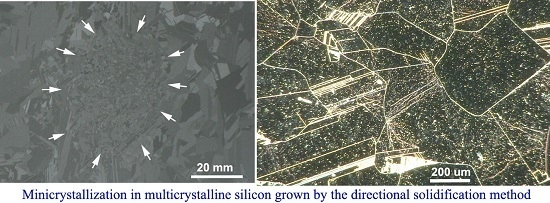

Study of Dislocations in the Minicrystallized Regions in Multicrystalline Silicon Grown by the Directional Solidification Method

Abstract

:1. Introduction

2. Experiment

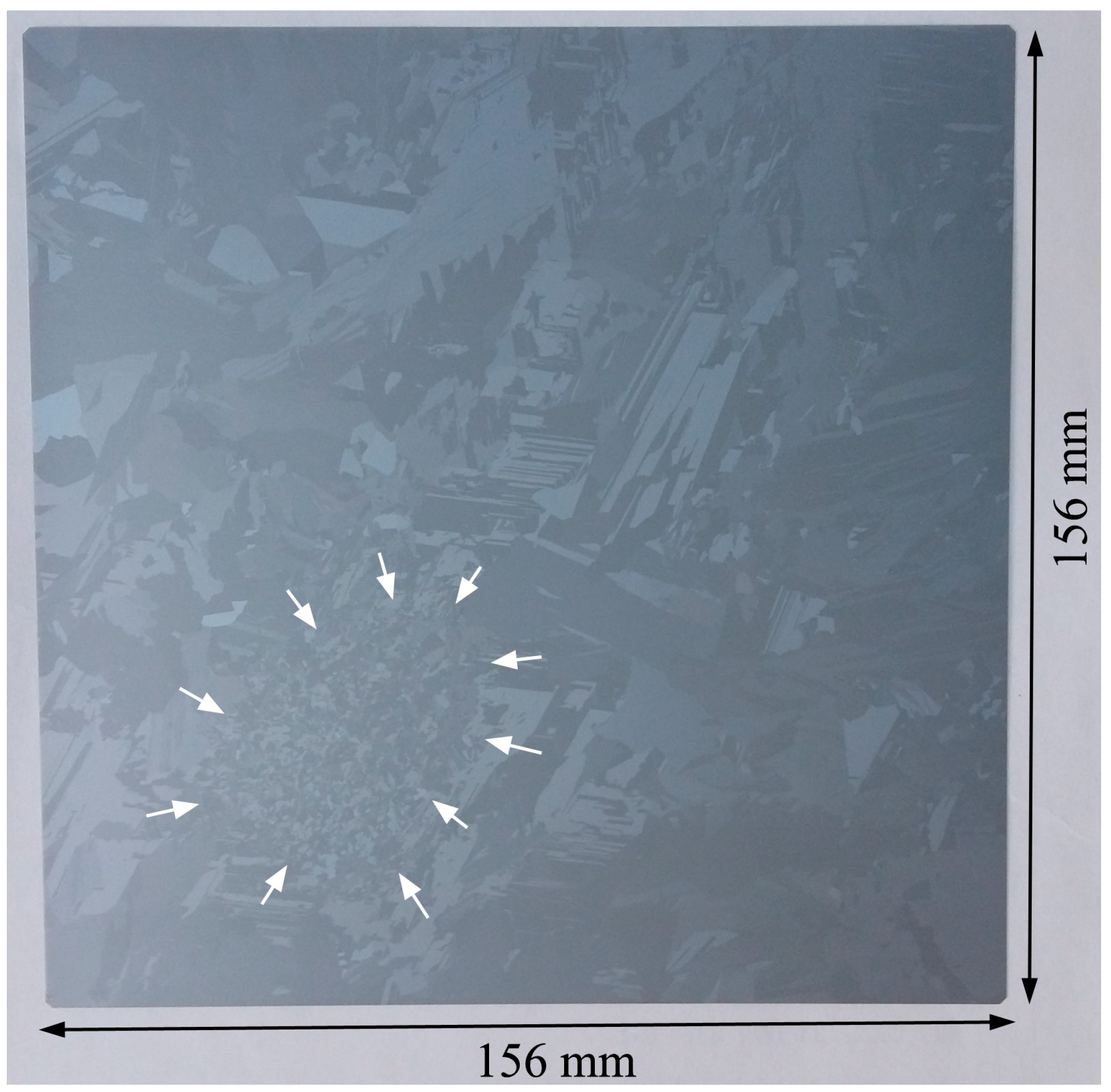

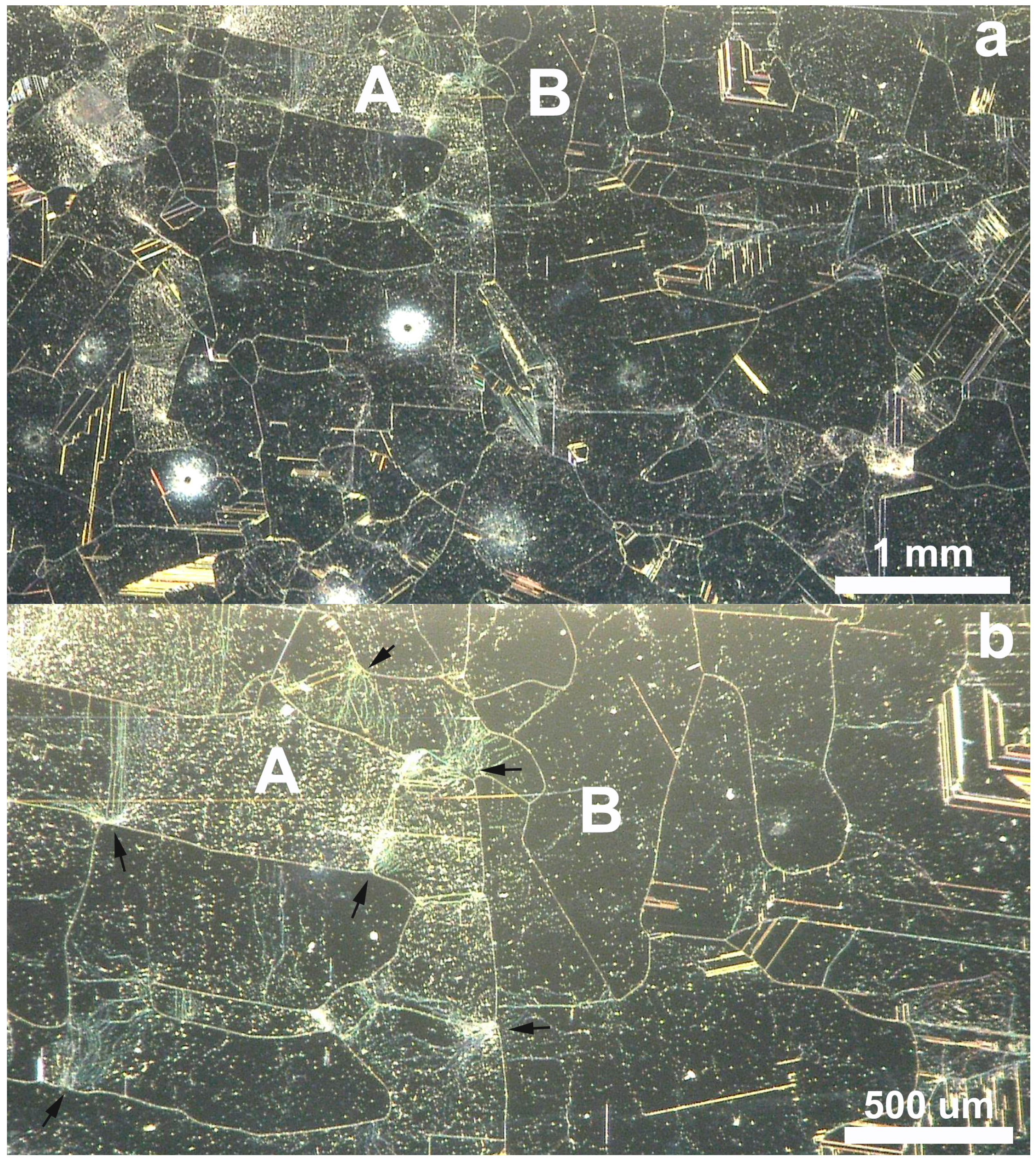

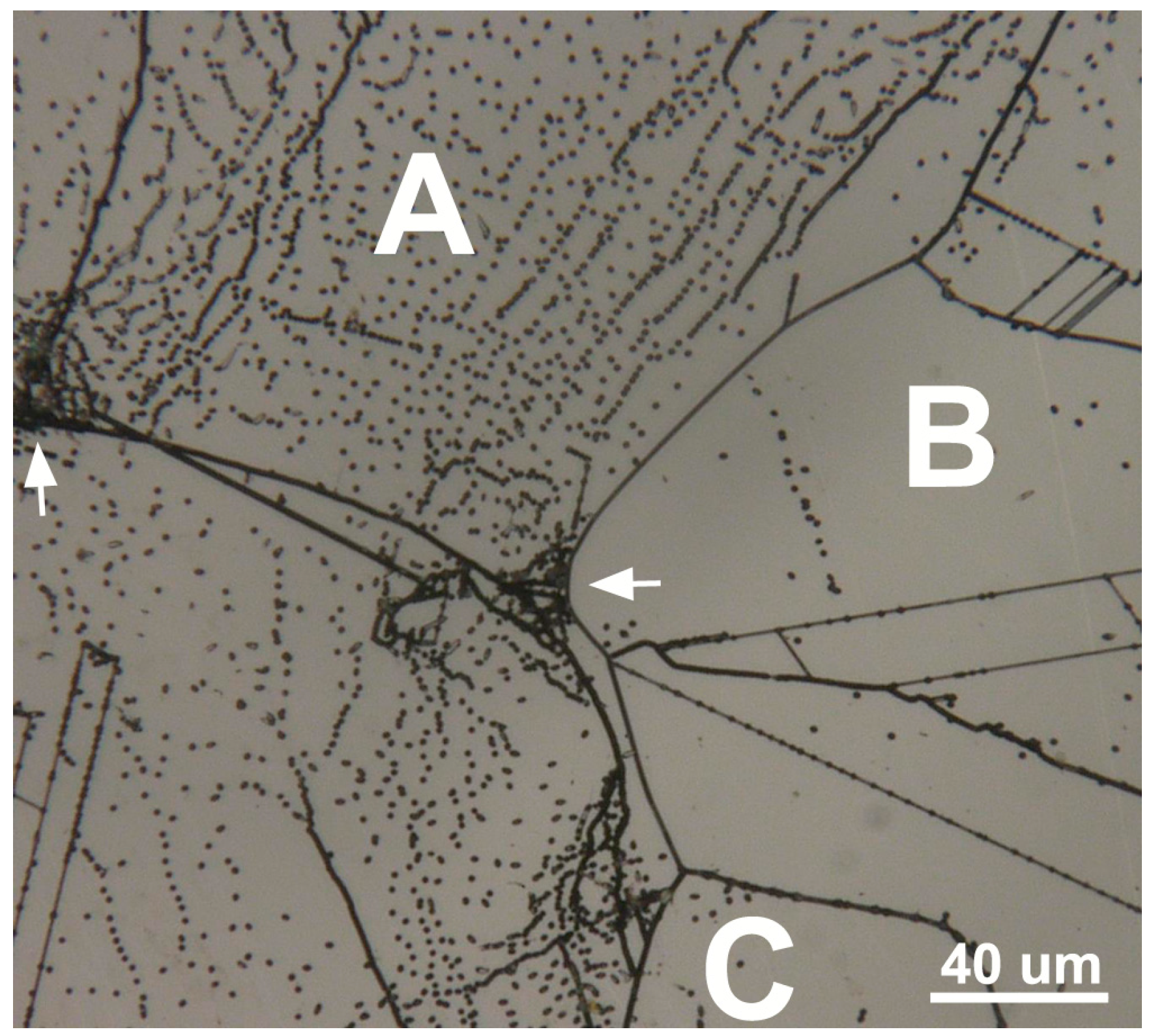

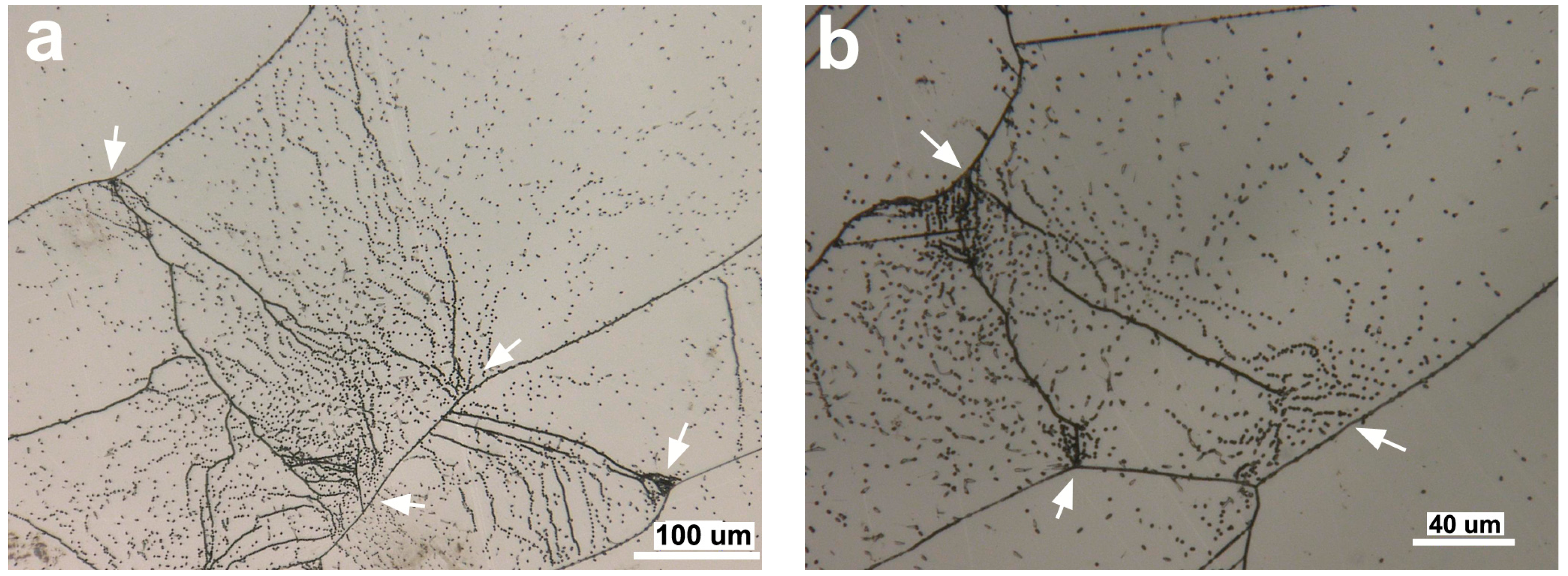

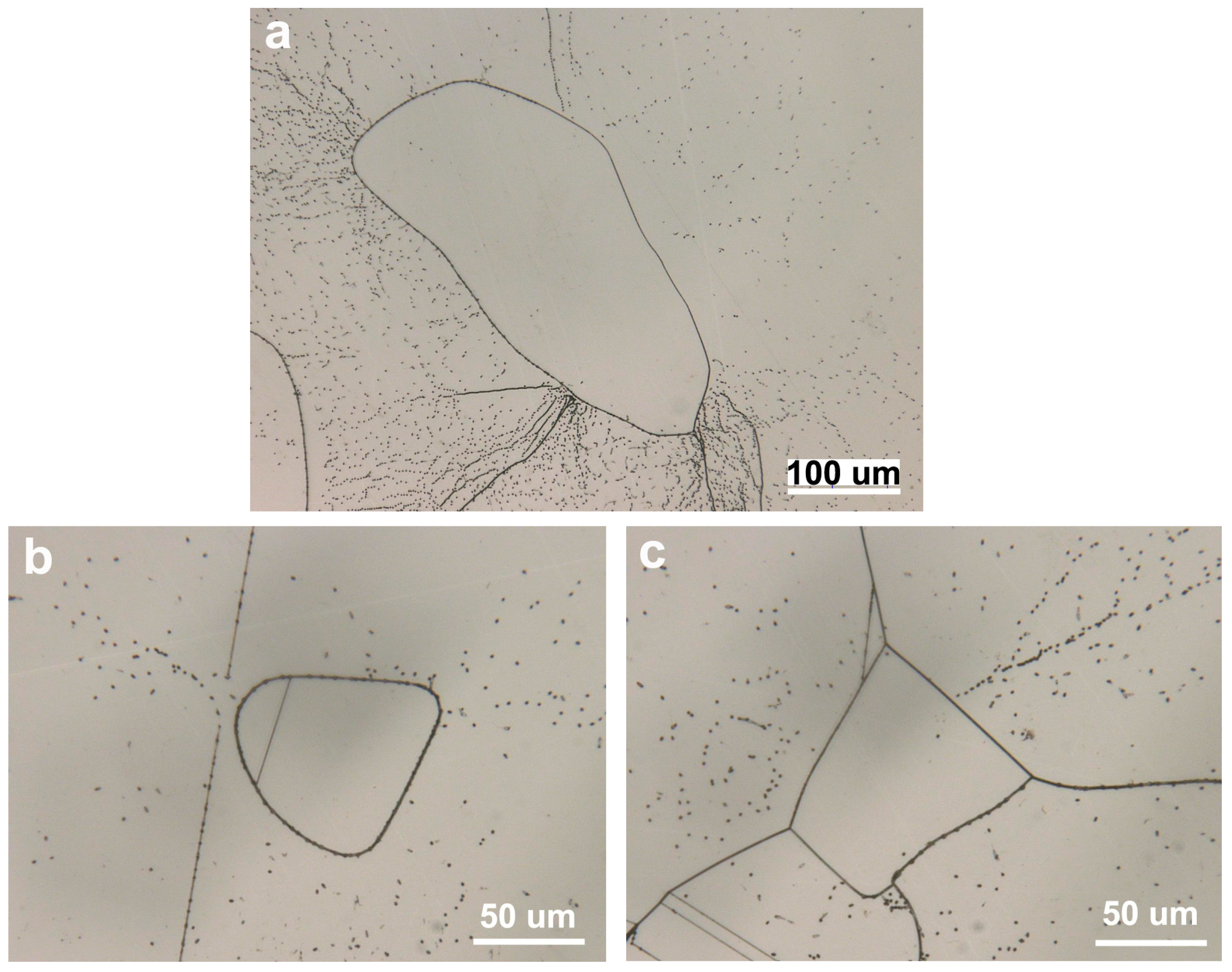

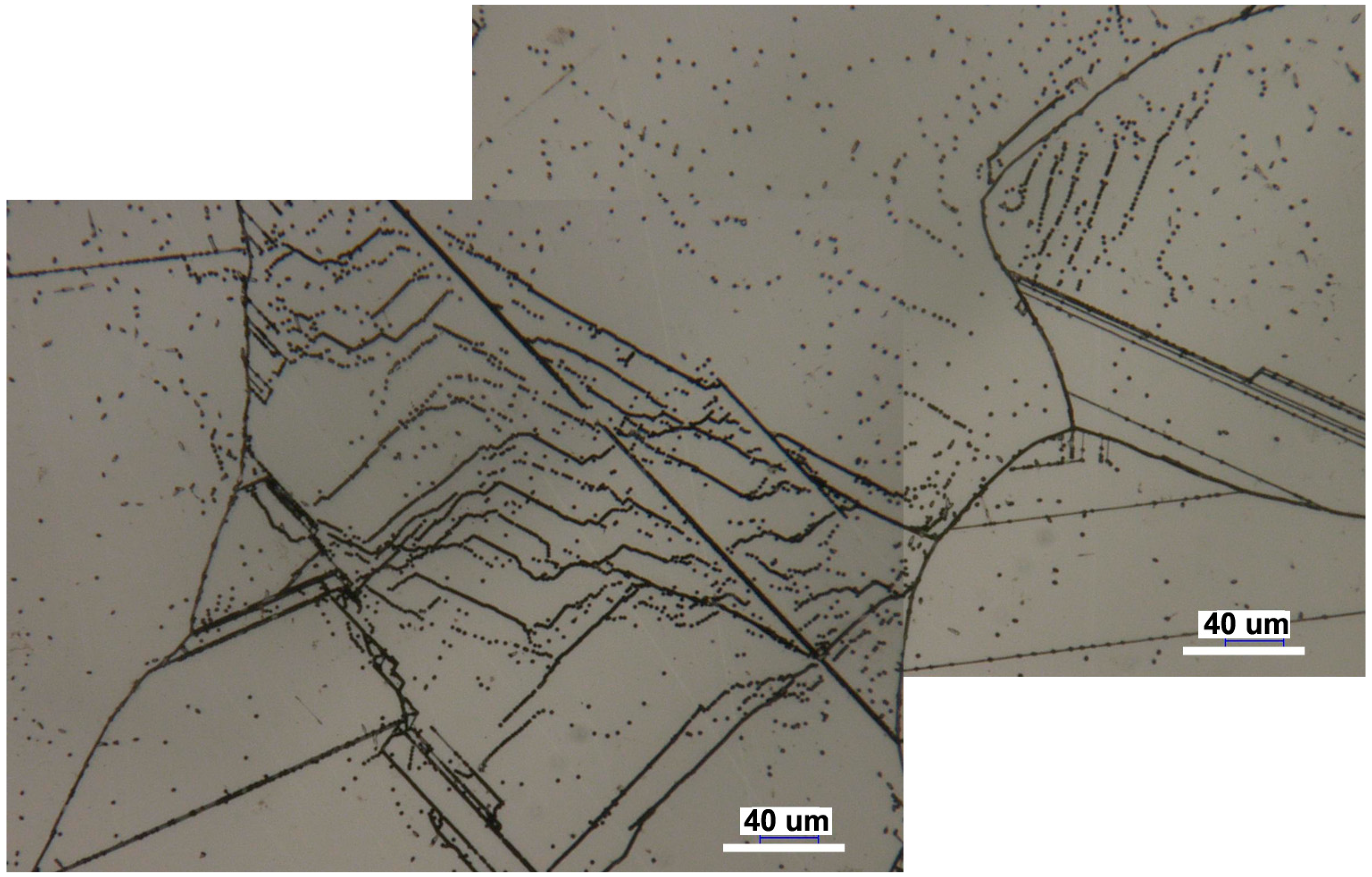

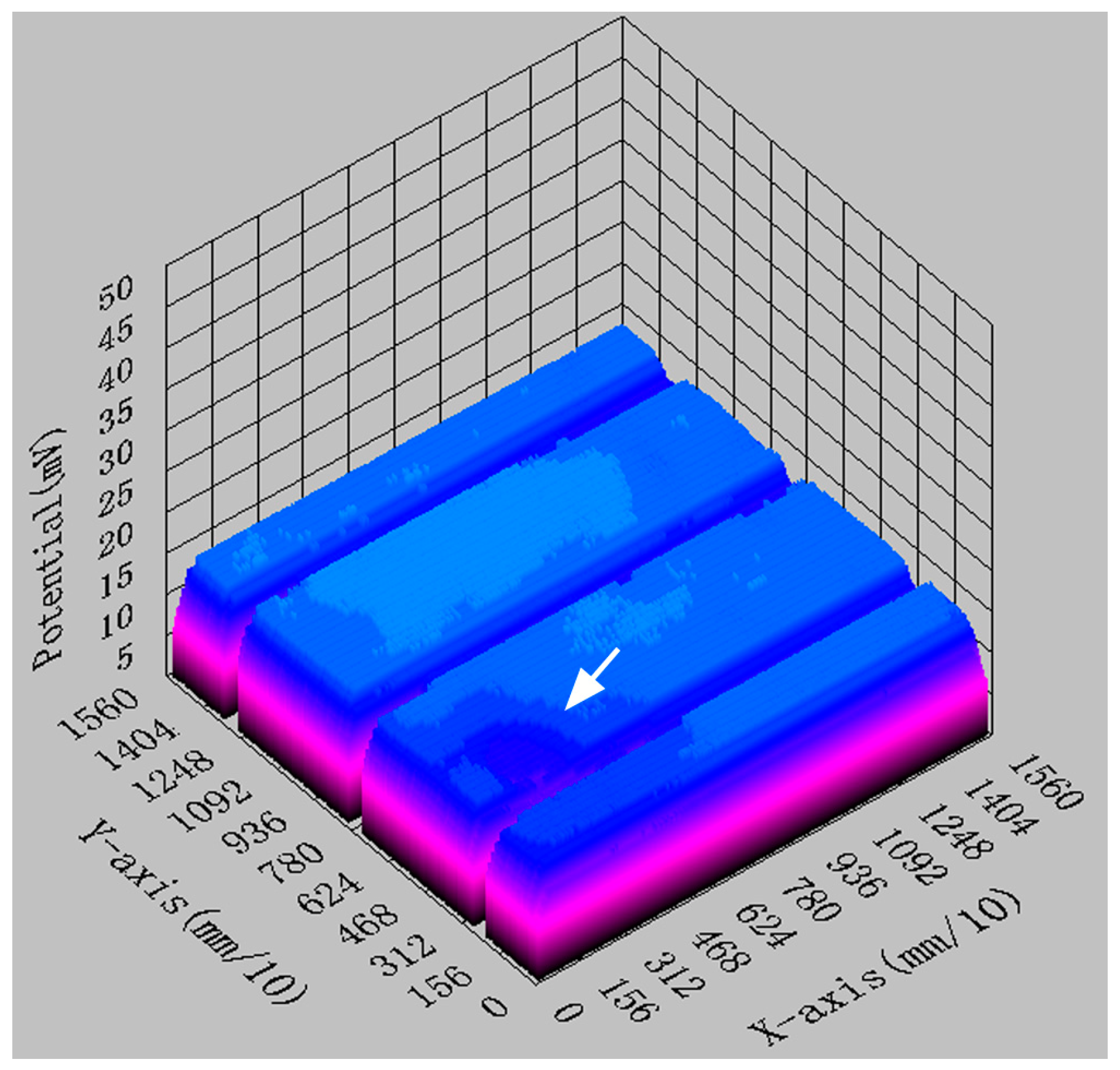

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Swanson, R.M. A vision for crystalline silicon photovoltaics. Prog. Photovolt. Res. Appl. 2006, 14, 443–453. [Google Scholar] [CrossRef]

- Budhraja, V.; Misra, D.; Ravindra, N.M. Advancements in PV multicrystalline silicon solar cells from 1980 to 2010—An overview. In Proceedings of the 37th IEEE Photovoltaic Specialists Conference, Seattle, WA, USA, 19–24 June 2011.

- Schumann, M.; Haas, T.; Orellana Pérez, T.; Riepe, S. Grain size distribution in multicrystalline silicon for structure characterization of silicon wafers. In Proceedings of the 26th European PV Solar Energy Conference and Exhibition, Hamburg, Germany, 2–9 September 2011.

- El Ghitani, H.; Pasquinelli, M.; Martinuzzi, S. Influence of dislocations on photovoltaic properties of multicrystalline silicon solar cells. J. Phys. III 1993, 3, 1941–1946. [Google Scholar] [CrossRef]

- Schindler, R.; Räuber, A. Defects in multicrystalline silicon. Solid State Phenom. 1991, 19–20, 341–352. [Google Scholar] [CrossRef]

- Sopori, B. Impurities and defects in photovoltaic Si devices: A review. In Proceedings of the 10th International Workshop on the Physics of Semiconductor Devices, Delhi, India, 14–18 December 1999.

- Hartman, K.; Bertoni, M.; Serdy, J.; Buonassisi, T. Dislocation density reduction in multicrystalline silicon solar cell material by high temperature annealing. Appl. Phys. Lett. 2008, 93, 122108. [Google Scholar] [CrossRef]

- Ryningen, B.; Stokkan, G.; Kivambe, M.; Ervik, T.; Lohne, O. Growth of dislocation clusters during directional solidification of multicrystalline silicon ingots. Acta Mater. 2011, 59, 7703–7710. [Google Scholar] [CrossRef]

- Stokkan, G.; Riepe, S.; Lohne, O.; Warta, W. Spatially resolved modeling of the combined effect of dislocations and grain boundaries on minority carrier lifetime in multicrystalline silicon. J. Appl. Phys. 2007, 101, 053515. [Google Scholar] [CrossRef]

- Fathi, M.; Bouhafs, D. A new detection technique of crystalline defects by sheet resistance measurement on multicrystalline silicon wafers. Semicond. Sci. Technol. 2006, 21, 437–442. [Google Scholar] [CrossRef]

- Kim, D.I.; Kim, Y.K. Characteristics of structural defects in the 240 kg silicon ingot grown by directional solidification process. Sol. Energy Mater. Sol. Cells 2006, 90, 1666–1672. [Google Scholar] [CrossRef]

- Istratov, A.A.; Hieslmair, H.; Vyvenko, O.F.; Weber, E.R.; Schindler, R. Defect recognition and impurity detection techniques in crystalline silicon for solar cells. Sol. Energy Mater. Sol. Cells 2002, 72, 441–451. [Google Scholar] [CrossRef]

- Luque, A.; Hegedus, S. Handbook of Photovoltaic Science and Engineering; John Wiley & Sons Ltd.: West Sussex, UK, 2003. [Google Scholar]

- El Ghitani, H.; Martinuzzi, S. Influence of dislocations on electrical properties of large grained polycrystalline silicon cells. I. Model. J. Appl. Phys. 1989, 66, 1717–1722. [Google Scholar] [CrossRef]

- Sopori, B.; Chen, W. Influence of distributed defects on the photoelectric characteristics of a large-area device. J. Cryst. Growth 2000, 210, 375–378. [Google Scholar] [CrossRef]

- Donolato, C. Modeling the effect of dislocations on the minority carrier diffusion length of a semiconductor. J. Appl. Phys. 1998, 84, 2656–2664. [Google Scholar] [CrossRef]

- Takahashi, I.; Usami, N.; Kutsukake, K.; Stokkan, G.; Morishita, K.; Nakajima, K. Generation mechanism of dislocations during directional solidification of multicrystalline silicon using artificially designed seed. J. Cryst. Growth 2010, 312, 897–901. [Google Scholar] [CrossRef]

- Choi, H.; Bertoni, M.; Hofstetter, J.; Fenning, D.; Powell, D.; Castellanos, S.; Buonassisi, T. Dislocation density reduction during impurity gettering in multicrystalline silicon. IEEE J. Photovolt. 2013, 3, 189–198. [Google Scholar] [CrossRef]

- Chen, N.; Qiu, S.; Liu, B.; Du, G.; Liu, G.; Sun, W. An optical microscopy study of dislocations in multicrystalline silicon grown by directional solidification method. Mater. Sci. Semicond. Process. 2010, 13, 276–280. [Google Scholar] [CrossRef]

- Isenberg, J.; Dicker, J.; Warta, W. Averaging of laterally inhomogeneous lifetimes for one-dimensional modeling of solar cells. J. Appl. Phys. 2003, 94, 4122–4130. [Google Scholar] [CrossRef]

- Kieliba, T.; Riepe, S.; Warta, W. Effect of dislocations on open circuit voltage in crystalline silicon solar cells. J. Appl. Phys. 2006, 100, 093708. [Google Scholar] [CrossRef]

- Chen, N.; Liu, B.; Qiu, S.; Liu, G.; Du, G. Study of SiC and Si3N4 inclusions in industrial multicrystalline silicon ingots grown by directional solidification method. Mater. Sci. Semicond. Process. 2010, 13, 231–238. [Google Scholar] [CrossRef]

- Søiland, A.K.; Ørelid, E.J.; Engh, T.A.; Lohne, O.; Tuset, J.K.; Gjerstad, Ø. SiC and Si3N4 inclusions in multicrystalline silicon ingots. Mater. Sci. Semicond. Process. 2004, 7, 39–43. [Google Scholar] [CrossRef]

- Lotnyk, A.; Bauer, J.; Breitenstein, O.; Blumtritt, H. A TEM study of SiC particles and filaments precipitated in multicrystalline Si for solar cells. Sol. Energy Mater. Sol. Cells 2008, 92, 1236–1240. [Google Scholar] [CrossRef]

- Yang, Y.M.; Yu, A.; Hsu, B.; Hsu, W.C.; Yang, A.; Lan, C.W. Development of high-performance multicrystalline silicon for photovoltaic industry. Prog. Photovolt. Res. Appl. 2015, 23, 340–351. [Google Scholar] [CrossRef]

- Fujiwara, K.; Pan, W.; Sawada, K.; Tokairin, M.; Usami, N.; Nose, Y.; Nomura, A.; Shishido, T.; Nakajima, K. Directional growth method to obtain high quality polycrystalline silicon from its melt. J. Cryst. Growth 2006, 292, 282–285. [Google Scholar] [CrossRef]

- Liu, B.; Chen, N.; Du, G.; Liu, G.; Li, Y.; Sun, W.; Rossetto, P. Minicrystallization in directionally solidified multicrystalline silicon and its effect on the photovoltaic properties of solar cells. Phys. Status Solidi A 2011, 208, 2478–2481. [Google Scholar] [CrossRef]

- Du, G.; Zhang, Y.; Li, W.; Chen, N.; Liu, B.; Sun, J. Performance enhancement of multicrystalline silicon solar cells and modules using double-layered SiNx:H antireflection coatings. Prog. Photovolt. Res. Appl. 2015, 23, 1806–1814. [Google Scholar] [CrossRef]

- Chadwick, G.A.; Smith, D.A. Grain Boundary Structure and Properties; Academic Press Inc.: New York, NY, USA, 1976. [Google Scholar]

- Wenham, S.R.; Green, M.A.; Watt, M.E.; Corkish, R. Applied Photovoltaics, 2nd ed.; Earthscan: London, UK, 2007. [Google Scholar]

- Reiche, M.; Kittler, M. Electronic and optical properties of dislocations in silicon. Crystals 2016, 6, 74. [Google Scholar] [CrossRef]

| Solar Cell | Minicrystallization | Voc (mV) | Isc (A) | Rs (Ω) | Rsh (Ω) | FF (%) | η (%) |

|---|---|---|---|---|---|---|---|

| 1 | Yes | 596.2 | 8.87 | 0.001 | 0.20 | 45.25 | 9.59 |

| 2 | No | 622.4 | 8.40 | 0.003 | 149.59 | 78.51 | 16.87 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, N.; Qiu, S.; Huang, J.; Du, G.; Liu, G. Study of Dislocations in the Minicrystallized Regions in Multicrystalline Silicon Grown by the Directional Solidification Method. Crystals 2016, 6, 130. https://doi.org/10.3390/cryst6100130

Chen N, Qiu S, Huang J, Du G, Liu G. Study of Dislocations in the Minicrystallized Regions in Multicrystalline Silicon Grown by the Directional Solidification Method. Crystals. 2016; 6(10):130. https://doi.org/10.3390/cryst6100130

Chicago/Turabian StyleChen, Nan, Shenyu Qiu, Jianhua Huang, Guoping Du, and Guihua Liu. 2016. "Study of Dislocations in the Minicrystallized Regions in Multicrystalline Silicon Grown by the Directional Solidification Method" Crystals 6, no. 10: 130. https://doi.org/10.3390/cryst6100130