1. Introduction

Facilitating the miniaturization of sensor and actuator components and their direct integration with conventional integrated circuits (ICs) is critical for emerging application areas, such as the internet of things (IoT) and wearable electronics. These applications frequently utilize components including micro electro-mechanical systems (MEMS) and imaging sensors that generally have to be capped to protect them from environmental influences such as dust or humidity. Encapsulation is typically one of the most expensive process steps in the entire device fabrication. An efficient and cost-effective capping process at the wafer-level is therefore crucial for the feasibility of a high-volume fabrication of MEMS and imaging components.

Existing capping methods typically rely on wafer bonding to join the device substrate with a capping substrate as a protection against influences from the environment. Wafer bonding has therefore become a key technology in the packaging of MEMS and imaging sensors [

1,

2]. Anodic bonding [

3], eutectic bonding [

4], and Si–Si direct bonding [

5] are among the most prevalent bonding methods in MEMS fabrication. However, these bonding technologies typically involve large thermal budgets and/or high voltages, and they typically require extremely flat bonding surfaces with low surface roughness, which makes these techniques challenging for use in some MEMS and imaging sensor applications. Thermocompression bonding of gold or copper films [

6,

7,

8] has been developed for hermetic encapsulation of vacuum cavities. Metallic thermocompression bonding is a versatile method for MEMS capping, although it typically requires a fairly large temperature budget to achieve high reliability. Adhesive wafer bonding [

1,

9] is a robust and low-cost process that is extensively used for capping and integration of optical sensors [

10,

11]. Various polymer adhesives that enable fairly low bonding temperatures and exceptional mechanical and chemical robustness have been developed. Most adhesives are transparent, which makes this bonding method well-suited for optical sensors and very cost-sensitive MEMS applications that do not require a fully hermetic package [

9,

12].

However, capping MEMS and optical devices without impeding their functionality typically requires selective adhesive bonding. Selective adhesive bonding describes a process in which only certain areas of the device wafer and the capping wafer are bonded, while other areas are left unbonded. This enables the encapsulation of MEMS and optical devices in sealed cavities, thus protecting them from environmental influences. Various approaches to selective adhesive bonding have been presented in the literature. Some of the more specialized approaches include localized laser heating [

13], localization of UV-curable adhesive by centrifugal spinning [

14], and transfer bonding of pre-formed benzocyclobutene (BCB) caps [

15]. More common approaches to selective adhesive bonding are based on patterning of photosensitive adhesives by photolithography, or masking and etching of non-photosensitive adhesives [

12,

16,

17,

18]. However, patterning by either photolithography or etching typically requires partial cross-linking of the polymer adhesive, for example by baking. Partial cross-linking before bonding lowers the resulting bond strength and bonding yield due to reduced re-flow behavior of the polymer adhesive [

18]. This creates a stringent trade-off between the capability of patterning the adhesive layer and the resulting bond strength; insufficient cross-linking renders the patterning of the polymer adhesive impossible, while excessive cross-linking compromises the bonding capability of the polymer adhesive. The result is a narrow process window, and thus a reduced robustness of the process. Other reported methods for the creation of patterned adhesive layers are local dispensing, screen printing, and stamp-printing [

9,

19,

20]. Dispensing and printing methods often suffer from poor layer thickness control, imprecise alignment, and limited resolution of the patterned adhesive layer. Furthermore, most of the mentioned capping methods using selective adhesive bonding substantially increase the process complexity and therefore result in increased fabrication costs.

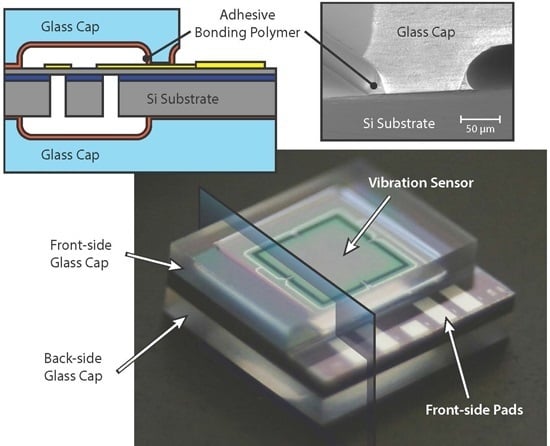

In this paper, we propose an extremely simple, robust, and cost-effective fabrication process for wafer-level capping of MEMS devices and imaging sensors by adhesive wafer bonding. In this process, a capping substrate with etched cavities covered by a thin layer of spray-coated polymer adhesive is bonded to the device substrate. No patterning of the adhesive is necessary. This ensures a uniform and pristine adhesive layer, which is otherwise not achievable with selective adhesive bonding approaches. Therefore, the proposed capping process provides excellent bonding yield and reduces the complexity and cost of the process. We demonstrate the capping process for two different MEMS devices: a vibration sensor and an acceleration switch. For these demonstrat ions, the thermosetting polymer benzocyclobutene (BCB) was used. BCB has a low bonding temperature of <250 °C which makes the proposed capping method fully compatible with complementary metal-oxide-semiconductor (CMOS) circuits.

2. Wafer-Level Capping Method

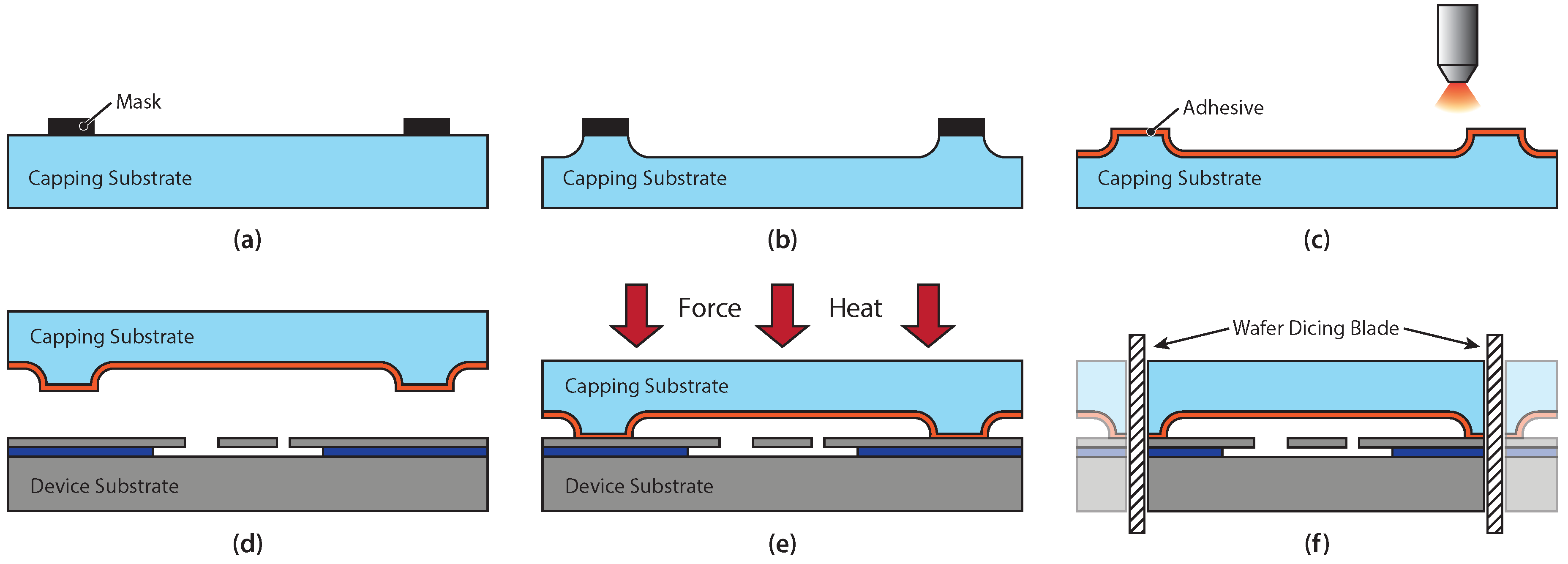

Our proposed capping method follows three basic fabrication steps, outlined in

Figure 1: first, preparation of the capping substrate and spray-coating of the adhesive polymer layer; second, adhesive wafer bonding; and last, die singulation to separate the wafer into single chips. The preparation of the capping substrate (shown in

Figure 1a–c) consists of patterning a mask, etching cavities, and applying a thin layer of polymer adhesive by spray-coating. In

Figure 1d,e, the capping substrate is aligned to a fully processed device substrate, containing the MEMS devices or imaging sensors, and subsequently bonded by applying the bonding force and heat to cure the polymer adhesive. As a final step, the devices are separated into individual chips by conventional wafer dicing, as indicated in

Figure 1f.

The capping process is designed such that the substrate preparation, which comprises the cavity formation and adhesive deposition, is performed entirely on the capping substrate. Therefore, no additional processing or preparation steps on the device substrate are required after the completed fabrication of the device to be capped. The simplicity and versatility of this capping method make it potentially interesting for a large number of MEMS and optical device applications.

In the following sections, we demonstrate the proposed method for the encapsulation of two different MEMS devices. For both demonstrations, BCB is used as the intermediate adhesive layer. However, the two different demonstrator devices are implemented utilizing two different electrical interconnection concepts, as discussed in

Section 2.3.

2.1. Materials for Demonstrator Device Fabrication

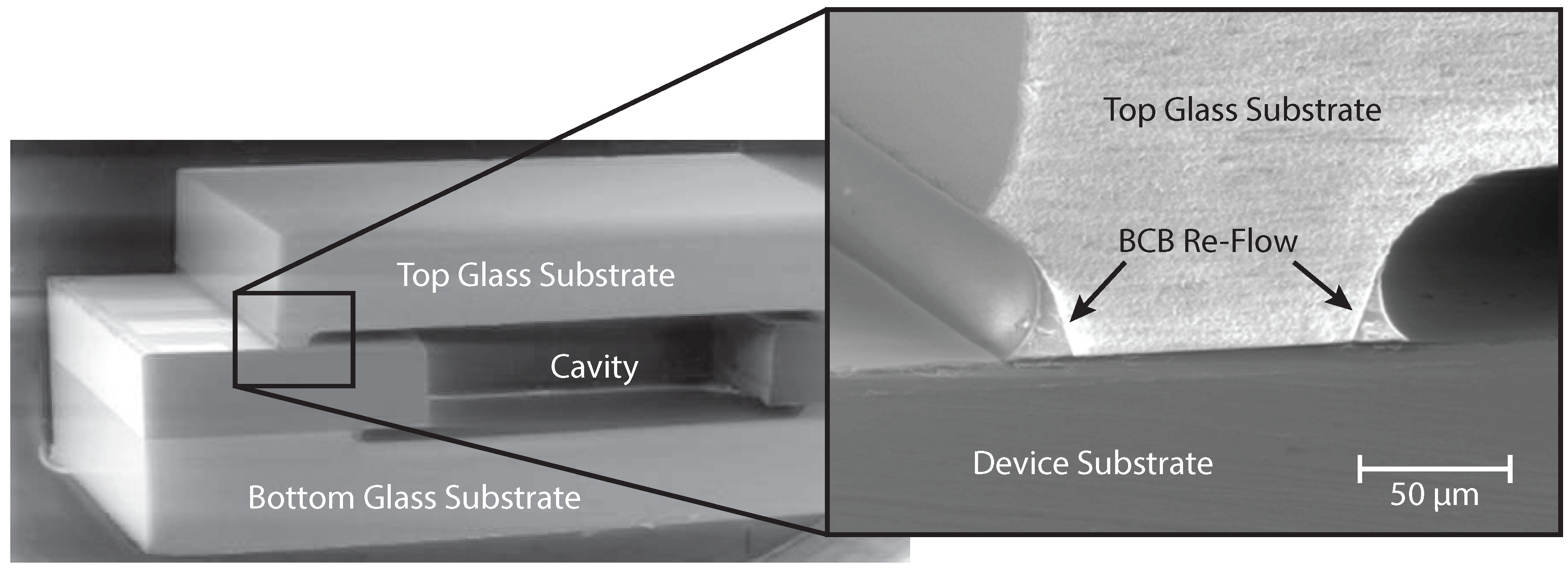

The capping process, as well as the choice of substrates and materials involved are specifically designed to be as simple, robust, and cost-effective as possible. For the two demonstrator devices, Borofloat 33 glass substrates were chosen for the capping wafers. Glass substrates are available at comparably low cost and can be easily processed by using, for example, hydrofluoric acid (HF) etching. Due to their transparent nature, glass substrates are also suitable as capping wafers for imaging sensors. In addition, glass capping substrates allow for visual inspection of the quality of the bond interface after the device encapsulation.

BCB (Cyclotene

3022-35, The Dow Chemical Company, Midland, MI, USA) was chosen as intermediate polymer adhesive due to its excellent mechanical stability, chemical inertness, and low curing temperature of

. BCB is highly transparent in the visible wavelength spectrum, with an optical transmittance of >99.63% for wavelengths above

[

21]. Furthermore, spray-coated and uncured BCB exhibits excellent re-flow capabilities and can easily compensate for wafer surface topographies during the wafer bonding step. During the curing process, BCB does not release any outgassing by-products, which lowers the risk of void formation and delamination at the bond interface [

9,

22]. After curing, BCB features a glass transition temperature of >350

and a very low moisture uptake of <0.2%, which ensures an excellent compatibility with a large variety of post-bonding processes. BCB is commercially available and widely used in the electronics and semiconductor industry.

BCB can be deposited at the wafer-level by spin-coating or spray-coating. Spin-coating offers a higher level of thickness control and uniformity than spray-coating. Thickness uniformity is, however, not crucial thanks to the re-flow ability of BCB. Spray-coating, on the other hand, uses smaller volumes of adhesive due to smaller material losses in the deposition process, and enables uniform coating of substrates with high surface topographies. Therefore, spray-coating was chosen to deposit the BCB on the capping substrate in order to minimize the material losses and optimize the cost-effectiveness of the presented capping method.

2.2. Fabrication Process for Demonstrator Devices

For both demonstrator devices, the preparation of the glass capping substrate starts with patterning a metal hard mask, defining the cavities by standard photolithography and metal etching, as shown in

Figure 1a. Metal combinations such as NiCr/Au or TiW/Au are suitable materials for the mask. The cavities are etched in 49% HF, which provides an etch rate of around

, as illustrated in

Figure 1b. The depth of the cavities can be easily adjusted in the range from a few hundred

to hundreds of

, depending on the requirements of the specific application. The deposition of the BCB adhesive by spray-coating is depicted in

Figure 1c. The uncured (i.e., not cross-linked) BCB used in this process has the ability to compensate for topography and particles due to its re-flow property, as long as the BCB layer thickness is larger than the topography or particle size. In this work, BCB layer thicknesses of

and

were used, which were achieved by manual spray-coating of diluted BCB with solvent ratios between 1:1 and 1:3 (T1100 rinse solvent, The Dow Chemical Company). The capping wafer is then baked on a hotplate at

for

to remove the solvents from the spray-coated BCB layer. It should be noted that this step does not initiate the cross-linking of the BCB polymer. Therefore, the BCB retains its full re-flow capability.

After the preparation of the capping substrate, both substrates are aligned and put into contact using a BA6 wafer bond aligner (Suss Microtec, Munich, Germany), as indicated in

Figure 1d. The device substrate contains fully fabricated MEMS structures, and no further preparations are required on the device substrate before the wafer bonding step. The bonding step, shown in

Figure 1e, is then performed in a Suss Microtec SB6 bonder. To reach the desired bonding condition, the chamber is evacuated to <500

, and the wafers are pre-heated to

for

for dehydration. Next, a bond force of

is applied, and the wafers are heated to a temperature of

for

, which completely cures the BCB. The total bond area is ∼4440

for the acceleration switch wafer and ∼5502

for the vibration sensor wafer, thus resulting in an effective bonding pressure of

and

, respectively. The bonded substrates are allowed to cool down inside the chamber prior to the extraction from the wafer bonder. As the final step after the bonding, the chips are separated by wafer dicing, as depicted in

Figure 1f.

2.3. Interconnection and Packaging Concepts

Most MEMS devices and imaging sensors require electrical connections from the inside of the encapsulated chip to the outside world. The electrical connection from within the encapsulation to a connection pad on the outside of the package can be established in two ways; either horizontal feed-throughs can be made that cross the bonded area, or alternatively, vertical through-silicon vias (TSVs) can be made that connect to a pad on the back-side of the substrate, thus avoiding crossing of the bonded area. The connection pads on the front or back-side of the chip are then coupled to the outside package by different integration schemes. Two of the most common integration schemes for chip-to-chip and chip-to-package interconnection are wire bonding and flip-chip bonding. Wire bonding is able to connect chips that are placed side-by-side or stacked on top of each other with an offset to reveal the underlying bond pads. Flip-chip bonding is based on vertical interconnection of stacked chips, which offers more compact integration and shorter signal lines; however, it typically increases the fabrication costs [

2].

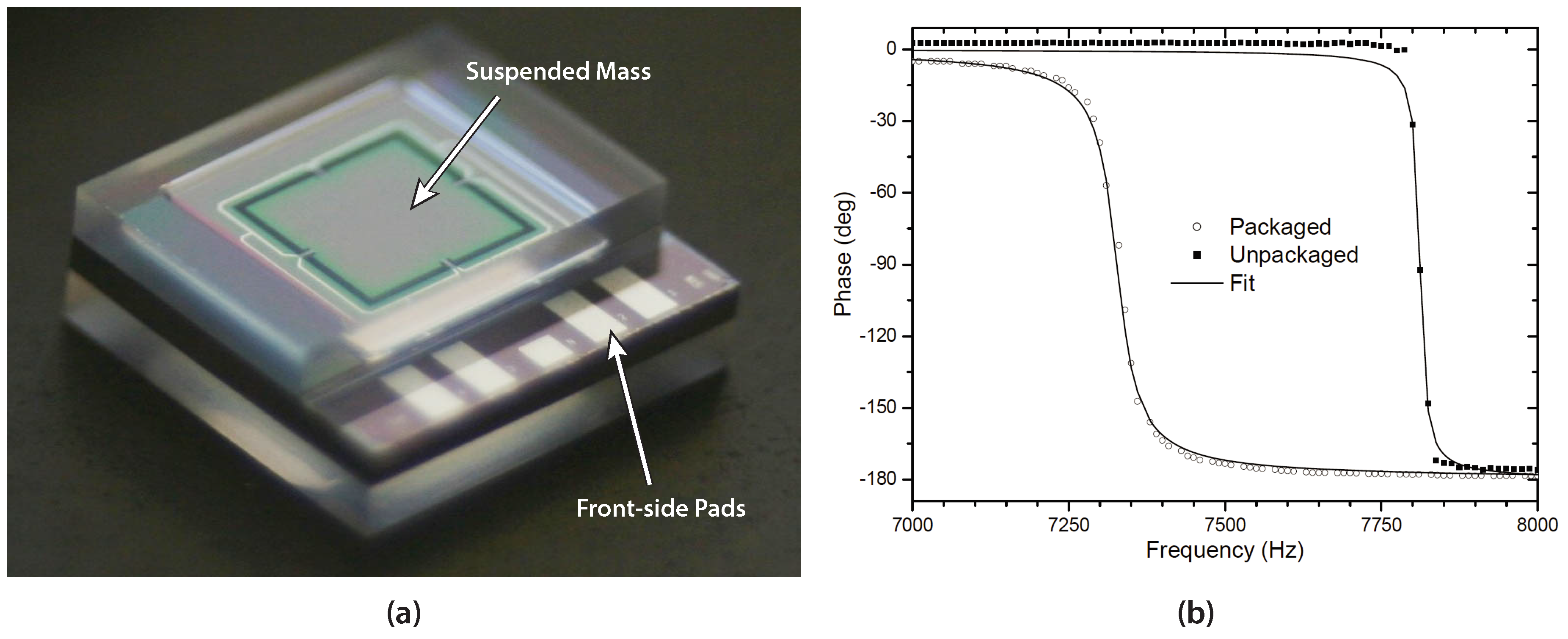

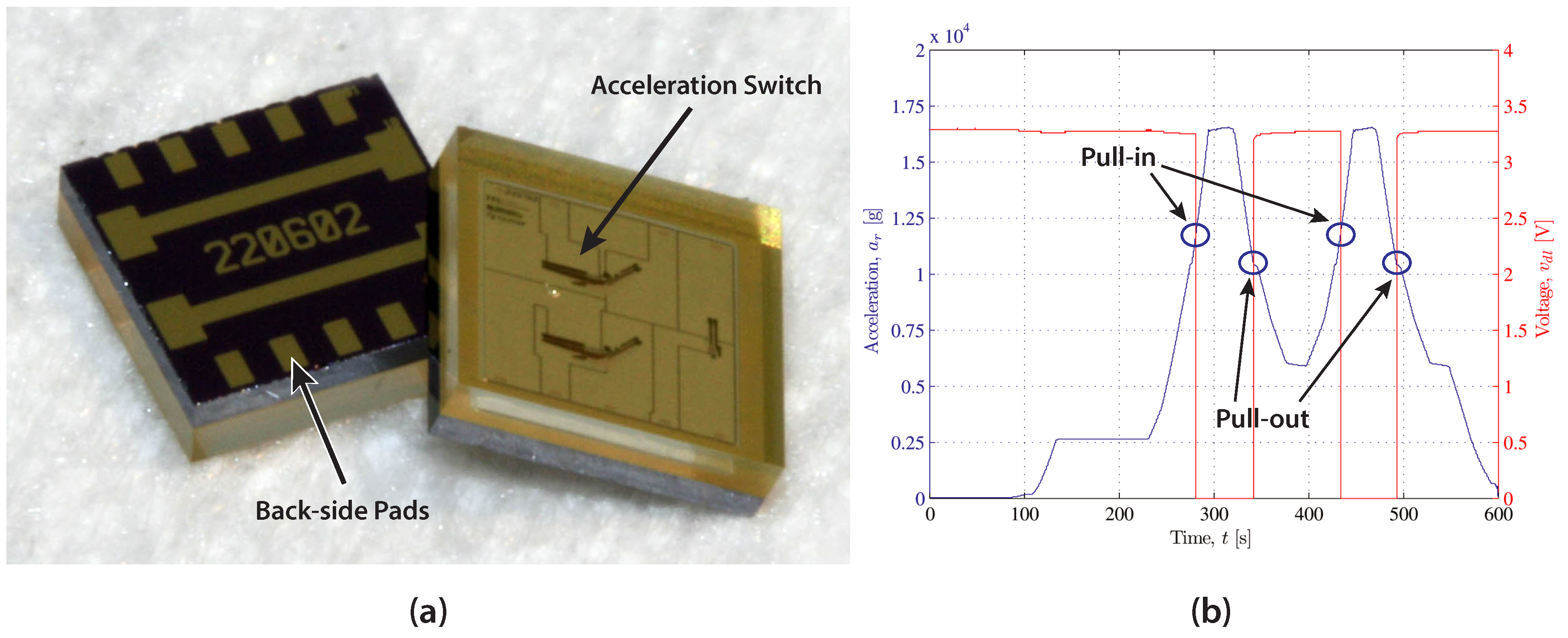

The presented capping method is compatible with both horizontal feed-throughs as well as vertical TSV connections, which is demonstrated in this paper by the integration and experimental verification of two different MEMS devices in fully functional packages. The capping method with horizontal feed-throughs is demonstrated by utilizing wire bonding integration, while the capping method with vertical TSVs is demonstrated by employing flip-chip integration [

22,

23]. A detailed schematic of the two interconnection approaches is depicted in a side-by-side comparison in

Figure 2. In both cases, the fabrication starts by establishing the electrical through-connections. The horizontal feed-through approach in

Figure 2a–d shows the deposition of a surface feed-through and front-side pad for later wire bonding in step (a). Next, the glass capping substrate is bonded to the device wafer, as indicated in

Figure 2b. This process step highlights the capability of capping the device substrate both on the front and back side, if required. To compensate for the topography of the surface feed-throughs passing through the bonded area, the chosen adhesive layer thickness has to be thicker than the metal layer. The front-side pad is then revealed by partial dicing that reaches just deep enough to cut through the glass lid, as illustrated in

Figure 2c. Due to the partial dicing, the surface feed-through approach requires deeper cavities on the order of 60 to

to ensure a sufficient margin for the precision of the dicing depth to avoid damaging the device substrate. The completed wafer is then separated into chips by wafer dicing, as shown in

Figure 2d.

The vertical TSV approach in

Figure 2e–h starts with the fabrication of the TSVs going through the entire device substrate, as depicted in

Figure 2e. The TSV fabrication is performed either before or after the MEMS fabrication, depending on the type of TSV used. Next, the glass capping wafer is bonded to the front-side of the device wafer, as shown in

Figure 2f. The back-side pads (depicted in

Figure 2g) are simply deposited on the back side of the substrate after the bonding step. Wafer dicing is employed to separate the completed wafer into individual chips, as indicated in

Figure 2h. Finally, the system integration of both the horizontal feed-through and the TSV capping approach is completed by connecting the chips to the package by wire bonding or flip-chip bonding, respectively.

4. Conclusions

A simple and cost-effective wafer-level capping method for MEMS and imaging sensors has been presented in this paper. The key advantages of this method over alternative packaging approaches are that it does not require any surface processing or structural preparation on the device substrate, and that no patterning of the adhesive polymer is necessary. Therefore, non-photosensitive adhesives can be used, which lowers the process complexity and fabrication costs. A low bonding temperature of ensures full compatibility for capping of CMOS wafers. The excellent mechanical and chemical stability of the bonding polymer enables a large variety of post-bonding fabrication processes. Additionally, the near-perfect optical transparency of BCB combined with the thinness of the deposited layer make this capping method very well suited for optical applications. The presented capping method was demonstrated by encapsulating MEMS vibration sensors and MEMS accelerations switches, using two separate approaches to create electrical interconnections from inside the cavity to the outside world. The experimental measurements confirm correct operation of both types of devices, integrated by both wire bonding and flip-chip bonding. Further analysis showed that the capping process does not introduce any significant mechanical stress to the devices and achieves a consistent bond strength of >20–30 . Thus, the demonstrated capping method is a very attractive approach for low-cost encapsulation of a variety of devices, including MEMS and imaging sensors.

As possible future work, a more detailed study of the sealing ring geometry could be envisioned. Optimizing the sealing ring width and minimizing the necessary clearance to the encapsulated device structure would allow for smaller device footprints and higher integration density.