A Feedback Control Method for Addressing the Production Scheduling Problem by Considering Energy Consumption and Makespan

Abstract

:1. Introduction

2. Related Works

3. The Feedback Control Method

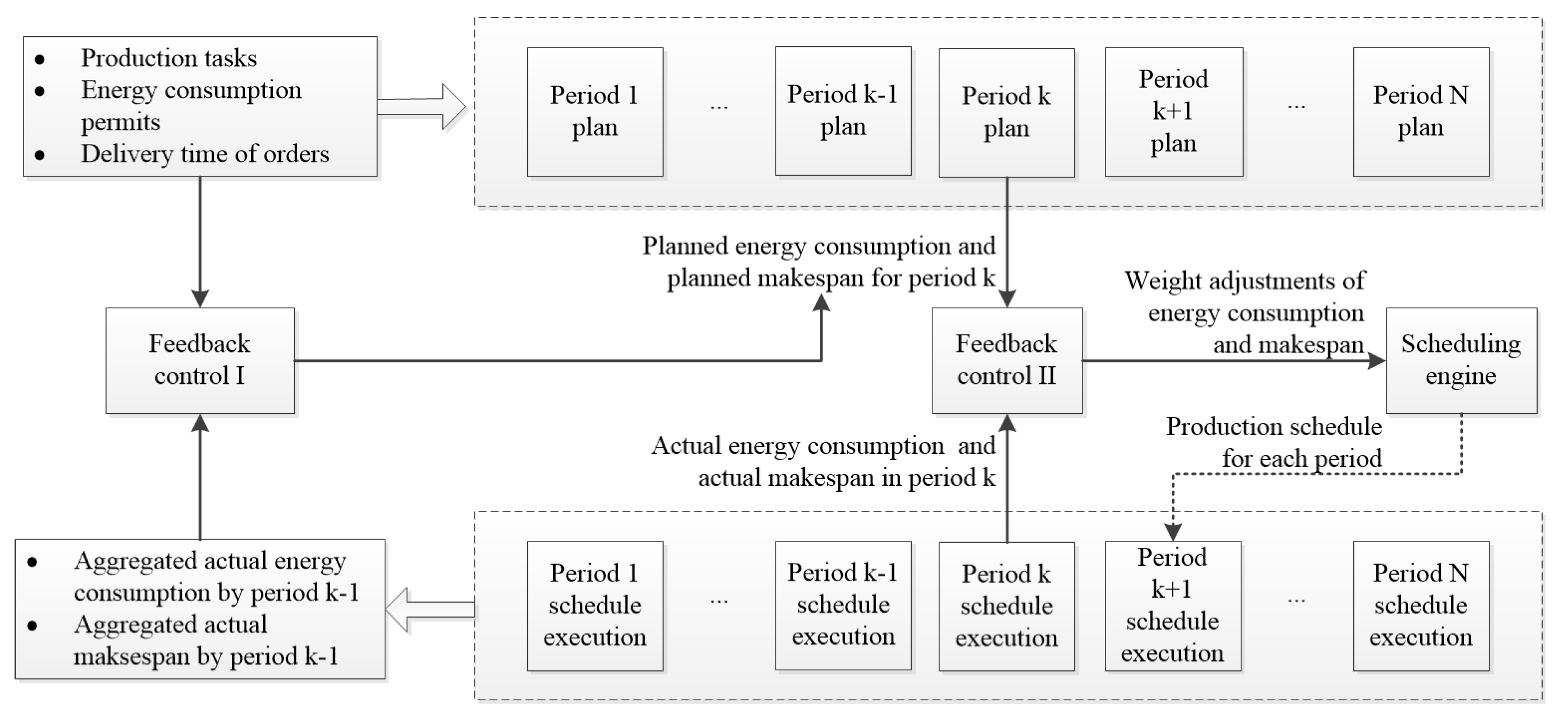

3.1. Framework of the Feedback Control Method

3.2. Multiple Objectives

3.3. Safety Threshold

3.4. Production Scheduling Process

3.5. Control Strategy

- (1)

- If and , the weight is suitable for the actual production, then , ;

- (2)

- If and , the actual EC exceeds the safety threshold, but the MS is under control, then, , ;

- (3)

- If and , the MS exceeds the safety threshold, but the EC is under control, then , ;

- (4)

- If and , both the actual MS and EC exceed the safety thresholds, and it requires an analysis of the low-level operation data and the experienced knowledge of workers to infer the weights and . The excess may also be caused by the inappropriate allocation of the planned and . In this case, further analysis of the low-level operation data and the experienced knowledge of workers will be necessary.

3.6. The Multi-Objective Optimization Model

- (1)

- The processing time of each operation of every job is assumed to be known.

- (2)

- For each machine, only one job can be processed on it at one time.

- (3)

- The setup time for each operation is negligible or included in the processing time.

- (4)

- Each operation should be processed on the specified machine which is known, and only after the current operation is finished, could the next operation begin.

- (5)

- Job processing cannot overlap.

- (6)

- Once job processing has begun, it cannot be interrupted.

- (7)

- The jobs’ processing times on every machine are not deterministic. They are stochastically generated by following the uniform distribution within a possible range.

- (8)

- The EC for processing, idle, starting up and transportation per unit time can be observed by the monitoring system.

4. Case Study

4.1. Effect of the Weights

4.2. Effect of the Feedback Control Mechanism

4.3. Discussion of the Safety Thresholds

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Marzband, M.; Moghaddam, M.M.; Akorede, M.F.; Khomeyrani, G. Adaptive load shedding scheme for frequency stability enhancement in microgrids. Electr. Power Syst. Res. 2016, 140, 78–86. [Google Scholar] [CrossRef]

- Marzband, M.; Ghazimirsaeid, S.S.; Uppal, H.; Fernando, T. A real-time evaluation of energy management systems for smart hybrid home microgrids. Electr. Power Syst. Res. 2017, 143, 624–633. [Google Scholar] [CrossRef]

- Marzband, M.; Azarinejadian, F.; Savaghebi, M.; Guerrero, J.M. An optimal energy management system for islanded microgrids based on multiperiod artificial bee colony combined with Markov chain. IEEE Syst. J. 2017, 99, 1–11. [Google Scholar] [CrossRef]

- Marzband, M.; Ardeshiri, R.R.; Moafi, M.; Uppal, H. Distributed generation for economic benefit maximization through coalition formation–based game theory concept. Int. Trans. Electr. Energy Syst. 2017, 27, 1–16. [Google Scholar] [CrossRef]

- Marzband, M.; Parhizi, N.; Savaghebi, M.; Guerrero, J.M. Distributed smart decision-making for a multimicrogrid system based on a hierarchical interactive architecture. IEEE Trans. Energy Convers. 2016, 31, 637–648. [Google Scholar] [CrossRef]

- Marzband, M.; Sumper, A.; Ruiz-Álvarez, A.; Domínguez-García, J.L.; Tomoiagă, B. Experimental evaluation of a real time energy management system for stand-alone microgrids in day-ahead markets. Appl. Energy 2013, 106, 365–376. [Google Scholar] [CrossRef]

- Marzband, M.; Sumper, A.; Domínguez-García, J.L.; Gumara-Ferret, R. Experimental validation of a real time energy management system for microgrids in islanded mode using a local day-ahead electricity market and MINLP. Energy Convers. Manag. 2013, 76, 314–322. [Google Scholar] [CrossRef]

- Marzband, M.; Ghadimi, M.; Sumper, A.; Domínguez-García, J.L. Experimental validation of a real-time energy management system using multi-period gravitational search algorithm for microgrids in islanded mode. Appl. Energy 2014, 128, 164–174. [Google Scholar] [CrossRef]

- Marzband, M.; Javadi, M.; Domínguez-García, J.L.; Moghaddam, M.M. Non-cooperative game theory based energy management systems for energy district in the retail market considering DER uncertainties. IET Gener. Transm. Distrib. 2016, 10, 2999–3009. [Google Scholar] [CrossRef]

- Marzband, M.; Parhizi, N.; Adabi, J. Optimal energy management for stand-alone microgrids based on multi-period imperialist competition algorithm considering uncertainties: Experimental validation. Int. Trans. Electr. Energy Syst. 2016, 26, 1358–1372. [Google Scholar] [CrossRef]

- Marzband, M.; Yousefnejad, E.; Sumper, A.; Domínguez-García, J.L. Real time experimental implementation of optimum energy management system in standalone Microgrid by using multi-layer ant colony optimization. Int. J. Electr. Power 2016, 75, 265–274. [Google Scholar] [CrossRef]

- Mourtzis, D.; Vlachou, E.; Doukas, M.; Kanakis, N.; Xanthopoulos, N.; Koutoupes, A. Cloud-based adaptive shop-floor scheduling considering machine tool availability. In Proceedings of the ASME 2015 International Mechanical Engineering Congress & Exposition, Houston, TX, USA, 13–19 November 2015. [Google Scholar]

- Mourtzis, D.; Vlachou, E.; Xanthopoulos, N.; Givehchi, M.; Wang, L. Cloud-based adaptive process planning considering availability and capabilities of machine tools. J. Manuf. Syst. 2016, 39, 1–8. [Google Scholar] [CrossRef]

- Fysikopoulos, A.; Stavropoulos, P.; Papacharalampopoulos, A.; Calefati, P.; Chryssolouris, G. A process planning system for energy efficiency. In Proceedings of the 14th International Conference on Modern Information Technology in the Innovation Processes of the Industrial Enterprises, Budapest, Hungary, 24–26 October 2012. [Google Scholar]

- Fysikopoulos, A.; Pastras, G.; Vlachou, A.; Chryssolouris, G. An approach to increase energy efficiency using shutdown and standby machine modes. In Advances in Production Management Systems. Innovative and Knowledge-Based Production Management in a Global-Local World, Proceedings of the APMS 2014: IFIP Advances in Information and Communication Technology, Ajaccio, France, 20–24 September 2014; Grabot, B., Vallespir, B., Gomes, S., Bouras, A., Kiritsis, D., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; Volume 439, pp. 205–212. [Google Scholar]

- Larreina, J.; Gontarz, A.; Giannoulis, C.; Nguyen, V.K.; Stavropoulos, P.; Sinceri, B. Smart manufacturing execution system (SMES): The possibilities of evaluating the sustainability of a production process. In Proceedings of the 11th Global Conference on Sustainable Manufacturing, Berlin, Germany, 23–25 September 2013; pp. 517–522. [Google Scholar]

- Gutowski, T.; Murphy, C.; Allen, D.; Bauer, D.; Bras, B.; Piwonka, T.; Sheng, P.; Sutherland, J.; Thurston, D.; Wolff, E. Environmentally benign manufacturing: Observations from Japan, Europe and the United States. J. Clean. Prod. 2005, 13, 1–17. [Google Scholar] [CrossRef]

- Guerrero, C.A.; Wang, J.; Li, J.; Arinez, J.; Biller, S.; Huang, N.; Xiao, G. Production system design to achieve energy savings in an automotive paint shop. Int. J. Prod. Res. 2011, 49, 6769–6785. [Google Scholar] [CrossRef]

- Bunse, K.; Vodicka, M.; Schönsleben, P.; Brülhart, M.; Ernst, F.O. Integrating energy efficiency performance in production management–Gap analysis between industrial needs and scientific literature. J. Clean. Prod. 2011, 19, 667–679. [Google Scholar] [CrossRef]

- Herrmann, C.; Thiede, S.; Kara, S.; Hesselbach, J. Energy oriented simulation of manufacturing systems–Concept and application. CIRP Ann. Manuf. Technol. 2011, 60, 45–48. [Google Scholar] [CrossRef]

- Weinert, N.; Chiotellis, S.; Seliger, G. Methodology for planning and operating energy-efficient production systems. CIRP Ann. Manuf. Technol. 2011, 60, 41–44. [Google Scholar] [CrossRef]

- Duflou, J.R.; Sutherland, J.W.; Dornfeld, D.; Herrmann, C.; Jeswiet, J.; Kara, S.; Hauschild, M.; Kellens, K. Towards energy and resource efficient manufacturing: A processes and systems approach. CIRP Ann. Manuf. Technol. 2012, 61, 587–609. [Google Scholar] [CrossRef]

- Du, S.; Zhu, L.; Liang, L.; Ma, F. Emission-dependent supply chain and environment-policy-making in the ‘Cap-and-trade’ system. Energy Policy 2013, 57, 61–67. [Google Scholar] [CrossRef]

- Sun, J.; Wu, J.; Liang, L.; Zhong, R.Y.; Huang, G.Q. Allocation of emission permits using DEA: Centralised and individual points of view. Int. J. Prod. Res. 2014, 52, 419–435. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, L. Impacts on CO2 emission allowance prices in China: A quantile regression analysis of the Shanghai Emission Trading Scheme. Sustainability 2016, 8, 1195. [Google Scholar] [CrossRef]

- Jiang, W.; Liu, J.; Liu, X. Impact of carbon quota allocation mechanism on emissions trading: An agent-based simulation. Sustainability 2016, 8, 826. [Google Scholar] [CrossRef]

- Ye, B.; Jiang, J.; Miao, L.; Li, J.; Peng, Y. Innovative carbon allowance allocation policy for the Shenzhen emission trading scheme in China. Sustainability 2016, 8, 3. [Google Scholar] [CrossRef]

- Seow, Y.; Rahimifard, S. A framework for modelling energy consumption within manufacturing systems. CIRP J. Manuf. Sci. Technol. 2011, 4, 258–264. [Google Scholar] [CrossRef]

- Li, Y.; He, Y.; Wang, Y.; Yan, P.; Liu, X. A framework for characterising energy consumption of machining manufacturing systems. Int. J. Prod. Res. 2014, 52, 314–325. [Google Scholar] [CrossRef]

- Jeon, H.W.; Taisch, M.; Prabhu, V. Modelling and analysis of energy footprint of manufacturing systems. Int. J. Prod. Res. 2014, 53, 7049–7059. [Google Scholar] [CrossRef]

- Kara, S.; Li, W. Unit process energy consumption models for material removal processes. CIRP Ann. Manuf. Technol. 2011, 60, 37–40. [Google Scholar] [CrossRef]

- Seow, Y.; Rahimifard, S.; Woolley, E. Simulation of energy consumption in the manufacture of a product. Int. J. Comput. Integr. Manuf. 2013, 26, 663–680. [Google Scholar] [CrossRef]

- Mouzon, G.; Yildirim, M.B.; Twomey, J. Operational methods for minimization of energy consumption of manufacturing equipment. Int. J. Prod. Res. 2007, 45, 4247–4271. [Google Scholar] [CrossRef]

- Fang, K.; Uhan, N.; Zhao, F.; Sutherland, J.W. A new approach to scheduling in manufacturing for power consumption and carbon footprint reduction. J. Manuf. Syst. 2011, 30, 234–240. [Google Scholar] [CrossRef]

- Bruzzone, A.A.G.; Anghinolfi, D.; Paolucci, M.; Tonelli, F. Energy-aware scheduling for improving manufacturing process sustainability: A mathematical model for flexible flow shops. CIRP Ann. Manuf. Technol. 2012, 61, 459–462. [Google Scholar] [CrossRef]

- Luo, H.; Du, B.; Huang, G.Q.; Chen, H.; Li, X. Hybrid flow shop scheduling considering machine electricity consumption cost. Int. J. Prod. Econ. 2013, 146, 423–439. [Google Scholar] [CrossRef]

- Moon, J.; Shin, K.; Park, J. Optimization of production scheduling with time-dependent and machine-dependent electricity cost for industrial energy efficiency. Int. J. Adv. Manuf. Technol. 2013, 68, 523–535. [Google Scholar] [CrossRef]

- Moon, J.; Park, J. Smart production scheduling with time-dependent and machine-dependent electricity cost by considering distributed energy resources and energy storage. Int. J. Prod. Res. 2014, 52, 3922–3939. [Google Scholar] [CrossRef]

- Dai, M.; Tang, D.; Giret, A.; Salido, M.A.; Li, W.D. Energy-efficient scheduling for a flexible flow shop using an improved genetic-simulated annealing algorithm. Robot. Comput. Integr. Manuf. 2013, 29, 418–429. [Google Scholar] [CrossRef]

- He, H.; Li, Y.; Wu, T.; Sutherland, J.W. An energy-responsive optimization method for machine tool selection and operation sequence in flexible machining job shops. J. Clean. Prod. 2014, 87, 245–254. [Google Scholar] [CrossRef]

- Pach, C.; Berger, T.; Sallez, Y.; Bonte, T.; Adam, E.; Trentesaux, D. Reactive and energy-aware scheduling of flexible manufacturing systems using potential fields. Comput. Ind. 2014, 65, 434–448. [Google Scholar] [CrossRef]

- Rossi, A.; Dini, G. Dynamic scheduling of FMS using a real-time genetic algorithm. Int. J. Prod. Res. 2000, 38, 1–20. [Google Scholar] [CrossRef]

- Li, L.; Jiang, Z. Self-adaptive dynamic scheduling of virtual production systems. Int. J. Prod. Res. 2007, 45, 1937–1951. [Google Scholar] [CrossRef]

- Fattahi, P.; Fallahi, A. Dynamic scheduling in flexible job shop systems by considering simultaneously efficiency and stability. CIRP J. Manuf. Sci. Technol. 2010, 2, 114–123. [Google Scholar] [CrossRef]

- Zhang, L.; Gao, L.; Li, X. A hybrid genetic algorithm and tabu search for a multiobjective dynamic job shop scheduling problem. Int. J. Prod. Res. 2013, 51, 3516–3531. [Google Scholar] [CrossRef]

- Shnits, B. Multi-criteria optimisation-based dynamic scheduling for controlling FMS. Int. J. Prod. Res. 2012, 50, 6111–6121. [Google Scholar] [CrossRef]

- Na, H.; Park, J. Multi-level job scheduling in a flexible job shop environment. Int. J. Prod. Res. 2014, 52, 3877–3887. [Google Scholar] [CrossRef]

- Keller, F.; Schultz, C.; Braunreuther, S.; Reinhart, G. Enabling energy-flexibility of manufacturing systems through new approaches within production planning and control. Procedia CIRP 2016, 57, 752–757. [Google Scholar] [CrossRef]

- Beier, J.; Thiede, S.; Herrmann, C. Energy flexibility of manufacturing systems for variable renewable energy supply integration: Real-time control method and simulation. J. Clean. Prod. 2017, 141, 648–661. [Google Scholar] [CrossRef]

- Cassettari, L.; Bendato, I.; Mosca, M.; Mosca, R. Energy resources intelligent management using on line real-time simulation: A decision support tool for sustainable manufacturing. Appl. Energy 2017, 190, 841–851. [Google Scholar] [CrossRef]

| 4 Jobs | ||||||||

|---|---|---|---|---|---|---|---|---|

| M1 | M2 | M3 | M4 | |||||

| J1 | 22 | 45 | 38 | 47 | ||||

| J2 | 72 | 45 | 58 | 27 | ||||

| J3 | 74 | 71 | 65 | 43 | ||||

| J4 | 36 | 41 | 43 | 59 | ||||

| 6 Jobs | ||||||||

| M1 | M2 | M3 | M4 | M5 | M6 | |||

| J1 | 22 | 45 | 38 | 47 | 29 | 59 | ||

| J2 | 72 | 45 | 58 | 27 | 35 | 65 | ||

| J3 | 74 | 71 | 65 | 43 | 41 | 53 | ||

| J4 | 36 | 41 | 43 | 59 | 59 | 69 | ||

| J5 | 62 | 49 | 67 | 70 | 56 | 36 | ||

| J6 | 58 | 64 | 37 | 38 | 57 | 56 | ||

| 8 Jobs | ||||||||

| M1 | M2 | M3 | M4 | M5 | M6 | M7 | M8 | |

| J1 | 22 | 45 | 38 | 47 | 29 | 59 | 46 | 39 |

| J2 | 72 | 45 | 58 | 27 | 35 | 65 | 72 | 47 |

| J3 | 74 | 71 | 65 | 43 | 41 | 53 | 69 | 28 |

| J4 | 36 | 41 | 43 | 59 | 59 | 69 | 44 | 59 |

| J5 | 62 | 49 | 67 | 70 | 56 | 36 | 21 | 69 |

| J6 | 58 | 64 | 37 | 38 | 57 | 56 | 27 | 59 |

| J7 | 33 | 67 | 50 | 55 | 56 | 61 | 22 | 67 |

| J8 | 59 | 60 | 49 | 62 | 37 | 21 | 30 | 66 |

| 4 Jobs | ||||||||

| M1 | M2 | M3 | M4 | |||||

| EC | 11 | 28 | 23 | 30 | ||||

| 6 Jobs | ||||||||

| M1 | M2 | M3 | M4 | M5 | M6 | |||

| EC | 11 | 28 | 23 | 30 | 16 | 38 | ||

| 8 Jobs | ||||||||

| M1 | M2 | M3 | M4 | M5 | M6 | M7 | M8 | |

| EC | 11 | 28 | 23 | 30 | 16 | 38 | 29 | 24 |

| 4 Jobs | ||||||||

| O1 | O2 | O3 | O4 | |||||

| J1 | M1 | M4 | M3 | M2 | ||||

| J2 | M2 | M3 | M1 | M4 | ||||

| J3 | M4 | M1 | M3 | M2 | ||||

| J4 | M3 | M1 | M2 | M4 | ||||

| 6 Jobs | ||||||||

| O1 | O2 | O3 | O4 | O5 | O | |||

| J1 | M1 | M4 | M3 | M2 | M6 | M5 | ||

| J2 | M4 | M5 | M1 | M2 | M3 | M6 | ||

| J3 | M6 | M1 | M3 | M2 | M5 | M4 | ||

| J4 | M3 | M1 | M2 | M4 | M5 | M6 | ||

| J5 | M6 | M5 | M1 | M3 | M2 | M4 | ||

| J6 | M5 | M1 | M6 | M2 | M3 | M4 | ||

| 8 Jobs | ||||||||

| O1 | O2 | O3 | O4 | O5 | O6 | O7 | O8 | |

| J1 | M1 | M4 | M3 | M2 | M6 | M7 | M5 | M8 |

| J2 | M4 | M5 | M8 | M2 | M3 | M6 | M7 | M1 |

| J3 | M6 | M7 | M3 | M2 | M5 | M8 | M1 | M4 |

| J4 | M3 | M1 | M2 | M7 | M8 | M6 | M4 | M5 |

| J5 | M6 | M5 | M1 | M8 | M7 | M4 | M3 | M2 |

| J6 | M7 | M1 | M6 | M8 | M3 | M4 | M5 | M2 |

| J7 | M8 | M3 | M2 | M6 | M7 | M5 | M1 | M4 |

| J8 | M4 | M3 | M7 | M8 | M2 | M5 | M1 | M6 |

| 4 Jobs | |||||||||||

| No. | No. | ||||||||||

| 1 | 1 | 0 | 289 | 5269 | 289 | 13 | 0.93 | 0.074 | 289 | 5269 | 658.676 |

| 2 | 0.995 | 0.056 | 289 | 5269 | 582.619 | 14 | 0.92 | 0.08 | 289 | 5269 | 687.4 |

| 3 | 0.99 | 0.004 | 289 | 5269 | 307.186 | 15 | 0.91 | 0.088 | 289 | 5269 | 726.662 |

| 4 | 0.985 | 0.01 | 289 | 5269 | 337.355 | 16 | 0.9 | 0.11 | 289 | 5269 | 839.69 |

| 5 | 0.98 | 0.13 | 289 | 5269 | 968.19 | 17 | 0.85 | 0.118 | 289 | 5269 | 867.392 |

| 6 | 0.975 | 0.064 | 289 | 5269 | 618.991 | 18 | 0.8 | 0.124 | 289 | 5269 | 884.556 |

| 7 | 0.97 | 0.028 | 289 | 5269 | 427.862 | 19 | 0.75 | 0.15 | 289 | 5269 | 1007.1 |

| 8 | 0.965 | 0.044 | 289 | 5269 | 510.721 | 20 | 0.7 | 0.165 | 289 | 5269 | 1071.685 |

| 9 | 0.96 | 0.084 | 289 | 5269 | 720.036 | 21 | 0.65 | 0.26 | 289 | 5269 | 1557.79 |

| 10 | 0.955 | 0.072 | 289 | 5269 | 655.363 | 22 | 0.6 | 0.4 | 289 | 5269 | 2281 |

| 11 | 0.95 | 0.036 | 289 | 5269 | 464.234 | 23 | 0.5 | 0.5 | 289 | 5269 | 2779 |

| 12 | 0.94 | 0.024 | 289 | 5269 | 398.116 | 24 | 0 | 1 | 289 | 5269 | 5269 |

| 6 Jobs | |||||||||||

| No. | No. | ||||||||||

| 1 | 1 | 0 | 515 | 19145 | 515 | 13 | 0.97 | 0.03 | 562 | 16908 | 1796.332 |

| 2 | 0.999 | 0.001 | 515 | 18681 | 1560.621 | 14 | 0.96 | 0.04 | 562 | 16908 | 1892.16 |

| 3 | 0.998 | 0.002 | 515 | 18681 | 588.694 | 15 | 0.95 | 0.05 | 557 | 17370 | 2036.544 |

| 4 | 0.997 | 0.003 | 521 | 18819 | 707.627 | 16 | 0.9 | 0.1 | 562 | 16908 | 2360.06 |

| 5 | 0.996 | 0.004 | 515 | 18681 | 2941.47 | 17 | 0.88 | 0.12 | 562 | 16908 | 2490.828 |

| 6 | 0.995 | 0.005 | 515 | 18681 | 1708.009 | 18 | 0.87 | 0.13 | 562 | 16908 | 2588.904 |

| 7 | 0.994 | 0.006 | 552 | 16955 | 1023.428 | 19 | 0.85 | 0.15 | 562 | 16908 | 3013.9 |

| 8 | 0.993 | 0.007 | 515 | 18681 | 1333.359 | 20 | 0.83 | 0.17 | 562 | 16908 | 3259.09 |

| 9 | 0.992 | 0.008 | 529 | 18676 | 2093.552 | 21 | 0.7 | 0.3 | 562 | 16908 | 4811.96 |

| 10 | 0.991 | 0.009 | 529 | 18676 | 1868.911 | 22 | 0.6 | 0.4 | 562 | 16908 | 7100.4 |

| 11 | 0.99 | 0.01 | 557 | 17370 | 1176.75 | 23 | 0.5 | 0.5 | 562 | 16908 | 8735 |

| 12 | 0.98 | 0.02 | 557 | 17370 | 962.74 | 24 | 0 | 1 | 562 | 16908 | 16908 |

| 8 Jobs | |||||||||||

| No. | No. | ||||||||||

| 1 | 1 | 0 | 636 | 27059 | 636 | 13 | 0.96 | 0.04 | 659 | 24611 | 1096.34 |

| 2 | 0.998 | 0.002 | 638 | 26339 | 662.423 | 14 | 0.95 | 0.05 | 664 | 25226 | 1616.56 |

| 3 | 0.996 | 0.004 | 641 | 26342 | 688.846 | 15 | 0.94 | 0.06 | 661 | 24550 | 1967.02 |

| 4 | 0.994 | 0.006 | 645 | 26751 | 718.103 | 16 | 0.92 | 0.08 | 673 | 22929 | 2402.36 |

| 5 | 0.992 | 0.008 | 638 | 26339 | 749.424 | 17 | 0.91 | 0.09 | 660 | 26391 | 2966.62 |

| 6 | 0.99 | 0.01 | 650 | 23803 | 740.804 | 18 | 0.85 | 0.15 | 660 | 26012 | 2837.7 |

| 7 | 0.988 | 0.012 | 650 | 23803 | 765.765 | 19 | 0.8 | 0.2 | 661 | 23210 | 5014.4 |

| 8 | 0.986 | 0.014 | 653 | 26782 | 788.918 | 20 | 0.75 | 0.25 | 661 | 23331 | 7191.1 |

| 9 | 0.984 | 0.016 | 655 | 23075 | 835.903 | 21 | 0.7 | 0.3 | 661 | 22549 | 9367.8 |

| 10 | 0.982 | 0.018 | 655 | 23075 | 834.36 | 22 | 0.6 | 0.4 | 661 | 22428 | 11544.5 |

| 11 | 0.98 | 0.02 | 655 | 23075 | 856.78 | 23 | 0.5 | 0.5 | 661 | 22428 | 15897.9 |

| 12 | 0.97 | 0.03 | 661 | 22428 | 878.67 | 24 | 0 | 1 | 661 | 22428 | 22428 |

| Traditional Scheduling Method | |||||||

| Period No. | Actual Data | Scheduling Plan and Planned MS, EC | Accumulative Deviation with Expected Value | ||||

| MSa | ECa | No. | MSp | ECp | ∆MS | ∆EC | |

| 1 | 654.3037 | 23,643.074 | 7 | 650 | 25,000 | −4.3037 | 1356.926 |

| 2 | 652.9354 | 23,860.521 | 7 | 650 | 25,000 | −7.2390 | 2496.405 |

| 3 | 648.0338 | 25,315.787 | 7 | 650 | 25,000 | −5.2728 | 2180.618 |

| 4 | 644.9283 | 22,434.408 | 7 | 650 | 25,000 | −0.2012 | 4746.210 |

| 5 | 655.4449 | 23,214.082 | 7 | 650 | 25,000 | −5.6461 | 6532.128 |

| 6 | 653.3379 | 24,842.227 | 7 | 650 | 25,000 | −8.9840 | 6689.901 |

| 7 | 648.7398 | 22,143.234 | 7 | 650 | 25,000 | −7.7238 | 9546.667 |

| 8 | 656.0027 | 23,094.805 | 7 | 650 | 25,000 | −13.7266 | 11,451.862 |

| 9 | 650.7913 | 24,064.828 | 7 | 650 | 25,000 | −14.5179 | 12,387.034 |

| 10 | 656.7875 | 22,462.283 | 7 | 650 | 25,000 | −21.3054 | 14,924.751 |

| The total deviations: ∆MS = Index − Actual = −21.31; ∆EC = Index – Actual = 14,925 | |||||||

| Feedback Control Scheduling Method | |||||||

| Period No. | Actual Data | Scheduling Plan and Planned MS, EC | Accumulative Deviation with Expected Value | ||||

| MSa | ECa | No. | MSp | ECp | ∆MS | ∆EC | |

| 1 | 654.3037 | 23,643.074 | 7 | 650 | 25,000 | −4.3037 | 1356.926 |

| 2 | 639.2677 | 26,424.922 | 5 | 649 | 25,150 | 6.4287 | –67.996 |

| 3 | 652.2067 | 23,837.922 | 6 | 651 | 24,991 | 4.2219 | 1094.082 |

| 4 | 655.5632 | 24,989.480 | 6 | 651 | 25,156 | –1.3413 | 1104.602 |

| 5 | 635.5636 | 26,633.080 | 5 | 650 | 25,184 | 13.0951 | –528.478 |

| 6 | 654.2048 | 23,396.280 | 6 | 653 | 24,894 | 8.8903 | 1075.242 |

| 7 | 652.8790 | 23,794.967 | 6 | 652 | 25,269 | 6.0113 | 2280.275 |

| 8 | 654.1343 | 23,332.523 | 6 | 652 | 25,760 | 1.8770 | 3947.752 |

| 9 | 655.3791 | 23,549.288 | 6 | 651 | 26,974 | −3.5021 | 5398.464 |

| 10 | 639.9936 | 27,176.507 | 5 | 646 | 30,399 | 6.5043 | 3221.957 |

| The total deviations: ∆MS = Index – Actual = 6.5; ∆EC = Index − Actual = 3221 | |||||||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Wang, L. A Feedback Control Method for Addressing the Production Scheduling Problem by Considering Energy Consumption and Makespan. Sustainability 2017, 9, 1185. https://doi.org/10.3390/su9071185

Xu J, Wang L. A Feedback Control Method for Addressing the Production Scheduling Problem by Considering Energy Consumption and Makespan. Sustainability. 2017; 9(7):1185. https://doi.org/10.3390/su9071185

Chicago/Turabian StyleXu, Jingjing, and Lei Wang. 2017. "A Feedback Control Method for Addressing the Production Scheduling Problem by Considering Energy Consumption and Makespan" Sustainability 9, no. 7: 1185. https://doi.org/10.3390/su9071185