Time-Efficient High-Resolution Large-Area Nano-Patterning of Silicon Dioxide

Abstract

:1. Introduction

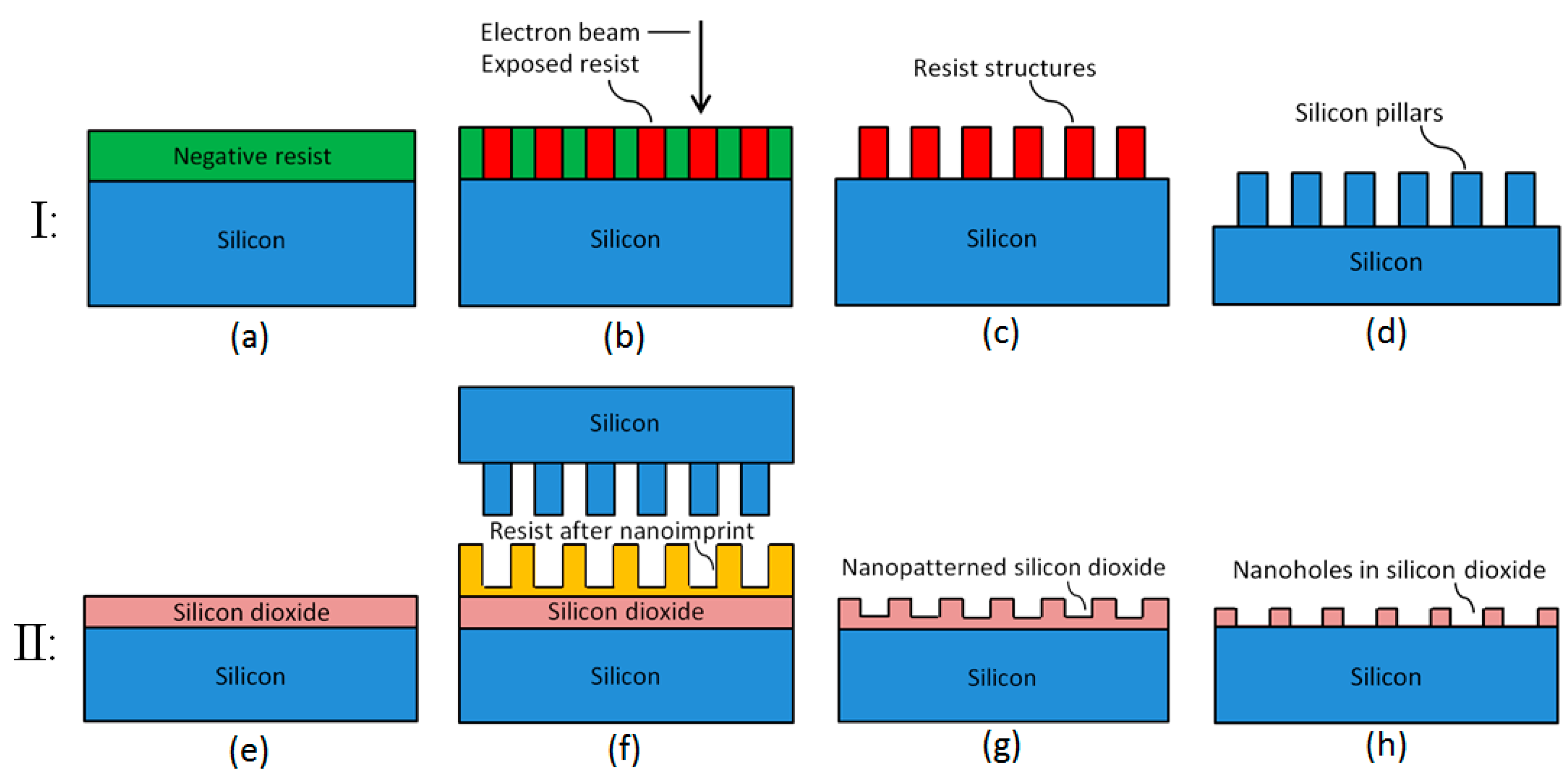

2. Fabrication Method

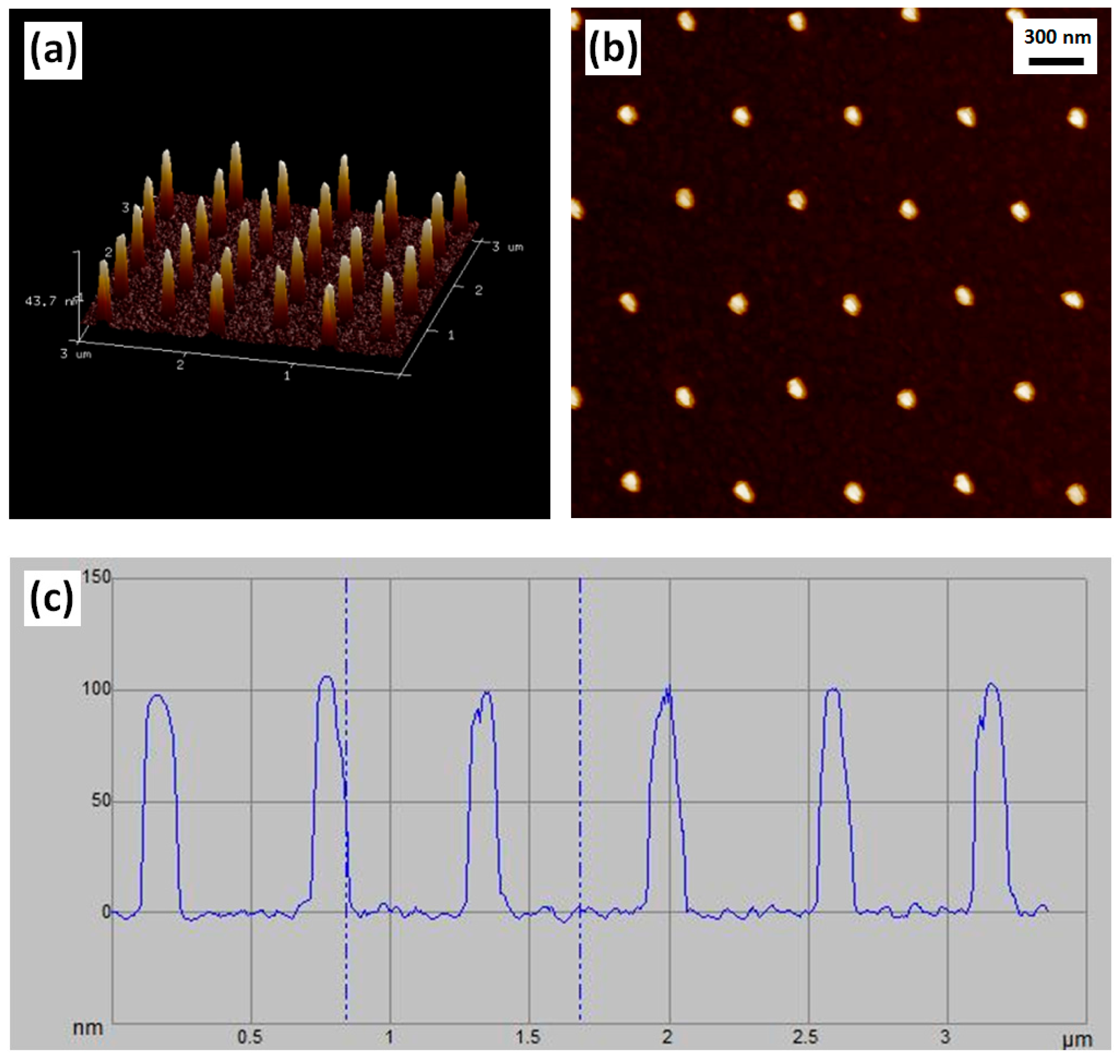

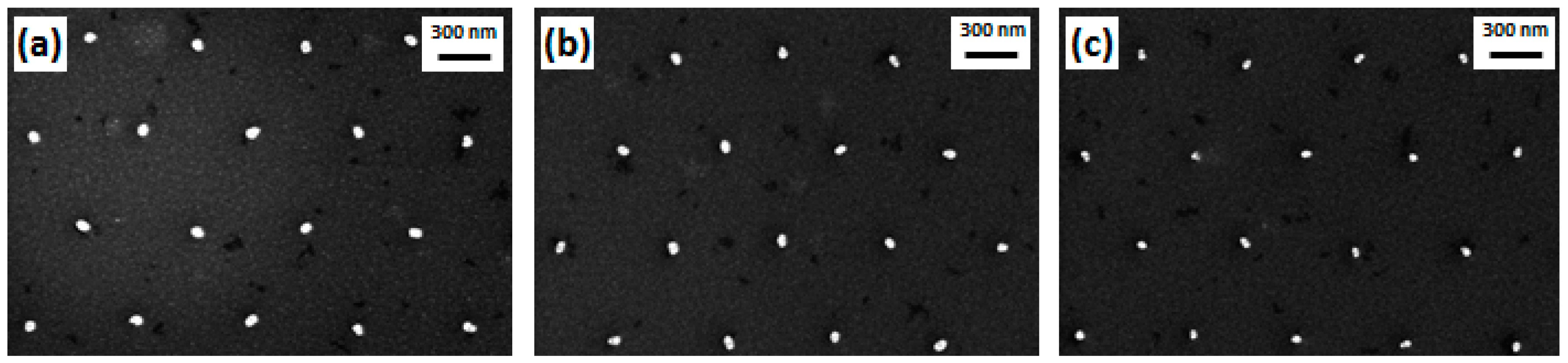

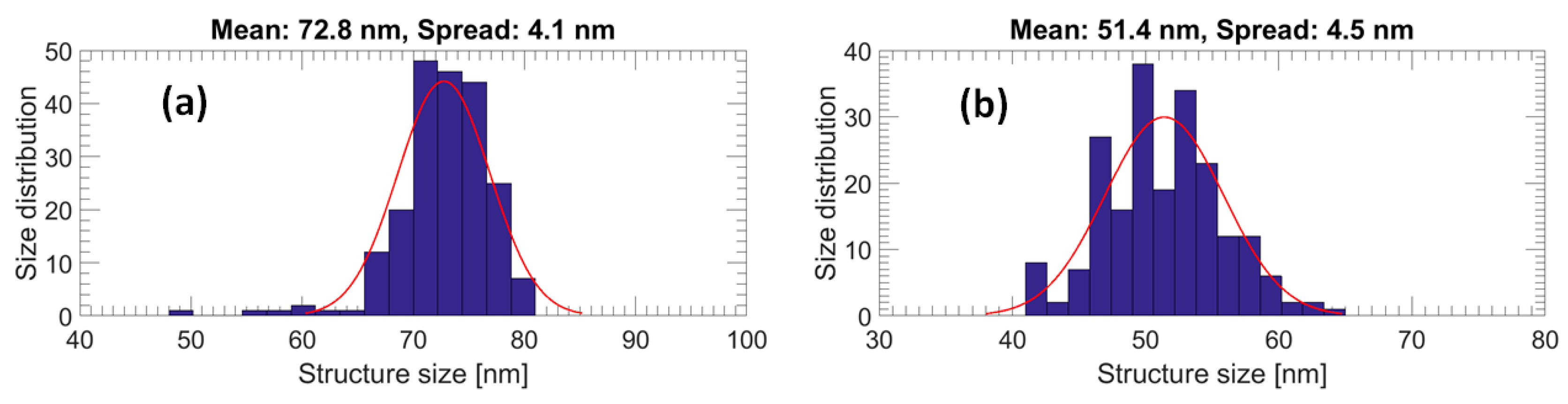

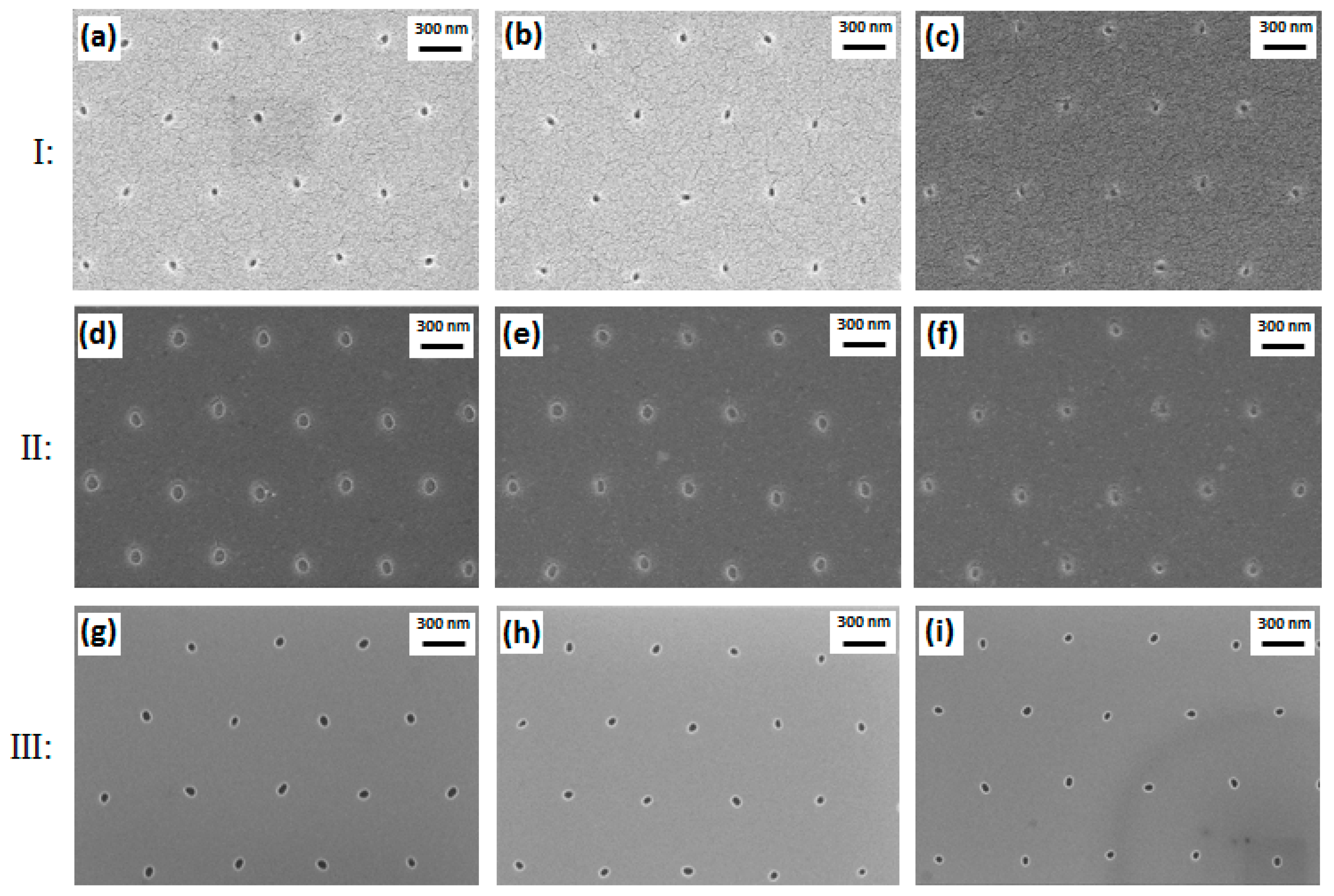

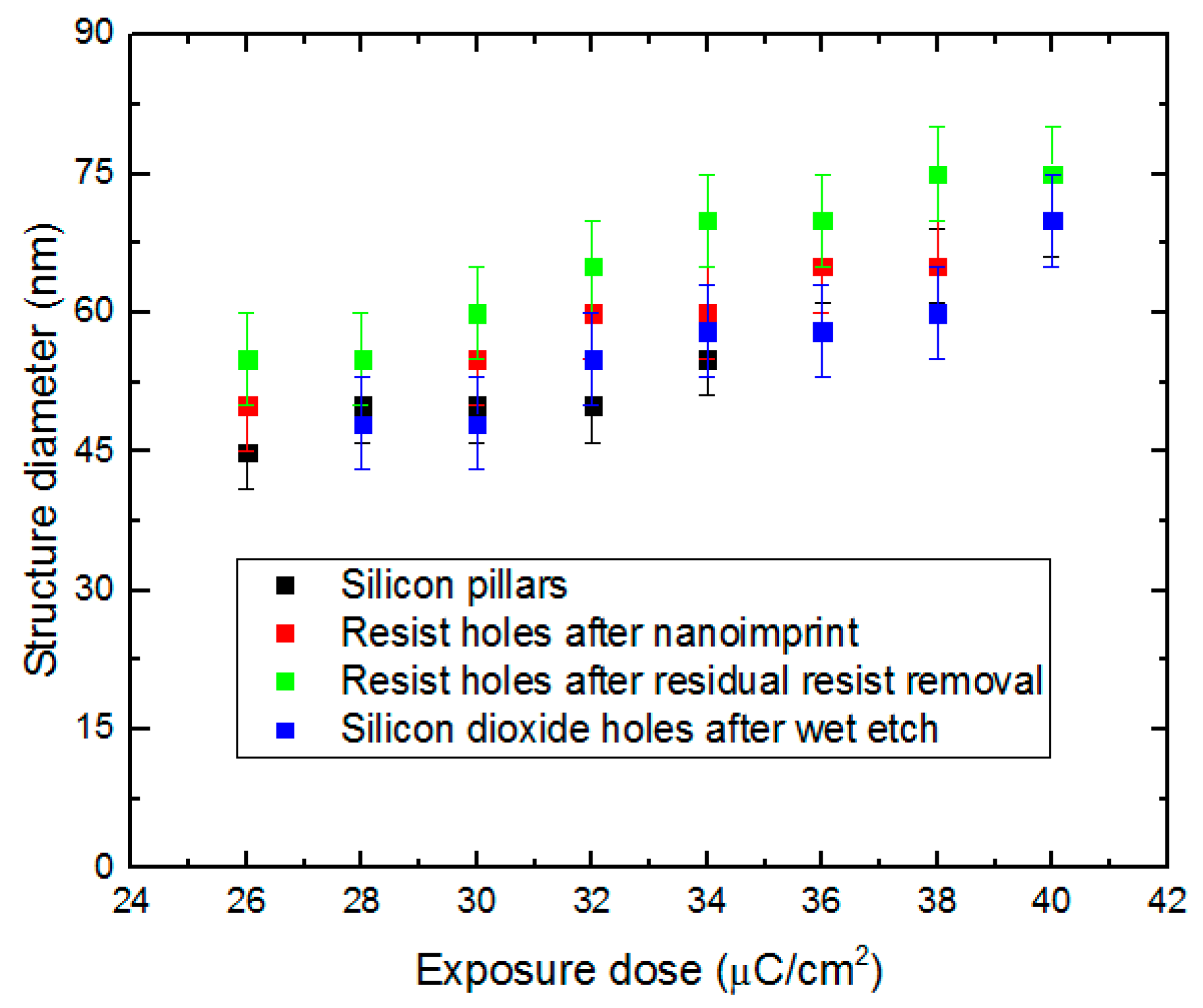

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Holm, J.V.; Jørgensen, H.I.; Krogstrup, P.; Nygård, J.; Liu, H.; Aagesen, M. Surface-passivated GaAsP single-nanowire solar cells exceeding 10% efficiency grown on silicon. Nat. Commun. 2013, 4, 1498. [Google Scholar] [CrossRef] [PubMed]

- Davydok, A.; Breuer, S.; Biermanns, A.; Geelhaar, L.; Pietsch, U. Lattice parameter accommodation between GaAs(111) nanowires and Si(111) substrate after growth via Au-assisted molecular beam epitaxy. Nanoscale Res. Lett. 2012, 7, 109. [Google Scholar] [CrossRef] [PubMed]

- Gudiksen, M.S.; Lauhon, L.J.; Wang, J.; Smith, D.C.; Lieber, C.M. Growth of nanowire superlattice structures for nanoscale photonics and electronics. Nature 2002, 415, 617–620. [Google Scholar] [CrossRef] [PubMed]

- Fadil, A.; Ou, Y.; Iida, D.; Kamiyama, S.; Petersen, P.M.; Ou, H. Combining surface plasmonic and light extraction enhancement on InGaN quantum-well light-emitters. Nanoscale 2016, 8, 16340–16348. [Google Scholar] [CrossRef] [PubMed]

- Ou, Y.; Corell, D.D.; Hansen, C.D.; Petersen, P.M.; Ou, H. Antireflective sub-wavelength structures for improvement of the extraction efficiency and color rendering index of monolithic white light-emitting diode. Opt. Express 2011, 19, A166–A172. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ou, Y.; Iida, D.; Fadil, A.; Ou, H. Enhanced emission efficiency of size-controlled InGaN/GaN green nanopillar light-emitting diodes. Int. J. Opt. Photonic Eng. 2016, 1, 6. [Google Scholar]

- Zhu, J.; Wang, L.; Zhang, S.; Wang, H.; Zhao, D.; Zhu, J.; Liu, Z.; Jiang, D.; Yang, H. The fabrication of GaN-based nanopillar light-emitting diodes. J. Appl. Phys. 2010, 108, 074302. [Google Scholar] [CrossRef]

- Teng, C.H.; Zhang, L.; Tsai, Y.L.; Lin, C.C.; Kuo, H.C.; Deng, H.; Ku, P.C. Monolithically integrated multi-color InGaN/GaN nanopillar light emitting diodes. In Proceedings of the 73rd Annual 2015 Device Research Conference (DRC), Culumbus, OH, USA, 21–24 June 2015.

- Sekiguchi, H.; Kishino, K.; Kikuchi, A. Emission color control from blue to red with nanocolumn diameter of InGaN/GaN nanocolumn arrays grown on same substrate. Appl. Phys. Lett. 2010, 96, 231104. [Google Scholar] [CrossRef]

- Chen, A.; Chua, S.J.; Chen, P.; Chen, X.Y.; Jian, L.K. Fabrication of sub-100 nm patterns in SiO2 templates by electron-beam lithography for the growth of periodic III–V semiconductor nanostructures. Nanotechnology 2006, 17, 3903–3908. [Google Scholar] [CrossRef]

- Shakya, J.; Kim, K.H.; Lin, J.Y.; Jiang, H.X. Enhanced light extraction in III-nitride ultraviolet photonic crystal light-emitting diodes. Appl. Phys. Lett. 2004, 85, 142–144. [Google Scholar] [CrossRef]

- Traub, M.C.; Longsine, W.; Truskett, V.N. Advances in nanoimprint lithography. Annu. Rev. Chem. Biomol. Eng. 2016, 7, 583–604. [Google Scholar] [CrossRef] [PubMed]

- Jiao, Q.; Chen, Z.; Feng, Y.; Li, S.; Jiang, S.; Li, J.; Chen, Y.; Yu, T.; Kang, X.; Shen, B.; et al. The effects of nanocavity and photonic crystal in InGaN/GaN nanorod LED arrays. Nanoscale Res. Lett. 2016, 11, 340. [Google Scholar] [CrossRef] [PubMed]

- Fadil, A.; Ou, Y.; Zhan, T.; Wu, K.; Suyatin, D.; Lu, W.; Petersen, P.M.; Liu, Z.; Ou, H. Fabrication and improvement of nanopillar InGaN/GaN light-emitting diodes using nanosphere lithography. J. Nanophotonics 2015, 9, 093062. [Google Scholar] [CrossRef]

- Ou, Y.; Zhu, X.; Jokubavicius, V.; Yakimova, R.; Mortensen, N.A.; Syväjärvi, M.; Xiao, S.; Ou, H. Broadband antireflection and light extraction enhancement in fluorescent SiC with nanodome structures. Sci. Rep. 2014, 4, 4662. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cheung, C.L.; Nikolic, R.J.; Reinhardt, C.E.; Wang, T.F. Fabrication of nanopillars by nanosphere lithography. Nanotechnology 2006, 17, 1339–1343. [Google Scholar] [CrossRef]

- Ou, Y.; Fadil, A.; Ou, H. Antireflective SiC surface fabricated by scalable self-assembled nanopatterning. Micromachines 2016, 7, 152. [Google Scholar] [CrossRef]

- Song, Y.M.; Choi, E.S.; Park, G.C.; Park, C.Y.; Jang, S.J.; Lee, Y.T. Disordered antireflective nanostructures on GaN-based light-emitting diodes using Ag nanoparticles for improved light extraction efficiency. Appl. Phys. Lett. 2010, 97, 093110. [Google Scholar] [CrossRef]

- Huang, H.W.; Kao, C.C.; Hsueh, T.H.; Yu, C.C.; Lin, C.F.; Chu, J.T.; Kuo, H.C.; Wang, S.C. Fabrication of GaN-based nanorod light emitting diodes using self-assemble nickel nano-mask and inductively coupled plasma reactive ion etching. Mater. Sci. Eng. B 2004, 113, 125–129. [Google Scholar] [CrossRef]

- Chien, F.S.S.; Hsieh, W.F.; Gwo, S.; Vladar, A.E.; Dagata, J.A. Silicon nanostructures fabricated by scanning probe oxidation and tetra-methyl ammonium hydroxide etching. J. Appl. Phys. 2002, 91, 10044–10050. [Google Scholar] [CrossRef]

- Kiani, A.; Venkatakrishnan, K.; Tan, B. Micro/nano scale amorphization of silicon by femtosecond laser Irradiation. Opt. Express 2009, 17, 16517–16526. [Google Scholar] [CrossRef] [PubMed]

- Mårtensson, T.; Carlberg, P.; Borgstrom, M.; Montelius, L.; Seifert, W.; Samuelson, L. Nanowire arrays defined by nanoimprint lithography. Nano Lett. 2004, 4, 699–702. [Google Scholar] [CrossRef]

- Munshi, A.M.; Dheeraj, D.L.; Fauske, V.T.; Kim, D.C.; Huh, J.; Reinertsen, J.F.; Ahtapodov, L.; Lee, K.D.; Heidari, B.; Helvoort, A.T.J.; et al. Position-controlled uniform GaAs nanowires on silicon using nanoimprint lithography. Nano Lett. 2014, 14, 960–966. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, E.H.; Greibe, T.; Mortensen, N.A.; Kristensen, A. Single-spot e-beam lithography for defining large arrays of nano-holes. Microelectron. Eng. 2014, 121, 104–107. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, L.; Ou, Y.; Aagesen, M.; Jensen, F.; Herstrøm, B.; Ou, H. Time-Efficient High-Resolution Large-Area Nano-Patterning of Silicon Dioxide. Micromachines 2017, 8, 13. https://doi.org/10.3390/mi8010013

Lin L, Ou Y, Aagesen M, Jensen F, Herstrøm B, Ou H. Time-Efficient High-Resolution Large-Area Nano-Patterning of Silicon Dioxide. Micromachines. 2017; 8(1):13. https://doi.org/10.3390/mi8010013

Chicago/Turabian StyleLin, Li, Yiyu Ou, Martin Aagesen, Flemming Jensen, Berit Herstrøm, and Haiyan Ou. 2017. "Time-Efficient High-Resolution Large-Area Nano-Patterning of Silicon Dioxide" Micromachines 8, no. 1: 13. https://doi.org/10.3390/mi8010013