Development of Micro-Grippers for Tissue and Cell Manipulation with Direct Morphological Comparison

Abstract

:1. Introduction

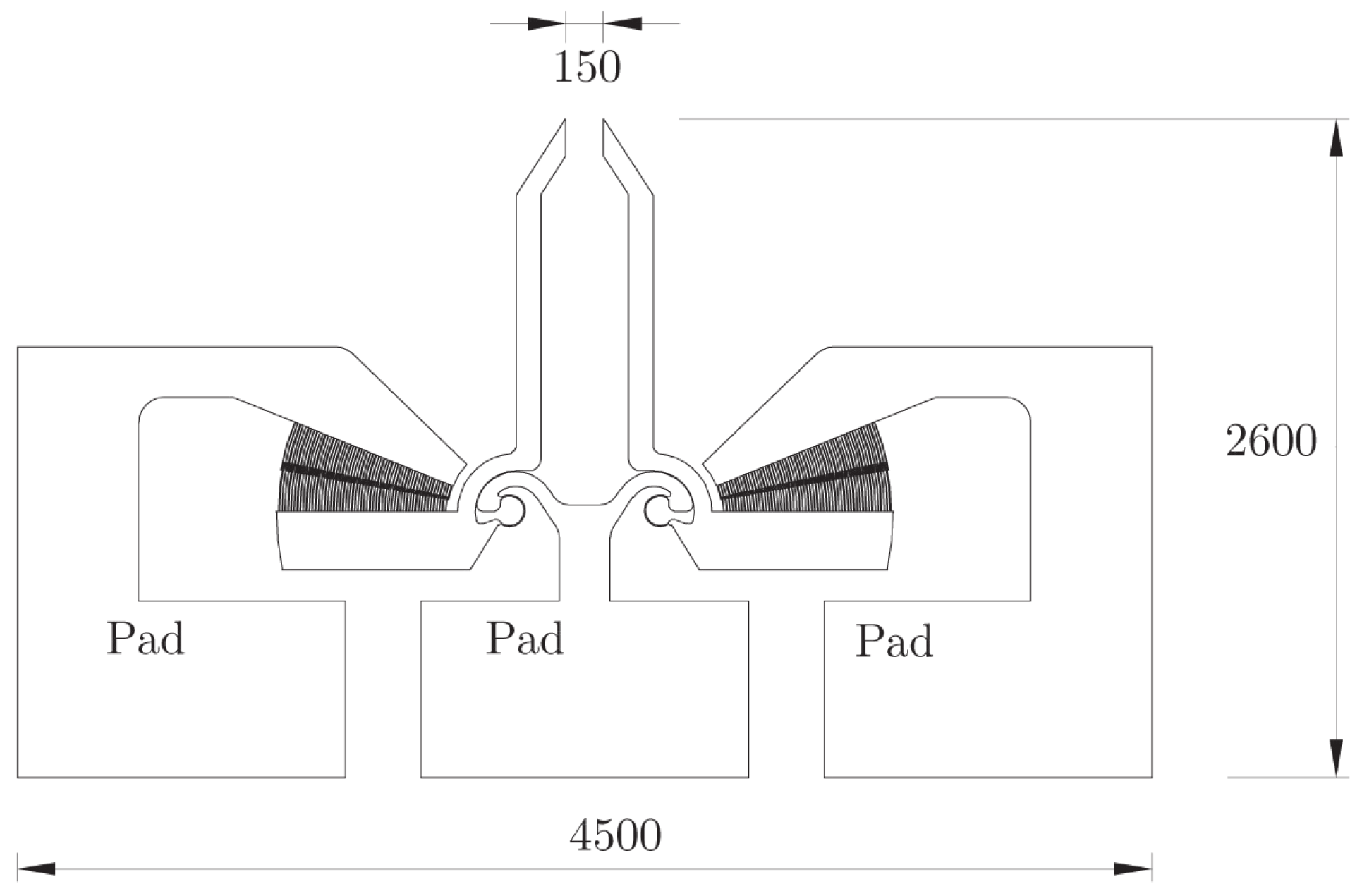

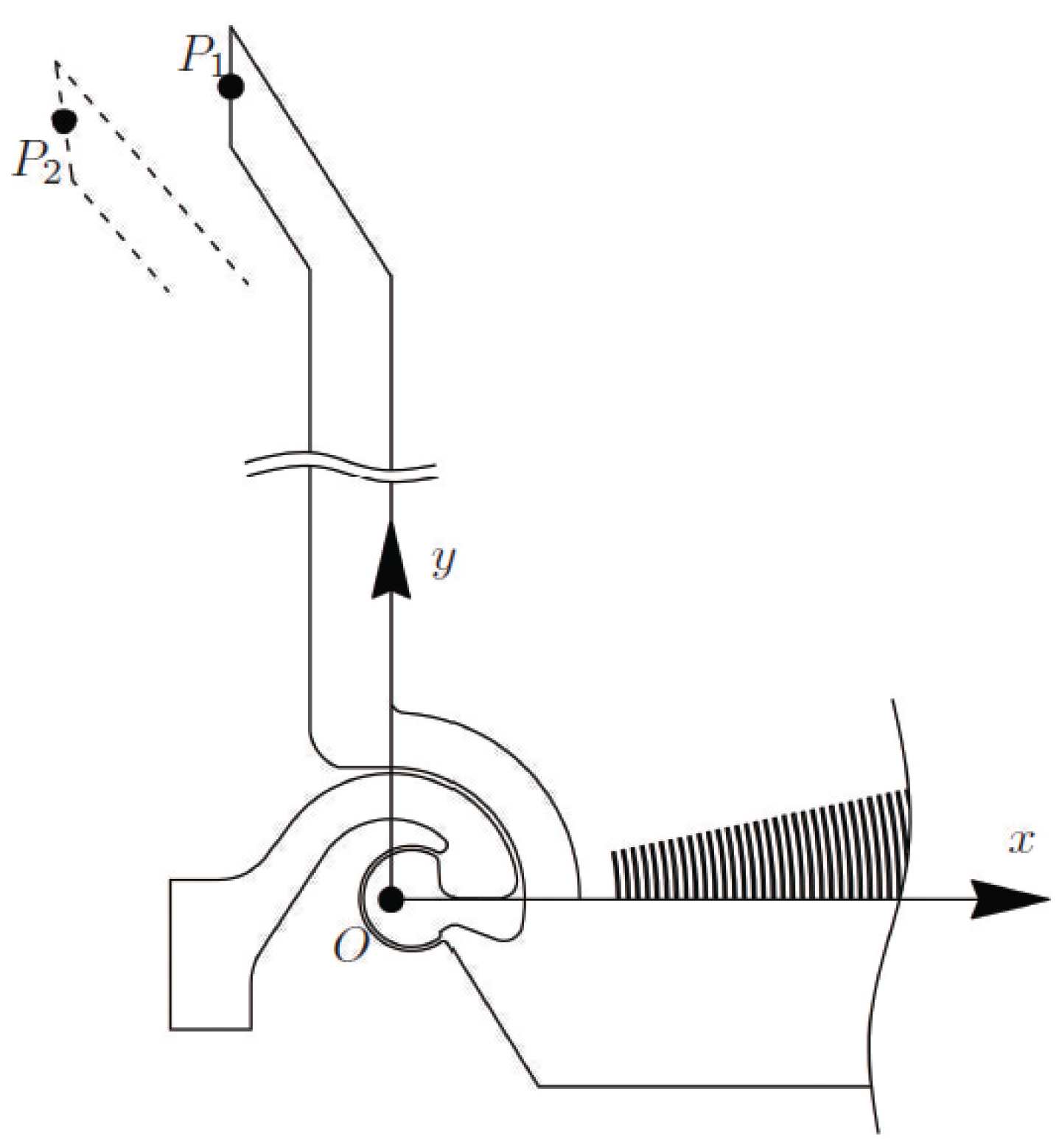

2. Design of a CSFH Silicon Micro Gripper

The center of its elastic weights is positioned in the center of the circular arc which represents the conjugate surfaces.

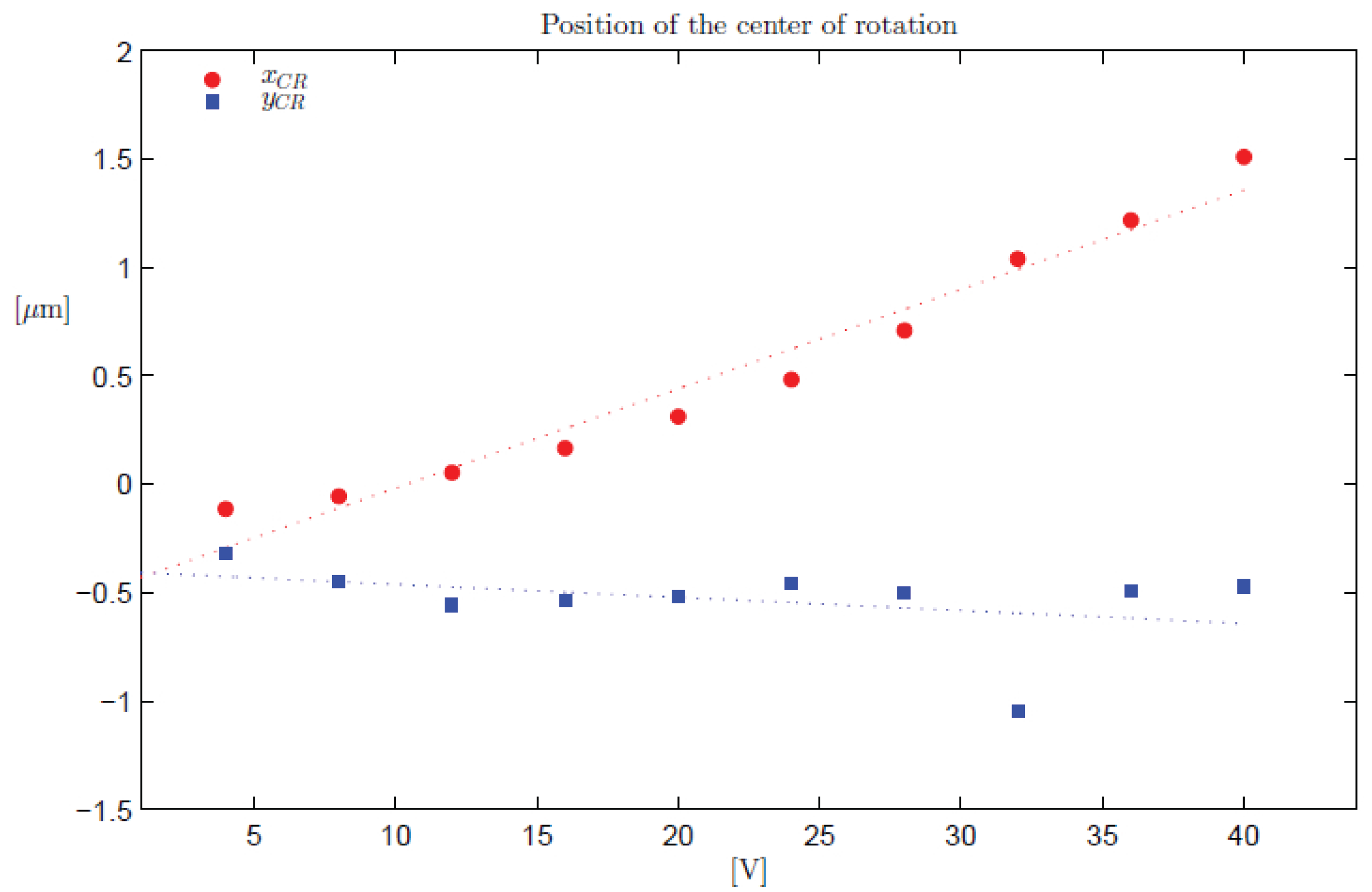

- The motion of the compliant mechanism (equipped with CSFHs) is very similar to the motion of the classical mechanisms that have been synthesized by means of the well-known kinematic methods;

- The overall stress is minimized in the flexible element.

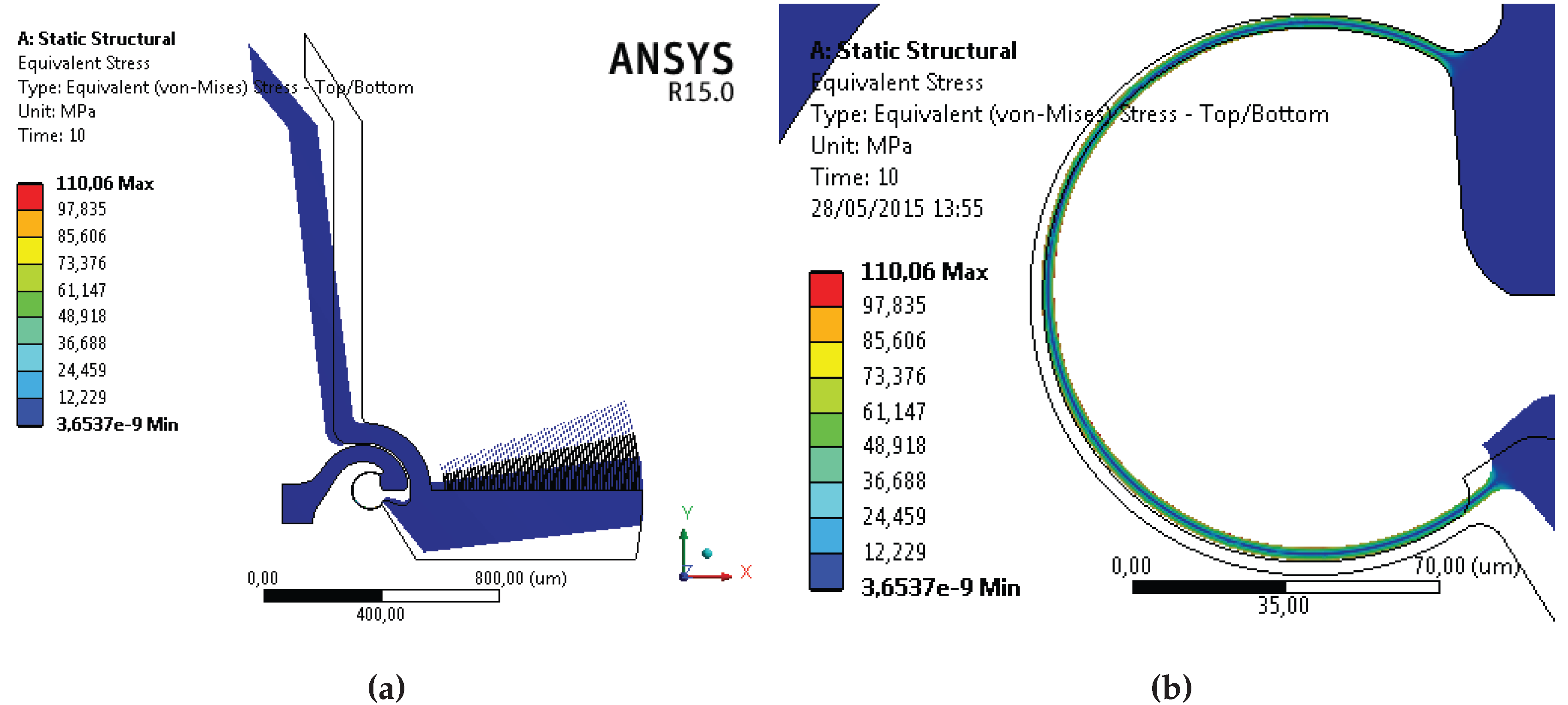

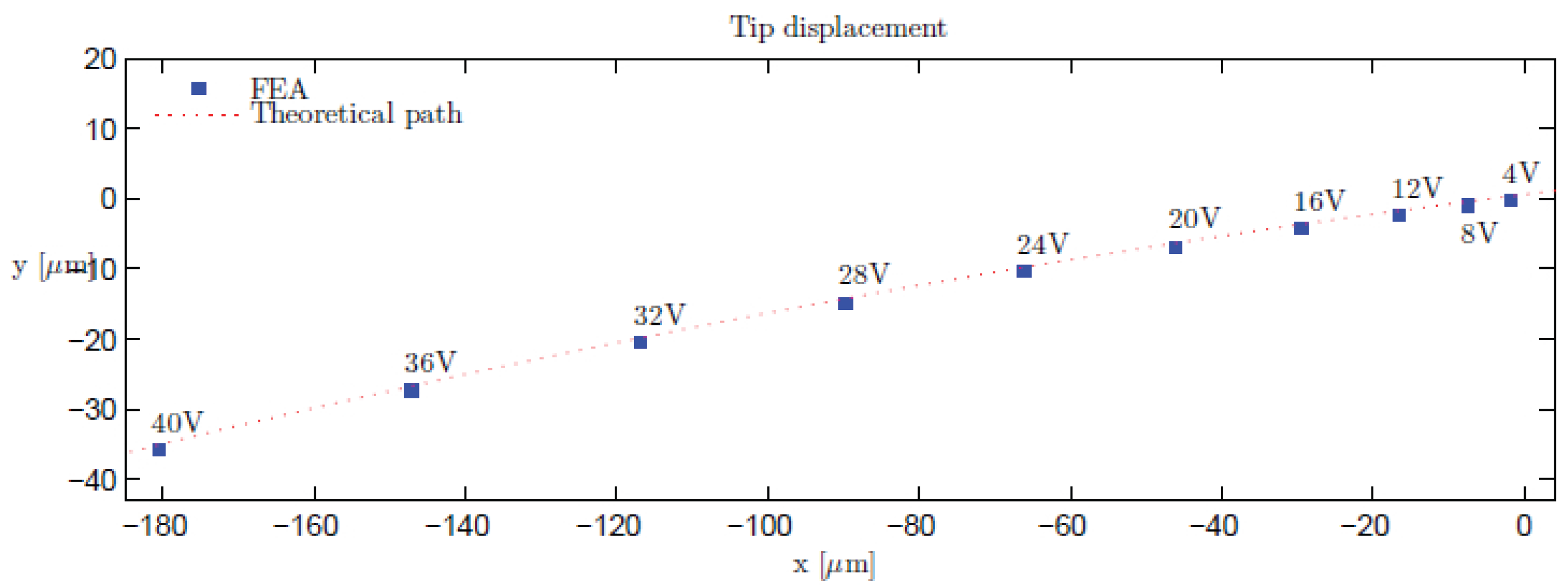

3. Simulation

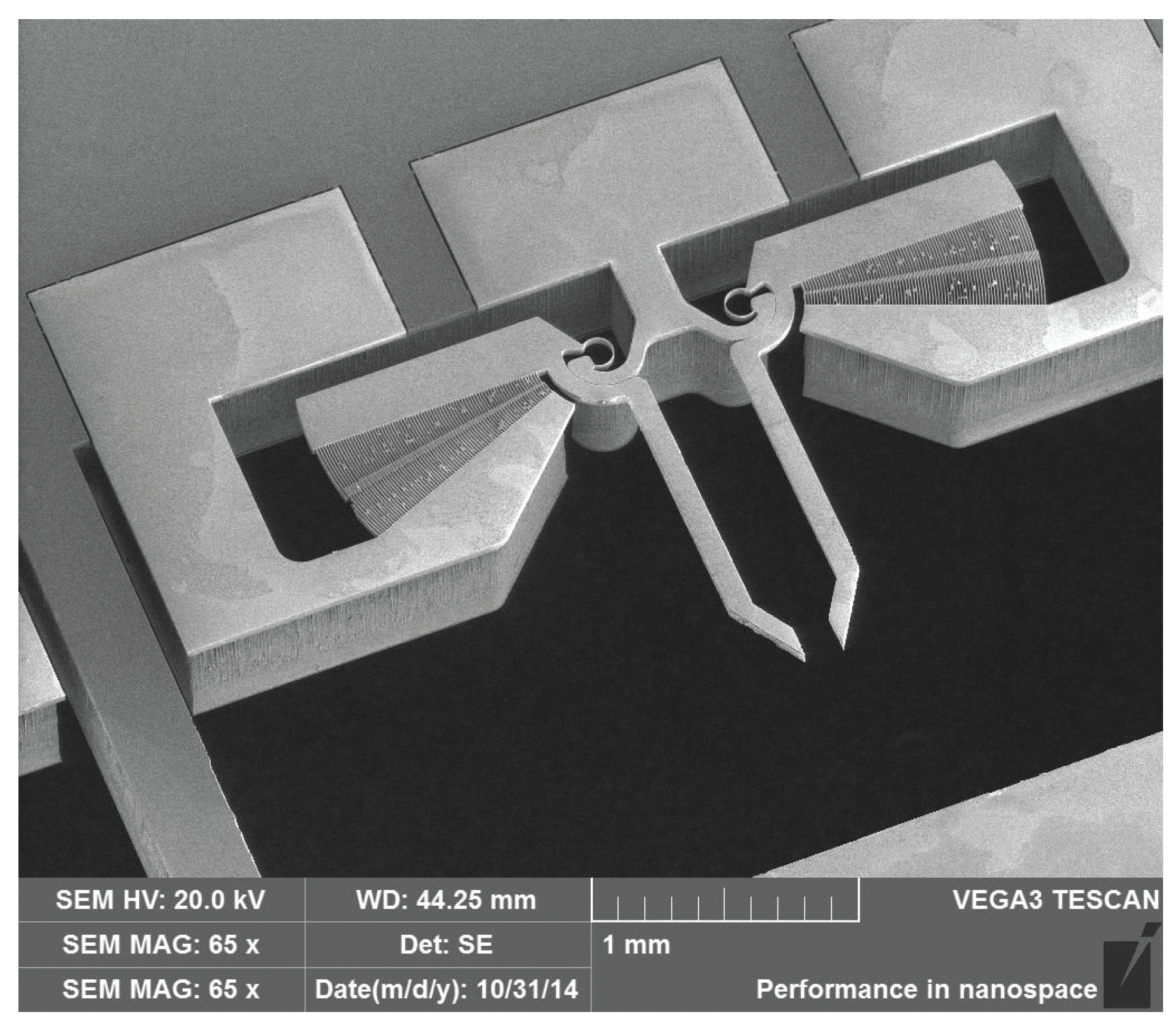

4. Technological Process Design and Actual Construction

- Device layer thickness of 40 μm;

- Buried SiO thickness of 2 μm;

- Handle wafer thickness of 475 μm.

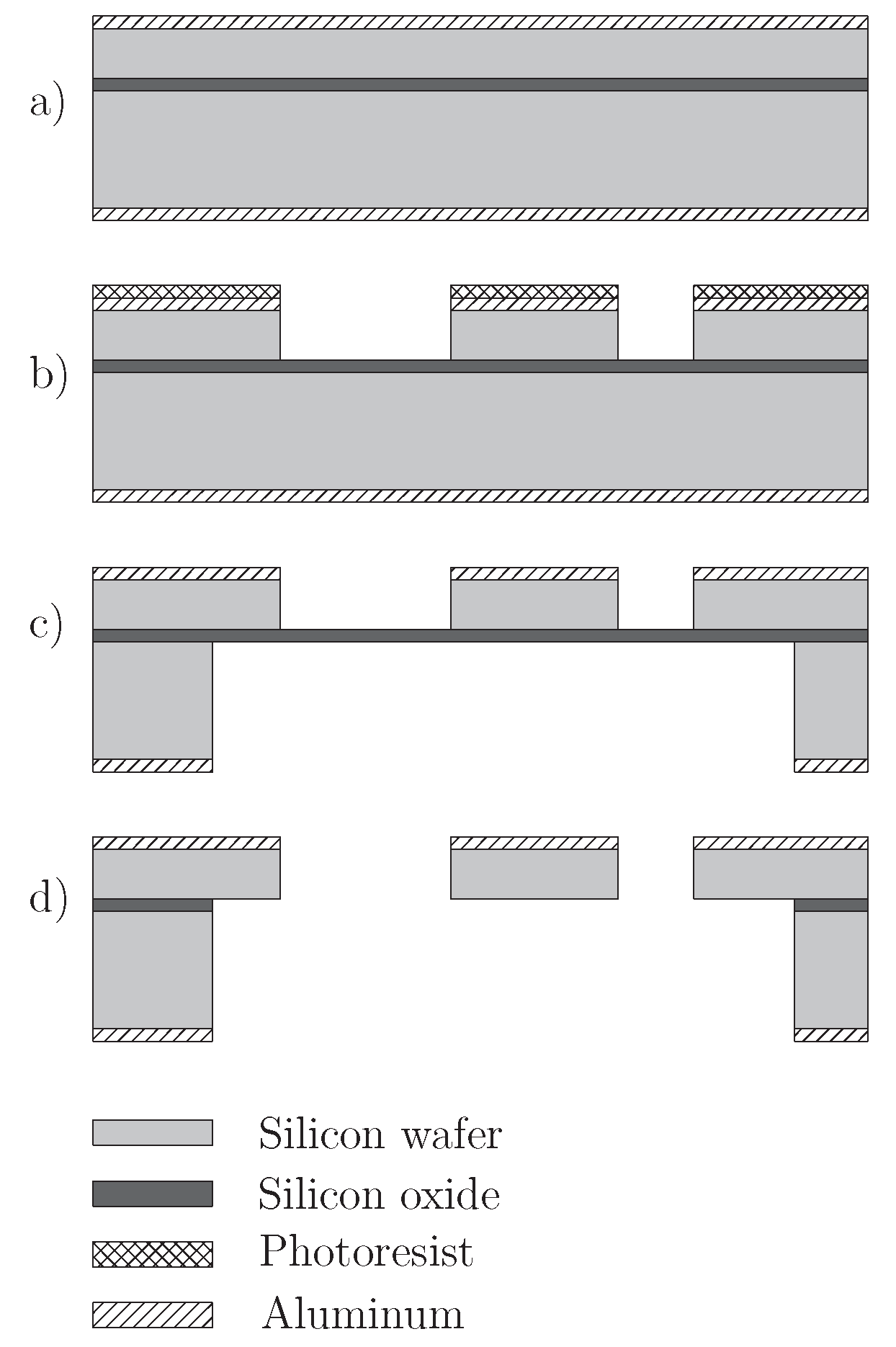

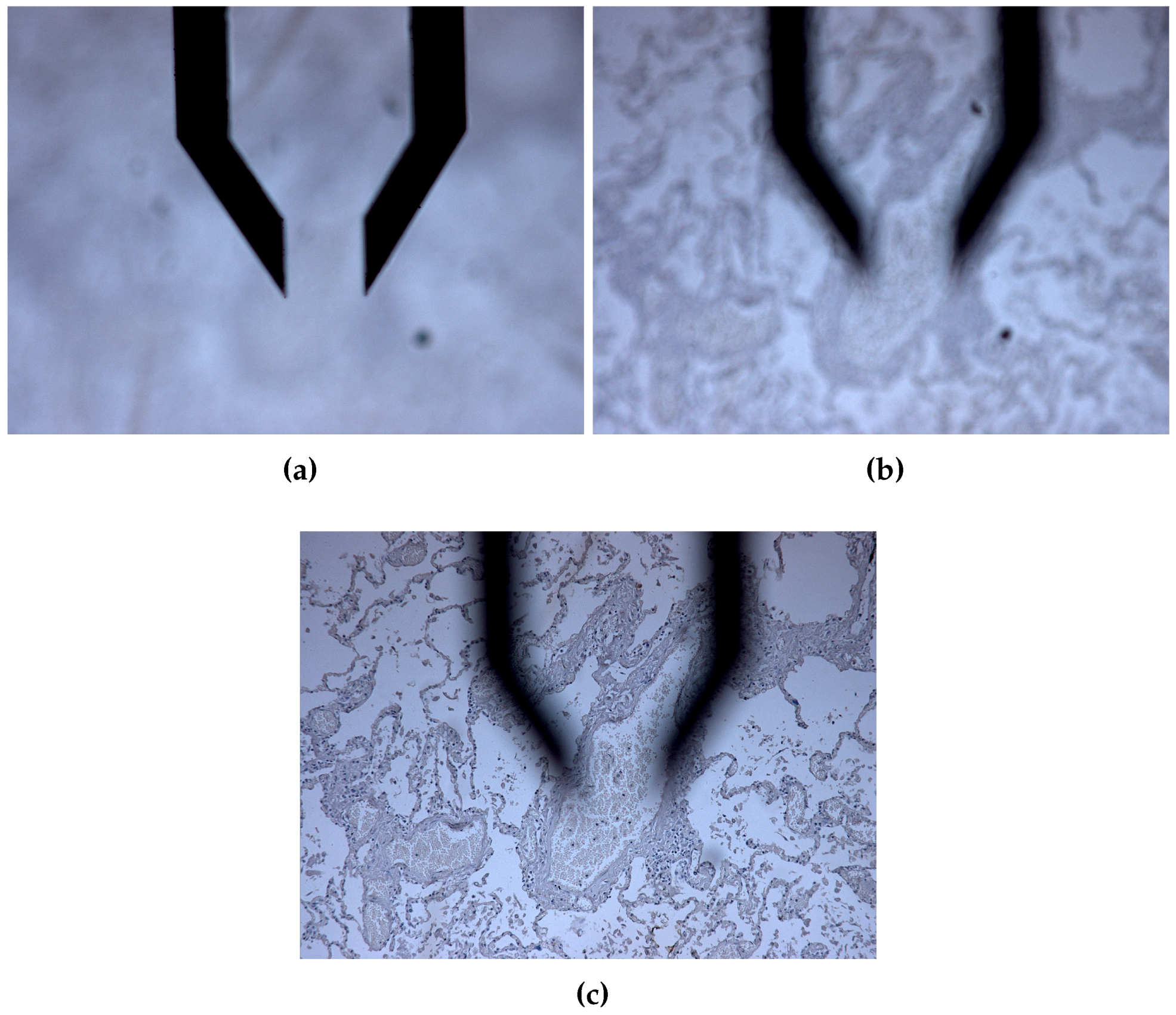

- The first step is the deposition of one 200 nm-thick layer of aluminum on both wafer sides by magnetron sputter deposition. An Eclipse sputter Physical Vapour Deposition (PVD) machine (OEM Group, Phoenix, AZ, USA) has been used at room temperature (Figure 7a).

- A 750 nm-thick photoresist layer is deposited on the aluminum front layer by spin coating (OIR674, Fujifilm, Tokyo, Japan).

- The third step consists of positioning the photolithographic mask, which contains the desired pattern, between the wafer and the UV source in order to perform the exposure (exposure tool: Karl Suss MA150 mask aligner (SUSS MicroTec, Garching, Germany) ).

- The mask features are transferred on the sample by photoresist development by using an EVG E110 spin process tool (EV Group, Suben, Austria).

- The unprotected aluminum layer is etched by a dedicated plasma etching process (Tegal6510 plasma etcher (Allwin21 Corp., Morgan Hill, CA, USA), Cl-HBr-O (23-20-20sccm), 60 W, 500 MHz).

- A deep reactive ion etching is then applied to the masked SOI wafer (Alcatel Micromachining Systems MS200 (Alcatel Micromachining Systems, Annecy, France), Bosch proprietary process sequence, chuck temperature −12 C).

- The process stops when the deep etching reaches the buried silicon oxide layer, obtaining a solid device constrained to the silicon oxide layer (Figure 7b).

- The same process chain is repeated on the bottom part, generating a tridimensional-shaped layer on both sides, joined by a continue layer of silicon dioxide (Figure 7c).

- Finally, the exposed silicon dioxide is etched using Texas Instruments etching solution HO : CHCOOH : 40% NHF at a 1:1:1 ratio) to preserve aluminum, and the floating parts are separated (Figure 7d).

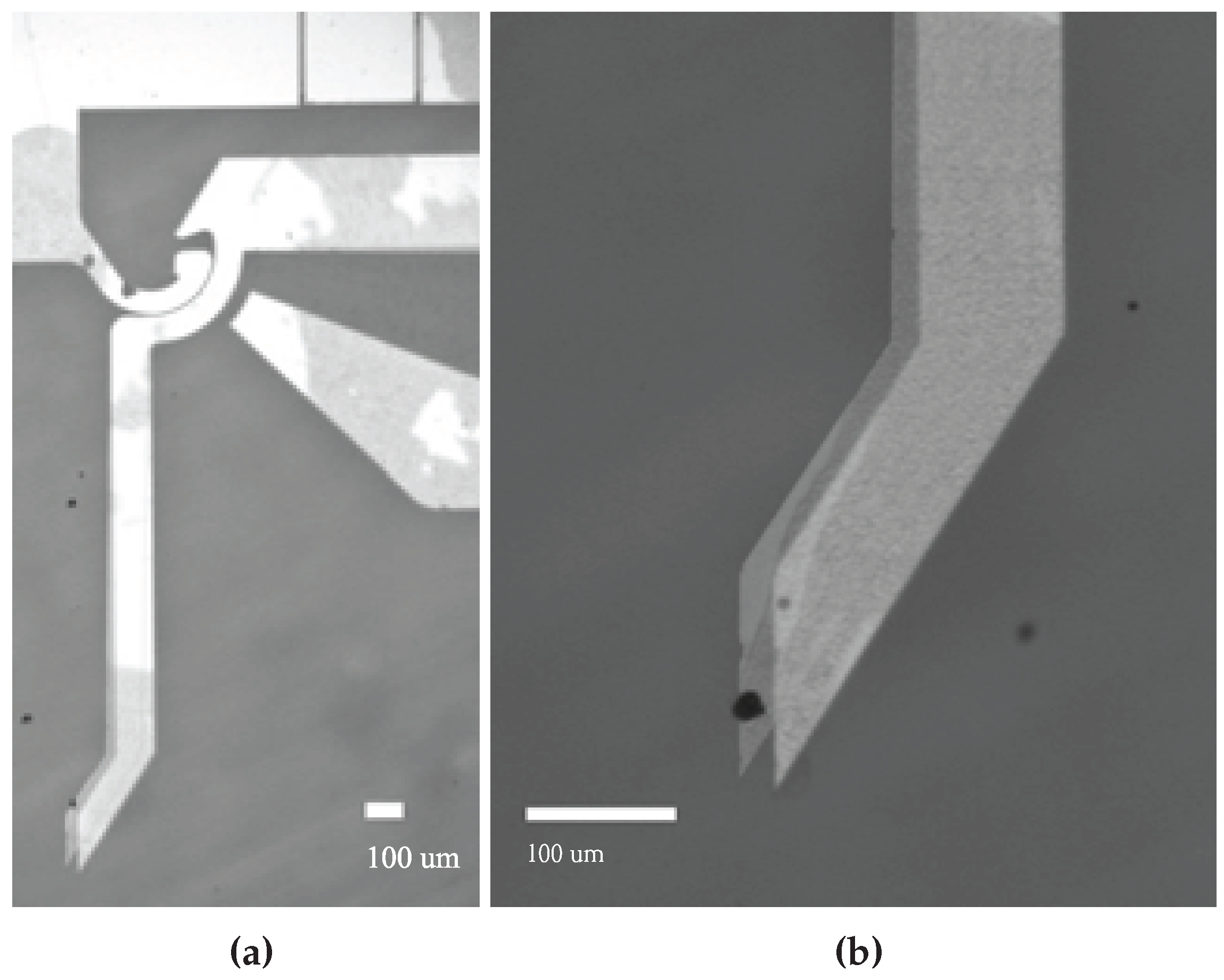

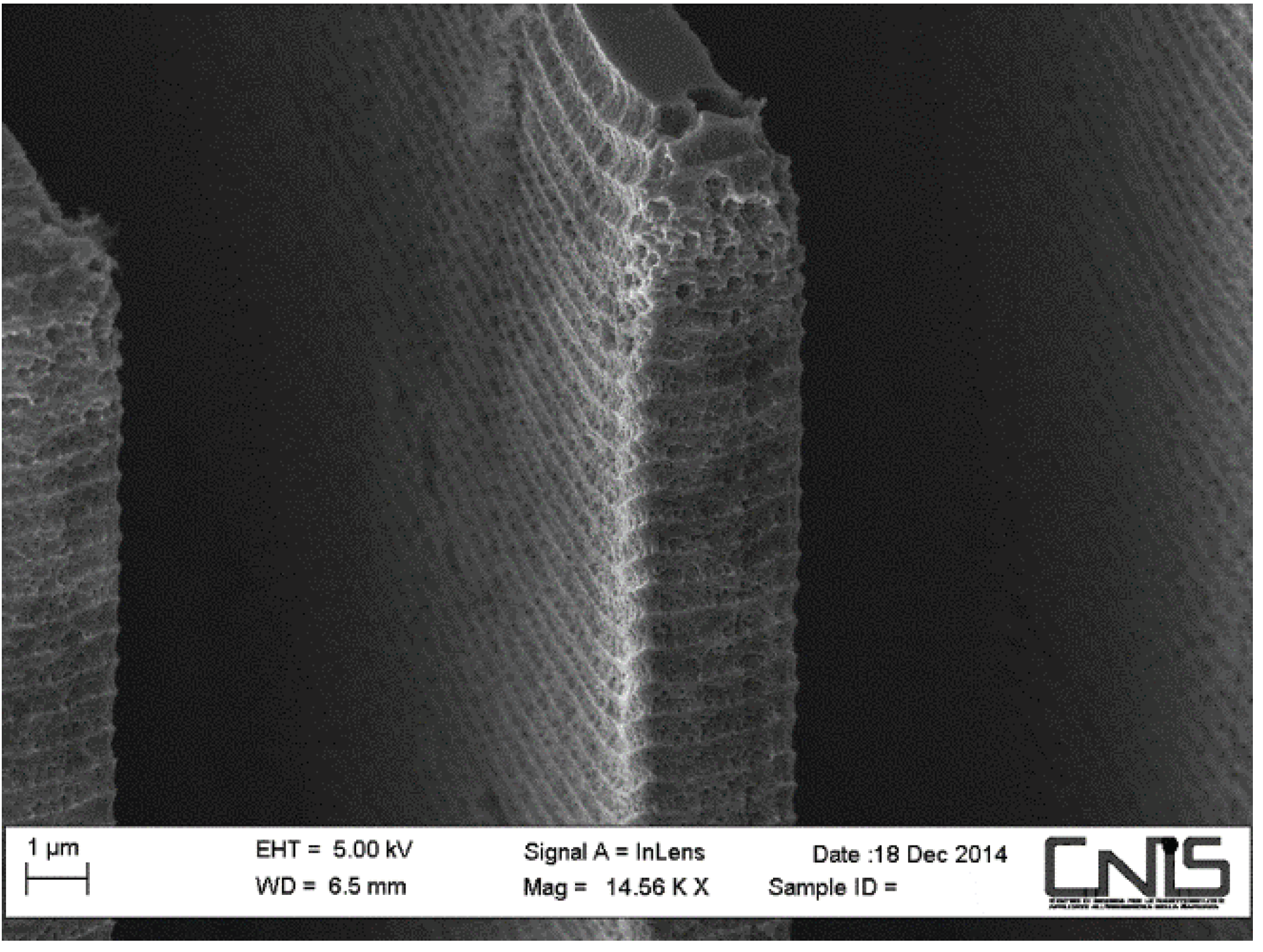

- Loading effects, due to the great difference between opening areas, plasma etching shows the limitations of etching homogeneity with respect to openings dimensions;

- Grass, unwanted silicon spikes due to resilient particles masking on the bottom of the etching cavity;

- Scalloping, a characteristic roughness of the vertical surfaces produced by the two phases of the Bosch-type DRIE process.

5. Experimental Testing on Prototype Samples

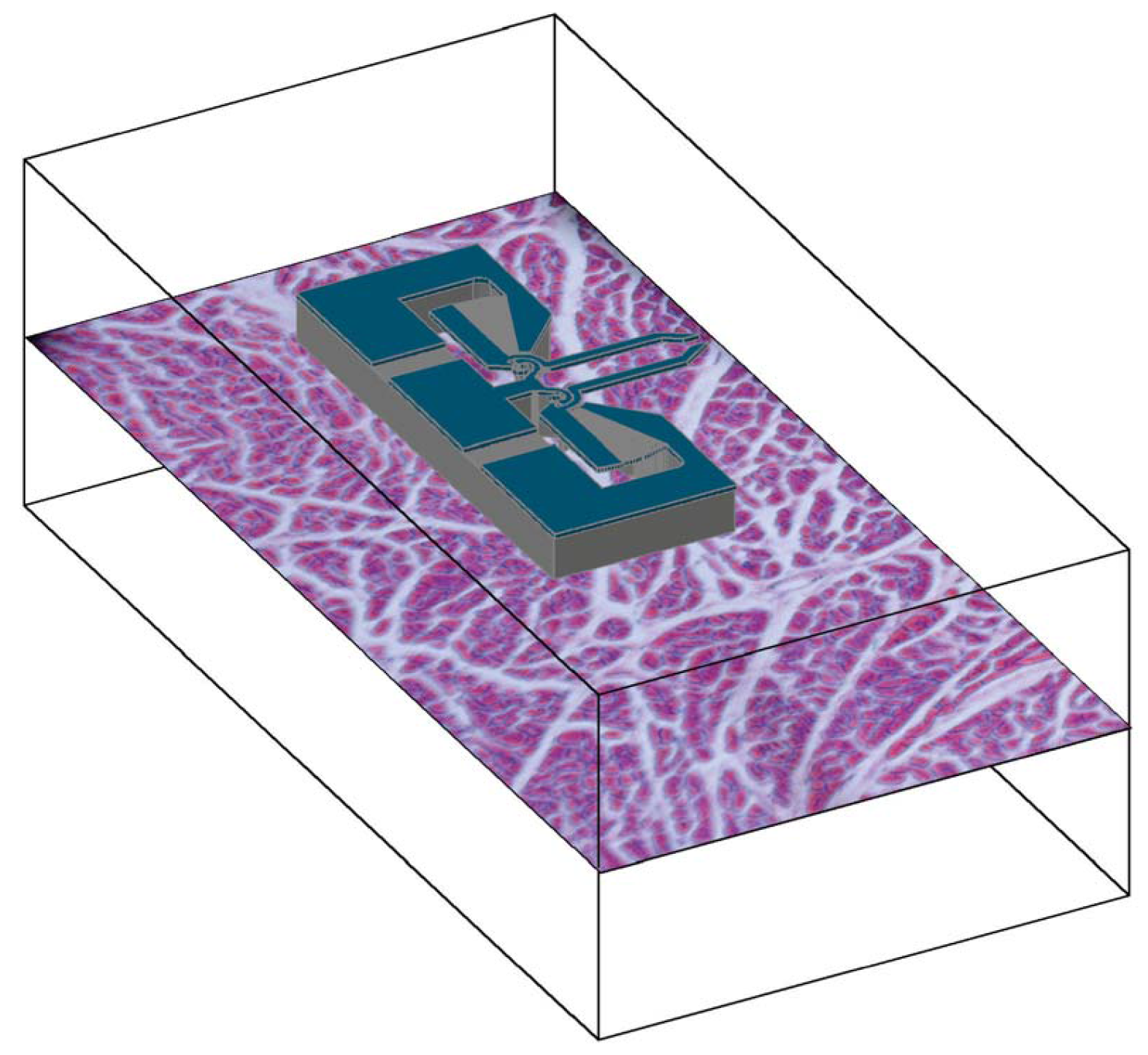

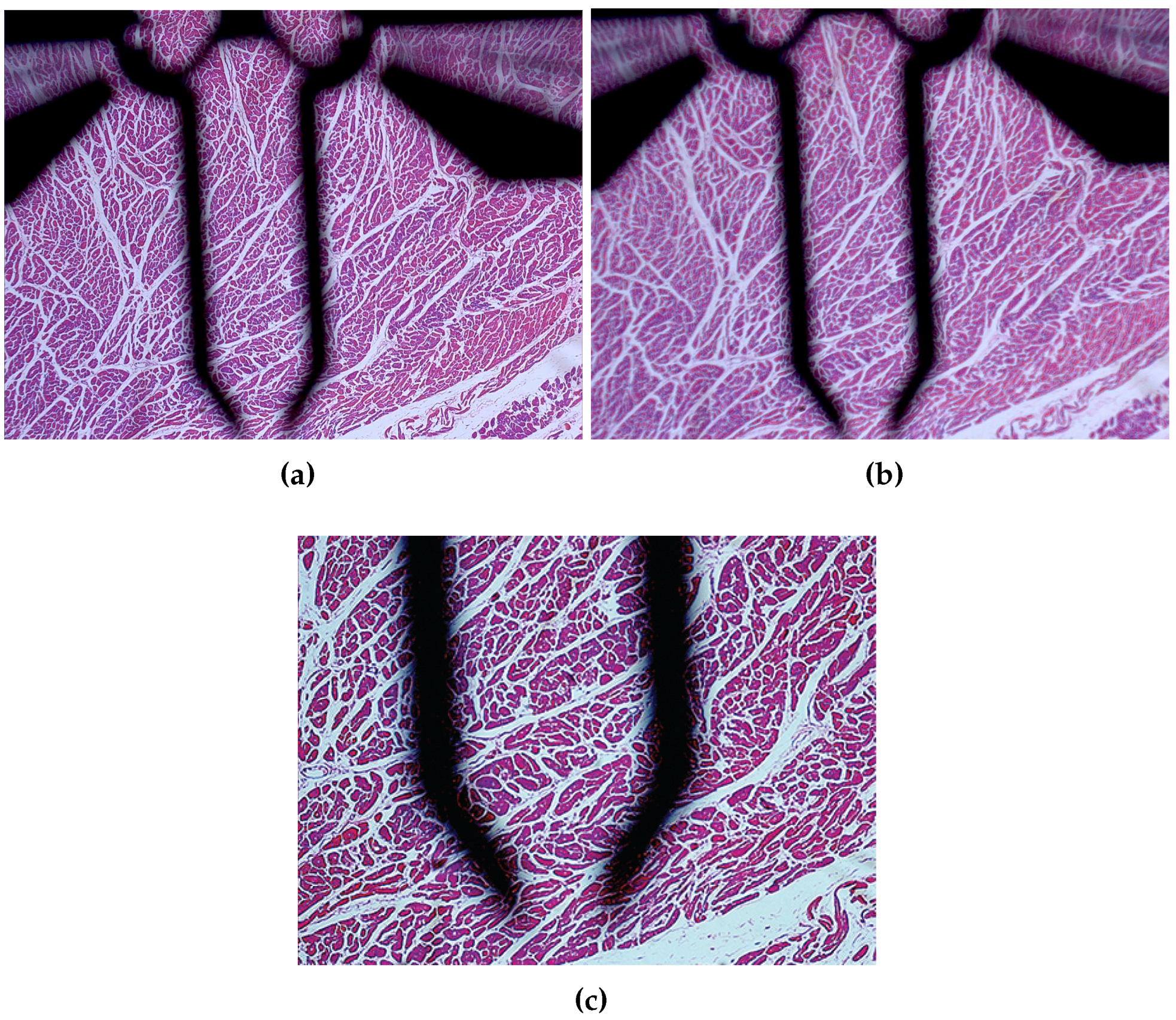

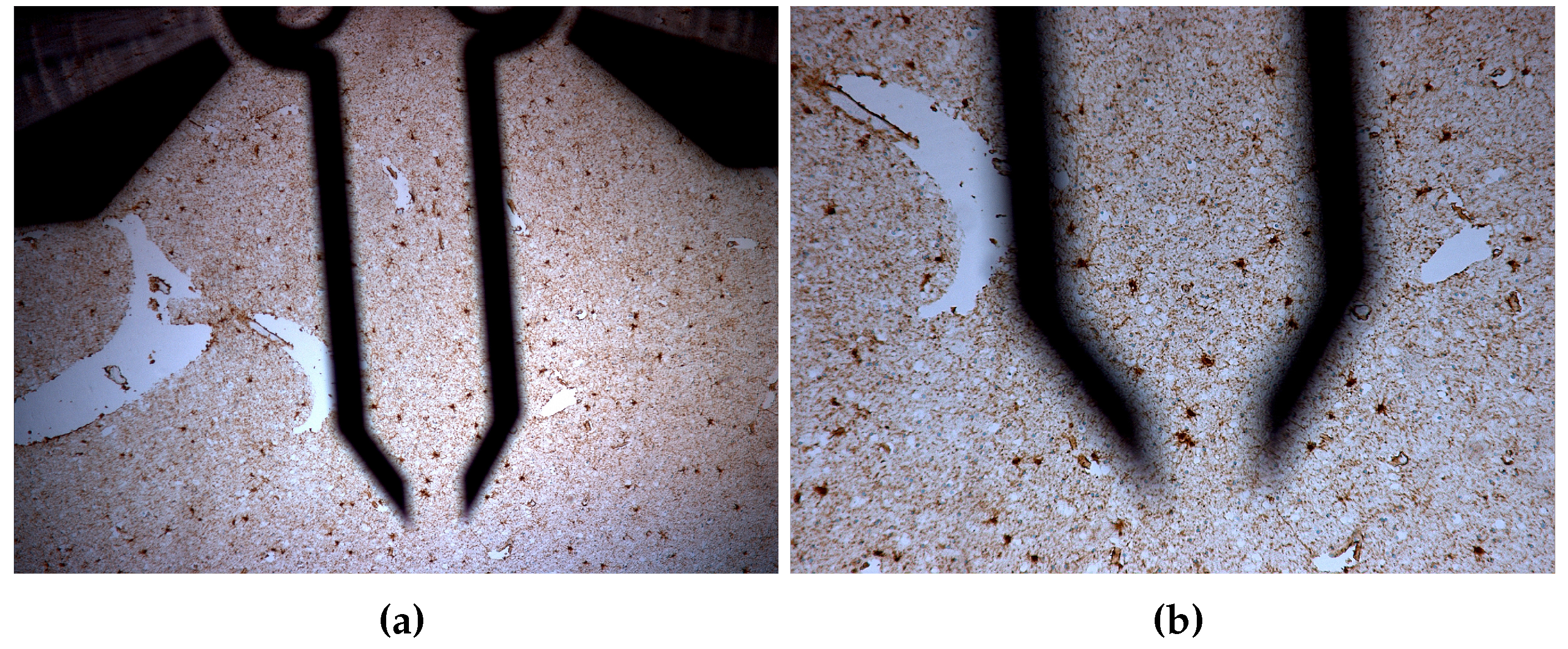

6. Morphological Analysis of in Vitro Microgripping Operations

7. Future Developments

7.1. Tests Development

7.2. Power Supply

7.3. Ethics in the Design of Active Biomedical Devices with an Increasing Degree of Independence

8. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bernassau, A.; Glynne-Jones, P.; Gesellchen, F.; Riehle, M.; Hill, M.; Cumming, D. Controlling acoustic streaming in an ultrasonic heptagonal tweezers with application to cell manipulation. Ultrasonics 2014, 54, 268–274. [Google Scholar] [CrossRef] [PubMed]

- Hagiwara, M.; Kawahara, T.; Yamanishi, Y.; Masuda, T.; Feng, L.; Arai, F. On-chip magnetically actuated robot with ultrasonic vibration for single cell manipulations. Lab Chip 2011, 11, 2049–2054. [Google Scholar] [CrossRef] [PubMed]

- Qiu, Y.; Demore, C.; Sharma, S.; Cochran, S.; Hughes, D.; Weijer, K. Multi-wavelength ultrasonic standing wave device for non-invasive cell manipulation and characterisation. In Proceedings of the 2011 IEEE International Ultrasonics Symposium (IUS), Orlando, FL, USA, 18–21 October 2011; pp. 188–191.

- Coakley, W.; Bardsley, D.; Grundy, M.; Zamani, F.; Clarke, D. Cell manipulation in ultrasonic standing wave fields. J. Chem. Technol. Biotechnol. 1989, 44, 43–62. [Google Scholar] [CrossRef]

- Wiklund, M.; Christakou, A.E.; Ohlin, M.; Iranmanesh, I.; Frisk, T.; Vanherberghen, B.; Önfelt, B. Ultrasound-induced cell-cell interaction studies in a multi-well microplate. Micromachines 2014, 5, 27–49. [Google Scholar] [CrossRef]

- Blomqvist, C.H.; Dinér, P.; Grøtli, M.; Goksör, M.; Adiels, C.B. A single-cell study of a highly effective Hog1 inhibitor for in situ yeast cell manipulation. Micromachines 2014, 5, 81–96. [Google Scholar] [CrossRef]

- Sakuma, S.; Kuroda, K.; Arai, F.; Taniguchi, T.; Ohtani, T.; Sakata, Y.; Kaneko, M. High resolution cell positioning based on a flow reduction mechanism for enhancing deformability mapping. Micromachines 2014, 5, 1188–1201. [Google Scholar] [CrossRef]

- Norregaard, K.; Jauffred, L.; Berg-Sorensen, K.; Oddershede, L.B. Optical manipulation of single molecules in the living cell. Phys. Chem. Chem. Phys. 2014, 16, 12614–12624. [Google Scholar] [CrossRef] [PubMed]

- Legtenberg, R.; Groeneveld, A.W.; Elwenspoek, M. Comb-drive actuators for large displacements. J. Micromech. Microeng. 1996, 6, 320. [Google Scholar] [CrossRef]

- Chang, H.; Zhao, H.; Ye, F.; Yuan, G.; Xie, J.; Kraft, M.; Yuan, W. A rotary comb-actuated microgripper with a large displacement range. Microsyst. Technol. 2014, 20, 119–126. [Google Scholar] [CrossRef]

- Yeh, J.A.; Chen, C.N.; Lui, Y.S. Large rotation actuated by in-plane rotary comb-drives with serpentine spring suspension. J. Micromech. Microeng. 2005, 15, 201. [Google Scholar] [CrossRef]

- Kim, C.J.; Pisano, A.; Muller, R. Silicon-processed overhanging microgripper. J. Microelectromech. Syst. 1992, 1, 31–36. [Google Scholar] [CrossRef]

- Rakotondrabe, M.; Ivan, I. Development and Force/Position Control of a New Hybrid Thermo-Piezoelectric MicroGripper Dedicated to Micromanipulation Tasks. IEEE Trans. Autom. Sci. Eng. 2011, 8, 824–834. [Google Scholar] [CrossRef] [Green Version]

- Wierzbicki, R.; Adda, C.; Hotzendorfer, H. Electrostatic Silicon Microgripper with Low Voltage of Actuation. In Proceedings of the International Symposium on Micro-NanoMechatronics and Human Science (MHS ’07), Nagoya, Japan, 11–14 November 2007; pp. 344–349.

- Hamedi, M.; Salimi, P.; Vismeh, M. Simulation and experimental investigation of a novel electrostatic microgripper system. Microelectron. Eng. 2012, 98, 467–471. [Google Scholar] [CrossRef]

- Piriyanont, B.; Moheimani, S.; Bazaei, A. Design and control of a MEMS micro-gripper with integrated electro-thermal force sensor. In Proceedings of the 2013 3rd Australian Control Conference (AUCC), Fremantle, WA, USA, 4–5 November 2013; pp. 479–484.

- Wierzbicki, R.; Houston, K.; Heerlein, H.; Barth, W.; Debski, T.; Eisinberg, A.; Menciassi, A.; Carrozza, M.; Dario, P. Design and fabrication of an electrostatically driven microgripper for blood vessel manipulation. Microelectron. Eng. 2006, 83, 1651–1654. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, B.K.; Liu, X.; Sun, Y. Autonomous robotic pick-and-place of microobjects. IEEE Trans. Robot. 2010, 26, 200–207. [Google Scholar] [CrossRef]

- Carrozza, M.C.; Eisinberg, A.; Menciassi, A.; Campolo, D.; Micera, S.; Dario, P. Towards a force-controlled microgripper for assembling biomedical microdevices. J. Micromech. Microeng. 2000, 10, 271. [Google Scholar] [CrossRef]

- Chen, T.; Chen, L.; Sun, L.; Li, X. Design and Fabrication of a Four-Arm-Structure MEMS Gripper. IEEE Trans. Ind. Electron. 2009, 56, 996–1004. [Google Scholar] [CrossRef]

- Kim, D.H.; Kim, B.; Kang, H. Development of a piezoelectric polymer-based sensorized microgripper for microassembly and micromanipulation. Microsyst. Technol. 2004, 10, 275–280. [Google Scholar] [CrossRef]

- Belfiore, N.P.; Pennestrì, E. An atlas of linkage-type robotic grippers. Mech. Mach. Theory 1997, 32, 811–833. [Google Scholar] [CrossRef]

- Tsai, Y.C.; Lei, S.H.; Sudin, H. Design and analysis of planar compliant microgripper based on kinematic approach. J. Micromech. Microeng. 2005, 15, 143. [Google Scholar] [CrossRef]

- Menciassi, A.; Eisinberg, A.; Mazzoni, M.; Dario, P. A sensorized μelectro discharge machined superelastic alloy microgripper for micromanipulation: Simulation and characterization. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Lausanne, Switzerland, 30 September–4 October 2002; Volume 2, pp. 1591–1595.

- Greminger, M.; Sezen, A.; Nelson, B. A four degree of freedom MEMS microgripper with novel bi-directional thermal actuators. In Proceedings of the 2005 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2005), Edmonton, AB, Canada, 2–6 August 2005; pp. 2814–2819.

- Chang, R.; Chen, C. Using Microgripper for Adhesive Bonding in Automatic Microassembly System. In Proceedings of the International Conference on Mechatronics and Automation (ICMA 2007), Harbin, China, 5–8 August 2007; pp. 440–445.

- Chronis, N.; Lee, L. Polymer MEMS-based microgripper for single cell manipulation. In Proceedings of the 17th IEEE International Conference on Micro Electro Mechanical Systems (MEMS 2004), Maastricht, The Netherlands, 25–29 January 2004; pp. 17–20.

- Sun, X.; Chen, W.; Fatikow, S.; Tian, Y.; Zhou, R.; Zhang, J.; Mikczinski, M. A novel piezo-driven microgripper with a large jaw displacement. Microsyst. Technol. 2015, 21, 931–942. [Google Scholar] [CrossRef]

- Chen, T.; Sun, L.; Chen, L.; Rong, W.; Li, X. A hybrid-type electrostatically driven microgripper with an integrated vacuum tool. Sens. Actuators A Phys. 2010, 158, 320–327. [Google Scholar] [CrossRef]

- Yeh, J.; Jiang, S.S.; Lee, C. MOEMS variable optical attenuators using rotary comb drive actuators. IEEE Photonics Technol. Lett. 2006, 18, 1170–1172. [Google Scholar] [CrossRef]

- Kim, K.; Liu, X.; Zhang, Y.; Sun, Y. Nanonewton force-controlled manipulation of biological cells using a monolithic MEMS microgripper with two-axis force feedback. J. Micromech. Microeng. 2008, 18, 055013. [Google Scholar] [CrossRef]

- Kim, K.; Liu, X.; Zhang, Y.; Cheng, J.; Yu, W.X.; Sun, Y. Elastic and viscoelastic characterization of microcapsules for drug delivery using a force-feedback MEMS microgripper. Biomed. Microdevices 2009, 11, 421–427. [Google Scholar] [CrossRef] [PubMed]

- Solano, B.; Wood, D. Design and testing of a polymeric microgripper for cell manipulation. Microelectron. Eng. 2007, 84, 1219–1222. [Google Scholar] [CrossRef]

- Zeman, M.J.F.; Bordatchev, E.V.; Knopf, G.K. Design, kinematic modeling and performance testing of an electro-thermally driven microgripper for micromanipulation applications. J. Micromech. Microeng. 2006, 16, 1540. [Google Scholar] [CrossRef]

- Zhang, R.; Chu, J.; Wang, H.; Chen, Z. A multipurpose electrothermal microgripper for biological micro-manipulation. Microsyst. Technol. 2013, 19, 89–97. [Google Scholar] [CrossRef]

- Chang, R.; Wang, H.; Wang, Y. Development of mesoscopic polymer gripper system guided by precision design axioms. Precis. Eng. 2003, 27, 362–369. [Google Scholar] [CrossRef]

- Kohl, M.; Just, E.; Pfleging, W.; Miyazaki, S. SMA microgripper with integrated antagonism. Sens. Actuators A Phys. 2000, 83, 208–213. [Google Scholar] [CrossRef]

- Kohl, M.; Krevet, B.; Just, E. SMA microgripper system. Sens. Actuators A Phys. 2002, 97–98, 646–652. [Google Scholar] [CrossRef]

- Chen, T.; Chen, L.; Sun, L.; Wang, J.; Li, X. A sidewall piezoresistive force sensor used in a MEMS gripper. In Intelligent Robotics and Applications; Springer: Berlin, Germany, 2008; pp. 207–216. [Google Scholar]

- Jeon, C.S.; Park, J.S.; Lee, S.Y.; Moon, C.W. Fabrication and characteristics of out-of-plane piezoelectric micro grippers using MEMS processes. Thin Solid Films 2007, 515, 4901–4904. [Google Scholar] [CrossRef]

- Kim, B.S.; Park, J.S.; Kang, B.H.; Moon, C. Fabrication and property analysis of a MEMS micro-gripper for robotic micro-manipulation. Robot. Comput. Integr. Manuf. 2012, 28, 50–56. [Google Scholar] [CrossRef]

- Zubir, M.N.M.; Shirinzadeh, B.; Tian, Y. Development of a novel flexure-based microgripper for high precision micro-object manipulation. Sens. Actuators A Phys. 2009, 150, 257–266. [Google Scholar] [CrossRef]

- Zubir, M.N.M.; Shirinzadeh, B.; Tian, Y. A new design of piezoelectric driven compliant-based microgripper for micromanipulation. Mech. Mach. Theory 2009, 44, 2248–2264. [Google Scholar] [CrossRef]

- Desmaële, D.; Boukallel, M.; Régniér, S. Actuation means for the mechanical stimulation of living cells via microelectromechanical systems: A critical review. J. Biomech. 2011, 44, 1433–1446. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Srinivasan, P.; Spearing, S. Optimal Materials Selection for Bimaterial Piezoelectric Microactuators. J. Microelectromech. Syst. 2008, 17, 462–472. [Google Scholar] [CrossRef]

- Jain, R.K.; Majumder, S.; Ghosh, B.; Saha, S. Design and manufacturing of mobile micro manipulation system with a compliant piezoelectric actuator based micro gripper. J. Manuf. Syst. 2015, 35, 76–91. [Google Scholar] [CrossRef]

- Verotti, M.; Crescenzi, R.; Balucani, M.; Belfiore, N.P. MEMS-Based Conjugate Surfaces Flexure Hinge. J. Mech. Des. Trans. ASME 2015, 137, 012301. [Google Scholar] [CrossRef]

- Belfiore, N.P. Atlas of remote actuated bevel gear wrist mechanisms of up to nine links. Int. J. Robot. Res. 1993, 12, 448–459. [Google Scholar] [CrossRef]

- Belfiore, N.P.; Pennestrì, E. Automatic sketching of planar kinematic chains. Mech. Mach. Theory 1994, 29, 177–193. [Google Scholar] [CrossRef]

- Belfiore, N.P. Distributed Databases for the development of Mechanisms Topology. Mech. Mach. Theory 2000, 35, 1727–1744. [Google Scholar] [CrossRef]

- Belfiore, N.P. Brief note on the concept of planarity for kinematic chains. Mech. Mach. Theory 2000, 35, 1745–1750. [Google Scholar] [CrossRef]

- Belfiore, N.P.; di Benedetto, A. Connectivity and redundancy in spatial robots. Int. J. Robot. Res. 2000, 19, 1245–1261. [Google Scholar] [CrossRef]

- Liberati, A.; Belfiore, N.P. A method for the identification of the connectivity in multi-loop kinematic chains: Analysis of chains with total and partial mobility. Mech. Mach. Theory 2006, 41, 1443–1466. [Google Scholar] [CrossRef]

- Pennestrì, E.; Belfiore, N.P. Modular Third-Order Analysis of Planar Linkages with Applications; American Society of Mechanical Engineers, Design Engineering Division (Publication) DE: New York, NY, USA, 1994; Volume 70, pp. 99–103. [Google Scholar]

- Pennestrì, E.; Belfiore, N.P. On the numerical computation of Generalized Burmester Points. Meccanica 1995, 30, 147–153. [Google Scholar] [CrossRef]

- Belfiore, N.P. Functional Synthesis of a New Class of Micro Electro-Mechanical Systems. In Advances in Soft Computing, Intelligent Robotics and Control; Fodor, J., Fuller, R., Eds.; Springer International Publishing: Cham, Switzerland, 2014; pp. 81–93. [Google Scholar]

- Belfiore, N.P.; EmamiMeibodi, M.; Verotti, M.; Crescenzi, R.; Balucani, M.; Nenzi, P. Kinetostatic Optimization of a MEMS-Based Compliant 3 DOF Plane Parallel Platform. In Proceedings of the IEEE 9th International Conference on Computational Cybernetics (ICCC 2013), Tihany, Hungary, 8–10 July 2013.

- Belfiore, N.P.; Simeone, P. Inverse kinetostatic analysis of compliant four-bar linkages. Mech. Mach. Theory 2013, 69, 350–372. [Google Scholar] [CrossRef]

- Belfiore, N.P.; Verotti, M.; Crescenzi, R.; Balucani, M. Design, Optimization and Construction of MEMS-Based Micro Grippers for Cell Manipulation. In Proceedings of the IEEE International Conference on System Science and Engineering (ICSSE 2013), Budapest, Hungary, 4–6 July 2013.

- Belfiore, N.; Balucani, M.; Crescenzi, R.; Verotti, M. Performance analysis of compliant mems parallel robots through pseudo-rigid-body model synthesis. In Proceedings of the ASME 2012 11th Biennial Conference on Engineering Systems Design and Analysis (ESDA 2012), Nantes, France, 2–4 July 2012; Volume 3, pp. 329–334.

- Nenzi, P.; Crescenzi, R.; Dolgyi, A.; Klyshko, A.; Bondarenko, V.; Belfiore, N.P.; Balucani, M. High density compliant contacting technology for integrated high power modules in automotive applications. In Proceedings of the Electronic Components and Technology Conference, San Diego, CA, USA, 29 May–1 June 2012; pp. 1976–1983.

- Balucani, M.; Belfiore, N.; Crescenzi, R.; Verotti, M. The development of a MEMS/NEMS-based 3 D.O.F. compliant micro robot. Int. J. Mech. Control 2011, 12, 3–10. [Google Scholar]

- Belfiore, N.P.; Prosperi, G.; Crescenzi, R. A SImple Application of Conjugate Profile Theory to the Development of a Silicon Micro Tribometer. In Proceedings of the ASME 2014 12th Biennial Conference on Engineering Systems Design and Analysis, Copenhagen, Denmark, 25–27 July 2014.

- Belfiore, N.; Broggiato, G.; Verotti, M.; Crescenzi, R.; Balucani, M.; Bagolini, A.; Bellutti, P.; Boscardin, M. Development of a MEMS technology CSFH based microgripper. In Proceedings of the 23rd International Conference on Robotics in Alpe-Adria-Danube Region (RAAD), Smolenice, Slovakia, 3–5 September 2014.

- Belfiore, N.P.; Broggiato, G.B.; Verotti, M.; Balucani, M.; Crescenzi, R.; Bagolini, A.; Bellutti, P.; Boscardin, M. Simulation and Construciton of a MEMS CSFH Based Microgripper. Int. J. Mech. Control 2015, 16, 21–30. [Google Scholar]

- Hou, M.T.K.; Huang, J.Y.; Jiang, S.S.; Yeh, J.A. In-plane rotary comb-drive actuator for a variable optical attenuator. J. Micro/Nanolithogr. MEMS MOEMS 2008, 7, 043015. [Google Scholar] [CrossRef]

- Hopcroft, M.; Nix, W.; Kenny, T. What is the Young’s Modulus of Silicon? J. Microelectromech. Syst. 2010, 19, 229–238. [Google Scholar] [CrossRef]

- Bottema, O.; Roth, B. Theoretical Kinematics; Courier Dover Publications: Mineola, NY, USA, 2011. [Google Scholar]

- Dixit, P.; Miao, J. Effect of SF6 flow rate on the etched surface profile and bottom grass formation in deep reactive ion etching process. J. Phys. Conf. Ser. 2006, 34, 577. [Google Scholar] [CrossRef]

- Sartori, I.; Napolitano, A.; Voss, K. Net zero energy buildings: A consistent definition framework. Energy Build. 2012, 48, 220–232. [Google Scholar] [CrossRef]

- Leckner, M.; Zmeureanu, R. Life cycle cost and energy analysis of a Net Zero Energy House with solar combisystem. Appl. Energy 2011, 88, 232–241. [Google Scholar] [CrossRef]

- Koeneman, P.; Busch-Vishniac, I.; Wood, K. Feasibility of micro power supplies for MEMS. J. Microelectromech. Syst. 1997, 6, 355–362. [Google Scholar] [CrossRef]

- Cook-Chennault, K.; Thambi, N.; Sastry, A. Powering MEMS portable devices—A review of non-regenerative and regenerative power supply systems with special emphasis on piezoelectric energy harvesting systems. Smart Mater. Struct. 2008, 17, 043001. [Google Scholar] [CrossRef]

- Guidetti, V.; Lucchese, F.; Bellini, B. Is the migrainous female brain different? Some new evidence. Brain 2012, 135, 2311–2313. [Google Scholar] [CrossRef] [PubMed]

- Lucchese, F.; Mecacci, L. Visual evoked potentials and heart rate during white noise stimulation. Int. J. Neurosci. 1999, 97, 109–114. [Google Scholar] [CrossRef] [PubMed]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cecchi, R.; Verotti, M.; Capata, R.; Dochshanov, A.; Broggiato, G.B.; Crescenzi, R.; Balucani, M.; Natali, S.; Razzano, G.; Lucchese, F.; et al. Development of Micro-Grippers for Tissue and Cell Manipulation with Direct Morphological Comparison. Micromachines 2015, 6, 1710-1728. https://doi.org/10.3390/mi6111451

Cecchi R, Verotti M, Capata R, Dochshanov A, Broggiato GB, Crescenzi R, Balucani M, Natali S, Razzano G, Lucchese F, et al. Development of Micro-Grippers for Tissue and Cell Manipulation with Direct Morphological Comparison. Micromachines. 2015; 6(11):1710-1728. https://doi.org/10.3390/mi6111451

Chicago/Turabian StyleCecchi, Rossana, Matteo Verotti, Roberto Capata, Alden Dochshanov, Giovanni Battista Broggiato, Rocco Crescenzi, Marco Balucani, Stefano Natali, Giovanna Razzano, Franco Lucchese, and et al. 2015. "Development of Micro-Grippers for Tissue and Cell Manipulation with Direct Morphological Comparison" Micromachines 6, no. 11: 1710-1728. https://doi.org/10.3390/mi6111451