Using LMDI to Analyze the Decoupling of Carbon Dioxide Emissions from China’s Heavy Industry

Abstract

:1. Introduction

2. Methodology

2.1. Decomposition Analysis

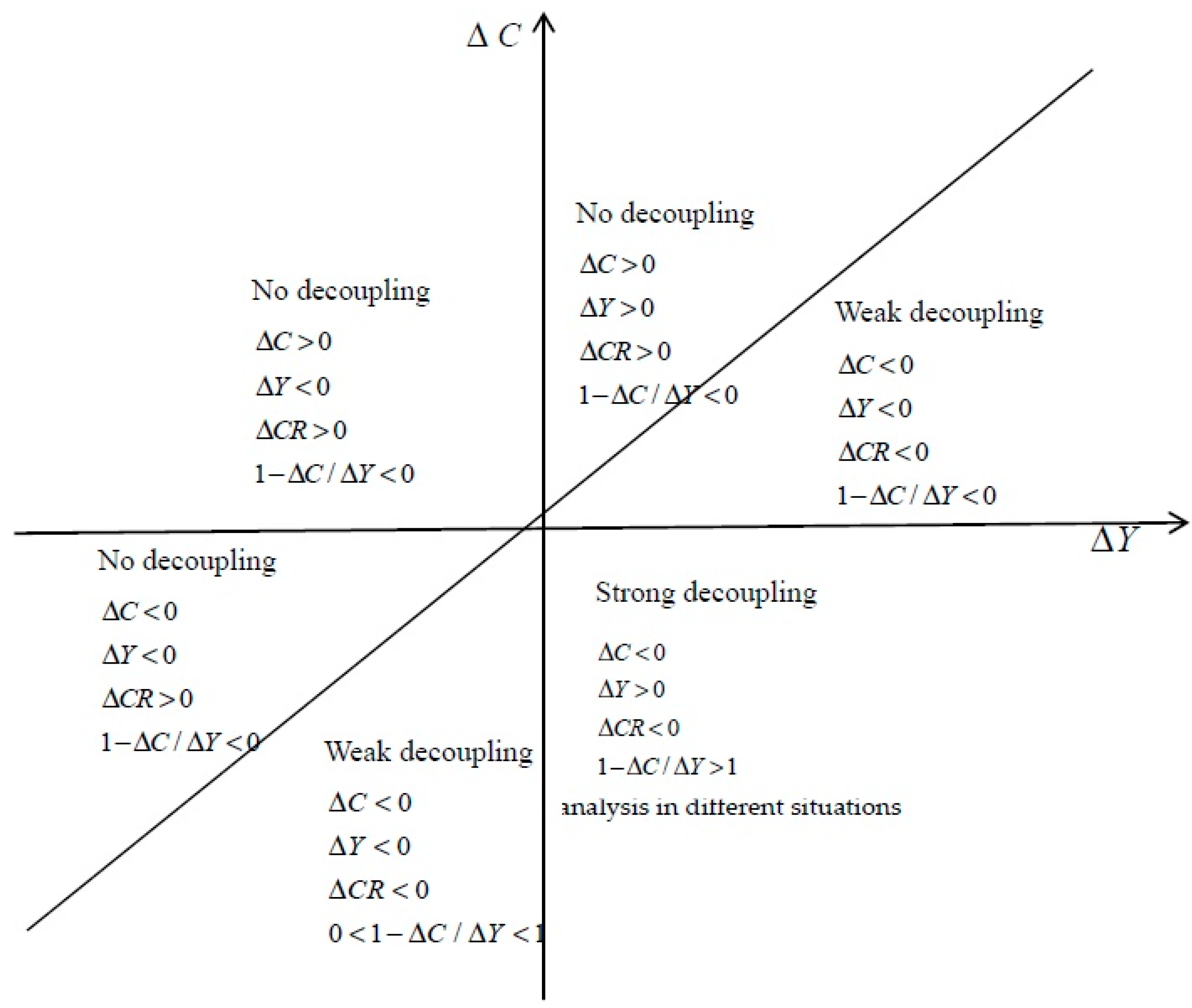

2.2. The Decomposition-Based Decoupling Model

3. Data

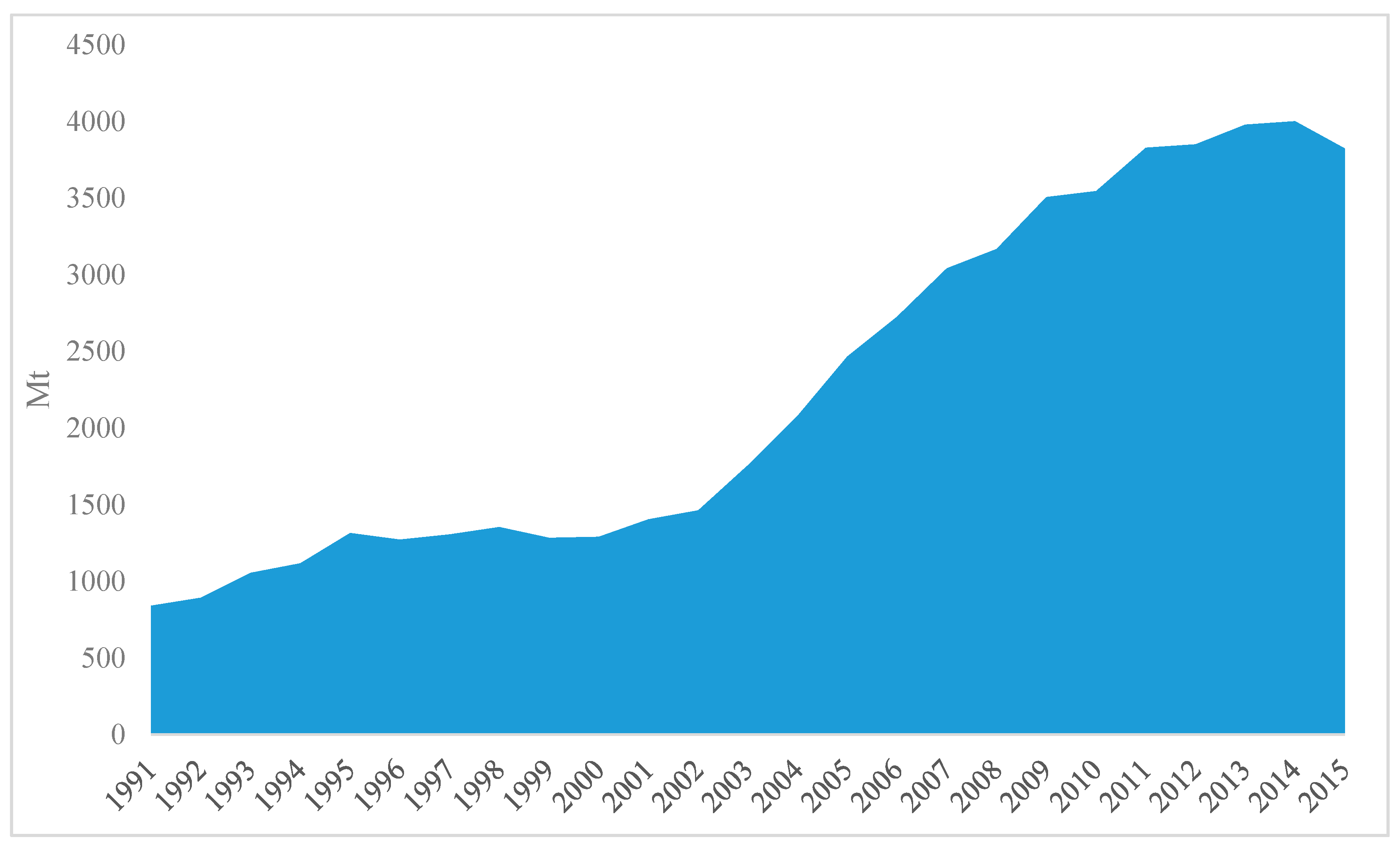

3.1. Energy Consumption

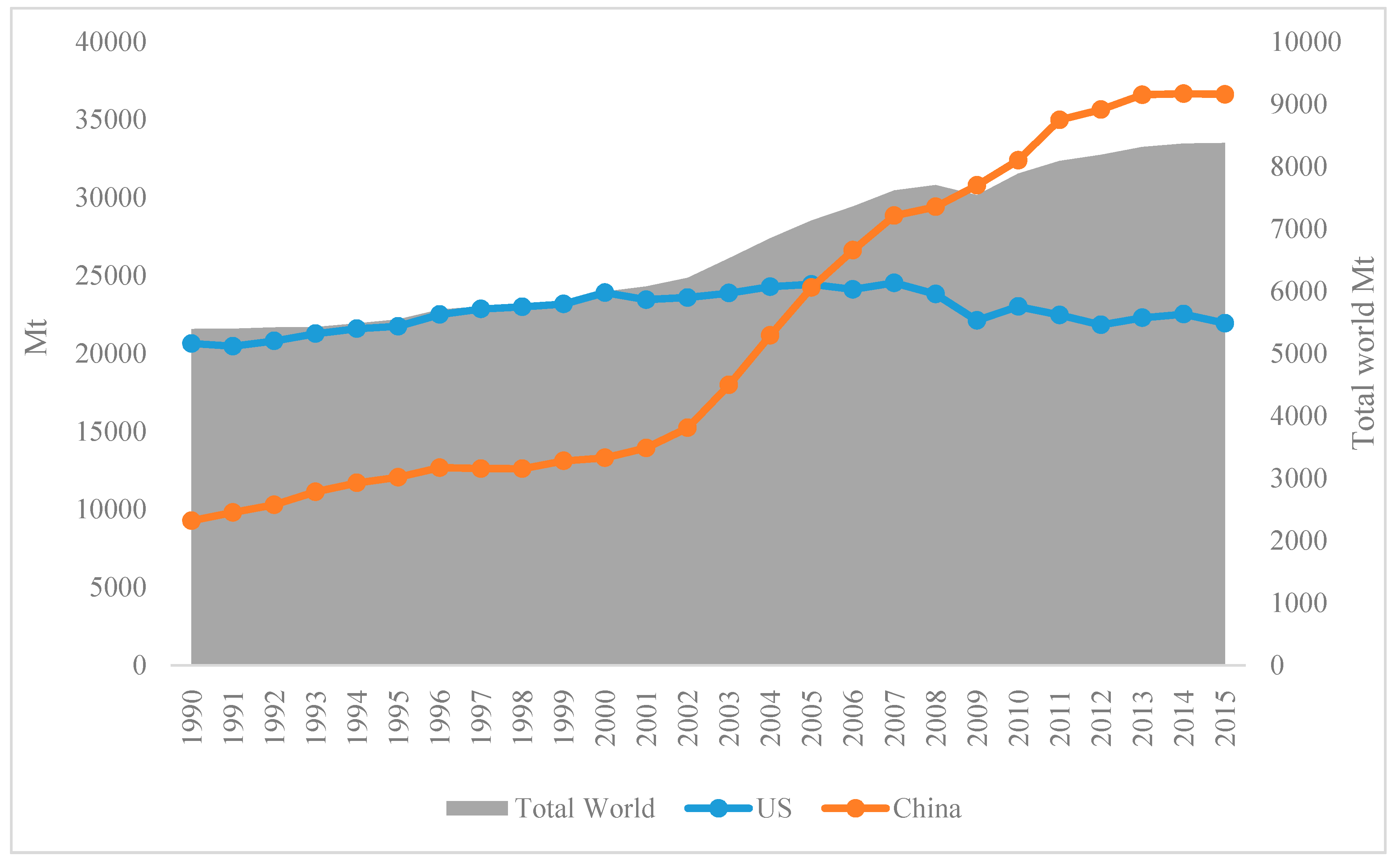

3.2. Carbon Emission

4. Results and Conclusion

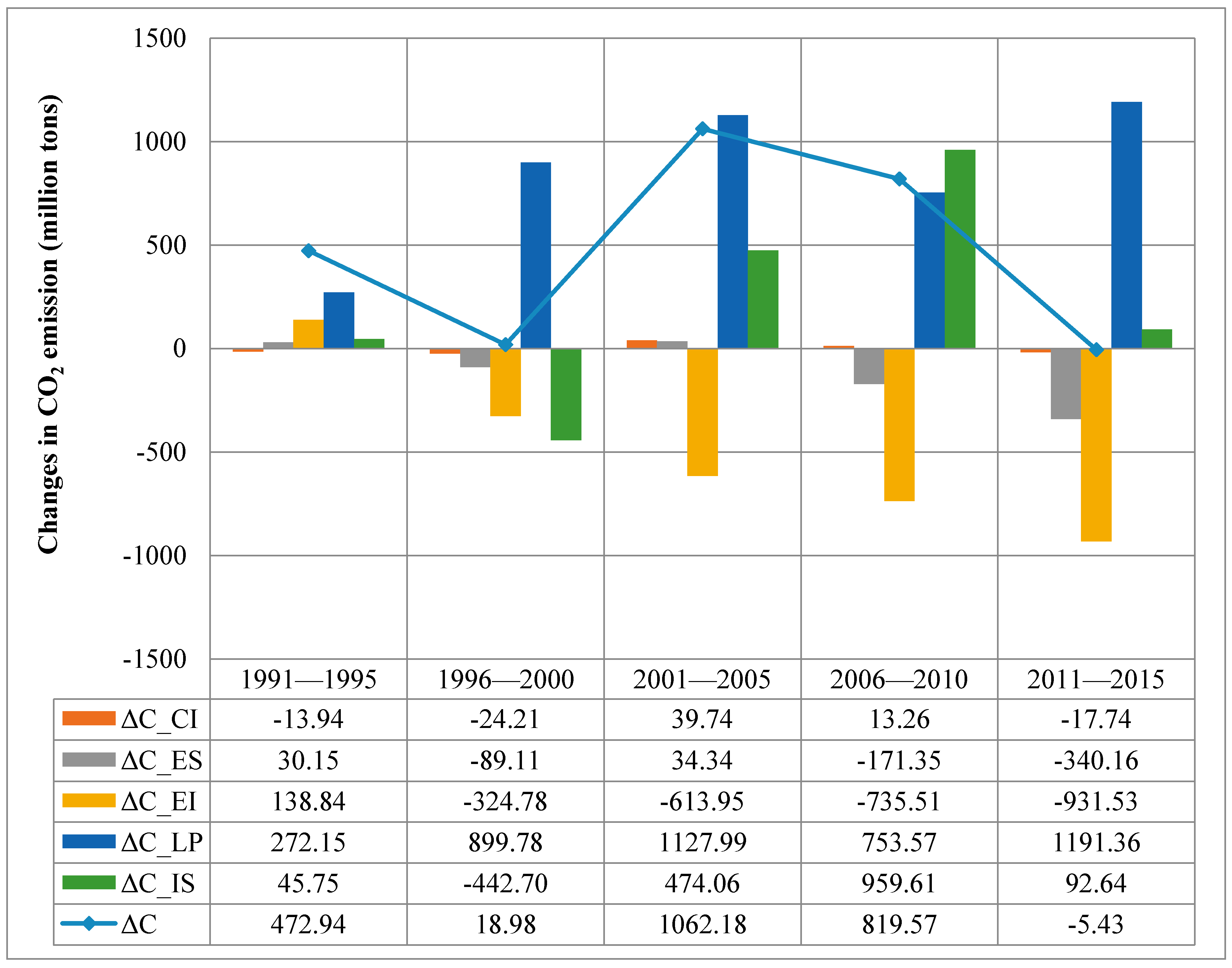

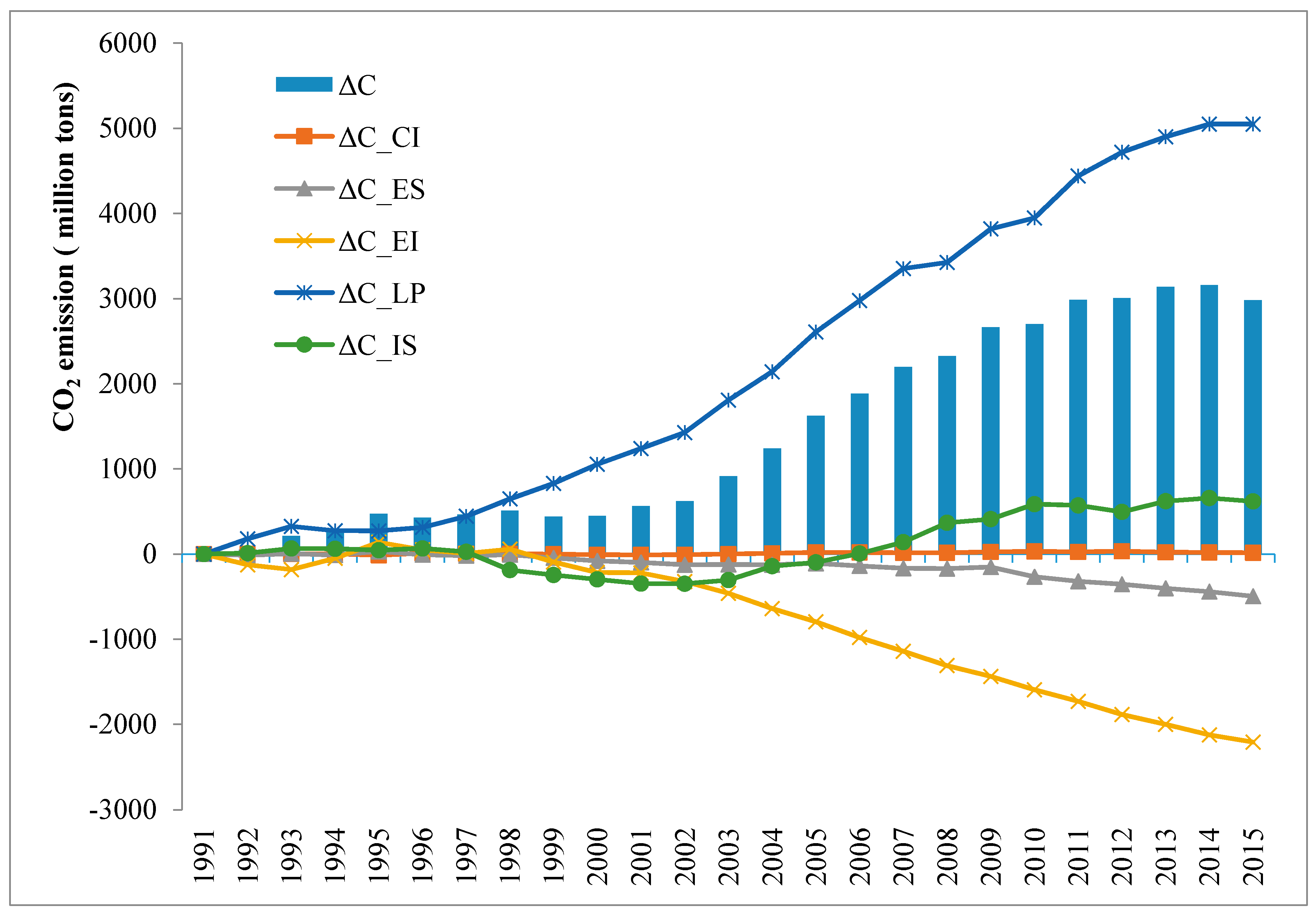

4.1. Decomposition of Carbon Emission

4.2. Decoupling Analysis

4.3. Conclusions and Discussions

- (1)

- The increase of labor productivity (LP) and the industry scale (IS) are the main reason for the increase of carbon emission in China’s heavy industry. LP, which is represented by industrial added value per capita, can ethier increase the carbon emission by the replacement of labor with machine, or reduce the carbon emission by the improvement in efficiency. China’s heavy industry has experienced a rapid development in the past several decades, which has also led to the rapid increase of mechanization and energy consumption.

- (2)

- Energy intensity (EI) had a significantly negative effect on carbon dioxide emissions since 1996. The negative effect on carbon emission can reflect the progress of energy efficiency in China’s heavy industry. The effect of energy structure (ES) became negative since 2006, and the absolute value has been increased during the last two periods. This indicates that the clean and low carbon transformation of China's energy structure has a certain effect.

- (3)

- The results of decoupling analysis shows weak decoupling during 1992–2015, and the decoupling effect continued to increase since 2005. This indicates that the existing efforts of carbon emission reduction have accomplished a certain effect, but it still needs to be strengthened as the decoupling index (DI) are all smaller than 1.

5. Policy Implications

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

| No. | SIC Code | Heavy Industry | No. | SIC Code | Light Industry |

|---|---|---|---|---|---|

| 1 | 6 | Mining and washing of coal | 27 | 13 | Agricultural food processing |

| 2 | 7 | Extraction of petroleum and natural gas | 28 | 14 | Manufacture of food |

| 3 | 8 | Mining and processing of ferrous metal ores | 29 | 15 | Manufacture of drink |

| 4 | 9 | Mining and processing of non-ferrous metal ores | 30 | 16 | Manufacture of tobacco |

| 5 | 10 | Mining and processing of nonmetal ores | 31 | 17 | Textile industry |

| 6 | 20 | Processing of timber, manufacture of wood, bamboo, rattan, palm and straw products | 32 | 18 | Manufacture of textile and garment, shoes, hats |

| 7 | 25 | Processing of petroleum, coking, processing of nuclear fuel | 33 | 19 | Manufacture of leather, fur, feather |

| 8 | 26 | Manufacture of raw chemical materials and chemical products | 34 | 21 | Manufacture of furniture |

| 9 | 27 | Manufacture of medicines | 35 | 22 | Paper and paper products |

| 10 | 29 | Manufacture of rubber | 36 | 23 | Copy of printing and recording medium |

| 11 | 30 | Manufacture of plastics | 37 | 24 | Manufacture of cultural and educational sporting goods |

| 12 | 31 | Manufacture of non-metallic mineral products | 38 | 28 | Manufacture of chemical fiber |

| 13 | 32 | Smelting and pressing of ferrous metals | 39 | 42 | Manufacture of arts and crafts, and other |

| 14 | 33 | Smelting and pressing of non-ferrous metals | |||

| 15 | 34 | Manufacture of metal products | |||

| 16 | 35 | Manufacture of general purpose machinery | |||

| 17 | 36 | Manufacture of special purpose machinery | |||

| 18 | 37 | Manufacture of transport equipment | |||

| 19 | 39 | Manufacture of electrical machinery and equipment | |||

| 20 | 40 | Manufacture of communication equipment, computers and other electronic Equipment | |||

| 21 | 41 | Manufacture of measuring instruments and machinery for cultural activity and Office work | |||

| 22 | 44 | Production and supply of electric power and heat power | |||

| 23 | 45 | Production and supply of gas | |||

| 24 | 46 | Production and supply of water | |||

| 25 | 11 | Mining of other ores | |||

| 26 | 43 | Recycling and disposal of waste |

References

- Lin, B.; Liu, K. How efficient is China’s heavy industry? A perspective of input–output analysis. Emerg. Mark. Financ. Trade 2016, 52, 2546–2564. [Google Scholar] [CrossRef]

- Chen, S. Reconstruction of sub-industrial statistical data in China (1980–2008). China Econ. Q. 2011, 10, 735–776. [Google Scholar]

- Lin, J.Y.; Cai, F.; Li, Z. The China Miracle: Development Strategy and Economic Reform; Chinese University Press: Hong Kong, China, 2003. [Google Scholar]

- Lin, B.; Li, J. The rebound effect for heavy industry: Empirical evidence from China. Energy Policy 2014, 74, 589–599. [Google Scholar] [CrossRef]

- Alcántara, V.; Padilla, E. Input–output subsystems and pollution: An application to the service sector and CO2 emissions in Spain. Ecol. Econ. 2009, 68, 905–914. [Google Scholar] [CrossRef]

- Rose, A.; Casler, S. Input–output structural decomposition analysis: A critical appraisal. Econ. Syst. Res. 1996, 8, 33–62. [Google Scholar] [CrossRef]

- Hoekstra, R.; Van den Bergh, J.C. Comparing structural decomposition analysis and index. Energy Econ. 2003, 25, 39–64. [Google Scholar] [CrossRef]

- Su, B.; Ang, B. Structural decomposition analysis applied to energy and emissions: Some methodological developments. Energy Econ. 2012, 34, 177–188. [Google Scholar] [CrossRef]

- Rose, A.; Chen, C.-Y. Sources of change in energy use in the US economy, 1972–1982: A structural decomposition analysis. Resour. Energy 1991, 13, 1–21. [Google Scholar] [CrossRef]

- Casler, S.D.; Rose, A. Carbon dioxide emissions in the US economy: A structural decomposition analysis. Environ. Resour. Econ. 1998, 11, 349–363. [Google Scholar] [CrossRef]

- Lenzen, M. Primary energy and greenhouse gases embodied in Australian final consumption: An input–output analysis. Energy Policy 1998, 26, 495–506. [Google Scholar] [CrossRef]

- Machado, G.; Schaeffer, R.; Worrell, E. Energy and carbon embodied in the international trade of Brazil: An input–output approach. Ecol. Econ. 2001, 39, 409–424. [Google Scholar] [CrossRef]

- Butnar, I.; Llop, M. Structural decomposition analysis and input–output subsystems: Changes in CO2 emissions of Spanish service sectors (2000–2005). Ecol. Econ. 2011, 70, 2012–2019. [Google Scholar] [CrossRef]

- Xie, S.-C. The driving forces of China’s energy use from 1992 to 2010: An empirical study of input–output and structural decomposition analysis. Energy Policy 2014, 73, 401–415. [Google Scholar] [CrossRef]

- Zhang, Y. Structural decomposition analysis of sources of decarbonizing economic development in China, 1992–2006. Ecol. Econ. 2009, 68, 2399–2405. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, H.; Li, L.; Liu, Z.; Liang, S. Carbon dioxide emission drivers for a typical metropolis using input–output structural decomposition analysis. Energy Policy 2013, 58, 312–318. [Google Scholar] [CrossRef]

- Wang, C. Decomposing energy productivity change: A distance function approach. Energy 2007, 32, 1326–1333. [Google Scholar] [CrossRef]

- Zhang, Y.-J.; Da, Y.-B. The decomposition of energy-related carbon emission and its decoupling with economic growth in China. Renew. Sustain. Energy Rev. 2015, 41, 1255–1266. [Google Scholar] [CrossRef]

- Fan, W.; Li, Y.; Lin, Z.; Zhang, M. PDA research on a novel pulverized coal combustion technology for a large utility boiler. Energy 2010, 35, 2141–2148. [Google Scholar] [CrossRef]

- Lin, B.; Du, K. Decomposing energy intensity change: A combination of index decomposition analysis and production-theoretical decomposition analysis. Appl. Energy 2014, 129, 158–165. [Google Scholar] [CrossRef]

- Du, K.; Lin, B. Understanding the rapid growth of China’s energy consumption: A comprehensive decomposition framework. Energy 2015, 90, 570–577. [Google Scholar] [CrossRef]

- Ang, B.W.; Zhang, F.Q.; Choi, K.H. Factorizing changes in energy and environmental indicators through decomposition. Energy 1998, 23, 489–495. [Google Scholar] [CrossRef]

- Ang, B.W.; Zhang, F.Q. A survey of index decomposition analysis in energy and environmental studies. Energy 2000, 25, 1149–1176. [Google Scholar] [CrossRef]

- Xu, J.-H.; Fleiter, T.; Eichhammer, W.; Fan, Y. Energy consumption and CO2 emissions in China’s cement industry: A perspective from LMDI decomposition analysis. Energy Policy 2012, 50, 821–832. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, M.; Zhou, M. Using LMDI method to analyze transport sector CO2 emissions in China. Energy 2011, 36, 5909–5915. [Google Scholar] [CrossRef]

- Zhang, M.; Li, H.; Zhou, M.; Mu, H. Decomposition analysis of energy consumption in Chinese transportation sector. Appl. Energy 2011, 88, 2279–2285. [Google Scholar] [CrossRef]

- Zha, D.L.; Ding, N. Elasticities of substitution between energy and non-energy inputs in China power sector. Econ. Model. 2014, 38, 564–571. [Google Scholar] [CrossRef]

- Ma, C.; Stern, D.I. China’s changing energy intensity trend: A decomposition analysis. Energy Econ. 2008, 30, 1037–1053. [Google Scholar] [CrossRef]

- Liu, L.-C.; Fan, Y.; Wu, G.; Wei, Y.-M. Using LMDI method to analyze the change of China’s industrial CO2 emissions from final fuel use: An empirical analysis. Energy Policy 2007, 35, 5892–5900. [Google Scholar] [CrossRef]

- Organisation for Economic Co-Operation and Development (OECD). Decoupling: A Conceptual Overview. OECD Pap. 2001, 5, 1–31. [Google Scholar]

- Secretariat, O. Indicators to measure decoupling of environmental pressure from economic growth. The oecd environment programme 2001. Available online: http://www.oecd.org/environment/indicators-modelling-outlooks/1933638.pdf (accessed on 3 April 2017).

- Ayres, R.U.; Ayres, L.W.; Warr, B. Exergy, power and work in the US economy, 1900–1998. Energy 2003, 28, 219–273. [Google Scholar] [CrossRef]

- Ma, Y.; Meng, S.; Yan, R. Heterogeneity Analysis on Decoupling Factor between Carbon Emissions and GDP in BRICS Countries. Int. J. Digit. Content Technol. Appl. 2013, 7, 834. [Google Scholar]

- Zhang, L.; Zhang, X. Decoupling relationship between industrial growth and carbon emissions in three northeastern provinces of China: Analysis based on stability and deviation. J. Discret. Math. Sci. Cryptogr. 2017, 20, 271–294. [Google Scholar] [CrossRef]

- Ren, S.; Yin, H.; Chen, X. Using LMDI to analyze the decoupling of carbon dioxide emissions by China’s manufacturing industry. Environ. Dev. 2014, 9, 61–75. [Google Scholar] [CrossRef]

- Organisation for Economic Co-Operation and Development (OECD). Decoupling: Illustrating some Open Questions on the Production Impact of Different Policy Instruments. OECD Pap. 2005, 5, 1–42. [Google Scholar]

- Kaya, Y. Impact of Carbon Dioxide Emission Control on GNP Growth: Interpretation of Proposed Scenarios; IPCC Energy and Industry Subgroup, Response Strategies Working Group: Paris, France, 1990; p. 76. [Google Scholar]

- Ang, B.; Lee, S. Decomposition of industrial energy consumption: Some methodological and application issues. Energy Econ. 1994, 16, 83–92. [Google Scholar] [CrossRef]

- International Energy Agency. Benign Energy? The Environmental Implications of Renewables; Massachusetts Institute of Technology: Cambridge, MA, USA, 2005; pp. 246–250. [Google Scholar]

- IPCC. 2006 IPCC Guidelines for National Greenhouse Gas Inventories. Available online: http://www/.ipcc-nggip.iges.or.jp./public/2006gl/index.html (accessed on 5 April 2017).

| Multiplier in Equation (2) | Abbreviation | Description |

|---|---|---|

| CI | Carbon intensity: The amount of carbon by weight emitted per unit of energy consumed. | |

| ES | Energy structure: the proportion of fossil energy in total energy consumption. | |

| EI | Energy intensity: energy consumption per unit of GDP. | |

| LP | Output per capita: industrial added value per capita. | |

| W | IS | Industry scale: the number of employees in the heavy industry. |

| Energy Type | Raw Coal | Cleaned Coal | Other Washed Coal | Coke |

|---|---|---|---|---|

| Carbon emissions coefficient | 1.980356 | 2.495249 | 1.107727 | 3.046316 |

| unit | Mt/Mt | Mt/Mt | Mt/Mt | Mt/Mt |

| Energy type | Coke oven gas | Other goal gas | Other coke products | Crude oil |

| Carbon emissions coefficient | 929.4696 | 776.149 | 3.135913 | 3.409916 |

| unit | Mt/Mm3 | Mt/Mm3 | Mt/Mt | Mt/Mt |

| Energy type | Gasoline | kerosene | Diesel oil | Fuel oil |

| Carbon emissions coefficient | 3.044655 | 3.198454 | 3.174568 | 3.04218 |

| unit | Mt/Mt | Mt/Mt | Mt/Mt | Mt/Mt |

| Energy type | LPG | Refinery dry gas | Other petroleum products | Natural gas |

| Carbon emissions coefficient | 3.022209 | 3.617395 | 3.35 | 2090.427 |

| unit | Mt/Mt | Mt/Mt | Mt/Mt | Mt/Mm3 |

| DI | DI | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1992 | 51.92 | 188.81 | −136.89 | 0.73 | 2004 | 323.87 | 1998.89 | −759.19 | 0.38 |

| 1993 | 161.43 | 390.92 | −177.57 | 0.45 | 2005 | 384.72 | 2510.61 | −886.19 | 0.35 |

| 1994 | 62.78 | 335.08 | −58.96 | 0.18 | 2006 | 259.78 | 2984.30 | −1100.10 | 0.37 |

| 1995 | 196.82 | 317.90 | 155.05 | −0.49 | 2007 | 315.24 | 3494.10 | −1294.65 | 0.37 |

| 1996 | −42.96 | 379.21 | 50.78 | −0.13 | 2008 | 126.05 | 3793.79 | −1468.29 | 0.39 |

| 1997 | 34.16 | 471.13 | −6.99 | 0.01 | 2009 | 338.89 | 4229.36 | −1564.97 | 0.37 |

| 1998 | 47.56 | 460.82 | 50.88 | −0.11 | 2010 | 39.39 | 4532.74 | −1828.96 | 0.40 |

| 1999 | −70.09 | 583.59 | −141.98 | 0.24 | 2011 | 282.43 | 5011.61 | −2025.40 | 0.40 |

| 2000 | 7.36 | 756.94 | −307.97 | 0.41 | 2012 | 22.69 | 5214.92 | −2206.01 | 0.42 |

| 2001 | 113.28 | 892.05 | −329.81 | 0.37 | 2013 | 128.41 | 5520.21 | −2382.90 | 0.43 |

| 2002 | 59.28 | 1078.33 | −456.81 | 0.42 | 2014 | 22.09 | 5705.91 | −2546.51 | 0.45 |

| 2003 | 294.31 | 1501.47 | −585.63 | 0.39 | 2015 | -178.61 | 5668.47 | −2687.68 | 0.47 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boqiang, L.; Liu, K. Using LMDI to Analyze the Decoupling of Carbon Dioxide Emissions from China’s Heavy Industry. Sustainability 2017, 9, 1198. https://doi.org/10.3390/su9071198

Boqiang L, Liu K. Using LMDI to Analyze the Decoupling of Carbon Dioxide Emissions from China’s Heavy Industry. Sustainability. 2017; 9(7):1198. https://doi.org/10.3390/su9071198

Chicago/Turabian StyleBoqiang, Lin, and Kui Liu. 2017. "Using LMDI to Analyze the Decoupling of Carbon Dioxide Emissions from China’s Heavy Industry" Sustainability 9, no. 7: 1198. https://doi.org/10.3390/su9071198