Material Services with Both Eyes Wide Open

Abstract

:1. Introduction

2. The “Problem” with Materials

3. Zero Eyes Open: Turning a Blind Eye to Materials

4. One Eye Open: Glancing at Materials but Fixed on Energy

The Weaknesses of a One Eye Strategy

5. Both Eyes Open: Looking but Not Really Seeing

5.1. Production Stage

5.2. Final Product and Consumer Side

5.3. End of Life

5.4. Material Efficiency: How to Go Beyond It?

6. Eyes Wide Open: Looking Forward to the Sustainable Development Horizon

6.1. Material Services: How Best to Unify the Concept?

“Those benefits that materials contribute to societal wellbeing, through fuels and products (regardless of whether or not they are supplied by the market) when they are put to proper use.”

6.2. What Should an Eyes Wide Open Strategy Consider?

6.2.1. Establishing Criteria for Better Materials

6.2.2. Stock Optimisation

6.2.3. Redefining Waste as a Concept

6.3. What an Eyes Wide Open World Might Look Like

6.4. Challenges to an Eyes Wide Open World

7. Discussion

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gutowski, T.; Cooper, D.; Sahni, S. Why we use more materials. Phil. Trans. R. Soc. A 2017. [Google Scholar] [CrossRef] [PubMed]

- Schandl, H.; Fischer-Kowalski, M.; West, J.; Giljum, S.; Dittrich, M.; Eisenmenger, N.; Geschke, A.; Lieber, M.; Wieland, H.; Schaffartzik, A. Global Material Flows and Resource Productivity: Forty Years of Evidence. J. Ind. Ecol. 2017. [Google Scholar] [CrossRef]

- Jackson, T. Prosperity without Growth. Economics for a Finite Planet London, 1st ed.; Earthscan: London, UK, 2009; ISBN 978-1-84971-323-8. [Google Scholar]

- Milios, L. Policies for Resource Efficient and Effective Solutions: A Review of Concepts, Current Policy Landscape and Future Policy Considerations for the Transition to a Circular Economy; International Institute for Industrial Environmental Economics at Lund University—Mistra: Lund, Sweden, 2016. [Google Scholar]

- Haefele, W. On energy demand. IAEA Bull. 1977, 19, 21–37. [Google Scholar]

- Nakićenović, N.; Grübler, A.; Inaba, A.; Messner, S.; Nilsson, S.; Nishimura, Y.; Rogner, H.-H.; Schäfer, A.; Schrattenholzer, L.; Strubegger, M. Long-term strategies for mitigating global warming. Energy 1993, 18, 401. [Google Scholar] [CrossRef]

- Gould, O.; Simeone, A.; Colwill, J.; Willey, R.; Rahimifard, S. A material flow modelling tool for resource efficient production planning in multi-product manufacturing systems. Proc. CIRP 2016, 41, 21–26. [Google Scholar] [CrossRef] [Green Version]

- Fischer-Kowalski, M.; Krausmann, F.; Giljum, S.; Lutter, S.; Mayer, A.; Bringezu, S.; Moriguchi, Y.; Schütz, H.; Schandl, H.; Weisz, H. Methodology and indicators of economy-wide material flow accounting. J. Ind. Ecol. 2011, 15, 855–876. [Google Scholar] [CrossRef]

- Allwood, J.M.; Cullen, J.M.; Carruth, M.A.; Cooper, D.R.; McBrien, M.; Milford, R.L.; Patel, A.C. Sustainable Materials: With Both Eyes Open, 1st ed.; UIT Cambridge: Cambridge, UK, 2012; ISBN 1-906860-07-6. [Google Scholar]

- Gates, B. Reduce, Reuse, Retool. Available online: https://www.gatesnotes.com/Books/Sustainable-Materials-With-Both-Eyes-Open (accessed on 5 May 2017).

- ABC of SCP: Clarifying Concepts on Sustainable Consumption and Production; United Nations Environment: Nairobi, Kenya, 2010.

- Cullen, J.M.; Allwood, J.M. The efficient use of energy: Tracing the global flow of energy from fuel to service. Energy Policy 2010, 38, 75–81. [Google Scholar] [CrossRef]

- Haberl, H.; Wiedenhofer, D.; Erb, K.H.; Görg, C.; Krausmann, F. The Material Stock–Flow–Service Nexus: A New Approach for Tackling the Decoupling Conundrum. Sustainability 2017. [Google Scholar] [CrossRef]

- Lane, R. Understanding the dynamic character of value in recycling metals from Australia. Resources 2014, 3, 416–431. [Google Scholar] [CrossRef]

- Baptist, S.; Hepburn, C. Intermediate inputs and economic productivity. Philos. Trans. R. Soc. A 2013, 371, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Kooroshy, J.; Meindersma, C.; Rademaker, M.; Sweijs, T.; Diederen, A.M.; Beerthuijzen, M.; De Goede, S. Scarcity of Minerals. A Strategic Security Issue; The Hague Centre for Strategic Studies: The Hague, The Netherlands, 2009. [Google Scholar]

- Ekvall, T.; Hirschnitz-Garbers, M.; Eboli, F.; Śniegocki, A. A systemic and systematic approach to the development of a policy mix for material resource efficiency. Sustainability 2016, 8, 373. [Google Scholar] [CrossRef]

- Schandl, H.; Fischer-Kowalski, M.; West, J.; Giljum, S.; Dittrich, M.; Eisenmenger, N.; Geschke, A.; Lieber, M.; Wieland, H.P.; Schaffartzik, A. Global Material Flows and Resource Productivity: Assessment Report for the UNEP International Resource Panel; United Nations Environment Programme: Paris, France, 2016. [Google Scholar]

- Krausmann, F.; Wiedenhofer, D.; Lauk, C.; Haas, W.; Tanikawa, H.; Fishman, T.; Miatto, A.; Schandl, H.; Haberl, H. Global socioeconomic material stocks rise 23-fold over the 20th century and require half of annual resource use. Proc. Natl. Acad. Sci. USA 2017, 114, 1880–1885. [Google Scholar] [CrossRef] [PubMed]

- Wiedmann, T.O.; Schandl, H.; Lenzen, M.; Moran, D.; Suh, S.; West, J.; Kanemoto, K. The material footprint of nations. Proc. Natl. Acad. Sci. USA 2015, 112, 6271–6276. [Google Scholar] [CrossRef] [PubMed]

- Dittrich, M.; Giljum, S.; Lutter, S.; Polzin, C. Green economies around the World? In Implications of Resource Use for Development and the Environment; Sustainable Europe Research Institute (SERI): Vienna, Austria, 2012; p. 43. [Google Scholar]

- Schandl, H.; Hatfield-Dodds, S.; Wiedmann, T.; Geschke, A.; Cai, Y.; West, J.; Newth, D.; Baynes, T.; Lenzen, M.; Owen, A. Decoupling global environmental pressure and economic growth: Scenarios for energy use, materials use and carbon emissions. J. Clean. Prod. 2016, 132, 45–56. [Google Scholar] [CrossRef]

- Fischer-Kowalski, M.; Swilling, M.; Von Weizsacker, E.U.; Ren, Y.; Moriguchi, Y.; Crane, W.; Krausmann, F.K.; Eisenmenger, N.; Giljum, S.; Hennicke, P. Decoupling: Natural Resource Use and Environmental Impacts from Economic Growth; United Nations Environment Programme: Paris, France, 2011; ISBN 92-807-3167-X. [Google Scholar]

- Chen, W.-Q.; Graedel, T.E. In-use product stocks link manufactured capital to natural capital. Proc. Natl. Acad. Sci. USA 2015, 112, 6265–6270. [Google Scholar] [CrossRef] [PubMed]

- Rogich, D.; Cassara, A.; Wernick, I.; Miranda, M. Material Flows in the United States: A Physical Accounting of the US Industrial Economy; World Resources Institute (WRI): Washington, DC, USA, 2008; p. 10. [Google Scholar]

- Weisz, H.; Suh, S.; Graedel, T.E. Industrial Ecology: The role of manufactured capital in sustainability. Proc. Natl. Acad. Sci. USA 2015, 112, 6260–6264. [Google Scholar] [CrossRef] [PubMed]

- Schnaiberg, A. Environment: From Surplus to Scarcity; Oxford University Press: Oxford, UK, 1980. [Google Scholar]

- Cullen, J.M. Circular Economy: Theoretical Benchmark or Perpetual Motion Machine? J. Ind. Ecol. 2017, 21, 483–486. [Google Scholar] [CrossRef]

- Kahneman, D.; Knetsch, J.L.; Thaler, R.H. Anomalies: The endowment effect, loss aversion, and status quo bias. J. Econ. Perspect. 1991, 5, 193–206. [Google Scholar] [CrossRef]

- Kallis, G. Radical dematerialization and degrowth. Philos. Trans. R. Soc. A 2017. [Google Scholar] [CrossRef] [PubMed]

- Burke, P.J.; Shahiduzzaman, M.; Stern, D.I. Carbon dioxide emissions in the short run: The rate and sources of economic growth matter. Glob. Environ. Chang. 2015, 33, 109–121. [Google Scholar] [CrossRef]

- Whiting, K.; Carmona, L.G.; Carrasco, A.; Sousa, T. Exergy Replacement Cost of Fossil Fuels: Closing the Carbon Cycle. Energies 2017, 10, 979. [Google Scholar] [CrossRef]

- Phillips, J.; Whiting, K. A geocybernetic analysis of the principles of the Extractive Industries Transparency Initiative (EITI). Resour. Policy 2016, 49, 248–265. [Google Scholar] [CrossRef]

- Peters, G.P.; Minx, J.C.; Weber, C.L.; Edenhofer, O. Growth in emission transfers via international trade from 1990 to 2008. Proc. Natl. Acad. Sci. USA 2011, 108, 8903–8908. [Google Scholar] [CrossRef] [PubMed]

- Lenzen, M.; Moran, D.; Kanemoto, K.; Foran, B.; Lobefaro, L.; Geschke, A. International trade drives biodiversity threats in developing nations. Nature 2012, 486, 109–112. [Google Scholar] [CrossRef] [PubMed]

- Lenzen, M.; Moran, D.; Bhaduri, A.; Kanemoto, K.; Bekchanov, M.; Geschke, A.; Foran, B. International trade of scarce water. Ecol. Econ. 2013, 94, 78–85. [Google Scholar] [CrossRef]

- Automobile Catalog: 1950 Ford (USA) Custom Tudor Sedan All Versions Specifications and Performance Data. Available online: http://www.automobile-catalog.com/make/ford_usa/full-size_ford_2gen/full-size_ford_2gen_custom_2-door_sedan/1950.html (accessed on 1 May 2017).

- The Pneumatic Tire. Available online: https://www.fueleconomy.gov/feg/pdfs/PneumaticTire_HS-810-561.pdf (accessed on 5 May 2017).

- Schirber, M. The Chemistry of Life: The Plastic in Cars. Available online: https://www.livescience.com/5449-chemistry-life-plastic-cars.html (accessed on 5 May 2017).

- Annual Energy Review 2011; Energy Information Administration: Washington, DC, USA, 2012.

- Habermacher, F. Modeling Material Inventories and Environmental Impacts of Electric Passenger Cars; Department of Environmental Science ETH: Zürich, Switzerland, 2011. [Google Scholar]

- Graedel, T. Rare Earths and Other Scarce Metals: Technologically Vital but Usually Thrown Away. Available online: http://www.rsc.org/images/Thomas-Graedel_tcm18-230232.pdf (accessed on 5 May 2017).

- Valero Capilla, A.; Valero Delgado, A. Thanatia: The Destiny of the Earth’s Mineral Resources: A Thermodynamic Cradle-to-cradle Assessment; World Scientific: Singapore, 2014; ISBN 981-4602-49-3. [Google Scholar]

- Del Duce, A.; Gauch, M.; Althaus, H.-J. Electric passenger car transport and passenger car life cycle inventories in ecoinvent version 3. Int. J. Life Cycle Assess. 2016, 21, 1314–1326. [Google Scholar] [CrossRef]

- Fuelly Toyota Prius MPG. Available online: http://www.fuelly.com/car/toyota/prius (accessed on 18 August 2017).

- MadeHow Typewriter. Available online: http://www.madehow.com/Volume-7/Typewriter.html (accessed on 5 May 2017).

- Hischier, R.; Classen, M.; Lehmann, M.; Scharnhorst, W. Life Cycle Inventories of Electric and Electronic Equipment: Production, Use and Disposal. Available online: http://www.ecoinvent.org/database/older-versions/ecoinvent-version-2/reports-on-ecoinvent-2/reports-on-ecoinvent-2.html#1662 (accessed on 24 August 2017).

- Technical Specifications of the Cisco Phone IP 7960G/7940G. Available online: http://www.cisco.com/c/en/us/td/docs/voice_ip_comm/cuipph/7960g_7940g/sip/7_5/english/administration/guide/ver7_5/sipaxc75.pdf (accessed on 1 May 2017).

- Koomey, J.G. A primer on the energy efficiency of computing. AIP Conf. Proc. 2015, 1652, 82–89. [Google Scholar]

- OldPhone 1957 Western Electric Telephone Model 500 Fully. Available online: http://www.oldphoneshop.com/products/1957-western-electric-telephone-model-500-fully-restored.html (accessed on 5 May 2017).

- The Henry Ford Zenith Saratoga Radio-Phonograph Combination, Model H664. 1950–1952. Available online: https://www.thehenryford.org/collections-and-research/digital-collections/artifact/295506 (accessed on 5 May 2017).

- How Light Bulb Is Made. Available online: http://www.madehow.com/Volume-1/Light-Bulb.html (accessed on 5 May 2017).

- How Heavy Is 15 Grams? Available online: http://www.bluebulbprojects.com/measureofthings/results.php?comp=weight&unit=gms&amt=15&sort=pr&p=1 (accessed on 1 May 2017).

- A Basic Guide to How LED Lights Work. Available online: http://www.compoundchem.com/2016/12/14/leds/ (accessed on 1 August 2017).

- Funk, J. New Light-Weight LED Bulb from Cree Costs Less, Is Brighter and Last 22 Years. Available online: http://www.cleveland.com/business/index.ssf/2014/10/new_light-weight_led_bulb_from.html (accessed on 5 May 2017).

- Light-Emitting Diode (LED). Available online: http://www.madehow.com/Volume-1/Light-Emitting-Diode-LED.html (accessed on 5 May 2017).

- How Energy-Efficient Light Bulbs Compare with Traditional Incandescents. Available online: https://energy.gov/energysaver/how-energy-efficient-light-bulbs-compare-traditional-incandescents (accessed on 5 May 2017).

- MacKay, D. Sustainable Energy-without the Hot Air; UIT Cambridge: Cambridge, UK, 2008; ISBN 0-9544529-3-3. [Google Scholar]

- Kushnir, D.; Sandén, B.A. The time dimension and lithium resource constraints for electric vehicles. Resour. Policy 2012, 37, 93–103. [Google Scholar] [CrossRef]

- Ericksen, G.E.; Vine, J.D.; Ballón, A.R. Chemical composition and distribution of lithium-rich brines in Salar de Uyuni and nearby salars in southwestern Bolivia. Energy 1978, 3, 355–363. [Google Scholar] [CrossRef]

- Garrett, D.E. Handbook of Lithium and Natural Calcium Chloride; Elsevier Academic Press: Oxford, UK, 2004; ISBN 0-08-047290-7. [Google Scholar]

- Aguilar-Fernández, R. Estimating the Opportunity Cost of Lithium Extraction in the Salar de Uyuni, Bolivia. Available online: https://dukespace.lib.duke.edu/dspace/bitstream/handle/10161/1554/Aguilar,%20Rodrigo_MP_2009.pdf (accessed on 18 August 2017).

- Hindery, D. From Enron to Evo: Pipeline Politics, Global Environmentalism, and Indigenous Rights in Bolivia; University of Arizona Press: Tucson, AZ, USA, 2013; ISBN 0-8165-0237-4. [Google Scholar]

- Romero, H.; Méndez, M.; Smith, P. Mining development and environmental injustice in the Atacama Desert of Northern Chile. Environ. Justice 2012, 5, 70–76. [Google Scholar] [CrossRef]

- Grosjean, M.; Geyh, M.A.; Messerli, B.; Schotterer, U. Late-glacial and early Holocene lake sediments, ground-water formation and climate in the Atacama Altiplano 22–24°S. J. Paleolimnol. 1995, 14, 241–252. [Google Scholar] [CrossRef]

- Derraik, J.G. The pollution of the marine environment by plastic debris: A review. Mar. Pollut. Bull. 2002, 44, 842–852. [Google Scholar] [CrossRef]

- Law, K.L.; Morét-Ferguson, S.; Maximenko, N.A.; Proskurowski, G.; Peacock, E.E.; Hafner, J.; Reddy, C.M. Plastic accumulation in the North Atlantic subtropical gyre. Science 2010, 329, 1185–1188. [Google Scholar] [CrossRef] [PubMed]

- Minter, A. The Burning Truth behind an E-Waste Dump in Africa. Available online: http://www.smithsonianmag.com/science-nature/burning-truth-behind-e-waste-dump-africa-180957597/ (accessed on 5 June 2017).

- Gutowski, T.G.; Allwood, J.M.; Herrmann, C.; Sahni, S. A global assessment of manufacturing: economic development, energy use, carbon emissions, and the potential for energy efficiency and materials recycling. Annu. Rev. Environ. Resour. 2013, 38, 81–106. [Google Scholar] [CrossRef]

- Allwood, J.M.; Cullen, J.M.; Milford, R.L. Options for achieving a 50% cut in industrial carbon emissions by 2050. Environ. Sci. Technol. 2010, 44, 1888–1894. [Google Scholar] [CrossRef] [PubMed]

- Gutowski, T.G.; Sahni, S.; Allwood, J.M.; Ashby, M.F.; Worrell, E. The energy required to produce materials: constraints on energy-intensity improvements, parameters of demand. Philos. Trans. R. Soc. A 2013. [Google Scholar] [CrossRef] [PubMed]

- Allwood, J.M.; Cullen, J.M. Sustainable Materials without the Hot Air: Making Buildings, Vehicles and Products Efficiently and with Less New Material, 2nd ed.; UIT Cambridge: Cambridge, UK, 2015; ISBN 978-1-906860-30-1. [Google Scholar]

- Gould, O.; Colwill, J. A framework for material flow assessment in manufacturing systems. J. Ind. Prod. Eng. 2015, 32, 55–66. [Google Scholar] [CrossRef] [Green Version]

- Jevons, W.S. The Coal Question: An Inquiry Concerning the Progress of the Nation, and the Probable Exhaustion of the Coal-Mines. Available online: https://archive.org/details/coalquestionani00jevogoog (accessed on 24 August 2017).

- Zink, T.; Geyer, R. Circular Economy Rebound. J. Ind. Ecol. 2017, 21, 593–602. [Google Scholar] [CrossRef]

- Stapleton, L.; Sorrell, S.; Schwanen, T. Estimating direct rebound effects for personal automotive travel in Great Britain. Energy Econ. 2016, 54, 313–325. [Google Scholar] [CrossRef]

- Allwood, J.M.; Gutowski, T.G.; Serrenho, A.C.; Skelton, A.C.; Worrell, E. Industry 1.61803: the transition to an industry with reduced material demand fit for a low carbon future. Philos. Transact. A Math. Phys. Eng. Sci. 2017. [Google Scholar] [CrossRef] [PubMed]

- House of Commons—Energy and Climate Change Committee. Future of Carbon Capture and Storage in the UK; HM Stationery Office: London, UK, 2016. [Google Scholar]

- Global CCS Institute The Global Status of CCS 2015: Summary Report. Available online: https://www.globalccsinstitute.com (accessed on 1 February 2017).

- Ayres, R.U.; Peiró, L.T. Material efficiency: rare and critical metals. Philos. Trans. R. Soc. A 2013. [CrossRef] [PubMed]

- Park, J.; Yoon, J.; Kim, K.-H. Critical Review of the Material Criteria of Building Sustainability Assessment Tools. Sustainability 2017, 9, 186. [Google Scholar] [CrossRef]

- Milford, R.L.; Pauliuk, S.; Allwood, J.M.; Müller, D.B. The roles of energy and material efficiency in meeting steel industry CO2 targets. Environ. Sci. Technol. 2013, 47, 3455–3462. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- MacKenzie, D.; Zoepf, S.; Heywood, J. Determinants of US passenger car weight. Int. J. Veh. Des. 2014, 65, 73–93. [Google Scholar] [CrossRef]

- Cabrera Serrenho, A.; Allwood, J.M. Material stock demographics: Cars in Great Britain. Environ. Sci. Technol. 2016, 50, 3002–3009. [Google Scholar] [CrossRef] [PubMed]

- Steinberger, J.K.; Krausmann, F.; Getzner, M.; Schandl, H.; West, J. Development and dematerialization: An international study. PLOS ONE 2013. [Google Scholar] [CrossRef] [PubMed]

- Pfaff, M.; Sartorius, C. Economy-wide rebound effects for non-energetic raw materials. Ecol. Econ. 2015, 118, 132–139. [Google Scholar] [CrossRef]

- Magee, C.L.; Devezas, T.C. A simple extension of dematerialization theory: Incorporation of technical progress and the rebound effect. Technol. Forecast. Soc. Chang. 2017, 117, 196–205. [Google Scholar] [CrossRef]

- Pauliuk, S.; Müller, D.B. The role of in-use stocks in the social metabolism and in climate change mitigation. Glob. Environ. Chang. 2014, 24, 132–142. [Google Scholar] [CrossRef] [Green Version]

- Cooper, D.R.; Gutowski, T.G. The environmental impacts of reuse: A review. J. Ind. Ecol. 2017, 21, 38–56. [Google Scholar] [CrossRef]

- Prabhu, J. Frugal innovation: doing more with less for more. Philos. Trans. R. Soc. A 2017. [Google Scholar] [CrossRef] [PubMed]

- Fletcher, K. Craft of Use: Post-Growth Fashion; Routledge: London, UK, 2016; ISBN 1-317-29782-2. [Google Scholar]

- Fletcher, K. Exploring demand reduction through design, durability and ‘usership’ of fashion clothes. Philos. Trans. R. Soc. A 2017. [Google Scholar] [CrossRef] [PubMed]

- Gracey, F.; Moon, D. Valuing our clothes: the evidence base; Waste & Resources Action Programme (WRAP). Available online: http://www.wrap.org.uk/sites/files/wrap/VoC%20FINAL%20online%202012%2007%2011.pdf (accessed on 1 August 2017).

- Chapman, J. Emotionally Durable Design: Objects, Experiences, and Empathy, 1st ed.; Earthscan: London, UK, 2005; ISBN 978-1-84407-181-4. [Google Scholar]

- Allwood, J.M.; Ashby, M.F.; Gutowski, T.G.; Worrell, E. Material efficiency: A white paper. Resour. Conserv. Recycl. 2011, 55, 362–381. [Google Scholar] [CrossRef]

- Serrenho, A.C.; Mourão, Z.S.; Norman, J.; Cullen, J.M.; Allwood, J.M. The influence of UK emissions reduction targets on the emissions of the global steel industry. Resour. Conserv. Recycl. 2016, 107, 174–184. [Google Scholar] [CrossRef] [Green Version]

- Tukker, A.; Bulavskaya, T.; Giljum, S.; de Koning, A.; Lutter, S.; Simas, M.; Stadler, K.; Wood, R. The Global Resource Footprint of Nations: Carbon, Water, Land and Materials Embodied in Trade and Final Consumption Calculated with EXIOBASE 2.1. Available online: http://www.truthstudio.com/content/CREEA_Global_Resource_Footprint_of_Nations.pdf (accessed on 24 August 2017).

- Söderholm, P.; Tilton, J.E. Material efficiency: An economic perspective. Resour. Conserv. Recycl. 2012, 61, 75–82. [Google Scholar] [CrossRef]

- Schatzberg, E. Symbolic culture and technological change: The cultural history of Aluminum as an industrial material. Enterp. Soc. 2003, 4, 226–271. [Google Scholar] [CrossRef]

- Shove, E. The Design of Everyday Life; Berg: Oxford, UK, 2007; ISBN 1-84520-683-5. [Google Scholar]

- Bethell, L. Historia de América latina. In América Latina Colonial: Economía, 1st ed.; Crítica: Barcelona, Spain, 1990; ISBN 84-7423-477-8. [Google Scholar]

- Ruiz, M.D.C.C. El atractivo turístico de una de las minas de mercurio más importantes del mundo: el parque minero de Almadén (Ciudad Real). Cuad. Tur. 2008, 21, 9–31. [Google Scholar]

- Pauliuk, S.; Sjöstrand, K.; Müller, D.B. Transforming the Norwegian dwelling stock to reach the 2 degrees Celsius climate target. J. Ind. Ecol. 2013, 17, 542–554. [Google Scholar] [CrossRef] [Green Version]

- Sousa, T.; Brockway, P.E.; Cullen, J.M.; Henriques, S.T.; Miller, J.; Serrenho, A.C.; Domingos, T. The Need for Robust, Consistent Methods in Societal Exergy Accounting. Ecol. Econ. 2017, 141, 11–21. [Google Scholar] [CrossRef]

- Nakićenović, N. Diffusion of pervasive systems: a case of transport infrastructures. Technol. Forecast. Soc. Chang. 1991, 39, 181–200. [Google Scholar] [CrossRef]

- Nakićenović, N.; Gilli, P.V.; Kurz, R. Regional and global exergy and energy efficiencies. Energy 1996, 21, 223–237. [Google Scholar] [CrossRef]

- Schaeffer, R.; Wirtshafter, R.M. An exergy analysis of the Brazilian economy: From energy production to final energy use. Energy 1992, 17, 841–855. [Google Scholar] [CrossRef]

- IEA Energy Technology Perspectives. 2012. Available online: www.iea.org/media/etp/2012/ETP2012_Sankey.pdf (accessed on 5 May 2017).

- Daily, G. Nature’s Services: Societal Dependence on Natural Ecosystems; Island Press: Washington, DC, USA, 1997; ISBN 1-55963-476-6. [Google Scholar]

- Costanza, R.; d’Arge, R.; De Groot, R.; Farber, S.; Grasso, M.; Hannon, B.; Limburg, K.; Naeem, S.; O’neill, R.V.; et al. The value of the world’s ecosystem services and natural capital. Nature 1997, 387, 253–260. [Google Scholar] [CrossRef]

- Millenium Ecosystem Assessment Ecosystems and Human Well-being: A Framework for Assessment, 1st ed.; World Resources Institute: Washington, DC, USA, 2005; ISBN 1-55963-403-0.

- De Groot, R.S.; Fisher, B.; Christie, M.; Aronson, J.; Braat, L.; Haines-Young, R.; Gowdy, J.; Maltby, E.; Neuville, A.; Polasky, S. Integrating the ecological and economic dimensions in biodiversity and ecosystem service valuation. In The Economics of Ecosystems and Biodiversity (TEEB): Ecological and Economic Foundations; Earthscan: London, UK, 2010; ISBN 1-84971-212-3. [Google Scholar]

- Modi, V.; McDade, S.; Lallement, D.; Saghir, J. Energy Services for the Millenium Development Goals; United Nations Development Programme: Washington, DC, USA, 2005. [Google Scholar]

- Anastas, P.T.; Warner, J.C. Green Chemistry: Theory and Practice; Oxford University Press: Oxford, UK, 1998; ISBN 0-19-850234-6. [Google Scholar]

- Henckens, M.; van Ierland, E.C.; Driessen, P.P.J.; Worrell, E. Mineral resources: Geological scarcity, market price trends, and future generations. Resour. Policy 2016, 49, 102–111. [Google Scholar] [CrossRef]

- Henckens, M.; Driessen, P.P.J.; Ryngaert, C.; Worrell, E. The set-up of an international agreement on the conservation and sustainable use of geologically scarce mineral resources. Resour. Policy 2016, 49, 92–101. [Google Scholar] [CrossRef]

- Braungart, M.; McDonough, W.; Bollinger, A. Cradle-to-cradle design: creating healthy emissions–a strategy for eco-effective product and system design. J. Clean. Prod. 2007, 15, 1337–1348. [Google Scholar] [CrossRef]

- Lavoie, E.T.; Heine, L.G.; Holder, H.; Rossi, M.S.; Lee, R.E., II; Connor, E.A.; Vrabel, M.A.; DiFiore, D.M.; Davies, C.L. Chemical Alternatives Assessment: Enabling Substitution to Safer Chemicals. Environ. Sci. Technol. 2011, 45, 1747. [Google Scholar] [CrossRef]

- Young, S.B. Responsible sourcing of metals: certification approaches for conflict minerals and conflict-free metals. Int. J. Life Cycle Assess. 2015. [Google Scholar] [CrossRef]

- Hosseinijou, S.A.; Mansour, S.; Shirazi, M.A. Social life cycle assessment for material selection: a case study of building materials. Int. J. Life Cycle Assess. 2014, 19, 620–645. [Google Scholar] [CrossRef]

- Llevot, A.; Meier, M.A. Renewability—A principle of utmost importance! Green Chem. 2016, 18, 4800–4803. [Google Scholar] [CrossRef]

- Sikkema, R.; Junginger, M.; van Dam, J.; Stegeman, G.; Durrant, D.; Faaij, A. Legal harvesting, sustainable sourcing and cascaded use of wood for bioenergy: Their coverage through existing certification frameworks for sustainable forest management. Forests 2014, 5, 2163–2211. [Google Scholar] [CrossRef]

- Sundararajan, A. The Sharing Economy: The End of Employment and the Rise of Crowd-based Capitalism; MIT Press: Cambridge, USA, 2016; ISBN 0-262-03457-3. [Google Scholar]

- Baines, T.; Lightfoot, H. Made to Serve: How Manufacturers Can Compete through Servitization and Product Service Systems; John Wiley & Sons: Hoboken, NJ, USA, 2013; ISBN 1-118-58528-3. [Google Scholar]

- Baxter, R.K. The Membership Economy: Find Your Super Users, Master the Forever Transaction, and Build Recurring Revenue; McGraw-Hill: New York, NY, USA, 2015; ISBN 0-07-183932-1. [Google Scholar]

- Mazzella, F. BlaBlaCar et le tourisme collaboratif. In Annales des Mines-Réalités industrielles; FFE: Dallas, TX, USA, 2015; pp. 54–57. [Google Scholar]

- Guttentag, D. Airbnb: Disruptive innovation and the rise of an informal tourism accommodation sector. Curr. Issues Tour. 2015, 18, 1192–1217. [Google Scholar] [CrossRef]

- Cusumano, M.A. How traditional firms must compete in the sharing economy. Commun. ACM 2015, 58, 32–34. [Google Scholar] [CrossRef]

- Belk, R. You are what you can access: Sharing and collaborative consumption online. J. Bus. Res. 2014, 67, 1595–1600. [Google Scholar] [CrossRef]

- Müller, D.B.; Cao, J.; Kongar, E.; Altonji, M.; Weiner, P.-H.; Graedel, A.T. Service lifetimes of mineral end uses. Available online: https://minerals.usgs.gov/mrerp/reports/Mueller-06HQGR0174.pdf (accessed on 24 August 2017).

- Skelton, A.C.; Allwood, J.M. Product life trade-offs: what if products fail early? Environ. Sci. Technol. 2013, 47, 1719–1728. [Google Scholar] [CrossRef] [PubMed]

- The Role of Transport in the Sustainable Development Goals. Available online: https://www.itdp.org/the-role-of-transport-in-the-sustainable-development-goals/ (accessed on 5 May 2017).

- McDonough, W.; Braungart, M. The Hannover Principles; William McDonough Architects: New York, NY, USA, 1992. [Google Scholar]

- McDonough, W.; Braungart, M. The Upcycle: Beyond Sustainability—Designing for Abundance; North Point Press: New York, NY, USA, 2013; ISBN 0-86547-748-5. [Google Scholar]

- Ellen MacArthur Foundation What Is a Circular Economy? Available online: https://www.ellenmacarthurfoundation.org/circular-economy (accessed on 13 Aug 2017).

- Henckens, M.; Driessen, P.P.J.; Worrell, E. How can we adapt to geological scarcity of antimony? Investigation of antimony’s substitutability and of other measures to achieve a sustainable use. Resour. Conserv. Recycl. 2016, 108, 54–62. [Google Scholar] [CrossRef]

- Benyus, J. Biomimicry: Innovation Inspired by Nature; William Morrow & Company: New York, NY, USA, 1997. [Google Scholar]

- De Pauw, I.C.; Kandachar, P.; Karana, E. Assessing sustainability in nature-inspired design. Int. J. Sustain. Eng. 2015, 8, 5–13. [Google Scholar] [CrossRef]

- The Hemp Trading Company. Available online: https://shop.thtc.co.uk (accessed on 15 June 2017).

- Warrillow, J. The Automatic Customer: Creating a Subscription Business in any Industry; Penguin: London, UK, 2015; ISBN 1-59184-746-X. [Google Scholar]

- Company Sustainable Products. Available online: http://materialimpacts.c-and-a.com/sustainable-products/ (accessed on 15 May 2017).

- Cumming, D. A Case Study Engaging Design for Textile Upcycling. J. Text. Des. Res. Pract. 2016, 4, 113–128. [Google Scholar] [CrossRef]

- Oyenuga, A.A.; Bhamidimarri, R. Upcycling Ideas for Sustainable Construction and Demolition Waste Management: Challenges, Opportunities and Boundaries. Available online: https://www.researchgate.net/publication/315762443_Upcycling_ideas_for_Sustainable_Construction_and_Demolition_Waste_Management_Challenges_Opportunities_and_Boundaries (accessed on 1 August 2017).

- Klein, N. Change the System Not the Climate World Social Forum Montreal 14th April 2017. Available online: https://www.youtube.com/watch?v=bjDXjVIdLnA (accessed on 15 June 2017).

- Raworth, K. Doughnut Economics: Seven Ways to Think Like a 21st-Century Economist; Chelsea Green Publishing: Vermont, VT, USA, 2017; ISBN 1-60358-674-1. [Google Scholar]

- Transforming Our World: The 2030 Agenda for Sustainable Development. Available online: https://sustainabledevelopment.un.org/content/documents/21252030%20Agenda%20for%20Sustainable%20Development%20web.pdf (accessed on 24 August 2017).

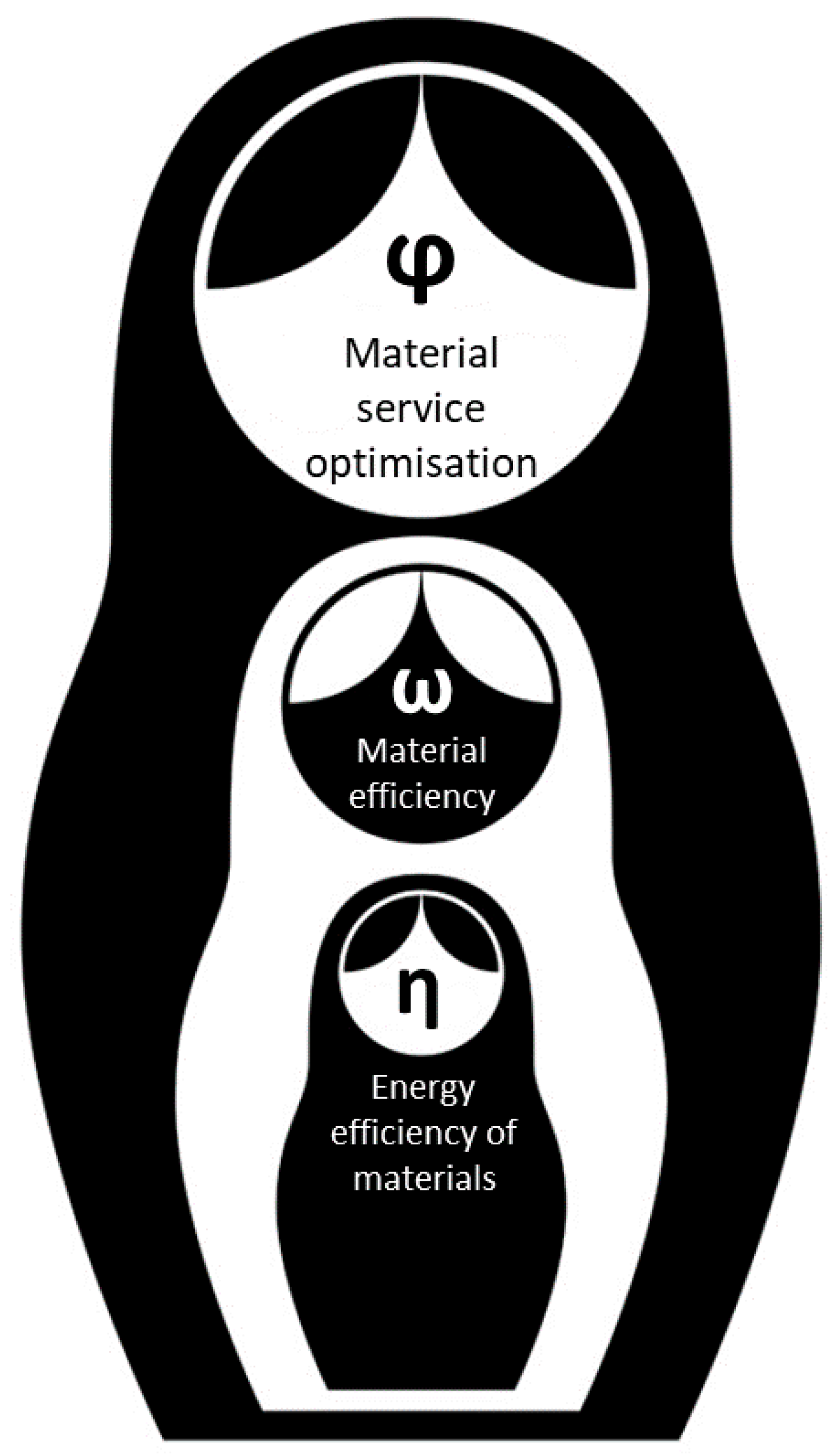

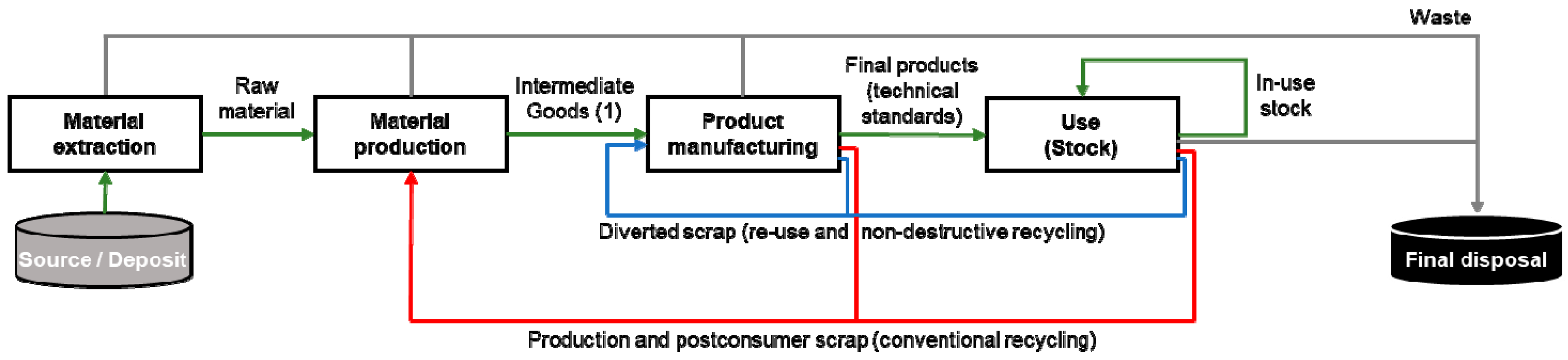

| Strategy | Strategy Focus | |||

|---|---|---|---|---|

| Production Stage | Final Product (Use) | Waste/End-Of-Life | Potential Benefits | |

| One eye open Energy efficiency of materials | Less utilities (energy, water) | Same product with improvements in energy efficiency | Conventional recycling and end-of-pipe technologies (e.g., carbon storage, urban mining) | Carbon savings and monetary cost reduction |

| Both eyes open Material efficiency | Less raw material (biomass, mineral ore) | Better products (durable, resistance, fixable, recyclable) | Direct re-use and non-destructive recycling | Innovation leading to further carbon reductions, a higher market price and better-quality products for the consumer |

| Eyes wide open Material service optimisation | Better materials (renewable, non-toxic, conflict free, etc.) | Stock optimisation via smarter demand and material service efficiency | Upcycling | Greater fulfilment of sustainable development goals due to an emphasis on socio-environmental aspects |

| Material Service | 1950 | 2017 | ||||

|---|---|---|---|---|---|---|

| Product | Mass and Main Chemical Elements | Energy Efficiency | Product | Mass and Main Chemical Elements | Energy Efficiency | |

| Transportation | 1950s car | 1440 kg—C, Co, Cr, Cu, Fe, N, O, Pb, Pt, S, Sn, Zn [37,38,39] | 15 Miles per Gallon [40] | Hybrid car | 1325 kg—Al, Ar, Au, Br, C, Cd, Ce, Cr, Co, Cu, Dy, Eu, F, Gd, Ga, In, I, Fe, Kr, La, Li, Mn, Mo, Nd, Ni, N, O, Pd, P, Pt, Pb, K, Cl, Pr, Re, Rh, Sm, Ag, Na, Sr, S, Ta, Te, Sn, U, Xe, Zn, Zr [41,42,43,44] | 50 Miles per Gallon [45] |

| Information storage and processing | Remington Typewriting | 3.6 kg—C, Cr, Fe, N, O, Zn [46] | No automatic performance | Laptop and printer | 2–3 kg (laptop) and 2–3 kg (printer)/ Around 45, including: Al, Ar, Au, Br, Cd, C, Ce, Cr, Co, Cu, Eu, F, Ga, H, In, I, Fe, La, Li, Mn, Mo, Nd, Ni, N, O, Pb, Pd, P, Pt, Pr, Rh, Sm, Ag, Sr, S, Ta, Te, Sn, Ti, Xe, Zn, Zr [47] Still telephones (1.6 kg) and mobile phones (150 g) are used [48]. In addition, headphones are added to laptop | Peak output efficiency = 1.5 ×1015 computations per kWh [49] |

| Tele-communication | Telephone | 4 kg [50] | No automatic performance | |||

| Entertainment | Radio | 15 kg [51] | No automatic performance | |||

| Lighting | Light bulb | 34 g—Ar, Al, B, C, Fe, N, Ni, O, Si [52] | 60 W/800 lumen [53] | LED | 56.6 g—Ag, Al, As, Au, C, Ga, H, In, N, O, P, Zn [54,55,56] | 11 W/815 lumen [57] |

| Stage | Action | Measurement of Savings |

|---|---|---|

| Production stage | Less metal, same service | ML = 1 − (New product mass/Original product mass) |

| Fabrication yield improvement | MY = 1 − (New fabrication actual mass yield/Original fabrication actual mass yield) | |

| Final Product (Use) | More intense use | MI = 1 − (New mass of products required to provide service/Original mass of products required to provide service) |

| Life extension | MX = 1 − [(New product mass/new mean product life)/(Original product mass/original mean product life)] | |

| Waste/End-of-life | Re-use | MR = Mass of scrap diverted for re-use/Original mass of end-of-life scrap sent for conventional recycling |

| Production scrap diversion | MD = Mass of scrap sent for non-destructive recycling/Original mass of production scrap sent for conventional recycling |

| Strategy | Key Concept | Year Term Is Introduced | No. Papers | Relevant Authors (with More than 5 Publications) | Publications Impact (h-Index) | Ngramar Viewer—Books in 2008 (×10−8) | Trend Average Interest on Search (Index) |

|---|---|---|---|---|---|---|---|

| One eye | Energy efficiency | 1907 | 48766 | >500 | 78–122 | 90.26 | 63 |

| Energy service | 1977 | 1371 | 25 | 56 | 2.53 | 77 | |

| Both eyes | Material consumption | 1910 (jump until 1951) | 1031 | 15 | 42 | 6.46 | 1 |

| Material efficiency | 1969 | 443 | 10 | 31 | 1.05 | 1 | |

| Eyes wide open | Material service | 1977 (jump until 1994) | 74 | 4 * | 11 | 1.39 | 5 |

| Final Service Categories * | Schaeffer and Wirtshafter [107] | IEA [108] | Cullen and Allwood [12] |

|---|---|---|---|

| Transport | Transport by mode (Bus and truck, Automobile and truck, Airplanes, Ship, Train) | Passenger transport by mode (sea, heavy road, light road, air, rail) | Passenger transport (passenger-km) |

| Freight transport by mode (sea, heavy road, light road, air, rail) | Freight transport (tonne-km) | ||

| Shelter (Housing and Buildings) | - | - | Structure (MPa2/3m3) |

| Thermal comfort | - | Space heating | Thermal comfort (m3 K air) |

| Refrigeration | Space cooling | ||

| Hygiene | Water heating | Water heating | Hygiene (m3 K hot water) |

| - | - | Hygiene (Nm work) | |

| Food | Cooking | Cooking | Sustenance (J food) |

| Communication and information storage | - | - | Communications (bytes) |

| Illumination | Lighting | Lighting | Illumination (lm-s) |

| Intermediate goods production (see Figure 2) | Industrial sector | Intermediate goods production by sectors (paper, iron and steel, aluminium, steel, cement) | Intermediate goods production by sectors (paper, iron and steel, aluminium, steel, cement), and later allocated to the final service as embodied energy |

| Better Material Criteria | Description | Measurement | Key References Supportive of the Concept |

|---|---|---|---|

| Resource depletion | Criticality of the raw material used in a product relative to natural reserve and market demand. | Mass of current product that can be easily substituted within a determined economy. | [115,116] |

| Toxicity | The number and concentration of hazardous chemicals in products along with the aggregated risk to the end user | Mass of toxic elements below acceptable level according to national legislation or corporate guidelines (CAS#) | [117,118] REACH 1907/2006 |

| Geographical location | Confirmed ethical sourcing from social perspectives Confirmed ethical sourcing from an environmental/ecological perspective | Independently certified as a conflict zone and slave/child labour free products e.g., Kimberley Process, Fair Trade Independently certified as sensitive to the environment e.g., Rainforest Alliance | [119,120] Dodd-Frank Act 2010; Conflict Mineral Directive 2017/821 |

| Resource renewability | The degree of renewable material utilised in the manufacture of a product or service. | Mass from renewable resources | [121,122] |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carmona, L.G.; Whiting, K.; Carrasco, A.; Sousa, T.; Domingos, T. Material Services with Both Eyes Wide Open. Sustainability 2017, 9, 1508. https://doi.org/10.3390/su9091508

Carmona LG, Whiting K, Carrasco A, Sousa T, Domingos T. Material Services with Both Eyes Wide Open. Sustainability. 2017; 9(9):1508. https://doi.org/10.3390/su9091508

Chicago/Turabian StyleCarmona, Luis Gabriel, Kai Whiting, Angeles Carrasco, Tânia Sousa, and Tiago Domingos. 2017. "Material Services with Both Eyes Wide Open" Sustainability 9, no. 9: 1508. https://doi.org/10.3390/su9091508