Ni Catalysts Supported on Modified Alumina for Diesel Steam Reforming

Abstract

:1. Introduction

2. Results and Discussion

2.1. Physicochemical Characteristics of the Supports

| Supports | Dopant Content (% mole) | SSAS (m2/g) | SSAAl (m2/g of Al2O3) | IEP | ||

|---|---|---|---|---|---|---|

| La | Ba | Ce | ||||

| Al | - | - | - | 152 | 152 | 7.98 |

| Al-La | 3 | - | - | 145 | 159 | 8.91 |

| Al-Ba | - | 10 | - | 128 | 149 | 8.98 |

| Al-(La+Ba) | 3 | 10 | - | 117 | 150 | 9.70 |

| Al-Ce | - | - | 3 | 162 | 170 | 7.88 |

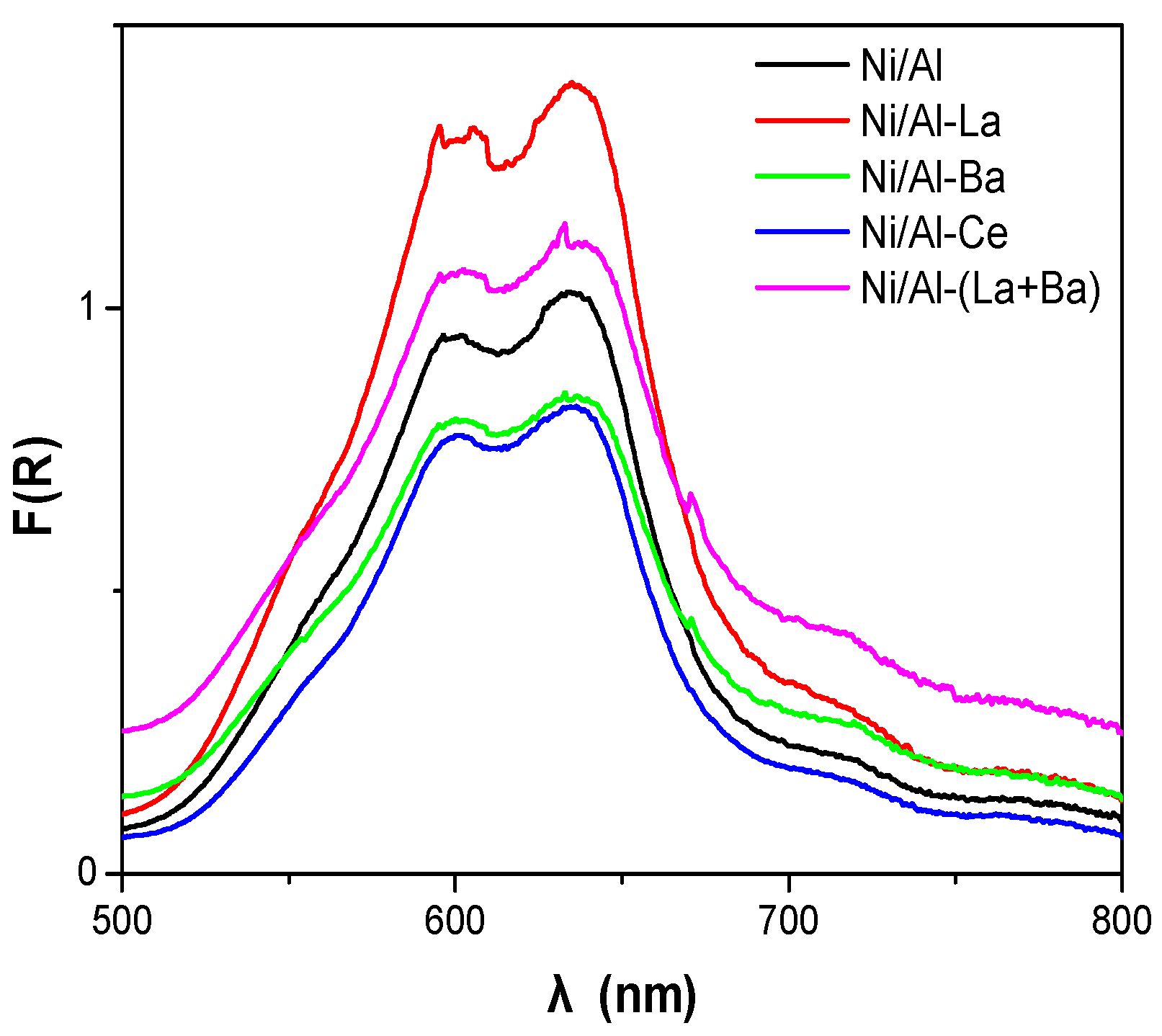

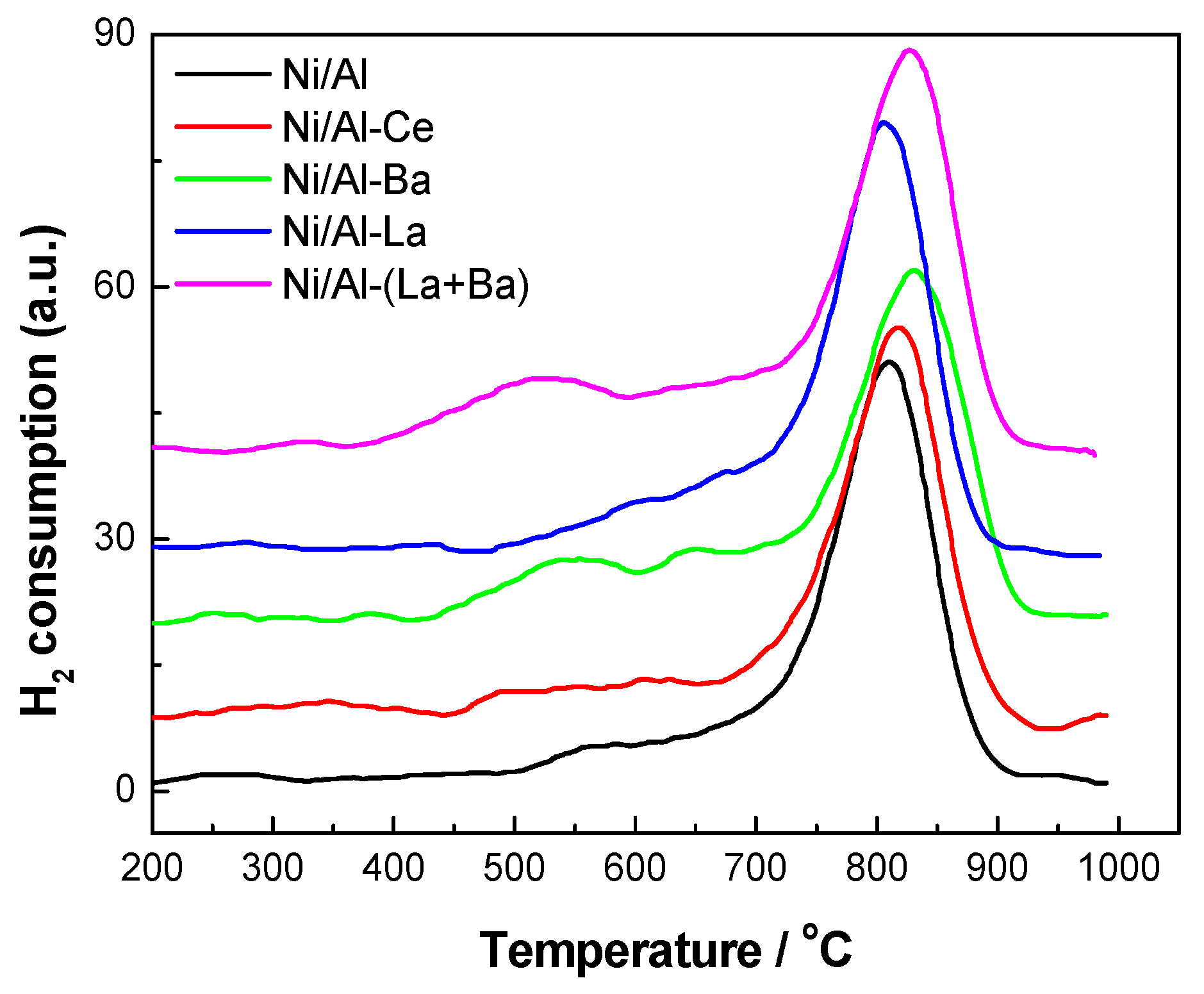

2.2. Physicochemical Characteristics of the Ni-Catalysts

| Catalysts | SSAC (m2/g) | Crystal Phases Detected by XRD | RDRS | RTPR | % Ni0 |

|---|---|---|---|---|---|

| Ni/Al | 132 | NiAl2O4, γ-Al2O3 | 4.86 | 3.75 | 79.9 |

| Ni/Al-La | 112 | NiAl2O4, γ-Al2O3 | 4.67 | 1.94 | 87.4 |

| Ni/Al-Ba | 105 | BaAl2O4, NiAl2O4, γ-Al2O3 | 3.11 | 1.67 | 86.1 |

| Ni/Al-(La+Ba) | 91 | BaAl2O4, NiAl2O4, γ-Al2O3 | 2.63 | 1.50 | 98.1 |

| Ni/Al-Ce | 124 | CeO2, NiAl2O4, γ-Al2O3 | 4.82 | 3.80 | 77.3 |

| Catalysts | Average Surface Composition (atoms %) | |||||

|---|---|---|---|---|---|---|

| Ni | Al | O | La | Ba | Ce | |

| Ni/Al | 2.5 | 32.5 | 65.0 | - | - | - |

| Ni/Al-La | 2.8 | 28.2 | 67.9 | 1.1 | - | - |

| Ni/Al-Ba | 5.1 | 28.6 | 64.7 | - | 1.6 | - |

| Ni/Al-(La+Ba) | 5.4 | 24.4 | 67.3 | 1.4 | 1.5 | - |

| Ni/Al-Ce | 2.6 | 32.3 | 64.9 | - | - | 0.2 |

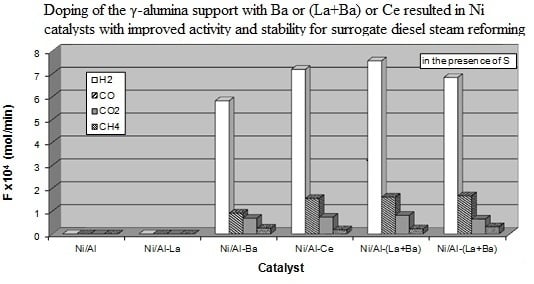

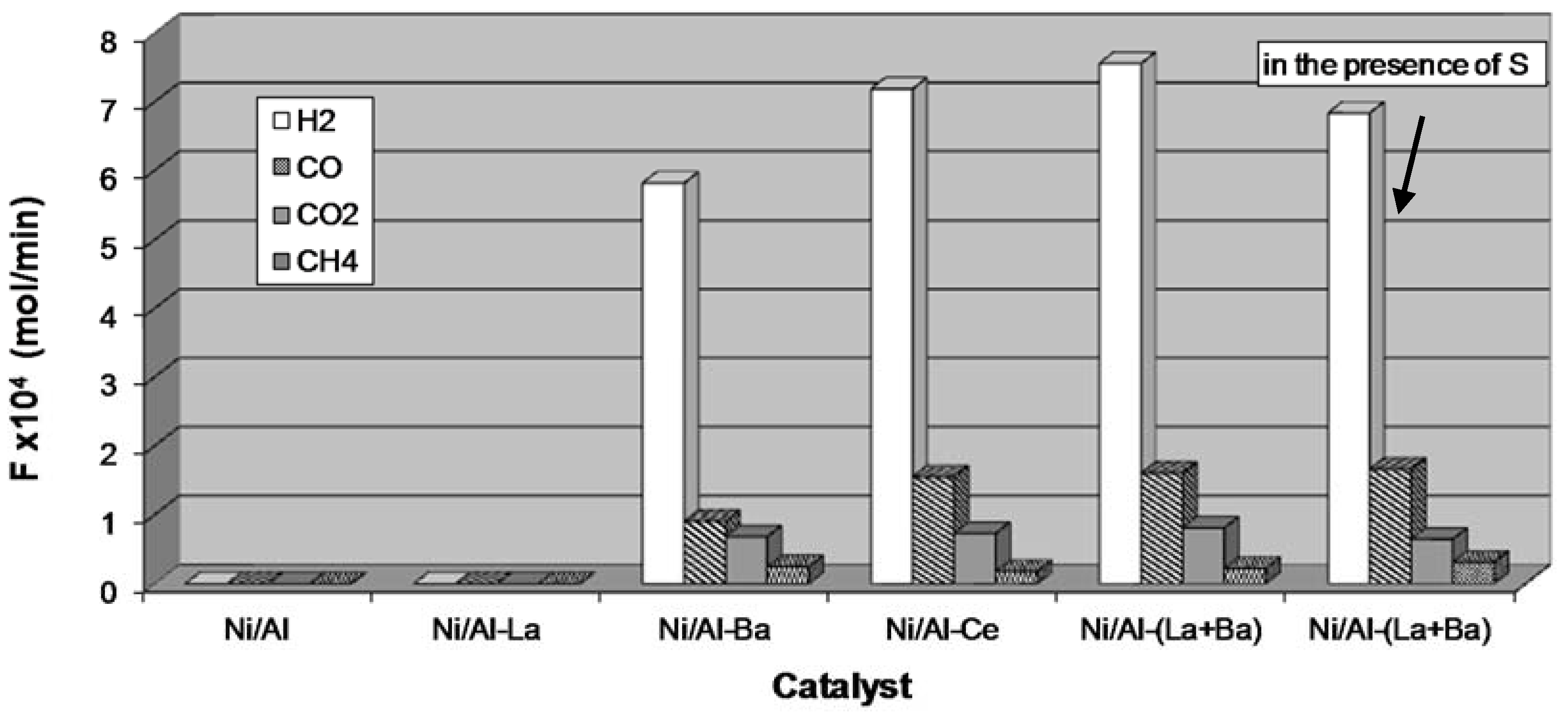

2.3. Catalyst Evaluation

3. Experimental Section

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Ogden, J.M.; Steinbugler, M.M.; Kreutz, T.G. A comparison of hydrogen, methanal and gasoline as fuels for fuel cell vehicles: implications for vehicle design and infrastructure development. J. Power Sources 1999, 79, 143–168. [Google Scholar] [CrossRef]

- Farrauto, R.; Hwang, S.; Shore, L.; Ruettinger, W.; Lampert, J.; Giroux, T.; Liu, Y.; Ilinich, O. New material needs for hydrocarbon fuel processing: Generating hydrogen for the PEM fuel cell. Annu. Rev. Mater. Res. 2003, 33, 1–27. [Google Scholar] [CrossRef]

- Cheekatamarla, P.K.; Finnerty, C.M. Reforming catalysts for hydrogen generation in fuel cell applications. J. Power Sources 2006, 160, 490–499. [Google Scholar] [CrossRef]

- Semelsberger, T.A.; Brown, L.F.; Borup, R.L.; Inbody, M.A. Equilibrium products from autothermal processes for generating hydrogen-rich fuel-cell feeds. Int. J. Hydrogen Energy 2004, 29, 1047–1064. [Google Scholar] [CrossRef]

- Song, C.S. Fuel processing for low-temperature and high-temperature fuel cells—Challenges, and opportunities for sustainable development in the 21st century. Catal. Today 2002, 77, 17–49. [Google Scholar] [CrossRef]

- Brown, L.F. A comparative study of fuels for on-board hydrogen production for fuel-cell-powered automobiles. Int. J. Hydrogen Energy 2001, 26, 381–397. [Google Scholar] [CrossRef]

- Remiro, A.; Valle, B.; Aramburu, B.; Aguayo, A.T.; Bilbao, J.; Gayubo, A.G. Steam reforming of the bio-oil aqueous fraction in a fluidized bed reactor with in situ CO2 capture. Ind. Eng. Chem. Res. 2013, 52, 17087–17098. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, W.; Wang, Z.Y.; Zhou, X.T.; Wang, Z.; Liu, C.-J. Steam reforming of methane over Ni/SiO2 catalyst with enhanced coke resistance at low steam to methane ratio. Catal. Today 2015, 256, 130–136. [Google Scholar] [CrossRef]

- Barrios, C.E.; Bosco, M.V.; Baltanas, M.A.; Bonivardi, A.L. Hydrogen production by methanol steam reforming: Catalytic performance of supported-Pd on zinc-cerium oxides' nanocomposites. Appl. Catal. B 2015, 179, 262–275. [Google Scholar] [CrossRef]

- Hou, T.F.; Yu, B.; Zhang, S.Y.; Zhang, J.H.; Wang, D.Z.; Xu, T.K.; Cui, L.; Cai, W.J. Hydrogen production from propane steam reforming over Ir/Ce0.75Zr0.25O2 catalyst. Appl. Catal. B 2015, 168, 524–530. [Google Scholar] [CrossRef]

- Jimenez-Gonzalez, C.; Boukha, Z.; de Rivas, B.; Ramon Gonzalez-Velasco, J.; Ignacio Gutierrez-Ortiz, J.; Lopez-Fonseca, R. Behaviour of nickel-alumina spinel (NiAl2O4) catalysts for isooctane steam reforming. Int. J. Hydrogen Energy 2015, 40, 5281–5288. [Google Scholar] [CrossRef]

- Remiro, A.; Valle, B.; Oar-Arteta, L.; Aguayo, A.T.; Bilbao, J.; Gayubo, A.G. Hydrogen production by steam reforming of bio-oil/bio-ethanol mixtures in a continuous thermal-catalytic process. Int. J. Hydrogen Energy 2014, 39, 6889–6898. [Google Scholar] [CrossRef]

- Thormann, J.; Pfeifer, P.; Schubert, K.; Kunz, U. Reforming of diesel fuel in a micro reactor for APU systems. Chem. Eng. J. 2008, 135, S74–S81. [Google Scholar] [CrossRef]

- Lakhapatri, S.L.; Abraham, M.A. Deactivation due to sulfur poisoning and carbon deposition on Rh-Ni/Al2O3 catalyst during steam reforming of sulfur-doped n-hexadecane. Appl. Catal. A 2009, 364, 113–121. [Google Scholar] [CrossRef]

- Faure, R.; Rossignol, F.; Chartier, T.; Bonhomme, C.; Maître, A.; Etchegoyen, G.; del Gallo, P.; Gary, D. Alumina foam catalyst supports for industrial steam reforming processes. J. Eur. Ceram. Soc. 2011, 31, 303–312. [Google Scholar] [CrossRef]

- Haynes, D.J.; Campos, A.; Smith, M.W.; Berry, D.A.; Shekhawat, D.; Spive, J.J. Reducing the deactivation of Ni-metal during the catalytic partial oxidation of a surrogate diesel fuel mixture. Catal. Today 2010, 154, 210–216. [Google Scholar] [CrossRef]

- Sanchez-Sanchez, M.C.; Navarro, R.M.; Fierro, J.L.G. Ethanol steam reforming over Ni/La-Al2O3 catalysts: Influence of lanthanum loading. Catal. Today 2007, 129, 336–345. [Google Scholar] [CrossRef]

- Sanchez-Sanchez, M.C.; Navarro, R.M.; Fierro, J.L.G. Ethanol steam reforming over Ni/MxOy-Al2O3 (M = Ce, La, Zr and Mg) catalysts: Influence of support on the hydrogen production. Int. J. Hydrogen Energy 2007, 32, 1462–1471. [Google Scholar] [CrossRef]

- Lucredio, A.F.; Filho, G.T.; Assaf, E.M. Co/Mg/Al hydrotalcite-type precursor, promoted with La and Ce, studied by XPS and applied to methane steam reforming reactions. Appl. Surf. Sci. 2009, 255, 5851–5856. [Google Scholar] [CrossRef]

- Xu, L.; Mi, W.; Su, Q. Hydrogen production through diesel steam reforming over rare-erth promoted Ni/γ-Al2O3 catalysts. J. Nat. Gas Chem. 2011, 20, 287–293. [Google Scholar] [CrossRef]

- Campos, C.H.; Osorio-Vargas, P.; Flores-Gonzalez, N.; Fierro, J.L.G.; Reyes, P. Effect of Ni Loading on Lanthanide (La and Ce) Promoted γ-Al2O3 Catalysts Applied to Ethanol Steam Reforming. Catal. Lett. 2015. [Google Scholar] [CrossRef]

- Bourikas, K.; Kordulis, C.; Lycourghiotis, A. The Role of the Liquid-Solid Interface in the Preparation of Supported Catalysts. Catal. Rev.-Sci. Eng. 2006, 48, 363–444. [Google Scholar] [CrossRef]

- Cavallaro, S.; Mondello, N.; Freni, S. Hydrogen produced from ethanol for internal reforming molten carbonate fuel cell. J. Power Sources 2001, 102, 198–204. [Google Scholar]

- Basagiannis, A.C.; Verykios, X.E. Catalytic steam reforming of acetic acid for hydrogen production. Int. J. Hydrogen Energy 2007, 32, 3343–3355. [Google Scholar] [CrossRef]

- Wang, R.; Li, Y.; Shi, R.; Yang, M. Effect of metal-support interaction on the catalytic performance of Ni/Al2O3 for selective hydrogenation of isoprene. J. Mol. Catal. A 2011, 344, 122–127. [Google Scholar] [CrossRef]

- Machida, M.; Eguchi, K.; Arai, H. Effect of Additives on the Surface Area of Oxide Supports for Catalytic Combustion. J. Catal. 1987, 103, 385–393. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Gan, N.; Lim, Z.Y.; Wu, C.Z.; Peng, J.; Wang, W.G. Evaluation of Ni/Y2O3/Al2O3 catalysts for hydrogen production by autothermal reforming of methane. Int. J. Hydrogen Energy 2014, 39, 10971–10979. [Google Scholar] [CrossRef]

- Boukha, Z.; Jiménez González, C.; de Rivas, B.; GonzálezVelasco, J.R.; Gutiérrez Ortiz, J.I.; López Fonseca, R. Synthesis, characterisation and performance evaluation of spinel-derived Ni/Al2O3 catalysts for various methane reforming reactions. Appl. Catal. B 2014, 158–159, 190–201. [Google Scholar] [CrossRef]

- Yang, R.; Zhang, Z.; Wu, J.; Li, X.; Wang, L. Hydrotreating Performance of La-Modified Ni/Al2O3 Catalysts Prepared by Hydrothermal Impregnation Method. Kinet. Catal. 2015, 56, 222–225. [Google Scholar] [CrossRef]

- Daza, C.E.; Gallego, J.; Mondragon, F.; Moreno, S.; Molina, R. High stability of Ce-promoted Ni/Mg-Al catalysts derived from hydrotalcites in dry reforming of methane. Fuel 2010, 89, 592–603. [Google Scholar] [CrossRef]

- Debek, R.; Radlik, M.; Motak, M.; Galvez, M.E.; Turek, W.; da Costa, P.; Grzybek, T. Ni-containing Ce-promoted hydrotalcite derived materials as catalysts for methane reforming with carbon dioxide at low temperature—On the effect of basicity. Catal. Today 2015, 257, 59–65. [Google Scholar] [CrossRef]

- Damyanova, S.; Pawelec, B.; Arishtirova, K.; Fierro, J.L.G. Ni-based catalysts for reforming of methane with CO2. Int. J. Hydrogen Energy 2012, 37, 15966–15975. [Google Scholar] [CrossRef]

- Kraleva, E.; Pohl, M.-M.; Jurgensen, A.; Ehrich, H. Hydrogen production by bioethanol partial oxidation over Ni based catalysts. Appl. Catal. B 2015, 179, 509–520. [Google Scholar] [CrossRef]

- Zaungouei, M.; Moghaddam, A.Z.; Arasteh, M. The Influence of Nickel Loading on Reducibility of NiO/Al2O3 Catalysts Synthesized by Sol-Gel Method. Chem. Eng. Res. Bull. 2010, 14, 97–102. [Google Scholar]

- Kaynar, A.D.D.; Dogu, D.; Nail, Y. Hydrogen production and coke minimization through reforming of kerosene over bi-metallic ceria-alumina supported Ru-Ni catalysts. Fuel Process. Technol. 2015, 140, 96–103. [Google Scholar] [CrossRef]

- Christensen, K.O.; Chen, D.; Lodeng, R.; Holmen, A. Effect of supports and Ni crystal size on carbon formation and sintering during steam methane reforming. Appl. Catal. A 2006, 314, 9–22. [Google Scholar] [CrossRef]

- Quitete, C.P.B.; Bittencourt, R.C.P.; Souza, M.M.V.M. Coking resistance evaluation of tar removal catalysts. Catal. Commun. 2015, 71, 79–83. [Google Scholar] [CrossRef]

- Fajardo, H.V.; Longo, E.; Mezalira, D.Z.; Nuernberg, G.B.; Almerindo, G.I.; Collasiol, A.; Probst, L.F.D.; Garcia, I.T.S.; Carreño, N.L.V. Influence of support on catalytic behavior of nickel catalysts in the steam reforming of ethanol for hydrogen production. Environ. Chem. Lett. 2010, 8, 79–85. [Google Scholar] [CrossRef]

- Zou, X.; Wang, X.; Li, L.; Shen, K.; Lu, X.; Ding, W. Development of highly effective supported nickel catalysts for pre-reforming of liquefied petroleum gas under low steam to carbon molar ratios. Int. J. Hydrogen Energy 2010, 35, 12191–12200. [Google Scholar] [CrossRef]

- Shekhawat, D.; Gardner, T.H.; Berry, D.A.; Salazar, M.; Haynes, D.J.; Spivey, J.J. Catalytic partial oxidation of n-tetradecane in the presence of sulfur or polynuclear aromatics: Effects of support and metal. Appl.Catal. A 2006, 311, 8–16. [Google Scholar] [CrossRef]

- Wagner, C.D.; Davis, L.E.; Zeller, M.V.; Taylor, J.A.; Raymond, R.H.; Gale, L.H. Empirical atomic sensitivity factors for quantitative analysis by electron spectroscopy for chemical analysis. Surf. Interface Anal. 1981, 3, 211–225. [Google Scholar] [CrossRef]

- Wagner, C.D.; Riggs, W.M.; Davis, L.E.; Moulder, J.F.; Muilenberg, G.E. Handbook of X-ray Photoelectron Spectroscopy; Perkin-Elmer Corp: Eden Prairie, MN, USA, 1979. [Google Scholar]

- Spanos, N.; Matralis, H.K.; Kordulis, C.; Lycourghiotis, A. Molybdenum-oxo Species Deposited on Titania by Adsorption and Characterization of the Calcined Samples. J. Catal. 1992, 136, 432–445. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tribalis, A.; Panagiotou, G.D.; Bourikas, K.; Sygellou, L.; Kennou, S.; Ladas, S.; Lycourghiotis, A.; Kordulis, C. Ni Catalysts Supported on Modified Alumina for Diesel Steam Reforming. Catalysts 2016, 6, 11. https://doi.org/10.3390/catal6010011

Tribalis A, Panagiotou GD, Bourikas K, Sygellou L, Kennou S, Ladas S, Lycourghiotis A, Kordulis C. Ni Catalysts Supported on Modified Alumina for Diesel Steam Reforming. Catalysts. 2016; 6(1):11. https://doi.org/10.3390/catal6010011

Chicago/Turabian StyleTribalis, Antonios, George D. Panagiotou, Kyriakos Bourikas, Labrini Sygellou, Stella Kennou, Spyridon Ladas, Alexis Lycourghiotis, and Christos Kordulis. 2016. "Ni Catalysts Supported on Modified Alumina for Diesel Steam Reforming" Catalysts 6, no. 1: 11. https://doi.org/10.3390/catal6010011