A CMOS MEMS Humidity Sensor Enhanced by a Capacitive Coupling Structure

Abstract

:1. Introduction

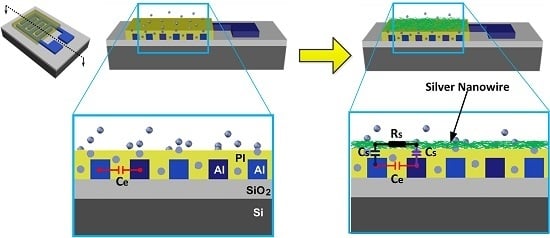

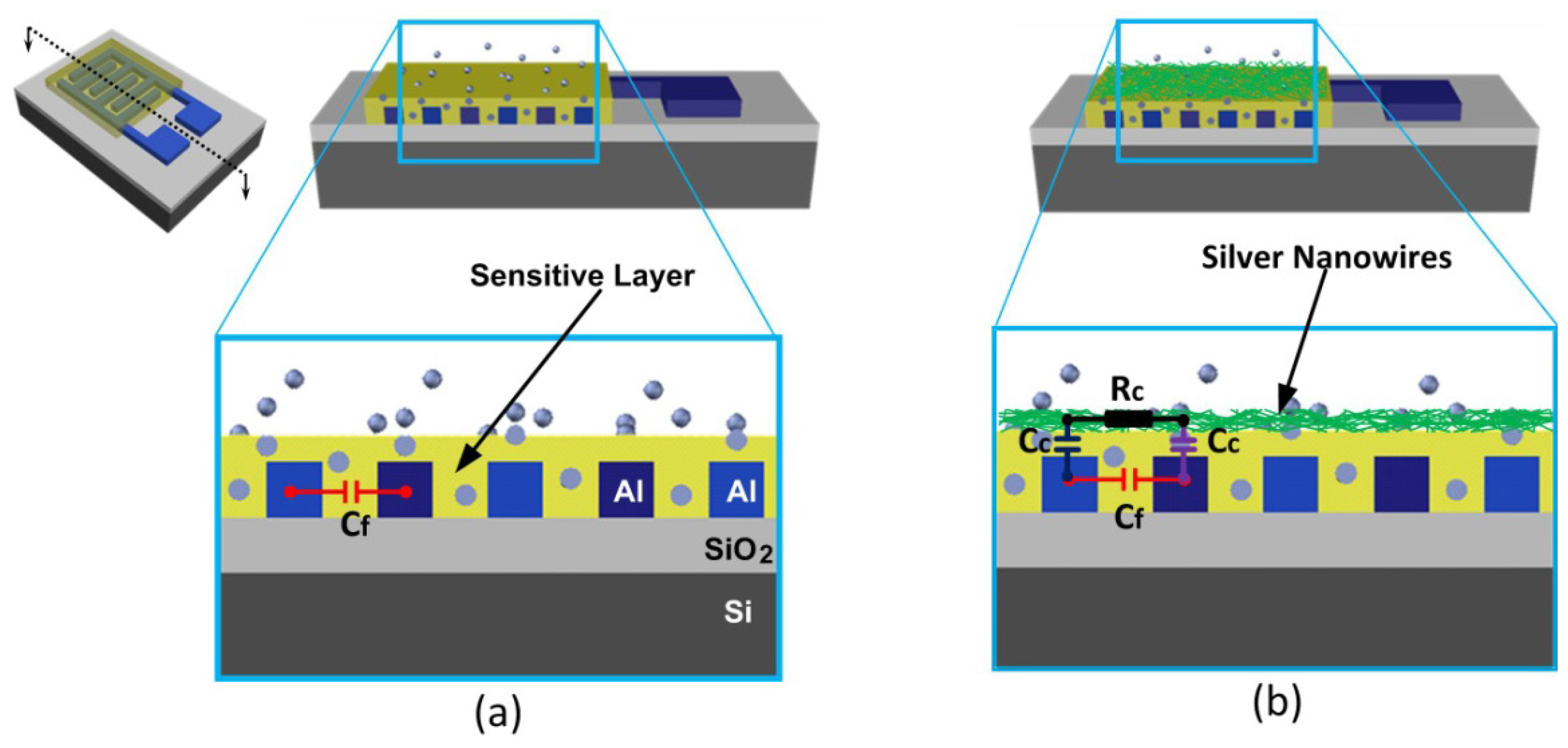

2. Structure and Operating Principle

3. Fabrication Process

4. Results

4.1. Static Measurements

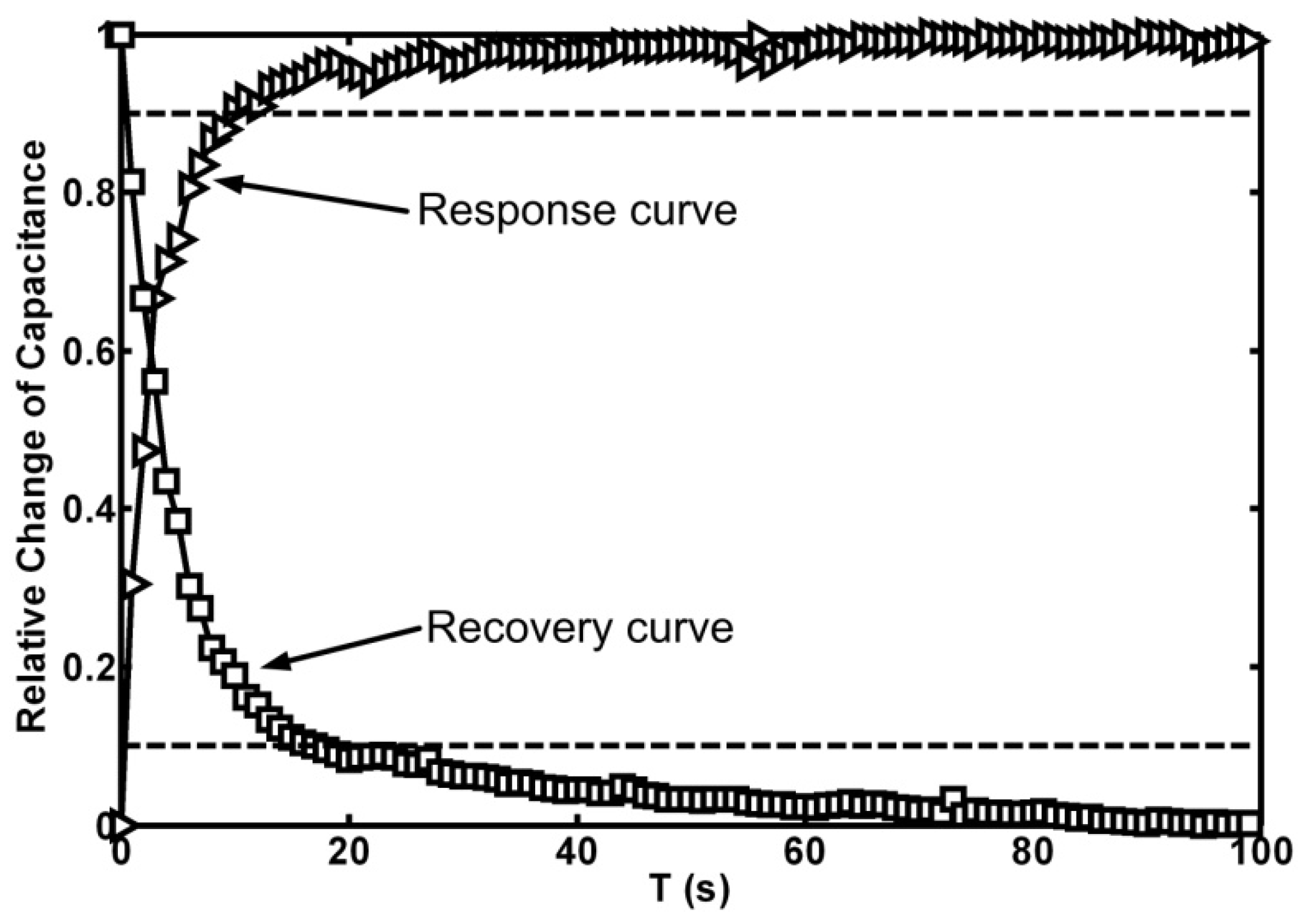

4.2. Dynamic Measurements

5. Discussion

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Farhani, H.; Wagiran, R.; Hamidon, M.N. Humidity sensors principle, mechanism and fabrication technologies: A comprehensive review. Sensors 2014, 14, 7881–7939. [Google Scholar] [CrossRef] [PubMed]

- Stanislav, A.K.; Neil, T.G.; Chengbo, M.; Kaiming, Z. Toward a new generation of photonic humidity sensors. Sensors 2014, 14, 3986–4013. [Google Scholar]

- Chia-Yen, L.; Gwo-Bin, L. Humidity sensors: A review. Sens. Lett. 2005, 3, 1–14. [Google Scholar]

- Chen, Z.; Lu, C. Humidity sensors: A review of materials and mechanisms. Sens. Lett. 2005, 3, 274–295. [Google Scholar] [CrossRef]

- Dunmore, F. An electric hygrometer and its application to radio meteorography. J. Res. Natl. Bur. Stand. 1938, 20, 723–744. [Google Scholar] [CrossRef]

- Doroftei, C.; Popa, P.D.; Iacomi, F. Study of the Influence of Nickel Ions Substitutes in Barium Stannates Used as Humidity Resistive Sensors. Sens. Actuators A Phys. 2012, 173, 24–29. [Google Scholar] [CrossRef]

- Lim, D.-I.; Cha, J.-R.; Gong, M.-S. Preparation of Flexible Resistive Micro-Humidity Sensors and Their Humidity-Sensing Properties. Sens. Actuators B Chem. 2013, 183, 574–582. [Google Scholar] [CrossRef]

- Lin, Q.; Li, Y.; Yang, M. Polyaniline Nanofiber Humidity Sensor Prepared by Electrospinning. Sens. Actuators B Chem. 2012, 161, 967–972. [Google Scholar] [CrossRef]

- Imran, Z.; Batool, S.S.; Jamil, H.; Usman, M.; Israr-Qadir, M.; Shah, S.H.; Jamil-Rana, S.; Rafiq, M.A.; Hasan, M.M.; Willander, M. Excellent Humidity Sensing Properties of Cadmium Titanate Nanofibers. Ceram. Int. 2013, 39, 457–462. [Google Scholar] [CrossRef]

- Li, J.; Lin, X.; Li, J.; Liu, Y.; Tang, M. Capacitive Humidity Sensor with a Coplanar Electrode Structure Based on Anodised Porous Alumina Film. Micro Nano Lett. 2012, 7, 1097–1100. [Google Scholar] [CrossRef]

- Dean, R.N.; Rane, A.K.; Baginski, M.E.; Richard, J.; Hartzog, Z.; Elton, D.J. A Capacitive Fringing Field Sensor Design for Moisture Measurement Based on Printed Circuit Board Technology. IEEE Trans. Instrum. Meas. 2012, 61, 1105–1112. [Google Scholar] [CrossRef]

- Fenner, R.; Zdankiewicz, E. Micromachined water vapor sensors: A review of sensing technologies. IEEE Sens. J. 2001, 1, 309–317. [Google Scholar] [CrossRef]

- Rittersma, Z.M. Recent Achievements in Miniaturised Humidity Sensors—A Review of Transduction Techniques. Sens. Actuators A Phys. 2002, 96, 196–210. [Google Scholar] [CrossRef]

- Ribeiro, L.E.B.; de Alcântara, G.P.; Andrade, C.M.G.; Fruett, F. Analysis of the Planar Electrode Morphology Applied to Zeolite Based Chemical Sensors. Sens. Transducers 2015, 193, 80–85. [Google Scholar]

- Rivadeneyra, A.; Fernández-Salmerón, J.; Banqueri, J.; López-Villanueva, J.A.; Capitan-Vallvey, L.F.; Palma, A.J. A novel electrode structure compared with interdigitated electrodes as capacitive sensor. Sens. Actuators B Chem. B 2014, 204, 552–560. [Google Scholar] [CrossRef]

- Kim, J.H.; Hong, S.M.; Moon, B.M.; Kim, K. High-Performance Capacitive Humidity Sensor with Novel Electrode and Polyimide Layer Based on MEMS Technology. Microsys. Technol. 2010, 16, 2017–2021. [Google Scholar] [CrossRef]

- A Comparison of Relative Humidity Sensing Technologies. Available online: http://pasternack.ucdavis.edu/files/6213/7271/8210/hyd151_read13.pdf (accessed on 22 April 2016).

- Dai, C.L. A capacitive humidity sensor integrated with micro heater and ring oscillator circuit fabricated by CMOS-MEMS technique. Sens. Actuators B Chem. 2007, 122, 375–380. [Google Scholar] [CrossRef]

- Nizhnik, O.; Higuchi, K.; Maenaka, K. Self-calibrated humidity sensor in CMOS without post-processing. Sensors 2012, 12, 226–232. [Google Scholar] [CrossRef] [PubMed]

- Gu, L.; Huang, Q.A.; Qin, M. A novel capacitive-type humidity sensor using CMOS fabrication technology. Sens. Actuators B Chem. 2004, 99, 491–498. [Google Scholar] [CrossRef]

- Rivadeneyra, A.; Fernández-Salmerón, J.; Agud, M.; López-Villanueva, J.A.; Capitan-Vallvey, L.F.; Palma, A.J. Design and characterization of a low thermal drift capacitive humidity sensor by inkjet-printing. Sens. Actuators B Chem. 2014, 195, 123–131. [Google Scholar] [CrossRef]

- Oprea, A.; Bâarsan, N.; Weimar, U.; Bauersfeld, M.L.; Ebling, D.; Wollenstein, J. Capacitive humidity sensors on flexible RFID labels. Sens. Actuators B Chem. 2008, 132, 404–410. [Google Scholar] [CrossRef]

- Lazarus, N.; Bedair, S.S.; Lo, C.C.; Fedder, G.K. CMOS-MEMS capacitive humidity sensor. J. Microelectromech. Syst. 2010, 19, 183–191. [Google Scholar] [CrossRef]

- Kim, J.H.; Moon, B.M.; Hong, S.M. Capacitive Humidity Sensors Based on a Newly Designed Interdigitated Electrode Structure. Microsyst. Technol. 2012, 18, 31–35. [Google Scholar] [CrossRef]

- Igreja, R.; Dias, C.J. Dielectric response of interdigital chemocapacitors: The role of the sensitive layer thickness. Sens. Actuators B Chem. 2006, 115, 69–78. [Google Scholar] [CrossRef]

- Zhao, C.L.; Qin, M.; Huang, Q.A. A fully packaged CMOS interdigital capacitive humidity sensor with polysilicon heaters. IEEE Sens. 2011, 11, 2986–2992. [Google Scholar] [CrossRef]

- Tricoli, A.; Pratsinis, S.E. Dispersed Nanoelectrode Devices. Nat. Nanotechnol. 2010, 5, 54–60. [Google Scholar] [CrossRef] [PubMed]

- Schrode, D.K. Semiconductor Material and Device Characterization, 1st ed.; John Wiley & Sons, Inc.: New York, NY, USA, 2006; pp. 371–372. [Google Scholar]

| Property | 5 °C | 15 °C | 25 °C | 35 °C |

|---|---|---|---|---|

| Sensitivity (fF/%RH) | 33.9 | 32.7 | 32.8 | 33.9 |

| Linearity | 1.5% | 3.6% | 2.7% | 0.4% |

| Hysteresis (%RH) | 3.5 | 1.9 | 1.0 | 1.0 |

| Structure | Improvement of Sensitivity | Linearity | Hysteresis | Recovery Time |

|---|---|---|---|---|

| Capacitive coupling structure | 2.9 times | good | 1.0 %RH | 17 s |

| Multi-stacked metal structure [23] | 2 times | good | Not reported | >20 s |

| Increased height structure [24] | 2.3 times | poor | 2.87 %RH | Not reported |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, J.-Q.; Li, B.; Chen, W. A CMOS MEMS Humidity Sensor Enhanced by a Capacitive Coupling Structure. Micromachines 2016, 7, 74. https://doi.org/10.3390/mi7050074

Huang J-Q, Li B, Chen W. A CMOS MEMS Humidity Sensor Enhanced by a Capacitive Coupling Structure. Micromachines. 2016; 7(5):74. https://doi.org/10.3390/mi7050074

Chicago/Turabian StyleHuang, Jian-Qiu, Baoye Li, and Wenhao Chen. 2016. "A CMOS MEMS Humidity Sensor Enhanced by a Capacitive Coupling Structure" Micromachines 7, no. 5: 74. https://doi.org/10.3390/mi7050074