Miniaturization and High-Density Arrangement of Microcantilevers in Proximity and Tactile Sensor for Dexterous Gripping Control

Abstract

:1. Introduction

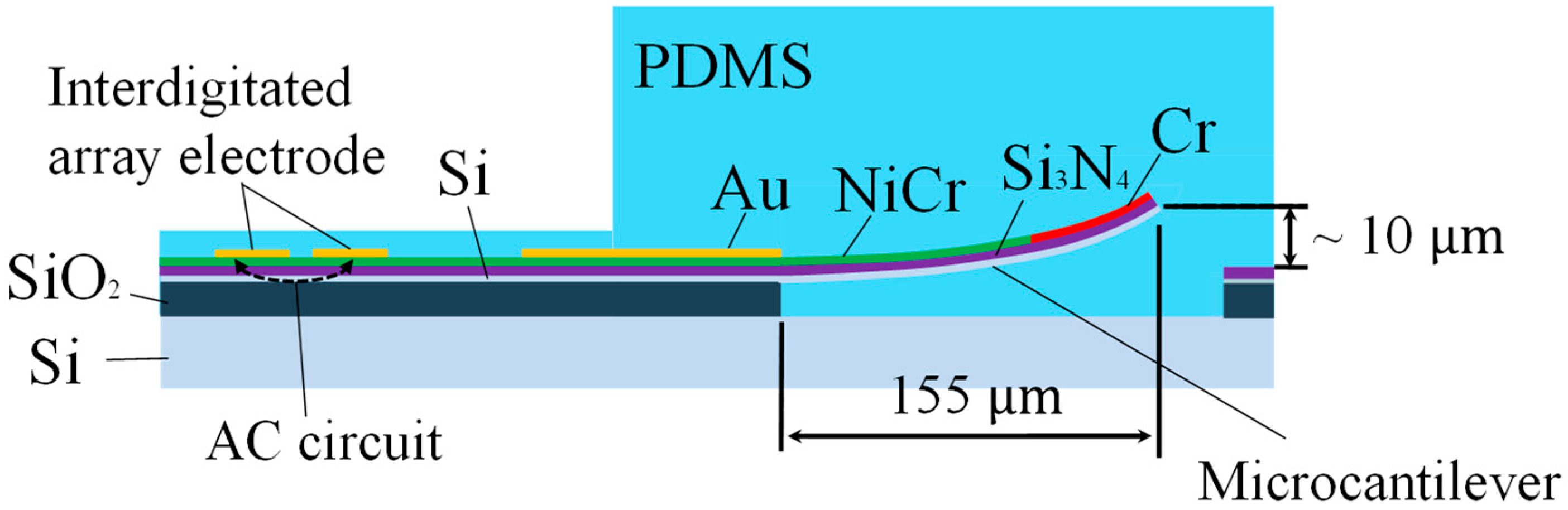

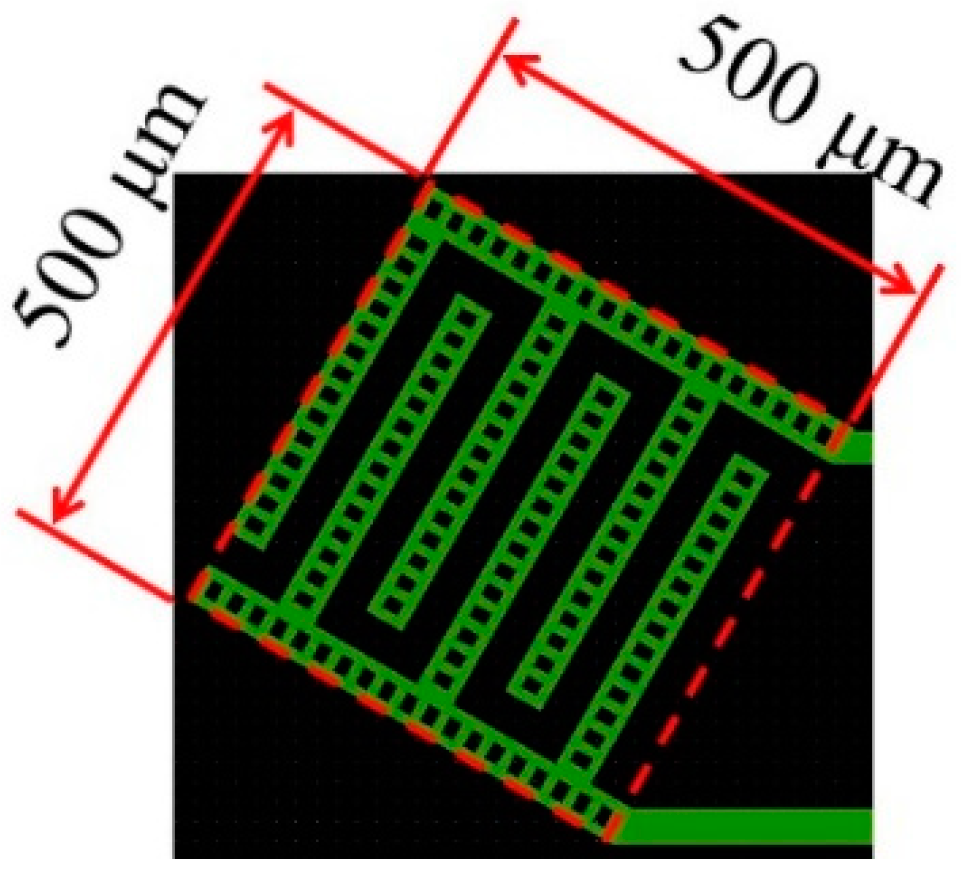

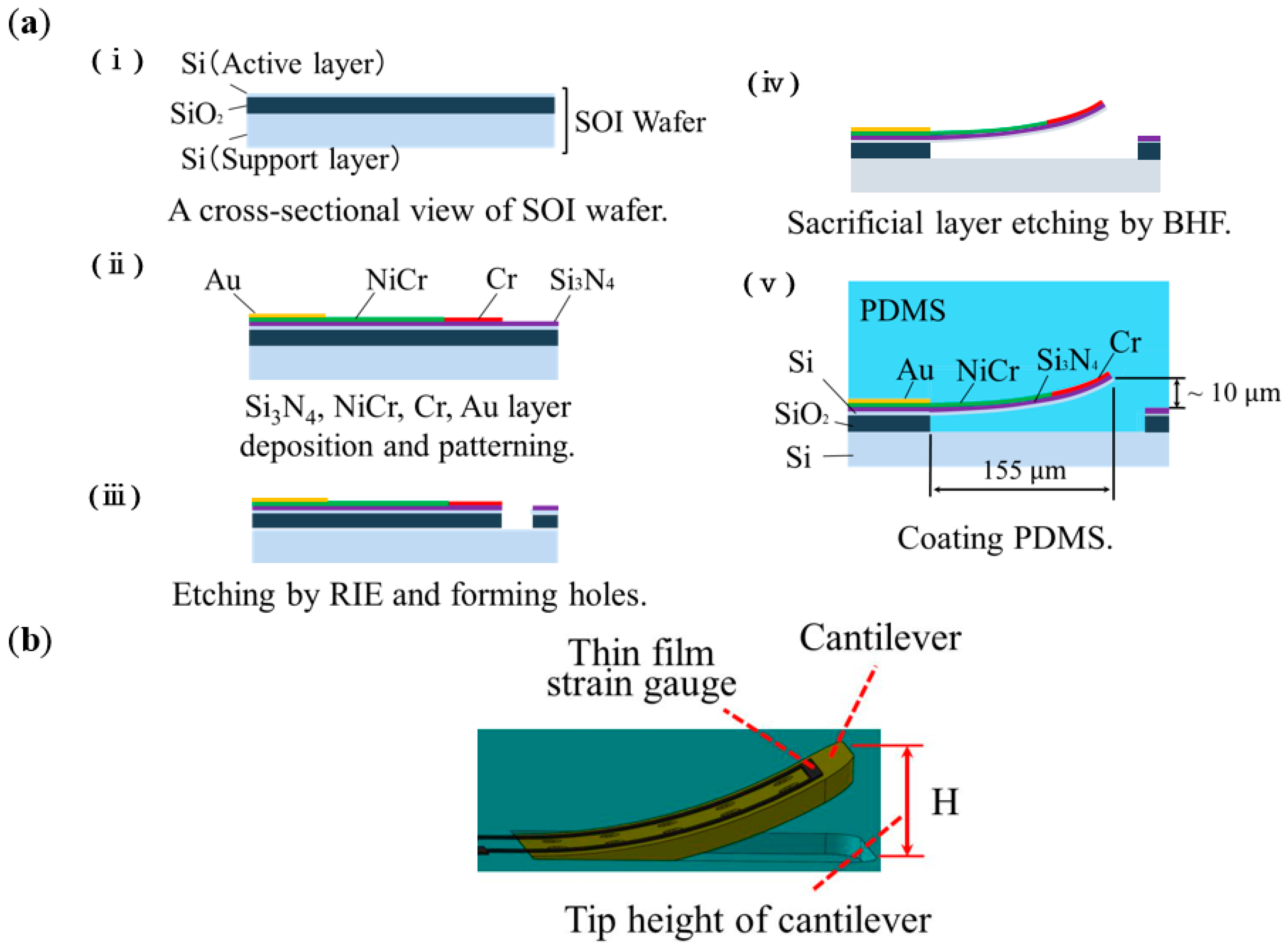

2. Design and Fabrication of Tactile Sensor

2.1. Design of the Sensor

2.2. Fabrication of the Sensor

3. Proximity and Tactile Measurement Principle

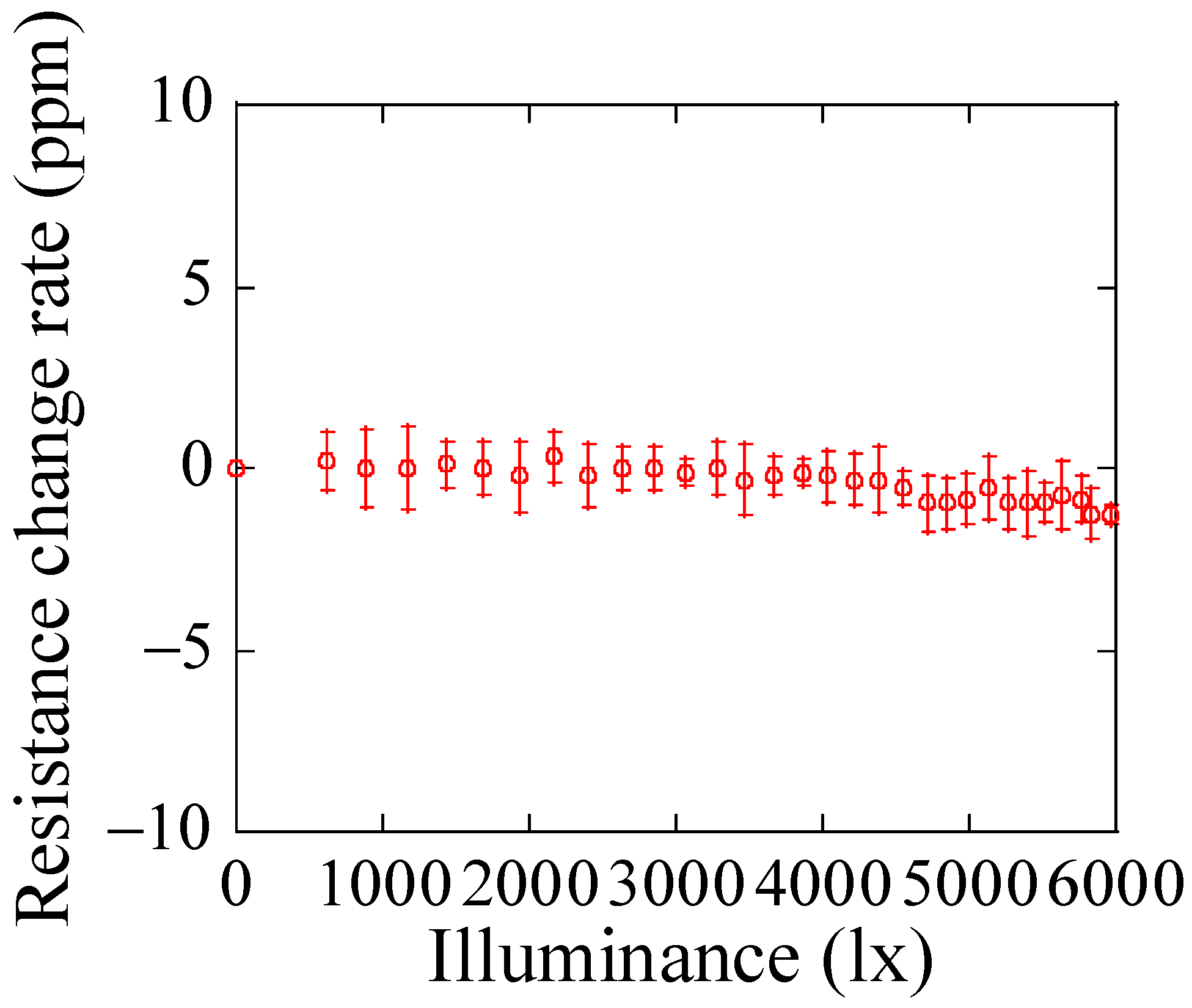

3.1. Optical Responsivity of Interdigitated Array Electrode

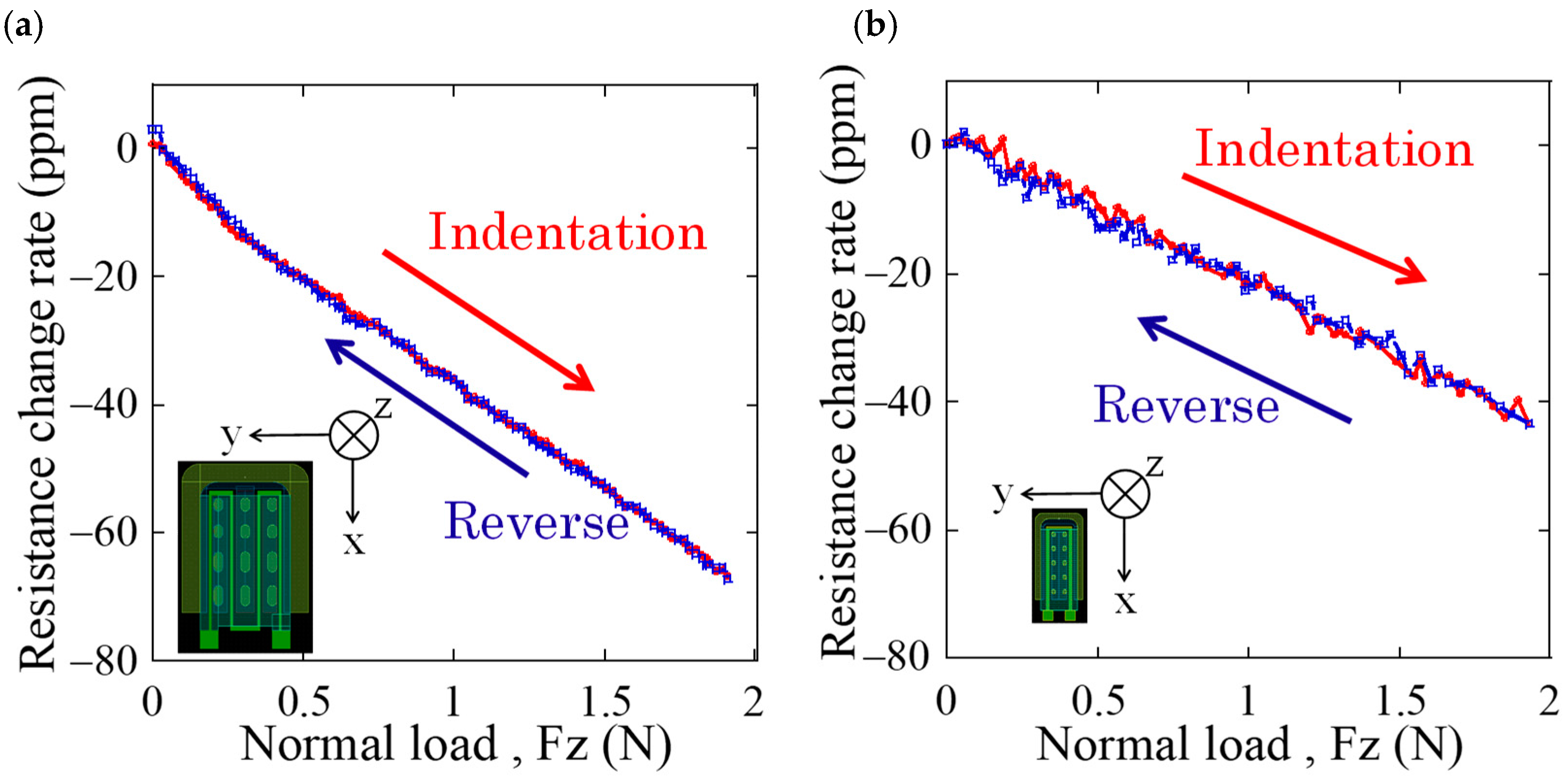

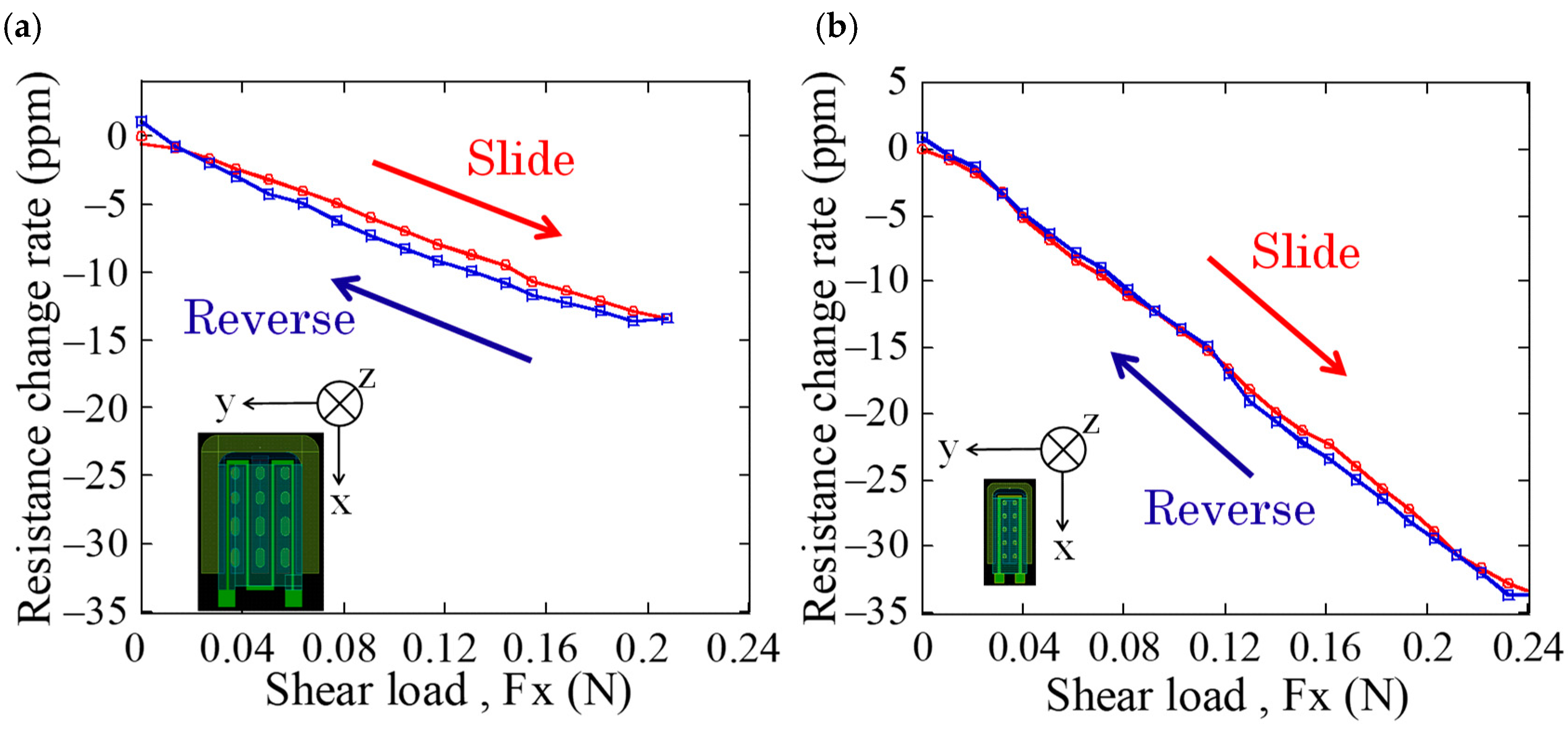

3.2. Optical and Load Responsivity of Fabricated Cantilever

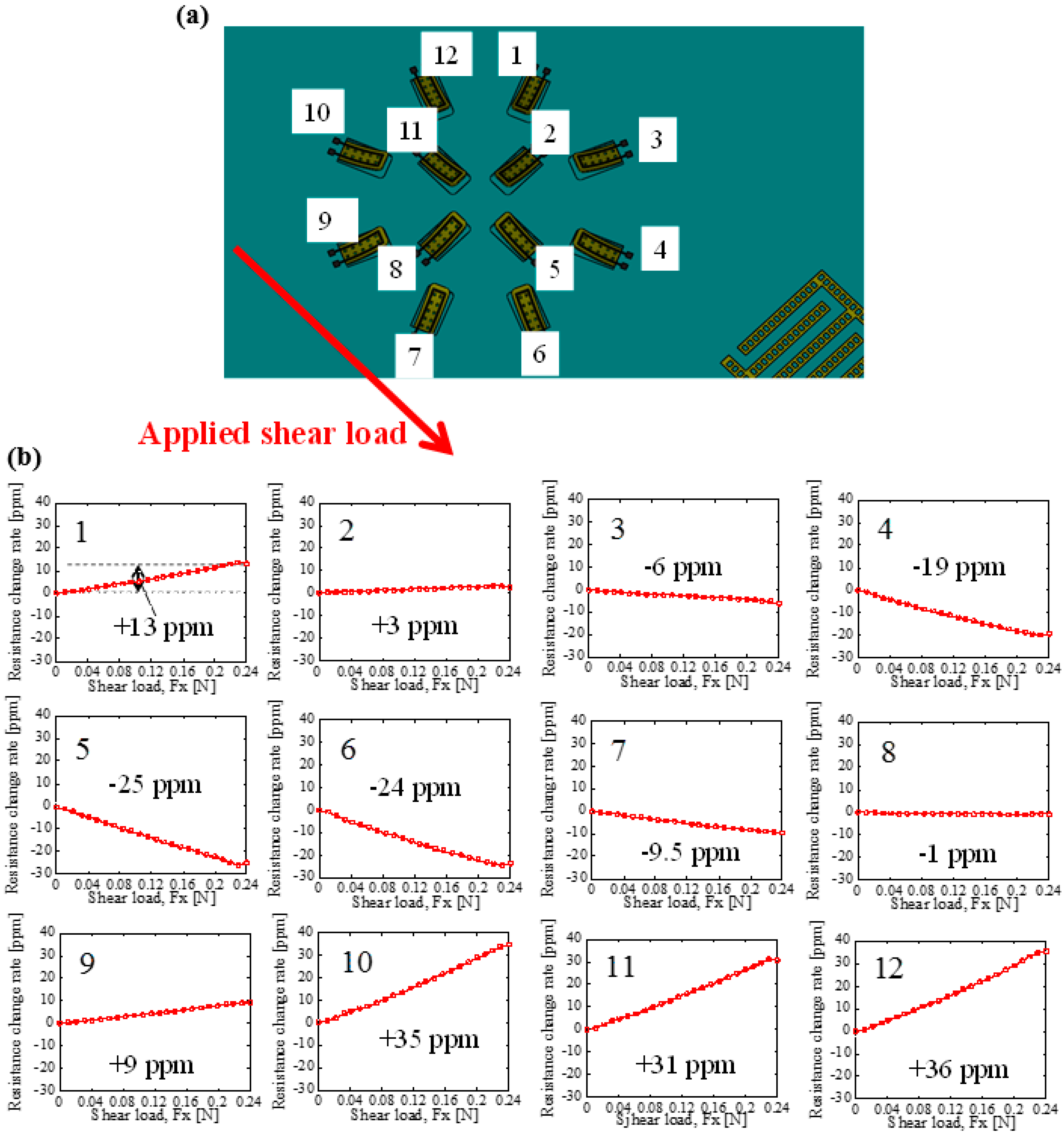

3.3. Demonstration of Tactile Sensing with High Density Cantilever Array

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- The Japan Institute for Labour Policy and Training. Labor Situation in Japan and Its Analysis: General Overview 2015/2016; Japan Institute for Labour Policy and Training: Tokyo, Japan, 2016; pp. 20–24.

- Takahashi, Y.; Komeda, T.; Miyagi, M.; Koyama, H. Development of the mobile robot system to aid in the daily life for physically handicapped. In Integration of Assistive Technology in the Information Age; Mokhtari, M., Ed.; IOS Press: Amsterdam, The Netherlands, 2001; pp. 186–191. [Google Scholar]

- Aravind, K.R.; Raja, P.; Pérez-Ruiz, M. Task-based agricultural mobil robots in arable farming: A review. Span. J. Agric. Res. 2017, 15, e02R01. [Google Scholar] [CrossRef]

- Dahiya, R.; Metta, G.; Valle, M.; Sandini, G. Tactile Sensing—From Humans to Humanoids. IEEE Trans. Robot. 2010, 26, 1–20. [Google Scholar] [CrossRef]

- Zhangping, J.; Hui, Z.; Huicong, L.; Nan, L.; Tao, C.; Zhan, Y.; Lining, S. The design and characterization of a flexible tactile sensing array for robot skin. Sensors 2016, 16, 2001. [Google Scholar]

- Ogura, Y.; Akikawa, H.; Shimomura, K.; Morishima, A.; Lim, H.; Takanishi, A. Development of a new humanoid robot WABIAN-2. In Proceedings of the 2006 IEEE International Conference on Robotics and Automation, Orlando, FL, USA, 15–19 May 2006; pp. 76–81. [Google Scholar]

- Noritsugu, T.; Sasaki, D.; Takaiwa, M. Application of artificial pneumatic rubber muscles to a human friendly robot. In Proceedings of the 2003 IEEE International Conference on Robotics and Automation, Taipei, Taiwan, 14–19 September 2003; Volume 3, pp. 4098–4103. [Google Scholar]

- Hall, E.L. Intelligent robot trends and predictions for the .net future. In Intelligent Robots and Computer Vision XX: Algorithms, Techniques, and Active Vision; International Society for Optics and Photonics: Boston, MA, USA, 2001; Volume 4572, pp. 70–80. [Google Scholar]

- Huebner, K.; Welke, K.; Przybylski, M.; Vahrenkamp, N.; Asfour, T.; Kragic, D.; Dillmann, R. Grasping known objects with humanoid robots: A box-based approach. In Proceedings of the 2009 International Conference on Advanced Robotics, Munich, Germany, 22–26 June 2009; pp. 1–6. [Google Scholar]

- Johansson, R.S. 19-Sensory control of dexterous manipulation in humans. In Hand and Brain the Neurophysiology and Psychology of Hand Movements; Academic Press: San Diego, CA, USA, 1996; pp. 381–414. [Google Scholar]

- Saxena, A.; Driemeyer, J.; Ng, A.Y. Robotic grasping of novel objects using vision. Int. J. Robot. Res. 2008, 27, 157–173. [Google Scholar] [CrossRef]

- Teshigawara, S.; Tadakuma, K.; Ming, A.; Ishikawa, M.; Shimojo, M. Development of high-sensitivity slip sensor using special characteristics of pressure conductive rubber. In Proceedings of the 2009 IEEE International Conference on Robotics and Automation, Kobe, Japan, 12–17 May 2009; pp. 3289–3294. [Google Scholar]

- Pham, A.K.; Nguyen, M.D.; Nguyen, B.K.; Phan, H.P.; Matsumoto, K.; Shimoyama, I. Multi-axis force sensor with dynamic range up to ultrasonic. In Proceedings of the 2014 IEEE 27th International Conference on Micro Electro Mechanical Systems (MEMS), San Francisco, CA, USA, 26–30 January 2014; pp. 769–772. [Google Scholar]

- Mizoguchi, Y.; Tadakuma, K.; Hasegawa, H.; Ming, A.; Ishikawa, M.; Shimojo, M. Development of intelligent robot hand using proximity, contact and slip sensing. Trans. Soc. Instrum. Control Eng. 2010, 46, 632–640. [Google Scholar] [CrossRef]

- Tsuji, S.; Kohama, T. A proximity and tactile sensor using self-capacitance measurement. IEEJ Trans. Sens. Micromach. 2014, 134, 400–405. [Google Scholar] [CrossRef]

- Sohgawa, M.; Nozawa, A.; Yokoyama, H.; Kanashima, T.; Okuyama, M.; Abe, T.; Noma, H.; Azuma, T. Multimodal measurement of proximity and touch force by light- and strain-sensitive multifunctional MEMS sensor. In Proceedings of the 2014 IEEE Conference on SENSORS, Valencia, Spain, 2–5 November 2014; pp. 317–320. [Google Scholar]

- Araki, R.; Suga, F.; Abe, T.; Noma, H.; Sohgawa, M. Gripping control of delicate and flexible object by electromotive manipulator with proximity and tactile combo mems sensor. In Proceedings of the 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017; pp. 1140–1143. [Google Scholar]

- Umeki, N.; Okuyama, M.; Noma, H.; Abe, T.; Sohgawa, M. Improvement of optical sensitivity for proximity and tactile combo sensor. IEEJ Trans. Sens. Micromach. 2016, 137, 146–150. [Google Scholar] [CrossRef]

- Sohgawa, M.; Hirashima, D.; Moriguchi, Y.; Uematsu, T.; Mito, W.; Kanashima, T.; Okuyama, M.; Noma, H. Tactile sensor array using microcantilever with nickel–chromium alloy thin film of low temperature coefficient of resistance and its application to slippage detection. Sens. Actuators A Phys. 2012, 186, 32–37. [Google Scholar] [CrossRef]

- Yokoyama, H.; Kanashima, T.; Okuyama, M.; Abe, T.; Noma, H.; Azuma, T.; Sohgawa, M. Active touch sensing by multi-axial force measurement using high-resolution tactile sensor with microcantilevers. IEEJ Trans. Sens. Micromach. 2014, 134, 58–63. [Google Scholar] [CrossRef]

| Work | Cantilever Size | Strain Gauge Resistance | Tip Height of Cantilever | Interdigitated Array Electrode | SEM Image |

|---|---|---|---|---|---|

| Previous work | Width: 200 µm, Length: 290 µm | 7 kΩ | 20–30 µm (±5.0 µm) | N/A |  |

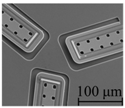

| This work | Width: 70 µm, Length: 155 µm | 2 kΩ | 9.60 µm (±0.7 µm) |  |  |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Araki, R.; Abe, T.; Noma, H.; Sohgawa, M. Miniaturization and High-Density Arrangement of Microcantilevers in Proximity and Tactile Sensor for Dexterous Gripping Control. Micromachines 2018, 9, 301. https://doi.org/10.3390/mi9060301

Araki R, Abe T, Noma H, Sohgawa M. Miniaturization and High-Density Arrangement of Microcantilevers in Proximity and Tactile Sensor for Dexterous Gripping Control. Micromachines. 2018; 9(6):301. https://doi.org/10.3390/mi9060301

Chicago/Turabian StyleAraki, Ryoma, Takashi Abe, Haruo Noma, and Masayuki Sohgawa. 2018. "Miniaturization and High-Density Arrangement of Microcantilevers in Proximity and Tactile Sensor for Dexterous Gripping Control" Micromachines 9, no. 6: 301. https://doi.org/10.3390/mi9060301