Economic and Environmental Cost Analysis of Incineration and Recovery Alternatives for Flammable Industrial Waste: The Case of South Korea

Abstract

:1. Introduction

2. Overview of Waste Treatment Methods

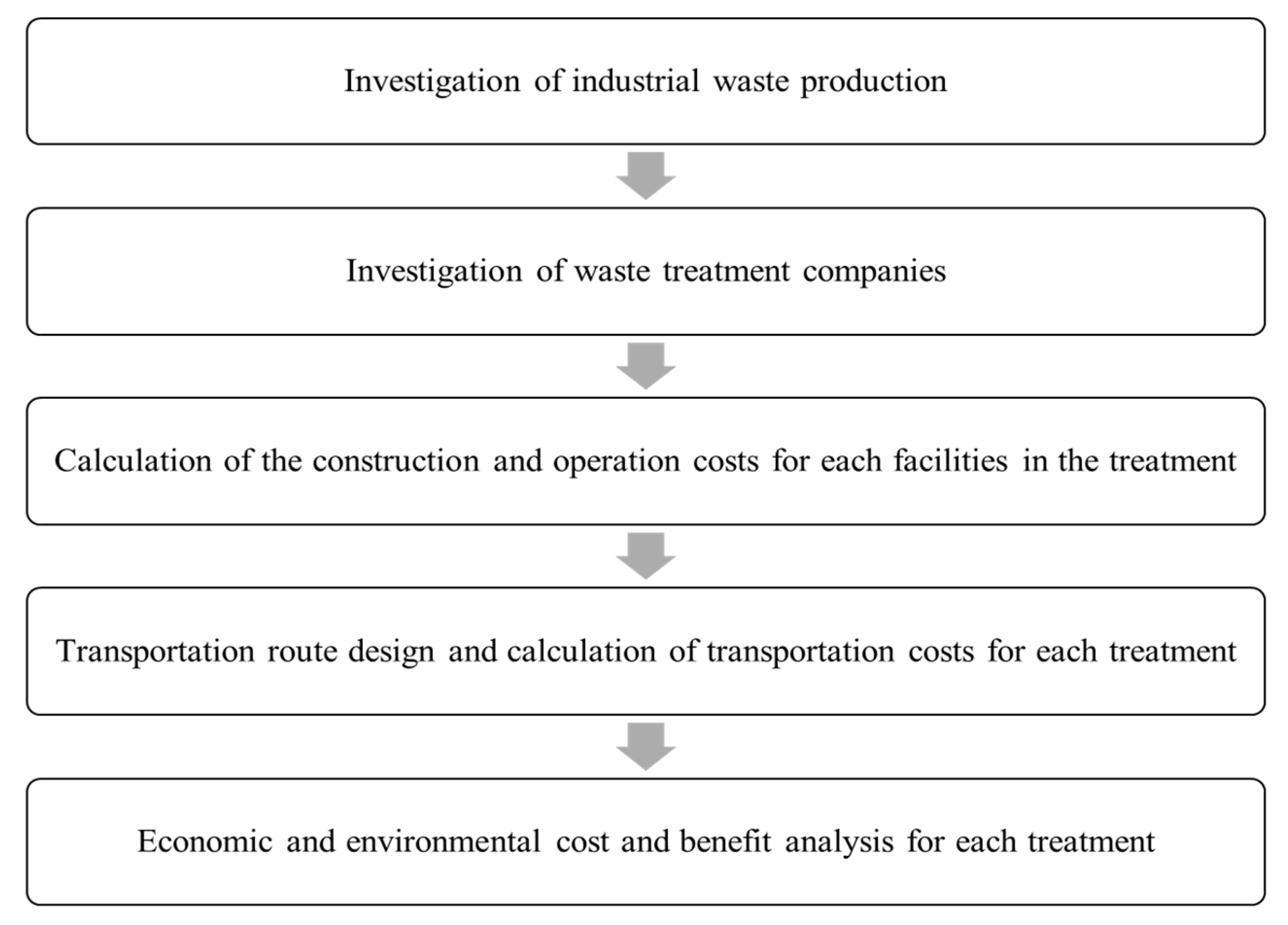

3. Cost Analysis by Treatment Path

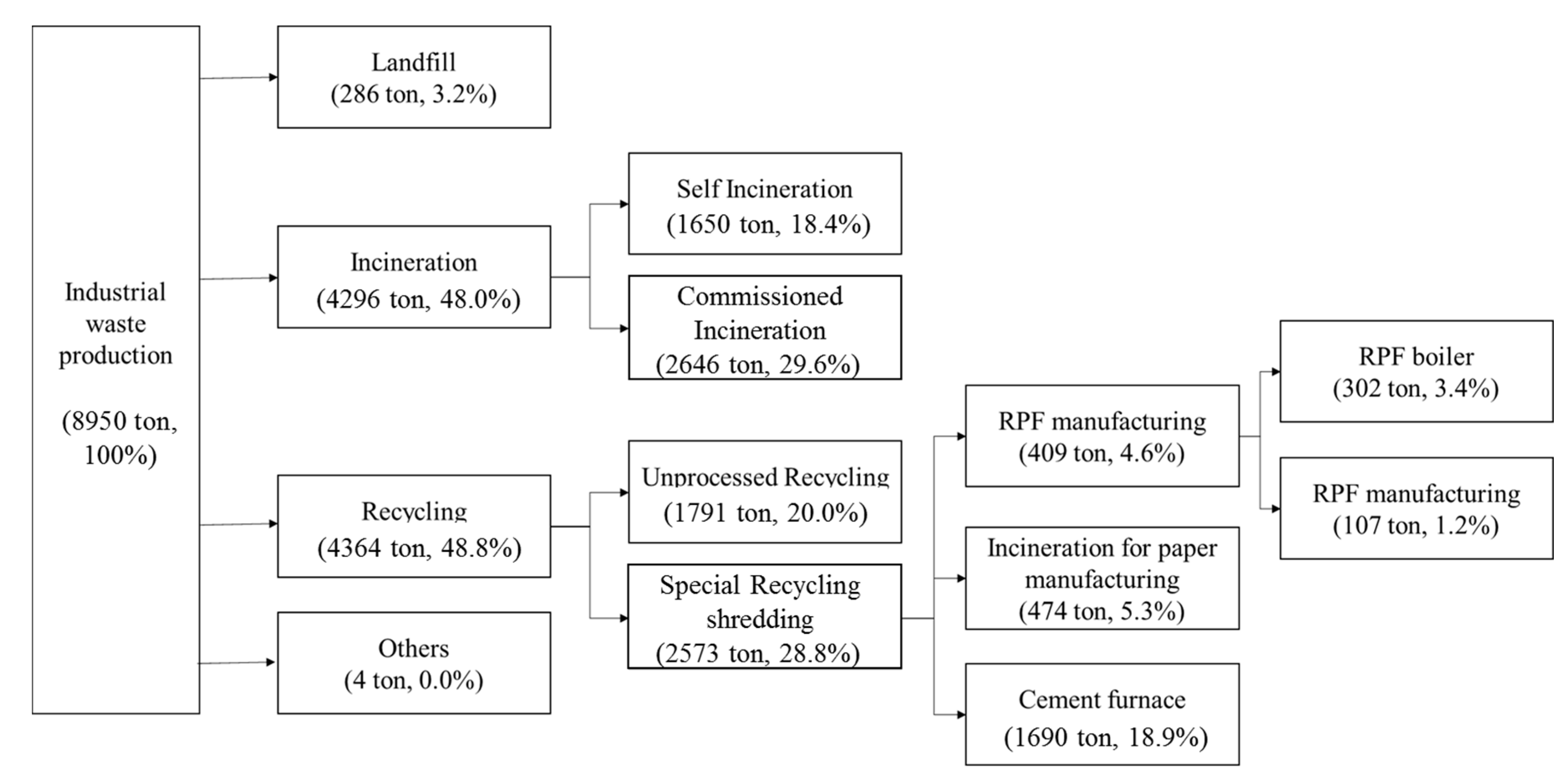

3.1. Investigation of Industrial Waste Production

3.2. Investigation of Waste Treatment Companies

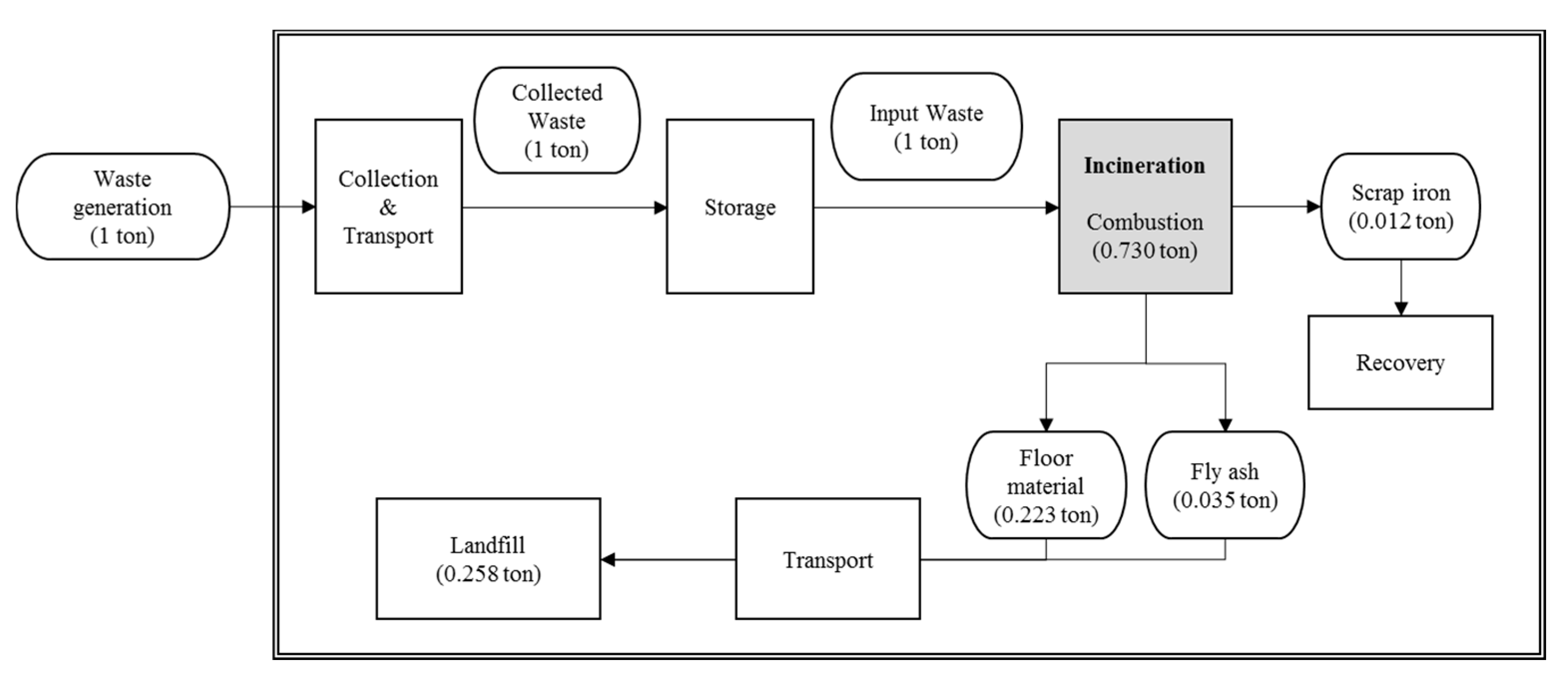

3.3. Calculation of the Construction and Operation Costs for Each Facility in the Treatment

3.4. Transporation Route Design and Calculation of Transportation Costs for Each Treatment

3.5. Economic and Environmental Cost and Benefit Analysis for Each Treatment

4. Experimental Results

4.1. Economic Cost Results

4.2. Environmental Cost Results

4.3. Profit Analysis by Treatment Method

4.4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

References

- Kneese, A.V.; Ayres, R.U.; d’Arge, R.C. Economics and the Environment: A Materials Balance Approach; Routledge: Abingdon, UK, 2015. [Google Scholar]

- Sadef, Y.; Nizami, A.S.; Batool, S.A.; Chaudary, M.N.; Ouda, O.K.M.; Asam, Z.Z.; Habib, K.; Rehan, M.; Demirbas, A. Waste-to-energy and recycling value for developing integrated solid waste management plan in Lahore. Energy Sources Part B 2016, 11, 569–579. [Google Scholar] [CrossRef]

- Ripa, M.; Fiorentino, G.; Giani, H.; Clausen, A.; Ulgiati, S. Refuse recovered biomass fuel from municipal solid waste. A life cycle assessment. Appl. Energy 2017, 186, 211–225. [Google Scholar] [CrossRef]

- Morrissey, A.J.; Browne, J. Waste management models and their application to sustainable waste management. Waste Manag. 2004, 24, 297–308. [Google Scholar] [CrossRef] [PubMed]

- Suh, Y.J.; Rousseaux, P. An LCA of alternative wastewater sludge treatment scenarios. Resour. Conserv. Recycl. 2002, 35, 191–200. [Google Scholar] [CrossRef]

- Tarantini, M.; Loprieno, A.D.; Cucchi, E.; Frenquellucci, F. Life Cycle Assessment of waste management systems in Italian industrial areas: Case study of 1st Macrolotto of Prato. Energy 2009, 34, 613–622. [Google Scholar] [CrossRef]

- Villeneuve, J.; Michel, P.; Fournet, D.; Lafon, C.; Menard, Y.; Wavrer, P.; Guyonnet, D. Process-based analysis of waste management system: A case study. Waste Manag. 2009, 29, 2–11. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Kim, J.; Park, I.; Kwon, O.; Lee, W. Comparative Analysis of Waste Incineration Methods and Its Application in Kyonggi-Do; Kyonggi Research Institute: Suwon, Korea, 2007. [Google Scholar]

- Cherubini, F.; Bargigli, S.; Ulgiati, S. Life cycle assessment (LCA) of waste management strategies: Landfilling, sorting plant and incineration. Energy 2009, 34, 2116–2123. [Google Scholar] [CrossRef]

- Wittmaier, M.; Langer, B.; Sawilla, S. Possibilities and limitations of life cycle assessment (LCA) in the development of waste utilization systems: Applied example for a region in Northern Germany. Waste Manag. 2009, 29, 1732–1738. [Google Scholar] [CrossRef] [PubMed]

- Mendes, M.R.; Aramaki, T.; Hanaki, K. Comparison of the environmental impact of incineration and landfilling in Sao Paulo City as determined by LCA. Resour. Conserv. Recycl. 2004, 41, 47–63. [Google Scholar] [CrossRef]

- Cleary, J. Life cycle assessment of municipal solid waste management systems: A comparative analysis of selected peer-reviewed literature. Environ. Int. 2009, 35, 1256–1266. [Google Scholar] [CrossRef] [PubMed]

- Samanlioglu, F. A multi-objective mathematical model for the industrial hazardous waste location-routing problem. Eur. J. Oper. Res. 2013, 226, 332–340. [Google Scholar] [CrossRef]

- Faizal, M.; Saidur, R.; Mekhilef, S.; Alim, M.A. Energy, economic and environmental analysis of metal oxides nanofluid for flat-plate solar collector. Energy Convers. Manag. 2013, 76, 162–168. [Google Scholar] [CrossRef]

- Balli, O.; Hepbasli, A. Exergoeconomic, sustainability and environmental damage cost analyses of T56 turboprop engine. Energy 2014, 64, 582–600. [Google Scholar] [CrossRef]

- Sen, S.; Ganguly, S. Opportunities, barriers and issues with renewable energy development—A discussion. Renew. Sustain. Energy Rev. 2017, 69, 1170–1181. [Google Scholar] [CrossRef]

- Heidari, N.; Pearce, J.M. A review of greenhouse gas emission liabilities as the value of renewable energy for mitigating lawsuits for climate change related damages. Renew. Sustain. Energy Rev. 2016, 55, 899–908. [Google Scholar] [CrossRef]

- Proskurina, S.; Sikkema, R.; Heinimö, J.; Vakkilainen, E. Five years left—How are the EU member states contributing to the 20% target for EU’s renewable energy consumption; the role of woody biomass. Biomass Bioenergy 2016, 95, 64–77. [Google Scholar] [CrossRef]

- Brennan, R.B.; Healy, M.G.; Morrison, L.; Hynes, S.; Norton, D.; Clifford, E. Management of landfill leachate: The legacy of European Union Directives. Waste Manag. 2016, 55, 355–363. [Google Scholar] [CrossRef] [PubMed]

- Lombardi, L.; Carnevale, E.; Corti, A. A review of technologies and performances of thermal treatment systems for energy recovery from waste. Waste Manag. 2015, 37, 26–44. [Google Scholar] [CrossRef] [PubMed]

- Cecere, G.; Martinelli, A. Drivers of knowledge accumulation in electronic waste management: An analysis of publication data. Res. Policy 2017, 46, 925–938. [Google Scholar] [CrossRef]

- Psomopoulos, C.S.; Bourka, A.; Themelis, N.J. Waste-to-energy: A review of the status and benefits in USA. Waste Manag. 2009, 29, 1718–1724. [Google Scholar] [CrossRef] [PubMed]

- Themelis, N.J.; Mussche, C. Municipal solid waste management and waste-to-energy in the United States, China and Japan. In Proceedings of the 2nd International Academic Symposium on Enhanced Landfill Mining, Houthalen-Helchteren, Belgium, 14–16 October 2013. [Google Scholar]

- Ohnishi, S.; Fujii, M.; Fujita, T.; Matsumoto, T.; Dong, L.; Akiyama, H.; Dong, H. Comparative analysis of recycling industry development in Japan following the Eco-Town program for eco-industrial development. J. Clean. Prod. 2016, 114, 95–102. [Google Scholar] [CrossRef]

- Korea Ministry of Environment (2005–2016) 2004–2015 Waste Statistics. Available online: http://www.recycling-info.or.kr (accessed on 17 July 2017).

- Yi, S.; Jang, Y.C. Life cycle assessment of solid refuse fuel production from MSW in Korea. J. Mater. Cycles Waste Manag. 2016. [Google Scholar] [CrossRef]

- Environmental Statistics Yearbook 2014. Available online: http://eng.me.go.kr/eng/web/index.do?menuId=29&findDepth=1 (accessed on 21 November 2016).

- Holland, M.; Watkiss, P. Estimates of Marginal External Costs of Air Pollution in Europe. 2002. Available online: http://ec.europa.eu/environment/enveco/air/pdf/betaec02a.pdf (accessed on 13 September 2017).

- United Nations Statistics Division (UNSD). Integrated Environmental and Economic Accounting: An Operational Manual. Available online: https://unstats.un.org/unsd/publication/SeriesF/SeriesF_78E.pdf (accessed on 11 September 2017).

- Korea Energy Agency. Available online: http://www.energy.or.kr/renew_eng/pr/pr/campaign.aspx (accessed on 21 November 2016).

- Markandya, A. The Indirect Costs and Benefits of Greenhouse Gas Limitations Handbook Reports: Economics of Greenhouse Gas Limitations; UNEP: Nairobi, Kenya, 2002. [Google Scholar]

| Classification | Details | |

|---|---|---|

| Incineration | Landfill after incineration treatment by intermediate processing companies (hereinafter referred to as “landfill after incineration”) | |

| Recovering | RPF manufacturing | Reuse as boiler fuel only after RPF manufacturing (hereinafter referred to as “RPF boiler”) |

| Reuse as cement furnace fuel after RPF manufacturing (hereinafter referred to as “RPF furnace”) | ||

| RPF non-manufacturing | Reuse as paper incinerator fuel after shredding the wastes (hereinafter referred to as “Paper incinerator”) | |

| Reuse as cement furnace fuel after shredding the wastes (hereinafter referred to as “Cement furnace”) | ||

| Treatment Method | Treatment Path and Detailed Characteristics | |

|---|---|---|

| Incineration | Treatment path | Workplace → incineration company → landfill site |

| Path characteristics |

| |

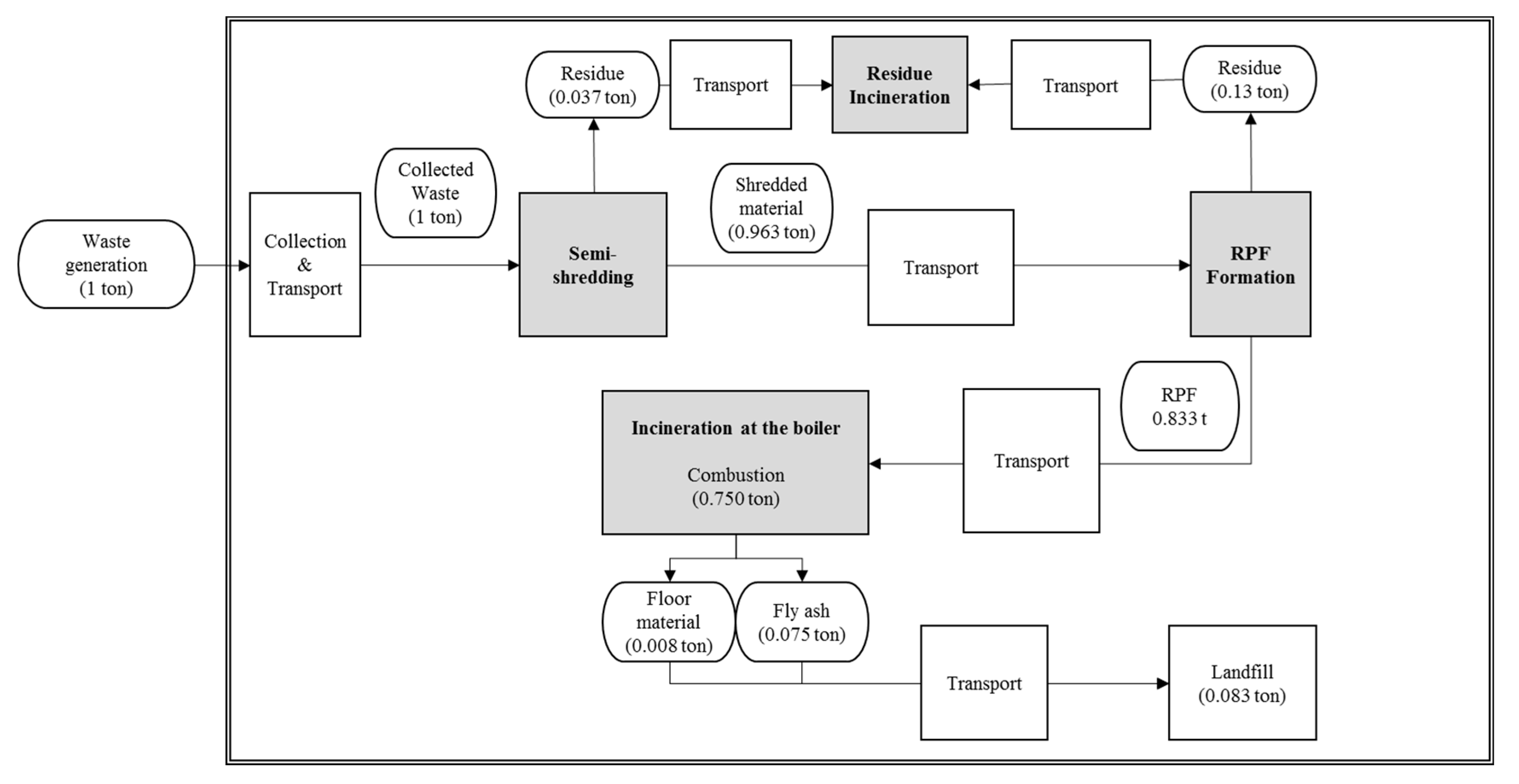

| RPF boiler | Treatment path | Workplace → semi-shredding company → micro-shredding company → RPF manufacturer → RPF boiler → landfill site |

| Path characteristics |

| |

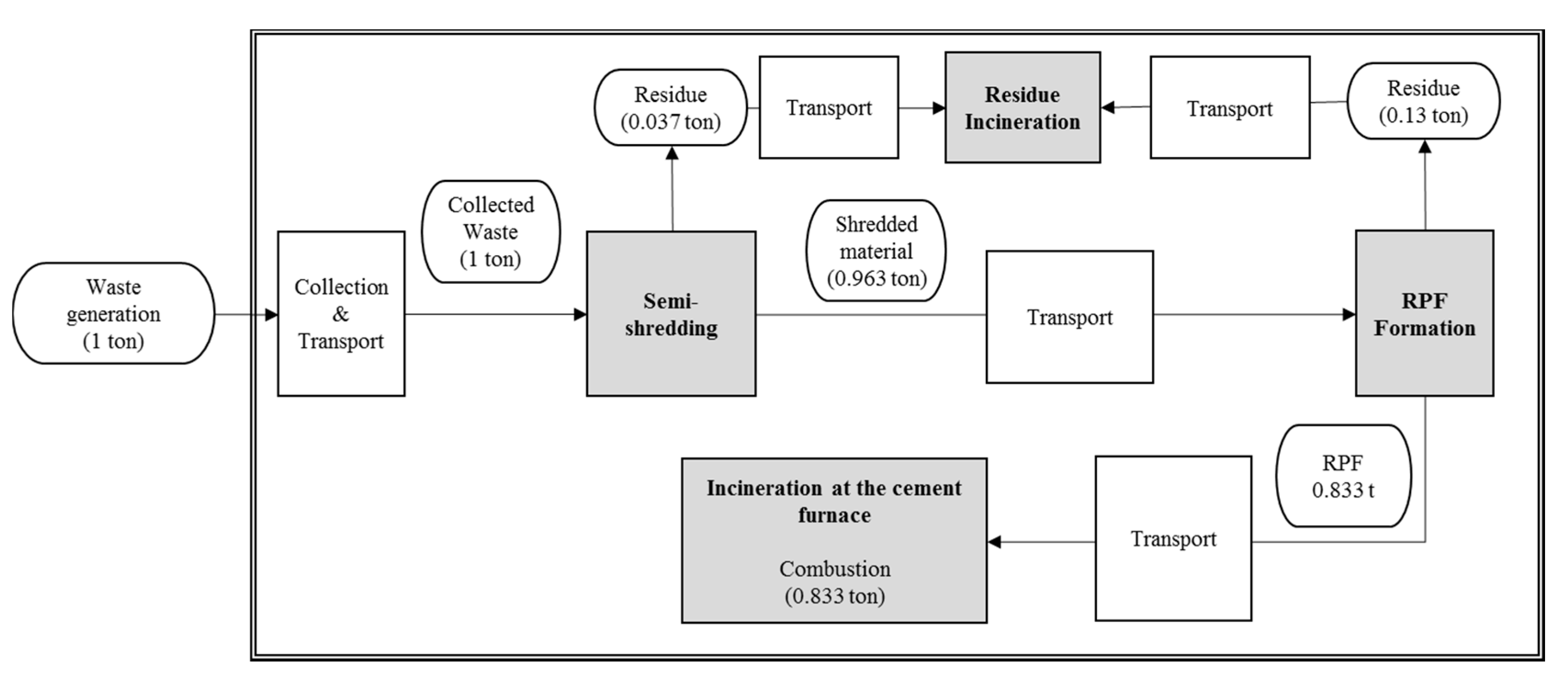

| RPF furnace | Treatment path | Workplace → semi-shredding company → micro-shredding company → RPF manufacturer → cement furnace |

| Path characteristics |

| |

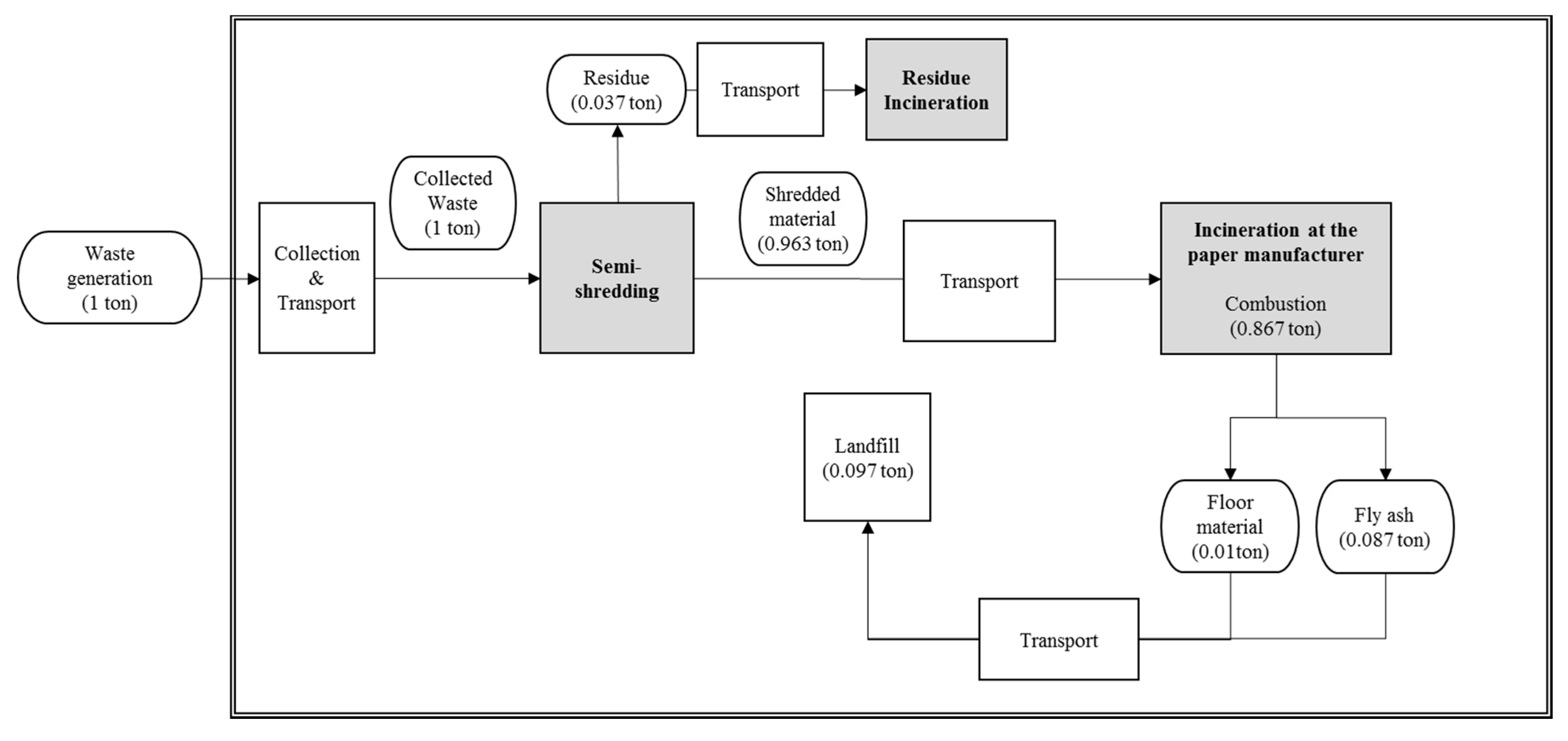

| Paper incinerator | Treatment path | Workplace → semi-shredding company → paper incinerator → landfill site |

| Path characteristics |

| |

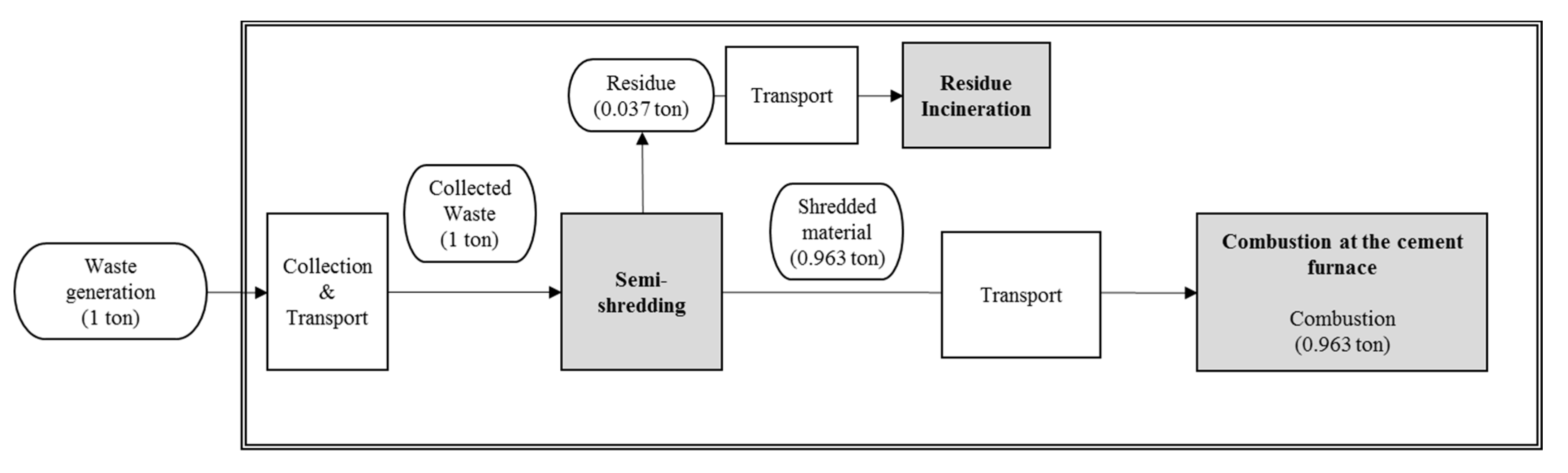

| Cement furnace | Treatment path | Workplace → semi-shredding company → cement furnace |

| Path characteristics |

| |

| City & Province | Total (Ton/Day) | Industrial Wastes (Ton/Day) | |||||

|---|---|---|---|---|---|---|---|

| Paper Wastes | Timber Wastes | Highly Synthetic Polymerized Compound Wastes | |||||

| Textile Wastes | Synthetic Resin Wastes | Synthetic Rubber Wastes | Leather Wastes | ||||

| Total | 8950.5 | 402.9 | 1665.7 | 232.0 | 6176.5 | 372.9 | 100.5 |

| Seoul | 28.8 | 1.9 | 1.4 | 0.4 | 25.0 | 0.1 | 0.0 |

| Busan | 287.6 | 4.1 | 17.4 | 5.9 | 241.2 | 10.3 | 8.7 |

| Daegu | 238.1 | 22.8 | 9.0 | 15.2 | 172.8 | 18.3 | 0.0 |

| Inchon | 643.6 | 32.8 | 267.5 | 28.4 | 304.7 | 8.4 | 1.8 |

| Gwangju | 98.4 | 21.7 | 9.0 | 10.1 | 34.3 | 23.3 | 0.0 |

| Daejeon | 200.6 | 1.3 | 3.2 | 1.7 | 174.0 | 19.9 | 0.5 |

| Ulsan | 455.5 | 63.8 | 116.0 | 17.2 | 234.8 | 23.4 | 0.3 |

| Gyeonggi | 2494.1 | 91.4 | 243.9 | 24.8 | 2059.8 | 37.4 | 36.8 |

| Gangwon | 42.6 | 1.5 | 7.8 | 2.7 | 28.5 | 2.0 | 0.1 |

| Chungbuk | 1074.0 | 16.9 | 121.8 | 23.0 | 809.4 | 88.7 | 14.2 |

| Chungnam | 669.2 | 41.5 | 117.6 | 10.5 | 486.3 | 13.0 | 0.3 |

| Jeonbuk | 687.5 | 19.5 | 286.0 | 5.9 | 339.0 | 1.6 | 35.6 |

| Jeonnam | 232.8 | 4.8 | 46.2 | 0.0 | 176.3 | 5.5 | 0.0 |

| Gyeongbuk | 644.8 | 20.0 | 75.3 | 68.7 | 451.5 | 27.8 | 1.5 |

| Gyeongnam | 1090.9 | 34.7 | 311.2 | 17.5 | 634.4 | 92.4 | 0.7 |

| Jeju | 62.0 | 24.3 | 32.5 | 0.0 | 4.5 | 0.7 | 0.0 |

| Criteria | Formula |

|---|---|

| RPF Purchasing Cost (A) | 100 (tons/day) × 40,000 (won/ton) = 4,000,000 (won/day) |

| RPF Combustion Heat Energy (B) | 100 (tons/day) × 8 (Gcal/ton) = 800 (Gcal/day) |

| Bunker C Oil Substitution (C) | (B) ÷ 9.79 (Gcal/kL) = 81.72 (kL/day) |

| Fuel Substitution (won/day) (D) | (C) × 499,500 (won/kL) = 40,819,140 (won/day) |

| Fuel Substitution Effects (won/day) | (D) − (A) = 36,819,140 (won/day) |

| Vehicle Type | CO | HC | NOx | PM | Total |

|---|---|---|---|---|---|

| Heavy-duty truck | 5.395 | 9.757 | 9.874 | 9.757 | 34.783 |

| Medium-duty truck | 5.725 | 6.152 | 2.461 | 8.858 | 23.195 |

| Small-duty truck | 4.593 | 4.935 | 1.974 | 7.106 | 18.608 |

| Emission Quantities of Air Pollutants | |||||

|---|---|---|---|---|---|

| TSP | CO | SOx | NOx | Total | |

| Emission quantity per ton (g/ton) | 47 | 56 | 85 | 1868 | - |

| Environmental damage (won/ton) | 5050 | 1532 | 3142 | 61,474 | 71,197 |

| Treatment Facility | Type | Unit | Average |

|---|---|---|---|

| Incineration facility | TSP | mg/m3 | 2.455 |

| CO | ppm | 2.993 | |

| SOx | ppm | 1.442 | |

| NOx | ppm | 46.183 | |

| NH3 | ppm | 0.794 | |

| HCl | ppm | 2.337 | |

| Furnace | Dust | mg/m3 | 4.034 |

| CO | ppm | 876.777 | |

| SOx | ppm | 4.518 | |

| NOx | ppm | 268.882 | |

| NH3 | ppm | 9.414 | |

| HCl | ppm | 1.181 |

| Parameters | Values | |

|---|---|---|

| Economic | Base period | 2007 year |

| Lifespan | 15 year | |

| Discount rate | 3% | |

| Inflation rate | 5% | |

| Capital ratio | 80% | |

| Facility consumption ratio | 5% | |

| Fuel substitution | Unit price of steam | 15,000 won/ton |

| Unit price of RPF sales | 40,000 won/ton | |

| Unit price of Bunker-C | 499,500 won/kL | |

| Unit price of bituminous coal | 73,700 won/ton | |

| Round-trip transportation | Greater than 400 km | 1,100,000 won/truck |

| 400–200 km | 916,667 won/truck | |

| 200–100 km | 733,333 won/truck | |

| 100–70 km | 428,333 won/truck | |

| 70–50 km | 332,833 won/truck | |

| 50–30 km | 290,833 won/truck | |

| Type | Case 1 (Won/Ton *) | Case 2 (Won/Ton *) |

|---|---|---|

| Incineration | −207,893 | −208,114 |

| RPF boiler | −418,959 | −420,002 |

| RPF furnace | −323,985 | −323,718 |

| Paper manufacturing | −310,955 | −314,523 |

| Cement furnace | −201,202 | −201,839 |

| Type | Case 1 (Won/Ton *) | Case 2 (Won/Ton *) |

|---|---|---|

| Incineration | −112,261 | −112,262 |

| RPF boiler | −73,490 | −73,771 |

| RPF furnace | −327,398 | −328,031 |

| Paper incinerator | −57,445 | −57,471 |

| Cement furnace | −417,638 | −417,843 |

| Type | Cases 1 and 2 (Won/Ton) | |||

|---|---|---|---|---|

| Fuel Substitution | Steam Sales | RPF Sales | Total | |

| Incineration | +167,861 | +74,660 | 0 | +242,521 |

| RPF boiler | +221,684 | 0 | +33,320 | +255,004 |

| RPF furnace | +42,239 | 0 | +33,320 | +75,559 |

| Paper incinerator | +218,227 | 0 | 0 | +218,227 |

| Cement furnace | +71,847 | 0 | 0 | +71,847 |

| Cases | Classifications | Incineration | RPF Boiler | RPF Furnace | Paper Incinerator | Cement Furnace | |

|---|---|---|---|---|---|---|---|

| Case 1 | Economic benefits | Treatment cost | −207,893 | −418,959 | −323,985 | −310,955 | −201,202 |

| Profit (RPF and stream sales + fuel substitution) | +242,521 | +255,004 | +75,559 | +218,227 | +71,847 | ||

| Sub total | +34,628 | −163,955 | −248,426 | −92,728 | −129,355 | ||

| Environmental costs | −112,261 | −73,490 | −327,398 | −57,445 | −417,638 | ||

| Total | −77,633 | −237,445 | −575,824 | −150,173 | −546,993 | ||

| Case 2 | Economic benefits | Treatment costs | −208,114 | −420,002 | −323,718 | −314,523 | −201,839 |

| Profit (RPF and stream sales + fuel substitution) | +242,521 | +255,004 | +75,559 | +218,227 | +71,847 | ||

| Sub total | +34,407 | −164,998 | −248,159 | −96,296 | −129,992 | ||

| Environmental costs | −112,262 | −73,771 | −328,031 | −57,471 | −417,843 | ||

| Total | −77,855 | −238,769 | −576,190 | −153,767 | −547,835 | ||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Jeong, S. Economic and Environmental Cost Analysis of Incineration and Recovery Alternatives for Flammable Industrial Waste: The Case of South Korea. Sustainability 2017, 9, 1638. https://doi.org/10.3390/su9091638

Kim J, Jeong S. Economic and Environmental Cost Analysis of Incineration and Recovery Alternatives for Flammable Industrial Waste: The Case of South Korea. Sustainability. 2017; 9(9):1638. https://doi.org/10.3390/su9091638

Chicago/Turabian StyleKim, Jihyun, and Sukjae Jeong. 2017. "Economic and Environmental Cost Analysis of Incineration and Recovery Alternatives for Flammable Industrial Waste: The Case of South Korea" Sustainability 9, no. 9: 1638. https://doi.org/10.3390/su9091638