Unconventional Electrochemistry in Micro-/Nanofluidic Systems

Abstract

:1. Introduction

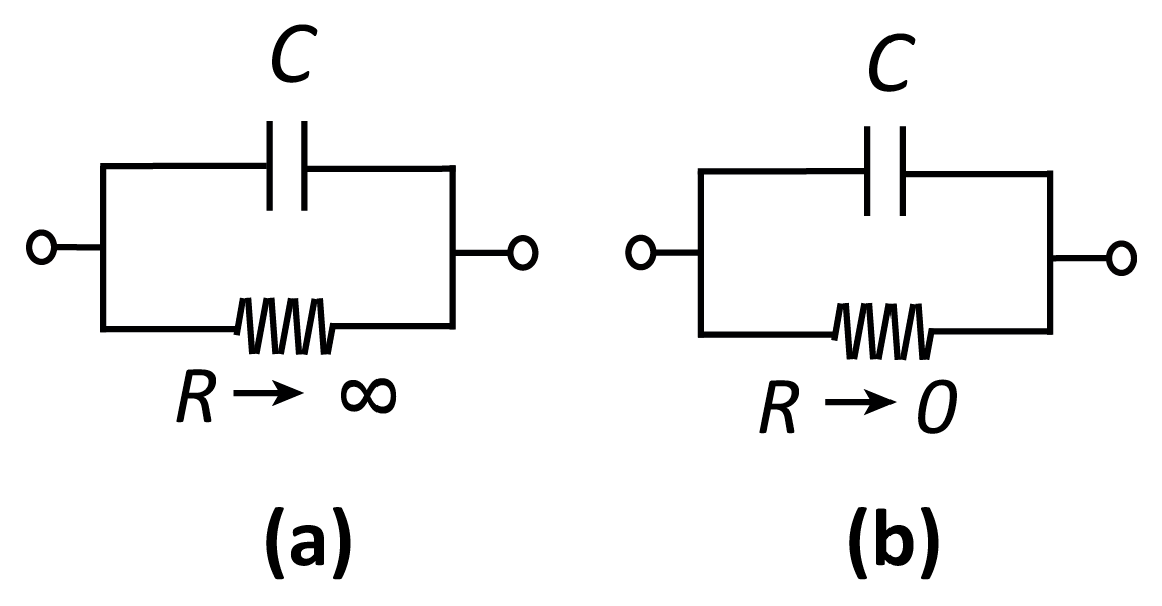

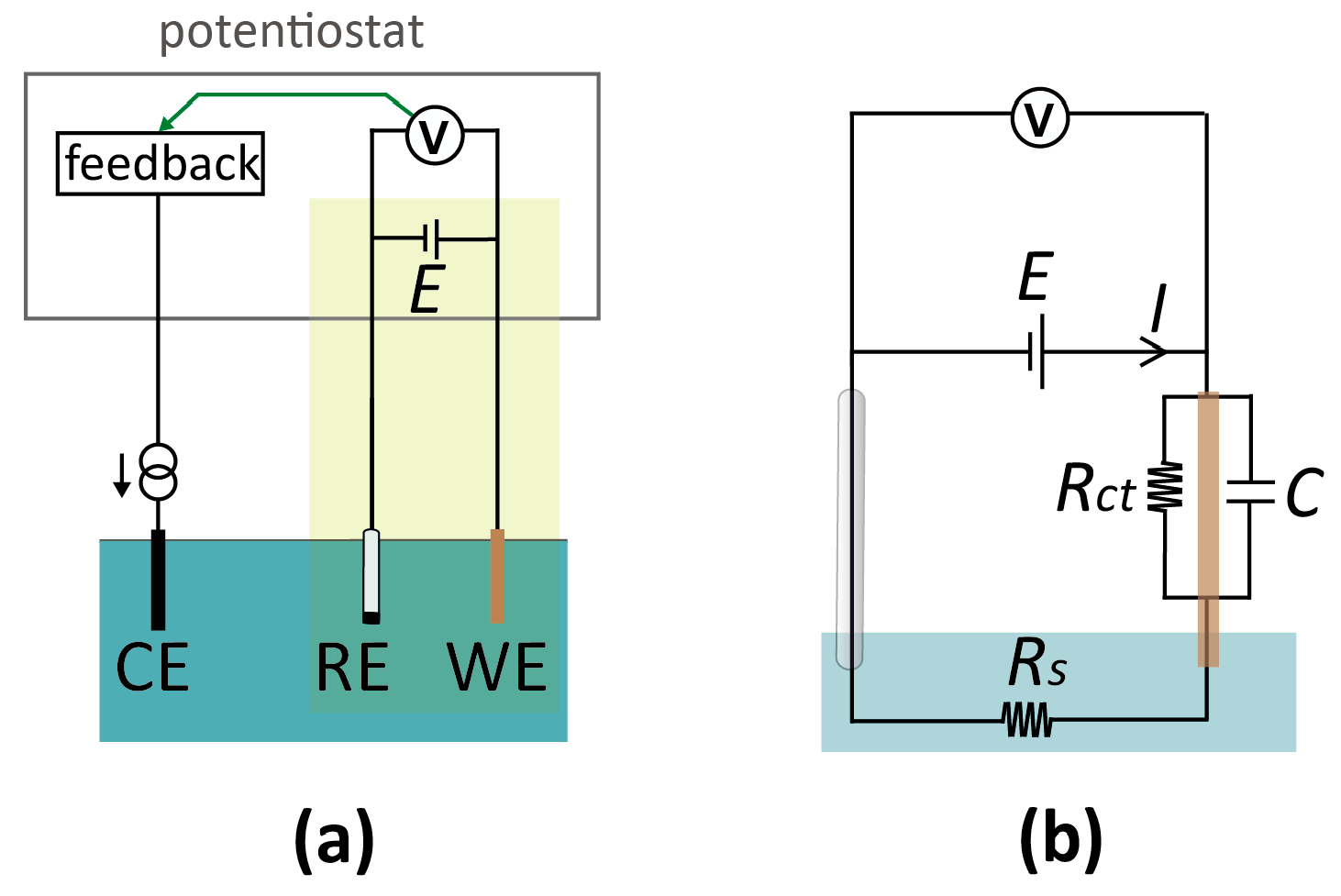

2. Anatomy of an Electrode

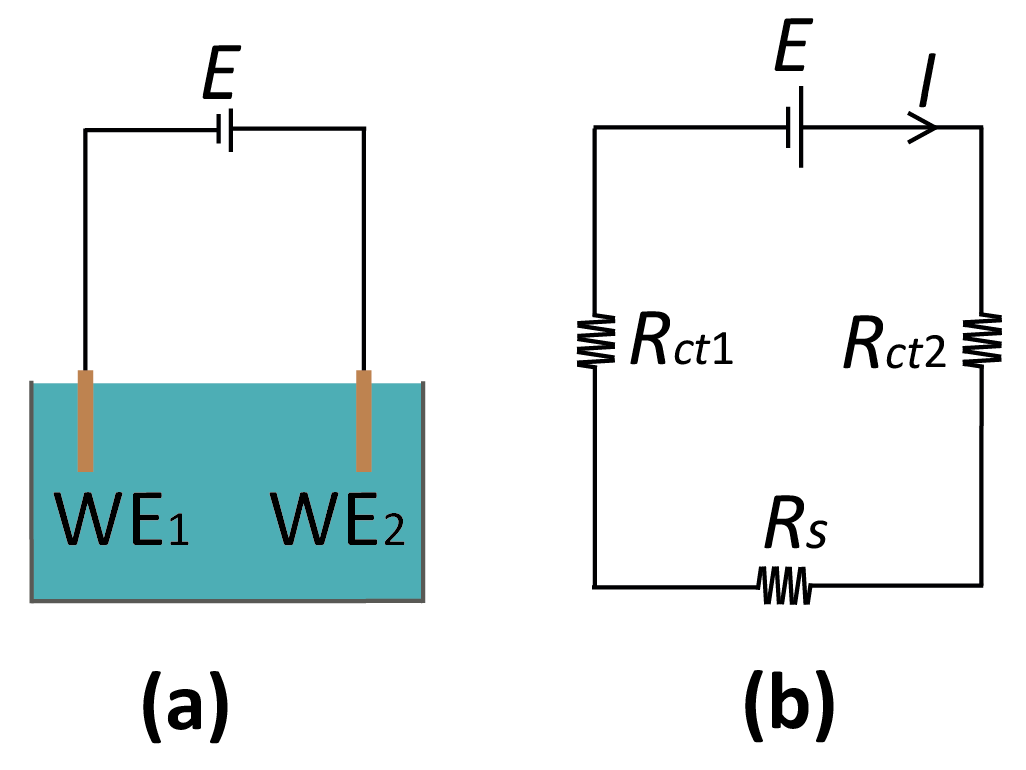

3. Reference Electrodes

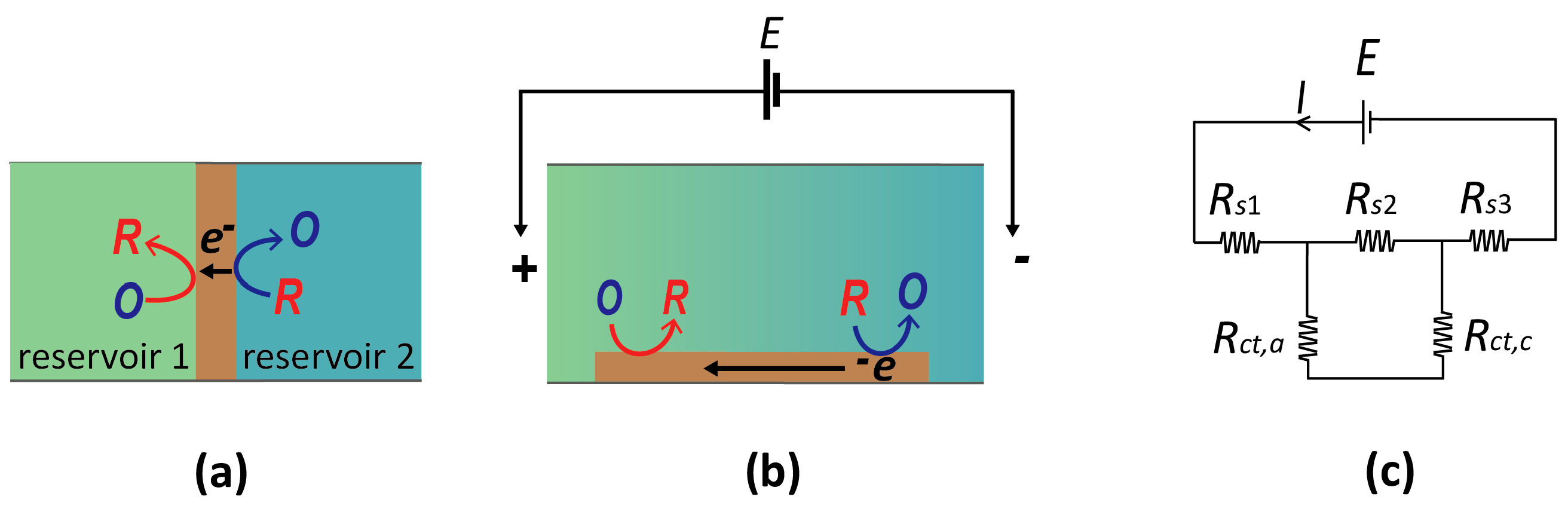

4. Systems without a Reference Electrode

5. Bipolar Electrodes

6. Potentiometry

7. Summary and Outlook

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Oja, S.M.; Fan, Y.S.; Armstrong, C.M.; Defnet, P.; Zhang, B. Nanoscale electrochemistry revisited. Anal. Chem. 2016, 88, 414–430. [Google Scholar] [PubMed]

- Oja, S.M.; Wood, M.; Zhang, B. Nanoscale electrochemistry. Anal. Chem. 2013, 85, 473–486. [Google Scholar] [CrossRef] [PubMed]

- Watkins, J.J.; Zhang, B.; White, H.S. Electrochemistry at nanometer-scaled electrodes. J. Chem. Educ. 2005, 82, 712–719. [Google Scholar] [CrossRef]

- Rackus, D.G.; Shamsi, M.H.; Wheeler, A.R. Electrochemistry, biosensors and microfluidics: A convergence of fields. Chem. Soc. Rev. 2015, 44, 5320–5340. [Google Scholar] [CrossRef] [PubMed]

- Rassaei, L.; Singh, P.S.; Lemay, S.G. Lithography-based nanoelectrochemistry. Anal. Chem. 2011, 83, 3974–3980. [Google Scholar] [CrossRef] [PubMed]

- Meier, J.; Schiotz, J.; Liu, P.; Norskov, J.K.; Stimming, U. Nano-scale effects in electrochemistry. Chem. Phys. Lett. 2004, 390, 440–444. [Google Scholar] [CrossRef]

- Arrigan, D.W.M. Nanoelectrodes, nanoelectrode arrays and their applications. Analyst 2004, 129, 1157–1165. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.; Lemay, S.G. Nanoelectrochemical methods. In Nanoelectrochemistry; Mirkin, M.V., Amemiya, S., Eds.; CRC Press: Boca Ratan, FL, USA, 2015; pp. 573–600. [Google Scholar]

- Micheal, M.V.; Amemiya, A. Nanoelectrochemistry; CRC Press: Boca Ratan, FL, USA, 2015. [Google Scholar]

- Lee, T.M.H. Over-the-counter biosensors: Past, present, and future. Sensors 2008, 8, 5535–5559. [Google Scholar] [CrossRef]

- Bakker, E.; Qin, Y. Electrochemical sensors. Anal. Chem. 2006, 78, 3965–3983. [Google Scholar] [CrossRef] [PubMed]

- Grieshaber, D.; MacKenzie, R.; Voros, J.; Reimhult, E. Electrochemical biosensors—Sensor principles and architectures. Sensors 2008, 8, 1400–1458. [Google Scholar] [CrossRef] [Green Version]

- Ino, K. Microchemistry- and MEMS-based integrated electrochemical devices for bioassay applications. Electrochemistry 2015, 83, 688–694. [Google Scholar] [CrossRef]

- Wei, D.; Bailey, M.J.A.; Andrew, P.; Ryhanen, T. Electrochemical biosensors at the nanoscale. Lab Chip 2009, 9, 2123–2131. [Google Scholar] [CrossRef] [PubMed]

- Gencoglu, A.; Minerick, A.R. Electrochemical detection techniques in micro- and nanofluidic devices. Microfluid. Nanofluid. 2014, 17, 781–807. [Google Scholar] [CrossRef]

- Bard, A.J.; Faulkner, L.R. Electrochemical Methods: Fundamentals and Applications; Wiley: New York, NY, USA, 2000. [Google Scholar]

- Brett, C.M.A.; Brett, A.M.O. Electrochemistry: Principles, Methods, and Applications; Oxford University Press: Oxford, UK, 1993. [Google Scholar]

- Moore, A.M.; Weiss, P.S. Functional and spectroscopic measurements with scanning tunneling microscopy. Annu. Rev. Anal. Chem. 2008, 1, 857–882. [Google Scholar] [CrossRef] [PubMed]

- Mirkin, M.V.; Nogala, W.; Velmurugan, J.; Wang, Y.X. Scanning electrochemical microscopy in the 21st century. Update 1: Five years after. Phys. Chem. Chem. Phys. 2011, 13, 21196–21212. [Google Scholar] [CrossRef] [PubMed]

- Sun, P.; Laforge, F.O.; Mirkin, M.V. Scanning electrochemical microscopy in the 21st century. Phys. Chem. Chem. Phys. 2007, 9, 802–823. [Google Scholar] [CrossRef] [PubMed]

- Macpherson, J.V.; Unwin, P.R. Noncontact electrochemical imaging with combined scanning electrochemical atomic force microscopy. Anal. Chem. 2001, 73, 550–557. [Google Scholar] [CrossRef] [PubMed]

- Shinwari, M.W.; Zhitomirsky, D.; Deen, I.A.; Selvaganapathy, P.R.; Deen, M.J.; Landheer, D. Microfabricated reference electrodes and their biosensing applications. Sensors 2010, 10, 1679–1715. [Google Scholar] [CrossRef] [PubMed]

- Hickling, A. Studies in electrode polarisation part IV—The automatic control of the potential of a working electrode. Trans. Faraday Soc. 1942, 38, 27–33. [Google Scholar] [CrossRef]

- Brezinski, D.P. Kinetic, static and stirring errors of liquid junction reference electrodes. Analyst 1983, 108, 425–442. [Google Scholar] [CrossRef]

- Mousavi, M.P.S.; Buhlmann, P. Reference electrodes with salt bridges contained in nanoporous glass: An underappreciated source of error. Anal. Chem. 2013, 85, 8895–8901. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.Y.; Hong, S.A.; Yang, S. A solid-state thin-film Ag/AgCl reference electrode coated with graphene oxide and its use in a pH sensor. Sensors 2015, 15, 6469–6482. [Google Scholar] [CrossRef] [PubMed]

- Webster, T.A.; Goluch, E.D. Electrochemical detection of pyocyanin in nanochannels with integrated palladium hydride reference electrodes. Lab Chip 2012, 12, 5195–5201. [Google Scholar] [CrossRef] [PubMed]

- Matsumoto, T.; Ohashi, A.; Ito, N. Development of a micro-planar Ag/AgCl quasi-reference electrode with long-term stability for an amperometric glucose sensor. Anal. Chim. Acta 2002, 462, 253–259. [Google Scholar] [CrossRef]

- Uludag, Y.; Olcer, Z.; Sagiroglu, M.S. Design and characterisation of a thin-film electrode array with shared reference/counter electrodes for electrochemical detection. Biosens. Bioelectron. 2014, 57, 85–90. [Google Scholar] [CrossRef] [PubMed]

- Rivas, I.; Puente, D.; Ayerdi, I.; Castano, E. Ag/AgI quasi-reference microelectrodes. In Proceedings of the 2005 Spanish Conference on Electron Devices, Tarragona, Spain, 2–4 Febuary 2005; pp. 465–468.

- Zhou, J.H.; Ren, K.N.; Zheng, Y.Z.; Su, J.; Zhao, Y.H.; Ryan, D.; Wu, H.K. Fabrication of a microfluidic Ag/AgCl reference electrode and its application for portable and disposable electrochemical microchips. Electrophoresis 2010, 31, 3083–3089. [Google Scholar] [CrossRef] [PubMed]

- Polk, B.J.; Stelzenmuller, A.; Mijares, G.; MacCrehan, W.; Gaitan, M. Ag/AgCl microelectrodes with improved stability for microfluidics. Sens. Actuator B Chem. 2006, 114, 239–247. [Google Scholar] [CrossRef]

- Da Silva, E.T.S.G.; Miserere, S.; Kubota, L.T.; Merkoci, A. Simple on-plastic/paper inkjet-printed solid-state Ag/AgCl pseudoreference electrode. Anal. Chem. 2014, 86, 10531–10534. [Google Scholar] [CrossRef] [PubMed]

- Desmond, D.; Lane, B.; Alderman, J.; Glennon, J.D.; Diamond, D.; Arrigan, D.W.M. Evaluation of miniaturised solid state reference electrodes on a silicon based component. Sens. Actuator B Chem. 1997, 44, 389–396. [Google Scholar] [CrossRef]

- Suzuki, H.; Shiroishi, H.; Sasaki, S.; Karube, I. Microfabricated liquid junction Ag/AgCl reference electrode and its application to a one-chip potentiometric sensor. Anal. Chem. 1999, 71, 5069–5075. [Google Scholar] [CrossRef]

- Suzuki, H. Advances in the microfabrication of electrochemical sensors and systems. Electroanalysis 2000, 12, 703–715. [Google Scholar] [CrossRef]

- Du, J.L.; Chen, Z.F.; Chen, C.C.; Meyer, T.J. A half-reaction alternative to water oxidation: Chloride oxidation to chlorine catalyzed by silver ion. J. Am. Chem. Soc. 2015, 137, 3193–3196. [Google Scholar] [CrossRef] [PubMed]

- Fritz, J.J. Thermodynamic properties of chloro-complexes of silver-chloride in aqueous-solution. J. Solut. Chem. 1985, 14, 865–879. [Google Scholar] [CrossRef]

- Da Silva, R.A.B.; de Almeida, E.G.N.; Rabelo, A.C.; da Silva, A.T.C.; Ferreira, L.F.; Richter, E.M. Three electrode electrochemical microfluidic cell: Construction and characterization. J. Braz. Chem. Soc. 2009, 20, 1235–1241. [Google Scholar] [CrossRef]

- Simonis, A.; Dawgul, M.; Luth, H.; Schoning, M.J. Miniaturised reference electrodes for field-effect sensors compatible to silicon chip technology. Electrochim. Acta 2005, 51, 930–937. [Google Scholar] [CrossRef]

- Franklin, R.K.; Johnson, M.D.; Scott, K.A.; Shim, J.H.; Nam, H.; Kipke, D.R.; Brown, R.B. Iridium oxide reference electrodes for neurochemical sensing with MEMS microelectrode arrays. In Proceedings of IEEE Sensors 2005, Irvine, CA, USA, 31 October–3 November 2005; pp. 1400–1403.

- Beati, A.A.G.F.; Reis, R.M.; Rocha, R.S.; Lanza, M.R.V. Development and evaluation of a pseudoreference Pt//Ag/AgCl electrode for electrochemical systems. Ind. Eng. Chem. Res. 2012, 51, 5367–5371. [Google Scholar] [CrossRef]

- Kasem, K.K.; Jones, S. Platinum as a reference electrode in electrochemical measurements. Platin. Met. Rev. 2008, 52, 100–106. [Google Scholar] [CrossRef]

- Dacuna, B.; Zaragoza, G.; Blanco, M.C.; Quintela, A.L.; Mira, J.; Rivas, J. Electrochemical synthesis of Fe/Ag and Co/Ag granular thin films. Mater. Sci. Forum 1998, 269–272, 307–312. [Google Scholar] [CrossRef]

- Yang, H.S.; Kang, S.K.; Choi, C.A.; Kim, H.; Shin, D.H.; Kim, Y.S.; Kim, Y.T. An iridium oxide reference electrode for use in microfabricated biosensors and biochips. Lab Chip 2004, 4, 42–46. [Google Scholar] [CrossRef] [PubMed]

- Xiong, J.W.; White, H.S. The I-V response of an electrochemical cell comprising two polarizable microelectrodes and the influence of impurities on the cell response. J. Electroanal. Chem. 2013, 688, 354–359. [Google Scholar] [CrossRef]

- Sarkar, S.; Mathwig, K.; Kang, S.; Nieuwenhuis, A.F.; Lemay, S.G. Redox cycling without reference electrodes. Analyst 2014, 139, 6052–6057. [Google Scholar] [CrossRef] [PubMed]

- Oja, S.M.; Zhang, B. Imaging transient formation of diffusion layers with fluorescence-enabled electrochemical microscopy. Anal. Chem. 2014, 86, 12299–12307. [Google Scholar] [CrossRef] [PubMed]

- Bradley, J.C.; Chen, H.M.; Crawford, J.; Eckert, J.; Ernazarova, K.; Kurzeja, T.; Lin, M.D.; McGee, M.; Nadler, W.; Stephens, S.G. Creating electrical contacts between metal particles using directed electrochemical growth. Nature 1997, 389, 268–271. [Google Scholar] [CrossRef]

- Loget, G.; Li, G.Z.; Fabre, B. Logic gates operated by bipolar photoelectrochemical water splitting. Chem. Commun. 2015, 51, 11115–11118. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Loget, G.; Zigah, D.; Bouffier, L.; Sojic, N.; Kuhn, A. Bipolar electrochemistry: From materials science to motion and beyond. Acc. Chem. Res. 2013, 46, 2513–2523. [Google Scholar] [CrossRef] [PubMed]

- Loget, G.; Roche, J.; Gianessi, E.; Bouffier, L.; Kuhn, A. Indirect bipolar electrodeposition. J. Am. Chem. Soc. 2012, 134, 20033–20036. [Google Scholar] [CrossRef] [PubMed]

- Loget, G.; Kuhn, A. Bipolar electrochemistry for cargo-lifting in fluid channels. Lab Chip 2012, 12, 1967–1971. [Google Scholar] [CrossRef] [PubMed]

- Fattah, Z.; Loget, G.; Lapeyre, V.; Garrigue, P.; Warakulwit, C.; Limtrakul, J.; Bouffier, L.; Kuhn, A. Straightforward single-step generation of microswimmers by bipolar electrochemistry. Electrochim. Acta 2011, 56, 10562–10566. [Google Scholar] [CrossRef]

- Loget, G.; Kuhn, A. Propulsion of microobjects by dynamic bipolar self-regeneration. J. Am. Chem. Soc. 2010, 132, 15918–15919. [Google Scholar] [CrossRef] [PubMed]

- Scida, K.; Sheridan, E.; Crooks, R.M. Electrochemically-gated delivery of analyte bands in microfluidic devices using bipolar electrodes. Lab Chip 2013, 13, 2292–2299. [Google Scholar] [CrossRef] [PubMed]

- Chang, B.Y.; Chow, K.F.; Crooks, J.A.; Mavre, F.; Crooks, R.M. Two-channel microelectrochemical bipolar electrode sensor array. Analyst 2012, 137, 2827–2833. [Google Scholar] [CrossRef] [PubMed]

- Sheridan, E.; Hlushkou, D.; Anand, R.K.; Laws, D.R.; Tallarek, U.; Crooks, R.M. Label-free electrochemical monitoring of concentration enrichment during bipolar electrode focusing. Anal. Chem. 2011, 83, 6746–6753. [Google Scholar] [CrossRef] [PubMed]

- Dumitrescu, I.; Anand, R.K.; Fosdick, S.E.; Crooks, R.M. Pressure-driven bipolar electrochemistry. J. Am. Chem. Soc. 2011, 133, 4687–4689. [Google Scholar] [CrossRef] [PubMed]

- Sequeira, C.A.C.; Cardoso, D.S.P.; Gameiro, M.L.F. Bipolar electrochemistry, a focal point of future research. Chem. Eng. Commun. 2016, 203, 1001–1008. [Google Scholar] [CrossRef]

- Wang, Y.; Hernandez, R.M.; Bartlett, D.J.; Bingham, J.M.; Kline, T.R.; Sen, A.; Mallouk, T.E. Bipolar electrochemical mechanism for the propulsion of catalytic nanomotors in hydrogen peroxide solutions. Langmuir 2006, 22, 10451–10456. [Google Scholar] [CrossRef] [PubMed]

- Kline, T.R.; Paxton, W.F.; Mallouk, T.E.; Sen, A. Catalytic nanomotors: Remote-controlled autonomous movement of striped metallic nanorods. Angew. Chem. Int. Ed. 2005, 44, 744–746. [Google Scholar] [CrossRef] [PubMed]

- Paxton, W.F.; Kistler, K.C.; Olmeda, C.C.; Sen, A.; St Angelo, S.K.; Cao, Y.Y.; Mallouk, T.E.; Lammert, P.E.; Crespi, V.H. Catalytic nanomotors: Autonomous movement of striped nanorods. J. Am. Chem. Soc. 2004, 126, 13424–13431. [Google Scholar] [CrossRef] [PubMed]

- Ma, C.X.; Zaino, L.P.; Bohn, P.W. Self-induced redox cycling coupled luminescence on nanopore recessed disk-multiscale bipolar electrodes. Chem. Sci. 2015, 6, 3173–3179. [Google Scholar] [CrossRef]

- Oleinick, A.I.; Battistel, D.; Daniele, S.; Svir, I.; Amatore, C. Simple and clear evidence for positive feedback limitation by bipolar behavior during scanning electrochemical microscopy of unbiased conductors. Anal. Chem. 2011, 83, 4887–4893. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Richter, M.M. Electrochemiluminescence (ECL). Chem. Rev. 2004, 104, 3003–3036. [Google Scholar] [CrossRef] [PubMed]

- Zevenbergen, M.A.G.; Wolfrum, B.L.; Goluch, E.D.; Singh, P.S.; Lemay, S.G. Fast electron-transfer kinetics probed in nanofluidic channels. J. Am. Chem. Soc. 2009, 131, 11471–11477. [Google Scholar] [CrossRef] [PubMed]

- Arora, A.; Eijkel, J.C.T.; Morf, W.E.; Manz, A. A wireless electrochemiluminescence detector applied to direct and indirect detection for electrophoresis on a microfabricated glass device. Anal. Chem. 2001, 73, 5633–5633. [Google Scholar] [CrossRef]

- Leinweber, F.C.; Eijkel, J.C.T.; Bower, J.G.; van den Berg, A. Continuous flow microfluidic demixing of electrolytes by induced charge electrokinetics in structured electrode arrays. Anal. Chem. 2006, 78, 1425–1434. [Google Scholar] [CrossRef] [PubMed]

- Bakker, E.; Pretsch, E. Modern potentiometry. Angew. Chem. Int. Ed. 2007, 46, 5660–5668. [Google Scholar] [CrossRef] [PubMed]

- Malon, A.; Vigassy, T.; Bakker, E.; Pretsch, E. Potentiometry at trace levels in confined samples: Ion-selective electrodes with subfemtomole detection limits. J. Am. Chem. Soc. 2006, 128, 8154–8155. [Google Scholar] [CrossRef] [PubMed]

- Bakker, E.; Pretsch, E. Nanoscale potentiometry. Trends Anal. Chem 2008, 27, 612–618. [Google Scholar] [CrossRef] [PubMed]

- Pungor, E.; Toth, K. Ion-selective membrane electrodes—A review. Analyst 1970, 95, 625–648. [Google Scholar] [CrossRef]

- Singh, P.S. From sensors to systems: CMOS-integrated electrocheimcal biosensors. IEEE Access 2015, 3, 249–259. [Google Scholar] [CrossRef]

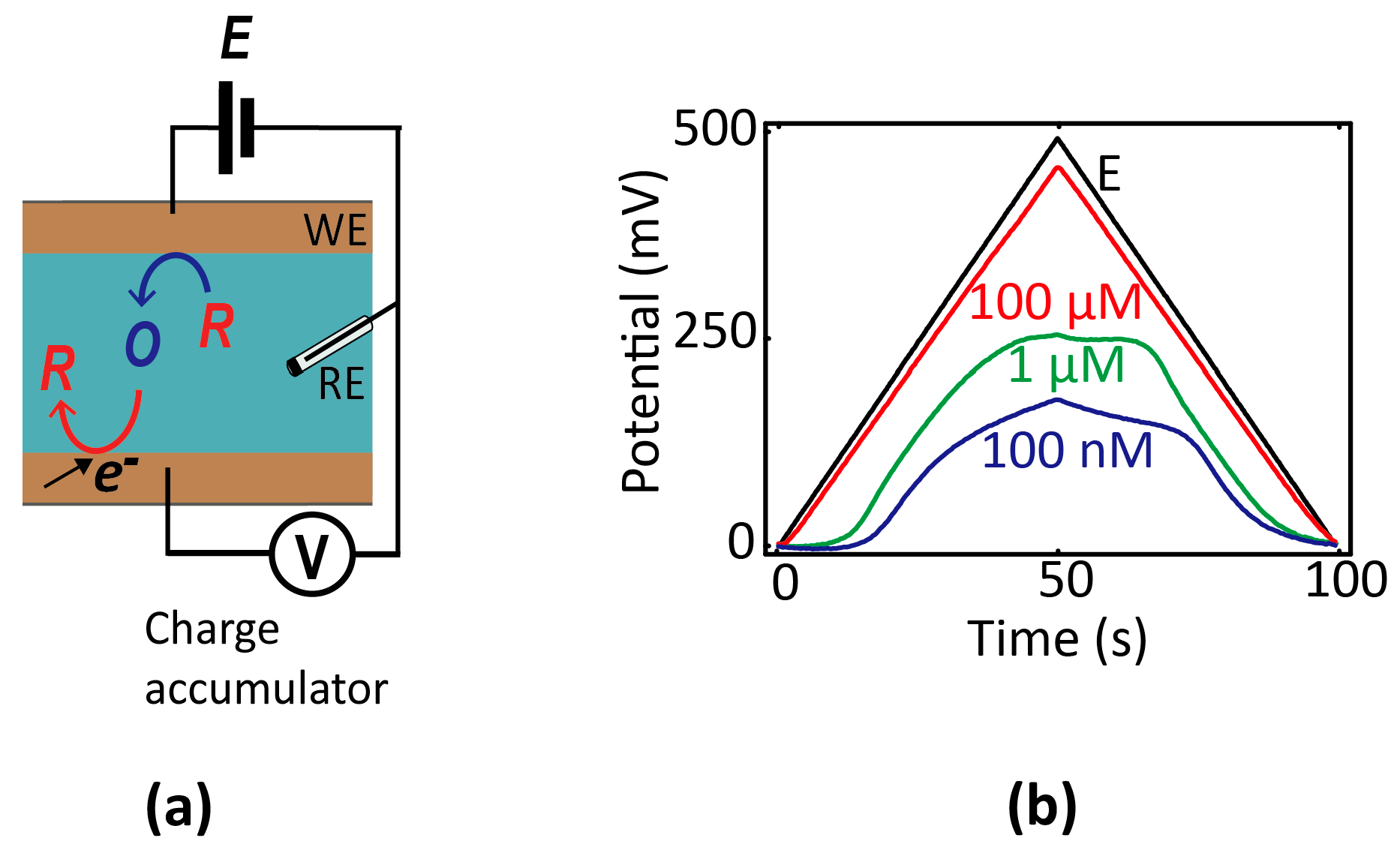

- Zhu, X.S.; Choi, J.W.; Ahn, C.H. A new dynamic electrochemical transduction mechanism for interdigitated array microelectrodes. Lab Chip 2004, 4, 581–587. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.S.; Ahn, C.H. Electrochemical determination of reversible redox species at interdigitated array micro/nanoelectrodes using charge injection method. IEEE Trans. Nanobiosci. 2005, 4, 164–169. [Google Scholar] [CrossRef]

- Zhu, X.S.; Ahn, C.H. On-chip electrochemical analysis system using nanoelectrodes and bioelectronic CMOS chip. IEEE Sens. J. 2006, 6, 1280–1286. [Google Scholar] [CrossRef]

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarkar, S.; Lai, S.C.S.; Lemay, S.G. Unconventional Electrochemistry in Micro-/Nanofluidic Systems. Micromachines 2016, 7, 81. https://doi.org/10.3390/mi7050081

Sarkar S, Lai SCS, Lemay SG. Unconventional Electrochemistry in Micro-/Nanofluidic Systems. Micromachines. 2016; 7(5):81. https://doi.org/10.3390/mi7050081

Chicago/Turabian StyleSarkar, Sahana, Stanley C. S. Lai, and Serge G. Lemay. 2016. "Unconventional Electrochemistry in Micro-/Nanofluidic Systems" Micromachines 7, no. 5: 81. https://doi.org/10.3390/mi7050081