A Disposable Dispensing Valve for Non-Contact Microliter Applications in a 96-Well Plate Format †

Abstract

:1. Introduction

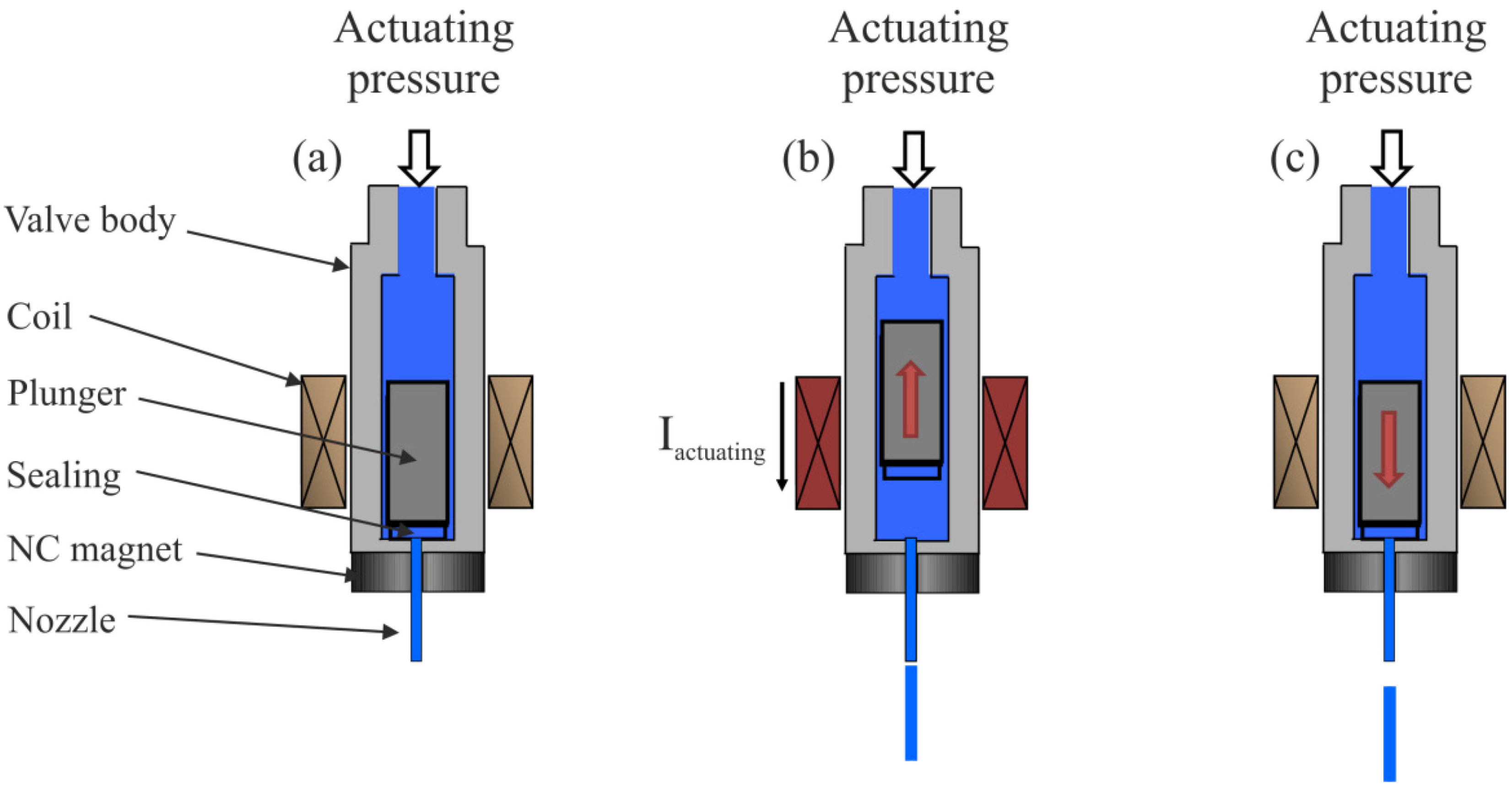

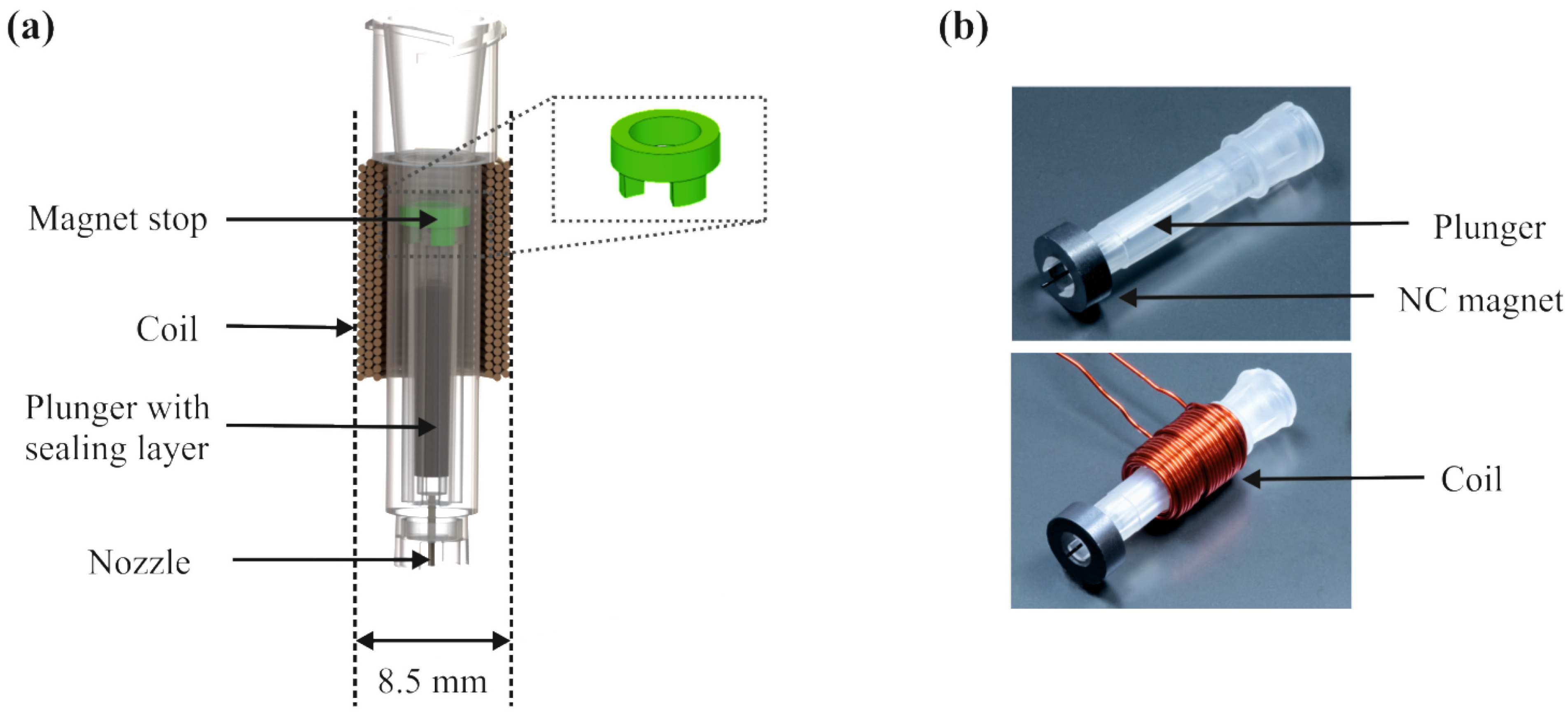

2. Miniaturization Process

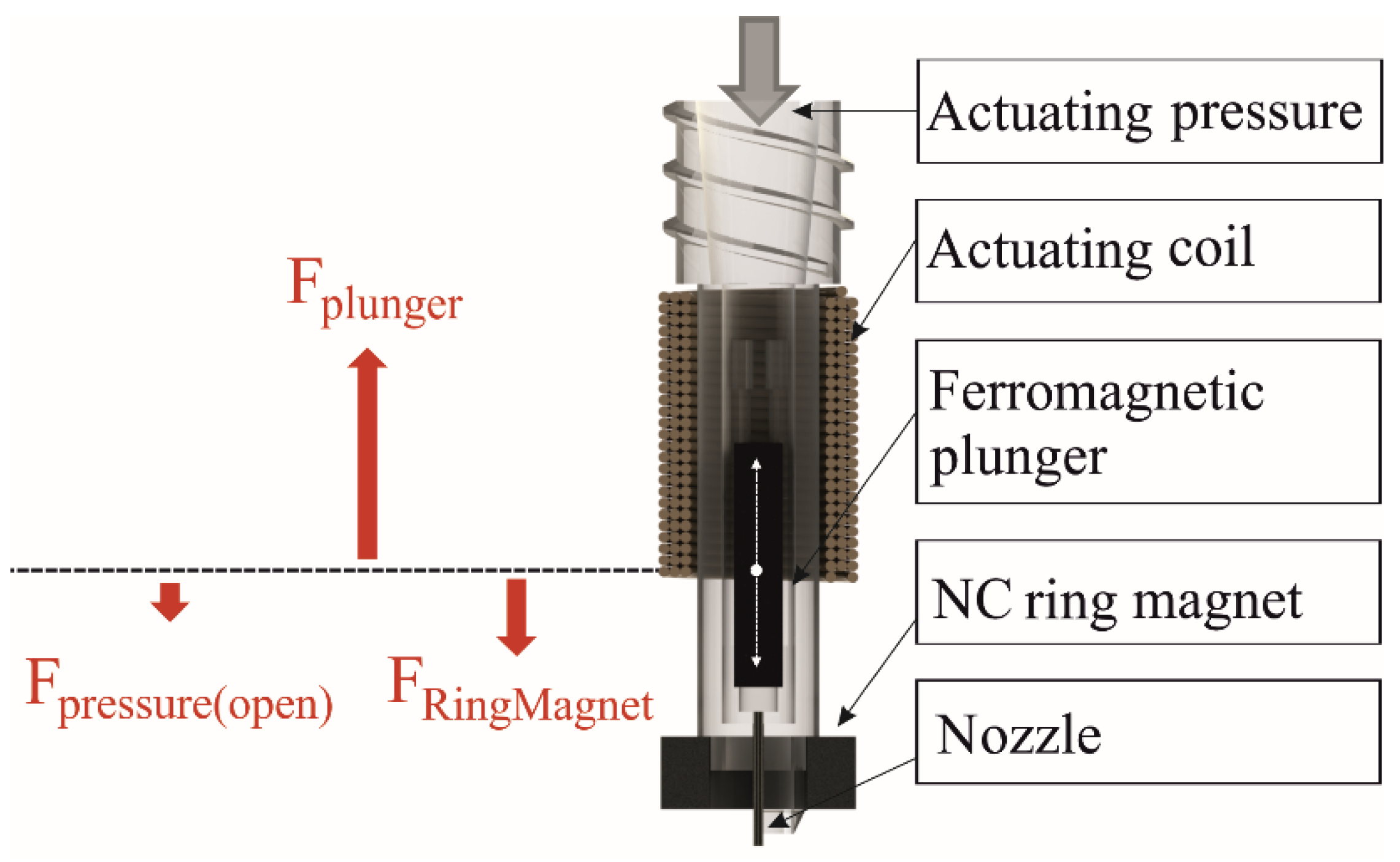

2.1. Main Acting Forces

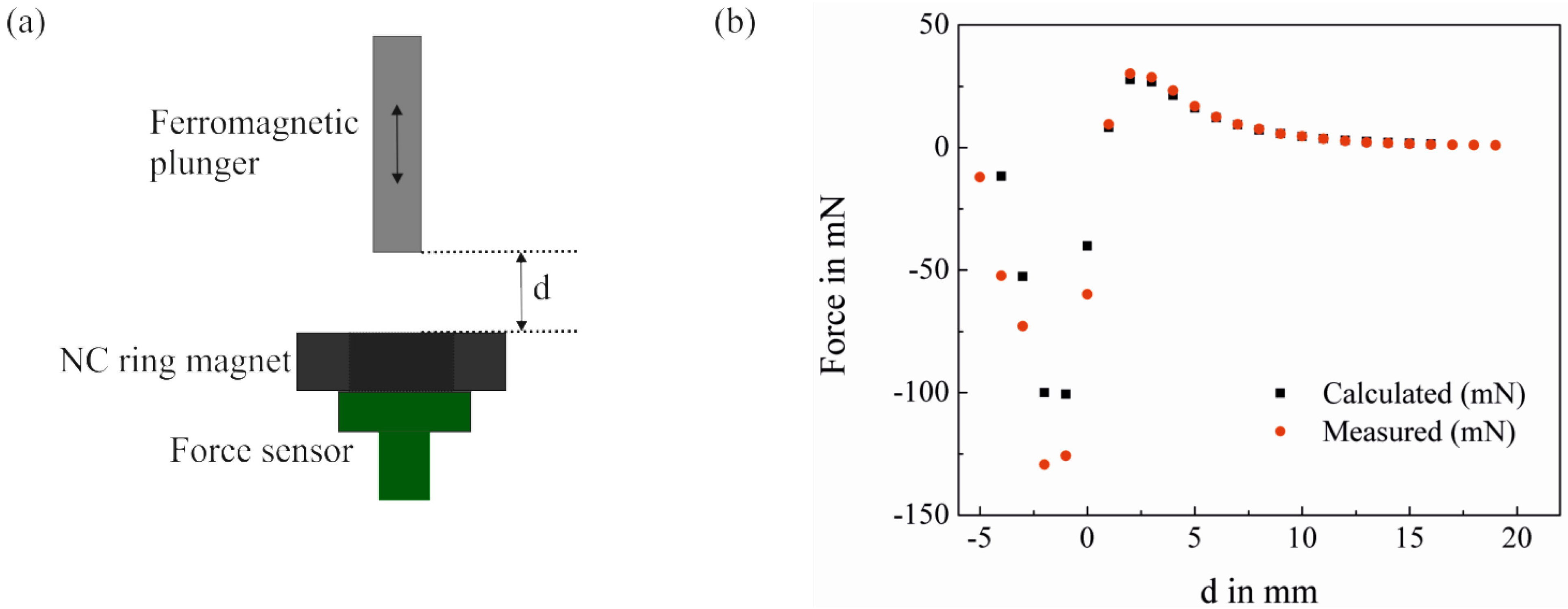

2.2. Force between Two Permanent Magnets

2.3. Pressure Force

2.4. Interactive Force between Coil and Plunger

| Dimensions | Prior functional model [5] | Miniaturized design |

|---|---|---|

| Coil outer diameter | 16.5 mm | 8.5 mm |

| Coil inner diameter | 9 mm | 5.5 mm |

| Coil length | 8.5. mm | 12 mm |

| Number of windings | 105 | 72 |

| Required peak current | 8 A | 5 A |

| Overall valve length | 27.1 mm | 29.35 mm |

3. Fabrication Process

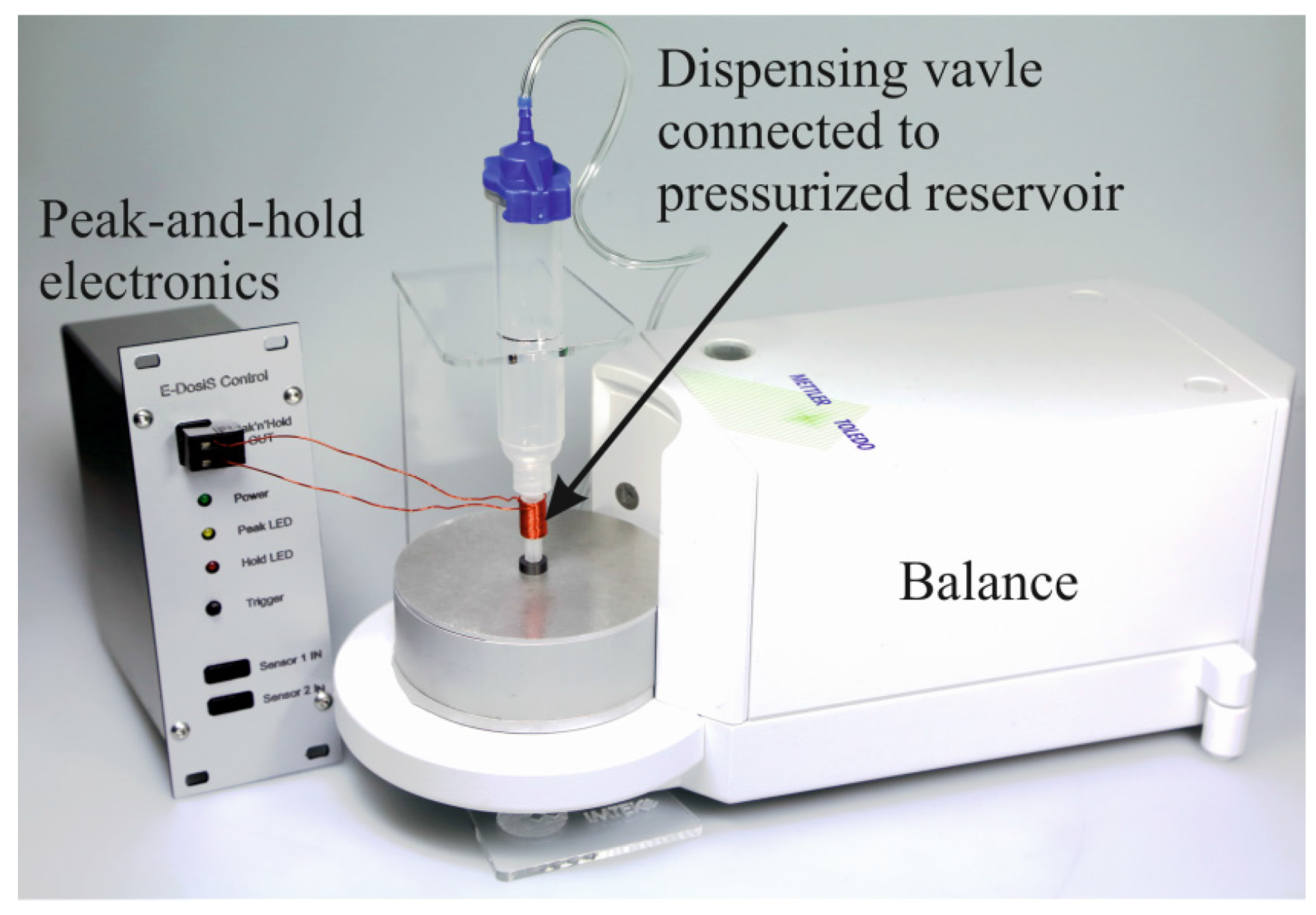

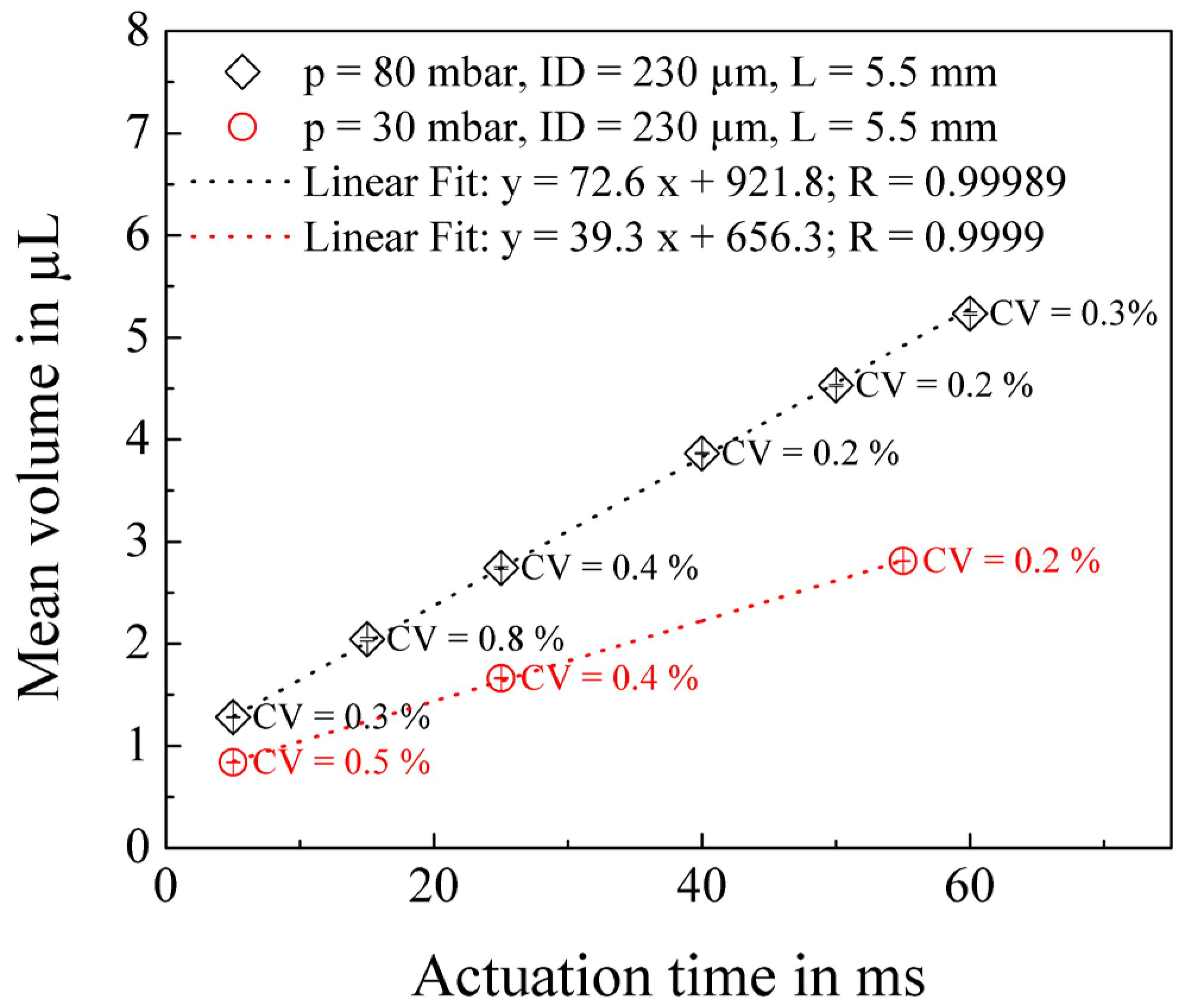

4. Results and Discussion

4.1. Dosing Performance at Different Actuation Pressures

4.2. Impact of Fabrication Tolerances of the Nozzle on the Tip-to-Tip CV

| Number | Nozzle | Material | Batch | CVintra-run | |

|---|---|---|---|---|---|

| S1 | PI capillary | BORMED HD 850 MO (Injection molding) | 1 | 0.5%–3.7% | 1.4% |

| S3 | PI capillary | Purell RP 270 G (Injection molding) | 2 | 0.9%–4.8% | 2.3% |

| S4 | PI capillary | Purell HP 570 U (Injection molding) | 2 | 0.4%–1.9% | 0.9% |

| V1 | Steel capillary | Visijet EX 200 (3D printing) | 1 | 0.6%–3.2% | 1.3% |

| V2 | Steel capillary | Visijet EX 200 (3D printing) | 1 | 0.7%–2.6% | 1.6% |

| V3 | Steel capillary | Visijet EX 200 (3D printing) | 1 | 0.7%–3.4% | 1.8% |

5. Conclusions and Summary

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bammesberger, S.B.; Ernst, A.; Losleben, N.; Tanguy, L.; Zengerle, R.; Koltay, P. Quantitative characterization of non-contact microdispensing technologies for the sub-microliter range. Drug Discov. Today 2013, 18, 435–446. [Google Scholar] [CrossRef] [PubMed]

- Streule, W.; Lindemann, T.; Birkle, G.; Zengerle, R.; Koltay, P. PipeJet: A Simple Disposable Dispenser for the Nano- and Microliter Range. J. Lab. Autom. 2004, 9, 300–306. [Google Scholar] [CrossRef]

- Rose, D. Microdispensing technologies in drug discovery. Drug Discov. Today 1999, 4, 411–419. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Kim, J. Development and characterization of a cartridge-type pneumatic dispenser with an integrated backflow stopper. J. Micromech. Microeng. 2010, 20, 015011. [Google Scholar] [CrossRef]

- Bammesberger, S.B.; Kartmann, S.; Tanguy, L.; Liang, D.; Mutschler, K.; Ernst, A.; Zengerle, R.; Koltay, P. A Low-Cost, Normally Closed, Solenoid Valve for Non-Contact Dispensing in the Sub-μL Range. Micromachines 2013, 4, 9–21. [Google Scholar] [CrossRef]

- Kong, F.; Yuan, L.; Zheng, Y.F.; Chen, W. Automatic Liquid Handling for Life Science: A Critical Review of the Current State of the Art. J. Lab. Autom. 2012, 17, 169–185. [Google Scholar] [CrossRef] [PubMed]

- Ravaud, R.; Lemarquand, G.; Lemarquand, V. Force and stiffness of passive magnetic bearings using permanent magnets. Part 1: Axial magnetization. IEEE Trans. Magn. 2009, 45, 2996–3002. [Google Scholar] [CrossRef]

- Mutschler, K.; Dwivedi, S.; Kartmann, S.; Bammesberger, S.B.; Koltay, P.; Zengerle, R.; Tanguy, L. Multi physics network simulation of a solenoid dispensing valve. Mechatronics 2014, 24, 209–221. [Google Scholar] [CrossRef]

- Avison, J. The World of Physics, 2nd ed.; Thomas Nelson and Sons Ltd: Cheltenham, UK, 1989. [Google Scholar]

- Liang, D.; Steinert, C.; Bammesberger, S.B.; Tanguy, L.; Ernst, A.; Zengerle, R.; Koltay, P. Novel gravimetric measurement technique for quantitative volume calibration in the sub-microliter range. Meas. Sci. Technol. 2013, 24, 025301. [Google Scholar] [CrossRef]

- Li, D.Q. Encyclopedia of Microfluidics and Nanofluidics; Springer: New York, NY, USA, 2008. [Google Scholar]

- SLI-Flow Meters for Life Science and Automation. Available online: http://www.sensirion.com/en/products/liquid-flow-sensors/industry-laboratory-devices/sli-universal-flow-meter/ (accessed on 2 February 2015).

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kartmann, S.; Koltay, P.; Zengerle, R.; Ernst, A. A Disposable Dispensing Valve for Non-Contact Microliter Applications in a 96-Well Plate Format. Micromachines 2015, 6, 423-436. https://doi.org/10.3390/mi6040423

Kartmann S, Koltay P, Zengerle R, Ernst A. A Disposable Dispensing Valve for Non-Contact Microliter Applications in a 96-Well Plate Format. Micromachines. 2015; 6(4):423-436. https://doi.org/10.3390/mi6040423

Chicago/Turabian StyleKartmann, Sabrina, Peter Koltay, Roland Zengerle, and Andreas Ernst. 2015. "A Disposable Dispensing Valve for Non-Contact Microliter Applications in a 96-Well Plate Format" Micromachines 6, no. 4: 423-436. https://doi.org/10.3390/mi6040423