Self-Calibration Method Based on Surface Micromaching of Light Transceiver Focal Plane for Optical Camera

Abstract

:1. Introduction

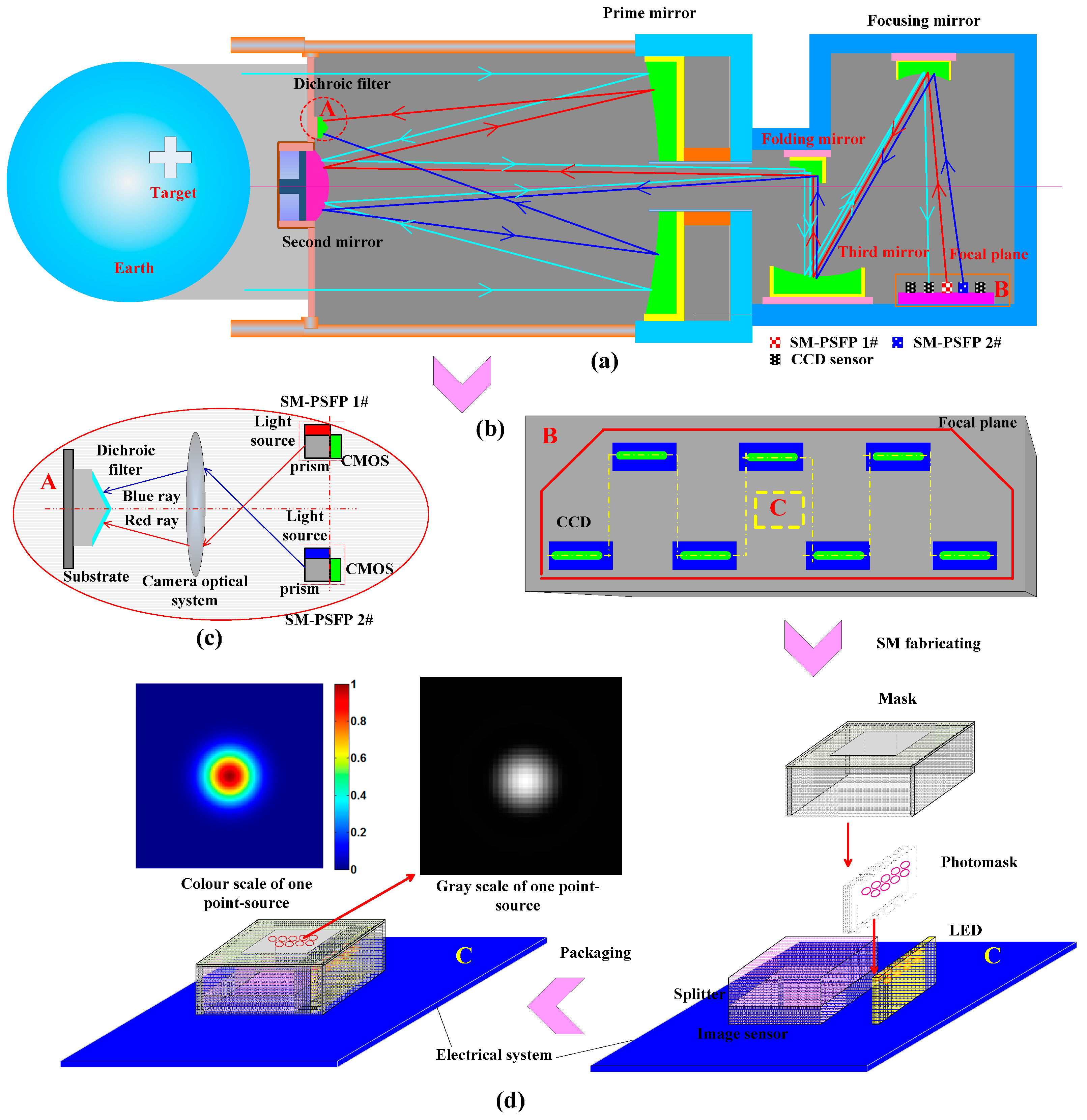

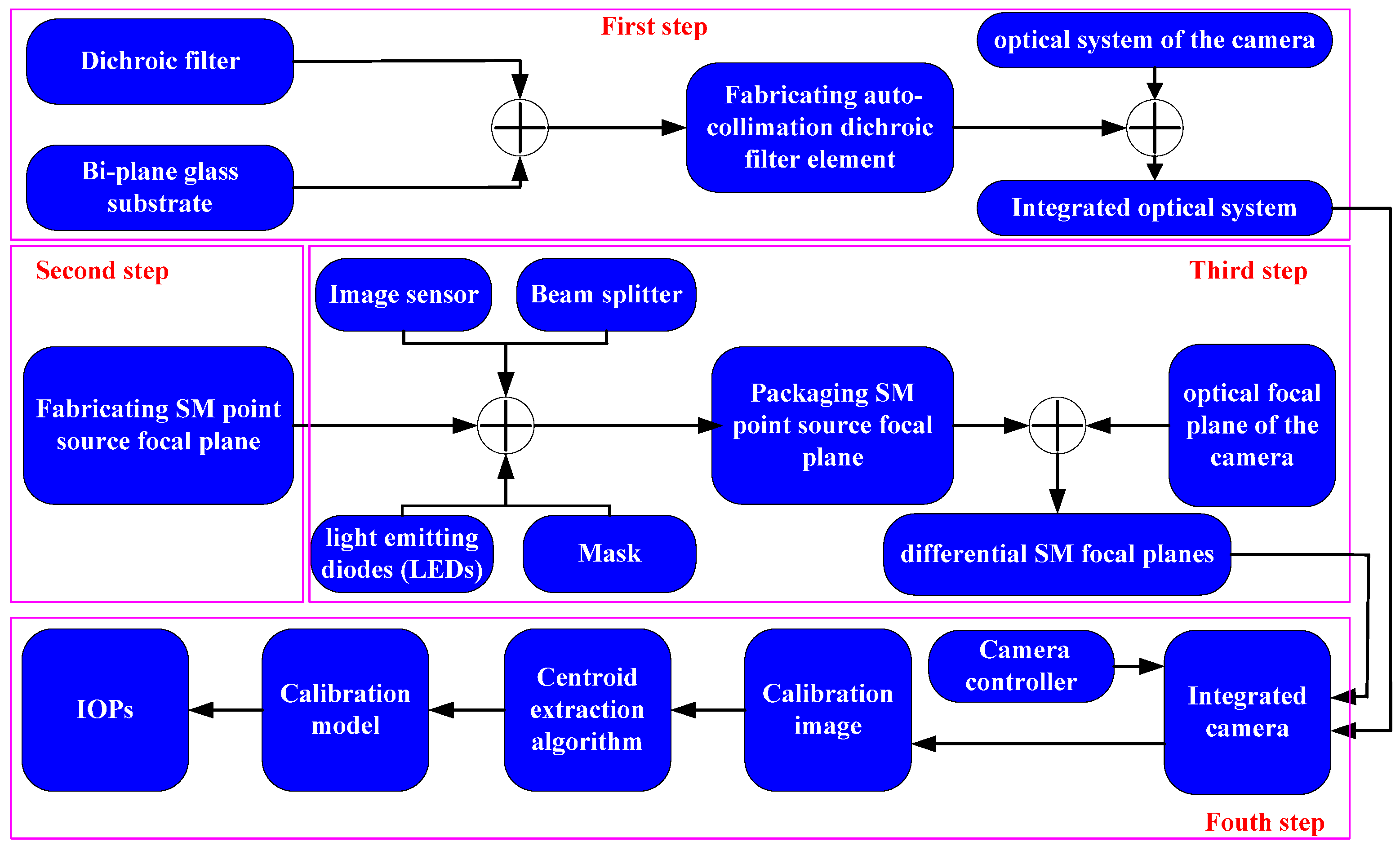

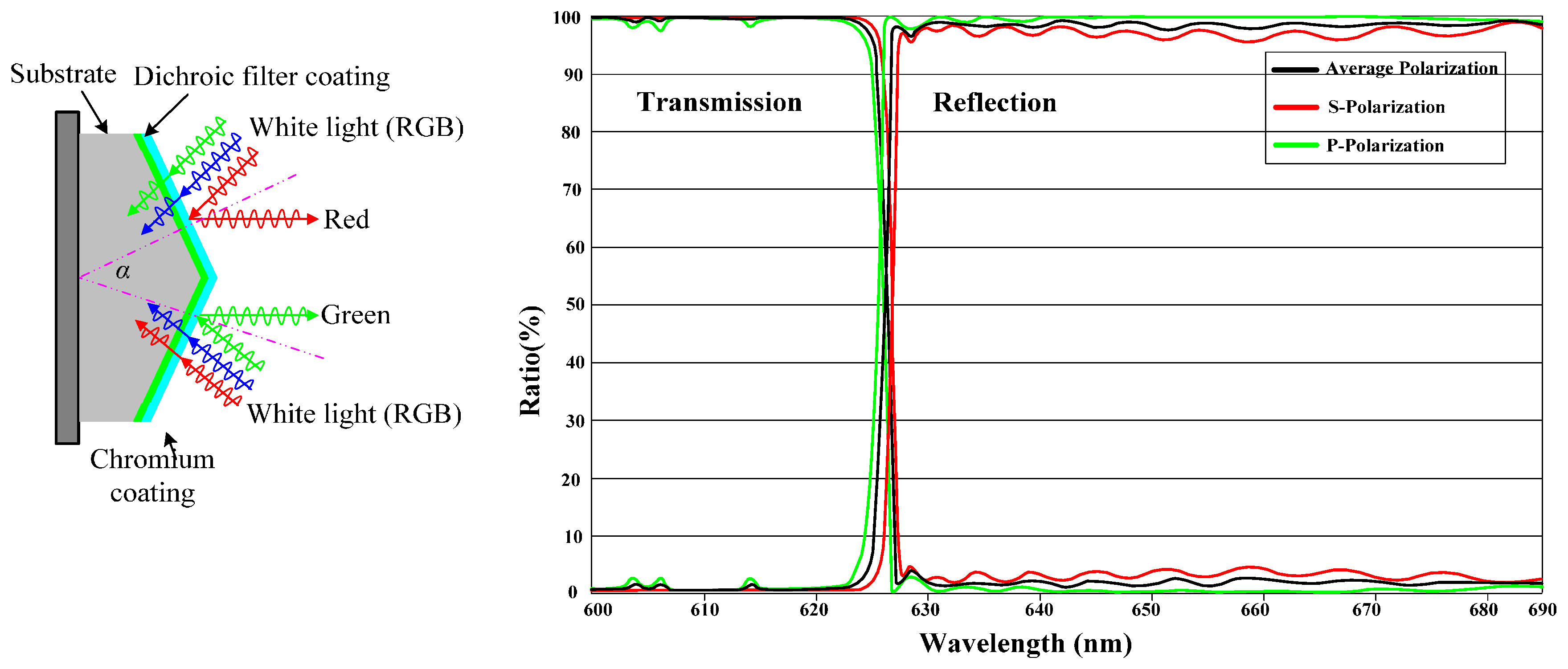

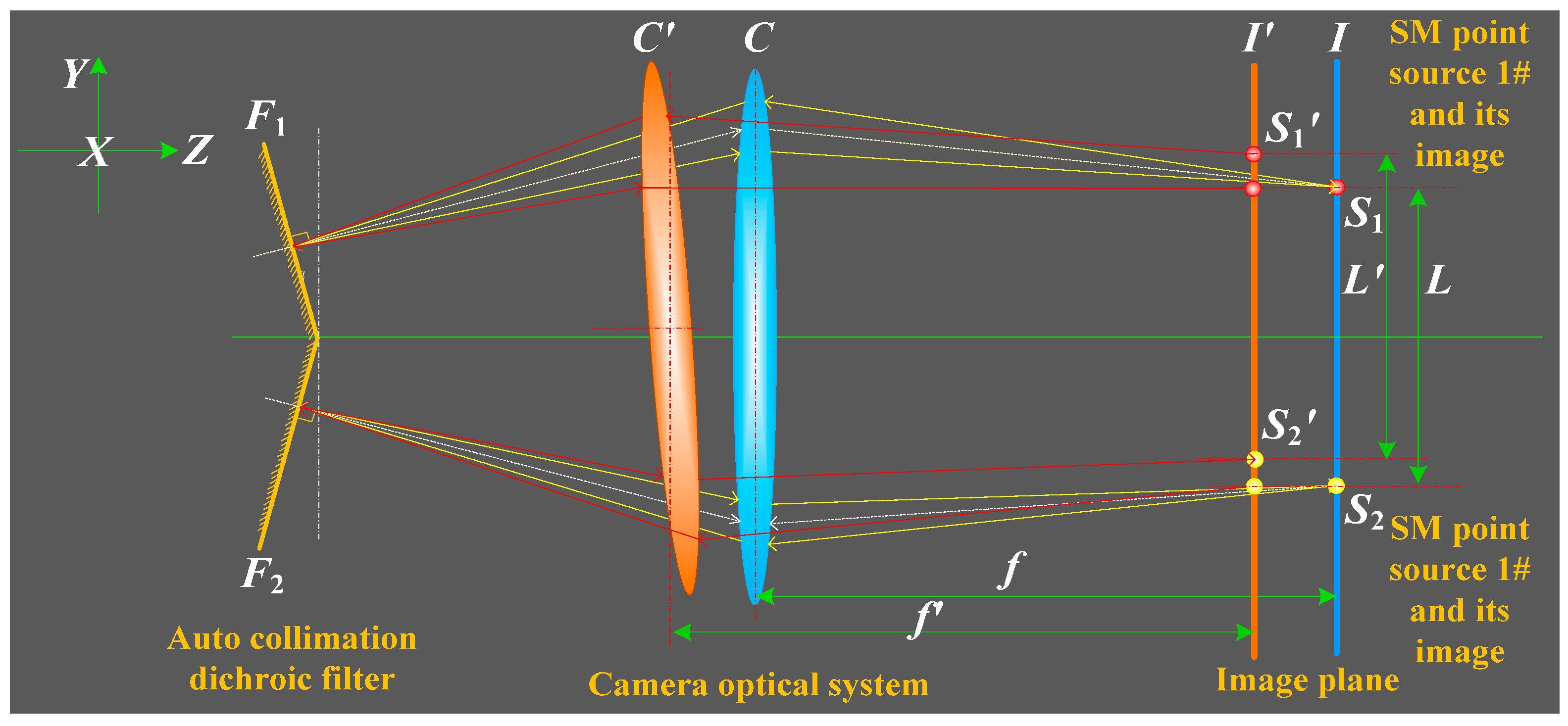

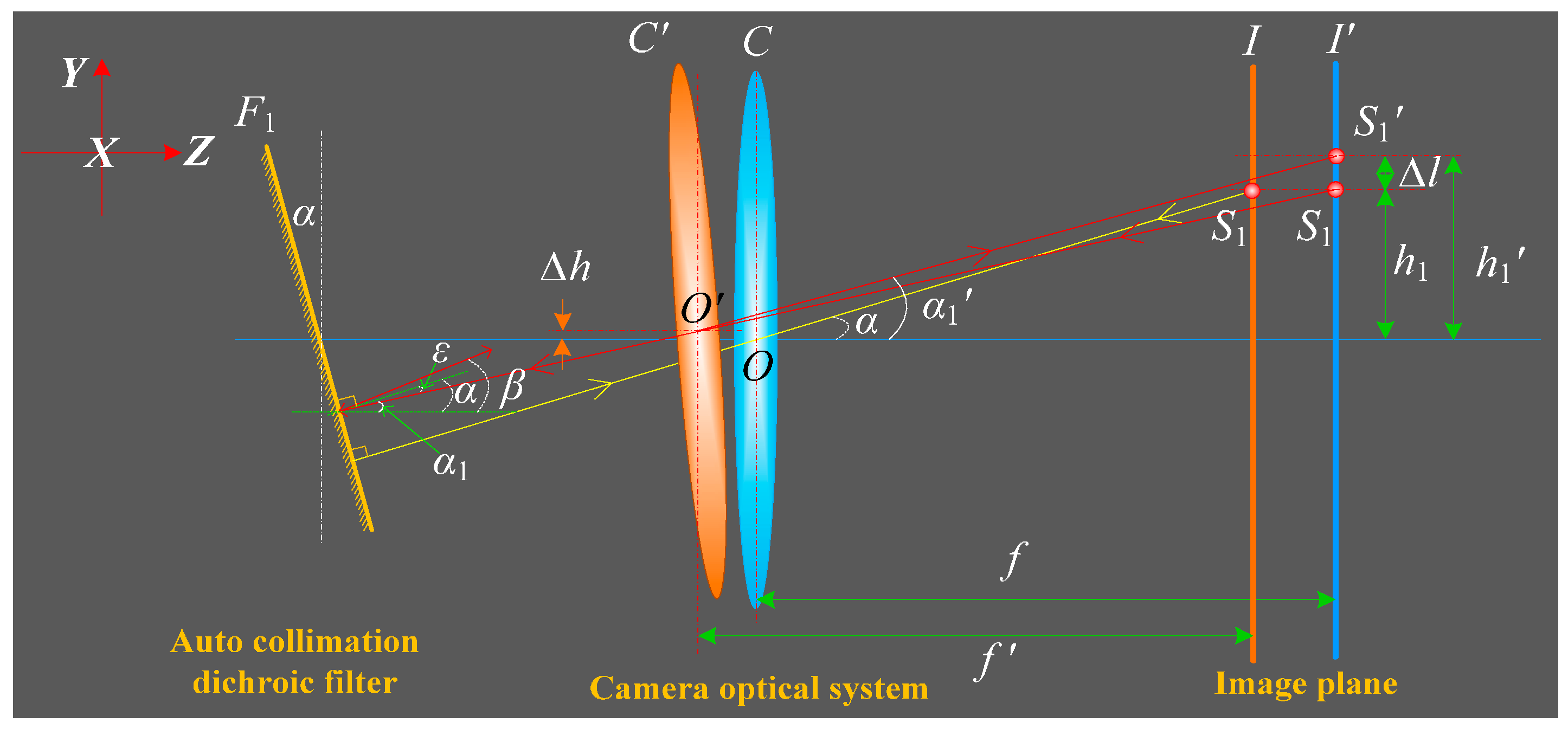

2. Proposed Self-Calibration Method

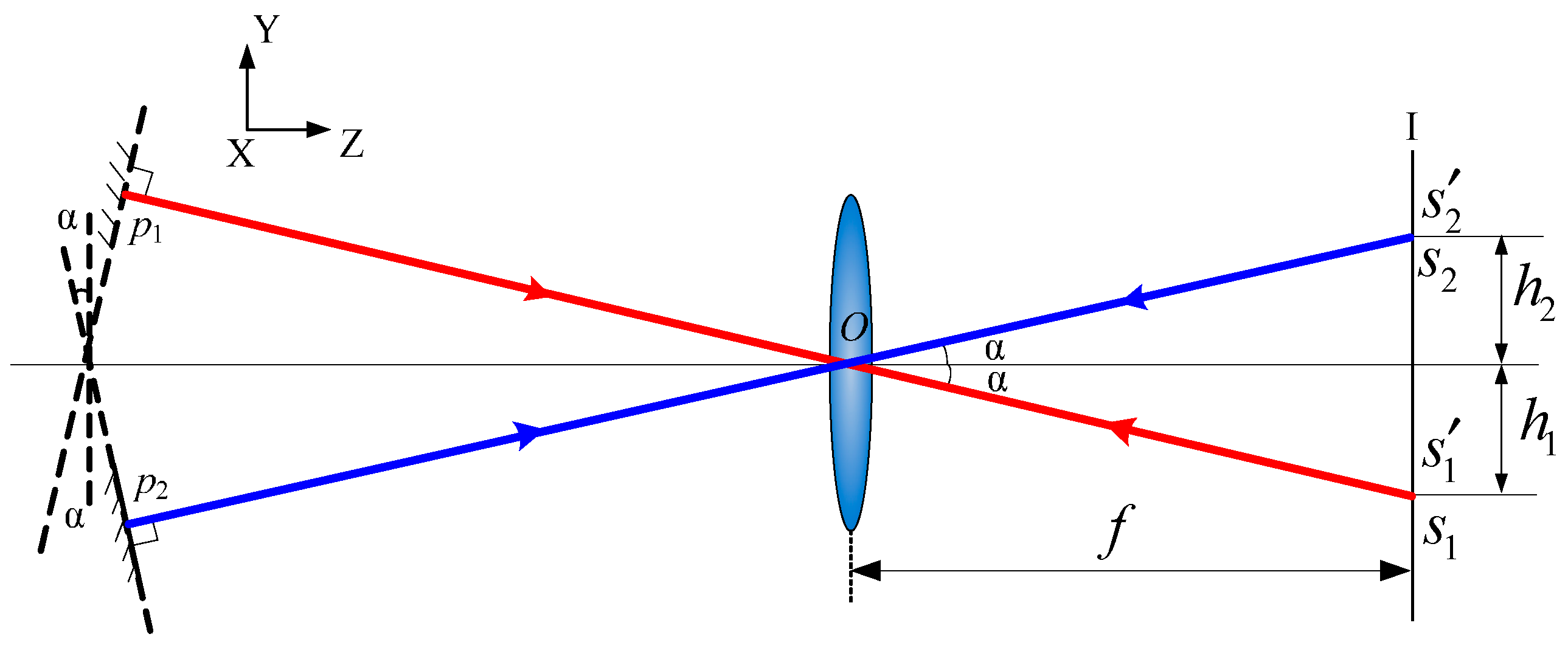

3. Calibration Calculation Based on Differential SMFPs

4. Experiment and Analysis

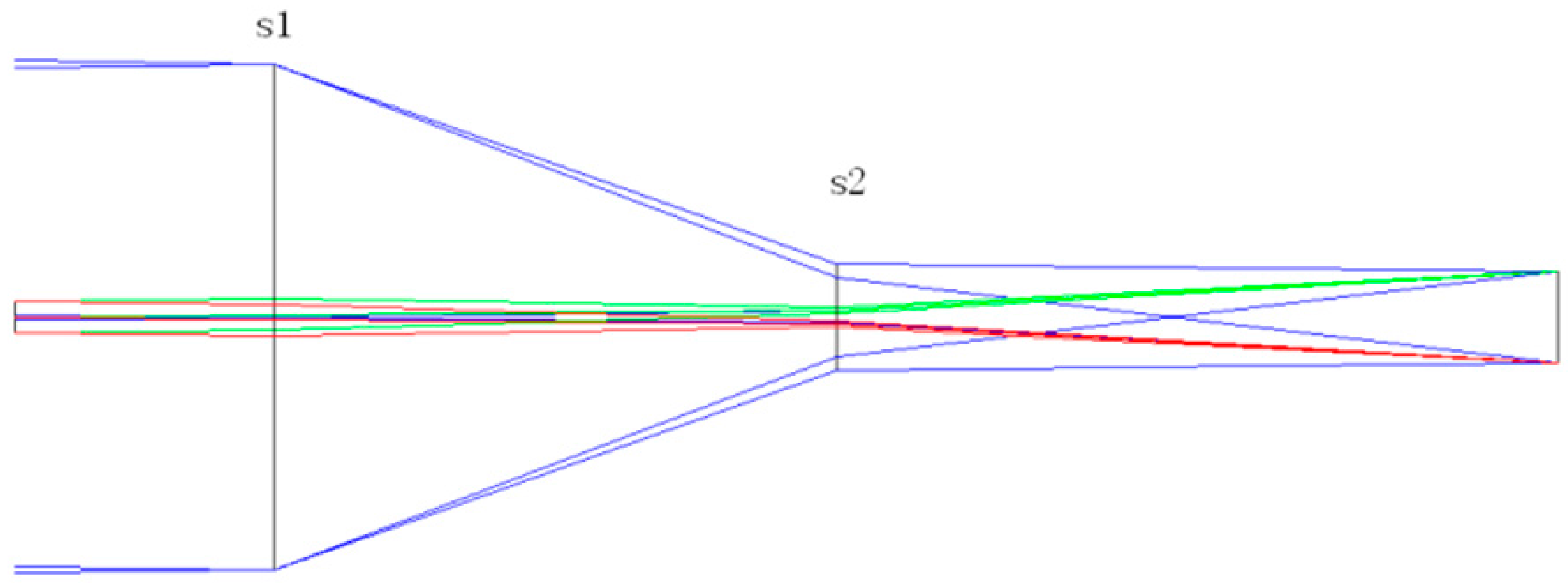

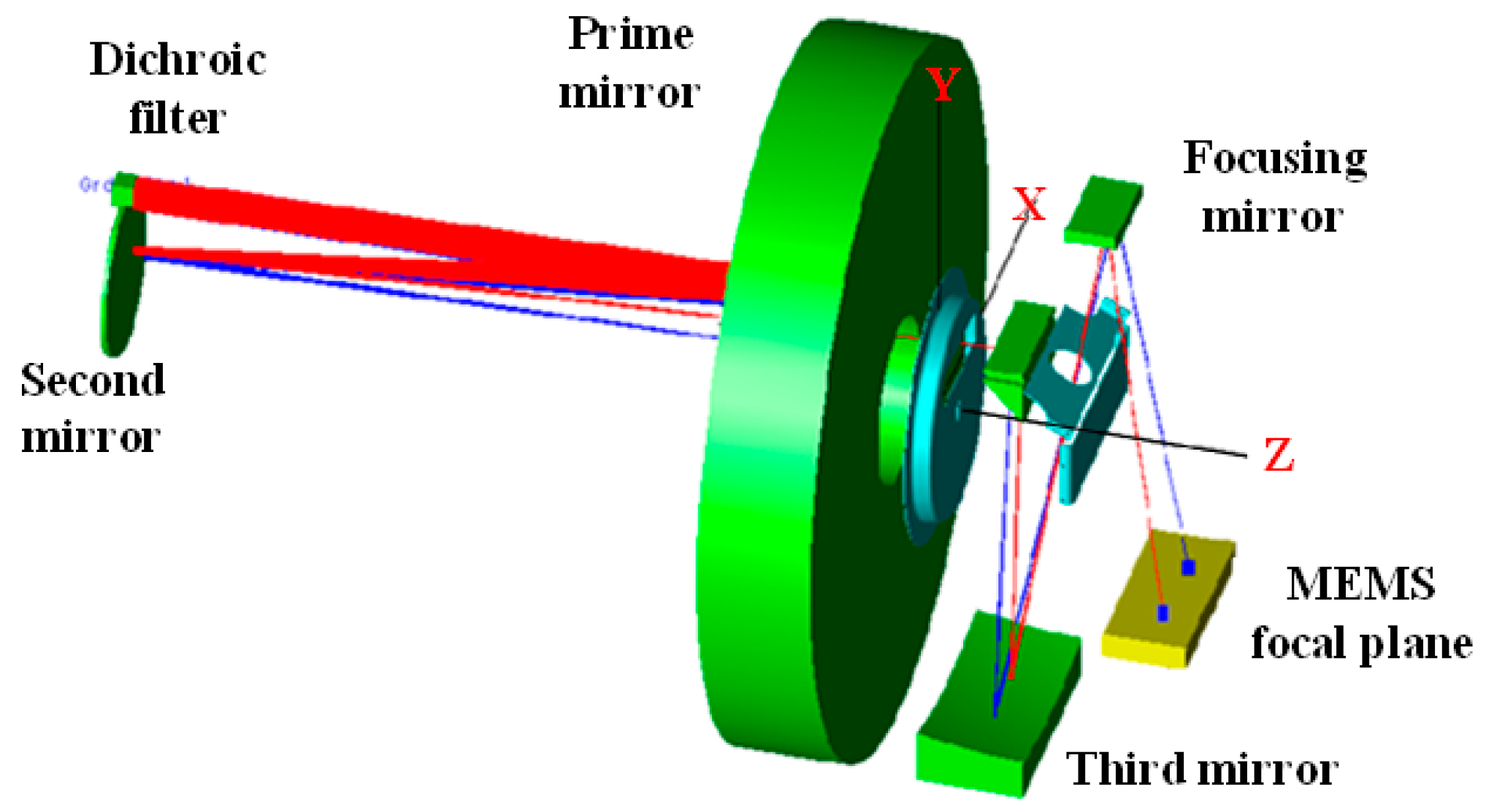

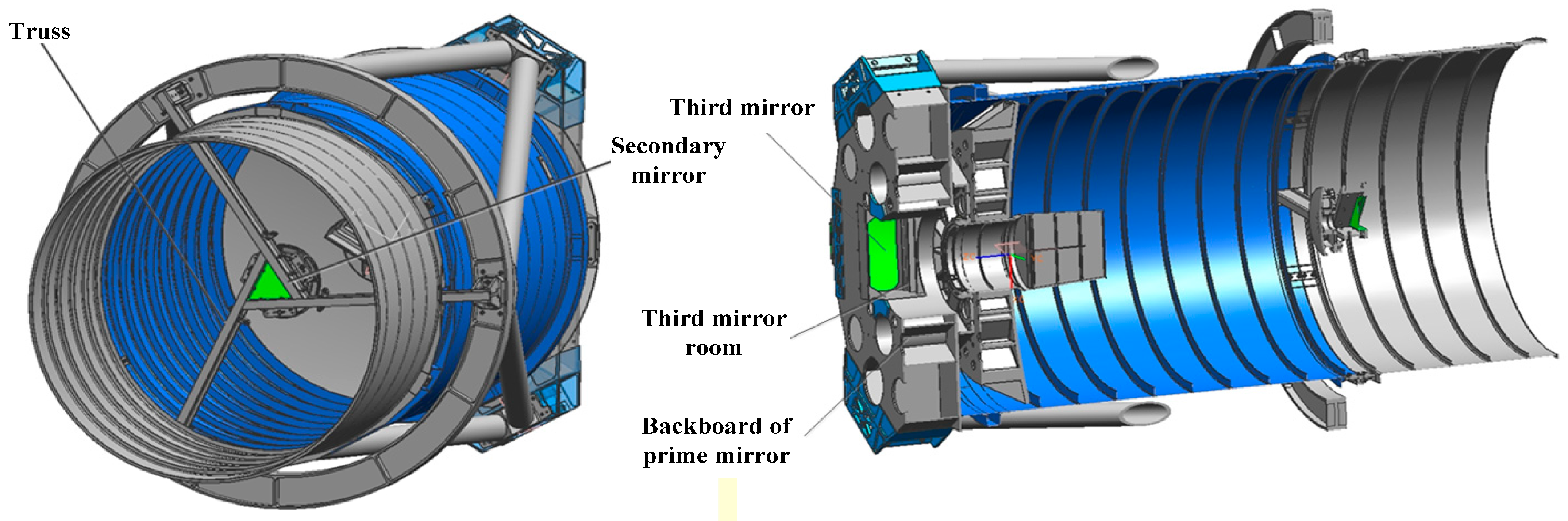

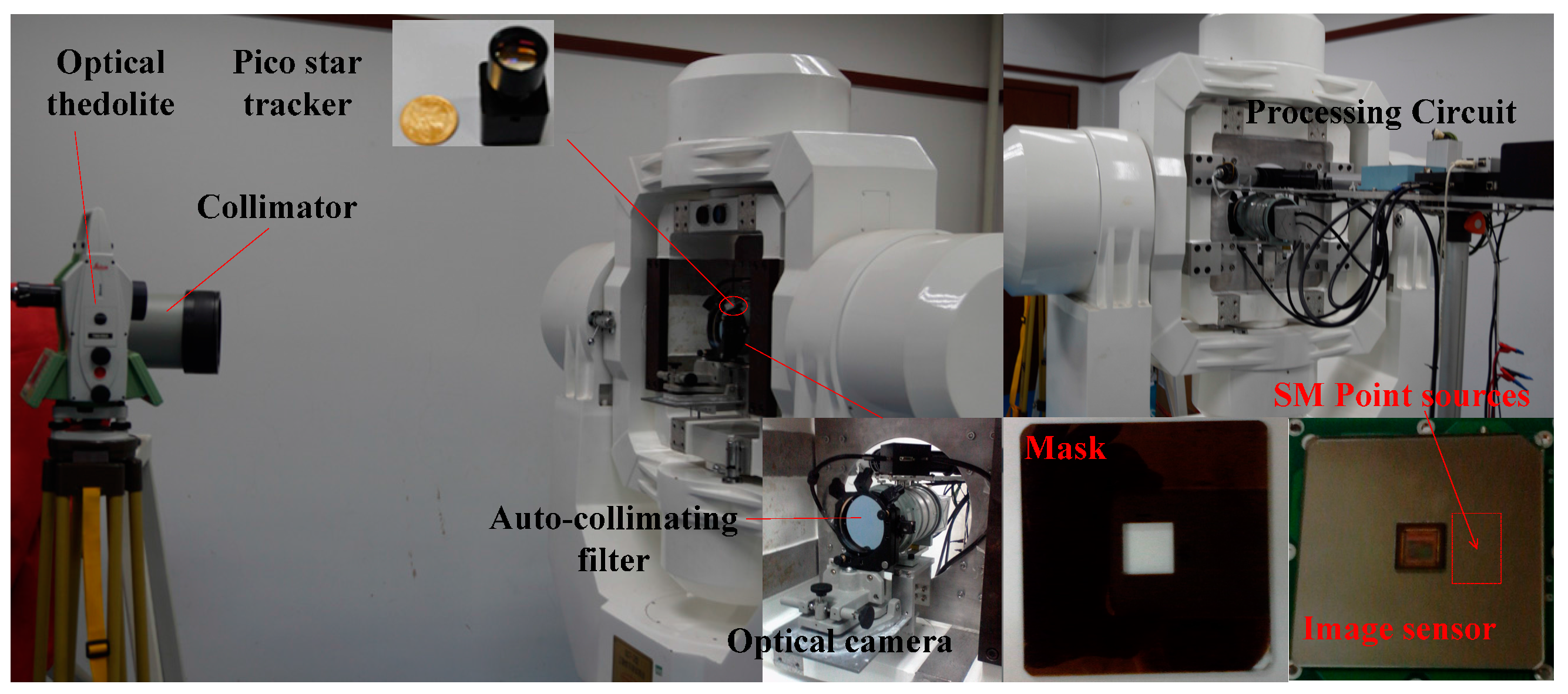

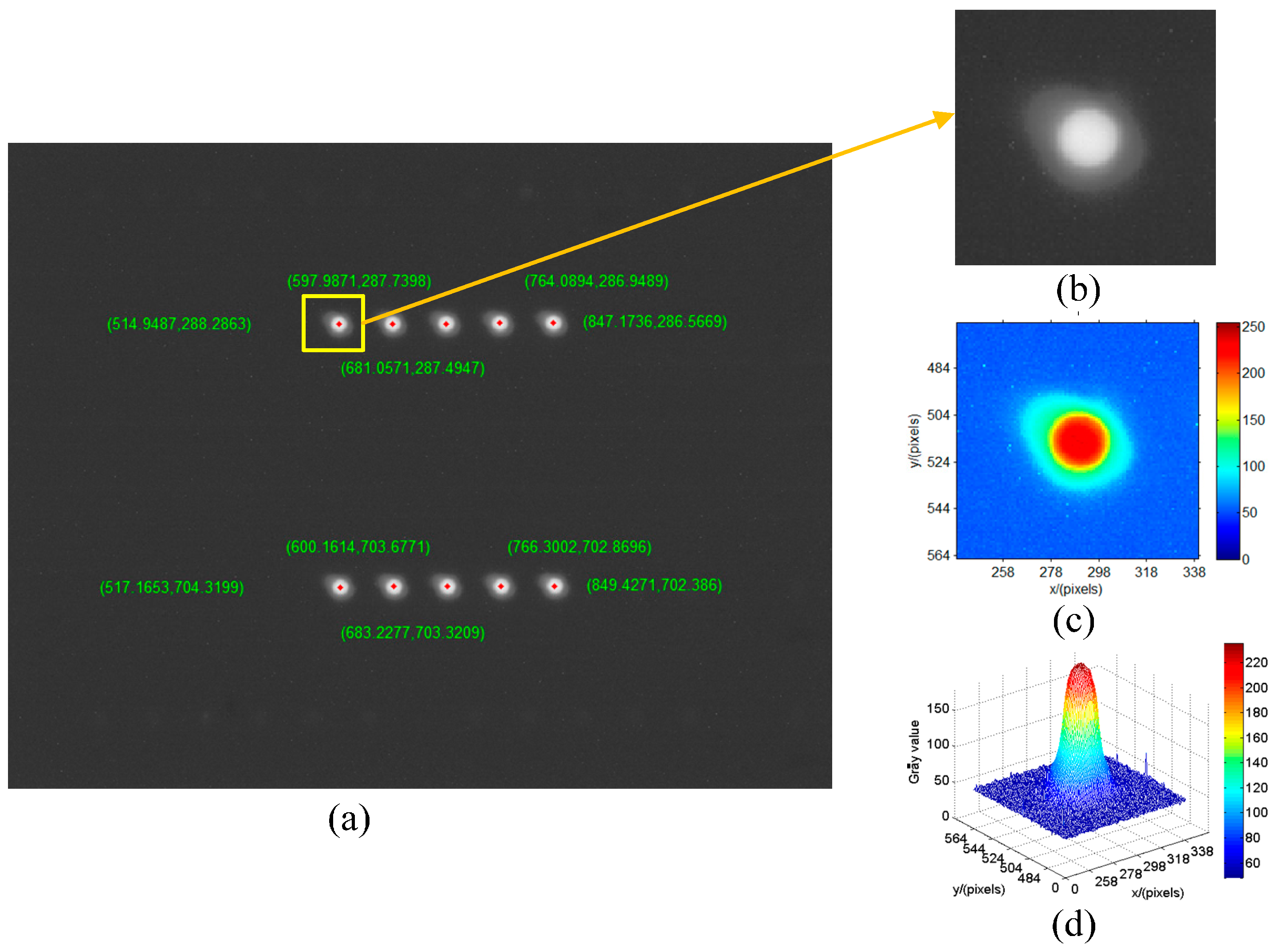

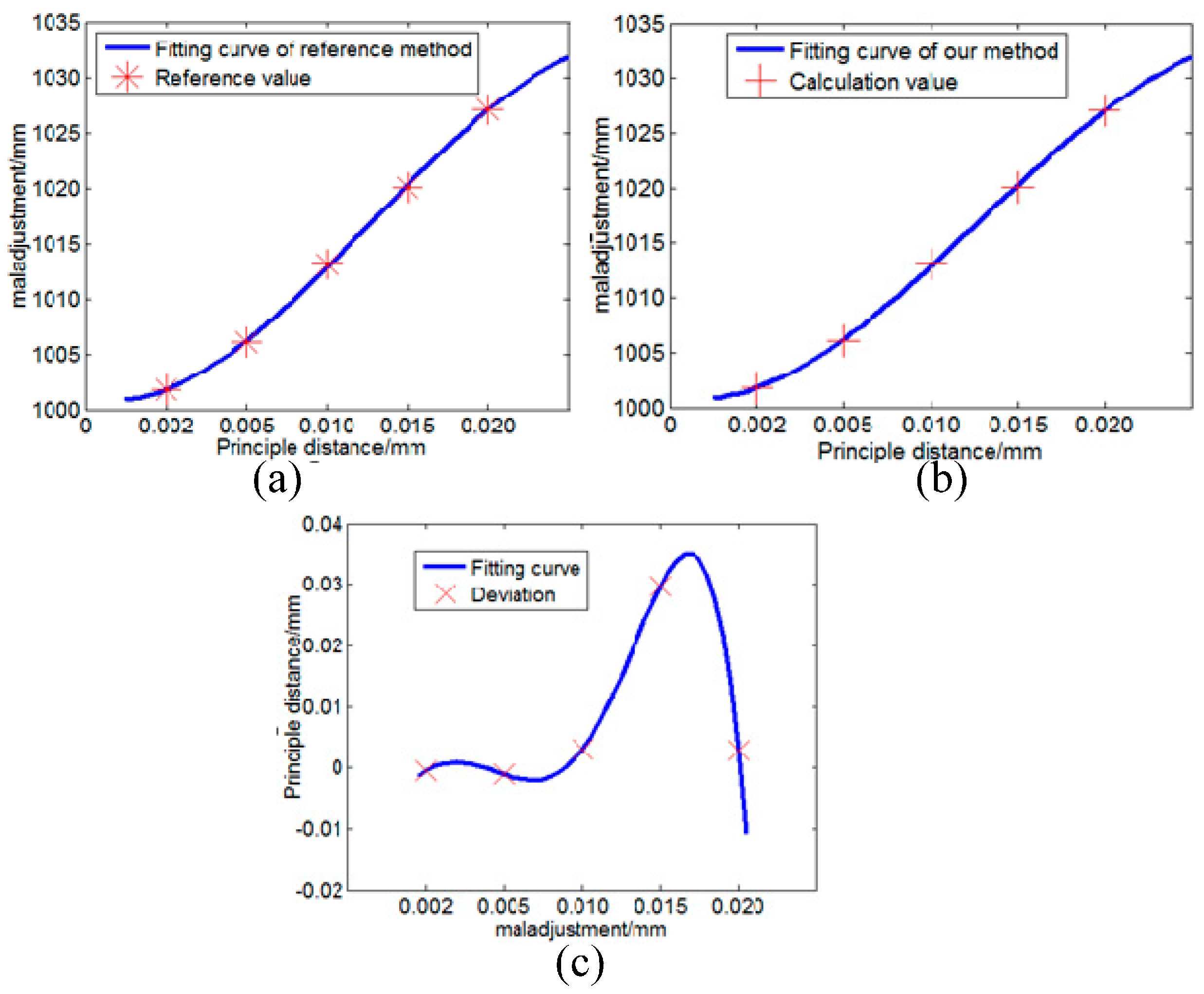

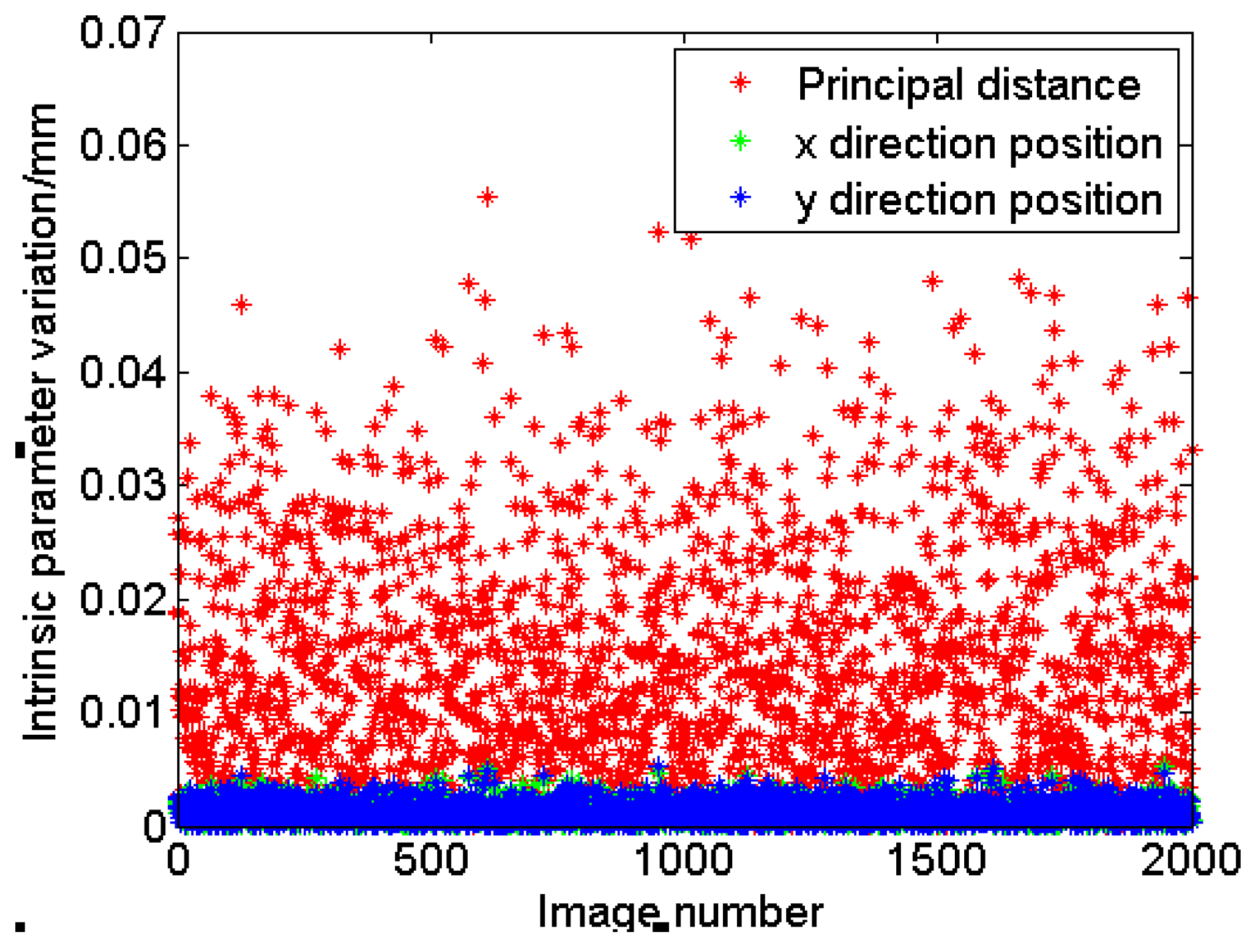

4.1. Experiment of Optical System

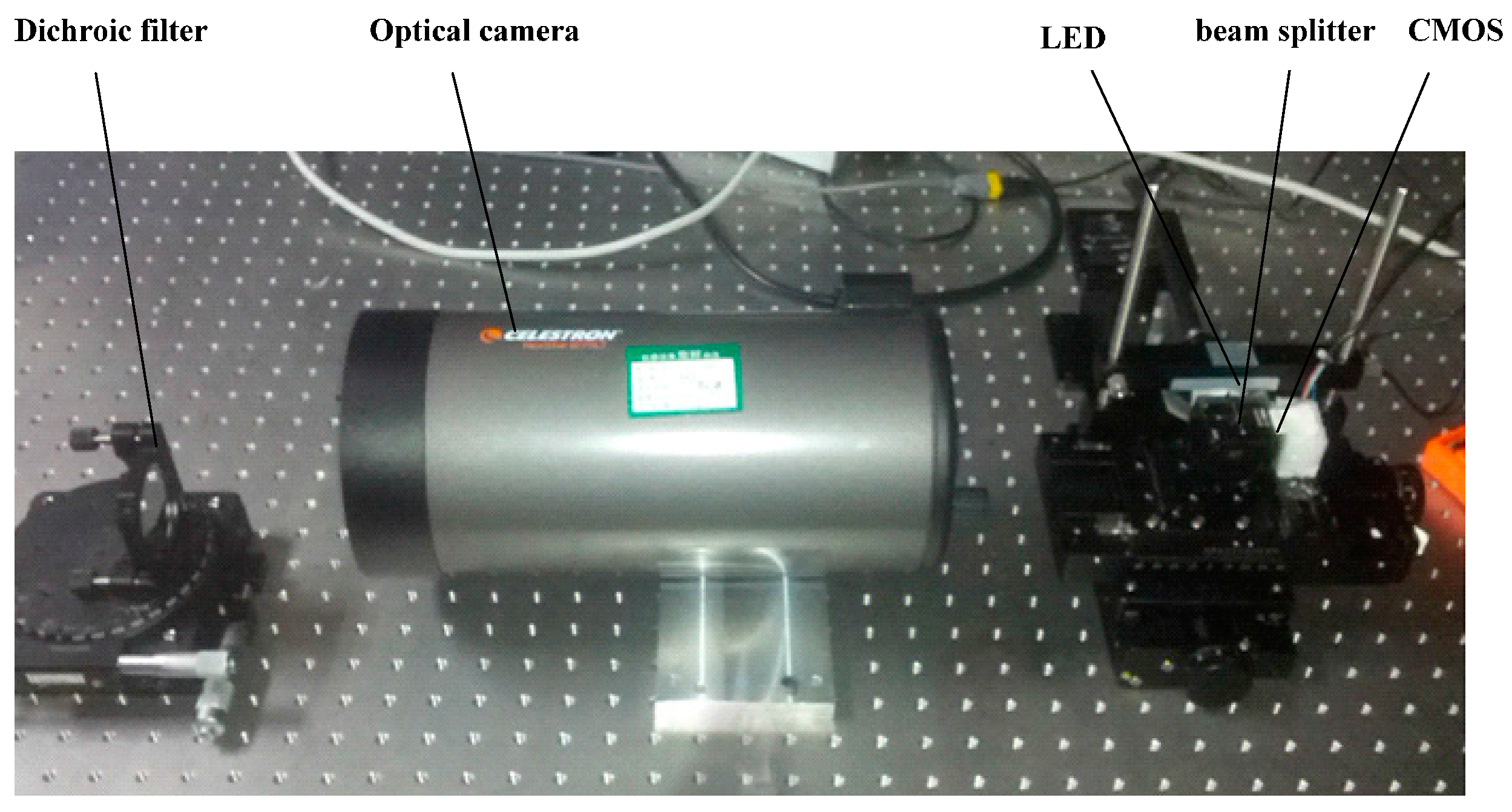

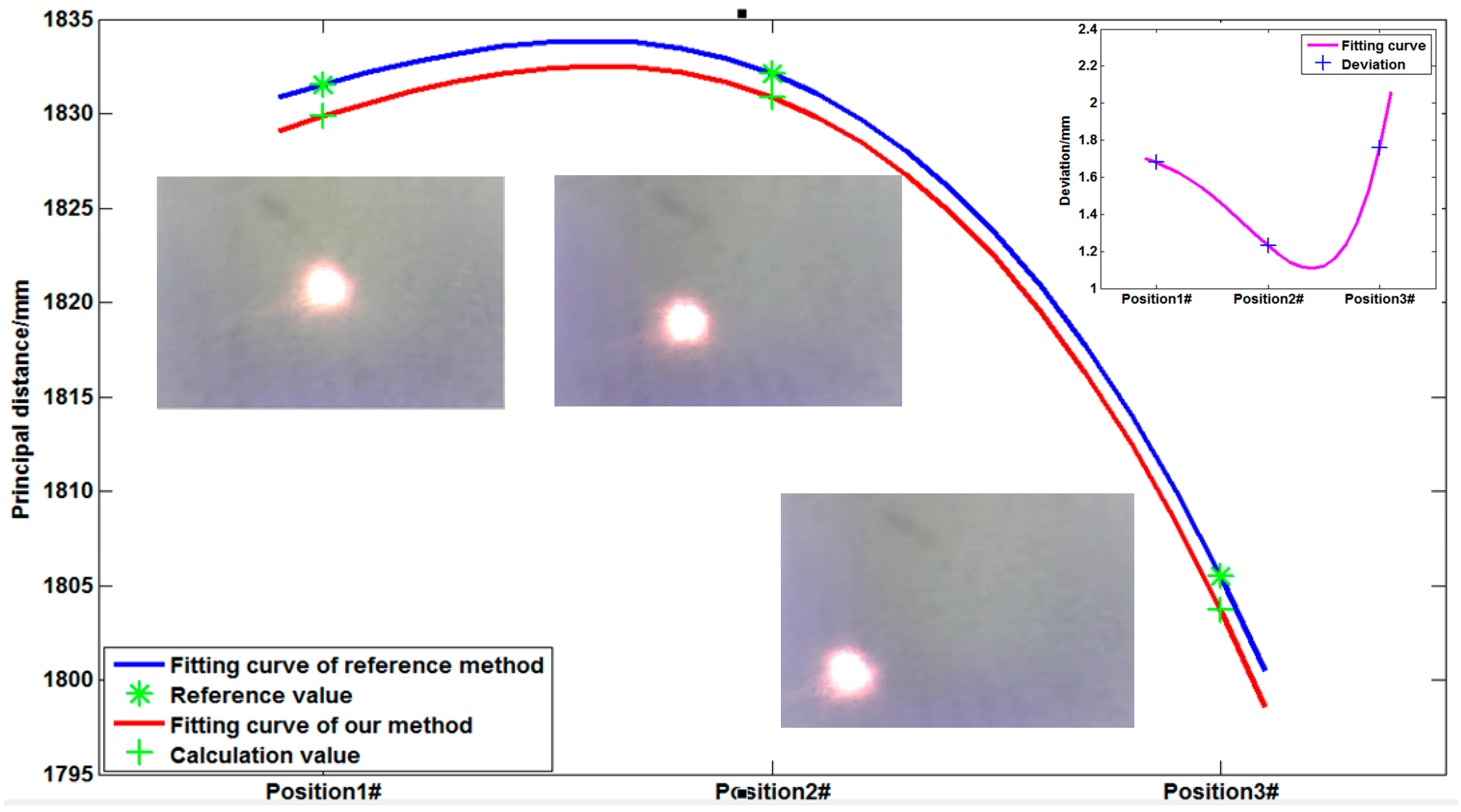

4.2. Experiment of Setup in Lab

5. Conclusions

Supplementary Files

Supplementary File 1Acknowledgments

Author Contributions

Conflicts of Interest

References

- Stuffler, T.; Kaufmann, C.; Hofer, S.; Forster, K.P.; Schreier, G.; Mueller, A.; Eckardt, A.; Bach, H.; Penne, B.; Benz, U. The EnMAP hyperspectral imager—An advanced optical payload for future applications in Earth Observation programmes. Acta Astronaut. 2007, 61, 115–120. [Google Scholar] [CrossRef]

- Teillet, P.M. A status overview of earth observation calibration/validation for terrestrial applications. Can. J. Remote Sens. 1997, 23, 291–298. [Google Scholar] [CrossRef]

- Fritz, L.W. Commercial earth observation satellites. Int. Arch. Photogramm. Remote Sens. 1996, 31, 273–282. [Google Scholar]

- Hu, Q. Input shaping and variable structure control for simultaneous precision positioning and vibration reduction of flexible spacecraft with saturation compensation. J. Sound Vib. 2008, 318, 18–35. [Google Scholar] [CrossRef]

- Wei, M.; Xing, F.; You, Z. An implementation method based on ERS imaging mode for sun sensor with 1 kHz update rate and 1 precision level. Opt. Express 2013, 21, 32524–32533. [Google Scholar] [CrossRef] [PubMed]

- Sun, T.; Xing, F.; You, Z.; Wei, M. Motion-blurred star acquisition method of the star tracker under high dynamic conditions. Opt. Express 2013, 21, 20096–20110. [Google Scholar] [CrossRef] [PubMed]

- Skaloud, J.; Cramer, M.; Schwarz, K.P. Exterior orientation by direct measurement of camera position and attitude. Int. Arch. Photogramm. Remote Sens. 1996, 31, 125–130. [Google Scholar]

- Fraser, C.S.; Ravanbakhsh, M. Georeferencing from Geoeye-1 imagery: Early indications of metric performance. In Proceedings of the International Society for Photogrammetry and Remote Sensing (ISPRS) Hannover Workshop, Hannover, Germany, 2–5 June 2009.

- Croft, J. GeoEye & ITT team up for out-of-this-world technology. Imaging Notes Mag. 2008, 23. [Google Scholar]

- Brian, C. Pleiades 1B and SPOT 6 image quality status after commissioning and 1st year in orbit. In Proceedings of the Joint Agency Commercial Imagery Evaluation (JACIE) Workshop, Louisville, KY, USA, 26–28 March 2014.

- Gaudin-Delrieu, C.; Lamard, J.L.; Cheroutre, P.; Bailly, B.; Dhuicq, P.; Puig, O. The High resolution optical instruments for the Pleiades earth observation satellites. In Proceedings of the 7th International Conference on Space Optics (ICSO), Toulouse, France, 14–17 October 2008.

- Luquet, P.; Chikouche, A.; Benbouzid, A.B.; Arnoux, J.J.; Chinal, E.; Massol, C.; Rouchit, P.; Zotti, S.D. NAOMI instrument: A product line of compact & versatile cameras designed for high resolution missions in Earth observation. In Proceedings of the 7th International Conference on Space Optics (ICSO), Toulouse, France, 14–17 October 2008.

- Li, J.; Xing, F.; You, Z. Space high-accuracy intelligence payload system with integrated attitude and position determination. Instrument 2015, 2, 3–16. [Google Scholar]

- Weng, J.; Cohen, P.; Herniou, M. Camera calibration with distortion models and accuracy evaluation. IEEE Trans. Pattern Anal. Mach. Intell. 1992, 14, 965–980. [Google Scholar] [CrossRef]

- Liang, J.; Williams, D.R.; Miller, D.T. Supernormal vision and high-resolution retinal imaging through adaptive optics. J. Opt. Soc. Am. A 1997, 14, 2884–2892. [Google Scholar] [CrossRef]

- Neil, M.A.A.; Booth, M.J.; Wilson, T. Closed-loop aberration correction by use of a modal Zernike wave-front sensor. Opt. Lett. 2000, 25, 1083–1085. [Google Scholar] [CrossRef] [PubMed]

- Jeong, T.M.; Menon, M.; Yoon, G. Measurement of wave-front aberration in soft contact lenses by use of a Shack-Hartmann wave-front sensor. Appl. Opt. 2005, 44, 4523–4527. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.L.; Tsai, W.H. Camera calibration by vanishing lines for 3-D computer vision. IEEE Trans. Pattern Anal. Mach. Intell. 1991, 13, 370–376. [Google Scholar] [CrossRef]

- Hong, Y.; Ren, G.; Liu, E. Non-iterative method for camera calibration. Opt. Express 2007, 23, 23992–24003. [Google Scholar] [CrossRef] [PubMed]

- Ricolfe-Viala, C.; Sanchez-Salmeron, A.J.; Valera, A. Calibration of a trinocular system formed with wide angle lens cameras. Opt. Express 2012, 20, 27691–27696. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z. Camera calibration with one-dimensional objects. IEEE Trans. Pattern Anal. Mach. Intell. 2004, 26, 892–899. [Google Scholar] [CrossRef] [PubMed]

- Lin, P.D.; Sung, C.K. Comparing two new camera calibration methods with traditional pinhole calibrations. Opt. Express 2007, 15, 3012–3022. [Google Scholar] [CrossRef] [PubMed]

- Wei, Z.; Liu, X. Vanishing feature constraints calibration method for binocular vision sensor. Opt. Express 2008, 23, 18897–18914. [Google Scholar] [CrossRef] [PubMed]

- Bauer, M.; Griebbach, D.; Hermerschmidt, A.; Kruger, S.; Scheele, M.; Schischmanow, A. Geometrical camera calibration with diffractive optical elements. Opt. Express 2008, 16, 20241–20248. [Google Scholar] [CrossRef] [PubMed]

- Ricolfe-Viala, C.; Sanchez-Salmeron, A. Camera calibration under optimal conditions. Opt. Express 2011, 19, 10769–10775. [Google Scholar] [CrossRef] [PubMed]

- Fu, R.; Zhang, Y.; Zhang, J. Study on geometric measurement methods for line-array stereo mapping camera. Spacecr. Recovery Remote Sens. 2011, 32, 62–67. [Google Scholar]

- Hieronymus, J. Comparison of methods for geometric camera calibration. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2012, 39, 595–599. [Google Scholar] [CrossRef]

- Yuan, F.; Qi, W.J.; Fang, A.P. Laboratory geometric calibration of areal digital aerial camera. Proc. SPIE 2013, 8921, 99–103. [Google Scholar] [CrossRef]

- Chen, T.; Shibasaki, R.; Lin, Z. A rigorous laboratory calibration method for interior orientation of airborne linear push-broom camera. Photogramm. Eng. Remote Sens. 2007, 73, 369–374. [Google Scholar] [CrossRef]

- Wu, G.; Han, B.; He, X. Calibration of geometric parameters of line array CCD camera based on exact measuring angle in lab. Opt. Precis. Eng. 2007, 15, 1628–1632. [Google Scholar]

- Yuan, F.; Qi, W.; Fang, A.; Ding, P.; Yu, X. Laboratory geometric calibration of non-metric digital camera. Proc. SPIE 2013, 8921, 99–103. [Google Scholar]

- Heikkila, J.; Silvén, O. A four-step camera calibration procedure with implicit image correction. In Proceedings of the IEEE Computer Society Conference: Computer Vision and Pattern Recognition, Washington, DC, USA, 17–19 June 1997; pp. 1106–1112.

- Faig, W. Calibration of close-range photogrammetric systems: Mathematical formulation. Photogramm. Eng. Remote Sens. 1975, 41, 1479–1486. [Google Scholar]

- Simon, T.; Aymen, A.; Pierre, D. Cross-diffractive optical elements for wide angle geometric camera calibration. Opt. Lett. 2011, 36, 4770–4772. [Google Scholar]

- Yilmazturk, F. Full-automatic self-calibration of color digital cameras using color targets. Opt. Express 2011, 19, 18164–18174. [Google Scholar] [CrossRef] [PubMed]

- Maybank, S.J.; Faugeras, O.D. A theory of self-calibration of a moving camera. Int. J. Comput. Vis. 1992, 8, 123–151. [Google Scholar] [CrossRef]

- Faugeras, O.D.; Luong, Q.T.; Maybank, S.J. Camera self-calibration: Theory and experiments. In Proceedings of the Springer European Conference on Computer Vision, Santa Margherita, Italy, 19–22 May 1992; pp. 321–334.

- Hartley, R.I. Euclidean reconstruction from uncalibrated views. In Proceedings of the Springer Joint European-US Workshop on Applications of Invariance in Computer Vision, Ponta Delgada, Portugal, 9–14 October 1993; pp. 235–256.

- Song, D.M. A self-calibration technique for active vision system. IEEE Trans Robot. Autom. 1996, 12, 114–120. [Google Scholar] [CrossRef]

- Caprile, B.; Torre, V. Using vanishing points for camera calibration. Int. J. Comput. Vis. 1990, 4, 127–139. [Google Scholar] [CrossRef]

- Gonzalez-Aguilera, D.; Rodriguez-Gonzalvez, P.; Armesto, J.; Arias, P. Trimble Gx200 and Riegl LMS-Z390i sensor self-calibration. Opt. Express 2011, 19, 2676–2693. [Google Scholar] [CrossRef] [PubMed]

- De Lussy, F.; Greslou, D.; Dechoz, C.; Amberg, V.; Delvit, J.M.; Lebegue, L.; Blanchet, G.; Fourest, S. Pleiades HR in flight geometrical calibration: Location and mapping of the focal plane. Int. Arch. Photogramm. Remote Sens. 2012, 39, 519–523. [Google Scholar] [CrossRef]

- Fourest, S.; Kubik, P.; Lebegue, L.; Dechoz, C.; Lacherade, S.; Blanchet, G. Star-based methods for Pleiades HR commissioning. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2012, 39, 513–518. [Google Scholar] [CrossRef]

- Fraser, C.S. Photogrammetric camera component calibration: A review of analytical techniques. In Calibration and Orientation of Cameras in Computer Vision; Gruen, A., Huang, T.S., Eds.; Springer: Berlin, Germany, 2001; pp. 95–121. [Google Scholar]

- Lichti, D.D.; Kim, C. A comparison of three geometric self-calibration methods for range cameras. Remote Sens. 2011, 3, 1014–1028. [Google Scholar] [CrossRef]

- Lipski, C.; Bose, D.; Eisemann, M.; Berger, K.; Magnor, M. Sparse bundle adjustment speedup strategies. In Proceedings of the WSCG Short Papers Post-Conference, Plzen, Czech Republic, 1–4 February 2010; Skala, V., Ed.; pp. 85–88.

- Greslou, D.; Lussy, F.D.; Amberg, V.; Dechoz, C.; Lenoir, F.; Delvit, J.; Lebegue, L. Pleiades-HR 1A&1B image quality commissioning: Innovative geometric calibration methods and results. Proc. SPIE 2013, 8866, 1–12. [Google Scholar]

- Delvit, J.M.; Greslou, D.; Amberg, V.; Dechoz, C.; de Lussy, F.; Lebegue, L.; Latry, C.; Artigues, S.; Bernard, L. Attitude assessment using Pléiades-HR capabilities. In Proceedings of the XXII ISPRS Congress, Remote Sensing and Spatial Information Sciences, Melbourne, Australia, 25 August–1 September 2012; pp. 525–530.

- Cook, M.K.; Peterson, B.A.; Dial, G.; Gibson, L.; Gerlach, F.W.; Hutchins, K.S.; Kudola, R.; Bowen, H.S. IKONOS technical performance assessment. Proc. SPIE 2001, 4381, 94–108. [Google Scholar]

- Kaveh, D.; Mazlan, H. Very high resolution optical satellites for DEM generation: A review. Eur. J. Sci. Res. 2011, 49, 542–554. [Google Scholar]

- You, Z.; Wang, C.; Xing, F.; Sun, T. Key technologies of smart optical payload in space remote sensing. Spacecr. Recovery Remote Sens. 2013, 34, 35–43. [Google Scholar]

- Karsten, J. Geometric calibration of space remote sensing cameras for efficient processing. Int. Arch. Photogramm. Remote Sens. 1998, 32, 33–43. [Google Scholar]

- Wang, M.; Yang, B.; Hu, F.; Zang, X. On-orbit geometric calibration model and its applications for high-resolution optical satellite imagery. Remote Sens. 2014, 6, 4391–4408. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, T.; You, H.; Dong, L.; Liu, F. On-orbit calibration of interior orientation for HJ1B-CCD camera. Remote Sens. Technol. Appl. 2011, 26, 309–314. [Google Scholar]

- Lv, H.; Han, C.; Xue, X.; Hu, C.; Yao, C. Autofocus method for scanning remote sensing camera. Appl. Opt. 2015, 54, 6351–6359. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Chen, X.; Tian, L.; Lian, F. Tracking radiometric responsivity of optical sensors without on-board calibration systems-case of the Chinese HJ-1A/1B CCD sensors. Opt. Express 2015, 23, 1829–1847. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Xing, F.; Sun, T.; You, Z. Efficient assessment method of on-board modulation transfer function of optical remote sensing sensors. Opt. Express 2015, 23, 6187–6208. [Google Scholar] [CrossRef] [PubMed]

| Maladjustments | f (mm) | Δf (mm) |

|---|---|---|

| Z direction + 0.01 | 4498.594192 | −1.405808 |

| Z direction + 0.015 | 4497.891609 | −2.108391 |

| Z direction + 0.02 | 4497.189260 | −2.810740 |

| Z direction + 0.05 | 4492.979717 | −7.020283 |

| Slant 30′′ around X | 4499.999777 | −0.000223 |

| Slant 30′′ around Y | 4499.999780 | −0.000220 |

| Decentration 0.02 mm in X direction | 4499.999997 | −2.68 × 10−6 |

| Decentration 0.02 mm in Y direction | 4499.999999 | −1.32 × 10−6 |

| Maladjustments | Δl (mm) | Δf (mm) | Deviation (μm) |

|---|---|---|---|

| Z direction + 0.01 | −0.068704 | −1.405803 | 4.82 × 10−3 |

| Z direction + 0.015 | −0.103040 | −2.108378 | 1.27 × 10−2 |

| Z direction + 0.02 | −0.137366 | −2.810749 | −9.24 × 10−3 |

| Z direction + 0.05 | −0.343092 | −7.020266 | 1.71 × 10−2 |

| Slant 30′′ around X | −0.000010 | −0.000203 | 1.95 × 10−2 |

| Slant 30′′ around X | −0.000010 | −0.000203 | 1.75 × 10−2 |

| Decentration 0.02 mm in X direction | 0 | 0 | 2.68 × 10−3 |

| Decentration 0.02 mm in Y direction | 0 | 0 | 1.32 × 10−3 |

| Parameters | Value |

|---|---|

| Size | 40 mm × 40 mm |

| Coordinate in the X direction | ±97.743 |

| Corresponding FOV in the X direction | ±0.7° |

| Coordinate in the Y direction | −76.797 |

| Corresponding FOV in the Y direction | −0.55° |

| Maladjustments | f (mm) |

|---|---|

| Z direction + 0.002 | 8001.8321 |

| Z direction + 0.005 | 8006.0262 |

| Z direction + 0.01 | 8013.0772 |

| Z direction + 0.015 | 8020.0584 |

| Z direction + 0.02 | 8027.0893 |

| Slant 5′′ around X | 7998.8212 |

| Slant 5′′ around Y | 7999.0352 |

| Decentration 0.02 mm in X direction | 7999.0317 |

| Decentration 0.02 mm in Y direction | 7999.1658 |

| Maladjustments | Δl (mm) | Δf (mm) | Deviation (mm) |

|---|---|---|---|

| Z direction + 0.002 | 0.1030 | 8001.8326 | 0.0005 |

| Z direction + 0.005 | 0.3080 | 8006.0273 | 0.0011 |

| Z direction + 0.01 | 0.6524 | 8013.0742 | −0.003 |

| Z direction + 0.015 | 0.9936 | 8020.0557 | −0.003 |

| Z direction + 0.02 | 1.3372 | 8027.0865 | −0.003 |

| Slant 5′′ around X | −0.0448 | 7998.8083 | −0.013 |

| Slant 5′′ around Y | −0.0336 | 7999.0374 | 0.0022 |

| Decentration 0.02 mm in X direction | −0.0338 | 7999.0333 | 0.0017 |

| Decentration 0.02 mm in Y direction | −0.0266 | 7999.1807 | 0.0148 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Zhang, Y.; Liu, S.; Wang, Z. Self-Calibration Method Based on Surface Micromaching of Light Transceiver Focal Plane for Optical Camera. Remote Sens. 2016, 8, 893. https://doi.org/10.3390/rs8110893

Li J, Zhang Y, Liu S, Wang Z. Self-Calibration Method Based on Surface Micromaching of Light Transceiver Focal Plane for Optical Camera. Remote Sensing. 2016; 8(11):893. https://doi.org/10.3390/rs8110893

Chicago/Turabian StyleLi, Jin, Yuan Zhang, Si Liu, and ZhengJun Wang. 2016. "Self-Calibration Method Based on Surface Micromaching of Light Transceiver Focal Plane for Optical Camera" Remote Sensing 8, no. 11: 893. https://doi.org/10.3390/rs8110893