Exploring Interface Problems in Taiwan’s Construction Projects Using Structural Equation Modeling

Abstract

:1. Introduction

2. Literature Review

2.1. Interface Issues in Construction Projects

2.2. Application of SEMs for Construction Projects

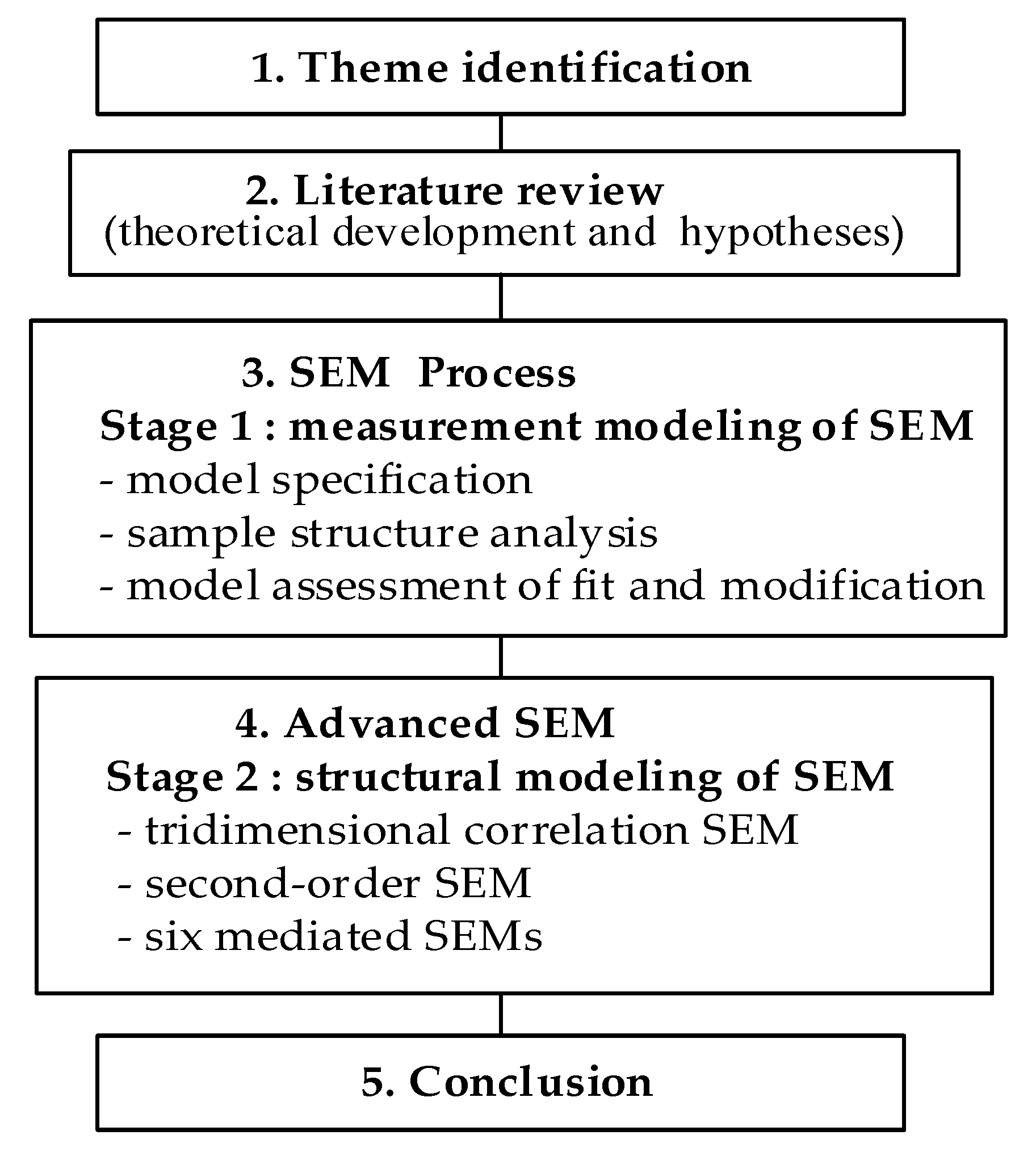

3. Structural Equation Modeling Process

3.1. Stage1 of SEM

3.1.1. Model Specification

3.1.2. Sample Structure Analysis

Sampling Method

Pre-Testing Process

Model Assessment of Fit and Modification

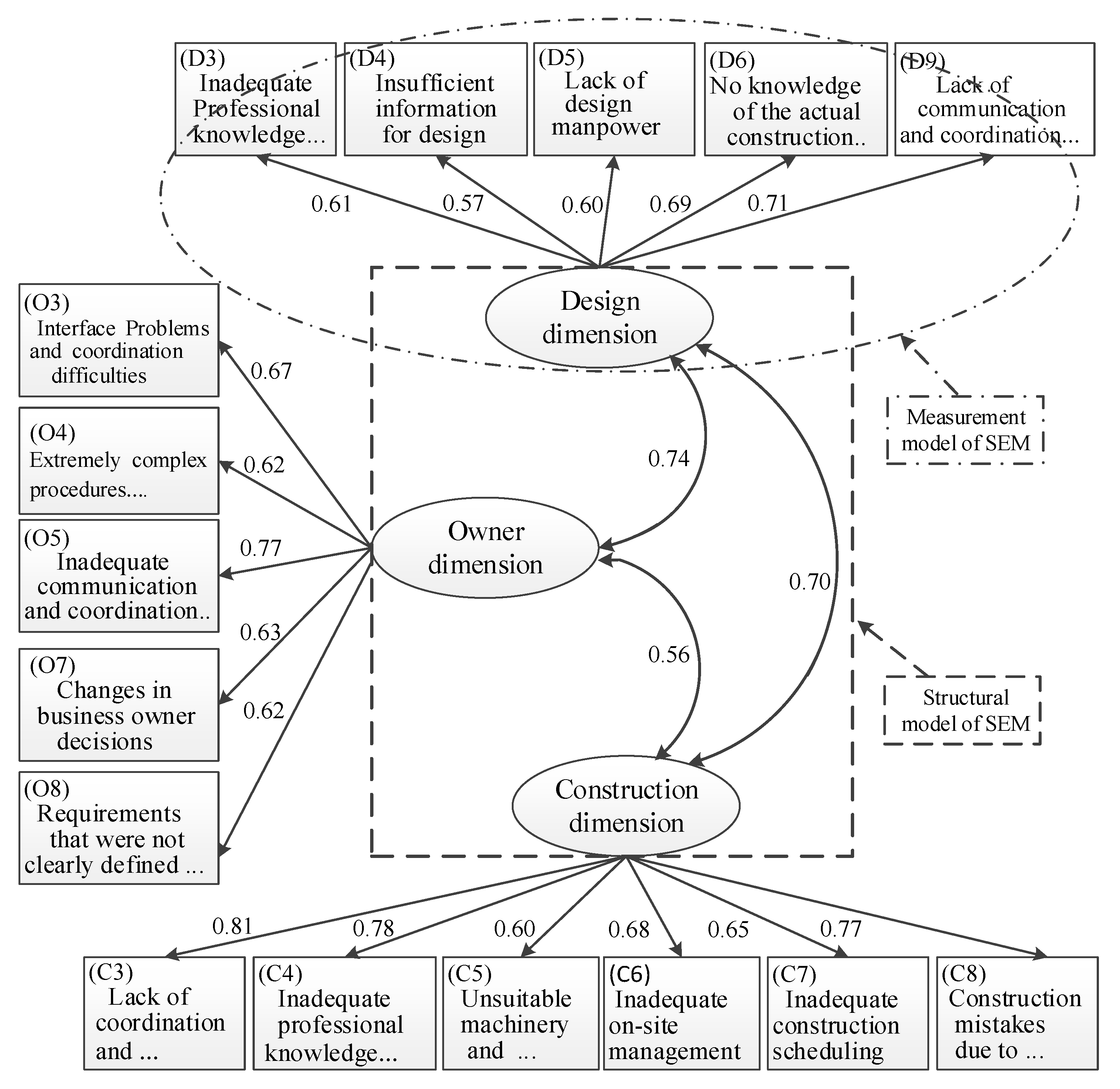

- (1)

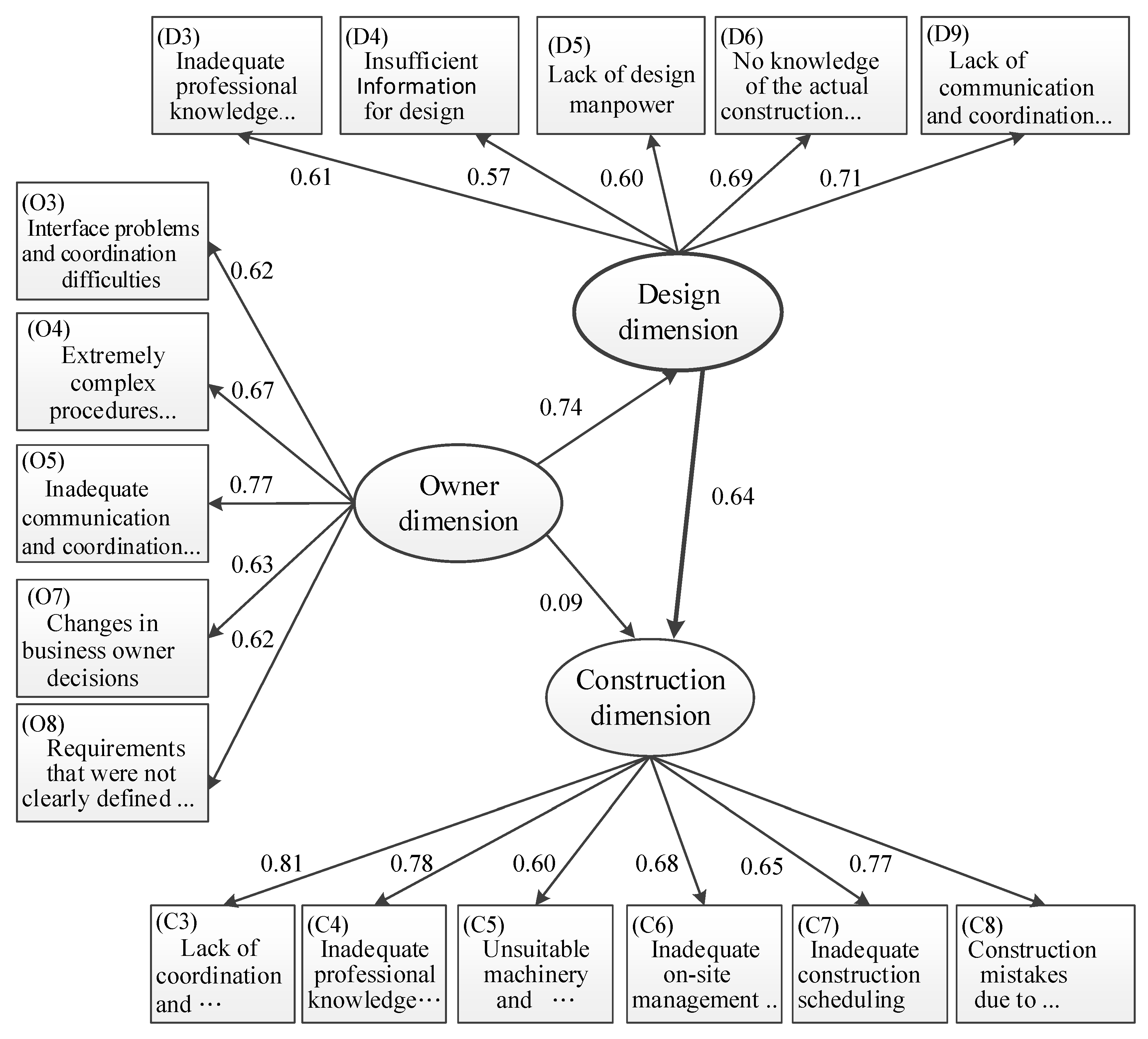

- The design dimension measurement model: Five observed variables were the main components that influenced the interface problems in the design dimension: D3 (F.L. = 0.61), D4 (F.L. = 0.57), D5 (F.L. = 0.60), D6 (F.L. = 0.69), and D9 (F.L. = 0.71). Therefore, D9 (lack of communication and coordination among design interfaces) is the most important influence factor for the design dimension.

- (2)

- The construction dimension measurement model: Six observed variables were the main components that influenced the interface problems in the construction dimension: C3 (F.L. = 0.81), C4 (F.L. = 0.78), C5 (F.L. = 0.60), C6 (F.L. = 0.68), C7 (F.L. = 0.65), and C8 (F.L. = 0.77). Therefore, C3 (lack of communication and coordination among various construction interfaces) is the most important influence factor for the construction dimension.

- (3)

- The owner dimension measurement model: Five observed variables were the main components that influenced the interface problems in the owner dimension: O3 (F.L. = 0.67), O4 (F.L. = 0.62), O5 (F.L. = 0.77), O7 (F.L. = 0.63), and O8 (F.L. = 0.62). Therefore, O5 (inadequate communication and coordination among various departments) is the most important influence factor for the owner dimension.

4. Advanced Structural Equation Modeling: Stage 2 of SEM

4.1. Tridimensional Correlation Structural Equation Model (TDC-SEM)

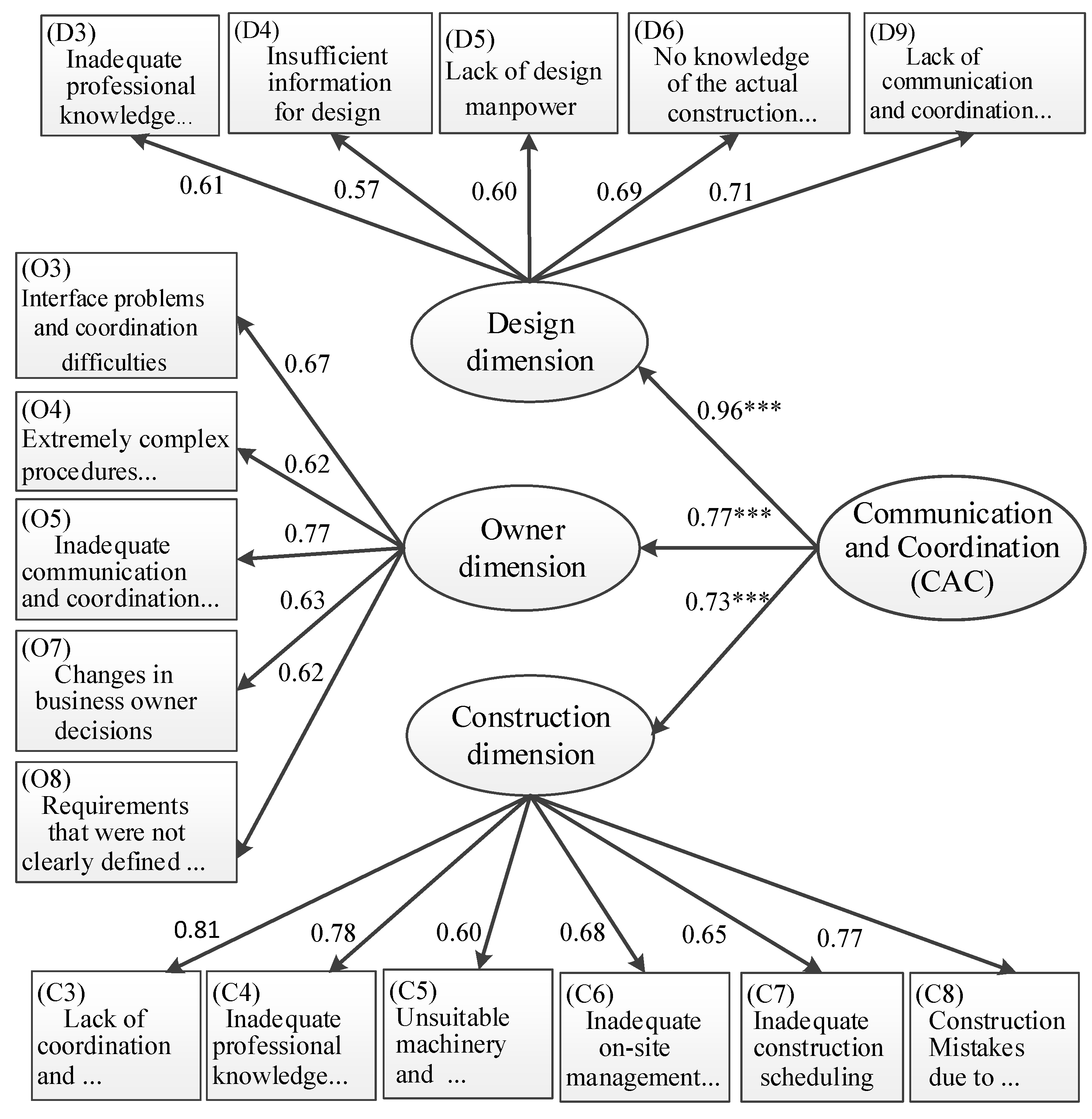

4.2. Second-Order SEM

4.3. Mediated SEM

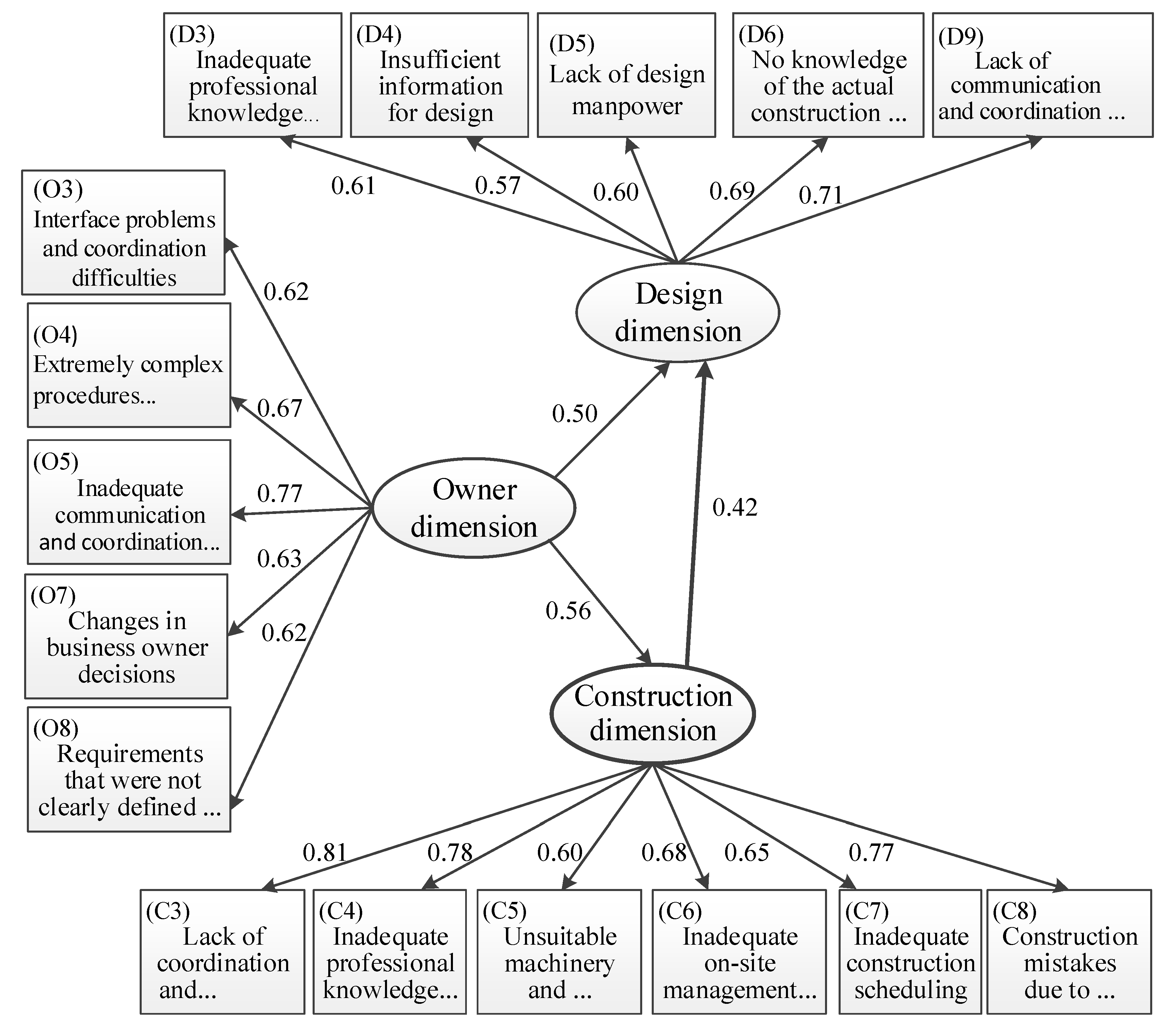

4.3.1. The Construction Mediated Structural Equation Model from the Owner Perspective (CM-SEM-O)

4.3.2. The Design Mediated Structural Equation Model from the Owner Perspective (DM-SEM-O)

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Al-Hammad, A.; Al-Hammad, I. Interface Problems between Building Owners and Designers. J. Perform. Constr. Facil. 1996, 10, 123–126. [Google Scholar] [CrossRef]

- Alarcón, L.F.; Mardones, D.A. Improving the design construction interface. In Proceedings of the 6th Annual Conference International Group for Lean Construction (IGLC-6), Guarujá, Brazil, 13–15 August 1998. [Google Scholar]

- Al-Hammad, A. Common Interface problems among various construction parties. J. Perform. Constr. Facil. 2000, 14, 71–74. [Google Scholar] [CrossRef]

- Arain, F.M.; Sadi, A.A. Consultant’s Prospects of the Sources of Design and Construction Interface Problems in Large Building Projects in Saudi Arabia. JKAU Environ. Des. Sci. 2007, 5, 15–37. [Google Scholar]

- Huang, R.Y.; Huang, C.T.; Lin, H. The study of interface problems among construction parties in MRT. J. Chin. Inst. Civ. Hydraul. Eng. 2008, 20, 269–283. [Google Scholar] [CrossRef]

- Chen, Q.; Reichard, G.; Beliveau, Y. Multi-perspective Approach to Exploring Comprehensive Cause Factors for Interface Issues. J. Constr. Eng. Manag. 2008, 134, 432–441. [Google Scholar] [CrossRef]

- Jarkas, A.M.; Radosavljevic, M. Motivational Factors Impacting the Productivity of Construction Master Craftsmen in Kuwait. J. Manag. Eng. 2013, 29, 446–454. [Google Scholar] [CrossRef]

- Molenaar, K.; Washington, S.; Diekmann, J. Structural equation model of construction contract dispute potential. J. Constr. Eng. Manag. 2000, 126, 268–277. [Google Scholar] [CrossRef]

- Wan Mohamed Radzi, C.W.J.B.; Salarzadeh Jenatabadi, H.; Hasbullah, M.B. Firm Sustainability Performance Index Modeling. Sustainability 2015, 7, 16196–16212. [Google Scholar] [CrossRef]

- Mainul Islam, M.D.; Faniran, O.O. Structural equation model of project planning effectiveness. Constr. Manag. Econ. 2005, 23, 215–223. [Google Scholar] [CrossRef]

- Yang, J.B.; Ou, S.F. Using structural equation modeling to analyze relationships among key causes of delay in construction. Can. J. Civ. Eng. 2008, 35, 321–332. [Google Scholar] [CrossRef]

- Cho, K.M.; Hong, T.H.; Chang, T.H. Effect of project characteristics on project performance in construction projects based on structural equation model. Expert Syst. Appl. 2009, 36, 10461–10470. [Google Scholar] [CrossRef]

- Kim, D.Y.; Han, S.H.; Kim, H.; Heedae, P. Structuring the prediction model of project performance for international construction projects: A comparative analysis. Expert Syst. Appl. 2009, 36, 1961–1971. [Google Scholar] [CrossRef]

- Yang, J.B.; Yang, C.C.; Kao, C.K. Evaluating schedule delay causes for private participating public construction works under the build Operate Transfer model. Int. J. Proj. Manag. 2010, 28, 569–579. [Google Scholar] [CrossRef]

- Thomas, S.N.; Yoki, M.W.W; James, W.M.W. A Structural Equation Model of Feasibility Evaluation and Project Success for Public-Private Partnerships in Hong Kong. IEEE Trans. Eng. Manag. 2010, 57, 310–322. [Google Scholar] [CrossRef]

- Zeynep, I.; David, A.; Irem, D.; Talat, B.M. Impact of Resources and Strategies on Construction Company Performance. J. Manag. Eng. 2010, 26, 9–18. [Google Scholar] [CrossRef]

- Hemanta, D.; Iyer, K.C.; Sawhney, A. Structural equation model for assessing impacts of contractor’s performance on project success. Int. J. Proj. Manag. 2011, 29, 687–695. [Google Scholar] [CrossRef]

- Bollen, K. Structural Equations with Latent Variables; Wiley-Interscience Inc.: Holoken, NJ, USA, 1989; ISBN 978-0-471-01171-2. [Google Scholar]

- Byrne, B.B. Structural Equation Modeling with AMOS: Basic Concepts, Applications, and Programming, 2nd ed.; Routledge: New York, NY, USA, 2010; ISBN 978-0-8058-6373-4. [Google Scholar]

- Anderson, J.C.; Gerbing, D.W. Structural Equation Modeling in Practice: A Review and Recommended Two-Step Approach. Psychol. Bull. 1988, 103, 411–423. [Google Scholar] [CrossRef]

- Kline, R.B. Principles and Practice of Structural Equation Modeling, 2nd ed.; Guilford Publications, Inc.: New York, NY, USA, 2005; ISBN 978-1-59385-057-3. [Google Scholar]

- Boomsma, A. The robustness of LISREL against small sizes in factor analysis models. In Systems under Indirect Observation: Causality, Structure, Prediction (Part I); Wold, H., Jöreskog, K.G., Eds.; North-Holland: Amsterdam, The Netherlands, 1982; pp. 149–173. [Google Scholar]

- Rigdon, E.E. Structural Equation Modeling: Nontraditional Alternatives. In Encyclopedia of Statistics in Behavioral Science; Brian, E., David, H., Eds.; Wiley: New York, NY, USA, 2005. [Google Scholar]

- Cronbach, L.J. Coefficient Alpha and the internal structure of tests. Psychometrika 1951, 16, 297–334. [Google Scholar] [CrossRef]

- Kline, R.B. Principles and Practice of Structural Equation Modeling, 3rd ed.; Guilford Publications, Inc.: New York, NY, USA, 2011; ISBN 978-1-60623-876-9. [Google Scholar]

- Schmacker, E.R.; Richard, G.L. A Beginer’s Guide to Structural Equation Modeling, 2nd ed.; Lawrence Erlbaum Associates: Mahwah, NJ, USA, 2004; ISBN 0-8058-4017-6. [Google Scholar]

- Jöreskog, K.G.; Sörbom, D. LISREL VI: Analysis of Linear Structural Relationships by the Method of Maximum Likelihood; National Educational Resources: Chicago, IL, USA, 1984; ISBN 0-8949-8024-6. [Google Scholar]

- Jöreskog, K.G.; Sörbom, D. LISREL VII: A Guide to the Program and Applications; SPSS: Chicago, IL, USA, 1991. [Google Scholar]

- Bentler, P.M. Comparative fit indexes in structural models. Psychol. Bull. 1990, 107, 238–246. [Google Scholar] [CrossRef] [PubMed]

- Browne, M.W.; Cudeck, R. Alternative ways of assessing model fit. In Testing Structural Equation Models; Bollen, K.A., Long, J.S., Eds.; Sage: New York, NY, USA, 1993; pp. 247–261. [Google Scholar] [CrossRef]

- Jöreskog, K.G.; Sörbom, D. LISREL 8: Structural Equation Modeling with the SIMPLIS Command Language; Scientific Software International: Chicago, IL, USA, 1993; ISBN 0-8949-8033-5. [Google Scholar]

- Hu, L.T.; Bentler, P.M. Cutoff Criteria for Fit Indexes in Covariance Structure Analysis: Conventional Criteria versus New Alternatives. Struct. Equ. Model. 1999, 6, 1–55. [Google Scholar] [CrossRef]

- Akter, S.; Ambra, J.D.; Ray, P. Trustworthiness in Health Information Services: An assessment of a Hierarchical Model with Mediating and Moderating Effects Using Partial Least Square (PLS). J. Am. Soc. Inf. Sci. 2011, 62, 100–116. [Google Scholar] [CrossRef]

- Fornell, C.; Bookstein, F.L. Two structural equation models: Lisrel and PLS applied to customer exit-voice theory. J. Mark. Res. 1982, 19, 440–452. [Google Scholar] [CrossRef]

| Factors | Factor Loading | Reliability (α) |

|---|---|---|

| Design dimension | ||

| D1-Short design time [4] | 0.47 | 0.87 |

| D2-Minimal funds [3,5,6] | 0.23 | |

| D3-Inadequate professional knowledge and experience [2,5] | 0.66 | |

| D4-Insufficient information for design [4,5,7] | 0.65 | |

| D5-Lack of design manpower [4] | 0.67 | |

| D6-No knowledge of the actual construction processes during design [4,14] | 0.65 | |

| D7-Inadequate integration of construction interfaces [2,6] | 0.51 | |

| D8-Lack of design standards [2,12] | 0.57 | |

| D9-Lack of communication and coordination among design interfaces [4,5,6,11] | 0.67 | |

| Construction dimension | ||

| C1-Short construction time [6] | 0.48 | 0.86 |

| C2-A low-cost contract [3,6,7] | 0.30 | |

| C3-Lack of communication and coordination among various construction interfaces [2,4,14] | 0.81 | |

| C4-Inadequate professional knowledge possessed by the construction and technical personnel [3,4,5,6] | 0.74 | |

| C5- Unsuitable machinery and materials for the construction methods [6] | 0.60 | |

| C6-Inadequate on-site management and supervision [1,3,4,6] | 0.67 | |

| C7-Inadequate construction scheduling [3,6] | 0.67 | |

| C8-Construction mistakes due to the improper reading of construction plans [4] | 0.78 | |

| C9-Construction mistakes and reworking [2,3,7] | 0.57 | |

| Owner dimension | ||

| O1-No quality control because of a low budget [3,5,6] | 0.37 | 0.79 |

| O2-Lack of supervision because of insufficient manpower [5,6] | 0.43 | |

| O3-Interface problems and coordination difficulties [5,6] | 0.63 | |

| O4-Extremely complex procedures for subcontracting (this study) | 0.63 | |

| O5-Inadequate communication and coordination among various departments [4,5,6] | 0.76 | |

| O6-Delayed payments [3,6,7] | 0.25 | |

| O7-Changes in business owner decisions [5,6,7] | 0.63 | |

| O8-Requirements that were not clearly defined in advance [1,3] | 0.62 | |

| O9-Delayed modification and approval of design documents [6,11] | 0.52 | |

| GOF Indices | Allowable Range (No Fit to Perfect Fit) | Measurement Model | |||||

|---|---|---|---|---|---|---|---|

| Design Dimension | Construction Dimension | Owner Dimension | |||||

| Initial Model | Final Model | Initial Model | Final Model | Initial Model | Final Model | ||

| χ2/df | 5 to 1 | 2.700 | 1.400 | 2.210 | 0.920 | 3.270 | 2.910 |

| GFI | 0 to 1 | 0.860 | 0.990 | 0.880 | 0.970 | 0.830 | 0.940 |

| AGFI | 0 to 1 | 0.760 | 0.910 | 0.790 | 0.930 | 0.730 | 0.810 |

| CFI | 0 to 1 | 0.790 | 0.990 | 0.890 | 0.999 | 0.720 | 0.920 |

| RMSEA | 1 to 0 | 0.137 | 0.066 | 0.115 | 0.001 | 0.158 | 0.145 |

| RMR | 1 to 0 | 0.076 | 0.034 | 0.073 | 0.033 | 0.095 | 0.062 |

| SRMR | 1 to 0 | 0.085 | 0.035 | 0.074 | 0.033 | 0.100 | 0.066 |

| CR | ~ to 0.7 (or >0.7) | 0.785 | 0. 812 | 0.857 | 0.864 | 0.791 | 0.797 |

| AVE | ~ to 0.5 (or >0.5) | 0.337 | 0.425 | 0.413 | 0.517 | 0.312 | 0.442 |

| Factors | Factor Loading | Ranking Influence |

|---|---|---|

| Design dimension | ||

| D3-Inadequate professional knowledge and experience | 0.61 | 3 |

| D4-Insufficient information for design | 0.57 | 5 |

| D5-Lack of design manpower | 0.60 | 4 |

| D6-No knowledge of the actual construction processes during design | 0.69 | 2 |

| D9-Lack of communication and coordination among design interfaces | 0.71 | 1 |

| Construction dimension | ||

| C3-Lack of communication and coordination among various construction interfaces | 0.81 | 1 |

| C4-Inadequate professional knowledge possessed by the construction and technical personnel | 0.78 | 2 |

| C5- Unsuitable machinery and materials for the construction methods | 0.60 | 6 |

| C6-Inadequate on-site management and supervision | 0.68 | 4 |

| C7-Inadequate construction scheduling | 0.65 | 5 |

| C8-Construction mistakes due to improper reading of construction plans | 0.77 | 3 |

| Owner dimension | ||

| O3-Interface problems and coordination difficulties | 0.67 | 2 |

| O4-Extremely complex procedures for subcontracting | 0.62 | 4 |

| O5-Inadequate communication and coordination among various departments | 0.77 | 1 |

| O7-Changes in business owner decisions | 0.63 | 3 |

| O8-Requirements that were not clearly defined in advance | 0.62 | 4 |

| Primary Perspective Dimension | Mediator | Direct Effect (1) | Mediated (Indirect) Effect (2) | Total Effect (1) + (2) |

|---|---|---|---|---|

| Owner | Construction (C) (CM-SEM-O) | O to D = 0.50 | O to C to D = 0.56 × 0.42 = 0.24 | 0.74 |

| Design (D) (DM-SEM-O) | O to C = 0.09 | O to D to C = 0.74 × 0.64 = 0.47 | 0.56 | |

| Design | Owner (O) | D to C = 0.64 | D to O to C = 0.74 × 0.09 = 0.06 | 0.70 |

| Construction (C) | D to O = 0.68 | D to C to O = 0.70 × 0.08 = 0.05 | 0.73 | |

| Construction | Design (D) | C to O = 0.08 | C to D to O = 0.70 × 0.68 = 0.47 | 0.55 |

| Owner (O) | C to D = 0.42 | C to O to D = 0.50 × 0.56 = 0.28 | 0.70 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, C.-L.; Jeng, C.-H. Exploring Interface Problems in Taiwan’s Construction Projects Using Structural Equation Modeling. Sustainability 2017, 9, 822. https://doi.org/10.3390/su9050822

Lin C-L, Jeng C-H. Exploring Interface Problems in Taiwan’s Construction Projects Using Structural Equation Modeling. Sustainability. 2017; 9(5):822. https://doi.org/10.3390/su9050822

Chicago/Turabian StyleLin, Chien-Liang, and Chen-Huu Jeng. 2017. "Exploring Interface Problems in Taiwan’s Construction Projects Using Structural Equation Modeling" Sustainability 9, no. 5: 822. https://doi.org/10.3390/su9050822