1. Introduction

In recent years, engineering has been constantly directing interest to the biomimetics paradigm for the solution of technological issues [

1]. Plants and animals offer a great variety of functional surfaces from which they take inspiration for superficial patterning [

2,

3,

4,

5]. The remarkable characteristic of such surfaces is the deep connection between materials and morphology: with a relatively small number of structural materials, nature has been able to achieve very complex functionalities by exploiting proper modeling of surfaces. In the case of plants, the ‘lotus effect’ has been widely investigated for the fabrication of self-cleaning surfaces [

6,

7,

8,

9]. Another promising phenomenon related to the pattern morphology of the leaves is the so-called ‘Salvinia effect’ [

10,

11,

12,

13,

14,

15,

16,

17]: when submerged by water, this floating fern can retain a thin layer of air on its surface thanks to the presence of ‘eggbeater’ hairs that can pin water on the tip while trapping air at the bottom. In this way the plant can have a reservoir of oxygen when under the water which can also provide thermal insulation. Both these properties could have a practical application in several technological fields. In particular the reproduction of such phenomena could be used in cases where the retaining of a gaseous phase in a liquid one is needed like in the case of thermal insulation, biological in vitro applications or for drag reduction like in the case of artificial nanofur inspired by Salvinia and

Notonecta glauca [

18,

19].

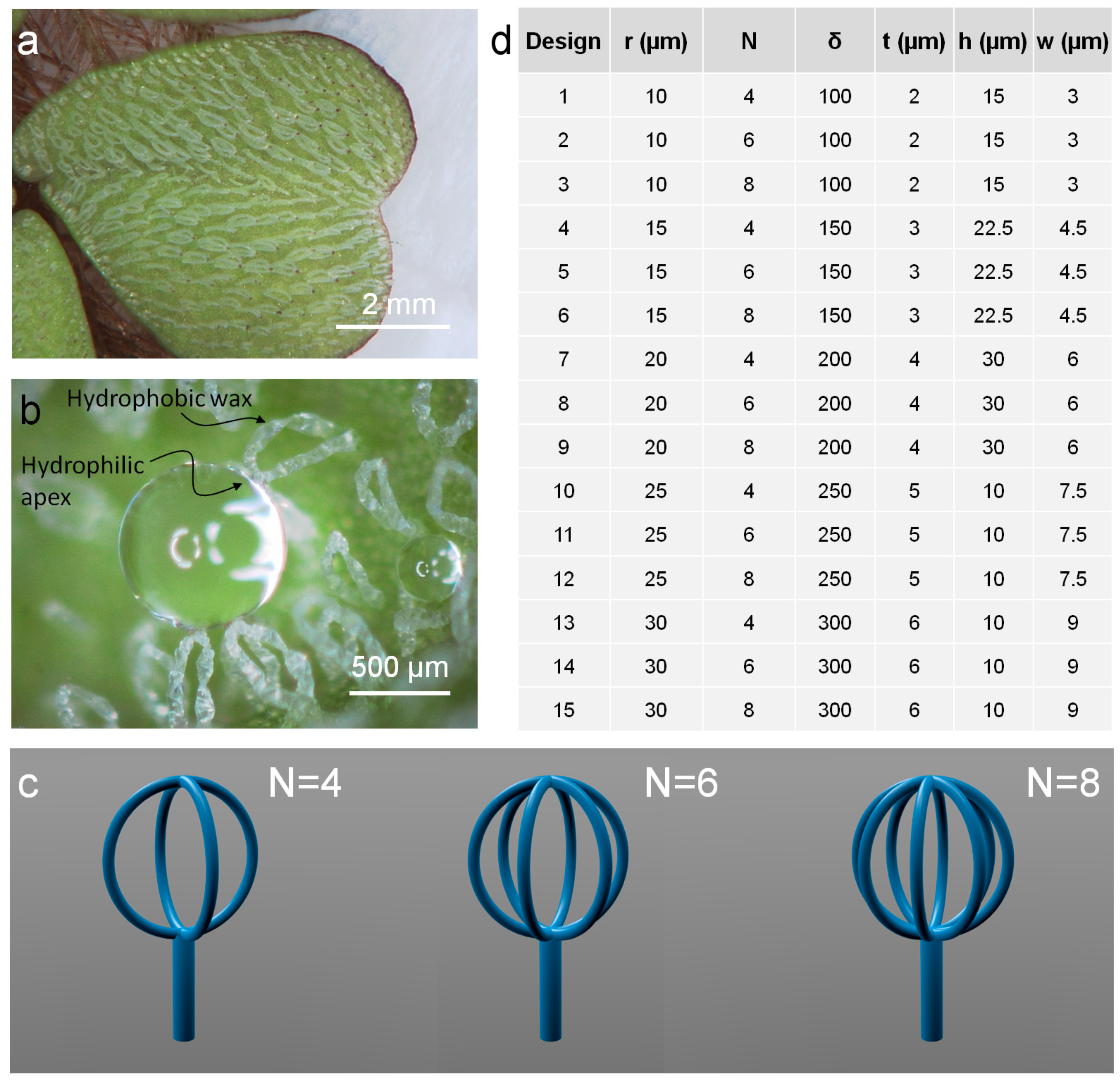

In the case of

Salvinia molesta (

Figure 1a), the air retaining performance is due to the combination of complex three-dimensional patterning and chemical coating [

10]. The hairs on the upper side of the leaf have a 1.5 mm long stalk which ends with a peculiar crown-like configuration made by four filaments, for a total height of the final quasi-spherical part of 500 µm. The apex of the filaments is composed of smooth dead cells, providing a sort of pinning point for the water droplets (

Figure 1b), while the rest of the hair is covered by hydrophobic wax crystals. Exploiting this configuration, the plant is able to trap air both between the stalks and inside the crown-like heads. Here we investigate the latter aspect that is the dynamics and the persistence of the air inside the head of artificial hairs: how long the structures are able to retain air in the heads and how the shape and the volumes of such air bubbles change over time.

Starting from the study of some peculiar plants and insects, the long term air retention mechanism has been investigated with the purpose of finding out the main features that a bioinspired surface should present in order to obtain the same performance. In fact, the main issue related to such surfaces is the instability of air layer due to external perturbations. The presence of hierarchical hairs and nanostructures, hydrophobicity, and micro- and nanocavities are all fundamental factors for reducing the instability of the air layer [

9].

Moreover, Konrad et al. defined the mathematical model for the existence of the air–water interface and its relative mechanical stability and temporal persistence in presence of diffusion. We followed this model in order to perform the experiments in the same theoretical conditions [

17].

How the geometrical disposition of the hairs affects the stability of the air layer has been already deeply investigated, even in the presence of hydrophilic structural materials that can show an opposite behavior—hydrophobicity—thanks to the three-dimensional arrangement, the microscopic morphology, and the roughness at the nano-scale [

2,

9]. For this reason, we downscaled the natural model from 8 up to 25 times, in the range of micrometers as characteristic dimension. As shown in our previous work, the dimensional scale and the peculiar features provide an air-retaining behavior without requiring chemical treatments [

20]: in that study, we mainly focused on the study of hydrophobicity of the proposed microstructures built with an hydrophilic material, while in this paper we focus on the air trapping mechanism and dynamics of this phenomenon not yet investigated. Here we used a hydrophilic cross-linked epoxy-based photoresist for the micro-fabrication of artificial hairs by means of direct laser lithography. This technique is the only one that ensures outstanding results for 3D structures in terms of resolution at the microscale, with features of hundreds of nanometers [

20,

21,

22]. In particular, we focus on two main aspects that can influence the dynamics and the time persistence of the air in the heads: the dimension and the geometry.

2. Materials and Methods

Salvinia-like artificial hairs were fabricated in negative tone SU-8 photoresist (MicroChem Corp., Westborough, MA, USA) on a glass substrate, by means of a direct laser lithography setup, Photonic Professional system (Nanoscribe GmbH, Eggenstein-Leopoldshafen, Germany). The laser paths coordinate corresponding to the desired shapes were programmed with MATLAB® (R2016b, The Mathworks, Inc., Natick, MA, USA), allowing the fabrication of different designs. The preparation of the sample required several steps for ensuring the adhesion of the structures on the glass. First of all the glass substrate was rinsed with acetone, isopropyl alcohol (IPA), and deionized water. It was submerged for 10 min in a 50 mL ethanol solution with eight drops of 3-(Trimethoxysilyl) propyl methacrylate. The glass was rinsed with deionized water and dried with air. Then the photoresist was spin coated on the substrate at a speed of 1000 rpm in order to achieve a thickness of 100 µm, which is enough to contain the artificial hairs. After a pre-bake process (10 min at 65 °C followed by a second step at 95 °C for 30 min), the sample was mounted in the laser lithography system (Photonic Professional GT, Nanoscribe GmbH) and exposed to the laser beam with a center wavelength of 780 nm (Calman laser source). The writing speed was 25 μm·s−1 and the laser power 7.5 mW. After a post-bake phase (1 min at 65 °C followed by a second step at 95 °C for 10 min) the sample was developed for 20 min in SU-8 Developer (MicroChem Corp., Westborough, MA, USA) and rinsed with IPA and deionized water.

The air trapping test was performed by submerging the sample with the microfabricated structures in water: in order to detect the presence of the air and to define the profile of the relative interfaces between structures, air and water, a dedicated setup based on a confocal microscope (C2 Confocal Microscope System, Nikon, Tokyo, Japan) was implemented. Since the SU-8 photoresist is fluorescent if excited at 401 nm, by marking the water with a fluorescent probe having different excitation wavelength, it is possible to selectively detect the structures, the water, the air, and their relative interfaces. For this reason, tetramethylrhodamine-5-(and-6)-isothiocyanate (5(6)-TRITC) (Life Technologies, Carlsbad, CA, USA) with a concentration of 0.01 mg·mL−1 was added to the water. Exciting the sample under the confocal microscope at 401 nm (excitation wavelength of SU-8) and 561 nm (excitation wavelength of TRITC), it was possible to distinguish them. Since experiments required prolonged immersion of the structures in small volume of liquid, samples were encapsulated by means of a poly-(dimethylsiloxane) (PDMS, Sylgard 184, Dow Corning Corp., Midland, MI, USA) ring (internal diameter 8 mm; thickness 200 μm) placed on the substrate glass around the structures and sealed with an additional glass after the deposition of 10 μL of TRITC-marked water.

The analysis of the air-retention performance of the samples was carried out by recording images of the microstructures (hairs) at different times; in particular, stacks of the crown-like air were acquired in order to obtain slices at a vertical distance of 500 nm. The scanning time for each slice is 4.6 s. According to the dimensions of the heads (related to the number of slices), the volumetric reconstruction has required a time between 3 min and 9 min.

It was possible to reconstruct the volume of the air inside the heads, finding out how the air–water interface changed over time, quantitatively evaluating the performance of different designs of the hairs. The detection of the interfaces in each image and the calculation of the air volumes were performed with a dedicated image processing script in MATLAB®. Air volumes were estimated by adding the air area in each slide multiplied by the vertical distance.

Static contact angle measurements were performed on flat SU-8 (100 μm thick) on glass, by means of an optical tensiometer (Attension, Biolin Scientific, Gothenburg, Sweden). Droplets of 5 μL water and water with 5(6)-TRITC (0.01 mg·mL−1) were tested in order to verify the effect of the colorant on the wettability properties.

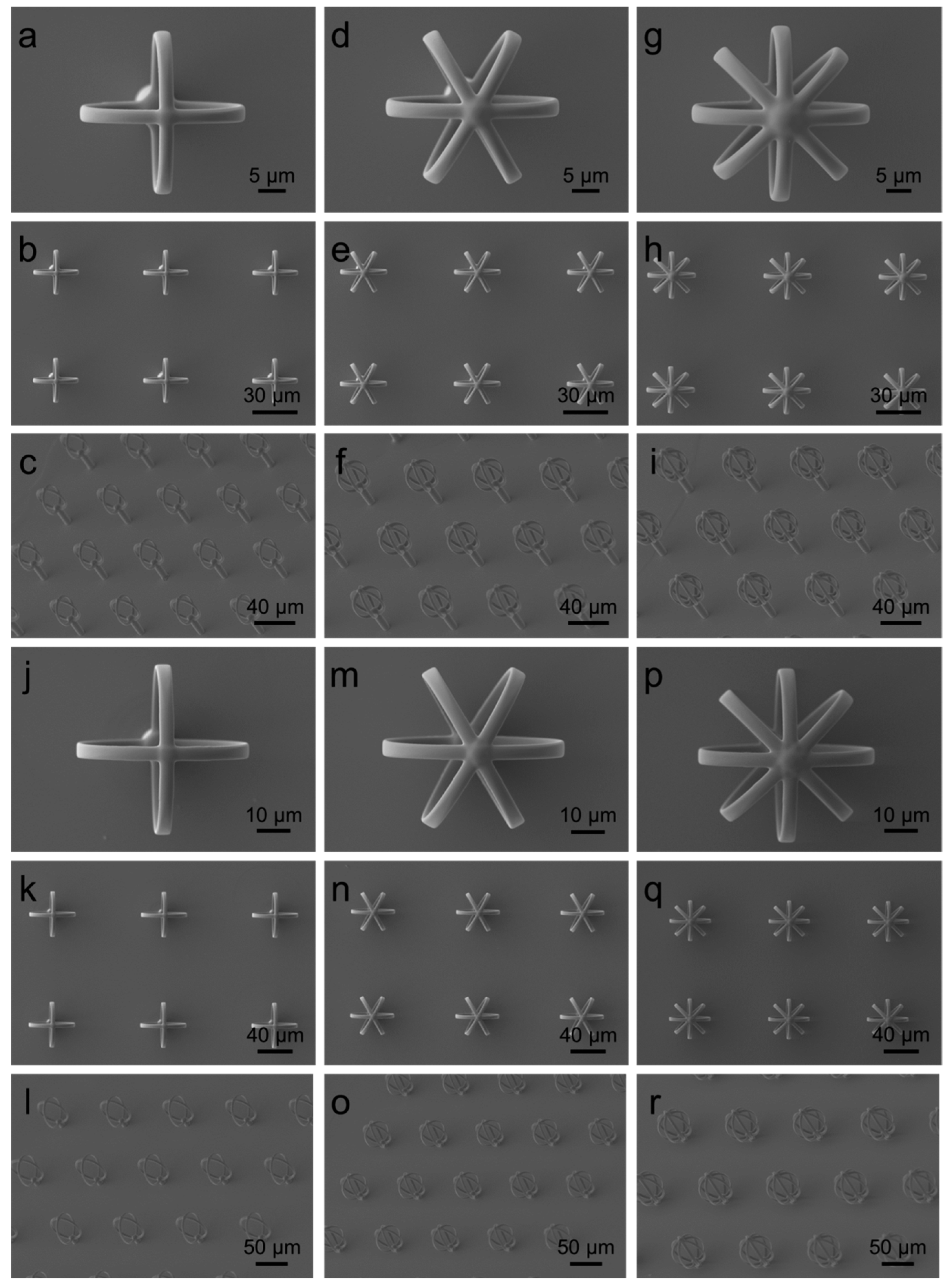

All SEM images of the artificial hairs have been acquired with an EVO MA10 (Zeiss, Oberkochen, Germany).

4. Experimental Results and Discussion

Since for all the experiments 5(6)-TRITC has been added to the water, contact angle measurements were performed in order to investigate the effect of the colorant on the wettability characteristics of the microstructures. As reported in

Figure S2, the contact angles of water and water with 5(6)-TRITC were 59° ± 0.4° and 58° ± 0.3°, demonstrating the negligible effect of the colorant presence.

According to Konrad et al. [

17], an air bubble submersed in water can persist only if its pressure (

pa) is lower or equal the above atmospheric pressure (

patm). In fact, when

pa >

patm, air particles start diffusing from the bubble and reach the atmosphere.

Considering an air bubble in water, starting from Young–Laplace Equation [

17],

(where

pw is the water pressure at the air–water interface,

σ is the surface tension, and

R is the radius of the bubble), and considering that

pw depends on the submersion depth

h [

17],

(where

is the water density and

g the gravitational acceleration), it is possible to find, in case of existence, the maximum depth for air bubbles persistence [

17]

Replacing the relative values for σ (0.073 N/m), R (30 µm, the worst case), (103 kg/m3), we obtain a limit depth h of about 50 cm which is fully satisfied in our experiments.

In fact, whatever is the tested design, once the artificial hairs are submerged in the water and sealed (

Figure 3a), the water forms a layer and fills the room between the structures, leaving the air inside the crown-like heads. This evidence suggests a first consideration about the dynamics of the interaction of the materials involved in the process. The hairs patterned on the glass represent a non-ideal rough solid surface for the water whose behavior can be described in terms of two different models, Wenzel and Cassie−Baxter, that are usually used for the computation of the contact angles between the phases [

8,

11,

23,

24]. In the proposed geometry, there are two states that can exist at the same time: a ‘macro’ Wenzel state in which the water fills all the room over the hairs and between the stalks, and a ‘micro’ Cassie–Baxter state corresponding to the crown-like heads [

20], as illustrated in

Figure 3b. The estimation of the contact angle is not possible in the proposed design for the Wenzel phase since the water does not assume the shape of a droplet, but only for the Cassie–Baxter phase in the heads. In fact, the static contact angle

θ (

Figure 3c) can be approximately estimated by adapting the Young equation [

25] that explains the relationship between the surface free energy of the solid

γS, the liquid surface tension

γL and the solid-water interfacial energy

γSLAnyway, the value of the contact angle and thus the shape of the profile of the water–air interface changes over time, due to the variation of the air volume inside the heads till it reaches a stable (or metastable) configuration. In fact, it is important to underline that for the micrometer-sized textured considered, the free-energy barriers are expected to be so large that metastable states can be very long-lived [

13,

26]. While the air diffuses into the water, the decrease of the contact angle is caused by the protrusion of the water inside the crown-like heads (

Figure 3c), making the shape of the air bubble more and more different to that of a sphere. At steady state, the curvature of the liquid–vapor interface will depend from the difference of pressure (inside/outside the bubble) following the Young–Laplace Equation (4).

All the tested designs experienced the same combination of ‘macro’ Wenzel and ‘micro’ Cassie–Baxter states. The first one is due to the fact that the Cassie–Baxter state is a higher energy state and so disadvantaged from a thermodynamic point of view. The energy barrier needed for the switching between the two states is proportional to the number of structures for unity of area [

18]: in the proposed samples the density of the structures is not enough for ensuring the Cassie–Baxter state between the stalks, thus isolating the phenomenon of air trapping inside the crown-like heads. In this regard, it is important to underline that, as reported in a previous work [

20], an additional mixed state,

“macro-Cassie−Baxter and micro-Wenzel”, can be compatible with proposed equations. Nevertheless, we do not observed it in any combination of geometrical parameters for our basic shape. We speculate that, in order to obtain this state, a combination of materials with different surface energy (with proper design) could be necessary.

The analysis at the confocal microscope confirms the presence of ‘macro’ Wenzel and ‘micro’ Cassie–Baxter states as illustrated in

Figure 3d–i, where it is represented, as an example, the middle section of the heads. In

Figure 3d,f,g three different geometries for the heads (

N = 4, 6, 8) show the structures at the beginning of the experiment: at this moment, the volume of air inside the heads assumes a peculiar shape in each design, in particular the higher the number of filaments, the more similar to a sphere the shape is. This means that four filaments can trap the lowest amount of air compared with the other geometries: the reason is in the reduced number of solid interfaces able to pin the water. As time goes by, the dimension of the air volume decreases as shown in

Figure 3e,g,i, which are the corresponding images taken after 150 min; after this change that happens in the first minutes, the shape of the water–air interface seems to settle to a definitive final conformation, proving also the stability of the system at least in static conditions.

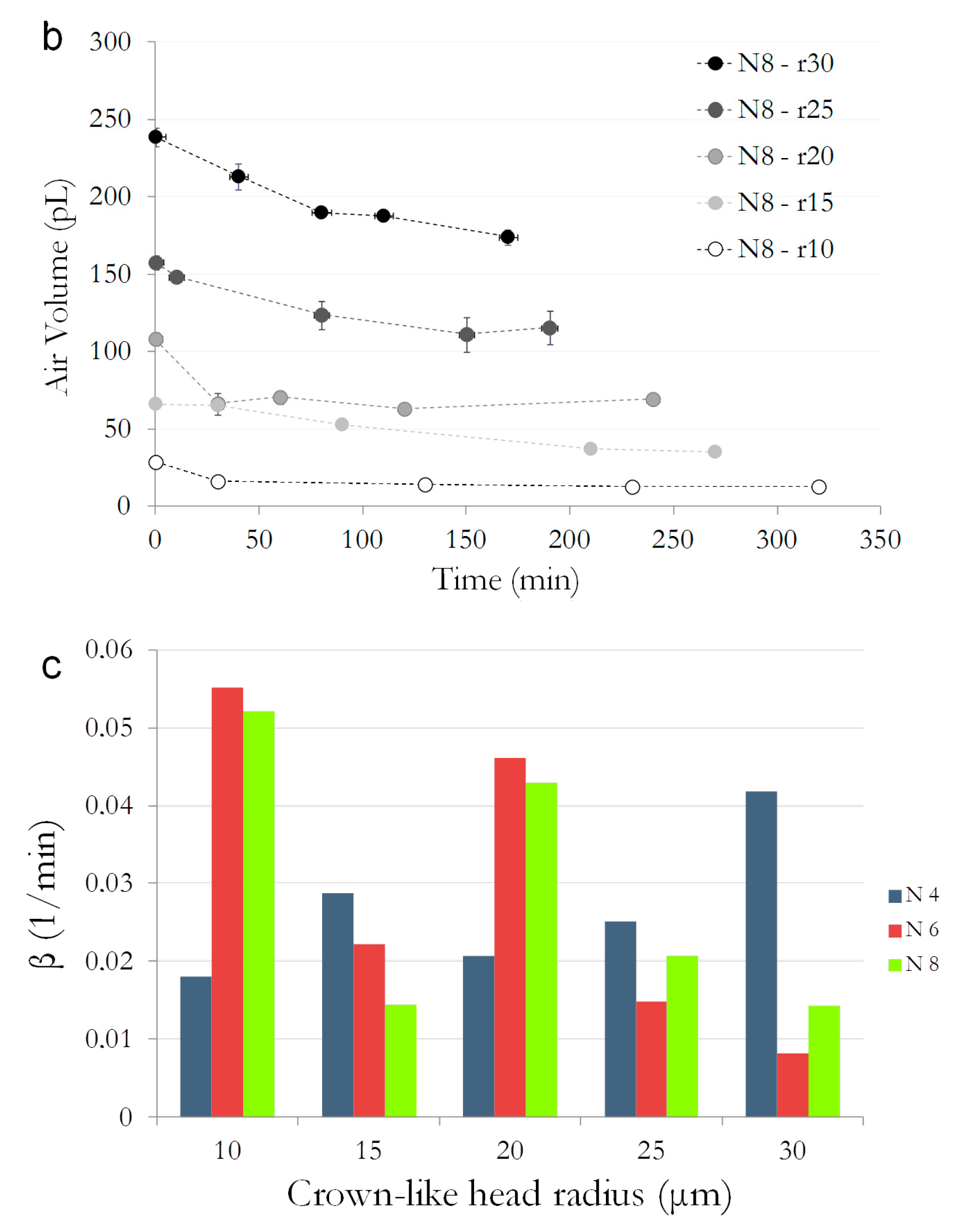

In order to quantitatively estimate the volumes of air trapped inside the crown-like heads, for each design the sum of the section areas has been calculated by means of a MATLAB

® program, starting from the pictures acquired with the experimental procedure already described. In

Figure 4, there are the results of the dynamics of the variation of the air volumes during time. Setting the dimension of the radius of the heads and comparing the different number of filaments, it is evident what was qualitatively appreciable from

Figure 3d,f,g, that is a higher number of filaments is able to trap more air (as in the example of radius 15 µm in

Figure 4a). On the other hand, setting the number of filaments and varying the dimension of the heads, the bigger one can trap, quite obviously, bigger air volumes (as in the example of

N = 8 in

Figure 4b). The results of dynamics of the variation of the air volumes trapped in the salvinia-like structures for all the designs in

Figure 1d are illustrated in

Figures S3 and S4.

To quantitatively evaluate the dynamics of volume reduction, we approximated that variation with a descending exponential trend, compatibly with a first order kinetics, as

where

Vf is the final volume of air (stable persistent value),

Vi is the value at the starting point and

β (min

−1) is a coefficient associated with the rate of the variation of the volume. The fluctuation of the volume until a stable value inside the heads is reached could be due to effects of gravity (even if it is expected to play a minor role at that scales) and pressure fluctuations, but mainly to air diffusion in the water since the sample containing the structures is completely sealed and there is no way for the air to reach the external environment (PDMS is somehow permeable to air, but, due to geometry of the sample, this effect is neglegible). This aspect is also confirmed by the fact that the Cassie–Baxter configuration remains stable up to 100 h. Moreover, it is important to underline that air diffusion in liquid is low dynamics which, however, does not alter the long-term thermodynamics [

27]. In respect, the final micro Cassie–Baxter state might indeed be metastable also in an open system if the structure (as in our case) owing to the re-entrant filaments. Nevertheless, this aspect was not investigated in open configuration because evaporation limits the sample living time.

Fitting the experimental data with the model Equation (5), we have extrapolated and compared the values of the parameter

β of the various designs as shown in

Figure 4d. Values for

β of the same order of magnitude can be deduced from the data, thus meaning that there are not really significant differences, at least at this dimensional scale, for the rate of air release from the crown-like hairs: it is practically of the same magnitude for all the designs, showing that it is quite likely related to the intrinsic mechanism of diffusion of the air inside the water. For this reason, the shape and the dimension could be simply chosen for having the bigger possible amount of air inside the crown-like heads, that is: a high number of filaments and, of course, big radii of the heads. Filaments also ensure another property related to the structural stability of the hairs that result in more resistance to mechanical stress.