Three-Dimensional Glass Monolithic Micro-Flexure Fabricated by Femtosecond Laser Exposure and Chemical Etching

Abstract

:1. Introduction

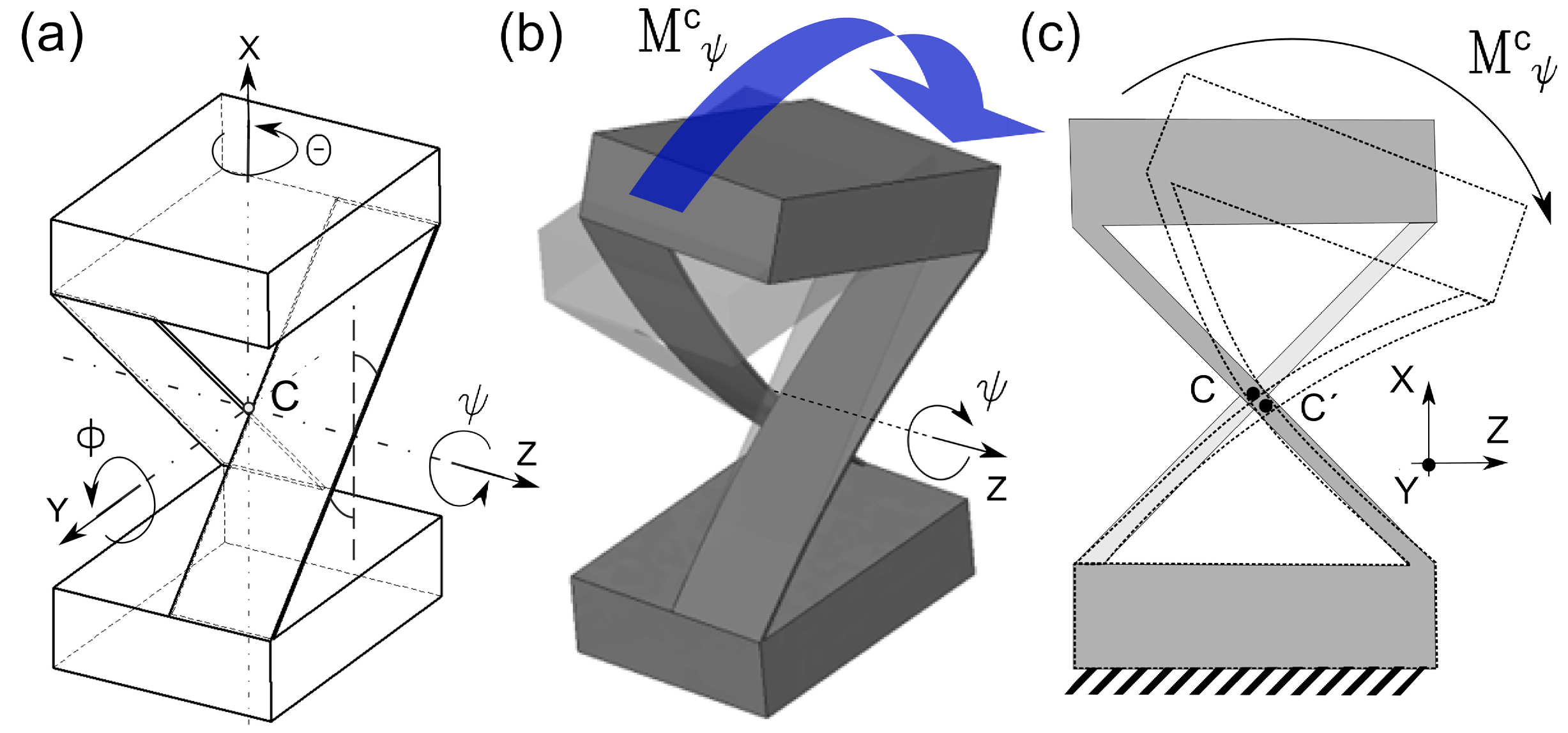

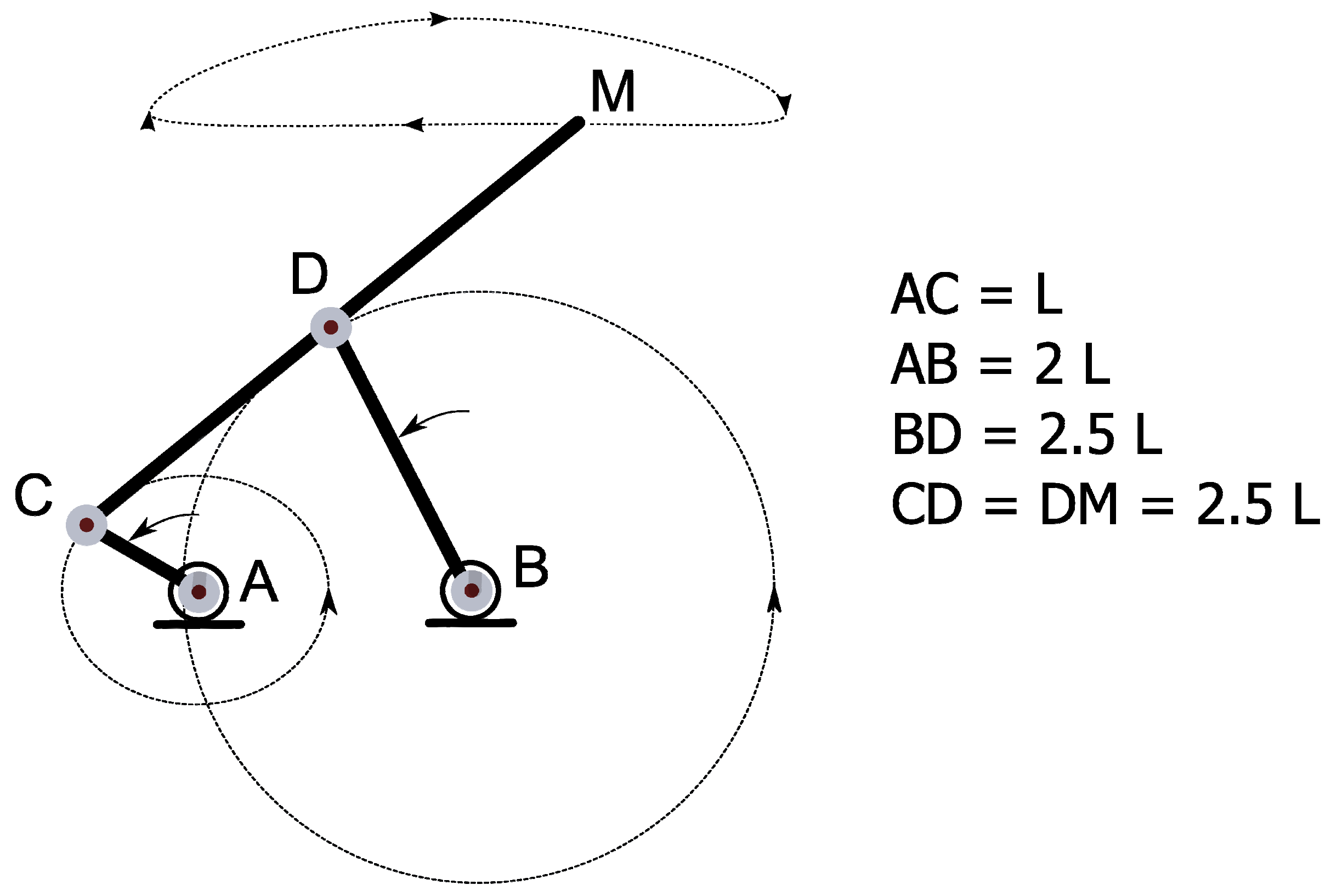

2. The Cross-Pivot as an Elemental Flexure

2.1. Working Principle and Relevance

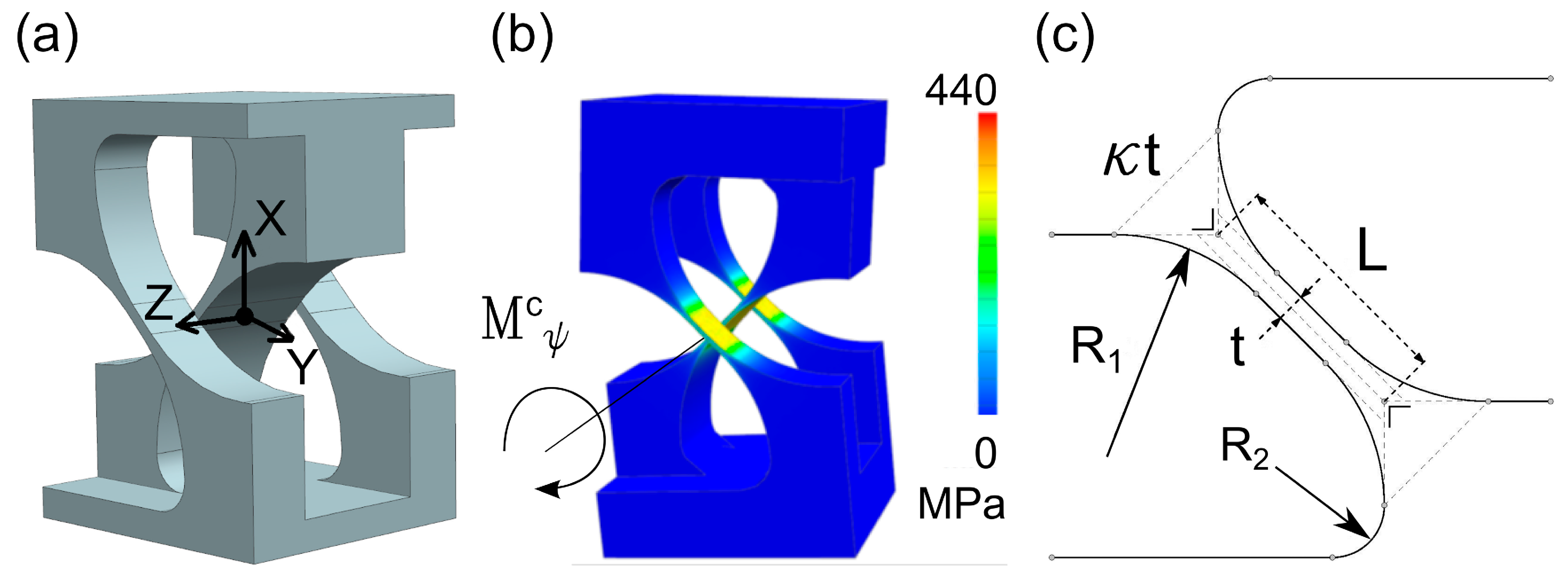

2.2. Stiffness Modeling of the Classical Cross-Spring Pivot

2.3. Design Optimization

| Stiffness component |  |  |  |  |  |  |  |

|---|---|---|---|---|---|---|---|

| Cross-spring pivot |  |  | 1 |  |  | 1 | 6s4 |

| Cantilever | s4 | 1 | s2 | s2 |  | 1 | 12 |

| Property | Hinge type | |||

|---|---|---|---|---|

| Cantilever * | Notch hinge | Cartwheel [1] | Cross-spring pivot *** | |

| Drift of the center of rotation (assuming a perfect loading case, i.e., a pure moment applied on the hinge) | δ = ζLθ2 | ~0 ** |  | δ = λLθ2 |

| Maximum angular deflection |  |  |  |  |

| Stress concentration | Low | High | Medium | Low |

| Complexity/manufacturability | Low | Medium | Medium | High (3D) |

3. Experimental Results

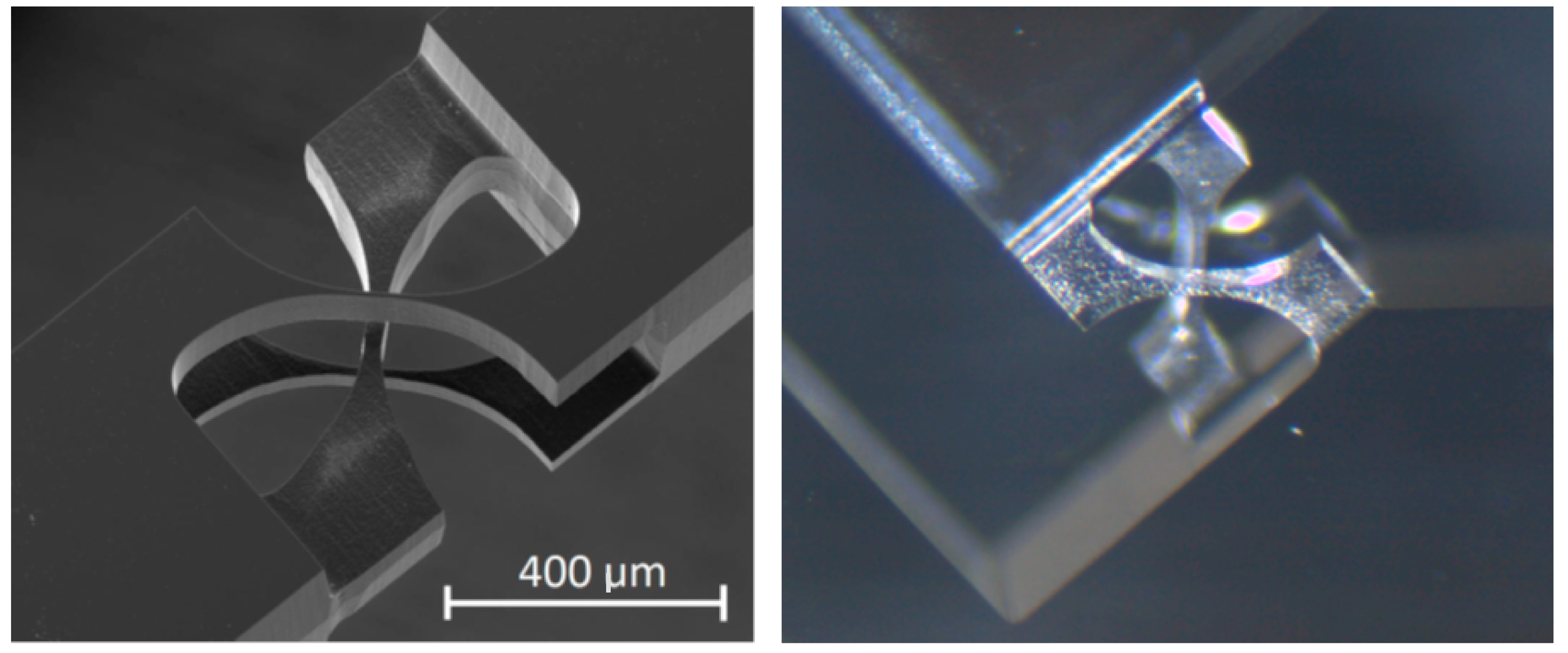

3.1. Device Fabrication

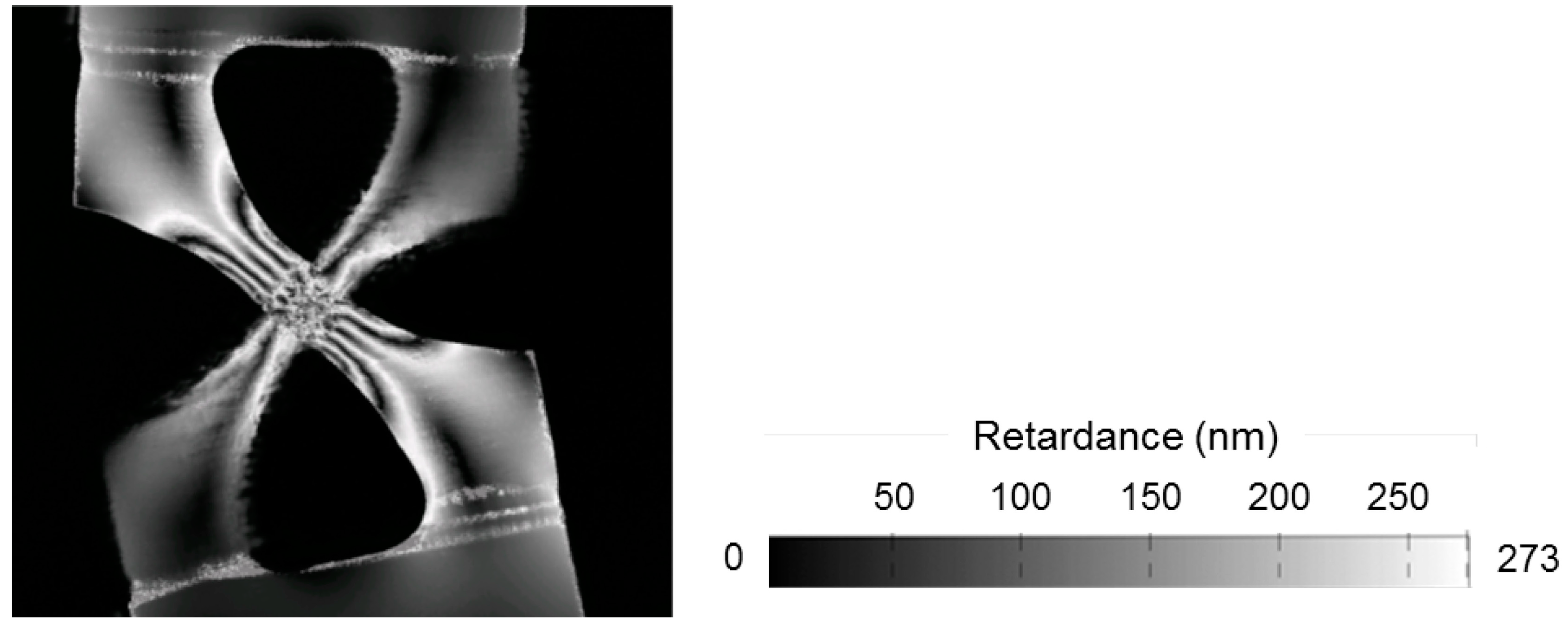

3.2. Stress-Induced Birefringence: Direct Measurement of Stress State in the Flexure

3.3. Integration of the Cross-Spring Flexure in a Pure Linear Guidance

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References and Notes

- Smith, S.T. Flexures: Elements of Elastic Mechanisms; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Lobontiu, N. Compliant Mechanisms: Design of Flexure Hinges; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Howell, L.L. Compliant Mechanisms; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Sears, J.E. A symmetrically opening optical slit. J. Sci. Instrum. 1933, 10, 376–377. [Google Scholar] [CrossRef]

- Haringx, J.A. The cross-spring pivot as a constructional element. Appl. Sci. Res. 1949, 1, 313–332. [Google Scholar] [CrossRef]

- Wittrick, W.H. The theory of symmetrical crossed flexure pivots. Aust. J. Sci. Res. Ser. A Phys. Sci. 1948, 1, 121–134. [Google Scholar]

- Mesnager, A. Sur les articulations à lames flexibles. Comptes rendus Hebdomadaires des Séances de l’Académie des Sciences 1903, 137, 908–909. (In French) [Google Scholar]

- Jones, R. V. An optical slit mechanism. J. Sci. Instrum. 1952, 29, 345–350. [Google Scholar] [CrossRef]

- Schellekens, P.; Rosielle, N.; Vermeulen, H.; Vermeulen, M.; Wetzels, S.; Pril, W. Design for precision: Current status and trends. CIRP Ann. Manuf. Technol. 1998, 47, 557–586. [Google Scholar] [CrossRef]

- Breguet, J.-M.; Henein, S.; Kjelberg, I.; Gumy, M.; Glettig, W.; Lecomte, S.; Boiko, D.; Mitev, V. Tunable extended-cavity diode laser based on a novel flexure-mechanism. Int. J. Optomechatronics 2013, 7, 181–192. [Google Scholar] [CrossRef]

- Marcinkevičius, A.; Juodkazis, S.; Watanabe, M.; Miwa, M.; Matsuo, S.; Misawa, H.; Nishii, J. Femtosecond laser-assisted three-dimensional microfabrication in silica. Opt. Lett. 2001, 26, 277–279. [Google Scholar]

- Kiyama, S.; Matsuo, S.; Hashimoto, S.; Morihira, Y. Examination of etching agent and etching mechanism on femotosecond laser microfabrication of channels inside vitreous silica substrates. J. Phys. Chem. C 2009, 113, 11560–11566. [Google Scholar] [CrossRef]

- Bellouard, Y.; Said, A.; Dugan, M.; Bado, P. Monolithic Three-Dimensional Integration of Micro-Fluidic Channels and Optical Waveguides in Fused Silica. In Proceedings of Materials Research Society Symposium, Warrendale, PA, USA; 2003; pp. 63–68. [Google Scholar]

- Bellouard, Y.; Champion, A.; Lenssen, B.; Matteucci, M.; Schaap, A.; Beresna, M.; Corbari, C.; Gecevicius, M.; Kazansky, P.; Chappuis, O.; Kral, M.; Clavel, R.; Barrot, F.; Breguet, J.-M.; Mabillard, Y.; Bottinelli, S.; Hopper, M.; Hoenninger, C.; Mottay, E.; Lopez, J. The Femtoprint Project. J. Laser Micro/Nanoeng. 2012, 7, 1–10. [Google Scholar]

- Bellouard, Y.; Said, A.; Bado, P. Integrating optics and micro-mechanics in a single substrate: A step toward monolithic integration in fused silica. Opt. Express 2005, 13, 6635–6644. [Google Scholar] [CrossRef] [PubMed]

- Lenssen, B.; Bellouard, Y. Optically transparent glass micro-actuator fabricated by femtosecond laser exposure and chemical etching. Appl. Phys. Lett. 2012, 101, 103503. [Google Scholar] [CrossRef]

- Cheng, Y.; Sugioka, K.; Midorikawa, K.; Masuda, M.; Toyoda, K.; Kawachi, M.; Shihoyama, K. Three-dimensional micro-optical components embedded in photosensitive glass by a femtosecond laser. Opt. Lett. 2003, 28, 1144–1146. [Google Scholar] [CrossRef] [PubMed]

- Juodkazis, S.; Yamasaki, K.; Mizeikis, V.; Matsuo, S.; Misawa, H. Formation of embedded patterns in glasses using femtosecond irradiation. Appl. Phys. A. 2004, 79, 1549–1553. [Google Scholar]

- Sugioka, K.; Masuda, M.; Hongo, T.; Cheng, Y.; Shihoyama, K.; Midorikawa, K. Three-dimensional microfluidic structure embedded in photostructurable glass by femtosecond laser for lab-on-chip applications. Appl. Phys. A: Mater. Sci. Process. 2004, 79, 815–817. [Google Scholar]

- Hasegawa, S.; Hayasaki, Y. Holographic vector wave femtosecond laser processing. Int. J. Optomechatronics 2014, 8, 73–88. [Google Scholar] [CrossRef]

- Bellouard, Y. On the bending strength of fused silica flexures fabricated by ultrafast lasers. Opt. Mater. Express 2011, 1, 816–831. [Google Scholar] [CrossRef]

- While it seems that the paternity of this linkage is to be attributed to Karl Hoecken (see [24]), the name Hoecken seems often misspelled and sometimes, this linkage is referred as Hoeken or Hoekens linkage, see for instance [23].

- Lu, S.; Zlatanov, D.; Ding, X.; Molfino, R. A new family of deployable mechanisms based on the Hoekens linkage. Mech. Mach. Theory 2014, 73, 130–153. [Google Scholar] [CrossRef]

- Kerle, H. About Karl Hoecken and Some of His Works on Mechanisms. In Explorations in the History of Machines and Mechanisms: Proceedings of HMM2012; Koetsier, T., Ceccarelli, M., Eds.; Springer Netherlands: Dordrecht, The Netherlands, 2012; Volume 15, pp. 123–134. [Google Scholar]

- Loncaric, J. Normal forms of stiffness and compliance matrices. IEEE J. Robot. Autom. 1987, 3, 567–572. [Google Scholar] [CrossRef]

- Ding, X.; Selig, J.M. On the compliance of coiled springs. Int. J. Mech. Sci. 2004, 46, 703–727. [Google Scholar] [CrossRef]

- Bellouard, Y. Microrobotics: Methods and Applications; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Von Mises, R. Motorrechnung, ein neues hilfsmittel in der mechanik. J. Appl. Math. Mech./Z. Angew. Math. Mech. 1924, 4, 155–181. (In German) [Google Scholar]

- Shusheng, B.; Hongzhe, Z.; Jingjun, Y. Modeling of a cartwheel flexural pivot. J. Mech. Des. 2009, 131, 061010. [Google Scholar] [CrossRef]

- Bellouard, Y.; Said, A.; Dugan, M.; Bado, P. Fabrication of high-aspect ratio, micro-fluidic channels and tunnels using femtosecond laser pulses and chemical etching. Opt. Express 2004, 12, 2120–2129. [Google Scholar] [CrossRef] [PubMed]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Tielen, V.; Bellouard, Y. Three-Dimensional Glass Monolithic Micro-Flexure Fabricated by Femtosecond Laser Exposure and Chemical Etching. Micromachines 2014, 5, 697-710. https://doi.org/10.3390/mi5030697

Tielen V, Bellouard Y. Three-Dimensional Glass Monolithic Micro-Flexure Fabricated by Femtosecond Laser Exposure and Chemical Etching. Micromachines. 2014; 5(3):697-710. https://doi.org/10.3390/mi5030697

Chicago/Turabian StyleTielen, Viktor, and Yves Bellouard. 2014. "Three-Dimensional Glass Monolithic Micro-Flexure Fabricated by Femtosecond Laser Exposure and Chemical Etching" Micromachines 5, no. 3: 697-710. https://doi.org/10.3390/mi5030697