Insect-scale robots may one day serve as multifunctional swarm agents, coordinated assembly tools, and disposable mobile sensors [

1]. Recent work on flying insect-scale robots (or “pico air vehicles” [

2]) has focused primarily on biomimetic propulsion mechanisms, i.e., the motion of flapping wings similar to an insect of the Diptera order. Significant progress has been made, including: controlled flight of a flapping wing robot with a piezoelectric actuator [

3]; takeoff of a robot with an electromagnetic actuator [

4]; and measured thrust using an electrostatic actuator [

5]. Nevertheless, biomimetic fliers are difficult to design, build, and control. To open up the design space beyond that afforded by these biomimetic structures it may be necessary to change not just the actuator but the propulsion mechanism itself.

Electrohydrodynamic (EHD) thrust results from the collisions between a neutral fluid and charged particles. Directional momentum transfer is produced by controlling the motion of the charged particles electrostatically, directly converting electrical energy into kinetic energy. The momentum transferring collisions producing the EHD force are more efficient when using ionized molecules instead of electrons due to their higher mass. The induced air flow from ion-neutral collisions has been called the “ion wind”. The effect was noted as early as 1709 and investigated by minds including Benjamin Franklin, Faraday, and Maxwell [

6]. A thorough review on the history as well as other applications of EHD force can be found in [

7]. Corona discharge is the preferred method of producing ions for EHD thrust in atmospheric conditions because it has been found to be relatively repeatable, stable, and high current [

8]. Design and fabrication are simplified by the fact that corona discharge is predominantly due to geometric enhancement of local electric field. A schematic illustrating the use of a self-sustained corona plasma to produce EHD force is shown in

Figure 1.

The EHD force was investigated for use in aircraft in the early 1960s, even being featured on the front cover of

Popular Mechanics in August 1964. At the time of the

Popular Mechanics article, the most successful demonstration of EHD thrust was with the “lifter” model now popular with students and hobbyists. The lifter is on the order of 0.1 to 1 square meter, typically constructed from balsa wood and aluminum foil, and can take off when connected to a high voltage (30 kV) power supply. After important fundamental research from investigators including Christenson, Moller, and Robinson, the effect was deemed to have too low of a thrust aerial density and too low of an efficiency for human-scale flight [

9,

10]. More recent theoretical work on a one dimensional model has seemingly confirmed their conclusions that electrohydrodynamic thrusters are not well suited for these types of applications [

11]. We stipulate that EHD is a viable propulsion mechanism not for macro-scale flying aircraft but for flying microrobots, for many of the same reasons that electrostatic motors have proven themselves useful in MEMS-based devices and walking microrobots. As an essentially electrostatic force, the EHD force per unit area remains constant as the device decreases in size.

EHD thrust as a flight mechanism for pico air vehicles has the unique advantages of silent flight and high durability due to requiring no moving parts, as well as high thrust to weight ratio due to requiring only sparse electrodes. Microfabricated thrusters generating over 10 N/m

2 with thrust to weight ratios over 20 have been demonstrated [

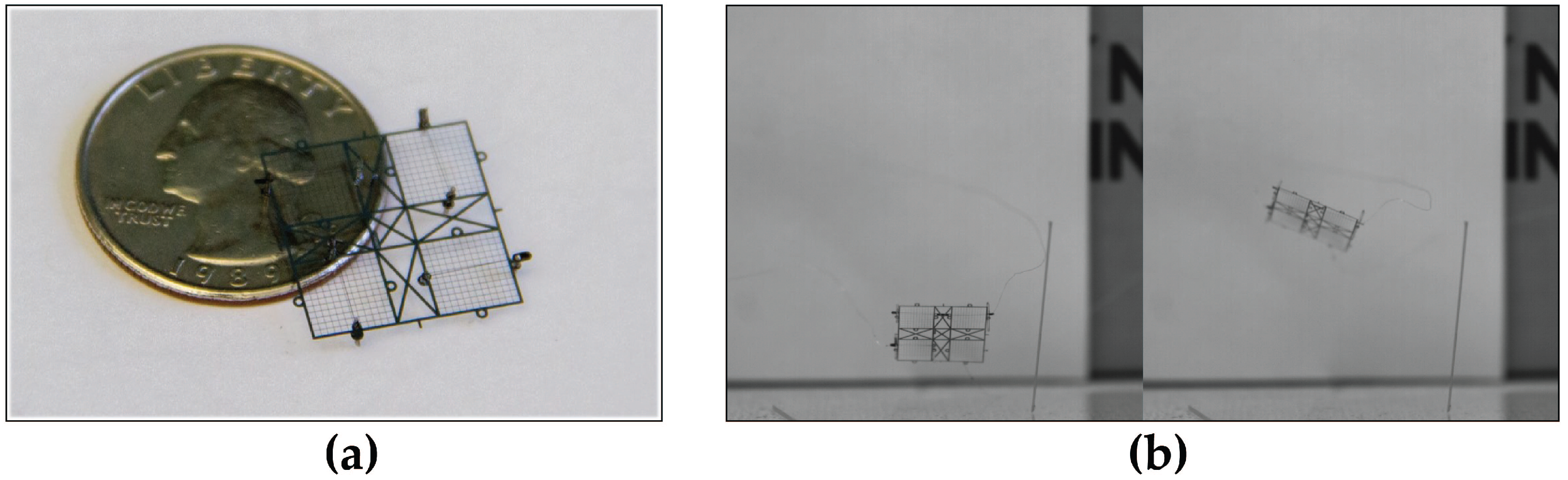

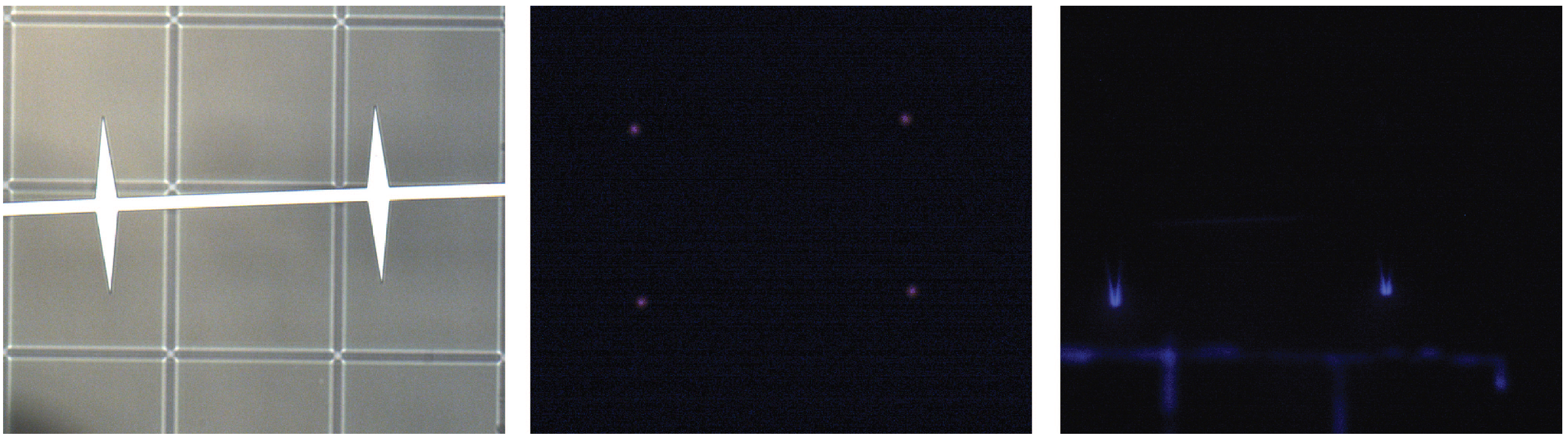

12]. A flying microrobot with four individually addressable EHD thrusters (see

Figure 2) has demonstrated vertical takeoff and rudimentary attitude control while tethered to an external power supply [

13]. These devices exhibit onset voltages around 2400 V and maximum thrust points closer to 3000 V. In order to present a clear path towards autonomy this operating voltage will have to be reduced to levels feasibly supplied by a combination of low mass boost circuitry, e.g., as shown in [

14], and arrays of batteries and/or solar cells. The largest current driver of miniaturization of corona discharge-based EHD devices is for thermal management applications (IC cooling). A review of this research can be found in [

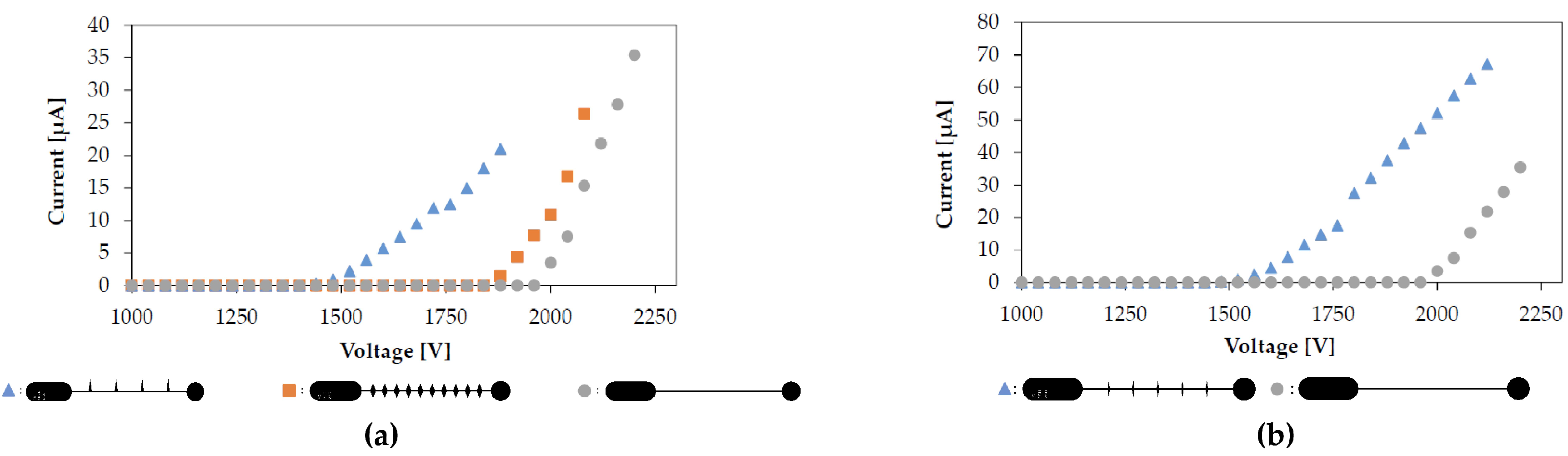

15]. It should be noted that millimeter-scale devices are rare. Ong et al. demonstrated microfabricated devices with onset voltages around 1.1 kV, but their low current makes them unsuitable for thruster applications [

16]. The important metric of thrust to weight ratio is also unique to thruster applications and is relatively unexplored in literature.

1.1. Electrohydrodynamic Force Scaling

A one dimensional model for electrohydrodynamic thrust based on the Coloumb electrostatic force on a volume of ions leads to an expression for force in terms of ion current,

I, distance the ions travel

d, and the ion mobility,

μ. Here

V is the applied potential and

A is the ion volume cross-sectional area. This assumes all ion current is due to applied drift field as opposed to bulk fluid motion, an assumption [

9] proved accurate for the 3 m/s maximum air velocities measured in this work versus ion velocity that is on the order of 100 m/s.

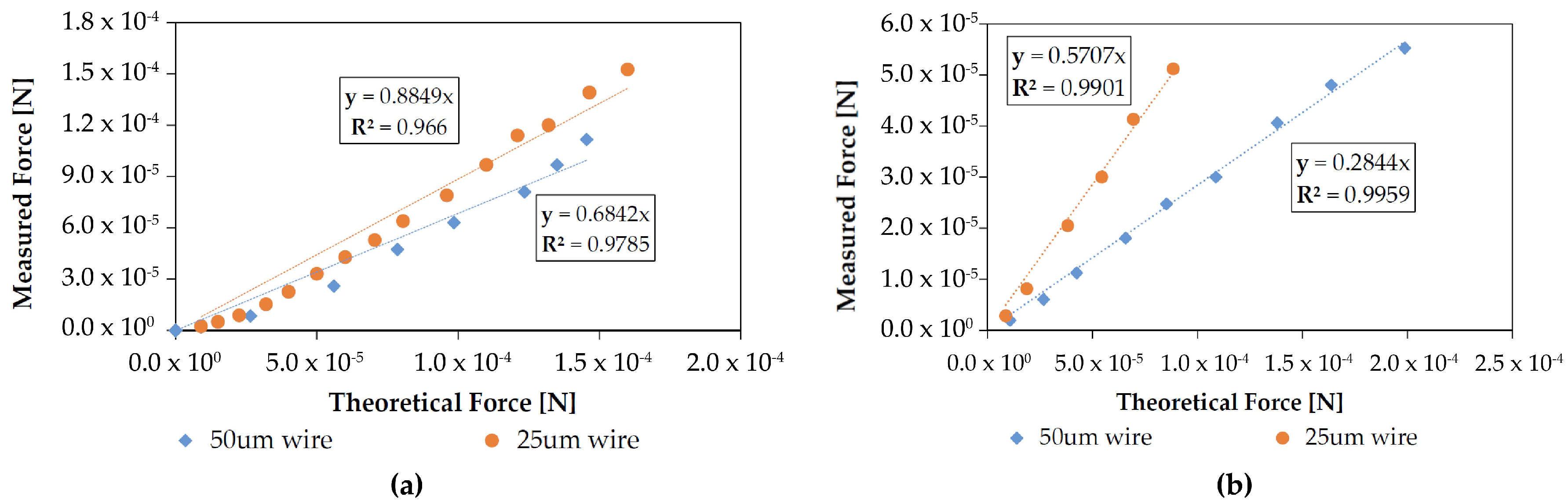

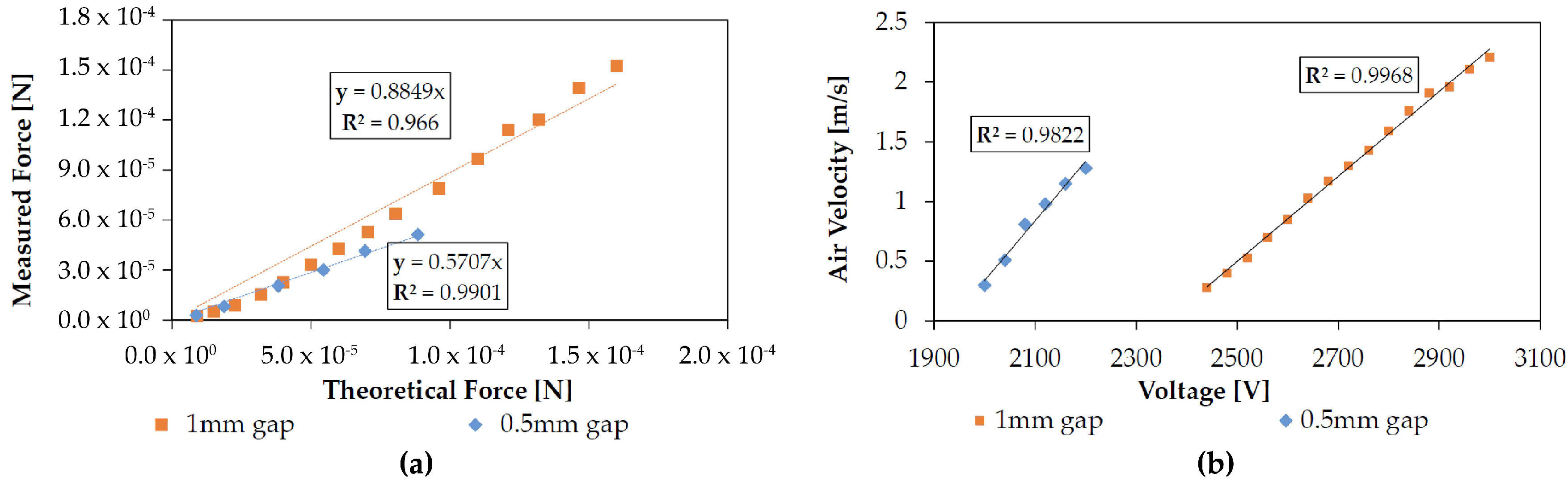

This represents the theoretical maximum force from an EHD thruster. Previous work measured loss factors of around 50% from this theoretical value using microfabricated silicon electrodes [

12].

Based on the Mott-Gurney law for space charge limited current density, (

2), this equation for electrostatic force on the ions can instead be expressed in terms of applied drift field

E and air permittivity

ϵ0:

Note that this is force acting on the ions; direct translation of this to thrust requires that all momentum is transferred in the preferred thrust direction by ion-neutral collisions. Assuming applied voltage is the same as the drift field potential and that ion current is the only current flow, this yields a thrust efficiency in terms of

N/

W of:

These equations indicate that unlike many flapping wing designs, an EHD thruster powered microrobot does not depend on a resonant system and can vary its thrust and thrust efficiency simply by changing the drift field magnitude. In practice, the minimum drift field value for a corona discharge-based system is set by the corona inception voltage. They also show that both the force and efficiency scale inversely with ion mobility. Prior work has shown that the mobility of positive ions is lower than that of negative ions for electrode gaps below 20 mm [

17]. Literature values for positive ion mobility in air range from 1.37 to 2.8 cm

2·V

−1·s

−1. This wide range of seemingly acceptable values makes it difficult to generalize results across the field of corona discharge devices, as the true value is also dependent on factors such as ambient humidity, electrode gap, field strength, temperature, and pressure.

1.2. Corona Discharge Scaling

The derivations given above for electrohydrodynamic force have assumed some concentration of ions injected into the drift field gap. As noted above, the most common method of atmospheric ion generation for EHD thrust is through the atmospherically-stable corona discharge phenomenon. Corona discharge is characterized by a self-sustained plasma localized around a charged conductor, the “emitter”, and ionic current flowing to a second electrode, the “collector”. The magnitude of the discharge is typically space-charge limited, with the polarity determined by whether high voltage is applied to the so-called emitter (“positive corona discharge”) or the collector (“negative corona discharge”) [

18].

In a positive corona discharge, when the potential gradient around the emitter is high enough due to a combination of applied voltage and geometric effects, an ambient electron initiates Towsend avalanche breakdown. At some distance away from the emitter the Towsend ionization criterion is no longer met, marking the corona plasma boundary and the beginning of the ion drift region. Because collisions in the ionization region do not strongly contribute to the net thrust of the system, it is important to minimize the ratio of the ionization region radius to drift distance.

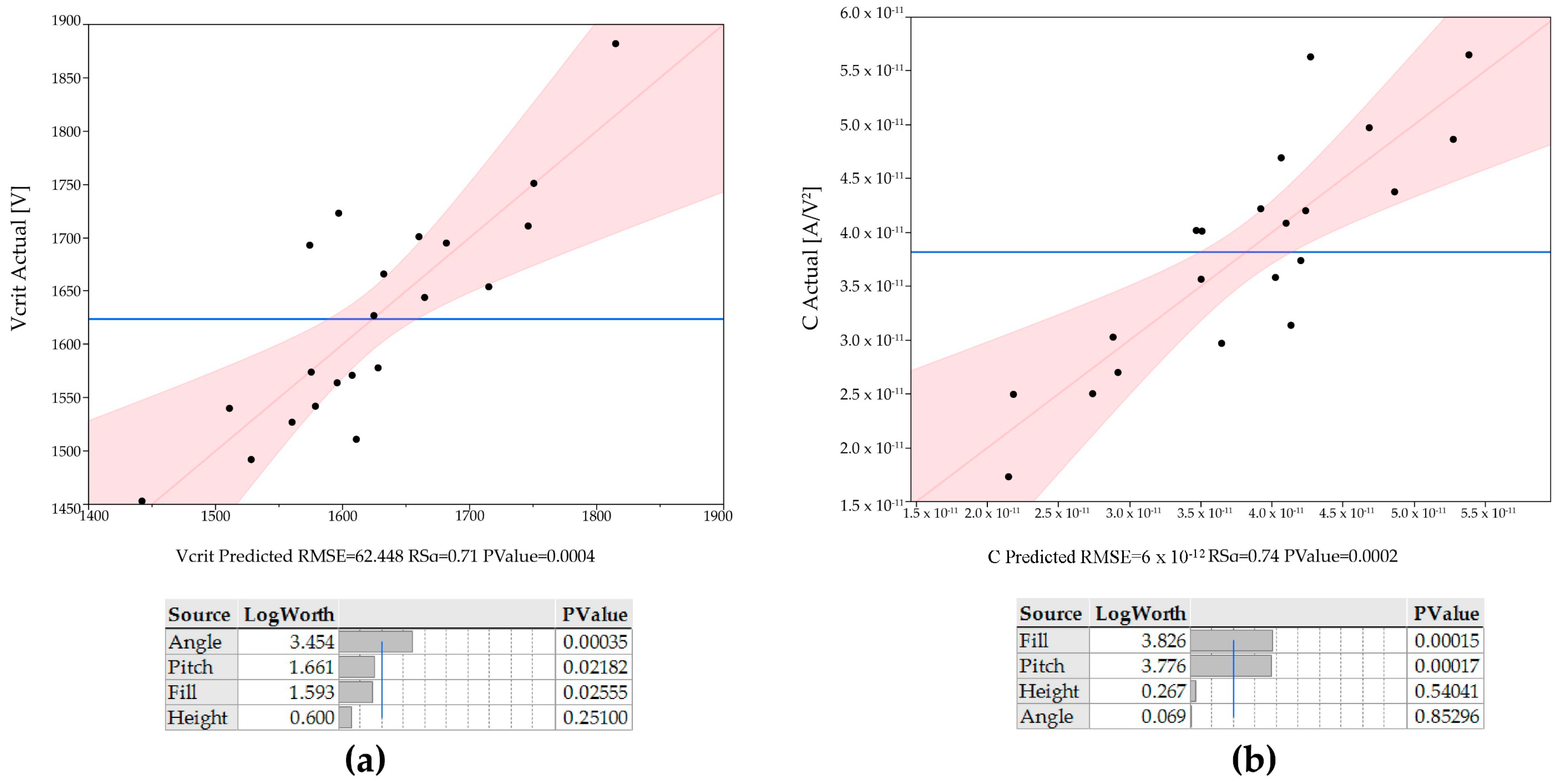

There are no widely reported wholly analytical solutions for corona discharge current. An equation of the form shown below, sometimes referred to as “Townsend’s relation”, has been experimentally confirmed over a wide range of geometries and is assumed true for space-charge limited discharges such as corona [

9].

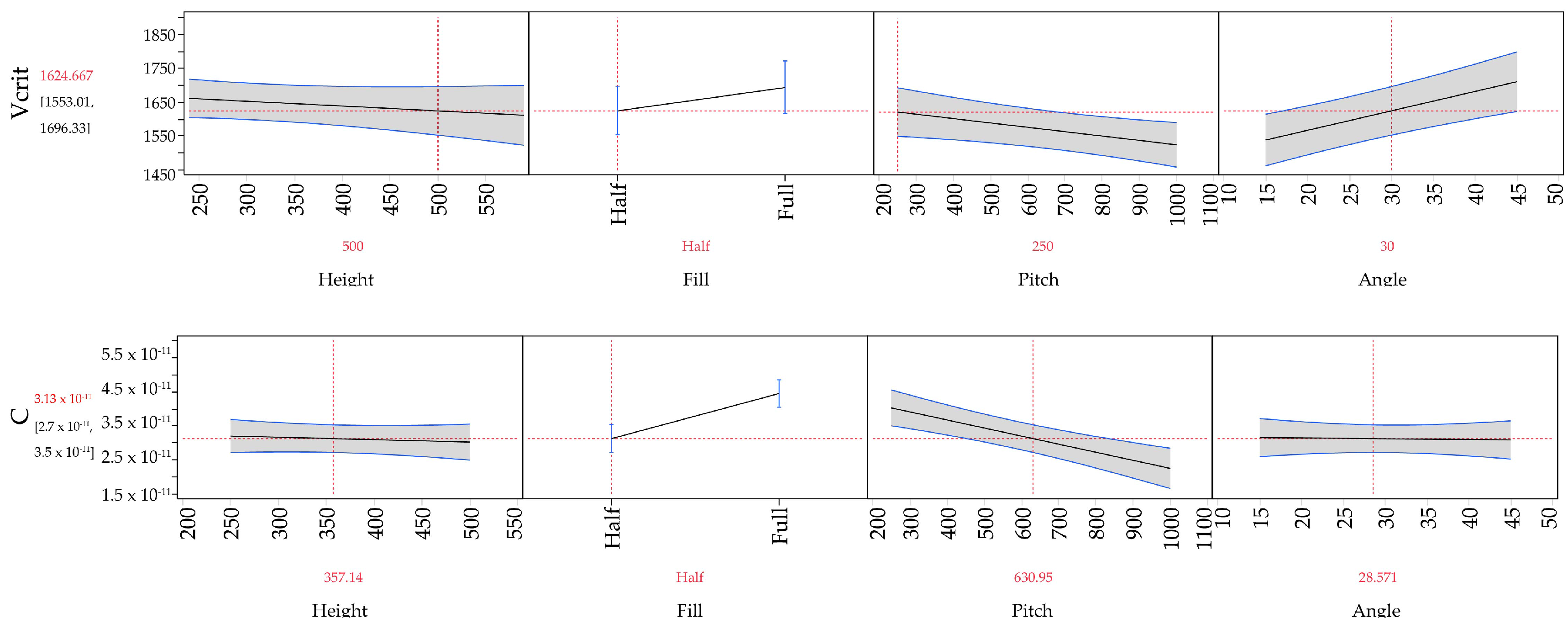

where

Vcrit is the corona inception voltage and

C is a constant with units of A/V

2 that depends on a combination of device geometry and ion mobility. Analytical values for

C exist for a few simple geometries, e.g., concentric cylinders, but are typically extracted from experimental data.

Peek provided solutions for the critical surface field, derived from the Townsend ionization criterion and empirical data, to initiate corona discharge for various geometries [

19]. Using the method of image charges to adapt Peek’s solution of the critical field between parallel wires for a wire and grounded plane, we find the critical potential for corona onset as:

where

d is the distance between the electrodes,

r is the wire radius, and

is the bulk breakdown field strength in air (approximately 30 kV/cm). This equation is widely used in literature and consistently produces predicted voltages accurate to within about 10%. The

term was empirically derived by Peek. He states further that the quantity

is approximately equal to the ionization region thickness, being the distance away from the conductor surface at which the electric field is equal to the bulk breakdown field strength. Because the electric field is a function of both radius and distance it is clear that this relationship, which has no distance term, cannot hold true for all values of the ratio

. The portion of Equation (

6) which does take into account the gap is from a simplified version of the wire to plane electric field equation which assumes

d is much larger than

r. Both the full and simplified version of this equation are shown below:

Electric fields in the vicinity of the emitter wire as calculated by (

8) versus the full version (

7) can deviate by as much as 50% for

ratios less than 20. These shortcomings may help explain why research exploring sub-millimeter corona discharge with

ratios on the order of 15 have seen greater divergence from Peek’s formulas [

20]. While Peek stated that corona discharge would occur at

ratios down to about 3, they (and others) have seemingly been unable to measure corona discharge before sparkover below a ratio of about 10. This work will investigate methods of decreasing apparent

r without the use of exotic materials or complicated processing steps in order to continue corona scaling to smaller gap sizes.

We assert that the ratio of ionization region to electrode gap distance is a critical factor to control in order to maximize EHD force. The fundamental electrostatic force given in (

1) is proportional to ion drift distance; if the ratio of ionization radius to gap distance is significant, then simply using the electrode gap to determine theoretical force is incorrect. This ratio is typically small for high

ratio devices and is safely ignored. However, Vuhuu and Comsa experimentally measured ionization radii on the order of hundreds of micrometers [

21], which would be a significant fraction of a sub-millimeter discharge.

1.3. Collector Electrode Effects

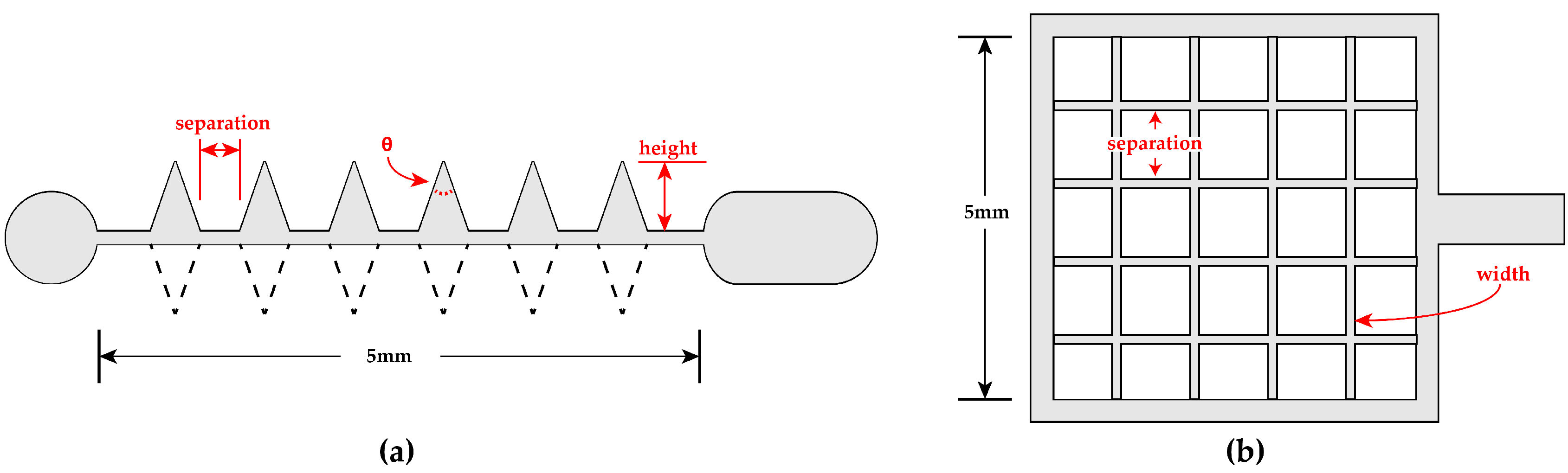

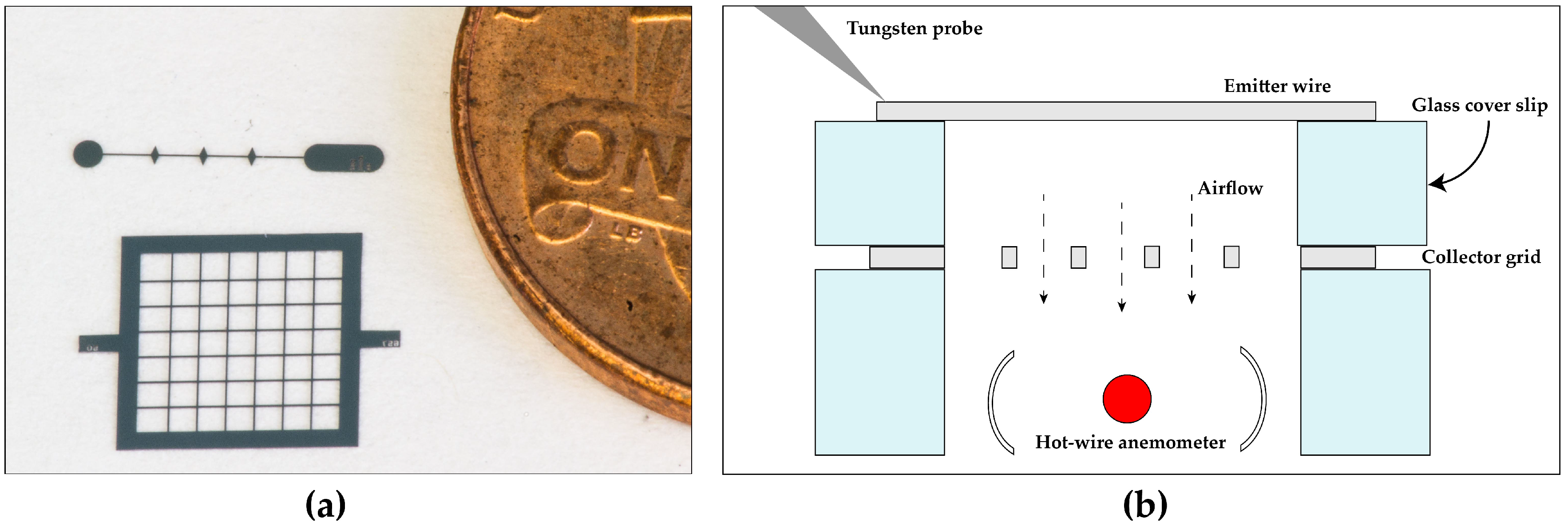

Previous work has noted that collector electrode geometry significantly affects both corona current and the resultant flow rate, with grid electrodes performing better than rings [

22]. Literature on airflow through micromeshes on the order of those studied here is sparse. O’Hern and Torcyznski measured drag coefficients on the order of 1-5 from photoetched meshes with wire widths of 50

m, thickness of 50

m, and separations of 318

m at similar Reynolds numbers to those expected in EHD microrobots [

23]. Computational values for drag coefficient from this work were found to be sensitive to mesh wire cross section and experimental results showed a strong dependence on wire separation, with drag coefficient decreasing by about 50% for a 20% reduction in open area fraction.

A further consideration is how the micromesh geometry affects the electric field profile of the device. Maxwell claimed that at gap distances equal to or greater than the grid separation the grid will look virtually identical to a solid plane at the emitter wire [

24]. If this holds true for corona discharge devices, decreasing gap distance will necessitate a decreased grid separation and therefore presumably higher drag coefficient.