Bonding-Based Wafer-Level Vacuum Packaging Using Atomic Hydrogen Pre-Treated Cu Bonding Frames

Abstract

:1. Introduction

2. Experimental

2.1. Remote-Type Hot-Wire Tool

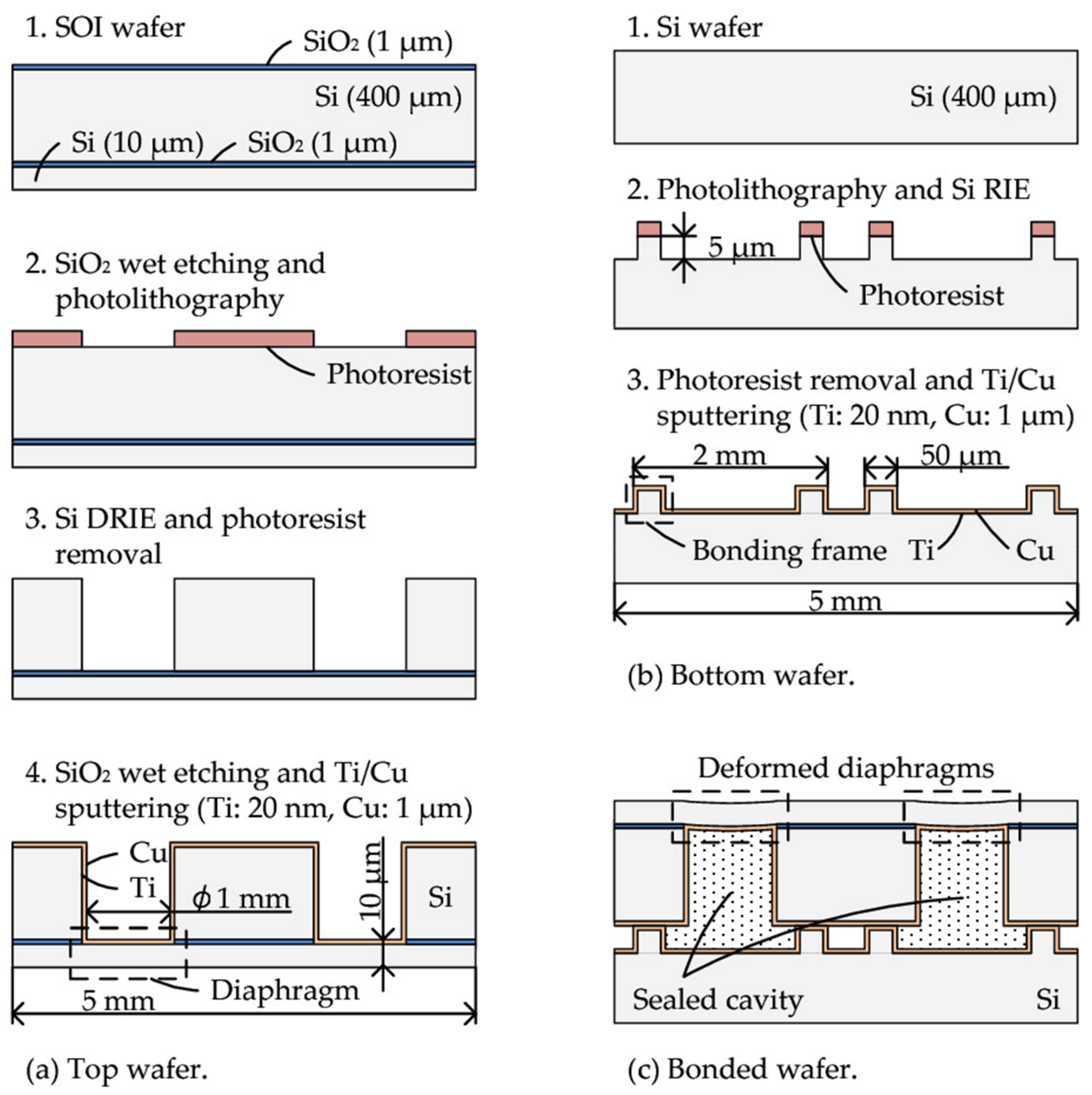

2.2. Bonding Sample Preparation

2.3. Pre-Treatment and Wafer Bonding

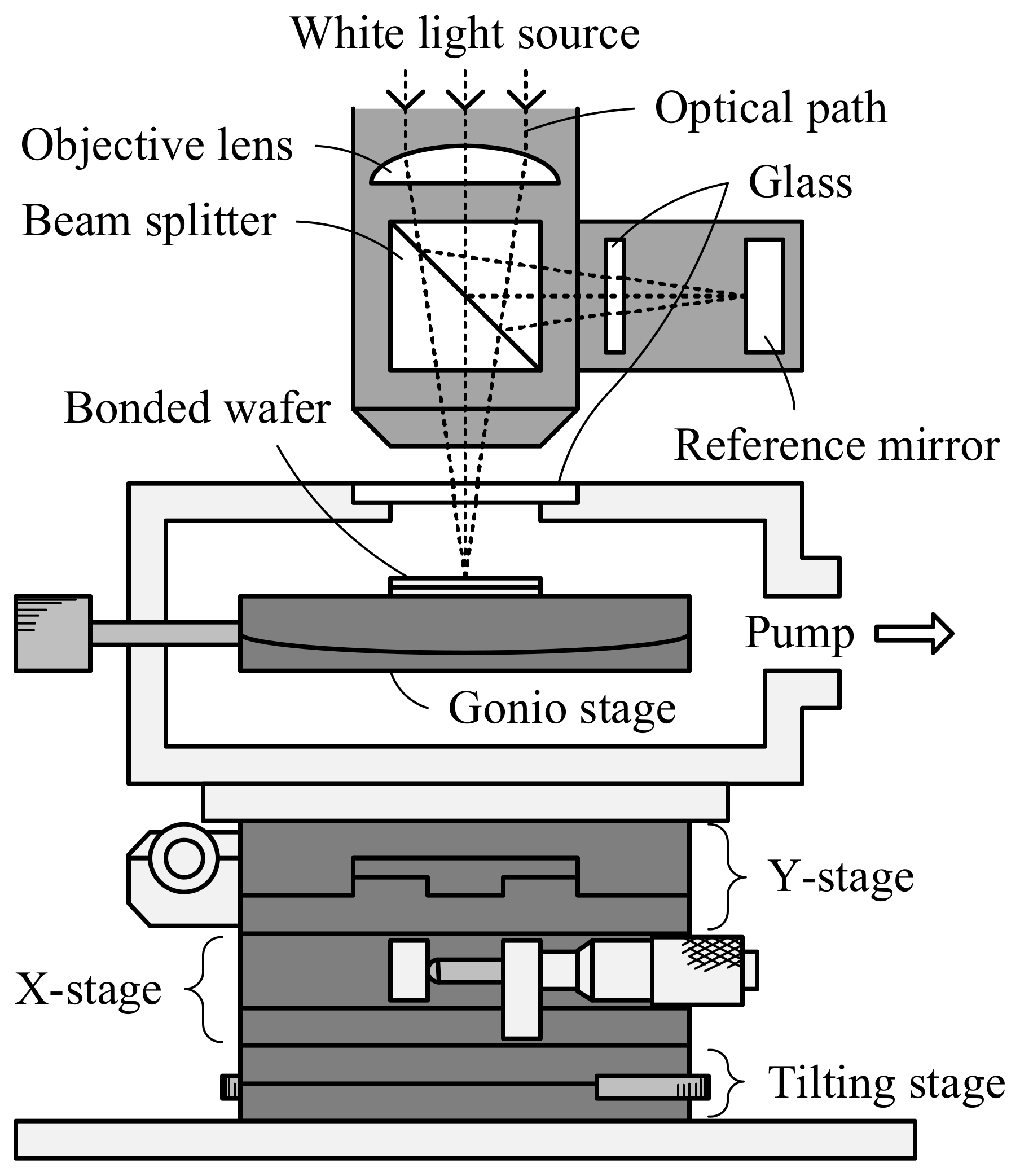

2.4. Evaluation of Bonding Performance

2.5. AES and TDS Measurements

3. Results

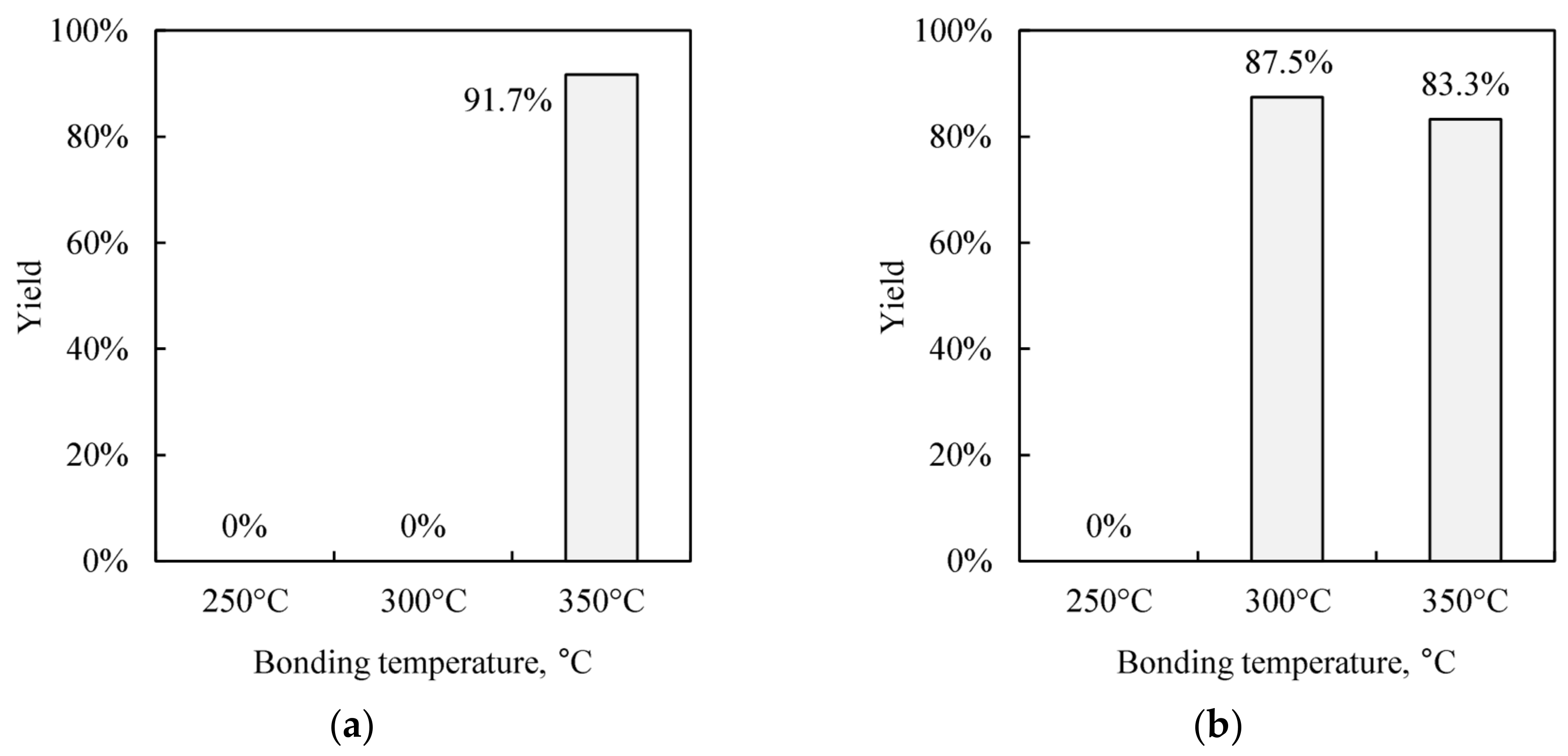

3.1. Yield of Hermetic Sealing

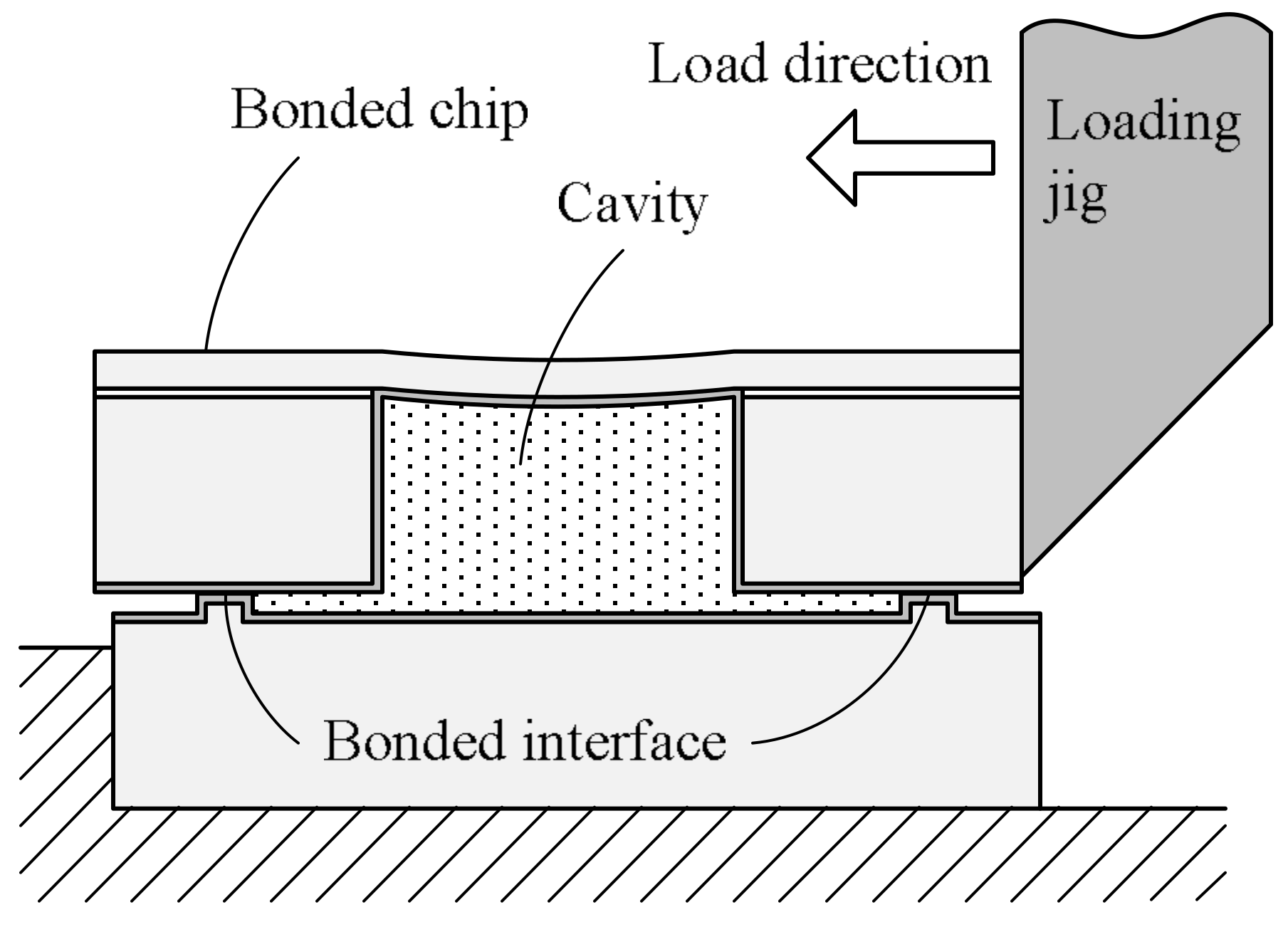

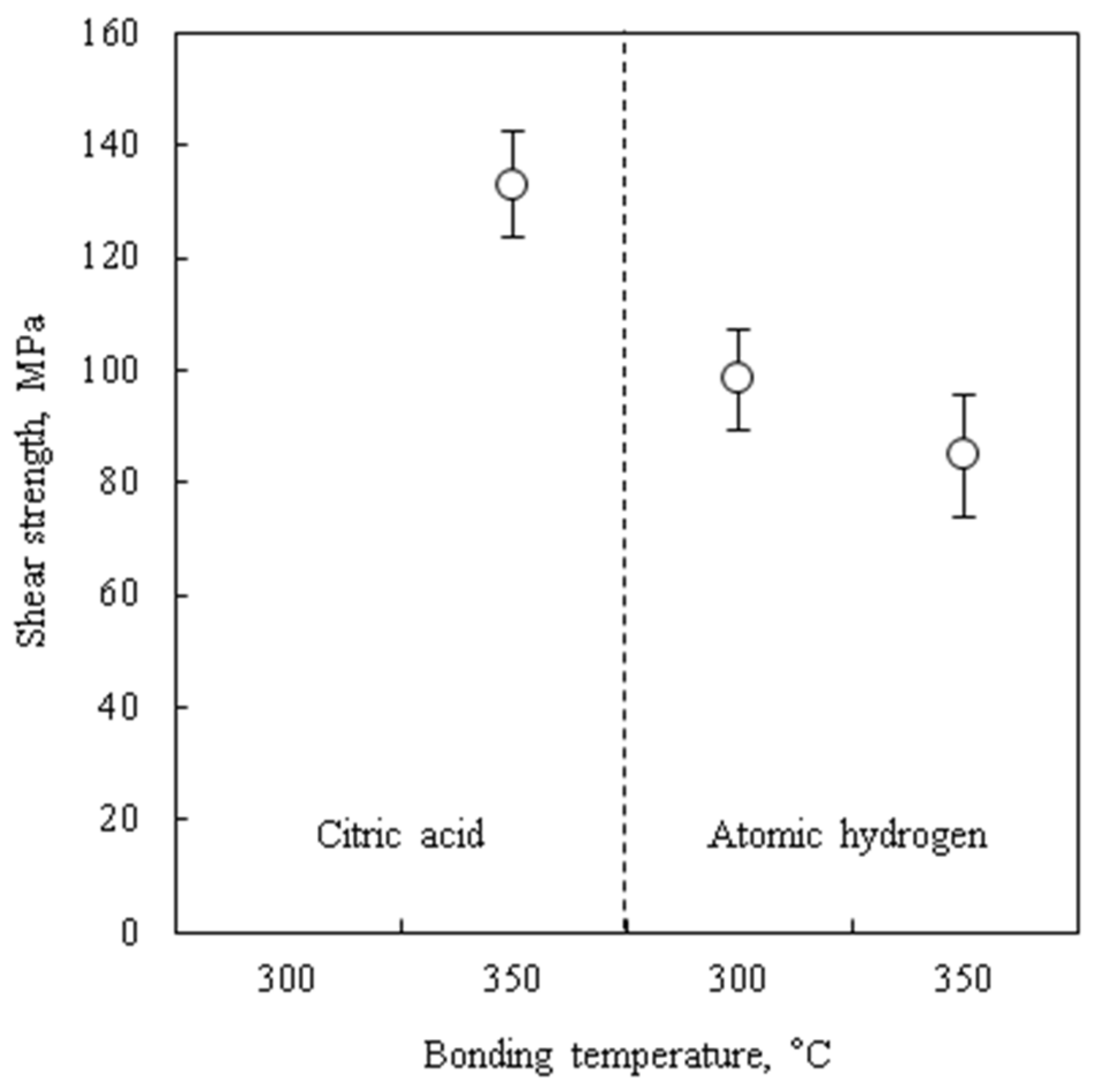

3.2. Bonding Strength

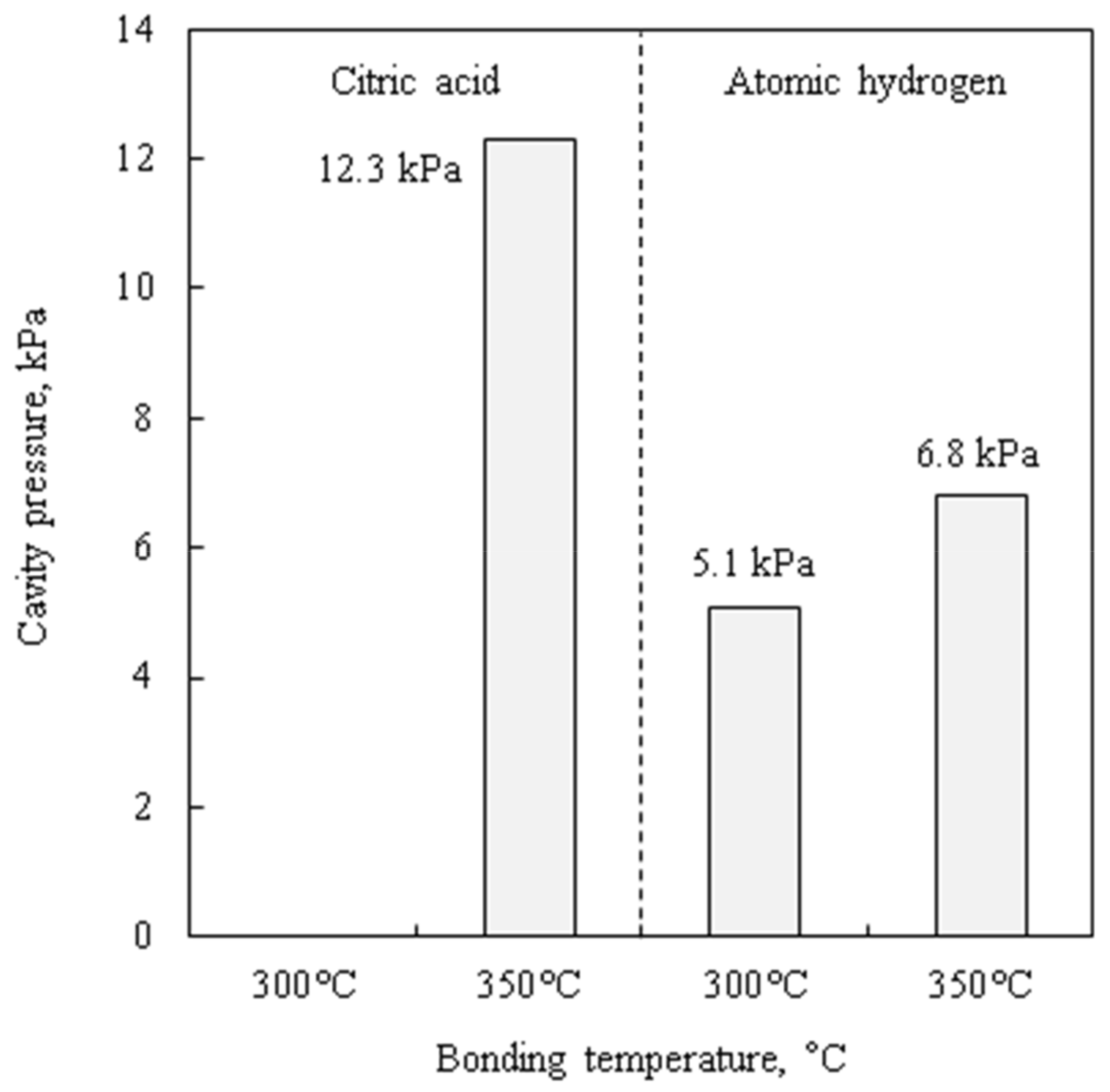

3.3. Pressure of Sealed Cavity

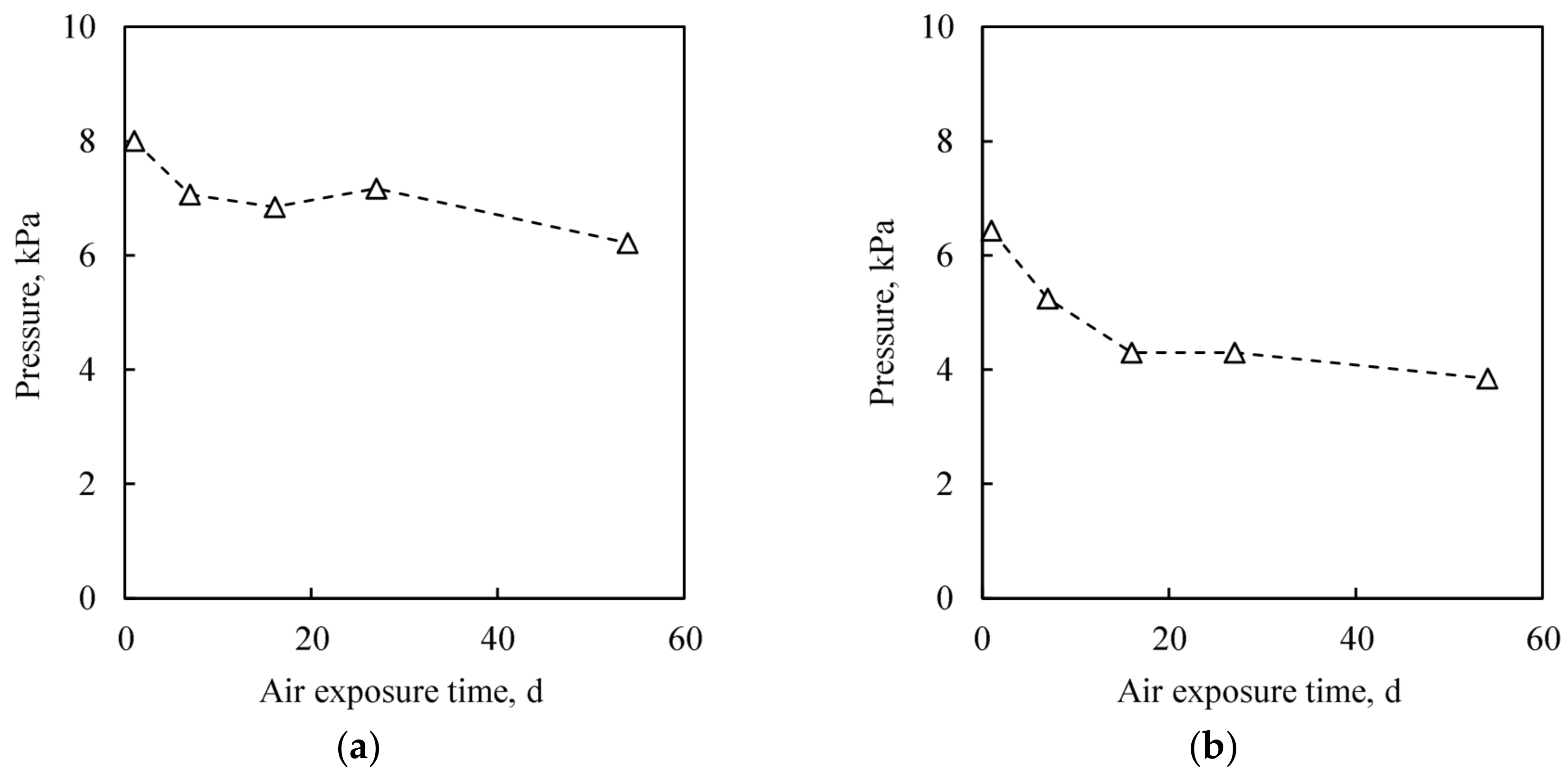

3.4. Leak Rate

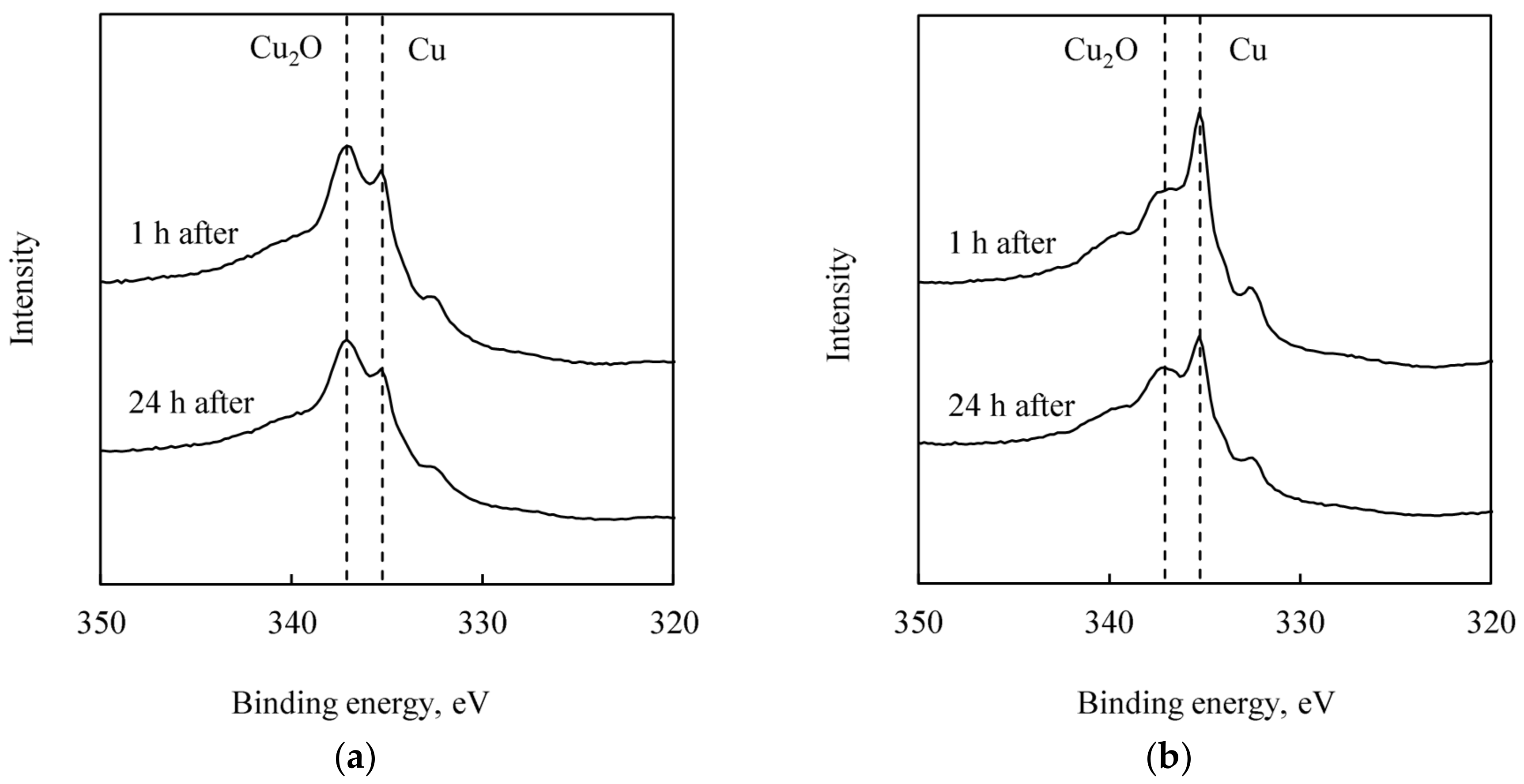

3.5. AES Measurements: Observation of Cu Re-Oxidation in Atmosphere

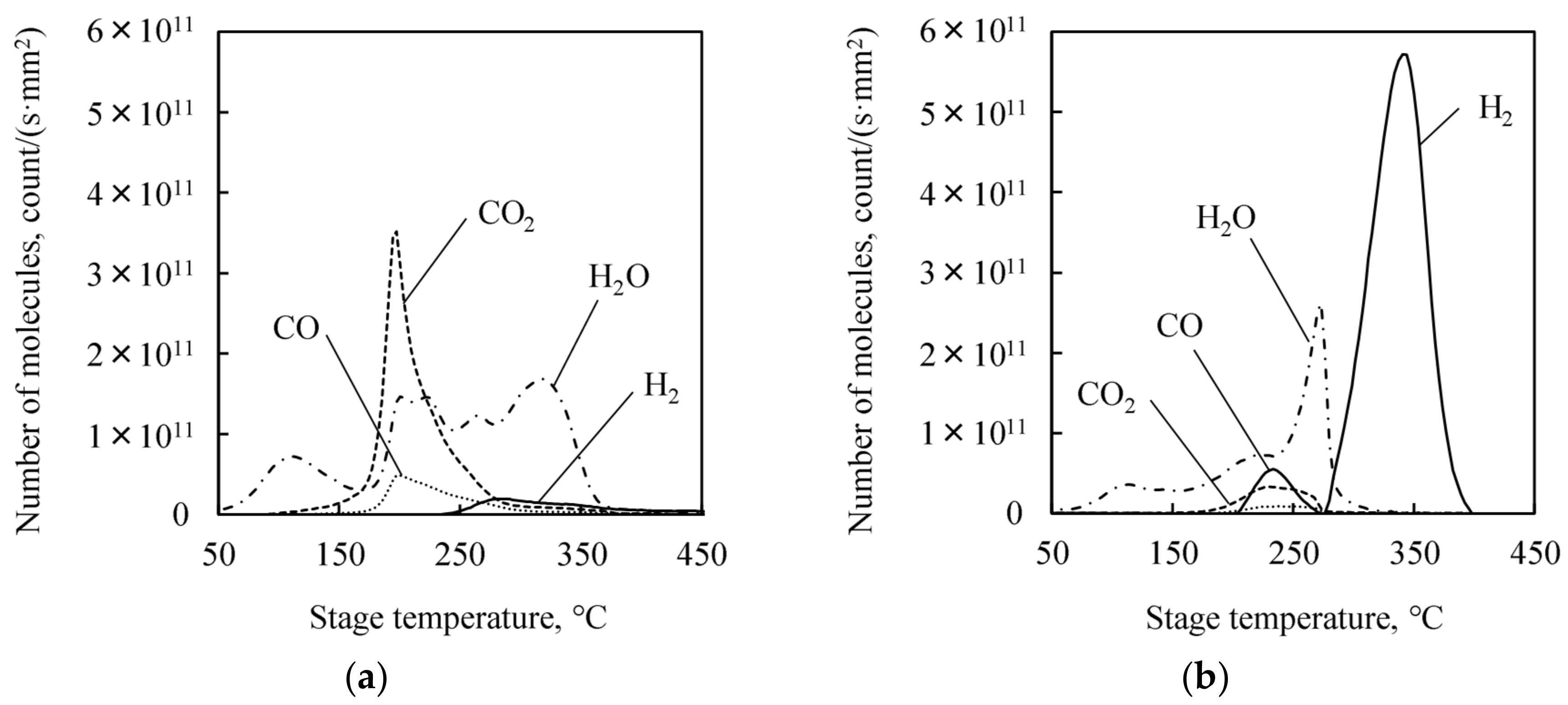

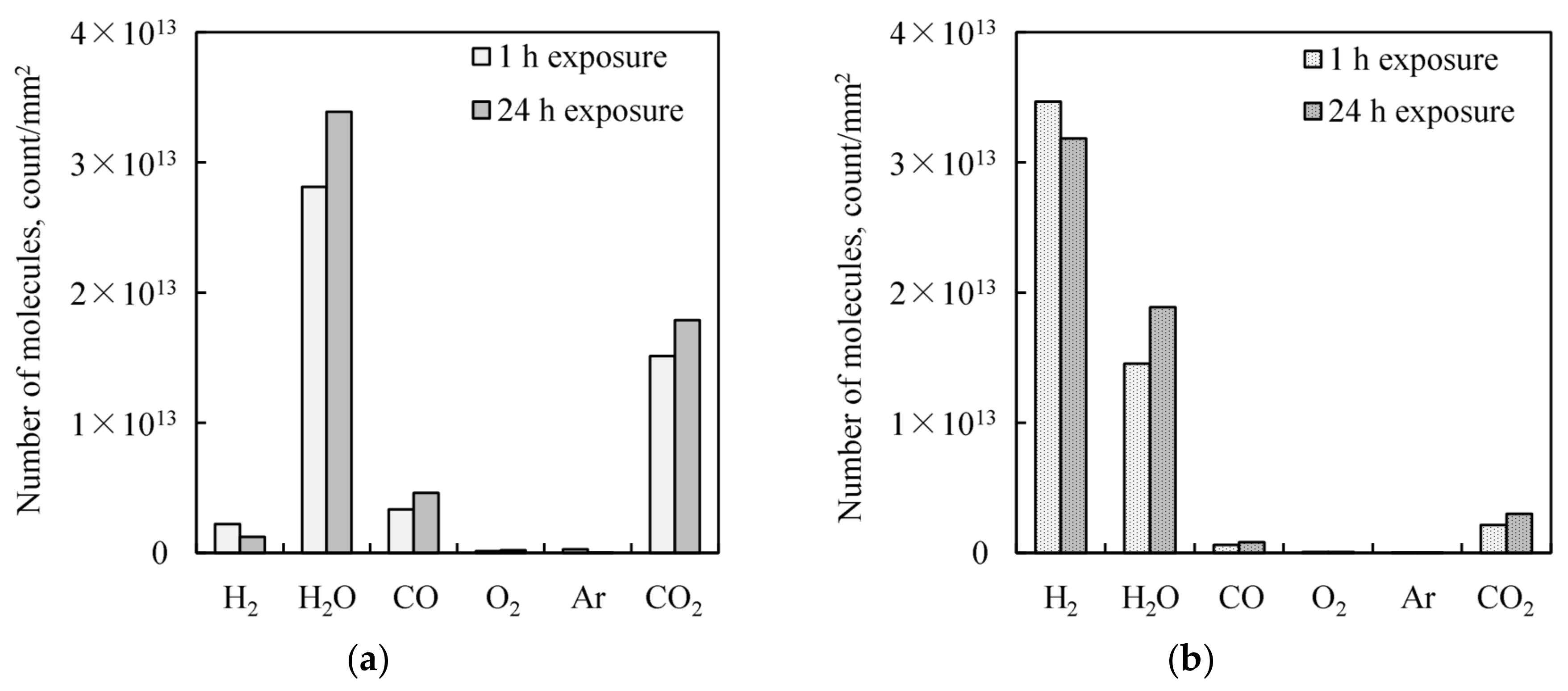

3.6. TDS Measurements: Observation of Chemisorbed Hydrogen Atoms on Cu Surface

3.7. Reasons for Low-temperature Vacuum Seal Capability after Storage in Atmospheric Condition

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Santagata, F.; Creemer, J.F.; Iervolino, E.; Sarro, P.M. Tube-shaped Pirani gauge for in situ hermeticity monitoring of SiN thin-film encapsulation. J. Micromech. Microeng. 2012, 22, 105025. [Google Scholar] [CrossRef]

- Esashi, M. Wafer level packaging of MEMS. J. Micromech. Microeng. 2008, 18, 73001. [Google Scholar] [CrossRef]

- Fischer, A.C.; Forsberg, F.; Lapisa, M.; Bleiker, S.J.; Stemme, G.; Roxhed, N.; Niklaus, F. Integrating MEMS and ICs. Microsyst. Nanoeng. 2015, 1, 15005. [Google Scholar] [CrossRef]

- Harendt, C.; Graf, H.G.; Hofflinger, B.; Penteker, E. Silicon fusion bonding and its characterization. J. Micromech. Microeng. 1992, 2, 113–116. [Google Scholar] [CrossRef]

- Henmi, H.; Shoji, S.; Shoji, Y.; Yoshimi, K.; Esashi, M. Vacuum packaging for microsensors by glass-silicon anodic bonding. Sens. Actuators A Phys. 1994, 43, 243–248. [Google Scholar] [CrossRef]

- Tanaka, S. Wafer-level hermetic MEMS packaging by anodic bonding and its reliability issue. Microelectron. Reliab. 2014, 54, 875–881. [Google Scholar] [CrossRef]

- Knechtel, R. Glass frit bonding: An universal technology for wafer level encapsulation and packaging. Microsyst. Technol. 2005, 12, 63–68. [Google Scholar] [CrossRef]

- Aasmundtveit, K.E.; Luu, T.T.; Tollefsen, T.A.; Wang, K.; Nguyen, H.V.; Hoivik, N. Solid-Liquid Interdiffusion (SLID) Bonding. In Proceedings of the 2016 Symposium on Design, Test, Integration & Packaging of MEMS and MOEMS, Budapest, Hungary, 30 May–2 June 2016. [Google Scholar]

- Al Farisi, M.S.; Hirano, H.; Frömel, J.; Tanaka, S. Wafer-level hermetic thermo-compression bonding using electroplated gold sealing frame planarized by fly-cutting. J. Micromech. Microeng. 2017, 27, 15029. [Google Scholar] [CrossRef]

- Chen, K.N.; Tan, C.S.; Fan, A.; Reif, R. Morphology and Bond Strength of Copper Wafer Bonding. Electrochem. Solid-State Lett. 2004, 7, G14. [Google Scholar] [CrossRef]

- Baum, M.; Hofmann, L.; Wiemer, M.; Schulz, S.; Gessner, T. Development and characterisation of 3D integration technologies for MEMS based on copper filled TSV’s and copper-to-copper metal thermo compression bonding. In Proceedings of the IEEE 2013 International Semiconductor Conference Dresden—Grenoble (ISCDG), Dresden, Germany, 26–27 September 2013; pp. 1–4. [Google Scholar]

- Kim, T.H.; Howlader, M.M.R.; Itoh, T.; Suga, T. Room temperature Cu–Cu direct bonding using surface activated bonding method. J. Vac. Sci. Technol. A 2003, 21, 449–453. [Google Scholar] [CrossRef]

- Wu, Z.; Cai, J.; Wang, Q.; Wang, J. Low temperature Cu–Cu bonding using copper nanoparticles fabricated by high pressure PVD. AIP Adv. 2017, 7, 035306. [Google Scholar] [CrossRef]

- Derby, B.; Wallach, E.R. Diffusion bonds in copper. J. Mater. Sci. 1984, 19, 3140–3148. [Google Scholar] [CrossRef]

- Takahashi, Y.; Takahashi, K.; Nishiguchi, K. A numerical analysis of void shrinkage processes controlled by coupled surface and interface diffusion. Acta Metall. Mater. 1991, 39, 3199–3216. [Google Scholar] [CrossRef]

- Sakai, T.; Imaizumi, N.; Sakuyama, S. A Low Temperature Cu-Cu Direct Bonding Method with VUV and HCOOH Treatment for 3D Integration. In Proceedings of the 2015 International Conference on Electronic Packaging and iMAPS All Asia Conference, Kyoto, Japan, 14–17 April 2015; pp. 464–467. [Google Scholar]

- Tateishi, H.; Susaki, A.; Nakada, T. Development of the System for Cu Oxide Film Removal from Semiconductor Interconnects in Atmosphere pressure. Ebara Eng. Rev. 2008, 218, 40–44. [Google Scholar]

- Lim, D.F.; Fan, J.; Peng, L.; Leong, K.C.; Tan, C.S. Cu–Cu Hermetic Seal Enhancement Using Self-Assembled Monolayer Passivation. J. Electron. Mater. 2013, 42, 502–506. [Google Scholar] [CrossRef]

- Tan, C.S.; Lim, D.F.; Singh, S.G.; Goulet, S.K.; Bergkvist, M. Cu–Cu diffusion bonding enhancement at low temperature by surface passivation using self-assembled monolayer of alkane-thiol. Appl. Phys. Lett. 2009, 95, 192108. [Google Scholar] [CrossRef]

- Chang, Y.; Leu, J.; Lin, B.; Wang, Y.; Cheng, Y. Comparison of H2 and NH3 Treatments for Copper Interconnects. Adv. Mater. Sci. Eng. 2013, 1–7. [Google Scholar] [CrossRef]

- Baklanov, M.R.; Shamiryan, D.G.; Tökei, Z.; Beyer, G.P.; Conard, T.; Vanhaelemeersch, S.; Maex, K. Characterization of Cu surface cleaning by hydrogen plasma. J. Vac. Sci. Technol. B 2001, 19, 1201. [Google Scholar] [CrossRef]

- Tanaka, K.; Wang, W.-S.; Baum, M.; Froemel, J.; Hirano, H.; Tanaka, S.; Wiemer, M.; Otto, T. Investigation of Surface Pre-Treatment Methods for Wafer-Level Cu–Cu Thermo-Compression Bonding. Micromachines 2016, 7, 234. [Google Scholar] [CrossRef]

- Izumi, A.; Ueno, T.; Miyazaki, Y.; Oizumi, H.; Nishiyama, I. Reduction of oxide layer on various metal surfaces by atomic hydrogen treatment. Thin Solid Films 2008, 516, 853–855. [Google Scholar] [CrossRef]

- Umemoto, H.; Ohara, K.; Morita, D.; Nozaki, Y.; Masuda, A.; Matsumura, H. Direct detection of H atoms in the catalytic chemical vapor deposition of the Si4/H2 system. J. Appl. Phys. 2002, 91, 1650–1656. [Google Scholar] [CrossRef]

- Karasawa, M.; Masuda, A.; Ishibashi, K.; Matsumura, H. Development of Cat-CVD apparatus—A method to control wafer temperatures under thermal influence of heated catalyzer. Thin Solid Films 2001, 395, 71–74. [Google Scholar] [CrossRef]

- Tanaka, K.; Kumano, M.; Tanaka, S. Removal of SU-8 by two types of hot-wire atomic hydrogen sources—Dissection of contributions by atomic hydrogen and substrate heating. J. Vac. Sci. Technol. B 2015, 33, 52001. [Google Scholar] [CrossRef]

- Morimoto, T.; Umemoto, H.; Yoneyama, K.; Masuda, A.; Matsumura, H.; Ishibashi, K.; Tawarayama, H.; Kawazoe, H. Quantification of Gas-Phase H-Atom Number Density by Tungsten Phosphate Glass. Jpn. J. Appl. Phys. 2005, 44, 732–735. [Google Scholar] [CrossRef]

- Matsuzaki, S.; Tanaka, S.; Esashi, M. Anodic bonding between LTCC wafer and Si wafer with Sn-Cu-based electrical connection. Electron. Commun. Jpn. 2012, 95, 49–56. [Google Scholar] [CrossRef]

- Timoshenko, S.; Woinowsky-krieger, S. Theory of Plates and Shells, 2nd ed.; McGraw-Hill Publishing Company: New York, NY, USA, 1989; ISBN 0070647798. [Google Scholar]

- Eaton, W.P.; Bitsie, F.; Smith, J.H.; Plummer, D.W. A New Analytical Solution for Diaphragm Deflection and Its Application to a Surface-Micromachined Pressure Sensor. In Technical Proceedings of the 1999 International Conference on Modeling and Simulation of Microsystems; Nano Science and Technology Institute: Danville, CA, USA, 1999; pp. 640–643. [Google Scholar]

- Hirashita, N.; Uchiyama, T. Quantitative desorption analysis of ultra large scale integration materials by thermal desorption spectroscopy. Bunseki Kagaku 1994, 43, 757–764. [Google Scholar] [CrossRef]

- Hirashita, N.; Urano, M.; Yoshida, H. Measurements of Outgassing Rates in a Field of Analysis. J. Vac. Soc. Jpn. 2014, 57, 214–218. [Google Scholar] [CrossRef]

- United States Department of Defense. Method 2019.7 Die Shear Strength. MIL-STD-883G. In Test Method Standard Microcircuits; Defense Supply Center Columbus ATTN: Columbus, OH, USA, 2003; pp. 1–5. [Google Scholar]

- United States Department of Defense. Method 1014.12. MIL-STD-883G. In Test Method Standard Microcircuits; Defense Supply Center Columbus ATTN: Columbus, OH, USA, 2006; pp. 1–6. [Google Scholar]

- McIntyre, N.S.; Sunder, S.; Shoesmith, D.W.; Stanchell, F.W. Chemical information from XPS—Applications to the analysis of electrode surfaces. J. Vac. Sci. Technol. 1981, 18, 714–721. [Google Scholar] [CrossRef]

- Sawada, Y.; Tamaru, H.; Kogoma, M.; Kawase, M.; Hashimoto, K. The reduction of copper oxide thin films with hydrogen plasma generated by an atmospheric-pressure glow discharge. J. Phys. D Appl. Phys. 1999, 29, 2539–2544. [Google Scholar] [CrossRef]

- Christmann, K. Interaction of hydrogen with solid surfaces. Surf. Sci. Rep. 1988, 9, 1–163. [Google Scholar] [CrossRef]

- Shin, S.; Higurashi, E.; Furuyama, K.; Suga, T. Hydrogen Radical Treatment for Suppression of Oxidation and Contamination at Copper Surfaces. In Proceedings of the 34th Sensor Symposium on Sensors Micromachines and Applied Systems, Hiroshima, Japan, 31 October–2 November 2017. [Google Scholar]

- Lim, D.F.; Singh, S.G.; Ang, X.F.; Wei, J.; Ng, C.M.; Tan, C.S. Achieving low temperature Cu to Cu diffusion bonding with self assembly monolayer (SAM) passivation. In Proceedings of the 2009 IEEE International Conference on 3D System Integration, San Francisco, CA, USA, 28–30 September 2009; IEEE: New York, NY, USA, 2009; pp. 1–5. [Google Scholar]

| Pre-Treatment | Treatment Temperature | Treatment Time | Remarks |

|---|---|---|---|

| Citric acid solution | 25 °C | 3 min | After 1 wt % citric acid solution in water, the wafers were rinsed by DI water and ethanol. |

| Atomic Hydrogen Irradiation | 100 °C | 10 min | H2 flow rate and gas pressure were 500 sccm and 130 Pa, respectively. The hot-wire was heated at 2000 °C. |

| Bonding Temperature | Bonding Duration | Bonding Pressure | Ambient Pressure |

|---|---|---|---|

| 250, 300, 350 °C | 40 min | 70 MPa | 1.0 × 10−2 Pa |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tanaka, K.; Hirano, H.; Kumano, M.; Froemel, J.; Tanaka, S. Bonding-Based Wafer-Level Vacuum Packaging Using Atomic Hydrogen Pre-Treated Cu Bonding Frames. Micromachines 2018, 9, 181. https://doi.org/10.3390/mi9040181

Tanaka K, Hirano H, Kumano M, Froemel J, Tanaka S. Bonding-Based Wafer-Level Vacuum Packaging Using Atomic Hydrogen Pre-Treated Cu Bonding Frames. Micromachines. 2018; 9(4):181. https://doi.org/10.3390/mi9040181

Chicago/Turabian StyleTanaka, Koki, Hideki Hirano, Masafumi Kumano, Joerg Froemel, and Shuji Tanaka. 2018. "Bonding-Based Wafer-Level Vacuum Packaging Using Atomic Hydrogen Pre-Treated Cu Bonding Frames" Micromachines 9, no. 4: 181. https://doi.org/10.3390/mi9040181