Se3. J. Appl. Phys. 2015, 118, 135713. [Google Scholar] [CrossRef]

- He, L.; Xiu, F.; Yu, X.; Teague, M.; Jiang, W.; Fan, Y.; Kou, X.; Lang, M.; Wang, Y.; Huang, G.; et al. Surface-Dominated Conduction in a 6 nm thick Bi2Se3 Thin Film. Nano Lett. 2012, 12, 1486–1490. [Google Scholar] [CrossRef] [PubMed]

- Park, B.C.; Kim, T.-H.; Sim, K.I.; Kang, B.; Kim, J.W.J.H.; Cho, B.; Jeong, K.-H.; Cho, M.-H.; Kim, J.W.J.H. Terahertz single conductance quantum and topological phase transitions in topological insulator Bi2Se3 ultrathin films. Nat. Commun. 2015, 6, 6552. [Google Scholar] [CrossRef] [PubMed]

- Aabdin, Z.; Peranio, N.; Winkler, M.; Bessas, D.; König, J.; Hermann, R.P.; Böttner, H.; Eibl, O. Sb2Te3 and Bi2Te3 Thin Films Grown by Room-Temperature MBE. J. Electron. Mater. 2012, 41, 1493–1497. [Google Scholar] [CrossRef]

- Caha, O.; Dubroka, A.; Humlíček, J.; Holý, V.; Steiner, H.; Ul-Hassan, M.; Sánchez-Barriga, J.; Rader, O.; Stanislavchuk, T.N.; Sirenko, A.A.; et al. Growth, Structure, and Electronic Properties of Epitaxial Bismuth Telluride Topological Insulator Films on BaF2(111) Substrates. Cryst. Growth Des. 2013, 13, 3365–3373. [Google Scholar] [CrossRef]

- Fülöp, A.; Song, Y.; Charpentier, S.; Shi, P.; Ekström, M.; Galletti, L.; Arpaia, R.; Bauch, T.; Lombardi, F.; Wang, S. Phase transition of bismuth telluride thin films grown by MBE. Appl. Phys. Express 2014, 7, 45503. [Google Scholar] [CrossRef]

- Kampmeier, J.; Weyrich, C.; Lanius, M.; Schall, M.; Neumann, E.; Mussler, G.; Schäpers, T.; Grützmacher, D. Selective area growth of Bi2Te3 and Sb2Te3 topological insulator thin films. J. Cryst. Growth 2016, 443, 38–42. [Google Scholar] [CrossRef]

- Liu, H.W.; Yuan, H.T.; Fukui, N.; Zhang, L.; Jia, J.F.; Iwasa, Y.; Chen, M.W.; Hashizume, T.; Sakurai, T.; Xue, Q.K. Growth of Topological Insulator Bi2Te3 Ultrathin Films on Si(111) Investigated by Low-Energy Electron Microscopy. Cryst. Growth Des. 2010, 10, 4491–4493. [Google Scholar] [CrossRef]

- Roy, A.; Guchhait, S.; Sonde, S.; Dey, R.; Pramanik, T.; Rai, A.; Movva, H.C.P.; Colombo, L.; Banerjee, S.K. Two-dimensional weak anti-localization in Bi2Te3 thin film grown on Si(111)-(7 × 7) surface by molecular beam epitaxy. Appl. Phys. Lett. 2013, 102, 163118. [Google Scholar] [CrossRef]

- Steiner, H.; Volobuev, V.; Caha, O.; Bauer, G.; Springholz, G.; Holý, V. Structure and composition of bismuth telluride topological insulators grown by molecular beam epitaxy. J. Appl. Crystallogr. 2014, 47, 1889–1900. [Google Scholar] [CrossRef]

- Wang, K.L.; Liu, Y.; Wang, W.; Meyer, N.; Bao, L.H.; He, L.; Lang, M.R.; Chen, Z.G.; Che, X.Y.; Post, K.; et al. High-quality Bi2Te3 thin films grown on mica substrates for potential optoelectronic applications. Appl. Phys. Lett. 2013, 103, 31605. [Google Scholar] [CrossRef]

- Yu, X.; He, L.; Lang, M.; Jiang, W.; Xiu, F.; Liao, Z.; Wang, Y.; Kou, X.; Zhang, P.; Tang, J.; et al. Separation of top and bottom surface conduction in Bi2Te3 thin films. Nanotechnology 2013, 24, 15705. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; DiVenere, A.; Wong, G.K.L.; Ketterson, J.B.; Cho, S.; Meyer, J.R. Structural and thermoelectric transport properties of Sb2Te3 thin films grown by molecular beam epitaxy. J. Appl. Phys. 2002, 91, 715–718. [Google Scholar] [CrossRef]

- Zeng, Z.; Morgan, T.A.; Fan, D.; Li, C.; Hirono, Y.; Hu, X.; Zhao, Y.; Lee, J.S.; Wang, J.; Wang, Z.M.; et al. Molecular beam epitaxial growth of Bi2Te3 and Sb2Te3 topological insulators on GaAs (111) substrates: A potential route to fabricate topological insulator p–n junction. AIP Adv. 2013, 3, 72112. [Google Scholar] [CrossRef]

- Kong, D.; Dang, W.; Cha, J.J.; Li, H.; Meister, S.; Peng, H.; Liu, Z.; Cui, Y. Few-Layer Nanoplates of Bi2Se3 and Bi2Te3 with Highly Tunable Chemical Potential. Nano Lett. 2010, 10, 2245–2250. [Google Scholar] [CrossRef] [PubMed]

- Steinberg, H.; Gardner, D.R.; Lee, Y.S.; Jarillo-Herrero, P. Surface State Transport and Ambipolar Electric Field Effect in Bi2Se3 Nanodevices. Nano Lett. 2010, 10, 5032–5036. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Checkelsky, J.G.; Hor, Y.S.; Cava, R.J.; Ong, N.P. Bulk Band Gap and Surface State Conduction Observed in Voltage-Tuned Crystals of the Topological Insulator Bi2Se3. Phys. Rev. Lett. 2011, 106, 196801. [Google Scholar] [CrossRef] [PubMed]

- Bansal, N.; Koirala, N.; Brahlek, M.; Han, M.-G.; Zhu, Y.; Cao, Y.; Waugh, J.; Dessau, D.S.; Oh, S. Robust topological surface states of Bi2Se3 thin films on amorphous SiO2/Si substrate and a large ambipolar gating effect. Appl. Phys. Lett. 2014, 104, 241606. [Google Scholar] [CrossRef]

- Zhang, L.; Hammond, R.; Dolev, M.; Liu, M.; Palevski, A.; Kapitulnik, A. High quality ultrathin Bi2Se3 films on CaF2 and CaF2/Si by molecular beam epitaxy with a radio frequency cracker cell. Appl. Phys. Lett. 2012, 101, 153105. [Google Scholar] [CrossRef]

- Lee, J.J.; Schmitt, F.T.; Moore, R.G.; Vishik, I.M.; Ma, Y.; Shen, Z.X. Intrinsic ultrathin topological insulators grown via molecular beam epitaxy characterized by in-situ angle resolved photoemission spectroscopy. Appl. Phys. Lett. 2012, 101, 13118. [Google Scholar] [CrossRef]

- Park, J.; Soh, Y.-A.; Aeppli, G.; Bland, S.R.; Zhu, X.-G.; Chen, X.; Xue, Q.-K.; Grey, F. Crystal structure and epitaxy of Bi2Te3 films grown on Si. Appl. Phys. Lett. 2012, 101, 221910. [Google Scholar] [CrossRef]

- Chen, X.; Ma, X.-C.; He, K.; Jia, J.-F.; Xue, Q.-K. Molecular Beam Epitaxial Growth of Topological Insulators. Adv. Mater. 2011, 23, 1162–1165. [Google Scholar] [CrossRef] [PubMed]

- Krumrain, J.; Mussler, G.; Borisova, S.; Stoica, T.; Plucinski, L.; Schneider, C.M.; Grützmacher, D. MBE growth optimization of topological insulator Bi2Te3 films. J. Cryst. Growth 2011, 324, 115–118. [Google Scholar] [CrossRef]

- Li, Y.-Y.; Wang, G.; Zhu, X.-G.; Liu, M.-H.; Ye, C.; Chen, X.; Wang, Y.-Y.; He, K.; Wang, L.-L.; Ma, X.-C.; et al. Intrinsic topological insulator Bi2Te3 thin films on Si and their thickness limit. Adv. Mater. 2010, 22, 4002–4007. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Bian, G.; Miller, T.; Bissen, M.; Chiang, T.-C. Topological limit of ultrathin quasi-free-standing Bi2Te3 films grown on Si(111). Phys. Rev. B 2012, 85, 195442. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.H.; Bian, G.; Zhang, Z.; Lee, S.S.; Fenter, P.A.; Tischler, J.Z.; Hong, H.; Chiang, T.C. Interfacial bonding and structure of Bi2Te3 topological insulator films on Si(111) determined by surface X-ray scattering. Phys. Rev. Lett. 2013, 110, 226103. [Google Scholar] [CrossRef] [PubMed]

- Plucinski, L.; Mussler, G.; Krumrain, J.; Herdt, A.; Suga, S.; Grützmacher, D.; Schneider, C.M. Robust surface electronic properties of topological insulators: Bi2Te3 films grown by molecular beam epitaxy. Appl. Phys. Lett. 2011, 98, 222503. [Google Scholar] [CrossRef]

- Harrison, S.E.; Li, S.; Huo, Y.; Zhou, B.; Chen, Y.L.; Harris, J.S. Two-step growth of high quality Bi2Te3 thin films on Al2O3 (0001) by molecular beam epitaxy. Appl. Phys. Lett. 2013, 102, 2011–2015. [Google Scholar] [CrossRef]

- Ngabonziza, P.; Heimbuch, R.; de Jong, N.; Klaassen, R.A.; Stehno, M.P.; Snelder, M.; Solmaz, A.; Ramankutty, S.V.; Frantzeskakis, E.; van Heumen, E.; et al. In situ spectroscopy of intrinsic Bi2Te3 topological insulator thin films and impact of extrinsic defects. Phys. Rev. B 2015, 92, 35405. [Google Scholar] [CrossRef]

- Xu, H.; Song, Y.; Gong, Q.; Pan, W.; Wu, X.; Wang, S. Raman spectroscopy of epitaxial topological insulator Bi2Te3 thin films on GaN substrates. Mod. Phys. Lett. B 2015, 29, 1550075. [Google Scholar] [CrossRef]

- Collins-McIntyre, L.J.; Wang, W.; Zhou, B.; Speller, S.C.; Chen, Y.L.; Hesjedal, T. Growth of Bi2Se3 and Bi2Te3 on amorphous fused silica by MBE. Phys. Status Solidi B 2015, 252, 1334–1338. [Google Scholar] [CrossRef]

- Rapacz, R.; Balin, K.; Wojtyniak, M.; Szade, J. Morphology and local conductance of single crystalline Bi2Te3 thin films on mica. Nanoscale 2015, 7, 16034–16038. [Google Scholar] [CrossRef] [PubMed]

- Fornari, C.I.; Rappl, P.H.O.; Morelhão, S.L.; Abramof, E. Structural properties of Bi2Te3 topological insulator thin films grown by molecular beam epitaxy on (111) BaF2 substrates. J. Appl. Phys. 2016, 119, 165303. [Google Scholar] [CrossRef]

- Wang, G.; Zhu, X.-G.; Sun, Y.-Y.; Li, Y.-Y.; Zhang, T.; Wen, J.; Chen, X.; He, K.; Wang, L.-L.; Ma, X.-C.; et al. Topological insulator thin films of Bi2Te3 with controlled electronic structure. Adv. Mater. 2011, 23, 2929–2932. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Sun, Y.Y.; Chen, M.; Wang, Y.; Li, Z.; Song, C.; He, K.; Wang, L.; Chen, X.; Xue, Q.-K.; et al. Fermi-Level Tuning of Epitaxial Sb2Te3 Thin Films on Graphene by Regulating Intrinsic Defects and Substrate Transfer Doping. Phys. Rev. Lett. 2012, 108, 66809. [Google Scholar] [CrossRef] [PubMed]

- Chien, Y.-J.; Zhou, Z.; Uher, C. Growth and transport properties of Sb2−xVxTe3 thin films on sapphire substrates. J. Cryst. Growth 2005, 283, 309–314. [Google Scholar] [CrossRef]

- Taskin, A.A.; Sasaki, S.; Segawa, K.; Ando, Y. Manifestation of topological protection in transport properties of epitaxial Bi2Se3 thin films. Phys. Rev. Lett. 2012, 109, 066803. [Google Scholar] [CrossRef] [PubMed]

- Bansal, N.; Kim, Y.S.; Brahlek, M.; Edrey, E.; Oh, S. Thickness-Independent Transport Channels in Topological Insulator Bi2Se3 Thin Films. Phys. Rev. Lett. 2012, 109, 116804. [Google Scholar] [CrossRef] [PubMed]

- Xiong, J.; Luo, Y.; Khoo, Y.; Jia, S.; Cava, R.J.; Ong, N.P. High-field Shubnikov-de Haas oscillations in the topological insulator Bi2Te2Se. Phys. Rev. B Condens. Matter Mater. Phys. 2012, 86, 045314. [Google Scholar] [CrossRef]

- Brahlek, M.; Koirala, N.; Bansal, N.; Oh, S. Transport properties of topological insulators: Band bending, bulk metal-to-insulator transition, and weak anti-localization. Solid State Commun. 2015, 215, 54–62. [Google Scholar] [CrossRef]

- Tung, Y.; Chiang, Y.F.; Chong, C.W.; Deng, Z.X.; Chen, Y.C.; Huang, J.C.A.; Cheng, C.-M.M.; Pi, T.-W.W.; Tsuei, K.-D.D.; Li, Z.; et al. Growth and characterization of molecular beam epitaxy-grown Bi2Te3−xSex topological insulator alloys. J. Appl. Phys. 2016, 119, 55303. [Google Scholar] [CrossRef]

- Ren, Z.; Taskin, A.A.; Sasaki, S.; Segawa, K.; Ando, Y. Large bulk resistivity and surface quantum oscillations in the topological insulator Bi2Te2Se. Phys. Rev. B 2010, 82, 241306(R). [Google Scholar] [CrossRef]

- Cha, J.J.; Kong, D.; Hong, S.-S.; Analytis, J.G.; Lai, K.; Cui, Y. Weak antilocalization in Bi2(Se(x)Te(1−x))3 nanoribbons and nanoplates. Nano Lett. 2012, 12, 1107–1111. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Chang, C.; Zhang, Z.; Wen, J.; Feng, X.; Li, K.; Liu, M.; He, K.; Wang, L.; Chen, X.; et al. Band structure engineering in (Bi1−xSbx)2Te3 ternary topological insulators. Nat. Commun. 2011, 2, 574. [Google Scholar] [CrossRef] [PubMed]

- Kellner, J.; Eschbach, M.; Kampmeier, J.; Lanius, M.; Młyńczak, E.; Mussler, G.; Holländer, B.; Plucinski, L.; Liebmann, M.; Grützmacher, D.; et al. Tuning the Dirac point to the Fermi level in the ternary topological insulator (Bi1−xSbx)2Te3. Appl. Phys. Lett. 2015, 107, 251603. [Google Scholar] [CrossRef]

- He, X.; Li, H.; Chen, L.; Wu, K. Substitution-induced spin-splitted surface states in topological insulator (Bi1−xSbx)2Te3. Sci. Rep. 2015, 5, 8830. [Google Scholar] [CrossRef] [PubMed]

- Tang, J.; Chang, L.T.; Kou, X.; Murata, K.; Choi, E.S.; Lang, M.; Fan, Y.; Jiang, Y.; Montazeri, M.; Jiang, W.; et al. Electrical detection of spin-polarized surface states conduction in (Bi0.53Sb0.47)2Te3 topological insulator. Nano Lett. 2014, 14, 5423–5429. [Google Scholar] [CrossRef] [PubMed]

- Weyrich, C.; Drögeler, M.; Kampmeier, J.; Eschbach, M.; Mussler, G.; Merzenich, T.; Stoica, T.; Batov, I.E.; Schubert, J.; Plucinski, L.; et al. Growth, characterization, and transport properties of ternary (Bi1−xSbx)2Te3 topological insulator layers. J. Phys. Condens. Matter 2015, 28, 495501. [Google Scholar] [CrossRef] [PubMed]

- Eschbach, M.; Młyńczak, E.; Kellner, J.; Kampmeier, J.; Lanius, M.; Neumann, E.; Weyrich, C.; Gehlmann, M.; Gospodarič, P.; Döring, S.; et al. Realization of a vertical topological p–n junction in epitaxial Sb2Te3/Bi2Te3 heterostructures. Nat. Commun. 2015, 6, 8816. [Google Scholar] [CrossRef] [PubMed]

- Lanius, M.; Kampmeier, J.; Weyrich, C.; Kölling, S.; Schall, M.; Schüffelgen, P.; Neumann, E.; Luysberg, M.; Mussler, G.; Koenraad, P.M.; et al. p–n Junctions in Ultrathin Topological Insulator Sb2Te3/Bi2Te3 Heterostructures Grown by Molecular Beam Epitaxy. Cryst. Growth Des. 2016, 16, 2057–2061. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, H.; Guo, X.; Jiang, Y.; Sun, Y.; Wang, H.; Wang, Y.; Li, H.-D.D.; Xie, M.-H.H.; Xie, X.-C.C.; et al. Crossover from 3D to 2D Quantum Transport in Bi2Se3/In2Se3 Superlattices. Nano Lett. 2014, 14, 5244–5249. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.Y.; Guo, X.; Li, H.D.; Wong, T.L.; Wang, N.; Xie, M.H. Superlattices of Bi2Se3/In2Se3: Growth characteristics and structural properties. Appl. Phys. Lett. 2011, 99, 023112. [Google Scholar] [CrossRef] [Green Version]

- Brahlek, M.J.; Koirala, N.; Liu, J.; Yusufaly, T.I.; Salehi, M.; Han, M.G.; Zhu, Y.; Vanderbilt, D.; Oh, S. Tunable inverse topological heterostructure utilizing (Bi1−xInx)2Se3 and multichannel weak-antilocalization effect. Phys. Rev. B 2016, 93, 125416. [Google Scholar] [CrossRef]

- Li, H.D.; Wang, Z.Y.; Guo, X.; Wong, T.L.; Wang, N.; Xie, M.H. Growth of multilayers of Bi2Se3/ZnSe: Heteroepitaxial interface formation and strain. Appl. Phys. Lett. 2011, 98, 043104. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; Garcia, T.A.; Hernandez-Mainet, L.C.; Zhao, L.; Deng, H.; Krusin-Elbaum, L.; Tamargo, M.C. Molecular beam epitaxial growth and characterization of Bi2Se3/II-VI semiconductor heterostructures. Appl. Phys. Lett. 2014, 105, 242105. [Google Scholar] [CrossRef]

- Luo, W.; Qi, X.L. Massive Dirac surface states in topological insulator/magnetic insulator heterostructures. Phys. Rev. B 2013, 87. [Google Scholar] [CrossRef]

- Matetskiy, A.V.; Kibirev, I.A.; Hirahara, T.; Hasegawa, S.; Zotov, A.V.; Saranin, A.A. Direct observation of a gap opening in topological interface states of MnSe/Bi2Se3 heterostructure. Appl. Phys. Lett. 2015, 107, 091604. [Google Scholar] [CrossRef]

- Jiang, Z.; Chang, C.Z.; Tang, C.; Zheng, J.G.; Moodera, J.S.; Shi, J. Structural and proximity-induced ferromagnetic properties of topological insulator-magnetic insulator heterostructures. AIP Adv. 2016, 6, 055809. [Google Scholar] [CrossRef]

- Chang, C.Z.; Tang, P.; Feng, X.; Li, K.; Ma, X.C.; Duan, W.; He, K.; Xue, Q.K. Band Engineering of Dirac Surface States in Topological-Insulator-Based van der Waals Heterostructures. Phys. Rev. Lett. 2015, 115, 136801. [Google Scholar] [CrossRef] [PubMed]

- Kane, C.L.; Mele, E.J. Z2 topological order and the quantum spin hall effect. Phys. Rev. Lett. 2005, 95, 146802. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Peng, J.P.; Zhang, H.M.; Wang, L.L.; He, K.; Ma, X.C.; Xue, Q.K. Molecular beam epitaxy of bilayer Bi(111) films on topological insulator Bi2Te3: A scanning tunneling microscopy study. Appl. Phys. Lett. 2012, 101, 081603. [Google Scholar] [CrossRef]

- Wang, M.-X.; Li, P.; Xu, J.-P.; Liu, Z.-L.; Ge, J.-F.; Wang, G.-Y.; Yang, X.; Xu, Z.-A.; Ji, S.-H.; Gao, C.L.; et al. Interface structure of a topological insulator/superconductor heterostructure. New J. Phys. 2014, 16, 123043. [Google Scholar] [CrossRef]

- Xu, S.-Y.; Alidoust, N.; Belopolski, I.; Richardella, A.; Liu, C.; Neupane, M.; Bian, G.; Huang, S.-H.; Sankar, R.; Fang, C.; et al. Momentum-space imaging of Cooper pairing in a half-Dirac-gas topological superconductor. Nat. Phys. 2014, 10, 943–950. [Google Scholar] [CrossRef]

- Xu, J.P.; Liu, C.; Wang, M.X.; Ge, J.; Liu, Z.L.; Yang, X.; Chen, Y.; Liu, Y.; Xu, Z.A.; Gao, C.L.; et al. Artificial topological superconductor by the proximity effect. Phys. Rev. Lett. 2014, 112, 217001. [Google Scholar] [CrossRef]

- Xu, J.P.; Wang, M.X.; Liu, Z.L.; Ge, J.F.; Yang, X.; Liu, C.; Xu, Z.A.; Guan, D.; Gao, C.L.; Qian, D.; et al. Experimental detection of a Majorana mode in the core of a magnetic vortex inside a topological insulator-superconductor Bi2Te3/NbSe2 heterostructure. Phys. Rev. Lett. 2015, 114, 017001. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.Y.; Liu, C.; Richardella, A.; Belopolski, I.; Alidoust, N.; Neupane, M.; Bian, G.; Samarth, N.; Hasan, M.Z. Fermi-level electronic structure of a topological-insulator/cuprate-superconductor based heterostructure in the superconducting proximity effect regime. Phys. Rev. B 2014, 90, 085128. [Google Scholar] [CrossRef]

- Yilmaz, T.; Pletikosic, I.; Weber, A.P.; Sadowski, J.T.; Gu, G.D.; Caruso, A.N.; Sinkovic, B.; Valla, T. Absence of a proximity effect for a thin-films of a Bi2Se3 topological insulator grown on top of a Bi2Sr2CaCu2O8+δ cuprate superconductor. Phys. Rev. Lett. 2014, 113, 067003. [Google Scholar] [CrossRef] [PubMed]

| Material | Substrate | μ cm2/Vs | n2D cm−2 | n3D cm−3 | t nm | T K | Reference |

|---|---|---|---|---|---|---|---|

| Bi2Se3 | Mica | 472 | 6.1 × 1013 | 10 | [70] | ||

| Bi2Se3 | Graphene | Intrinsic | <10 | [66] | |||

| Bi2Se3 | SrTiO3(111) | 1.9–3.1 × 1013 | 5–50 | [71] | |||

| Bi2Se3 | Graphene and Al2O3(0001) | ~1 × 1019 | 11–45 | [72] | |||

| Bi2Se3 | InP(111)A | 3500 | ~1 × 1018 | 2 | [38] | ||

| Bi2Se3 | Si(111) Vicinal | 1600 | 5 × 1018 | 200 | 2 | [57] | |

| Bi2Se3 | Si(111) Flat | 1200 | 3 × 1019 | 200 | 2 | [57] | |

| Bi2Se3 | Si(111) | 1.25 × 1013 | 7 | 200 | [39] | ||

| Bi2Se3 | SiO2 | ~4 × 1013 | 20 | 2 | [73] | ||

| Bi2Se3 | Graphene | 5000 [6] | ~1.1 × 1019 | 400 | 20 | [65] | |

| Bi2Se3 | AlOx | 623 | ∼3 × 1013 | 100 | 300 | [62] | |

| Bi2Se3 | GaAs (111)B | 100−1000 | 8.06–40 × 1018 | 4.2 | [36] | ||

| Bi2Se3 | SiO2/Si | ∼2.2 × 1013 | 7 | [74] | |||

| Bi2Se3 | Al2O3(110) | 150 | 9.4 × 1018 | 20 | 13 | [75] | |

| Bi2Se3 | Al2O3(0001) | 0.5–3.5 × 1019 | 2–40 | [76] | |||

| Bi2Se3 | Rough InP(111)B | 2000 | 9 × 1017 | 100 | 4 | [34] | |

| Bi2Se3 | CdS(0001) | ~4000 [6] | ~6 × 1011 | 6 | 2 | [77] | |

| Bi2Se3 | CdS(0001) | ~400 [7] | ~1 × 1013 | 6 | 2 | [77] | |

| Bi2Se3 | Si (100) | 2880 [6] | 8.4 × 1010 | 8 | [78] | ||

| Bi2Se3 | Si (100) | 54 [8] | 4.5 × 1012 | 8 | [78] | ||

| Bi2Te3 [1] | SiO2 | 2.8 | 1 × 1021 | ~100 | 300 | [79] | |

| Sb2Te3 [1] | SiO2 | 42 | 2.4 × 1019 [9] | ~100 | 300 | [79] | |

| Bi2Te3 [1a] | SiO2 | 80 | 2.7 x 1019 | ~100 | 300 | [79] | |

| Sb2Te3 [1a] | SiO2 | 402 | 2.6 × 1019 [9] | ~100 | 300 | [79] | |

| Bi2Te3 | BaF2(111) | 1.3 × 1019 | [2] | [80] | |||

| Bi2Te3 | Si(111) | 1030 | 4.7 × 1019 | [81] | |||

| Bi2Te3 | BaF2(111) | 2000–4600 | 2–4 × 1012 | 10–50 | [3] | [51] | |

| Bi2Te3 | Prestructured Si(111) SOI | 110 | 1.6 × 1014 | [5] | [82] | ||

| Sb2Te3 | Prestructured Si(111) SOI | 636 | 6.7 × 1013 [9] | [5] | [82] | ||

| Bi2Te3 | Si(111) | 7 × 1012 | 1.32 × 1019 | 5.3 | 300 | [83] | |

| Bi2Te3 | n-type Si(111) | 35 | 1.2 × 1014 | 4 | 2 | [84] | |

| Bi2Te3 | BaF2(111) | 1500 | 2–10 × 1018 | 350 | 77 | [85] | |

| Bi2Te3 | Mica | 4800 | 2.45 × 1012 | 4 | [4] | [86] | |

| Bi2Te3 | GaAs(111)B | 10.6 × 1012 | 2 | [87] | |||

| Sb2Te3 | CdTe(111)B | 279 | 7.48 × 1018 | ~300 | 290 | [88] | |

| Sb2Te3 | V-GaAs(111)B | 781 | 9.13 × 1018 | 400 | 1.8 | [89] |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ginley, T.P.; Wang, Y.; Law, S. Topological Insulator Film Growth by Molecular Beam Epitaxy: A Review. Crystals 2016, 6, 154. https://doi.org/10.3390/cryst6110154

Ginley TP, Wang Y, Law S. Topological Insulator Film Growth by Molecular Beam Epitaxy: A Review. Crystals. 2016; 6(11):154. https://doi.org/10.3390/cryst6110154

Chicago/Turabian StyleGinley, Theresa P., Yong Wang, and Stephanie Law. 2016. "Topological Insulator Film Growth by Molecular Beam Epitaxy: A Review" Crystals 6, no. 11: 154. https://doi.org/10.3390/cryst6110154