Erbium Luminescence Centres in Single- and Nano-Crystalline Diamond—Effects of Ion Implantation Fluence and Thermal Annealing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples Preparation

2.2. Samples Characterization

3. Results

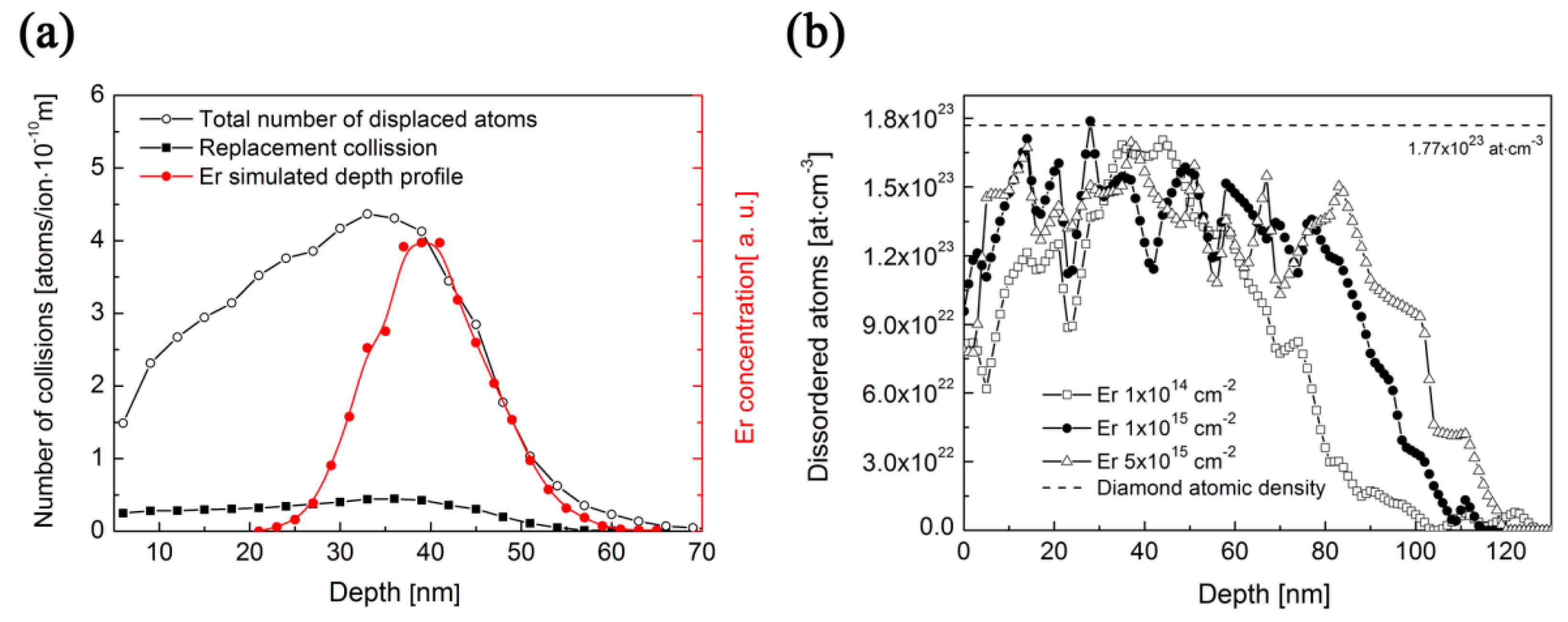

3.1. Er-Induced Defects Depth Distribution—Simulations Using SRIM

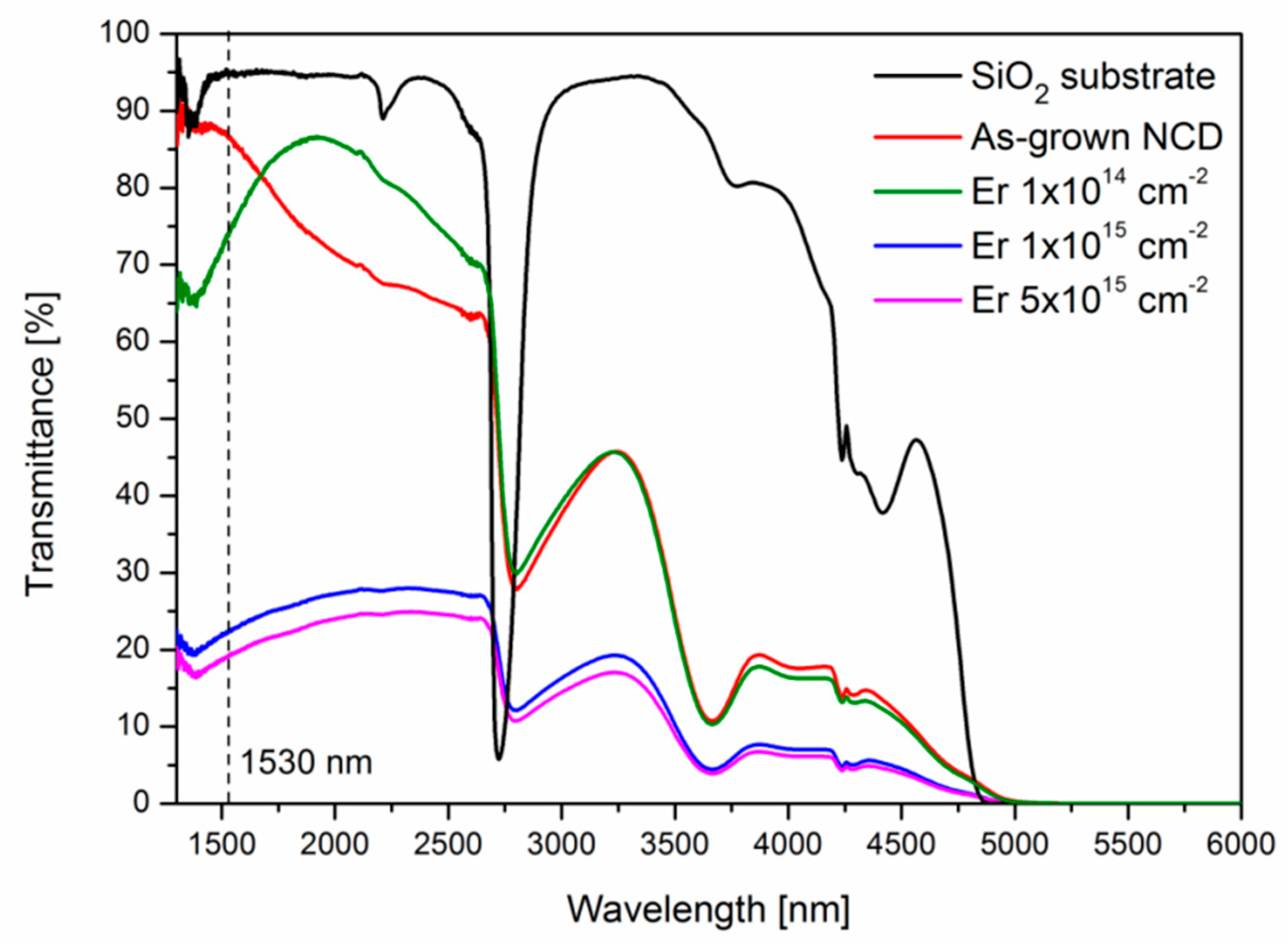

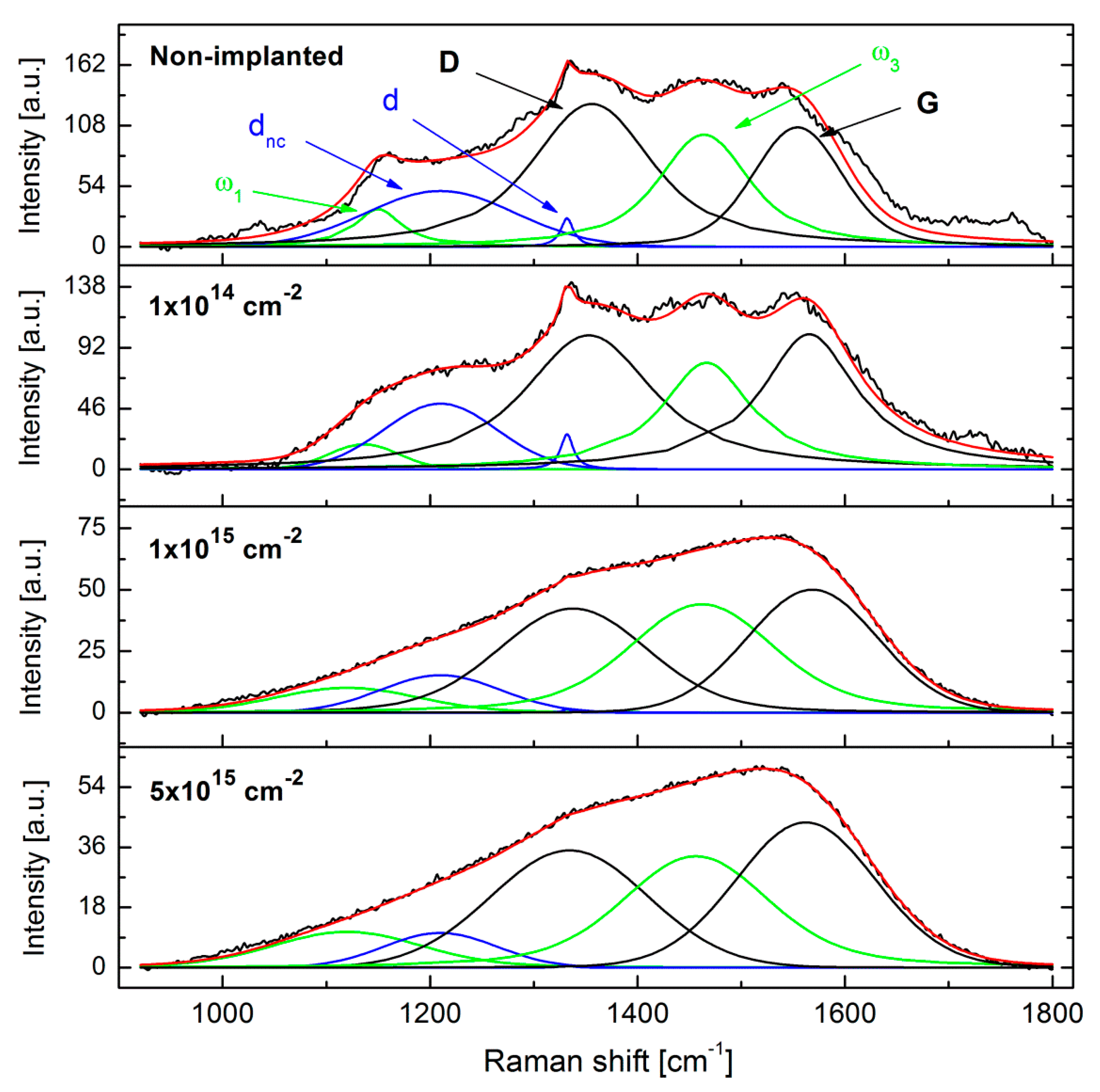

3.2. Er-Ion Implantation—As-Implanted Samples Characterization

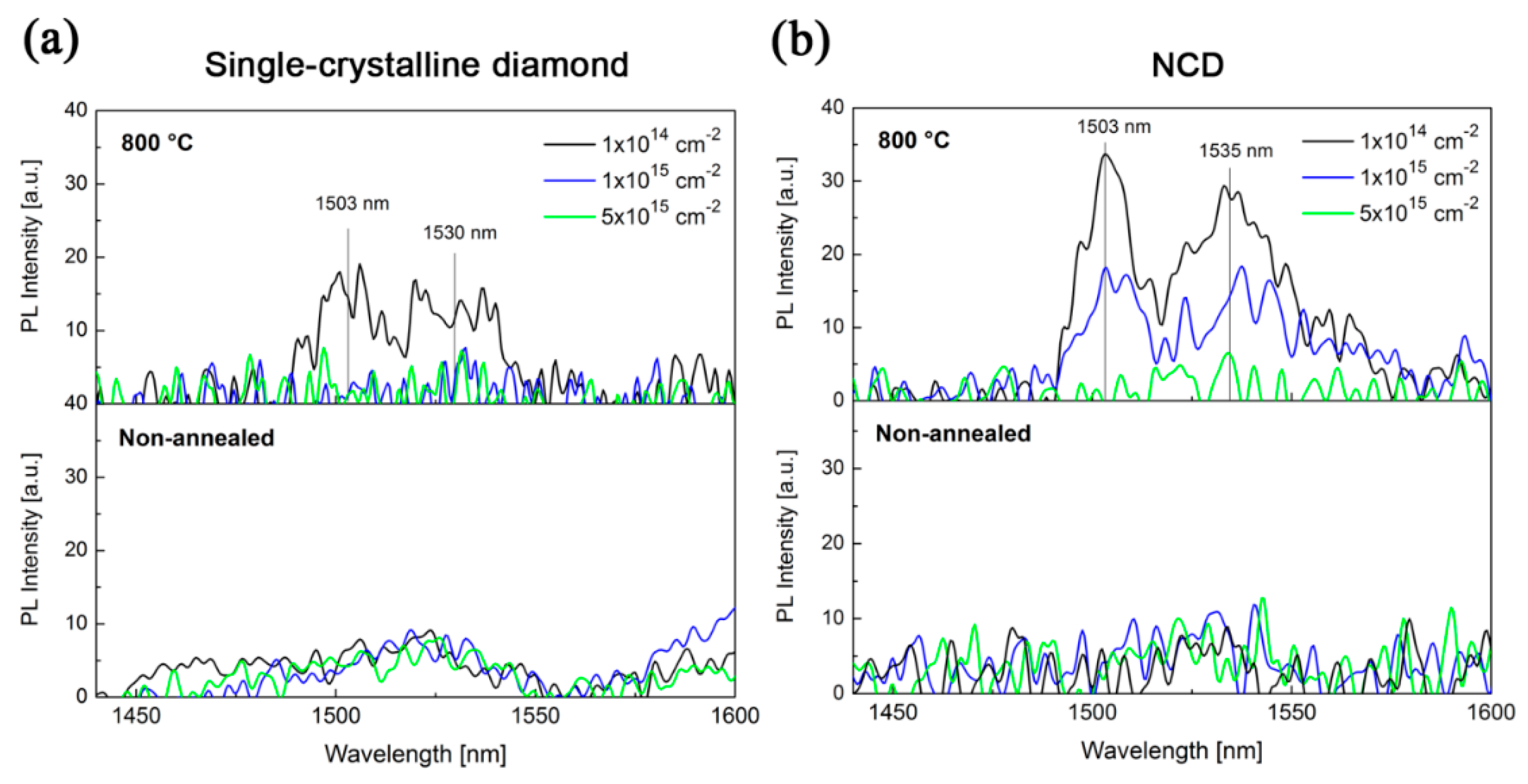

3.3. Post-Implantation Thermal Annealing—As-Annealed Samples Characterization

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Greentree, A.D.; Fairchild, B.A.; Hossain, F.M.; Prawer, S. Diamond integrated quantum photonics. Mater. Today 2008, 11, 22–31. [Google Scholar] [CrossRef]

- Aharonovich, I.; Neu, E. Diamond nanophotonics. Adv. Opt. Mater. 2014, 2, 911–928. [Google Scholar] [CrossRef]

- Zaitsev, A.M. Optical Properties of Diamond: A Data Handbook; Springer Science & Business Media: Berlin, Germany, 2013; ISBN 978-3-642-08585-7. [Google Scholar]

- Orwa, J.O.; Greentree, A.D.; Aharonovich, I.; Alves, A.D.C.; Van Donkelaar, J.; Stacey, A.; Prawer, S. Fabrication of single optical centres in diamond—A review. J. Lumin. 2010, 130, 1646–1654. [Google Scholar] [CrossRef]

- Gruber, A.; Dräbenstedt, A.; Tietz, C.; Fleury, L.; Wrachtrup, J.; Von Borczyskowski, C. Scanning confocal optical microscopy and magnetic resonance on single defect centers. Science 1997, 276, 2012–2014. [Google Scholar] [CrossRef]

- Beveratos, A.; Kühn, S.; Brouri, R.; Gacoin, T.; Poizat, J.P.; Grangier, P. Room temperature stable single-photon source. Eur. Phys. J. D At. Mol. Opt. Plasma Phys. 2002, 18, 191–196. [Google Scholar] [CrossRef] [Green Version]

- Clark, C.D.; Kanda, H.; Kiflawi, I.; Sittas, G. Silicon defects in diamond. Phys. Rev. B 1995, 51, 16681. [Google Scholar] [CrossRef]

- Gaebel, T.; Popa, I.; Gruber, A.; Domhan, M.; Jelezko, F.; Wrachtrup, J. Stable single-photon source in the near infrared. New J. Phys. 2004, 6, 98. [Google Scholar] [CrossRef]

- Aharonovich, I.; Castelletto, S.; Simpson, D.A.; Stacey, A.; McCallum, J.; Greentree, A.D.; Prawer, S. Two-level ultrabright single photon emission from diamond nanocrystals. Nano Lett. 2009, 9, 3191–3195. [Google Scholar] [CrossRef] [PubMed]

- Foy, C.P.; do Carmo, M.C.; Davies, G.; Lightowlers, E.C. Uniaxial stress measurements on the 0.97 eV line in irradiated silicon. J. Phys. C Solid State Phys. 1981, 14, L7. [Google Scholar] [CrossRef]

- Magyar, A.; Hu, W.; Shanley, T.; Flatté, M.E.; Hu, E.; Aharonovich, I. Synthesis of luminescent europium defects in diamond. Nat. Commun. 2014, 5, 3523. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aharonovich, I.; Castelletto, S.; Simpson, D.A.; Su, C.H.; Greentree, A.D.; Prawer, S. Diamond-based single-photon emitters. Rep. Prog. Phys. 2011, 74, 076501. [Google Scholar] [CrossRef]

- Delerue, C.; Lannoo, M. Description of the trends for rare-earth impurities in semiconductors. Phys. Rev. Lett. 1991, 67, 3006. [Google Scholar] [CrossRef] [PubMed]

- Polman, A. Erbium as a probe of everything? Phys. B Conden. Matter 2001, 300, 78–90. [Google Scholar] [CrossRef]

- Kenyon, A.J. Erbium in silicon. Semicond. Sci. Technol. 2005, 20, R65. [Google Scholar] [CrossRef]

- Nekvindova, P.; Svecova, B.; Cajzla, J.; Mackova, A.; Malinsky, P.; Oswald, J.; Kolistsch, A.; Spirkova, J. Erbium ion implantation into different crystallographic cuts of lithium niobate. Opt. Mater. 2012, 34, 652–659. [Google Scholar] [CrossRef]

- Mika, M.; Kolek, O.; Spirkova, J.; Capek, P.; Berneschi, S.; Brenci, M.; Conti, G.N.; Pelli, S.; Sebastiani, S.; Righini, G.C. The effect of Ca2+, Mg2+, and Zn2+ on optical properties of Er3+ doped silicate glass. In Proceedings of the Optical Components and Materials II, San Jose, CA, USA, 22–27 January 2005; Volume 5723, pp. 63–71. [Google Scholar]

- Mackova, A.; Malinsky, P.; Pupikova, H.; Nekvindova, P.; Cajzl, J.; Svecova, B.; Oswald, J.; Wilhelm, R.A.; Kolitsche, A. A comparison of the structural changes and optical properties of LiNbO3, Al2O3 and ZnO after Er+ ion implantation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2014, 331, 182–186. [Google Scholar] [CrossRef]

- Van den Hoven, G.N.; Polman, A.; Alves, E.; Da Silva, M.F.; Melo, A.A.; Soares, J.C. Lattice site and photoluminescence of erbium implanted in α–Al2O3. J. Mater. Res. 1997, 12, 1401–1404. [Google Scholar] [CrossRef]

- Aharonovich, I.; Castelletto, S.; Johnson, B.C.; McCallum, J.C.; Simpson, D.A.; Greentree, A.D.; Prawer, S. Chromium single-photon emitters in diamond fabricated by ion implantation. Phys. Rev. B 2010, 81, 121201. [Google Scholar] [CrossRef]

- Wang, C.; Kurtsiefer, C.; Weinfurter, H.; Burchard, B. Single photon emission from SiV centres in diamond produced by ion implantation. J. Phys. B At. Mol. Opt. Phys. 2005, 39, 37. [Google Scholar] [CrossRef]

- Tchernij, S.D.; Herzig, T.; Forneris, J.; Küpper, J.; Pezzagna, S.; Traina, P.; Moreva, E.; Degiovanni, I.P.; Brida, G.; Skukan, N.; et al. Single-photon-emitting optical centers in diamond fabricated upon Sn implantation. ACS Photonics 2017, 4, 2580–2586. [Google Scholar] [CrossRef]

- Schröder, T.; Trusheim, M.E.; Walsh, M.; Li, L.; Zheng, J.; Schukraft, M.; Sipahigil, A.; Evans, R.E.; Sukachev, D.D.; Nguyen, C.T.; et al. Scalable focused ion beam creation of nearly lifetime-limited single quantum emitters in diamond nanostructures. Nat. Commun. 2017, 8, 15376. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Naydenov, B.; Richter, V.; Beck, J.; Steiner, M.; Neumann, P.; Balasubramanian, G.; Achard, J.; Jelezko, F.; Wrachtrup, J.; Kalish, R. Enhanced generation of single optically active spins in diamond by ion implantation. Appl. Phys. Lett. 2010, 96, 163108. [Google Scholar] [CrossRef]

- Himics, L.; Toth, S.; Veres, M.; Toth, A.; Koos, M. Effective implantation of light emitting centers by plasma immersion ion implantation and focused ion beam methods into nanosized diamond. Appl. Surf. Sci. 2015, 328, 577–582. [Google Scholar] [CrossRef]

- Lai, P.F.; Prawer, S.; Bursill, L.A. Recovery of diamond after irradiation at high energy and annealing. Diam. Relat. Mater. 2001, 10, 82–86. [Google Scholar] [CrossRef]

- Kalish, R.; Reznik, A.; Prawer, S.; Saada, D.; Adler, J. Ion-implantation-induced defects in diamond and their annealing: Experiment and simulation. Phys. Stat. Sol. A 1999, 174, 83–99. [Google Scholar] [CrossRef]

- Prati, E.; Celebrano, M.; Ghirardini, L.; Biagioni, P.; Finazzi, M.; Shimizu, Y.; Tu, Y.; Inoue, K.; Nagai, Y.; Shinada, T.; et al. Revisiting room-temperature 1.54 μm photoluminescence of ErOx centers in silicon at extremely low concentration. In Proceedings of the 2017 Silicon Nanoelectronics Workshop (SNW), Kyoto, Japan, 4–5 June 2017; pp. 105–106. [Google Scholar]

- Cajzl, J.; Nekvindová, P.; Macková, A.; Malinský, P.; Sedmidubský, D.; Hušák, M.; Remeš, Z.; Varga, M.; Kromka, A.; Böttger, R.; et al. Erbium ion implantation into diamond–measurement and modelling of the crystal structure. Phys. Chem. Chem. Phys. 2017, 19, 6233–6245. [Google Scholar] [CrossRef] [PubMed]

- Ziegler, J.F.; Ziegler, M.D.; Biersack, J.P. SRIM—The stopping and range of ions in matter. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2010, 268, 1818–1823. [Google Scholar] [CrossRef]

- Ehrhart, P.; Schilling, W.; Ullmaier, H. Radiation damage in crystals. Digit. Encycl. Appl. Phys. 2003. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Raman spectroscopy of amorphous, nanostructured, diamond–like carbon, and nanodiamond. Philos. Trans. R. Soc. Lond. A Math. Phys. Eng. Sci. 2004, 362, 2477–2512. [Google Scholar] [CrossRef] [PubMed]

- Klauser, F.; Steinmüller-Nethl, D.; Kaindl, R.; Bertel, E.; Memmel, N. Raman Studies of Nano-and Ultra-nanocrystalline Diamond Films Grown by Hot-Filament CVD. Chem. Vap. Depos. 2010, 16, 127–135. [Google Scholar] [CrossRef]

- Mayer, M. SIMNRA Version 6.06, Max-Planck-Institut fur Plasmaphysik, Garching, Germany. 2011. Available online: http://home.rzg.mpg.de/~mam/ (accessed on 15 June 2018).

- IBANDL. Available online: http://www-nds.iaea.org/ibandl/GISA (accessed on 15 June 2018).

- Nastasi, M.; Mayer, J.W.; Wang, Y. Ion Beam Analysis: Fundamentals and Applications; Taylor and Francis: Boca Raton, FL, USA, 2014; ISBN 978-1-4398-4638-4. [Google Scholar]

- Ferrari, A.C. A model to interpret the Raman spectra of disordered, amorphous and nanostructured carbons. MRS Online Proc. Libr. Arch. 2001, 675. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Origin of the 1150 cm−1 Raman mode in nanocrystalline diamond. Phys. Rev. B 2001, 63, 121405. [Google Scholar] [CrossRef]

- Williams, O.A.; Kriele, A.; Hees, J.; Wolfer, M.; Müller-Sebert, W.; Nebel, C.E. High Young’s modulus in ultra thin nanocrystalline diamond. Chem. Phys. Lett. 2010, 495, 84–89. [Google Scholar] [CrossRef]

- Kozák, M.; Trojánek, F.; Galář, P.; Varga, M.; Kromka, A.; Malý, P. Coherent phonon dynamics in micro-and nanocrystalline diamond. Opt. Express 2013, 21, 31521–31529. [Google Scholar] [CrossRef] [PubMed]

- Macková, A.; Malinský, P.; Pupíková, H.; Nekvindová, P.; Cajzl, J.; Sofer, J.; Wilhelm, R.A.; Kolitsch, A.; Oswald, J. The structural changes and optical properties of LiNbO3 after Er implantation using high ion fluencies. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2014, 332, 74–79. [Google Scholar] [CrossRef]

- Baranov, A.M.; Sleptsov, V.V.; Nefedov, A.A.; Varfolomeev, A.E.; Fanchenko, S.S.; Calliari, L.; Speranza, G.; Ferrari, M.; Chiasera, A. Erbium photoluminescence in hydrogenated amorphous carbon. Phys. Stat. Sol. B 2002, 234, R1–R3. [Google Scholar] [CrossRef]

- Foong, Y.M.; Hsieh, J.; Li, X.; Chua, D.H. Comparative study between erbium and erbium oxide-doped diamondlike carbon films deposited by pulsed laser deposition technique. J. Vac. Sci. Technol. A Vac. Surf. Films 2010, 28, 449–455. [Google Scholar] [CrossRef]

- Foong, Y.M.; Hsieh, J.; Li, X.; Chua, D.H.C. The study on the effect of erbium on diamond-like carbon deposited by pulsed laser deposition technique. J. Appl. Phys. 2009, 106, 064904. [Google Scholar] [CrossRef]

- Hsu, H.-L.; Leong, K.R.; Halamicek, M.; Teng, I.-J.; Mahtani, P.; Juang, J.-Y.; Jian, S.-R.; Qian, L.; Kherani, N.P. In-situ doping of erbium in hydrogenated amorphous carbon by low temperature metalorganic radio frequency plasma enhanced chemical vapor deposition. Thin Solid Films 2014, 570, 429–435. [Google Scholar] [CrossRef]

- Orwa, J.O.; Nugent, K.W.; Jamieson, D.N.; Prawer, S. Raman investigation of damage caused by deep ion implantation in diamond. Phys. Rev. B 2000, 62, 5461. [Google Scholar] [CrossRef]

- Cajzl, J.; Akhetova, B.; Nekvindová, P.; Macková, P.; Malinský, P.; Oswald, J.; Remeš, Z.; Varga, M.; Kromka, A. Co-implantation of Er and Yb ions into single-crystalline and nano-crystalline diamond. Surf. Interface Anal. 2018. [Google Scholar] [CrossRef]

| Peak No. | Peak Position | Peak Fitting Function | Peak/Band Description |

|---|---|---|---|

| 1 | ≈1150 cm−1 | Voight | t-Pa = trans-polyacetylene (ω1) |

| 2 | ≈1200–1250 cm−1 | Gaussian | dnc (VDOS) = diamond crystallites |

| 3 | 1332 cm−1 | Lorentzian | d-peak = diamond |

| 4 | ≈1350 cm−1 | Voight | D-band (disordered) = sp2 rings |

| 5 | ≈1480 cm−1 | Voight | t-Pa = trans-polyacetylene (ω3) |

| 6 | ≈1580 cm−1 | Voight | G-band = all sp2 atoms in both rings and chains |

| Ion-Implantation Conditions | Single-Crystalline Diamond * | NCD | ||

|---|---|---|---|---|

| RP [nm] | ΔRP [nm] | RP [nm] | ΔRP [nm] | |

| SRIM Er+, 190 keV | 40 | 6 | - | - |

| Er+, 190 keV, 1.0 × 1014 ions/cm2 | 44 | 9 | 42 | 21 |

| Er+, 190 keV, 1.0 × 1015 ions/cm2 | 41 | 12 | 46 | 14 |

| Er+, 190 keV, 5.0 × 1015 ions/cm2 | 44 | 12 | 50 | 15 |

| Sample * | Description | ID/IG | AD/AG | Id/I(dnc) | sp3 [%] (from G-Band Position) ** | sp3 [%] (from AD/AG Ratio) ** |

|---|---|---|---|---|---|---|

| REF | Non-implanted | 1.20 | 1.82 | 0.51 | 35 | 33 |

| 1 × 1014 cm−2 (I-303) | As-implanted | 0.99 | 1.26 | 0.53 | 30 | 40 |

| 400 °C | 1.00 | 1.26 | 0.62 | 30 | 40 | |

| 600 °C | 0.81 | 0.87 | 0.42 | 30 | 45 | |

| 800 °C | 0.98 | 1.40 | 0.89 | 33 | 36 | |

| 1 × 1015 cm−2 (I-304) | As-implanted | 0.85 | 1.01 | 0.09 | 28 | 43 |

| 400 °C | 0.93 | 1.21 | 0.03 | 25 | 41 | |

| 600 °C | 1.11 | 1.90 | 0.07 | 24 | 31 | |

| 800 °C | 1.11 | 1.67 | 0.00 | 25 | 34 | |

| 5 × 1015 cm−2 (I-305) | As-implanted | 0.81 | 0.90 | 0.06 | 30 | 43 |

| 400 °C | 0.93 | 1.14 | 0.00 | 28 | 41 | |

| 600 °C | 1.15 | 2.13 | 0.00 | 25 | 29 | |

| 800 °C | 1.11 | 1.74 | 0.00 | 26 | 32 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cajzl, J.; Nekvindová, P.; Macková, A.; Malinský, P.; Oswald, J.; Remeš, Z.; Varga, M.; Kromka, A.; Akhetova, B.; Böttger, R.; et al. Erbium Luminescence Centres in Single- and Nano-Crystalline Diamond—Effects of Ion Implantation Fluence and Thermal Annealing. Micromachines 2018, 9, 316. https://doi.org/10.3390/mi9070316

Cajzl J, Nekvindová P, Macková A, Malinský P, Oswald J, Remeš Z, Varga M, Kromka A, Akhetova B, Böttger R, et al. Erbium Luminescence Centres in Single- and Nano-Crystalline Diamond—Effects of Ion Implantation Fluence and Thermal Annealing. Micromachines. 2018; 9(7):316. https://doi.org/10.3390/mi9070316

Chicago/Turabian StyleCajzl, Jakub, Pavla Nekvindová, Anna Macková, Petr Malinský, Jiří Oswald, Zdeněk Remeš, Marián Varga, Alexander Kromka, Banu Akhetova, Roman Böttger, and et al. 2018. "Erbium Luminescence Centres in Single- and Nano-Crystalline Diamond—Effects of Ion Implantation Fluence and Thermal Annealing" Micromachines 9, no. 7: 316. https://doi.org/10.3390/mi9070316