Synthesis of Small-Sized SAPO-34 Crystals with Varying Template Combinations for the Conversion of Methanol to Olefins

Abstract

:1. Introduction

2. Results and Discussion

2.1. Characterization of the SAPO-34 Catalysts

2.2. The Catalytic Performance of the Catalysts

3. Materials and Methods

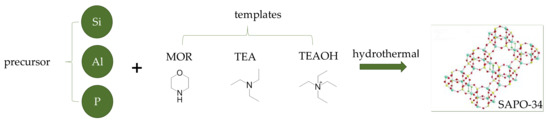

3.1. Synthesis of SAPO-34 Molecular Sieve

3.2. Characterization of Samples

3.3. Catalyst Testing in MTO Reaction

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dwyer, F.G.; Hanson, F.V.; Schwartz, A.B. Conversion of Methanol to Gasoline Product. U.S. Patent US4035430A, 12 July 1977. [Google Scholar]

- Wilson, S.; Barger, P. The characteristics of SAPO-34 which influence the conversion of methanol to light olefins. Microporous Mesoporous Mater. 1999, 29, 117–126. [Google Scholar] [CrossRef]

- Chen, D.; Moljord, K.; Fuglerud, T.; Holmen, A. The effect of crystal size of SAPO-34 on the selectivity and deactivation of the MTO reaction. Microporous Mesoporous Mater. 1999, 29, 191–203. [Google Scholar] [CrossRef]

- Dahl, I.M.; Mostad, H.; Akporiaye, D.; Wendelbo, R. Structural and chemical influences on the MTO reaction: A comparison of chabazite and SAPO-34 as MTO catalysts. Microporous Mesoporous Mater. 1999, 29, 185–190. [Google Scholar] [CrossRef]

- Najafi, N.; Askari, S.; Halladj, R. Hydrothermal synthesis of nanosized SAPO-34 molecular sieves by different combinations of multi templates. Powder Technol. 2014, 254, 324–330. [Google Scholar] [CrossRef]

- Wu, L.; Liu, Z.; Qiu, M.; Yang, C.; Xia, L.; Liu, X.; Sun, Y. Morphology control of SAPO-34 by microwave synthesis and their performance in the methanol to olefins reaction. React. Kinet. Mech. Catal. 2014, 111, 319–334. [Google Scholar] [CrossRef]

- Yang, M.; Tian, P.; Wang, C.; Yuan, Y.; Yang, Y.; Xu, S.; He, Y.; Liu, Z. A top-down approach to prepare silicoaluminophosphate molecular sieve nanocrystals with improved catalytic activity. Chem. Commun. 2014, 50, 1845–1847. [Google Scholar] [CrossRef] [PubMed]

- Charghand, M.; Haghighi, M.; Saedy, S.; Aghamohammadi, S. Efficient hydrothermal synthesis of nanostructured SAPO-34 using ultrasound energy: Physicochemical characterization and catalytic performance toward methanol conversion to light olefins. Adv. Powder Technol. 2014, 25, 1728–1736. [Google Scholar] [CrossRef]

- Briend, M.; Vomscheid, R.; Peltre, M.J.; Man, P.P.; Barthomeuf, D. Influence of the Choice of the Template on the Short- and Long-Term Stability of SAPO-34 Zeolite. J. Phys. Chem. 1995, 99, 142–145. [Google Scholar] [CrossRef]

- Lee, Y.J.; Baek, S.C.; Jun, K.W. Methanol conversion on SAPO-34 catalysts prepared by mixed template method. Appl. Catal. A Gen. 2007, 329, 130–136. [Google Scholar] [CrossRef]

- Wang, P.; Lv, A.; Hu, J.; Xu, J.A.; Lu, G. The synthesis of SAPO-34 with mixed template and its catalytic performance for methanol to olefins reaction. Microporous Mesoporous Mater. 2012, 152, 178–184. [Google Scholar] [CrossRef]

- Rostami, R.B.; Ghavipour, M.; Behbahani, R.M.; Aghajafari, A. Improvement of SAPO-34 performance in MTO reaction by utilizing mixed-template catalyst synthesis method. J. Nat. Gas Sci. Eng. 2014, 20, 312–318. [Google Scholar] [CrossRef]

- Sedighi, M.; Bahrami, H.; Towfighidarian, J. Thorough investigation of varying template combinations on SAPO-34 synthesis, catalytic activity and stability in the methanol conversion to light olefin. RSC Adv. 2014, 4, 49762–49769. [Google Scholar] [CrossRef]

- Salmasi, M.; Fatemi, S.; Najafabadi, A.T. Improvement of light olefins selectivity and catalyst lifetime in MTO reaction; using Ni and Mg-modified SAPO-34 synthesized by combination of two templates. J. Ind. Eng. Chem. 2011, 17, 755–761. [Google Scholar] [CrossRef]

- Chen, J.; Thomas, J.M.; Wright, P.A.; Townsend, R.P. Silicoaluminophosphate number eighteen (SAPO-18): A new microporous solid acid catalyst. Catal. Lett. 1994, 28, 241–248. [Google Scholar] [CrossRef]

- Inui, T.; Matsuda, H.; Okaniwa, H.; Miyamoto, A. ChemInform Abstract: Preparation of Silico-Alumino-Phosphates by the Rapid Crystallization Method and Their Catalytic Performance in the Conversion of Methanol to Light Olefins. Appl. Catal. 1990, 58, 155–163. [Google Scholar] [CrossRef]

- Álvaro-Muñoz, T.; Márquez-Álvarez, C.; Sastre, E. Use of different templates on SAPO-34 synthesis: Effect on the acidity and catalytic activity in the MTO reaction. Catal. Today 2012, 179, 27–34. [Google Scholar] [CrossRef] [Green Version]

- Luo, M.; Zang, H.; Hu, B.; Wang, B.; Mao, G. Evolution of confined species and their effects on catalyst deactivation and olefin selectivity in SAPO-34 catalyzed MTO process. RSC Adv. 2016, 6, 17651–17658. [Google Scholar] [CrossRef]

- Sedighi, M.; Ghasemi, M.; Sadeqzadeh, M.; Hadi, M. Thorough study of the effect of metal-incorporated SAPO-34 molecular sieves on catalytic performances in MTO process. Powder Technol. 2016, 291, 131–139. [Google Scholar] [CrossRef]

- Kustov, L.M.; Kazansky, V.B. Infrared spectroscopic study of the interaction of cations in zeolites with simple molecular probes. Part 1.—Adsorption of molecular hydrogen on alkaline forms of zeolites as a test for localization sites. J. Chem. Soc. Faraday Trans. 1991, 87, 2675–2678. [Google Scholar] [CrossRef]

- Popova, M.; Minchev, C.; Kanazirev, V. Methanol conversion to light alkenes over SAPO-34 molecular sieves synthesized using various sources of silicon and aluminium. Appl. Catal. A Gen. 1998, 169, 227–235. [Google Scholar] [CrossRef]

- Lee, Y.; Park, S.Y.; Chung, H.J.; Park, T.G. New Sol-Gel Transition Hydrogels Based on Pluronic-Mimicking Copolymers Grafted with Oligo (lactic acids). Macromol. Symp. 2007, 249–250, 130–136. [Google Scholar] [CrossRef]

- Maschmeyer, T.; Oldroyd, R.D.; Sankar, G.; Thomas, J.M.; Shannon, I.J.; Catlow, C.R.A.; Klepetko, J.A.; Masters, A.F.; Beattie, J.K. Designing a Solid Catalyst for the Selective Low-Temperature Oxidation of Cyclohexane to Cyclohexanone. Angew. Chem. Int. Ed. Engl. 1997, 36, 1639–1642. [Google Scholar] [CrossRef]

- Anderson, M.W.; Sulikowski, B.; Barrie, P.J.; Klinowski, J. In situ solid-state NMR studies of the catalytic conversion of methanol on the molecular sieve SAPO-34. J. Phys. Chem. 1990, 94, 2730–2734. [Google Scholar] [CrossRef]

- Prakash, A.M.; Unnikrishnan, S. Synthesis of SAPO-34: High silicon incorporation in the presence of morpholine as template. J. Chem. Soc. Faraday Trans. 1994, 90, 2291–2296. [Google Scholar] [CrossRef]

- Sastre, G.; Lewis, D.W.; Catlow, C.R.A. Modeling of Silicon Substitution in SAPO-5 and SAPO-34 Molecular Sieves. J. Phys. Chem. B 1997, 101, 5249–5262. [Google Scholar] [CrossRef]

- Liu, G.; Tian, P.; Li, J.; Zhang, D.; Zhou, F.; Liu, Z. Synthesis, characterization and catalytic properties of SAPO-34 synthesized using diethylamine as a template. Microporous Mesoporous Mater. 2008, 111, 143–149. [Google Scholar] [CrossRef]

- Vomscheid, R.; Briend, M.; Peltre, M.J.; Man, P.P.; Barthomeuf, D. The Role of the Template in Directing the Si Distribution in SAPO Zeolites. J. Phys. Chem. 1994, 98, 9614–9618. [Google Scholar] [CrossRef]

- Kim, H.S.; Lee, S.G.; Kim, Y.H.; Lee, D.H.; Lee, J.B.; Park, C.S. Improvement of lifetime using transition metal-incorporated SAPO-34 catalysts in conversion of dimethyl ether to light olefins. J. Nanomater. 2013, 2013, 4. [Google Scholar] [CrossRef]

- Tan, J.; Liu, Z.; Bao, X.; Liu, X.; Han, X.; He, C.; Zhai, R. Crystallization and Si incorporation mechanisms of SAPO-34. Microporous Mesoporous Mater. 2002, 53, 97–108. [Google Scholar] [CrossRef] [Green Version]

- Vistad, Ø.B.; Akporiaye, D.E.; Taulelle, F.; Lillerud, K.P. Morpholine, an in Situ 13C NMR pH Meter for Hydrothermal Crystallogenesis of SAPO-34. Chem. Mater. 2003, 15, 1650–1654. [Google Scholar] [CrossRef]

| Sample | Surface Area (m2/g) | Pore Volume (cm3/g) | Mean Pore Size (nm) | ||||

|---|---|---|---|---|---|---|---|

| Smicro | Sext | Stotal | Vmicro | Vmeso | Vtotal | ||

| S-1 | 490 | 20 | 510 | 0.22 | 0.05 | 0.27 | 0.46 |

| S-2 | 545 | 25 | 570 | 0.26 | 0.05 | 0.31 | 0.48 |

| S-3 | 569 | 42 | 611 | 0.27 | 0.08 | 0.35 | 0.43 |

| S-4 | 584 | 52 | 636 | 0.25 | 0.12 | 0.37 | 0.43 |

| S-5 | 596 | 63 | 659 | 0.27 | 0.13 | 0.40 | 0.43 |

| S-6 | 299 | 81 | 380 | 0.13 | 0.31 | 0.44 | 0.52 |

| Sample | Weight Loss (%) <200 °C | Weight Loss (%) 200~750 °C | Organic Content (%) | Moles of Template Per Cage | |

|---|---|---|---|---|---|

| Decomposition of Template 200~500 °C | Organic Residues >500 °C | ||||

| S-1 | 5.16 | 16.97 | 84.58 | 15.42 | 1.76 |

| S-2 | 3.14 | 14.71 | 67.84 | 32.16 | 1.30 |

| S-3 | 2.35 | 17.73 | 74.25 | 25.75 | 1.44 |

| Sample | Weak Acid Desorption Peak Position (°C) | Strong Acid Desorption Peak Position (°C) | Weak Acid Desorption Peak Relative Content (%) | Strong Acid Desorption Peak Relative Content (%) |

|---|---|---|---|---|

| S-1 | 254.72 | 511.50 | 39.81 | 60.19 |

| S-2 | 221.84 | 474.93 | 44.65 | 55.35 |

| S-3 | 271.70 | 499.31 | 59.82 | 40.18 |

| S-4 | 261.03 | 514.28 | 42.31 | 57.69 |

| S-5 | 223.57 | 455.54 | 49.74 | 50.26 |

| S-6 | 224.84 | 419.41 | 54.39 | 45.61 |

| Sample | B Acid Peak (cm−1) | L Acid Peak (cm−1) | B Acid Content/mmol∙g−1 | L Acid Content/mmol∙g−1 | Total Acids/mmol∙g−1 |

|---|---|---|---|---|---|

| S-1 | 1460 | 1620 | 1.605 | 0.291 | 1.896 |

| S-2 | 1460 | 1620 | 1.736 | 0.308 | 2.044 |

| S-3 | 1462 | 1620 | 1.789 | 0.270 | 2.059 |

| Sample | Distribution of Silicon Environments (%) | ||||

|---|---|---|---|---|---|

| Si(4Al) | Si(3Al) | Si(2Al) | Si(1Al) | Si(0Al) | |

| S-1 | 68.81 | 22.69 | 2.21 | 3.36 | 2.93 |

| S-3 | 66.30 | 25.74 | 1.78 | 2.67 | 3.51 |

| Sample | Molar Composition | Si/(Al + P) Gel | Si/(Al + P) Solid | Si Incorporation a |

|---|---|---|---|---|

| S-1 | Si0.11Al0.46P0.35O2 | 0.15 | 0.14 | 0.93 |

| S-2 | Si0.12Al0.43P0.32O2 | 0.15 | 0.16 | 1.04 |

| S-3 | Si0.14Al0.48P0.36O2 | 0.15 | 0.17 | 1.1 |

| Sample | Net Charge, the Template Number Per Cage/(Al + Si + P) mol | Ma | Mb | The Maximum Si(4Al) Contents/(Al + Si + P) mol |

|---|---|---|---|---|

| S-1 | −0.1117 | 1.32 | 0.44 | 0.0757 |

| S-3 | −0.1201 | 1.44 | 0 | 0.0928 |

| Catalyst | Synthesis Gel Composition (Molar Basis) | Temperature (°C) | Time (h) |

|---|---|---|---|

| S-1 | 1.0Al2O3:0.6SiO2:1.0P2O5:3Mor:100H2O | 200 | 48 |

| S-2 | 1.0Al2O3:0.6SiO2:1.0P2O5:1.5Mor:1.5TEA:100H2O | 200 | 48 |

| S-3 | 1.0Al2O3:0.6SiO2:1.0P2O5:1.0Mor:1.0TEA:1.0TEAOH:100H2O | 200 | 48 |

| S-4 | 1.0Al2O3:0.6SiO2:1.0P2O5:1.25Mor:1.25TEA:0.5TEAOH:100H2O | 200 | 48 |

| S-5 | 1.0Al2O3:0.4SiO2:1.0P2O5:1.25Mor:1.25TEA:0.5TEAOH:100H2O | 200 | 48 |

| S-6 | 1.0Al2O3:0.2SiO2:1.0P2O5:1.25Mor:1.25TEA:0.5TEAOH:100H2O | 200 | 48 |

| Agent | Abbreviation | Structure | The pKa Values |

|---|---|---|---|

| morpholine | Mor |  | 8.8 |

| tetraethyl ammonium hydroxide | TEAOH |  | 12.9 |

| triethylamine | TEA |  | 11.01 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Ren, Z.; Wang, Y.; Deng, Y.; Li, J. Synthesis of Small-Sized SAPO-34 Crystals with Varying Template Combinations for the Conversion of Methanol to Olefins. Catalysts 2018, 8, 570. https://doi.org/10.3390/catal8120570

Zhang Y, Ren Z, Wang Y, Deng Y, Li J. Synthesis of Small-Sized SAPO-34 Crystals with Varying Template Combinations for the Conversion of Methanol to Olefins. Catalysts. 2018; 8(12):570. https://doi.org/10.3390/catal8120570

Chicago/Turabian StyleZhang, Yanjun, Zhibo Ren, Yinuo Wang, Yinjie Deng, and Jianwei Li. 2018. "Synthesis of Small-Sized SAPO-34 Crystals with Varying Template Combinations for the Conversion of Methanol to Olefins" Catalysts 8, no. 12: 570. https://doi.org/10.3390/catal8120570