Karman Vortex Creation Using Cylinder for Flutter Energy Harvester Device

Abstract

:1. Introduction

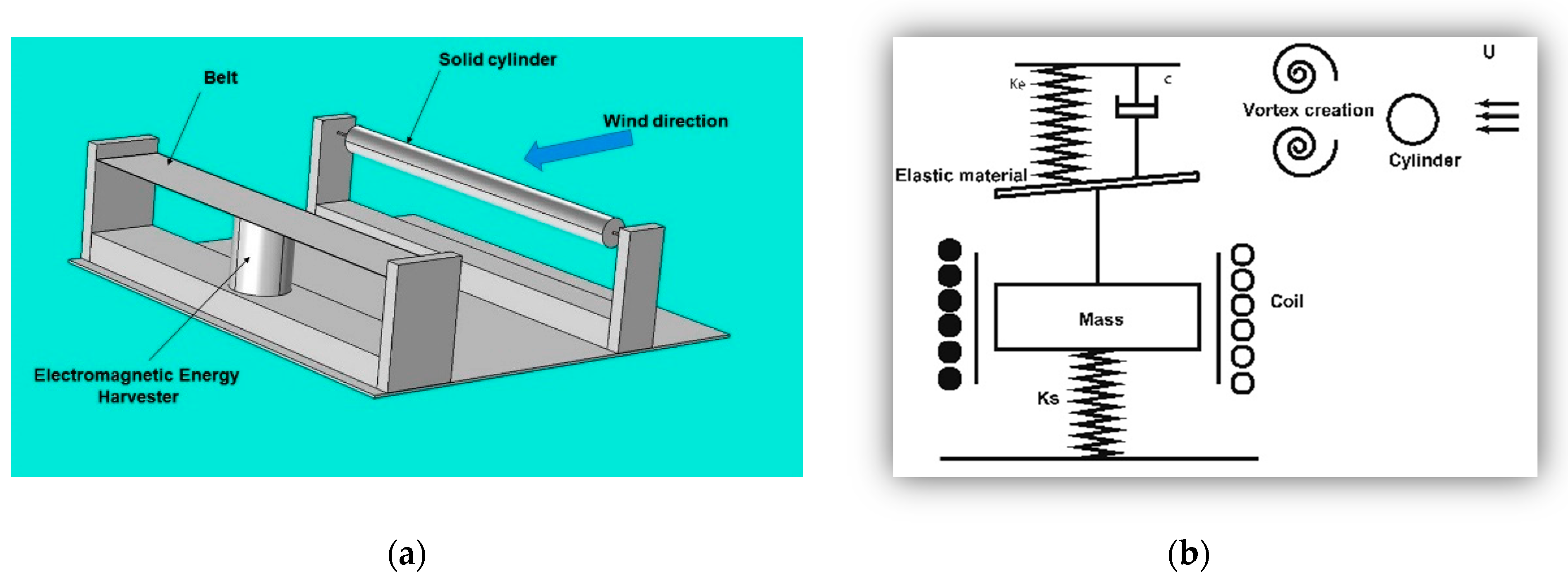

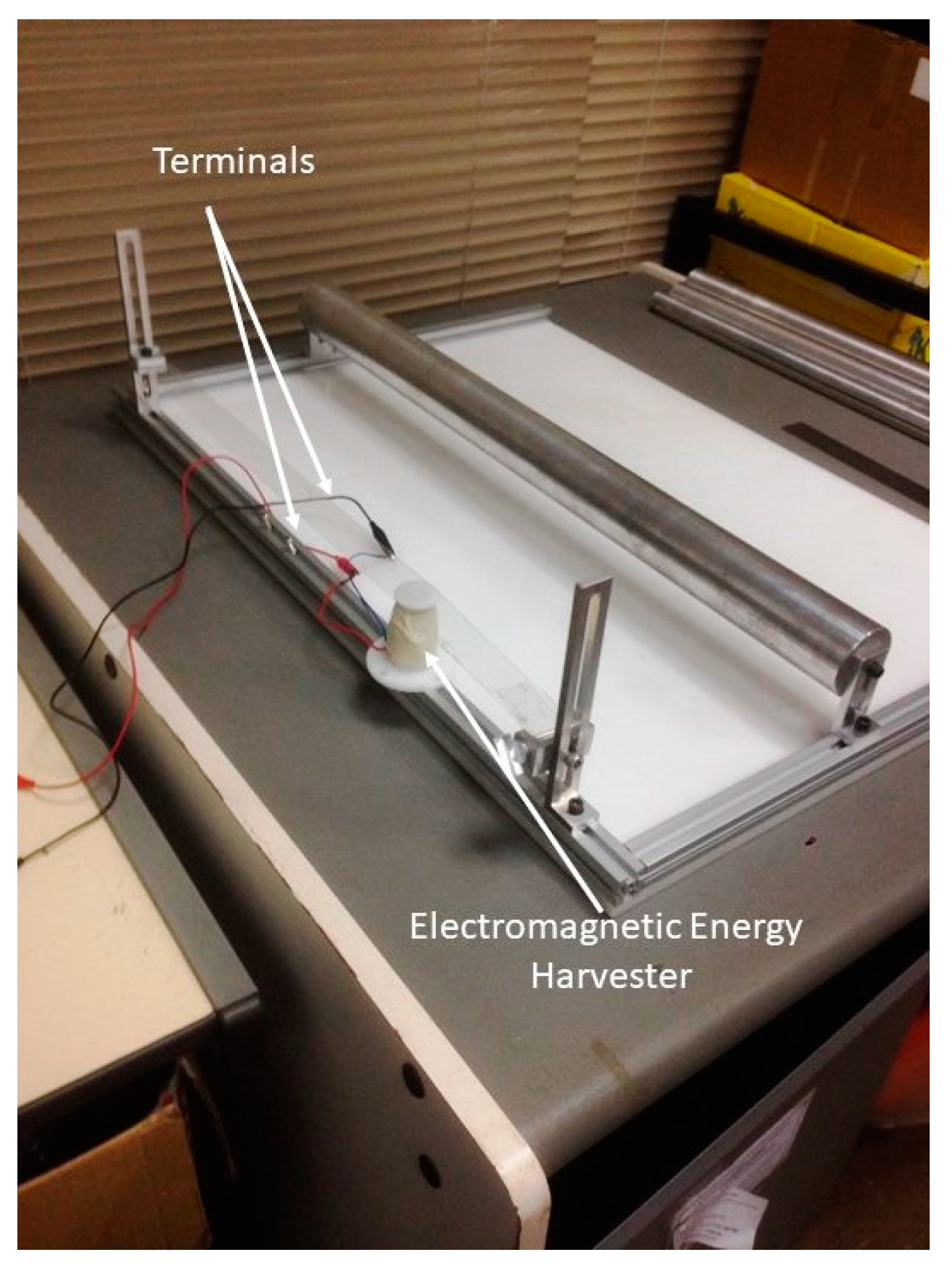

2. Energy Harvester Device

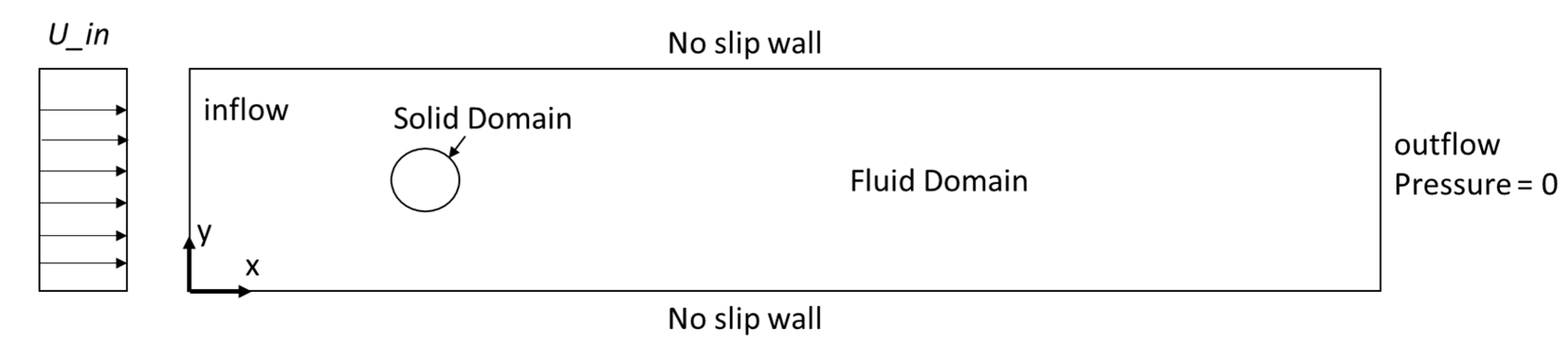

2.1. Model Setup

2.2. Theoretical Background

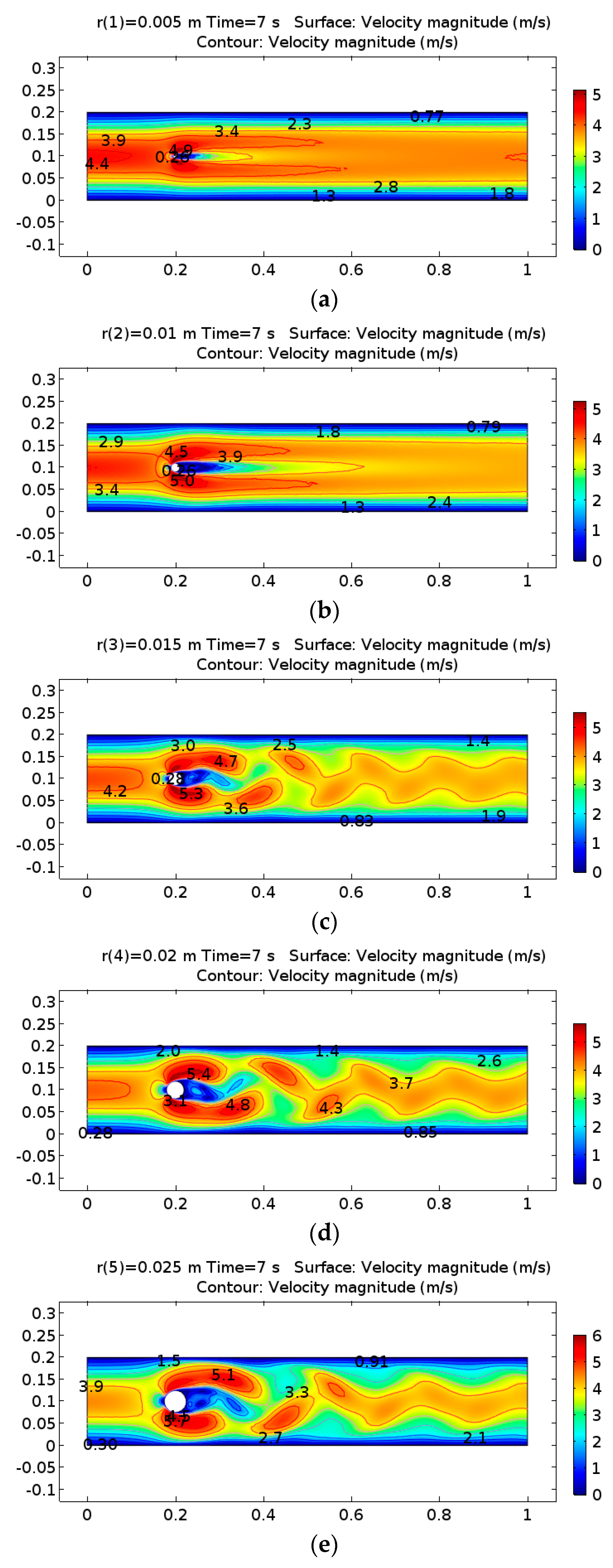

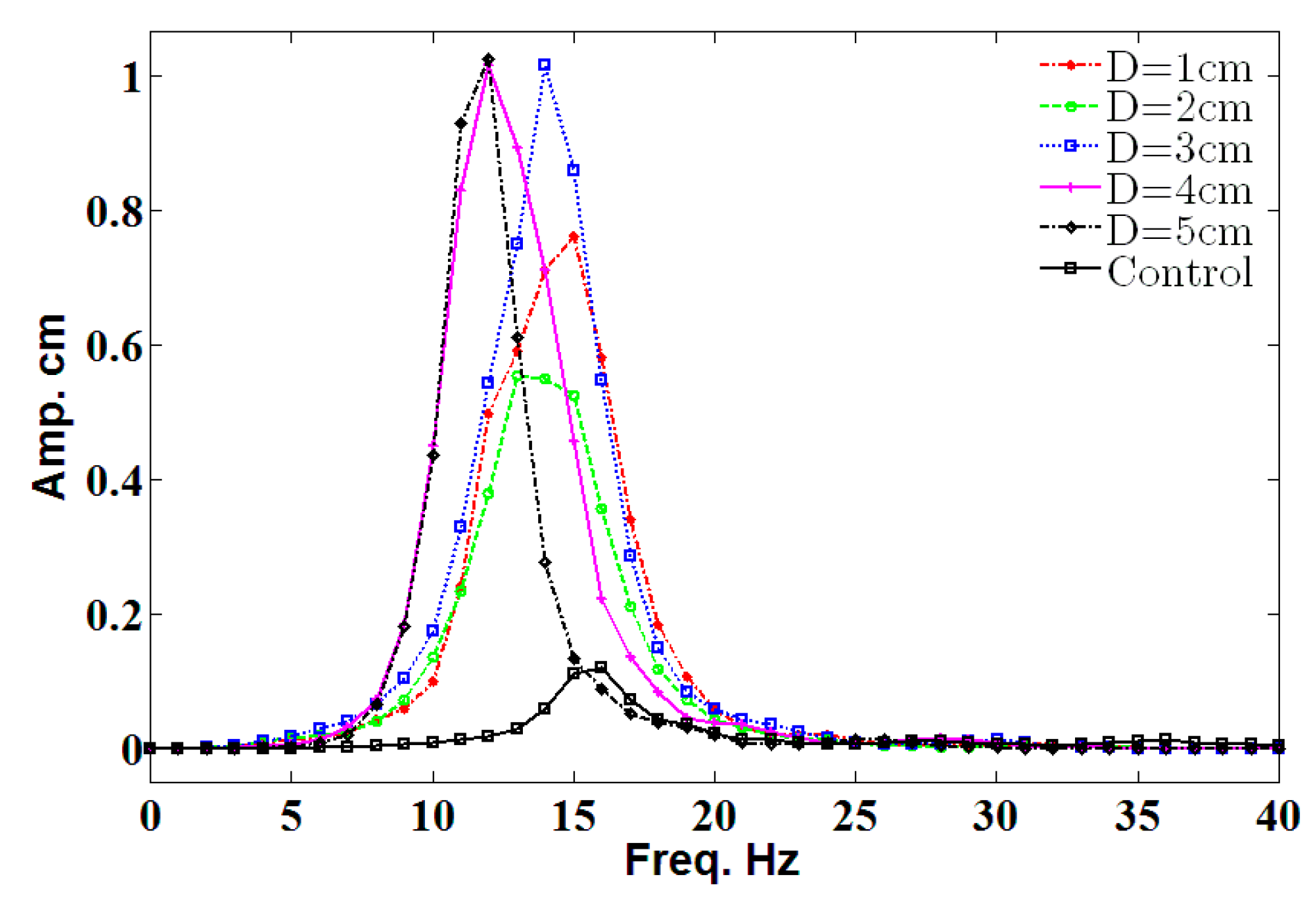

3. Parametric Analysis for Vortex Creation

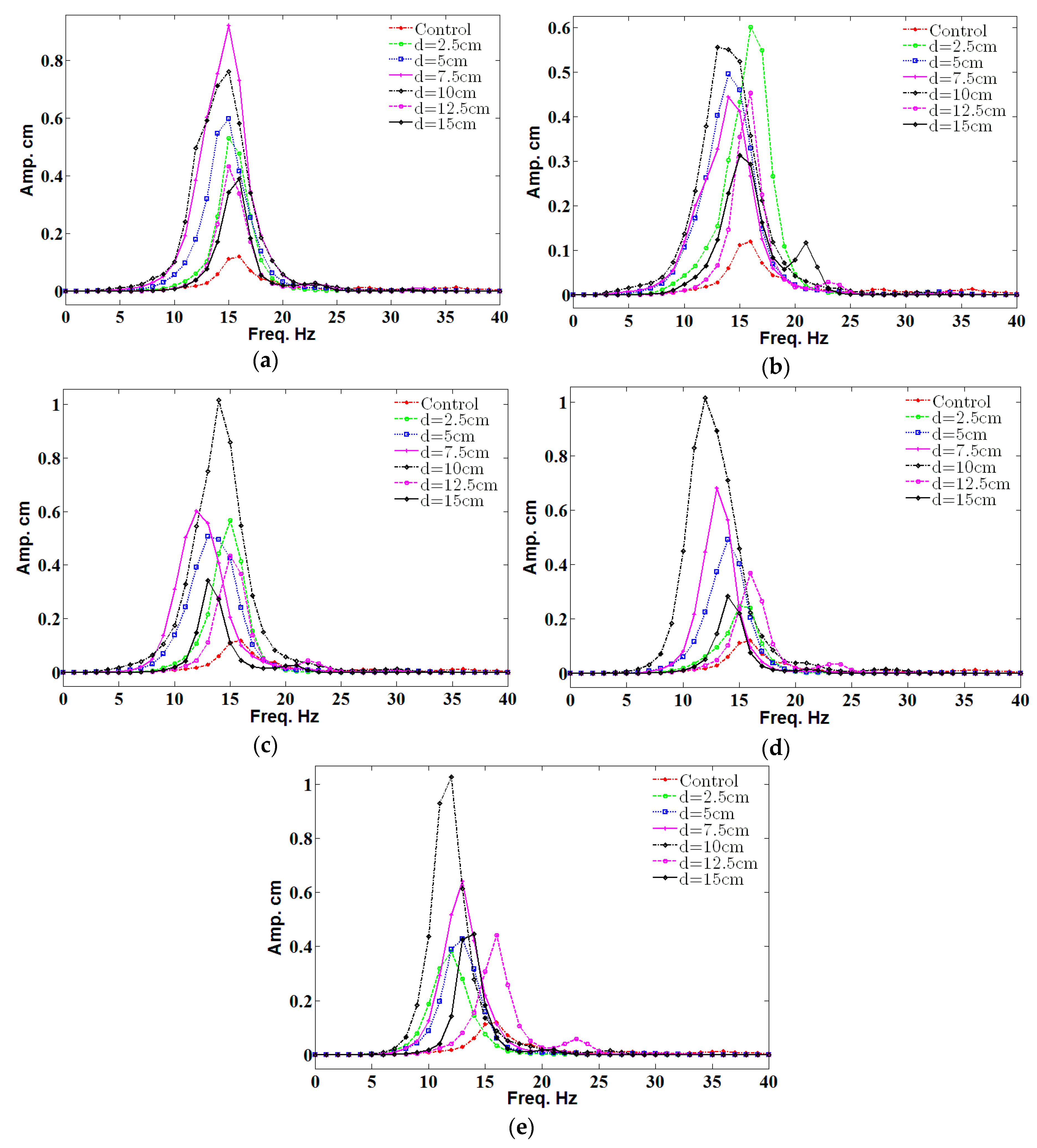

4. Experimental Results and Discussion

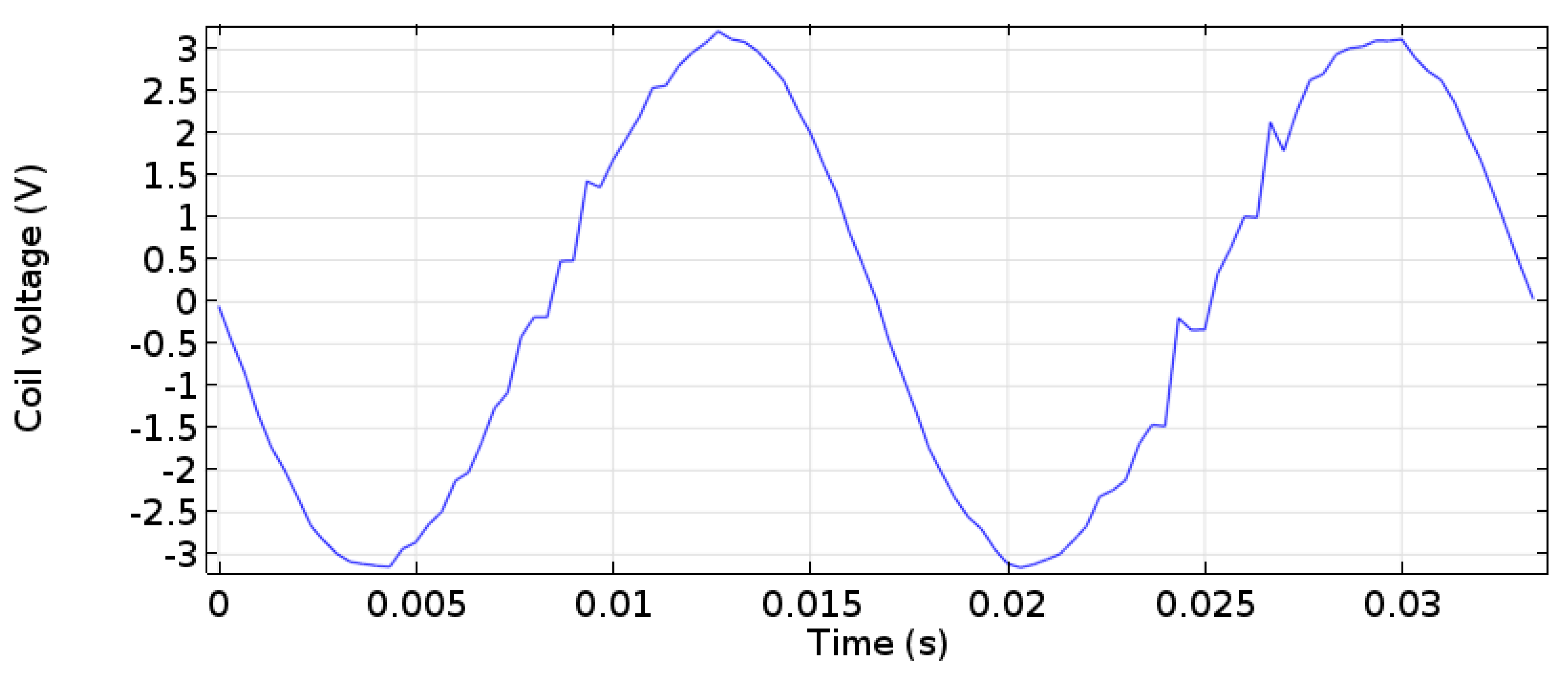

5. Open-Circuit Voltage

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mahmoudi, S.; Kacem, N.; Bouhaddi, N. Enhancement of the performance of a hybrid nonlinear vibration energy harvester based on piezoelectric and electromagnetic transductions. Smart Mater. Struct. 2014, 23, 75024. [Google Scholar] [CrossRef]

- Seol, M.-L.; Han, J.-W.; Park, S.-J.; Jeon, S.-B.; Choi, Y.-K. Hybrid energy harvester with simultaneous triboelectric and electromagnetic generation from an embedded floating oscillator in a single package. Nano Energy 2016, 23, 50–59. [Google Scholar] [CrossRef]

- Xu, Z.; Shan, X.; Chen, D.; Xie, T. A Novel Tunable Multi-Frequency Hybrid Vibration Energy Harvester Using Piezoelectric and Electromagnetic Conversion Mechanisms. Appl. Sci. 2016, 6, 10. [Google Scholar] [CrossRef]

- Xia, Y.; Zhou, J.; Chen, T.; Liu, H. A hybrid flapping-leaf microgenerator for harvesting wind-flow energy. In Proceedings of the 2016 IEEE 29th International Conference on Micro Electro Mechanical Systems (MEMS), Shanghai, China, 24–28 January 2016. [Google Scholar]

- Boco, E.; Nico, V.; O’Donoghue, D. A 2DOFvibrational Energy Harvester Exploiting Velocity Amplification: Modeling and Testing. In Proceedings of the International Conference on Smart Cities and Green ICT Systems, Lisbon, Portugal, 20–22 May 2015. [Google Scholar]

- Wang, W.; Cao, J.; Zhang, N.; Lin, J.; Liao, W.-H. Magnetic-spring based energy harvesting from human motions: Design, modeling and experiments. Energy Convers. Manag. 2017, 132, 189–197. [Google Scholar] [CrossRef]

- Deng, W.; Wang, Y. Systematic parameter study of a nonlinear electromagnetic energy harvester with matched magnetic orientation: Numerical simulation and experimental investigation. Mech. Syst. Signal Process. 2017, 85, 591–600. [Google Scholar] [CrossRef]

- Salauddin, M.; Halim, M.A.; Park, J.Y. A magnetic-spring-based, low-frequency-vibration energy harvester comprising a dual Halbach array. Smart Mater. Struct. 2016, 25, 95017. [Google Scholar] [CrossRef]

- Halim, M.A.; Cho, H.; Salauddin, M.; Park, J.Y. A miniaturized electromagnetic vibration energy harvester using flux-guided magnet stacks for human-body-induced motion. Sens. Actuators A Phys. 2016, 249, 23–31. [Google Scholar] [CrossRef]

- Abdelkefi, A. Aeroelastic energy harvesting: A review. Int. J. Eng. Sci. 2016, 100, 112–135. [Google Scholar] [CrossRef]

- Cepnik, C.; Wallrabe, U. Approaches for a fair comparison and benchmarking of electromagnetic vibration energy harvesters. Micromachines 2013, 4, 286–305. [Google Scholar] [CrossRef]

- Xu-Xu, J.; Barrero-Gil, A.; Velazquez, A. Dual mass system for enhancing energy extraction from Vortex-induced Vibrations of a circular cylinder. Int. J. Mar. Energy 2016, 16, 250–261. [Google Scholar] [CrossRef]

- Nammari, A.; Doughty, S.; Savage, D.; Weiss, L.; Jaganathan, A.; Bardaweel, H. Broadband magnetic levitation-based nonlinear energy harvester. Proc. SPIE 2016, 9865, 98650L. [Google Scholar] [CrossRef]

- Liu, H.; Chen, T.; Sun, L.; Lee, C. An Electromagnetic MEMS Energy Harvester Array with Multiple Vibration Modes. Micromachines 2015, 6, 984–992. [Google Scholar] [CrossRef]

- Abed, I.; Kacem, N.; Bouhaddi, N.; Bouazizi, M.L. Nonlinear dynamics of magnetically coupled beams for multi-modal vibration energy harvesting. Proc. SPIE 2016, 9799, 97992C. [Google Scholar] [CrossRef]

- Abed, I.; Kacem, N.; Bouhaddi, N.; Bouazizi, M.L. Multi-modal vibration energy harvesting approach based on nonlinear oscillator arrays under magnetic levitation. Smart Mater. Struct. 2016, 25, 25018. [Google Scholar] [CrossRef]

- Juillard, J.; Bonnoit, A.; Avignon, E.; Hentz, S.; Kacem, N.; Colinet, E. From MEMS to NEMS: Closed-loop actuation of resonant beams beyond the critical Duffing amplitude. In Proceedings of the 2008 IEEE Sensors, Lecce, Italy, 26–29 October 2008; pp. 510–513. [Google Scholar]

- Kacem, N.; Baguet, S.; Hentz, S.; Dufour, R. Nonlinear phenomena in nanomechanical resonators: Mechanical behaviors and physical limitations. Mech. Ind. 2010, 11, 521–529. [Google Scholar] [CrossRef]

- Bitar, D.; Kacem, N.; Bouhaddi, N.; Collet, M. Collective dynamics of periodic nonlinear oscillators under simultaneous parametric and external excitations. Nonlinear Dyn. 2015, 82, 749–766. [Google Scholar] [CrossRef]

- Fei, F.; Zhou, S.; Mai, J.D.J.; Li, W.W.J. Development of an indoor airflow energy harvesting system for building environment monitoring. Energies 2014, 7, 2985–3003. [Google Scholar] [CrossRef]

- Quy, V.D.; van Sy, N.; Hung, D.T.; Huy, V.Q. Wind tunnel and initial field tests of a micro generator powered by fluid-induced flutter. Energy Sustain. Dev. 2016, 33, 75–83. [Google Scholar]

- Drachinsky, A.; Raveh, D.E. Limit-cycle oscillations of a pre-tensed membrane strip. J. Fluids Struct. 2016, 60, 1–22. [Google Scholar] [CrossRef]

- Windbelt, Cheap Generator Alternative, Set to Power Third World. Available online: http://www.popularmechanics.com/science/energy/a2152/4224763/ (accessed on 13 June 2017).

- Rostami, A.B.; Armandei, M. Renewable energy harvesting by vortex-induced motions: Review and benchmarking of technologies. Renew. Sustain. Energy Rev. 2017, 70, 193–214. [Google Scholar] [CrossRef]

- Demori, M.; Ferrari, M.; Ferrari, V.; Farisè, S.; Poesio, P. Energy Harvesting from Von Karman Vortices in Airflow for Autonomous Sensors. Procedia Eng. 2014, 87, 775–778. [Google Scholar] [CrossRef]

- Paxson, B.; Wickenheiser, A.M. Design Considerations for Small-Scale Wind Energy Harvesters Driven by Broadband Vortex-Induced Vibrations. Proc. SPIE 2014, 9057, 90571K. [Google Scholar] [CrossRef]

- Peters, H.; Chen, L.; Kessissoglou, N. The effect of flow on the natural frequencies of a flexible plate. In Proceedings of the 43rd International Congress on Noise Control Engineering, Melbourne, Australia, 16–19 November 2014; pp. 1–7. [Google Scholar]

- Park, J.; Morgenthal, G.; Kwon, S.; Law, K. Power Evaluation for Flutter-Based Elctromagnetic Energy Harvester Using CFD Simulations. In Proceedings of the First International Conference on Performance-based and Life-cyle Structural Engineering (PLSE 2012), Hongkong, China, 5–7 December 2012. [Google Scholar]

- El-hami, M.; Glynne-Jones, P.; White, N.M.; Hill, M.; Beeby, S.; James, E.; Brown, A.D.; Ross, J.N. Design and fabrication of a new vibration-based electromechanical power generator. Sens. Actuators A Phys. 2001, 92, 335–342. [Google Scholar] [CrossRef]

- Zhao, M.; Cheng, L. Numerical simulation of vortex-induced vibration of four circular cylinders in a square configuration. J. Fluids Struct. 2012, 31, 125–140. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atrah, A.B.; Ab-Rahman, M.S.; Salleh, H.; Nuawi, M.Z.; Mohd Nor, M.J.; Jamaludin, N.B. Karman Vortex Creation Using Cylinder for Flutter Energy Harvester Device. Micromachines 2017, 8, 227. https://doi.org/10.3390/mi8070227

Atrah AB, Ab-Rahman MS, Salleh H, Nuawi MZ, Mohd Nor MJ, Jamaludin NB. Karman Vortex Creation Using Cylinder for Flutter Energy Harvester Device. Micromachines. 2017; 8(7):227. https://doi.org/10.3390/mi8070227

Chicago/Turabian StyleAtrah, Ahmed B., Mohd Syuhaimi Ab-Rahman, Hanim Salleh, Mohd Zaki Nuawi, Mohd Jailani Mohd Nor, and Nordin Bin Jamaludin. 2017. "Karman Vortex Creation Using Cylinder for Flutter Energy Harvester Device" Micromachines 8, no. 7: 227. https://doi.org/10.3390/mi8070227