Mechanically-Tunable Photonic Devices with On-Chip Integrated MEMS/NEMS Actuators

Abstract

:1. Introduction

2. Micro and Nano Fabrication

3. MEMS/NEMS Tunable Si Photonics

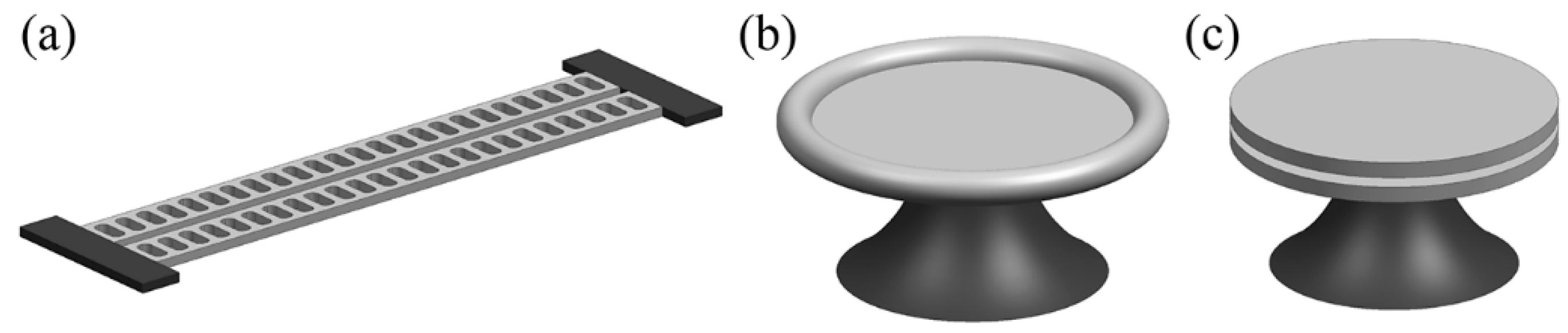

3.1. Waveguide

3.2. Ring/Disk Resonator

3.3. Photonic Crystal (PhC) Resonator

4. MEMS/NEMS Tunable Plasmonics and Chip-scale Optomechanics: An Outlook

4.1. MEMS/NEMS Tunable Plasmonic Devices

4.2. Chip-Scale Optomechanics

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Minasian, R.A. Photonic signal processing of microwave signals. IEEE Trans. Microw. Theory 2006, 54, 832–846. [Google Scholar] [CrossRef]

- Capmany, J.; Mora, J.; Gasulla, I.; Sancho, J.; Lloret, J.; Sales, S. Microwave photonic signal processing. J. Lightwave Technol. 2013, 31, 571–586. [Google Scholar] [CrossRef]

- Tsybeskov, L.; Lockwood, D.J.; Ichikawa, M. Silicon photonics cmos going optical. Proc. IEEE 2009, 97, 1161–1165. [Google Scholar] [CrossRef]

- Baehr-Jones, T.; Pinguet, T.; Lo Guo-Qiang, P.; Danziger, S.; Prather, D.; Hochberg, M. Myths and rumours of silicon photonics. Nat. Photonics 2012, 6, 206–208. [Google Scholar] [CrossRef]

- Soref, R. The past, present, and future of silicon photonics. IEEE J. Sel. Top. Quant. 2006, 12, 1678–1687. [Google Scholar] [CrossRef]

- Hochberg, M.; Baehr-Jones, T. Towards fabless silicon photonics. Nat. Photonics 2010, 4, 492–494. [Google Scholar] [CrossRef]

- Capmany, J.; Novak, D. Microwave photonics combines two worlds. Nat. Photonics 2007, 1, 319–330. [Google Scholar] [CrossRef]

- Neilson, D.T. Photonics for switching and routing. IEEE J. Sel. Top. Quant. 2006, 12, 669–678. [Google Scholar] [CrossRef]

- Jalali, B. Silicon photonics. J. Lightwave Technol. 2006, 24, 4600–4615. [Google Scholar] [CrossRef]

- Reed, G.T.; Mashanovich, G.; Gardes, F.Y.; Thomson, D.J. Silicon optical modulators. Nat. Photonics 2010, 4, 518–526. [Google Scholar] [CrossRef] [Green Version]

- Pruessner, M.W.; Stievater, T.H.; Ferraro, M.S.; Rabinovich, W.S. Thermo-optic tuning and switching in soi waveguide Fabry-Pérot microcavities. Opt. Express 2007, 15, 7557–7563. [Google Scholar] [CrossRef] [PubMed]

- Guarino, A.; Poberaj, G.; Rezzonico, D.; Degl’Innocenti, R.; Gunter, P. Electro-optically tunable microring resonators in lithium niobate. Nat. Photonics 2007, 1, 407–410. [Google Scholar] [CrossRef]

- Wang, T.J.; Chu, C.H.; Lin, C.Y. Electro-optically tunable microring resonators on lithium niobate. Opt. Lett. 2007, 32, 2777–2779. [Google Scholar] [CrossRef] [PubMed]

- Scrymgeour, D.; Malkova, N.; Kim, S.; Gopalan, V. Electro-optic control of the superprism effect in photonic crystals. Appl. Phys. Lett. 2003, 82, 3176. [Google Scholar] [CrossRef]

- Chollet, F. Devices based on co-integrated MEMES actuators and optical waveguide: A review. Micromachines 2016, 7, 18. [Google Scholar] [CrossRef]

- St-Gelais, R.; Guha, B.; Zhu, L.X.; Fan, S.H.; Lipson, M. Demonstration of strong near-field radiative heat transfer between integrated nanostructures. Nano Lett. 2014, 14, 6971–6975. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Pepin, A. Nanofabrication: Conventional and nonconventional methods. Electrophoresis 2001, 22, 187–207. [Google Scholar] [CrossRef]

- Kowalski, Z.W.; Rangelow, I.W. Microelectronic and medical applications of an ion-beam milling system. J. Mater. Sci. 1983, 18, 741–752. [Google Scholar] [CrossRef]

- Jansen, H.; Gardeniers, H.; deBoer, M.; Elwenspoek, M.; Fluitman, J. A survey on the reactive ion etching of silicon in microtechnology. J. Micromech. Microeng. 1996, 6, 14–28. [Google Scholar] [CrossRef]

- Pang, S.W.; Rathman, D.D.; Silversmith, D.J.; Mountain, R.W.; DeGraff, P.D. Damage induced in Si by ion milling or reactive ion etching. J. Appl. Phys. 1983, 54, 3272. [Google Scholar] [CrossRef]

- Marty, F.; Rousseau, L.; Saadany, B.; Mercier, B.; Français, O.; Mita, Y.; Bourouina, T. Advanced etching of silicon based on deep reactive ion etching for silicon high aspect ratio microstructures and three-dimensional micro- and nanostructures. Microelectron. J. 2005, 36, 673–677. [Google Scholar] [CrossRef]

- Laermer, F.; Urban, A. Challenges, developments and applications of silicon deep reactive ion etching. Microelectron. Eng. 2003, 67–68, 349–355. [Google Scholar] [CrossRef]

- Choy, K.L. Chemical vapour deposition of coatings. Prog. Mater. Sci. 2003, 48, 57–170. [Google Scholar] [CrossRef]

- Helmersson, U.; Lattemann, M.; Bohlmark, J.; Ehiasarian, A.P.; Gudmundsson, J.T. Ionized physical vapor deposition (IPVD): A review of technology and applications. Thin Solid Films 2006, 513, 1–24. [Google Scholar] [CrossRef]

- Singh, J.; Wolfe, D.E. Nano and macro-structured component fabrication by electron beam-physical vapor deposition (EB-PVD). J. Mater. Sci. 2005, 40, 1–26. [Google Scholar] [CrossRef]

- Rossnagel, S.M. Metal ion deposition from ionized mangetron sputtering discharge. J. Vacuum Sci. Technol. B Microelectron. Nanometer Struct. 1994, 12, 449. [Google Scholar] [CrossRef]

- Lee, Y.I.; Park, K.H.; Lee, J.; Lee, C.S.; Yoo, H.J.; Kim, C.J.; Yoon, Y.S. Dry release for surface micromachining with hf vapor-phase etching. J. Microelectromech. Syst. 1997, 6, 226–233. [Google Scholar] [CrossRef]

- Loncar, M.; Doll, T.; Vuckovic, J.; Scherer, A. Design and fabrication of silicon photonic crystal optical waveguides. J. Lightwave Technol. 2000, 18, 1402–1411. [Google Scholar] [CrossRef]

- Jiang, Y.Q.; Jiang, W.; Gu, L.L.; Chen, X.N.; Chen, R.T. 80-micron interaction length silicon photonic crystal waveguide modulator. Appl. Phys. Lett. 2005, 87, 221105. [Google Scholar] [CrossRef]

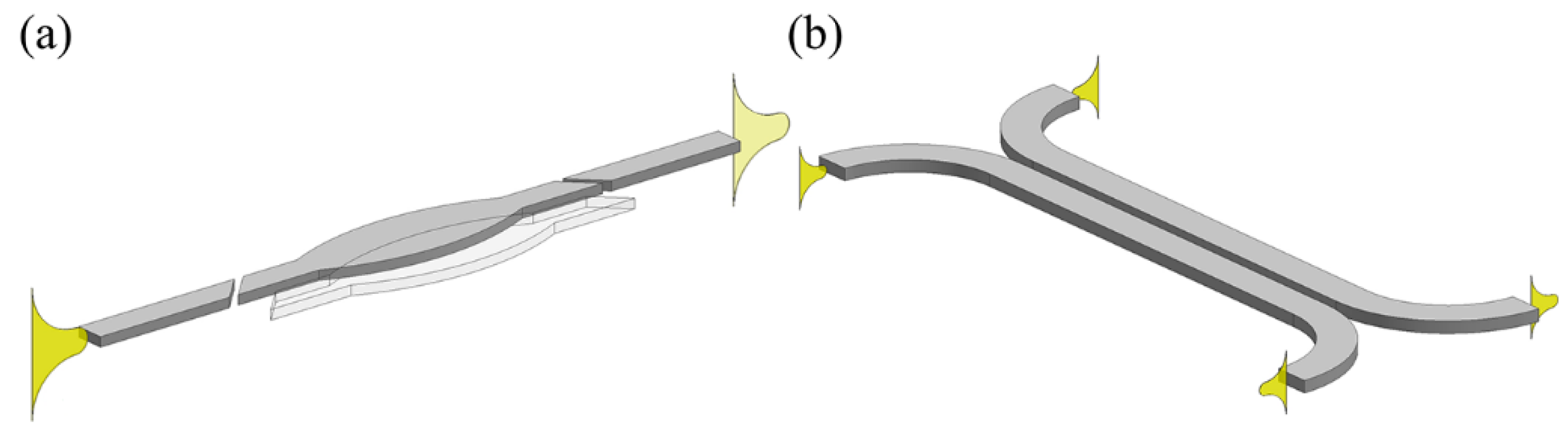

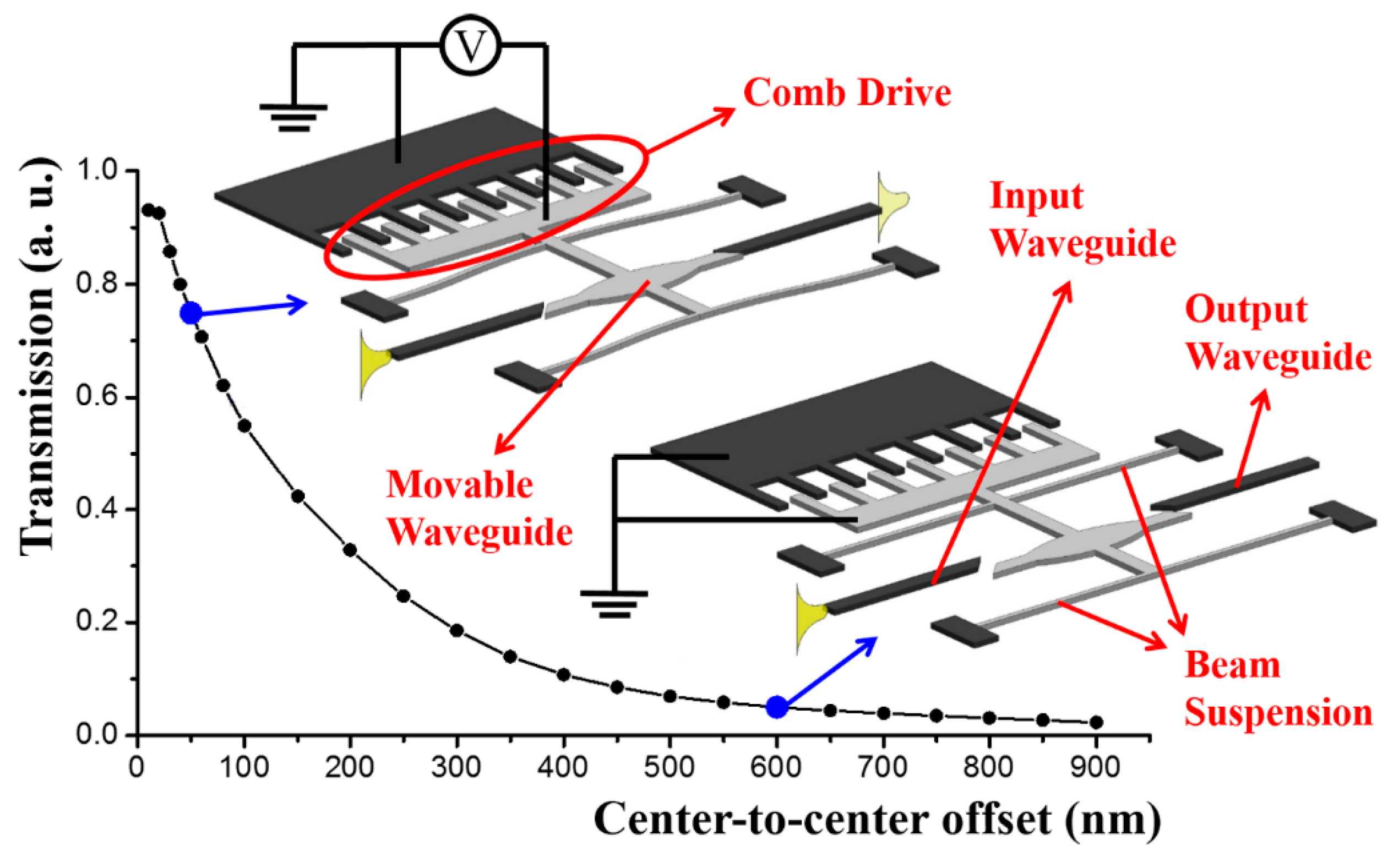

- Bulgan, E.; Kanamori, Y.; Hane, K. Submicron silicon waveguide optical switch driven by microelectromechanical actuator. Appl. Phys. Lett. 2008, 92, 101110. [Google Scholar] [CrossRef]

- Tang, W.C.; Nguyen, T.C.H.; Judy, M.W.; Howe, R.T. Electrostatic-comb drive of lateral polysilicon resonators. Sens. Actuators A Phys. 1990, 21, 328–331. [Google Scholar] [CrossRef]

- Tang, W.C.; Nguyen, T.C.H.; Howe, R.T. Laterally driven polysilicon resonant microstructures. Sens. Actuators 1989, 20, 25–32. [Google Scholar] [CrossRef]

- Legtenberg, R.; Groeneveld, A.W.; Elwenspoek, M. Comb-drive actuators for large displacements. J. Micromech. Microeng. 1996, 6, 320–329. [Google Scholar] [CrossRef]

- Li, M.; Pernice, W.H.P.; Tang, H.X. Broadband all-photonic transduction of nanocantilevers. Nat. Nanotechnol. 2009, 4, 377–382. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.B.; Zhou, G.Y.; Chew, X.Y.; Sinha, S.K.; Chau, F.S. Nano-tribometer integrated with a nano-photonic displacement-sensing mechanism. J. Micromech. Microeng. 2011, 21, 065014. [Google Scholar] [CrossRef]

- Lee, M.C.M.; Hah, D.Y.; Lau, E.K.; Toshiyoshi, H.; Wu, M. MEMS-actuated photonic crystal switches. IEEE Photonic Tech. Lett. 2006, 18, 358–360. [Google Scholar] [CrossRef]

- Mudachathi, R.; Nair, P. Low-voltage widely tunable photonic crystal channel drop filter in soi wafer. J. Microelectromech Syst. 2012, 21, 190–197. [Google Scholar] [CrossRef]

- Li, M.; Pernice, W.H.P.; Tang, H.X. Tunable bipolar optical interactions between guided lightwaves. Nat. Photonics 2009, 3, 464–468. [Google Scholar] [CrossRef]

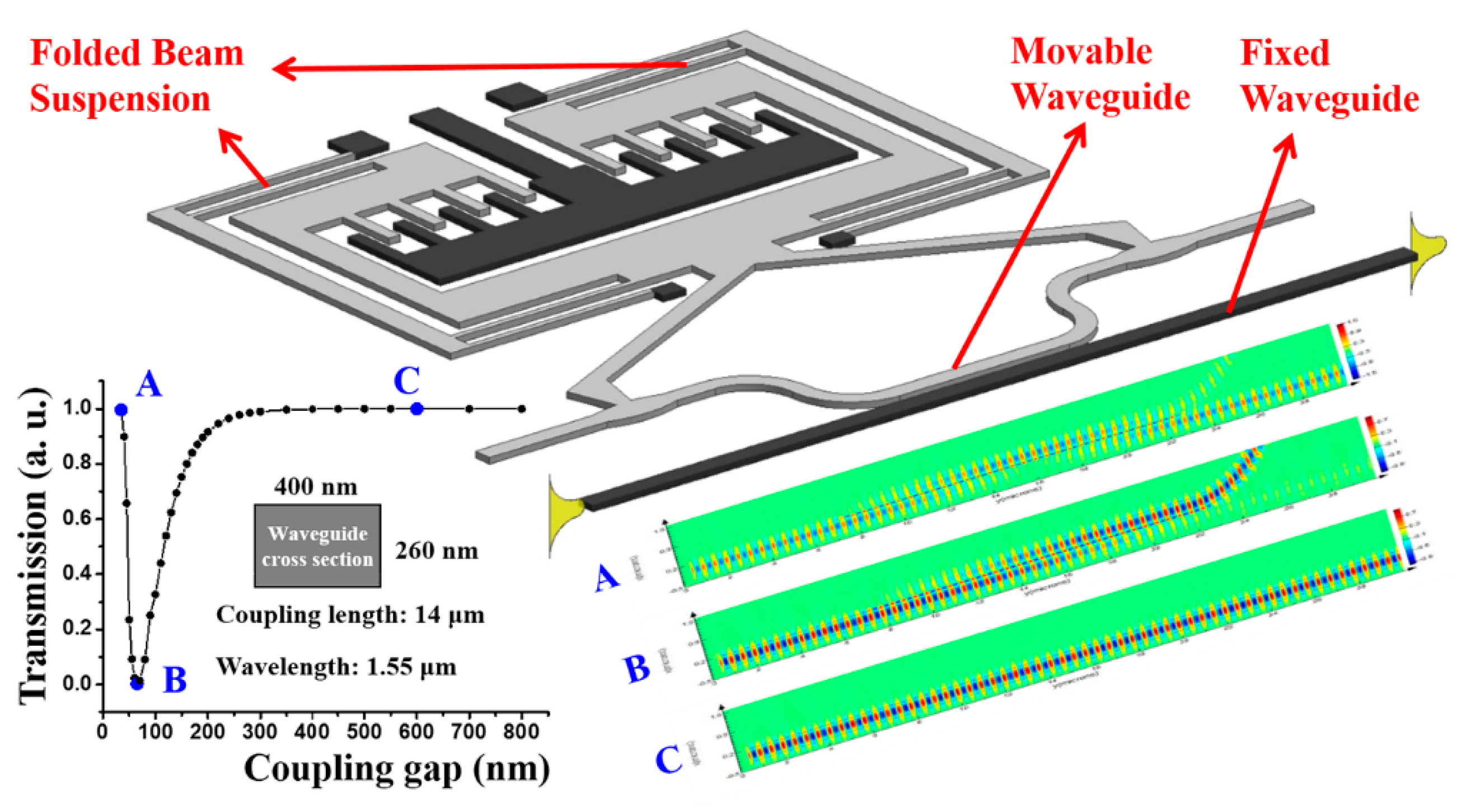

- Abe, S.; Hane, K. Variable-gap silicon photonic waveguide coupler switch with a nanolatch mechanism. IEEE Photonic Tech L 2013, 25, 675–677. [Google Scholar] [CrossRef]

- Akihama, Y.; Kanamori, Y.; Hane, K. Ultra-small silicon waveguide coupler switch using gap-variable mechanism. Opt. Express 2011, 19, 23658–23663. [Google Scholar] [CrossRef] [PubMed]

- Abe, S.; Chu, M.H.; Sasaki, T.; Hane, K. Time response of a microelectromechanical silicon photonic waveguide coupler switch. IEEE Photonic Tech. Lett. 2014, 26, 1553–1556. [Google Scholar] [CrossRef]

- Akihama, Y.; Hane, K. Single and multiple optical switches that use freestanding silicon nanowire waveguide couplers. Light Sci. Appl. 2012, 1, e16. [Google Scholar] [CrossRef]

- Akihama, Y.; Hane, K. An analytical coupling coefficient for MEMS tunable silicon nanowire waveguide coupler devices. Microsyst. Technol. 2013, 19, 583–589. [Google Scholar] [CrossRef]

- Munemasay, Y.; Hane, K. A compact 1 x 3 silicon photonic waveguide switch based on precise investigation of coupling characteristics of variable-gap coupler. Jpn. J. Appl. Phys. 2013, 52, 06GL15. [Google Scholar] [CrossRef]

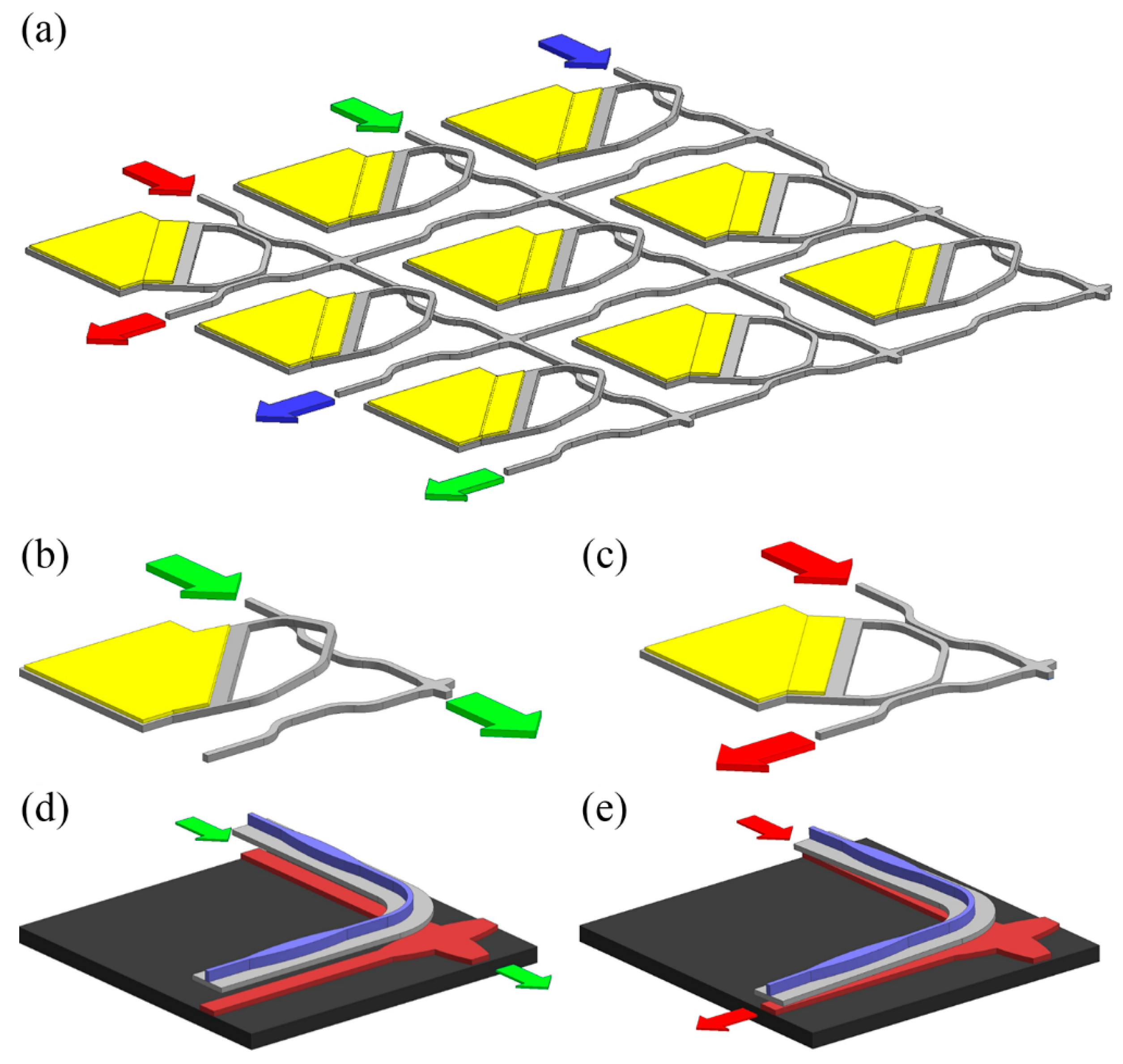

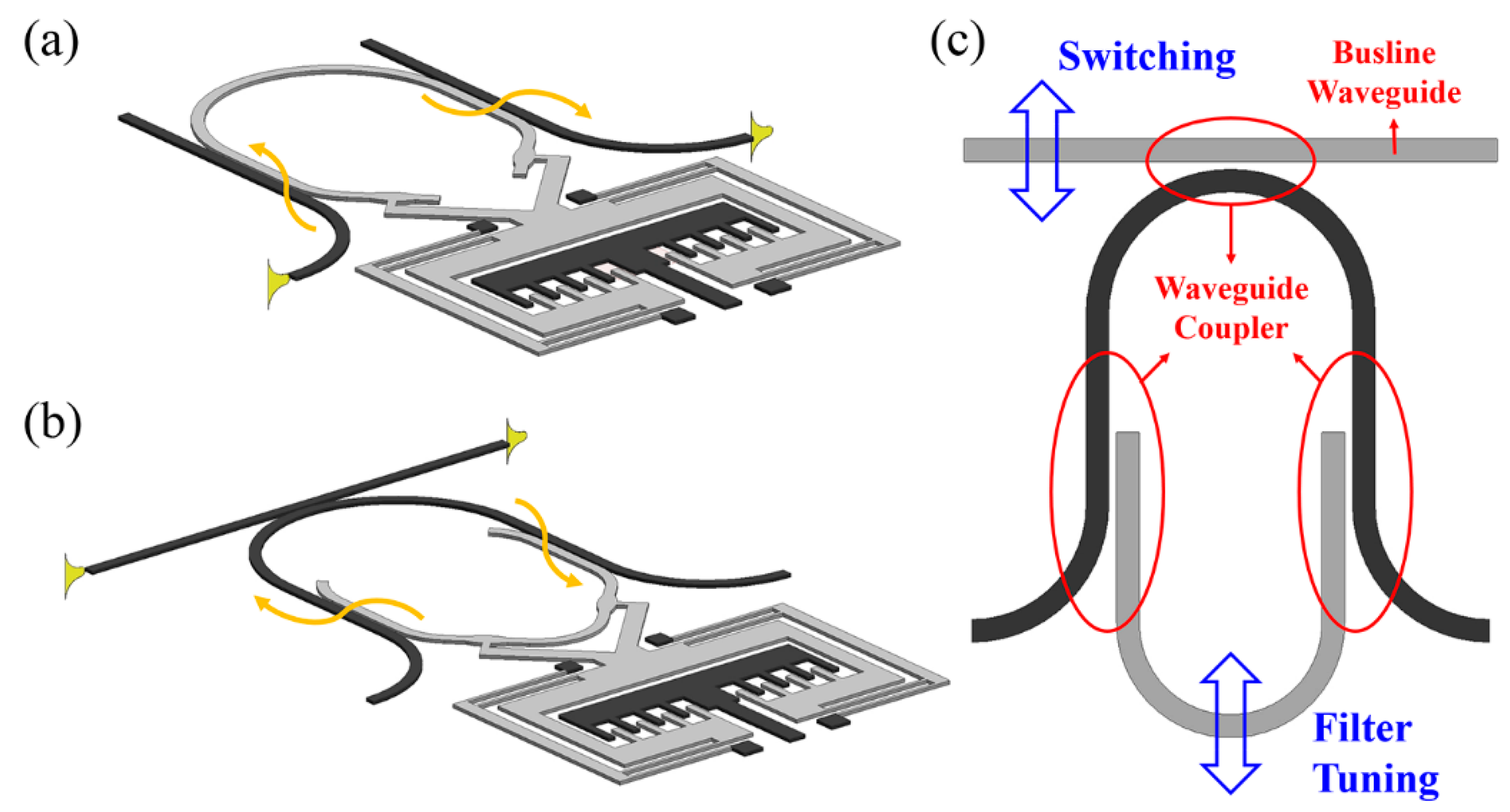

- Han, S.; Seok, T.J.; Quack, N.; Yoo, B.W.; Wu, M.C. Large-scale silicon photonic switches with movable directional couplers. Optica 2015, 2, 370–375. [Google Scholar] [CrossRef]

- Seok, T.J.; Quack, N.; Han, S.; Muller, R.S.; Wu, M.C. Large-scale broadband digital silicon photonic switches with vertical adiabatic couplers. Optica 2016, 3, 64. [Google Scholar] [CrossRef]

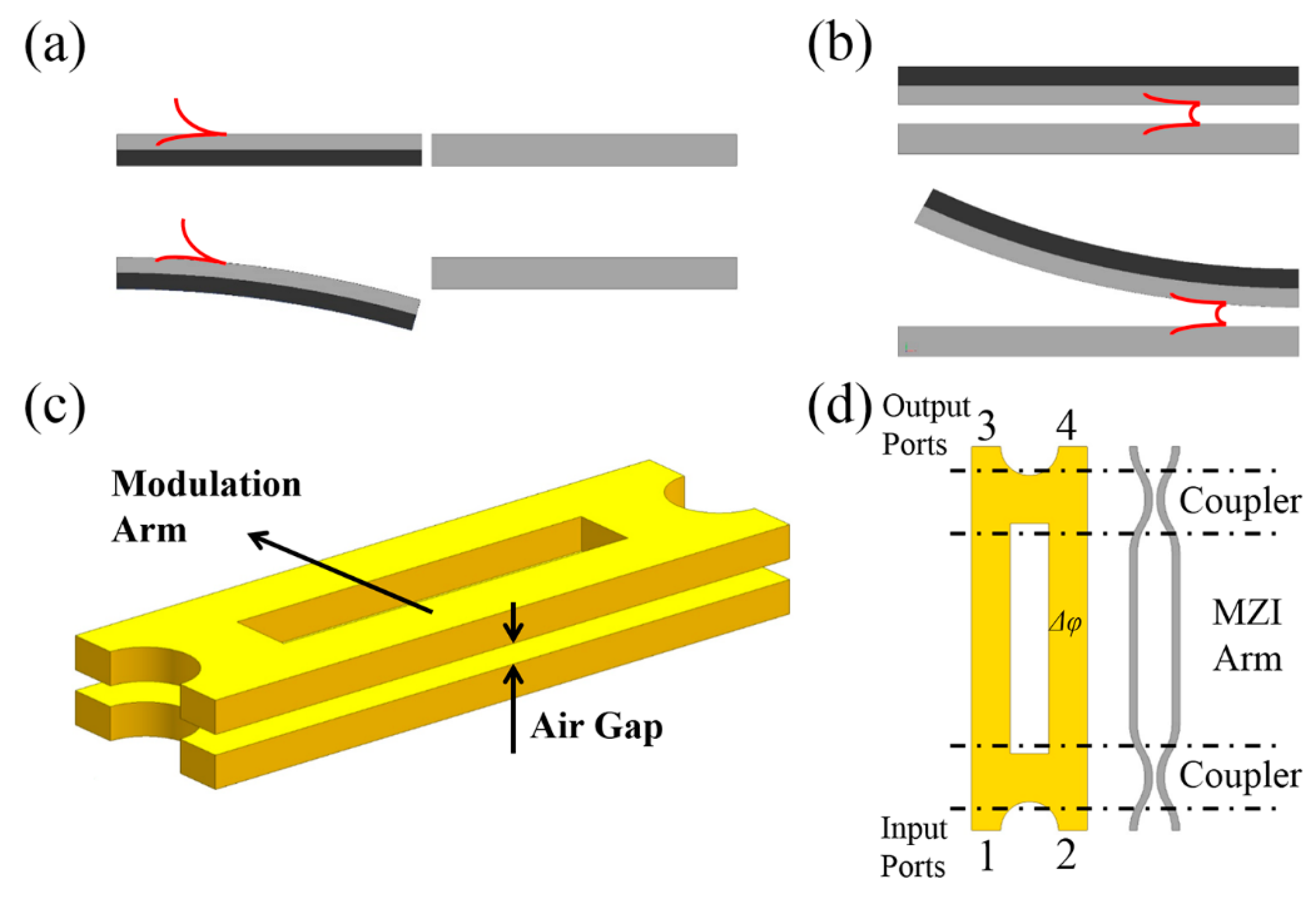

- Van Acoleyen, K.; Roels, J.; Mechet, P.; Claes, T.; Van Thourhout, D.; Baets, R. Ultracompact phase modulator based on a cascade of NEMS-operated slot waveguides fabricated in silicon-on-insulator. IEEE Photonics J. 2012, 4, 779–788. [Google Scholar] [CrossRef] [Green Version]

- Ikeda, T.; Takahashi, K.; Kanamori, Y.; Hane, K. Phase-shifter using submicron silicon waveguide couplers with ultra-small electro-mechanical actuator. Opt. Express 2010, 18, 7031–7037. [Google Scholar] [CrossRef] [PubMed]

- Ikeda, T.; Hane, K. A microelectromechanically tunable microring resonator composed of freestanding silicon photonic waveguide couplers. Appl. Phys. Lett. 2013, 102, 221113. [Google Scholar] [CrossRef]

- Chu, H.M.; Hane, K. A wide-tuning silicon ring-resonator composed of coupled freestanding waveguides. IEEE Photonic Tech. Lett. 2014, 26, 1411–1413. [Google Scholar] [CrossRef]

- Ikeda, T.; Hane, K. A tunable notch filter using microelectromechanical microring with gap-variable busline coupler. Opt. Express 2013, 21, 22034–22042. [Google Scholar] [CrossRef] [PubMed]

- Vahala, K.J. Optical microcavities. Nature 2003, 424, 839–846. [Google Scholar] [CrossRef] [PubMed]

- Abe, S.; Hane, K. A silicon microring resonator with a nanolatch mechanism. Microsyst. Technol. 2015, 21, 2019–2024. [Google Scholar] [CrossRef]

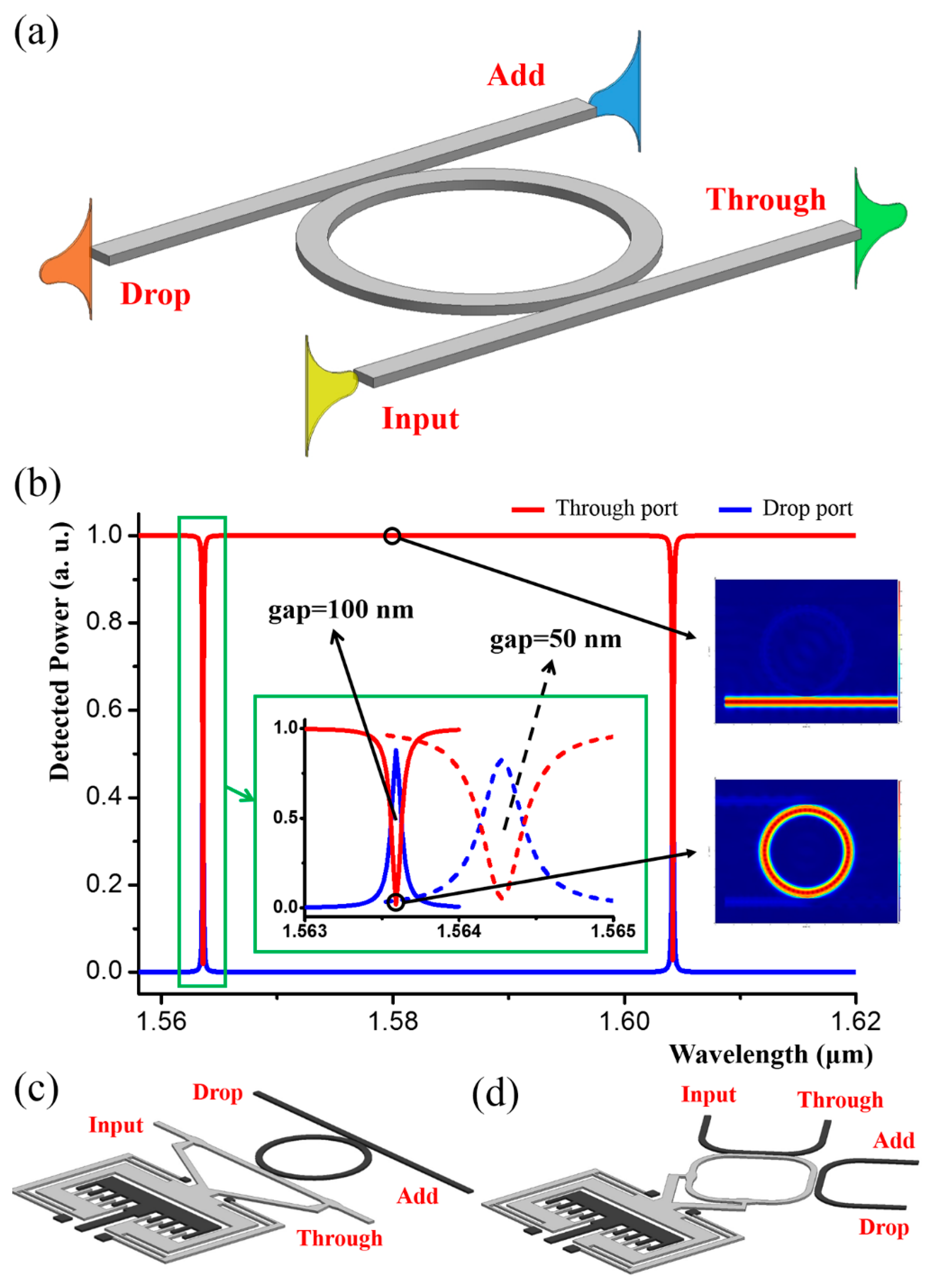

- Kanamori, Y.; Sato, Y.; Hane, K. Fabrication of silicon microdisk resonators with movable waveguides for control of power coupling ratio. Japn. J. Appl. Phys. 2013, 52, 06GL19. [Google Scholar] [CrossRef]

- Ordu, M.; Hane, K. Transmission-width-tunable silicon-photonic microelectromechanical ring resonator. IEEE Photonic Tech. Lett. 2013, 25, 2236–2238. [Google Scholar] [CrossRef]

- Takahashi, K.; Kanamori, Y.; Kokubun, Y.; Hane, K. A wavelength-selective add-drop switch using silicon microring resonator with a submicron-comb electrostatic actuator. Opt. Express 2008, 16, 14421–14428. [Google Scholar] [CrossRef] [PubMed]

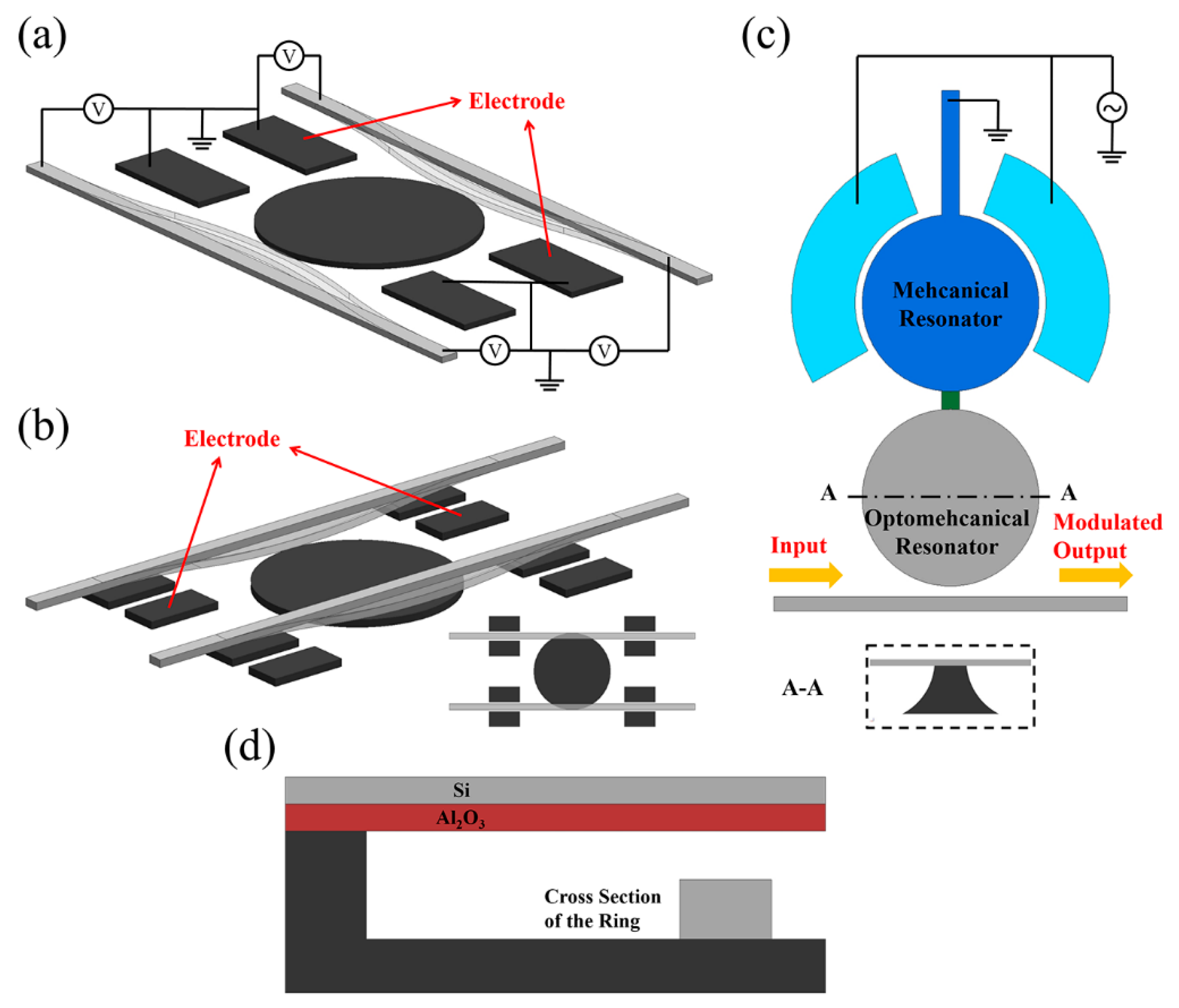

- Lee, M.C.M.; Wu, M.C. MEMS-actuated microdisk resonators with variable power coupling ratios. IEEE Photonic Tech. Lett. 2005, 17, 1034–1036. [Google Scholar] [CrossRef]

- Yao, J.; Leuenberger, D.; Lee, M.C.M.; Wu, M.C. Silicon microtoroidal resonators with integrated MEMS tunable coupler. IEEE J. Sel. Top. Quant. 2007, 13, 202–208. [Google Scholar] [CrossRef]

- Lee, M.C.M.; Wu, M.C. Tunable coupling regimes of silicon microdisk resonators using MEMS actuators. Opt. Express 2006, 14, 4703–4712. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.C.M.; Wu, M.C. Variable bandwidth of dynamic add-drop filters based on coupling-controlled microdisk resonators. Opt. Lett. 2006, 31, 2444–2446. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Leuenberger, D.; Lee, M.C.M.; Willner, A.E.; Wu, M.C. Experimental demonstration of dynamic bandwidth allocation using a MEMS-actuated bandwidth-tunable microdisk resonator filter. IEEE Photonic Tech. Lett. 2007, 19, 1508–1510. [Google Scholar] [CrossRef]

- Sridaran, S.; Bhave, S.A. Electrostatic actuation of silicon optomechanical resonators. Opt. Express 2011, 19, 9020–9026. [Google Scholar] [CrossRef] [PubMed]

- Tien, N.C. Silicon micromachined thermal sensors and actuators. Microscale Thermophys. Eng. 1997, 1, 275–292. [Google Scholar] [CrossRef]

- Guha, B.; Lipson, M. Controlling thermo-optic response in microresonators using bimaterial cantilevers. Opt. Lett. 2015, 40, 103–106. [Google Scholar] [CrossRef] [PubMed]

- Yablonovitch, E. Inhibited spontaneous emission in solid-state physics and electronics. Phys. Rev. Lett. 1987, 58, 2059–2062. [Google Scholar] [CrossRef] [PubMed]

- John, S. Strong localization of photons in certain disordered dielectric superlattices. Phys. Rev. Lett. 1987, 58, 2486–2489. [Google Scholar] [CrossRef] [PubMed]

- Thorhauge, M.; Frandsen, L.H.; Borel, P.I. Efficient photonic crystal directional couplers. Opt. Lett. 2003, 28, 1525–1527. [Google Scholar] [CrossRef] [PubMed]

- Akahane, Y.; Asano, T.; Song, B.S.; Noda, S. High-q photonic nanocavity in a two-dimensional photonic crystal. Nature 2003, 425, 944–947. [Google Scholar] [CrossRef] [PubMed]

- Song, B.S.; Noda, S.; Asano, T.; Akahane, Y. Ultra-high-q photonic double-heterostructure nanocavity. Nat. Mater. 2005, 4, 207–210. [Google Scholar] [CrossRef]

- Notomi, M.; Kuramochi, E.; Taniyama, H. Ultrahigh-Q nanocavity with 1D photonic gap. Opt. Express 2008, 16, 11095–11102. [Google Scholar] [CrossRef] [PubMed]

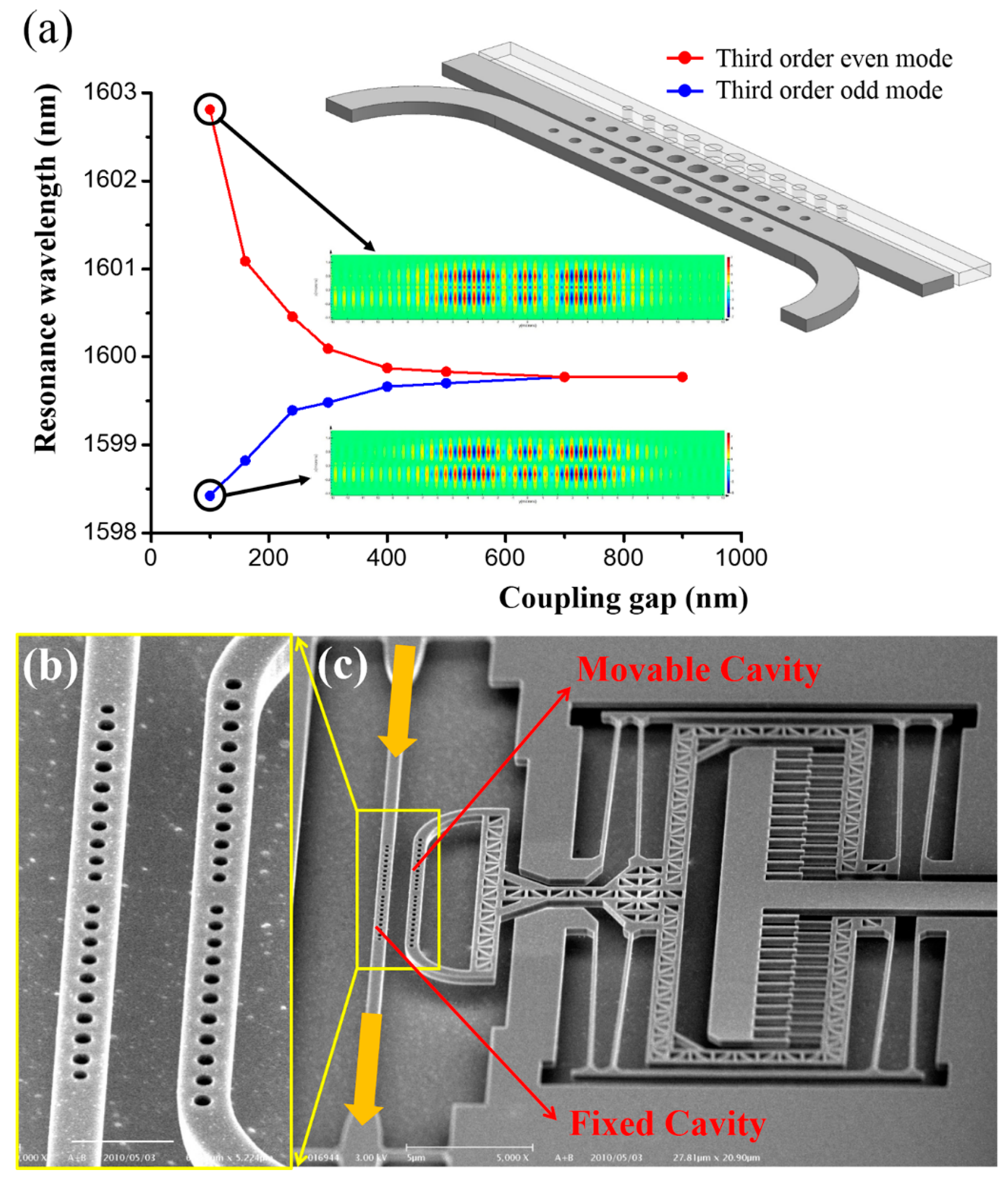

- Kanamori, Y.; Takahashi, K.; Hane, K. An ultrasmall wavelength-selective channel drop switch using a nanomechanical photonic crystal nanocavity. Appl. Phys. Lett. 2009, 95, 171911. [Google Scholar] [CrossRef]

- Hennessy, K.; Badolato, A.; Winger, M.; Gerace, D.; Atature, M.; Gulde, S.; Falt, S.; Hu, E.L.; Imamoglu, A. Quantum nature of a strongly coupled single quantum dot-cavity system. Nature 2007, 445, 896–899. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Lu, J.; Sun, C.P. Coherent control of photon transmission: Slowing light in a coupled resonator waveguide doped withλatoms. Phys. Rev. A 2007, 76, 012313. [Google Scholar] [CrossRef]

- Yanik, M.F.; Fan, S. Stopping light all optically. Phys. Rev. Lett. 2004, 92, 083901. [Google Scholar] [CrossRef] [PubMed]

- Mahnkopf, S.; Marz, R.; Kamp, M.; Duan, G.H.; Lelarge, F.; Forchel, A. Tunable photonic crystal coupled-cavity laser. IEEE J. Quantum Elect. 2004, 40, 1306–1314. [Google Scholar] [CrossRef]

- Pustai, D.M.; Sharkawy, A.; Shi, S.Y.; Prather, D.W. Tunable photonic crystal microcavities. Appl. Optics 2002, 41, 5574–5579. [Google Scholar] [CrossRef]

- Schmidt, B.; Xu, Q.F.; Shakya, J.; Manipatruni, S.; Lipson, M. Compact electro-optic modulator on silicon-on-insulator substrates using cavities with ultra-small modal volumes. Opt. Express 2007, 15, 3140–3148. [Google Scholar] [CrossRef] [PubMed]

- Abdulla, S.M.C.; Kauppinen, L.J.; Krijnen, G.J.M.; Ridder, R.M.d. Mechano-optical wavelength tuning in a photonic crystal microcavity with sub-1 V drive voltage. Opt. Lett. 2012, 37, 2010–2012. [Google Scholar] [CrossRef] [PubMed]

- Abdulla, S.M.C.; Kauppinen, L.J.; Dijkstra, M.; Berenschot, E.; de Boer, M.J.; de Ridder, R.M.; Krijnen, G.J.M. Mechano-optical switching in a MEMS integrated photonic crystal slab waveguide. In Proceedings of the IEEE 24th International Conference on Micro Electro Mechanical Systems (MEMS), Cancun, Mexico, 23–27 January 2011; pp. 9–12.

- Nielson, G.N.; Seneviratne, D.; Lopez-Royo, F.; Rakich, P.T.; Avrahami, Y.; Watts, M.R.; Haus, H.A.; Tuller, H.L.; Barbastathis, G. Integrated wavelength-selective optical MEMS switching using ring resonator filters. IEEE Photonic Tech. Lett. 2005, 17, 1190–1192. [Google Scholar] [CrossRef]

- Abdulla, S.M.C.; Kauppinen, L.J.; Dijkstra, M.; de Boer, M.J.; Berenschot, E.; Jansen, H.V.; de Ridder, R.M.; Krijnen, G.J.M. Tuning a racetrack ring resonator by an integrated dielectric MEMS cantilever. Opt. Express 2011, 19, 15864–15878. [Google Scholar] [CrossRef] [PubMed]

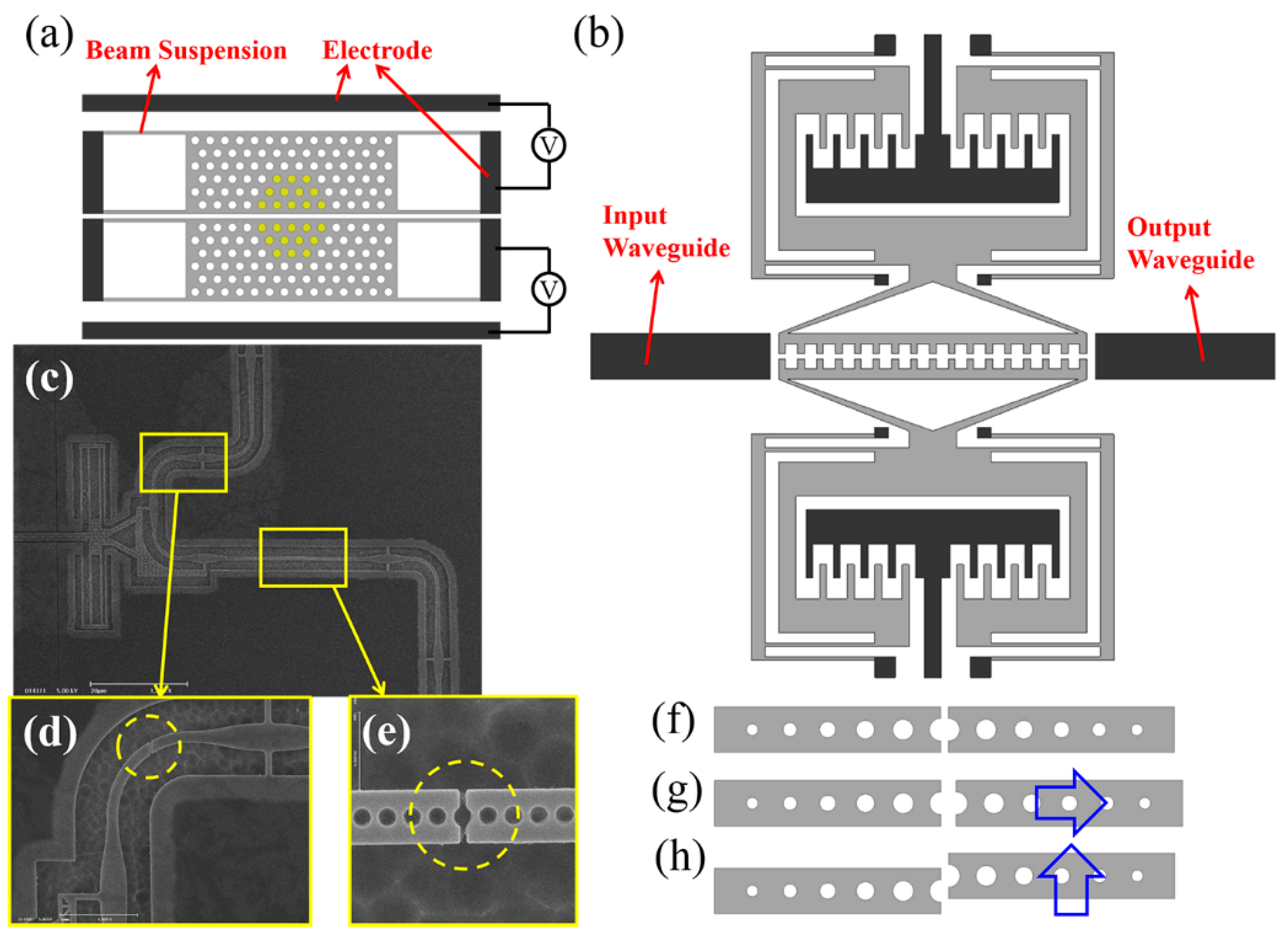

- Chew, X.Y.; Zhou, G.Y.; Yu, H.B.; Chau, F.S.; Deng, J.; Loke, Y.C.; Tang, X.S. An in-plane nano-mechanics approach to achieve reversible resonance control of photonic crystal nanocavities. Opt. Express 2010, 18, 22232–22244. [Google Scholar] [CrossRef] [PubMed]

- Chew, X.Y.; Zhou, G.Y.; Chau, F.S.; Deng, J. Enhanced resonance tuning of photonic crystal nanocavities by integration of optimized near-field multitip nanoprobes. J. Nanophotonics 2011, 5, 059503. [Google Scholar] [CrossRef]

- Poot, M.; Tang, H.X. Broadband nanoelectromechanical phase shifting of light on a chip. Appl. Phys. Lett. 2014, 104, 061101. [Google Scholar] [CrossRef]

- Chatterjee, R.; Wong, C.W. Nanomechanical proximity perturbation for switching in silicon-based directional couplers for high-density photonic integrated circuits. J. Microelectromech. Syst. 2010, 19, 657–662. [Google Scholar] [CrossRef]

- Sauer, V.T.K.; Diao, Z.; Freeman, M.R.; Hiebert, W.K. Nanophotonic detection of side-coupled nanomechanical cantilevers. Appl. Phys. Lett. 2012, 100, 261102. [Google Scholar] [CrossRef]

- Sauer, V.T.K.; Diao, Z.; Freeman, M.R.; Hiebert, W.K. Optical racetrack resonator transduction of nanomechanical cantilevers. Nanotechnology 2014, 25, 055202. [Google Scholar] [CrossRef] [PubMed]

- Basarir, O.; Bramhavar, S.; Ekinci, K.L. Motion transduction in nanoelectromechanical systems (NEMS) arrays using near-field optomechanical coupling. Nano Lett. 2012, 12, 534–539. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Wang, T.; Su, Y.K.; Yan, M.; Qiu, M. Coupled mode theory analysis of mode-splitting in coupled cavity system. Opt. Express 2010, 18, 8367–8382. [Google Scholar] [CrossRef] [PubMed]

- Frank, I.W.; Deotare, P.B.; McCutcheon, M.W.; Loncar, M. Programmable photonic crystal nanobeam cavities. Opt. Express 2010, 18, 8705–8712. [Google Scholar] [CrossRef] [PubMed]

- Midolo, L.; Yoon, S.N.; Pagliano, F.; Xia, T.; van Otten, F.W.M.; Lermer, M.; Hofling, S.; Fiore, A. Electromechanical tuning of vertically-coupled photonic crystal nanobeams. Opt. Express 2012, 20, 19255–19263. [Google Scholar] [CrossRef] [PubMed]

- Chew, X.Y.; Zhou, G.Y.; Chau, F.S.; Deng, J.; Tang, X.S.; Loke, Y.C. Dynamic tuning of an optical resonator through MEMS-driven coupled photonic crystal nanocavities. Opt. Lett. 2010, 35, 2517–2519. [Google Scholar] [CrossRef] [PubMed]

- Chew, X.; Zhou, G.Y.; Chau, F.S.; Deng, J. Nanomechanically tunable photonic crystal resonators utilizing triple-beam coupled nanocavities. IEEE Photonic Tech. Lett. 2011, 23, 1310–1312. [Google Scholar] [CrossRef]

- Tian, F.; Zhou, G.Y.; Chau, F.S.; Deng, J.; Akkipeddi, R. Measurement of coupled cavities' optomechanical coupling coefficient using a nanoelectromechanical actuator. Appl. Phys. Lett. 2013, 102, 081101. [Google Scholar] [CrossRef]

- Gao, J.; McMillan, J.F.; Wu, M.C.; Zheng, J.J.; Assefa, S.; Wong, C.W. Demonstration of an air-slot mode-gap confined photonic crystal slab nanocavity with ultrasmall mode volumes. Appl. Phys. Lett. 2010, 96, 051123. [Google Scholar] [CrossRef]

- Yamamoto, T.; Notomi, M.; Taniyama, H.; Kuramochi, E.; Yoshikawa, Y.; Torii, Y.; Kuga, T. Design of a high-q air-slot cavity based on a width-modulated line-defect in a photonic crystal slab. Opt. Express 2008, 16, 13809–13817. [Google Scholar] [CrossRef] [PubMed]

- Winger, M.; Blasius, T.D.; Alegre, T.P.M.; Safavi-Naeini, A.H.; Meenehan, S.; Cohen, J.; Stobbe, S.; Painter, O. A chip-scale integrated cavity-electro-optomechanics platform. Opt. Express 2011, 19, 24905–24921. [Google Scholar] [CrossRef] [PubMed]

- Pitanti, A.; Fink, J.M.; Safavi-Naeini, A.H.; Hill, J.T.; Lei, C.U.; Tredicucci, A.; Painter, O. Strong opto-electro-mechanical coupling in a silicon photonic crystal cavity. Opt. Express 2015, 23, 3196–3208. [Google Scholar] [CrossRef] [PubMed]

- Tian, F.; Zhou, G.Y.; Chau, F.S.; Deng, J.; Du, Y.; Tang, X.S.; Akkipeddi, R.; Loke, Y.C. Tuning of split-ladder cavity by its intrinsic nano-deformation. Opt. Express 2012, 20, 27697–27707. [Google Scholar] [CrossRef] [PubMed]

- Shi, P.; Du, H.; Chau, F.S.; Zhou, G.Y.; Deng, J. Tuning the quality factor of split nanobeam cavity by nanoelectromechanical systems. Opt. Express 2015, 23, 19338–19347. [Google Scholar] [CrossRef] [PubMed]

- Lin, T.; Tian, F.; Shi, P.; Chau, F.S.; Zhou, G.Y.; Tang, X.S.; Deng, J. Design of mechanically-tunable photonic crystal split-beam nanocavity. Opt. Lett. 2015, 40, 3504–3507. [Google Scholar] [CrossRef] [PubMed]

- Lin, T.; Zhang, X.W.; Zou, Y.C.; Chau, F.S.; Deng, J.; Zhou, G.Y. Out-of-plane nano-electro-mechanical tuning of the fano resonance in photonic crystal split-beam nanocavity. Appl. Phys. Lett. 2015, 107, 153107. [Google Scholar] [CrossRef]

- Boysel, R.M.; McDonald, T.G.; Magel, G.A.; Smith, G.C.; Leonard, J.L. Integration of deformable mirror devices with optical fibers and waveguides. Proc. SPIE 1993, 1793, 34–39. [Google Scholar]

- Magel, G.A. Integrated optic devices using micromachined metal membrane. Proc. SPIE 1996, 2686, 54–63. [Google Scholar]

- Hah, D.; Bordelon, J.; Zhang, D. Mechanically tunable optical filters with a microring resonator. Appl. Optics 2011, 50, 4320–4327. [Google Scholar] [CrossRef] [PubMed]

- Gramotnev, D.K.; Bozhevolnyi, S.I. Plasmonics beyond the diffraction limit. Nat. Photonics 2010, 4, 83–91. [Google Scholar] [CrossRef]

- Brolo, A.G. Plasmonics for future biosensors. Nat. Photonics 2012, 6, 709–713. [Google Scholar] [CrossRef]

- Anker, J.N.; Hall, W.P.; Lyandres, O.; Shah, N.C.; Zhao, J.; Van Duyne, R.P. Biosensing with plasmonic nanosensors. Nat. Mater. 2008, 7, 442–453. [Google Scholar] [CrossRef] [PubMed]

- Kosaka, P.M.; Pini, V.; Ruz, J.J.; da Silva, R.A.; Gonzalez, M.U.; Ramos, D.; Calleja, M.; Tamayo, J. Detection of cancer biomarkers in serum using a hybrid mechanical and optoplasmonic nanosensor. Nat. Nanotechnol. 2014, 9, 1047–1053. [Google Scholar] [CrossRef] [PubMed]

- Ozbay, E. Plasmonics: Merging photonics and electronics at nanoscale dimensions. Science 2006, 311, 189–193. [Google Scholar] [CrossRef] [PubMed]

- Holmgaard, T.; Chen, Z.; Bozhevolnyi, S.I.; Markey, L.; Dereux, A.; Krasavin, A.V.; Zayats, A.V. Wavelength selection by dielectric-loaded plasmonic components. Appl. Phys. Lett. 2009, 94, 051111. [Google Scholar] [CrossRef]

- Melikyan, A.; Alloatti, L.; Muslija, A.; Hillerkuss, D.; Schindler, P.C.; Li, J.; Palmer, R.; Korn, D.; Muehlbrandt, S.; Van Thourhout, D.; et al. High-speed plasmonic phase modulators. Nat. Photonics 2014, 8, 229–233. [Google Scholar] [CrossRef]

- Briggs, R.M.; Grandidier, J.; Burgos, S.P.; Feigenbaum, E.; Atwater, H.A. Efficient coupling between dielectric-loaded plasmonic and silicon photonic waveguides. Nano Lett. 2010, 10, 4851–4857. [Google Scholar] [CrossRef] [PubMed]

- Henzie, J.; Lee, J.; Lee, M.H.; Hasan, W.; Odom, T.W. Nanofabrication of plasmonic structures. Annu. Rev. Phys. Chem. 2009, 60, 147–165. [Google Scholar] [CrossRef] [PubMed]

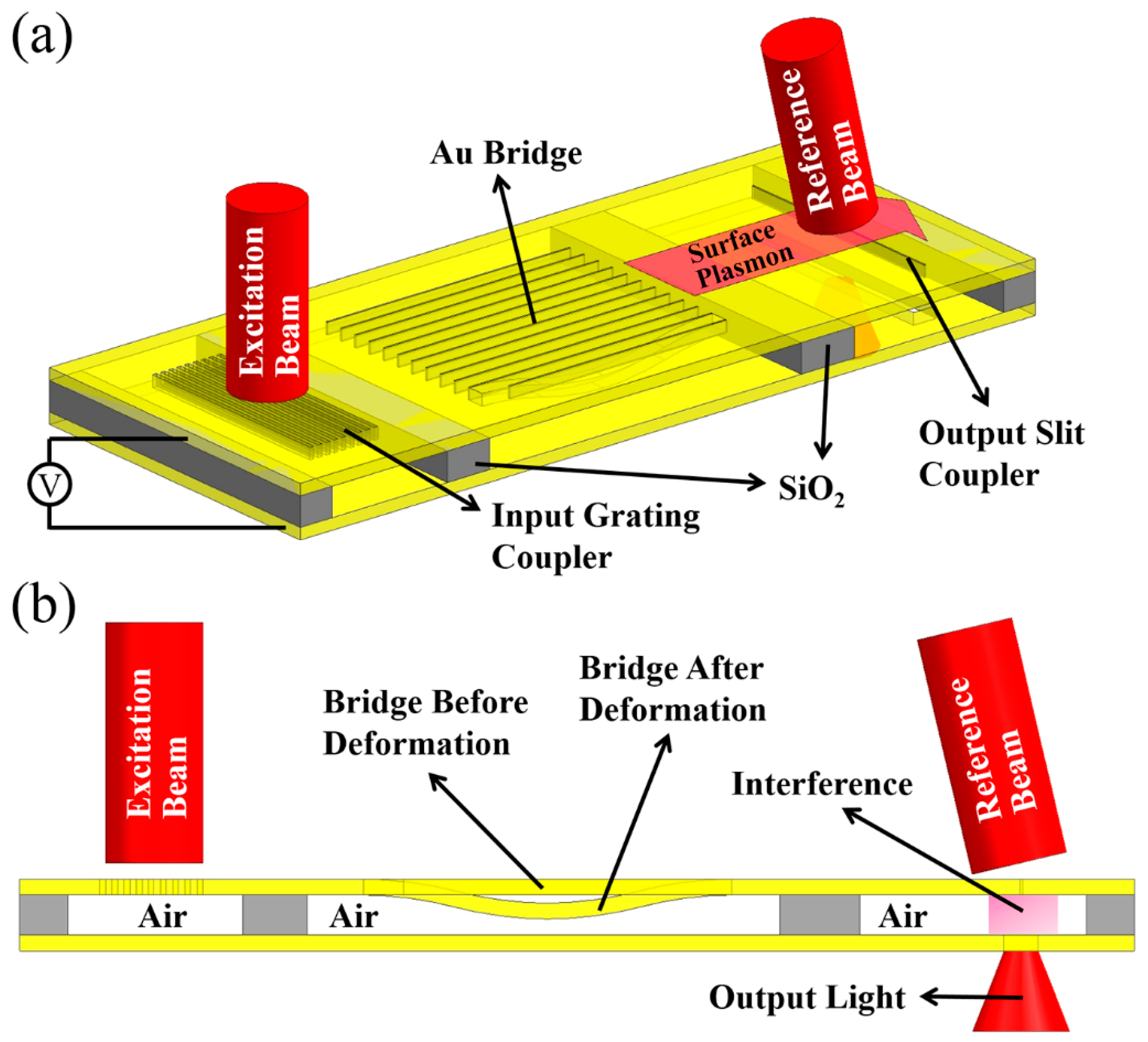

- Dennis, B.S.; Haftel, M.I.; Czaplewski, D.A.; Lopez, D.; Blumberg, G.; Aksyuk, V.A. Compact nanomechanical plasmonic phase modulators. Nat. Photonics 2015, 9, 267–273. [Google Scholar] [CrossRef]

- Pile, D.F.P.; Ogawa, T.; Gramotnev, D.K.; Matsuzaki, Y.; Vernon, K.C.; Yamaguchi, K.; Okamoto, T.; Haraguchi, M.; Fukui, M. Two-dimensionally localized modes of a nanoscale gap plasmon waveguide. Appl. Phys. Lett. 2005, 87, 261114. [Google Scholar] [CrossRef] [Green Version]

- Gramotnev, D.K.; Vernon, K.C.; Pile, D.F.P. Directional coupler using gap plasmon waveguides. Appl. Phys. B 2008, 93, 99–106. [Google Scholar] [CrossRef]

- Song, E.Y.; Cho, J.; Kim, H.; Choi, W.Y.; Lee, B. Double bi-material cantilever structures for complex surface plasmon modulation. Opt. Express 2015, 23, 5500–5507. [Google Scholar] [CrossRef] [PubMed]

- Aksyuk, V.A. Design and modeling of an ultra-compact 2x2 nanomechanical plasmonic switch. Opt. Express 2015, 23, 11404–11411. [Google Scholar] [CrossRef] [PubMed]

- Fedyanin, D.Y.; Arsenin, A.V. Transmission of surface plasmon polaritons through a nanowire array: Mechano-optical modulation and motion sensing. Opt. Express 2010, 18, 20115–20124. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Wang, S.M.; Cao, J.X.; Liu, H.; Zhu, S.N. Cavity-involved plasmonic metamaterial for optical polarization conversion. Appl. Phys. Lett. 2010, 97, 261113. [Google Scholar] [CrossRef]

- Hao, J.; Wang, J.; Liu, X.; Padilla, W.J.; Zhou, L.; Qiu, M. High performance optical absorber based on a plasmonic metamaterial. Appl. Phys. Lett. 2010, 96, 251104. [Google Scholar] [CrossRef]

- Ou, J.Y.; Plum, E.; Zhang, J.; Zheludev, N.I. An electromechanically reconfigurable plasmonic metamaterial operating in the near-infrared. Nat. Nanotechnol. 2013, 8, 252–255. [Google Scholar] [CrossRef] [PubMed]

- Liu, A.Q.; Zhu, W.M.; Tsai, D.P.; Zheludev, N.I. Micromachined tunable metamaterials: A review. J. Optics 2012, 14, 114009. [Google Scholar] [CrossRef]

- Zheludev, N.I.; Kivshar, Y.S. From metamaterials to metadevices. Nat. Mater. 2012, 11, 917–924. [Google Scholar] [CrossRef] [PubMed]

- Tao, H.; Padilla, W.J.; Zhang, X.; Averitt, R.D. Recent progress in electromagnetic metamaterial devices for terahertz applications. IEEE J. Sel. Top. Quant. 2011, 17, 92–101. [Google Scholar] [CrossRef]

- Boardman, A.D.; Grimalsky, V.V.; Kivshar, Y.S.; Koshevaya, S.V.; Lapine, M.; Litchinitser, N.M.; Malnev, V.N.; Noginov, M.; Rapoport, Y.G.; Shalaev, V.M. Active and tunable metamaterials. Laser Photonics Rev. 2011, 5, 287–307. [Google Scholar] [CrossRef]

- Roels, J.; De Vlaminck, I.; Lagae, L.; Maes, B.; Van Thourhout, D.; Baets, R. Tunable optical forces between nanophotonic waveguides. Nat. Nanotechnol. 2009, 4, 510–513. [Google Scholar] [CrossRef] [PubMed]

- Tian, F.; Zhou, G.Y.; Du, Y.; Chau, F.S.; Deng, J.; Tang, X.S.; Akkipeddi, R. Energy-efficient utilization of bipolar optical forces in nano-optomechanical cavities. Opt. Express 2013, 21, 18398–18407. [Google Scholar] [CrossRef] [PubMed]

- Deotare, P.B.; Bulu, I.; Frank, I.W.; Quan, Q.M.; Zhang, Y.N.; Ilic, R.; Loncar, M. All optical reconfiguration of optomechanical filters. Nat. Commun. 2012, 3, 846. [Google Scholar] [CrossRef] [PubMed]

- Rosenberg, J.; Lin, Q.; Painter, O. Static and dynamic wavelength routing via the gradient optical force. Nat. Photonics 2009, 3, 478–483. [Google Scholar] [CrossRef]

- Kippenberg, T.J.; Vahala, K.J. Cavity optomechanics: Back-action at the mesoscale. Science 2008, 321, 1172–1176. [Google Scholar] [CrossRef] [PubMed]

- Eichenfield, M.; Camacho, R.; Chan, J.; Vahala, K.J.; Painter, O. A picogram- and nanometre-scale photonic-crystal optomechanical cavity. Nature 2009, 459, 550–555. [Google Scholar] [CrossRef] [PubMed]

- Kippenberg, T.J.; Rokhsari, H.; Carmon, T.; Scherer, A.; Vahala, K.J. Analysis of radiation-pressure induced mechanical oscillation of an optical microcavity. Phys. Rev. Lett. 2005, 95, 033901. [Google Scholar] [CrossRef] [PubMed]

- Lin, Q.; Rosenberg, J.; Jiang, X.; Vahala, K.J.; Painter, O. Mechanical oscillation and cooling actuated by the optical gradient force. Phys. Rev. Lett. 2009, 103, 103601. [Google Scholar] [CrossRef] [PubMed]

- Teufel, J.D.; Donner, T.; Castellanos-Beltran, M.A.; Harlow, J.W.; Lehnert, K.W. Nanomechanical motion measured with an imprecision below that at the standard quantum limit. Nat. Nanotechnol. 2009, 4, 820–823. [Google Scholar] [CrossRef] [PubMed]

- Verlot, P.; Tavernarakis, A.; Briant, T.; Cohadon, P.F.; Heidmann, A. Backaction amplification and quantum limits in optomechanical measurements. Phys. Rev. Lett. 2010, 104, 133602. [Google Scholar] [CrossRef] [PubMed]

- Anetsberger, G.; Arcizet, O.; Unterreithmeier, Q.P.; Rivière, R.; Schliesser, A.; Weig, E.M.; Kotthaus, J.P.; Kippenberg, T.J. Near-field cavity optomechanics with nanomechanical oscillators. Nat. Phys. 2009, 5, 909–914. [Google Scholar] [CrossRef]

- Conti, L.; De Rosa, M.; Marin, F.; Taffarello, L.; Cerdonio, M. Room temperature gravitational wave bar detector with optomechanical readout. J. Appl. Phys. 2003, 93, 3589. [Google Scholar] [CrossRef]

- Ou, J.Y.; Plum, E.; Jiang, L.; Zheludev, N.I. Reconfigurable photonic metamaterials. Nano Lett. 2011, 11, 2142–2144. [Google Scholar] [CrossRef] [PubMed]

- Valente, J.; Ou, J.-Y.; Plum, E.; Youngs, I.J.; Zheludev, N.I. Reconfiguring photonic metamaterials with currents and magnetic fields. Appl. Phys. Lett. 2015, 106, 111905. [Google Scholar] [CrossRef]

- Tao, H.; Strikwerda, A.C.; Fan, K.; Padilla, W.J.; Zhang, X.; Averitt, R.D. Reconfigurable terahertz metamaterials. Phys. Rev. Lett. 2009, 103, 147401. [Google Scholar] [CrossRef] [PubMed]

- Tao, H.; Strikwerda, A.C.; Fan, K.; Padilla, W.J.; Zhang, X.; Averitt, R.D. MEMS based structurally tunable metamaterials at terahertz frequencies. J. Infrared Millimeter Terahertz Waves 2011, 32, 580–595. [Google Scholar] [CrossRef]

- Liu, X.; Padilla, W.J. Dynamic manipulation of infrared radiation with MEMS metamaterials. Adv. Opt. Mater. 2013, 1, 559–562. [Google Scholar] [CrossRef]

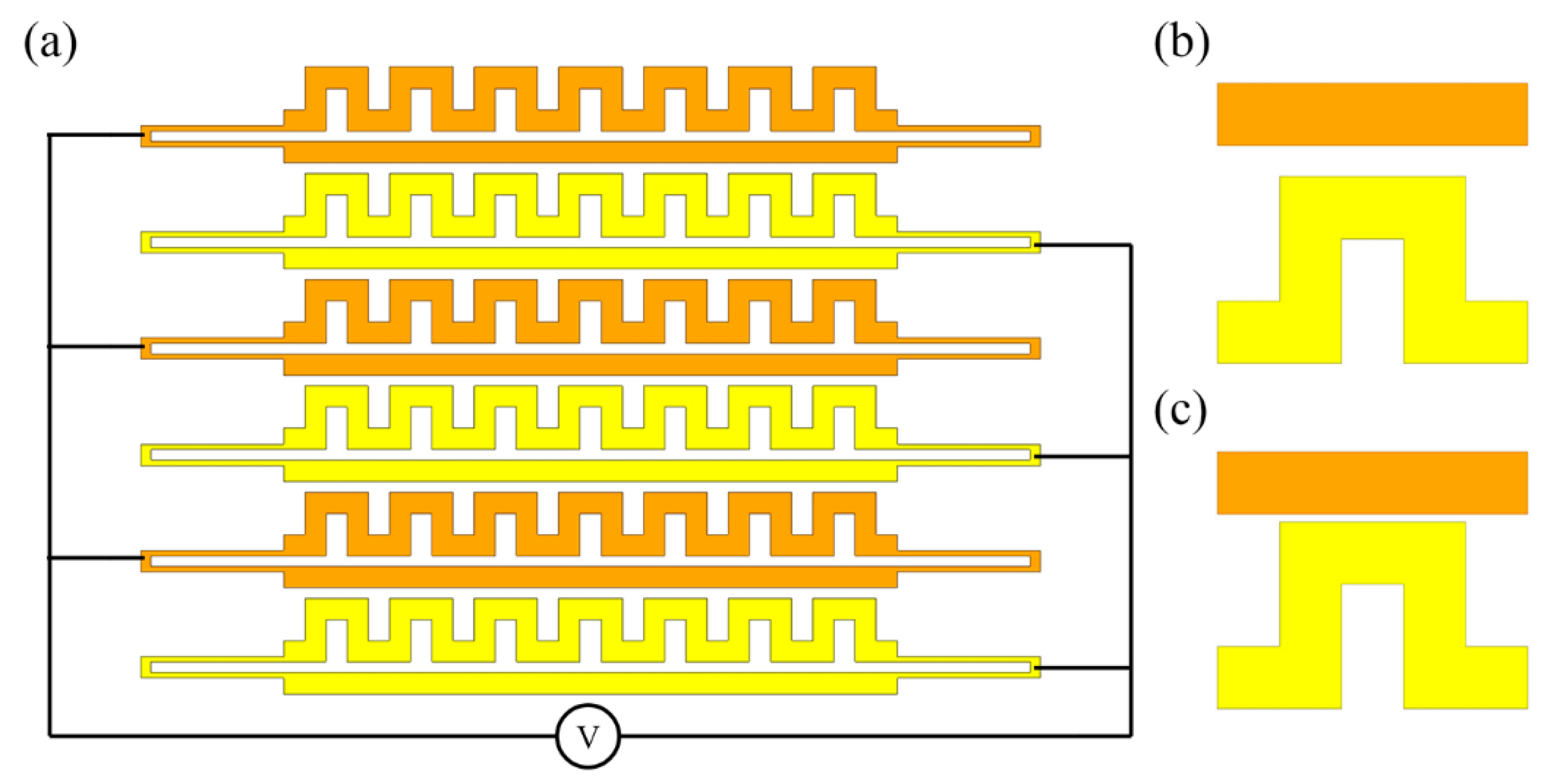

- Fu, Y.H.; Liu, A.Q.; Zhu, W.M.; Zhang, X.M.; Tsai, D.P.; Zhang, J.B.; Mei, T.; Tao, J.F.; Guo, H.C.; Zhang, X.H.; et al. A micromachined reconfigurable metamaterial via reconfiguration of asymmetric split-ring resonators. Adv. Funct. Mater. 2011, 21, 3589–3594. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, A.Q.; Zhu, W.M.; Li, E.P.; Tanoto, H.; Wu, Q.Y.; Teng, J.H.; Zhang, X.H.; Tsai, M.L.J.; Lo, G.Q.; et al. Micromachined switchable metamaterial with dual resonance. Appl. Phys. Lett. 2012, 101, 151902. [Google Scholar] [CrossRef]

- Zhang, W.; Zhu, W.M.; Cai, H.; Tsai, M.-L.J.; Lo, G.-Q.; Tsai, D.P.; Tanoto, H.; Teng, J.-H.; Zhang, X.-H.; Dim-Lee Kwong, F.; et al. Resonance switchable metamaterials using MEMS fabrications. IEEE J. Sel. Top. Quant. 2013, 19, 4700306. [Google Scholar] [CrossRef]

- Zhu, W.M.; Liu, A.Q.; Bourouina, T.; Tsai, D.P.; Teng, J.H.; Zhang, X.H.; Lo, G.Q.; Kwong, D.L.; Zheludev, N.I. Microelectromechanical maltese-cross metamaterial with tunable terahertz anisotropy. Nat. Commun. 2012, 3, 1274. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.M.; Liu, A.Q.; Zhang, X.M.; Tsai, D.P.; Bourouina, T.; Teng, J.H.; Zhang, X.H.; Guo, H.C.; Tanoto, H.; Mei, T.; et al. Switchable magnetic metamaterials using micromachining processes. Adv. Mater. 2011, 23, 1792–1796. [Google Scholar] [CrossRef] [PubMed]

- Ho, C.P.; Pitchappa, P.; Lin, Y.-S.; Huang, C.-Y.; Kropelnicki, P.; Lee, C. Electrothermally actuated microelectromechanical systems based omega-ring terahertz metamaterial with polarization dependent characteristics. Appl. Phys. Lett. 2014, 104, 161104. [Google Scholar] [CrossRef]

- Lin, Y.S.; Ma, F.; Lee, C. Three-dimensional movable metamaterial using electric split-ring resonators. Opt. Lett. 2013, 38, 3126–3128. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.-S.; Huang, C.-Y.; Lee, C. Reconfiguration of resonance characteristics for terahertz u-shape metamaterial using MEMS mechanism. IEEE J. Sel. Top. Quant. 2015, 21, 93–99. [Google Scholar]

- Lin, Y.-S.; Lee, C. Tuning characteristics of mirrorlike t-shape terahertz metamaterial using out-of-plane actuated cantilevers. Appl. Phys. Lett. 2014, 104, 251914. [Google Scholar] [CrossRef]

- Lin, Y.-S.; Qian, Y.; Ma, F.; Liu, Z.; Kropelnicki, P.; Lee, C. Development of stress-induced curved actuators for a tunable thz filter based on double split-ring resonators. Appl. Phys. Lett. 2013, 102, 111908. [Google Scholar] [CrossRef]

- Ma, F.; Lin, Y.-S.; Zhang, X.; Lee, C. Tunable multiband terahertz metamaterials using a reconfigurable electric split-ring resonator array. Light Sci. Appl. 2014, 3, e171. [Google Scholar] [CrossRef]

- Ma, F.; Qian, Y.; Lin, Y.-S.; Liu, H.; Zhang, X.; Liu, Z.; Ming-Lin Tsai, J.; Lee, C. Polarization-sensitive microelectromechanical systems based tunable terahertz metamaterials using three dimensional electric split-ring resonator arrays. Appl. Phys. Lett. 2013, 102, 161912. [Google Scholar] [CrossRef]

- Pitchappa, P.; Ho, C.P.; Cong, L.; Singh, R.; Singh, N.; Lee, C. Reconfigurable digital metamaterial for dynamic switching of terahertz anisotropy. Adv. Opt. Mater. 2016, 4, 391–398. [Google Scholar] [CrossRef]

- Pitchappa, P.; Ho, C.P.; Dhakar, L.; Lee, C. Microelectromechanically reconfigurable interpixelated metamaterial for independent tuning of multiple resonances at terahertz spectral region. Optica 2015, 2, 571. [Google Scholar] [CrossRef]

- Pitchappa, P.; Ho, C.P.; Qian, Y.; Dhakar, L.; Singh, N.; Lee, C. Microelectromechanically tunable multiband metamaterial with preserved isotropy. Sci. Rep. 2015, 5, 11678. [Google Scholar] [CrossRef] [PubMed]

- Pitchappa, P.; Pei Ho, C.; Kropelnicki, P.; Singh, N.; Kwong, D.-L.; Lee, C. Micro-electro-mechanically switchable near infrared complementary metamaterial absorber. Appl. Phys. Lett. 2014, 104, 201114. [Google Scholar] [CrossRef]

- Pitchappa, P.; Pei Ho, C.; Lin, Y.-S.; Kropelnicki, P.; Huang, C.-Y.; Singh, N.; Lee, C. Micro-electro-mechanically tunable metamaterial with enhanced electro-optic performance. Appl. Phys. Lett. 2014, 104, 151104. [Google Scholar] [CrossRef]

- Lapine, M.; Shadrivov, I.V.; Powell, D.A.; Kivshar, Y.S. Magnetoelastic metamaterials. Nat. Mater. 2012, 11, 30–33. [Google Scholar] [CrossRef] [PubMed]

- Matsui, T.; Liu, M.; Powell, D.A.; Shadrivov, I.V.; Kivshar, Y.S. Electromagnetic tuning of resonant transmission in magnetoelastic metamaterials. Appl. Phys. Lett. 2014, 104, 161117. [Google Scholar] [CrossRef]

| Metrics | Principle | Applications | Remarks | Reference | |

|---|---|---|---|---|---|

| Configurations | |||||

| Waveguide | Segmented | Transmission modulation | Switch | High extinction ratio | [30] |

| Motion detection | Moderate sensitivity | [35] | |||

| Coupled | Evanescent coupling | Switch | High extinction ratio | [39,40,41,42] | |

| Phase modulator | High operation speed by deforming waveguides | [47] | |||

| Wavelength tunable filter | Forming a ring resonator with adjustable round-trip length; low Q factor | [51] | |||

| Evanescent field perturbation | Proximity perturbation | Phase modulator | High operation speed | [84] | |

| Switch | Moderate extinction ratio | [85] | |||

| Switch, attenuator, or filter with non-monolithically integrated actuator | Complex fabrication process | [103,104] | |||

| Ring/Disk resonator | Add-drop filter with tunable gap between the resonator and channel waveguide | Coupling strength tuning; loss controlling | Switchable filter | Moderate extinction ratio | [53] |

| Bandwidth tunable filter | Moderate bandwidth tuning range with slight resonance wavelength variation | [55,58,60,61] | |||

| Switch | Moderate extinction ratio | [56] | |||

| Add-drop filter with evanescent field perturbation | Proximity perturbation | Switchable filter | High extinction ratio | [80] | |

| Wavelength tunable filter | Small tuning range | [81,105] | |||

| PhC cavity | Coupled | Mode splitting variation by tuning coupling strength | Resonance control for such as tunable filter or router | Wide tuning range of resonance wavelength, with drawbacks of split modes | [90,91,92,93] |

| 2D air-slot cavity | Cavity deformation | Dynamic optical signal processing | High operation speed | [97,98] | |

| Transversely split 1D cavity | Cavity deformation | Resonance control | Wide tuning range of resonance wavelength | [99] | |

| Longitudinally split 1D cavity | Cavity deformation | Q factor tuning | Wide Q factor tuning range with slight resonance wavelength variation | [100] | |

| Evanescent field perturbation | Proximity perturbation | Resonance control | Moderate tuning range of resonance wavelength, yet with energy loss induced by perturbation | [78,79,82,83] |

| Metrics | Tuning Range | Modulation Depth | Operation Speed | Reference | |

|---|---|---|---|---|---|

| Configurations & Actuation Methods | |||||

| MEMS/NEMS tunable Si photonic devices | Electrostatic | Moderate | High | Fast | Refer to Table 1 |

| MEMS/NEMS tunable plasmonic devices, for guided mode | Electrostatic | Moderate | High | Fast | [115] |

| Mechanically tunable metamaterials, for free-space light | Thermal | Moderate | High | Slow | [140,141,142,143] |

| Electrostatic | Wide | High | Moderate | [144,145,146,147,148,149,150,151,152,153,154,155,156,157,158,159,160,161] | |

| Magnetoelastic | Moderate | Low | Slow | [162,163] | |

| Chip-scale optomechanics | Driving with optical force | Small | Low | Ultra-fast | [133,134,135] |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, H.; Chau, F.S.; Zhou, G. Mechanically-Tunable Photonic Devices with On-Chip Integrated MEMS/NEMS Actuators. Micromachines 2016, 7, 69. https://doi.org/10.3390/mi7040069

Du H, Chau FS, Zhou G. Mechanically-Tunable Photonic Devices with On-Chip Integrated MEMS/NEMS Actuators. Micromachines. 2016; 7(4):69. https://doi.org/10.3390/mi7040069

Chicago/Turabian StyleDu, Han, Fook Siong Chau, and Guangya Zhou. 2016. "Mechanically-Tunable Photonic Devices with On-Chip Integrated MEMS/NEMS Actuators" Micromachines 7, no. 4: 69. https://doi.org/10.3390/mi7040069