Decomposition and Decoupling Analysis of Life-Cycle Carbon Emission in China’s Building Sector

Abstract

:1. Introduction

2. Methods and Data

2.1. Methodologies

2.1.1. Method for Calculating CO2 Emission

2.1.2. Logarithmic Mean Divisia Index Technique

- represents the carbon emissions in the t year, the subscript i represents energy type; the superscript t represents year;

- is the carbon emissions from the i-th energy in the t year;

- is the consumption of the i-th energy in the t year;

- is total energy consumption in the t year;

- is the economical outputs of building industry;

- denotes the carbon coefficient of i-th energy;

- illustrates the energy structure effect of i-th energy;

- represents energy intensity; and

- is the effects of intensity of indirect carbon emission.

2.1.3. Decoupling Elasticity Model

2.1.4. Decoupling Effort Index

2.2. Data Sources and Definition

3. Result and Analysis

3.1. Estimation of CO2 Emissions from China’s Building Industry

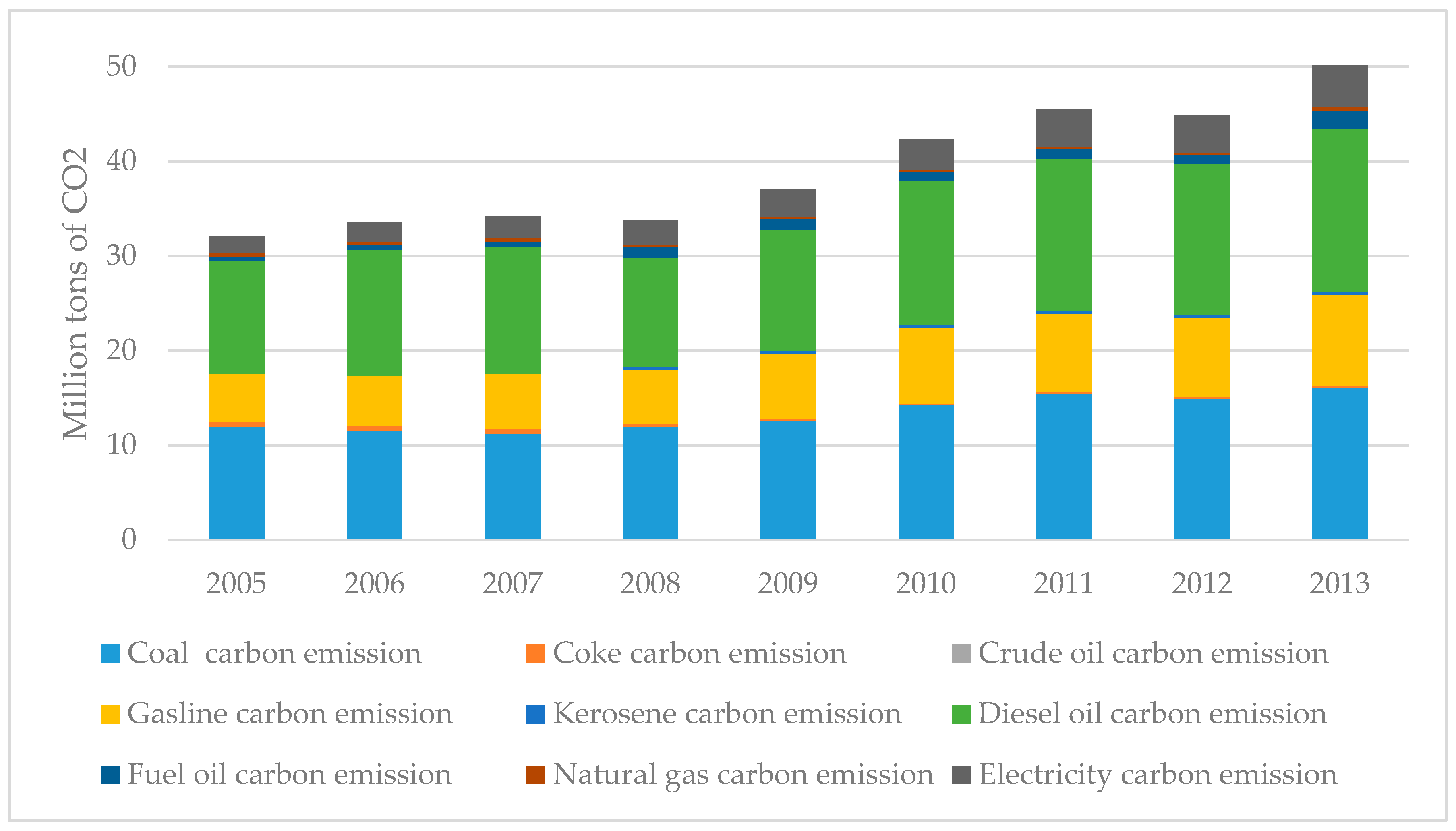

3.1.1. Estimated Direct Carbon Emission

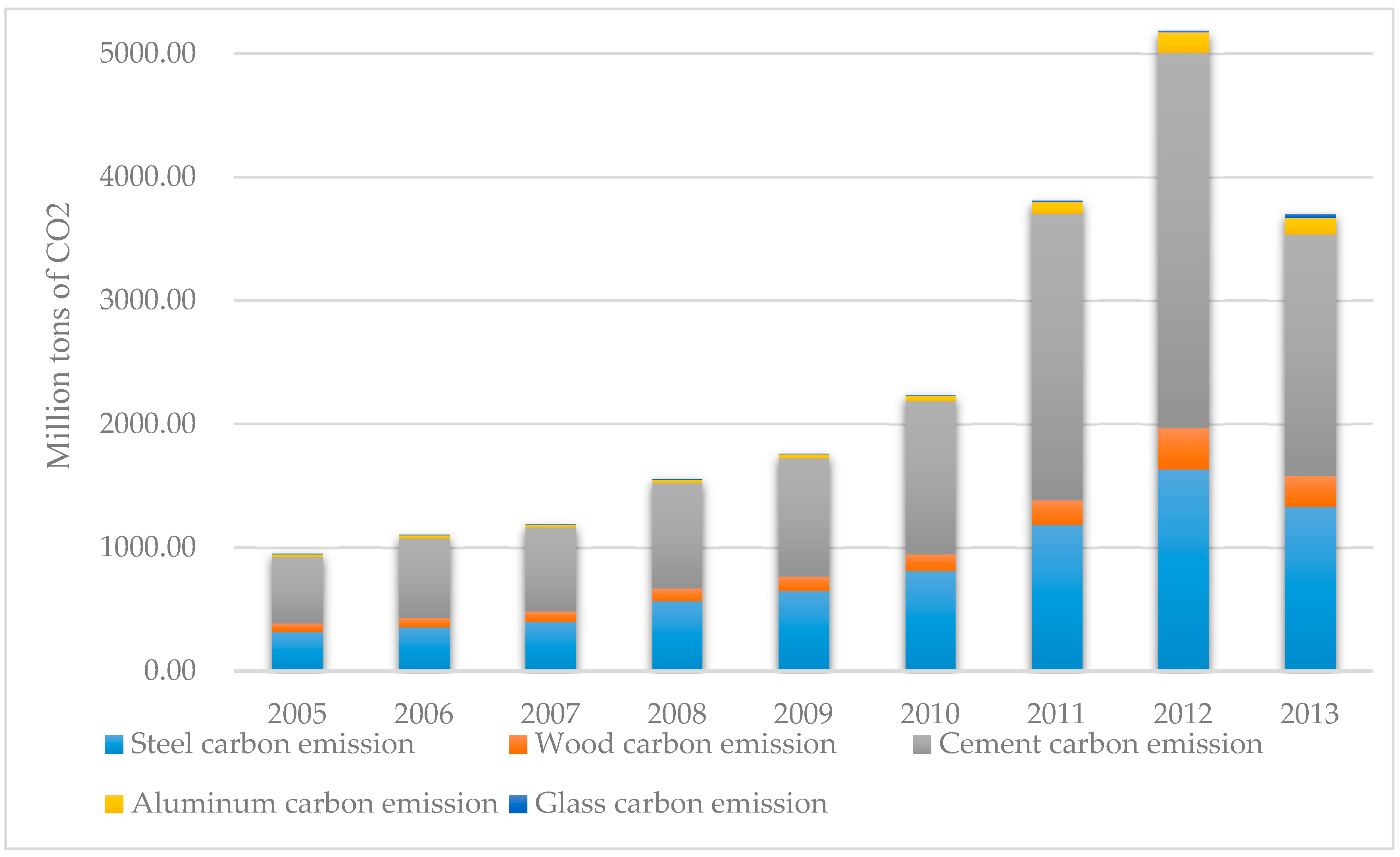

3.1.2. Estimated Indirect Carbon Emission

3.1.3. Estimated Total Carbon Emission

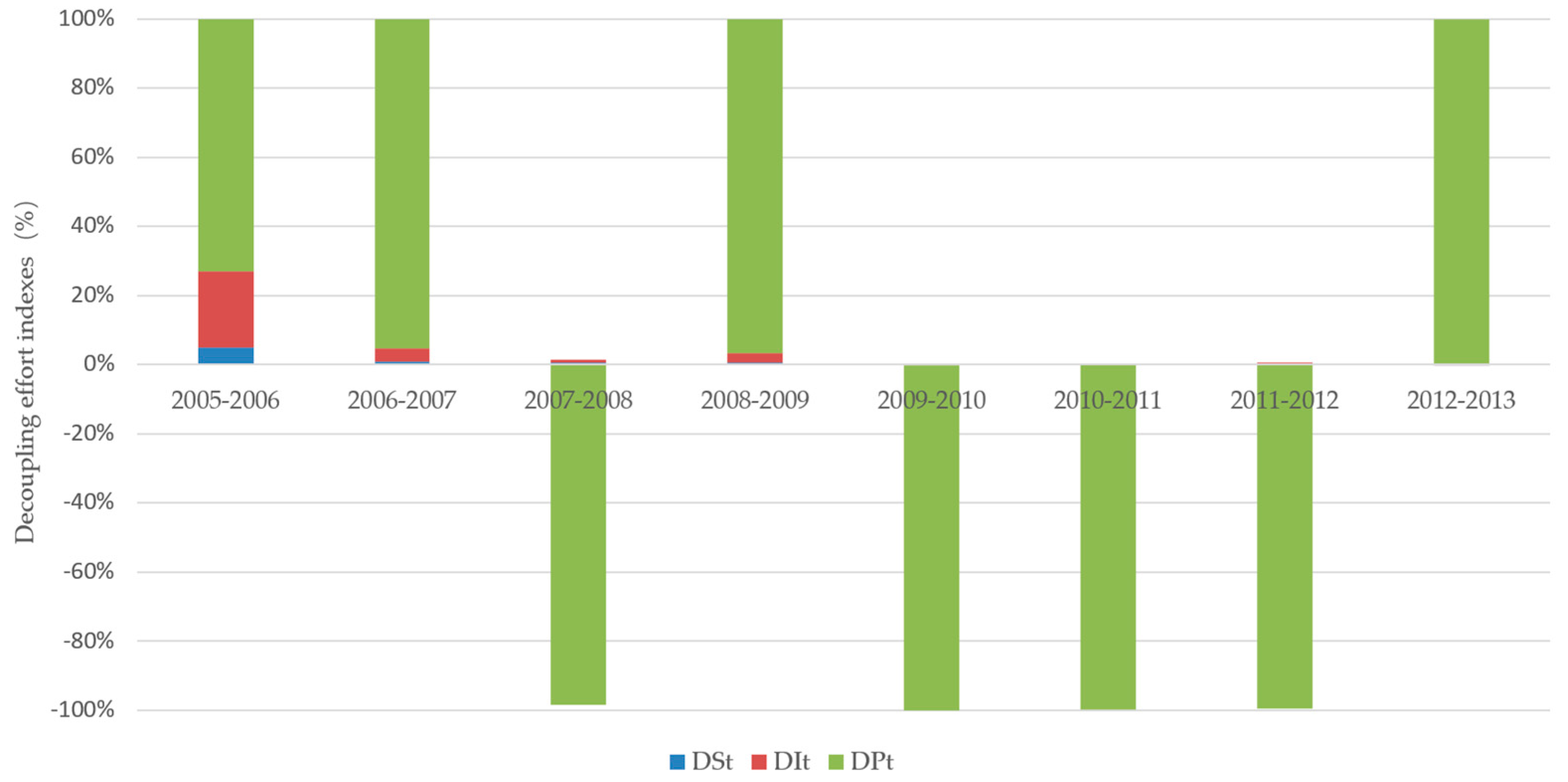

3.2. Decomposition Analysis

3.2.1. Economic Effects

3.2.2. Indirect Emission Intensity Effects

3.2.3. Energy Intensity Effects and Energy Structure Effects

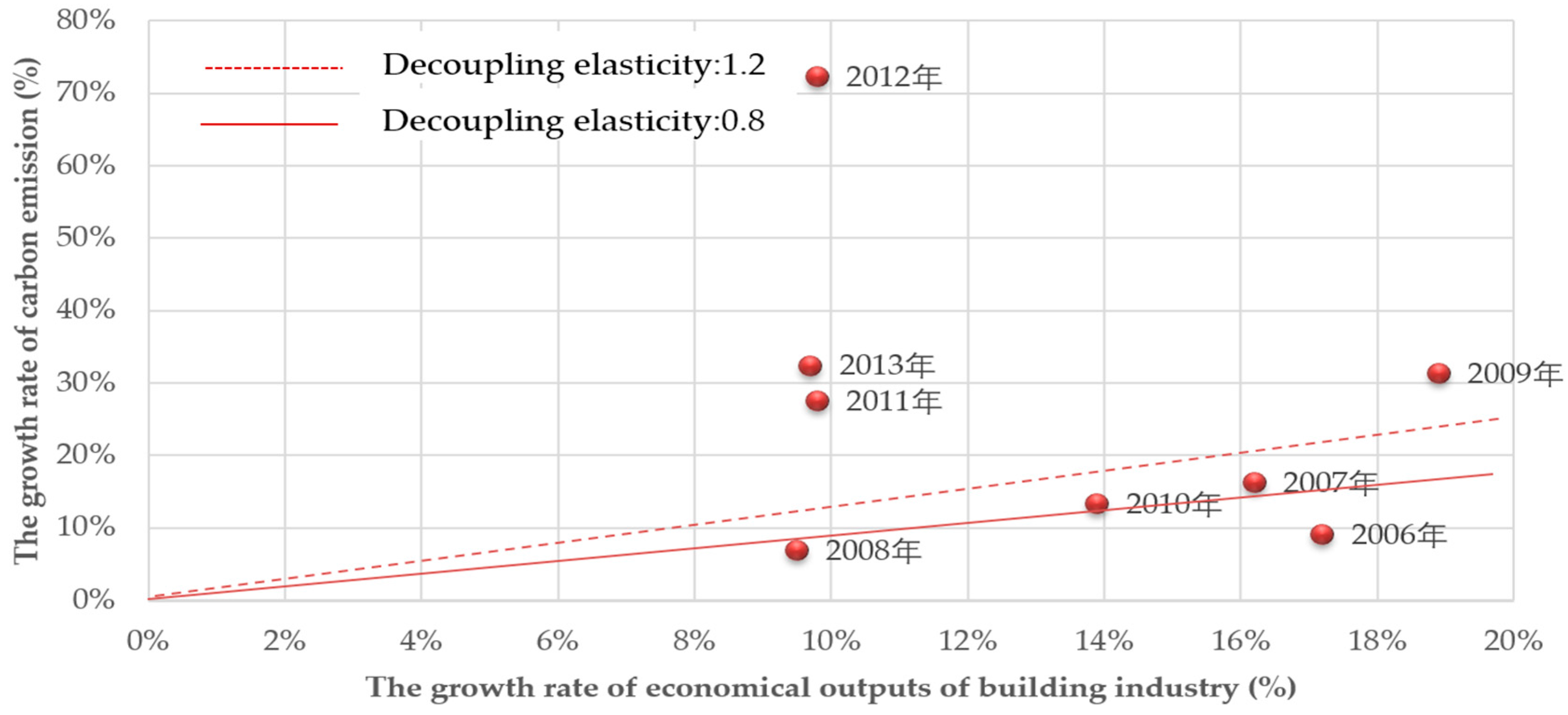

3.3. Decoupling Analysis

4. Conclusions and Policy Implication

4.1. Conclusions

4.2. Policy Implication

- (1)

- Reducing the indirect emission intensity: Above all, the reduction of indirect emission intensity is a key to delinking economic output from carbon emission, given that indirect emission is the overwhelming dominant source of carbon emission in China’s building industry. The measures to reduction of indirect emission intensity include, but are not limited to: (i) development of new building materials to reduce the consumption of traditional building materials, such as cement, steel, and aluminum; (ii) improving energy efficiency to lower carbon intensity of traditional building materials; and (iii) phasing out the low energy efficient building materials as soon as possible.

- (2)

- Reducing energy intensity: As shown in our study, energy intensity effects were leading contributor to offset carbon emission in China’s building industry. Improving energy efficiency is a cost-effective approach to decouple between economic output and carbon in China’s building industry. The government should introduce policies and establish financial support systems to promote the development of low-carbon technologies, and encourage construction companies to adopt low-carbon construction technology to optimize building design, thereby improving energy efficiency and improving the suppression effect of energy intensity on carbon emission.

- (3)

- Optimizing energy structure: We can fully develop the use of hydropower, wind energy, solar energy and other clean energy, reduce dependence on high-carbon energy, and establish a sound energy-saving emission reduction standard building system.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- National Bureau of Statistics of China. National Economical Industry Classification; China Statistics Press: Beijing, China, 2013; p. 2012. (In Chinese)

- Allen, S.K.; Plattner, G.K.; Nauels, A.; Xia, Y.; Stocker, T.F. Climate Change 2013: The Physical Science Basis. In An Overview of the Working Group 1 Contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change (IPCC). 2014. Available online: http://www.ipcc.ch/report/ar5/wg1/ (accessed on 8 May 2017).

- United Nations Environment Programme. Buildings and Climate Change; United Nations Environment Programme Sustainable Buildings & Climate Initiative: Paris, France, 2009. [Google Scholar]

- Berardi, U. A cross-country comparison of the building energy consumptions and their trends. Resour. Conserv. Recycl. 2017. [Google Scholar] [CrossRef]

- Cubi, E.; Doluweera, G.; Bergerson, J. Incorporation of electricity GHG emissions intensity variability into building environmental assessment. Appl. Energy 2015, 159, 62–69. [Google Scholar] [CrossRef]

- Herrera, J.C.; Chamorro, C.R.; Martín, M.C. Experimental analysis of performance, greenhouse gas emissions and economic parameters for two cooling systems in a public administration building. Energy Build. 2015, 108, 145–155. [Google Scholar] [CrossRef]

- Chau, C.K.; Hui, W.K.; Ng, W.Y.; Powell, G. Assessment of CO2 emissions reduction in high-rise concrete office buildings using different material use options. Resour. Conserv. Recycl. 2012, 61, 22–34. [Google Scholar] [CrossRef]

- Wang, Q.; Li, R. Journey to burning half of global coal: Trajectory and drivers of China’s coal use. Renew. Sustain. Energy Rev. 2016, 58, 341–346. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F. Life-cycle assessment and control measures for carbon emissions of typical buildings in China. Building Environ. 2015, 86, 89–97. [Google Scholar] [CrossRef]

- Wang, Q. China has the capacity to lead in carbon trading. Nature 2013, 493, 273. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.-R.; Hui, E.C.-M.; Choguill, C.; Jia, S.-H. The new urbanization policy in China: Which way forward? Habitat Int. 2015, 47, 279–284. [Google Scholar] [CrossRef]

- Chauvin, J.P.; Glaeser, E.; Ma, Y.; Tobio, K. What is Different about Urbanization in Rich and Poor Countries? Cities in Brazil, China, India and the United States. J. Urb. Econ. 2016. [Google Scholar] [CrossRef]

- Wang, Q. China should aim for a total cap on emissions. Nature 2014, 512, 115. [Google Scholar] [CrossRef] [PubMed]

- Chmutina, K. Building energy consumption and its regulations in China. In China Policy Institute, School of Contemporary Chinese Studies, International House; The University of Nottingham: Nottingham, UK, 2010. [Google Scholar]

- Yu, S.; Evans, M.; Delgado, A. Building Energy Efficiency in India: Compliance Evaluation of Energy Conservation Building Code. Curr. Politics Econ. North. West. Asia 2015, 24, 119. [Google Scholar]

- Salvalai, G.; Masera, G.; Sesana, M.M. Italian local codes for energy efficiency of buildings: Theoretical definition and experimental application to a residential case study. Renew. Sustain. Energy Rev. 2015, 42, 1245–1259. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, X. Energy policies for managing China’s carbon emission. Renew. Sustain. Energy Rev. 2015, 50, 470–479. [Google Scholar] [CrossRef]

- Qiang, W.; Li, R.; Hua, L. Toward Decoupling: Growing GDP without Growing Carbon Emissions. Environ. Sci. Technol. 2016, 50, 11435. [Google Scholar]

- Dodman, D. Blaming cities for climate change? An analysis of urban greenhouse gas emissions inventories. Environ. Urban. 2009, 21, 185–201. [Google Scholar] [CrossRef]

- Wang, Q.; Li, R. Impact of cheaper oil on economic system and climate change: A SWOT analysis. Renew. Sustain. Energy Rev. 2016, 54, 925–931. [Google Scholar] [CrossRef]

- Wang, Q.; Li, R. Drivers for energy consumption: A comparative analysis of China and India. Renew. Sustain. Energy Rev. 2016, 62, 954–962. [Google Scholar] [CrossRef]

- Acquaye, A.A.; Duffy, A.P. Input–output analysis of Irish construction sector greenhouse gas emissions. Build. Environ. 2010, 45, 784–791. [Google Scholar] [CrossRef]

- Nässén, J.; Holmberg, J.; Wadeskog, A.; Nyman, M. Direct and indirect energy use and carbon emissions in the production phase of buildings: An input–output analysis. Energy 2007, 32, 1593–1602. [Google Scholar] [CrossRef]

- Buchanan, A.H.; Honey, B.G. Energy and carbon dioxide implications of building construction. Energy Build. 1994, 20, 205–217. [Google Scholar] [CrossRef]

- Ali, H.H.; Al Nsairat, S.F. Developing a green building assessment tool for developing countries—Case of Jordan. Build. Environ. 2009, 44, 1053–1064. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, X.; Jha, A.N.; Rogers, H. Natural gas from shale formation—The evolution, evidences and challenges of shale gas revolution in United States. Renew. Sustain. Energy Rev. 2014, 30, 1–28. [Google Scholar] [CrossRef]

- Wang, Q.; Li, R. Sino-Venezuelan oil-for-loan deal–the Chinese strategic gamble? Renew. Sustain. Energy Rev. 2016, 64, 817–822. [Google Scholar] [CrossRef]

- Rodríguez Serrano, A.; Porras Álvarez, S. Life Cycle Assessment in Building: A Case Study on the Energy and Emissions Impact Related to the Choice of Housing Typologies and Construction Process in Spain. Sustainability 2016, 8, 287. [Google Scholar] [CrossRef]

- Zabalza, I.; Scarpellini, S.; Aranda, A.; Llera, E.; Jáñez, A. Use of LCA as a tool for building ecodesign: A case study of a low energy building in Spain. Energies 2013, 6, 3901–3921. [Google Scholar] [CrossRef]

- Wang, Q.; Li, R.; Jiang, R. Decoupling and Decomposition Analysis of Carbon Emissions from Industry: A Case Study from China. Sustainability 2016, 8, 1059. [Google Scholar] [CrossRef]

- Wang, Q. Effective policies for renewable energy—The example of China’s wind power—Lessons for China’s photovoltaic power. Renew. Sustain. Energy Rev. 2010, 14, 702–712. [Google Scholar] [CrossRef]

- Han, M.; Chen, G.; Shao, L.; Li, J.; Alsaedi, A.; Ahmad, B.; Guo, S.; Jiang, M.; Ji, X. Embodied energy consumption of building construction engineering: Case study in E-town, Beijing. Energy Build. 2013, 64, 62–72. [Google Scholar] [CrossRef]

- Zhang, X.; Shen, L.; Zhang, L. Life cycle assessment of the air emissions during building construction process: A case study in Hong Kong. Renew. Sustain. Energy Rev. 2013, 17, 160–169. [Google Scholar] [CrossRef]

- Wang, Q.; Li, R. Natural gas from shale formation: A research profile. Renew. Sustain. Energy Rev. 2016, 57, 1–6. [Google Scholar] [CrossRef]

- Duranton, G. Growing through cities in developing countries. World Bank Res. Obs. 2015, 30, 39–73. [Google Scholar] [CrossRef]

- Evans, M.; Shui, B.; Halverson, M.; Delgado, A. Enforcing Building Energy Codes in China: Progress and Comparative Lessons. Available online: http://www.pnl.gov/main/publications/external/technical_reports/PNNL-19247.pdf (accessed on 8 May 2017).

- Ortiz, O.; Castells, F.; Sonnemann, G. Sustainability in the construction industry: A review of recent developments based on LCA. Constr. Build. Mater. 2009, 23, 28–39. [Google Scholar] [CrossRef]

- Hammond, G.P.; Jones, C.I. Embodied energy and carbon in construction materials. Proc. Inst. Civ. Eng. Energy 2008, 161, 87–98. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Barreneche, C.; Miró, L.; Morera, J.M.; Bartolí, E.; Fernández, A.I. Low carbon and low embodied energy materials in buildings: A review. Renew. Sustain. Energy Rev. 2013, 23, 536–542. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Liu, R.J. Carbon Emissions in the Construction Sector Based on Input-Output Analyses. Available online: http://en.cnki.com.cn/Article_en/CJFDTOTAL-QHXB201301010.htm (accessed on 8 May 2017).

- Li, Z. Study on the Life Cycle Consumption of Energy and Resource of Air Conditioning in Urban Residential Buildings in China. Available online: http://www.globethesis.com/?t=1102360272977717 (accessed on 8 May 2017).

- Ang, B.; Choi, K.-H. Decomposition of aggregate energy and gas emission intensities for industry: A refined Divisia index method. Energy J. 1997, 18, 59–73. [Google Scholar] [CrossRef]

- González, P.F.; Landajo, M.; Presno, M. Tracking European Union CO2 emissions through LMDI (logarithmic-mean Divisia index) decomposition. The activity revaluation approach. Energy 2014, 73, 741–750. [Google Scholar] [CrossRef]

- Ang, B.W.; Zhang, F.Q.; Choi, K.H. Factorizing changes in energy and environmental indicators through decomposition. Energy 1998, 23, 489–495. [Google Scholar] [CrossRef]

- Kaya, Y. Impact of Carbon Dioxide Emission Control on GNP Growth: Interpretation of Proposed Scenarios. Available online: http://www.ipcc.ch/ipccreports/sres/emission/index.php?idp=48 (accessed on 8 May 2017).

- Ang, B.W. The LMDI approach to decomposition analysis: A practical guide. Energy Policy 2005, 33, 867–871. [Google Scholar] [CrossRef]

- Gray, D.; Anable, J.; Illingworth, L.; Graham, W. Decoupling the Link between Economic Growth, Transport Growth and Carbon Emissions in Scotland. Available online: https://www.researchgate.net/publication/267221393 (accessed on 8 May 2017).

- Tapio, P. Towards a theory of decoupling: Degrees of decoupling in the EU and the case of road traffic in Finland between 1970 and 2001. Transp. Policy 2005, 12, 137–151. [Google Scholar] [CrossRef]

- Zhao, J.; Shi-Ping, H.E. Research on the Vibration Characteristics of Simply Supported Plate Covered by a Decoupling Layer and Immersed in Water. Available online: http://en.cnki.com.cn/Article_en/CJFDTOTAL-JCKX201302005.htm (accessed on 8 May 2017).

- Arrow, K.; Bolin, B.; Costanza, R.; Dasgupta, P. Economic growth, carrying capacity, and the environment. Science 1995, 268, 520. [Google Scholar] [CrossRef] [PubMed]

- De Bruyn, S.M.; van den Bergh, J.C.; Opschoor, J.B. Economic growth and emissions: Reconsidering the empirical basis of environmental Kuznets curves. Ecol. Econ. 1998, 25, 161–175. [Google Scholar] [CrossRef]

- Lu, Q.; Yang, H.; Huang, X.; Chuai, X.; Wu, C. Multi-sectoral decomposition in decoupling industrial growth from carbon emissions in the developed Jiangsu Province, China. Energy 2015, 82, 414–425. [Google Scholar] [CrossRef]

- Diakoulaki, D.; Mandaraka, M. Decomposition analysis for assessing the progress in decoupling industrial growth from CO2 emissions in the EU manufacturing sector. Energy Econ. 2007, 29, 636–664. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, L. Delinking indicators on regional industry development and carbon emissions: Beijing–Tianjin–Hebei economic band case. Ecol. Indic. 2015, 48, 41–48. [Google Scholar] [CrossRef]

- China Statistics Press. China Energy Statistical Yearbook; China Statistics Press: Beijing, China, 2005. (In Chinese)

- China Statistics Press. China Energy Statistical Yearbook; China Statistics Press: Beijing, China, 2010. (In Chinese)

- China Statistics Press. China Energy Statistical Yearbook; China Statistics Press: Beijing, China, 2013. (In Chinese)

- China Statistics Press. China Statistical Yearbook on Construction; China Statistics Press: Beijing, China, 2005. (In Chinese)

- China Statistics Press. China Statistical Yearbook on Construction; China Statistics Press: Beijing, China, 2010. (In Chinese)

- China Statistics Press. China Statistical Yearbook on Construction; China Statistics Press: Beijing, China, 2013. (In Chinese)

- United States Agency for International Development. GHG Protocol Tool For Energy Consumption in China. 2013. Available online: http://www.ghgprotocol.org/calculation-tools/all-tools/ (accessed on 8 May 2017).

- HE Ai-zhong, L.P. Factor decomposition and decoupling analysis on CO2 emissions: Evidence from China’s circulation sector. China Environ. Sci. 2015, 35, 953–960. [Google Scholar]

- Fan, Y.; Liu, L.-C.; Wu, G.; Tsai, H.-T.; Wei, Y.-M. Changes in carbon intensity in China: Empirical findings from 1980–2003. Ecol. Econ. 2007, 62, 683–691. [Google Scholar] [CrossRef]

- Feng, B.; Wang, X.Q. Research on Carbon Decoupling Effect and Influence Factors of Provincial Construction Industry in China. China Popul. Resour. Environ. 2015, 25, 28–34. [Google Scholar]

- Ren, S.; Yin, H.; Chen, X.H. Using LMDI to analyze the decoupling of carbon dioxide emissions by China’s manufacturing industry. Environ. Dev. 2013, 9, 61–75. [Google Scholar] [CrossRef]

- Voigt, S.; Cian, E.D.; Schymura, M.; Verdolini, E. Energy intensity developments in 40 major economies: Structural change or technology improvement? Energy Econ. 2014, 41, 47–62. [Google Scholar] [CrossRef]

- Xu, S.C.; He, Z.X.; Long, R.Y. Factors that influence carbon emissions due to energy consumption in China: Decomposition analysis using LMDI. Appl. Energy 2014, 127, 182–193. [Google Scholar] [CrossRef]

- Ang, B.W. LMDI decomposition approach: A guide for implementation. Energy Policy 2015, 86, 233–238. [Google Scholar] [CrossRef]

- Wang, Q. China’s citizens must act to save their environment. Nature 2013, 497, 159. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Chen, X.; Yi-Chong, X. Accident like the Fukushima unlikely in a country with effective nuclear regulation: Literature review and proposed guidelines. Renew. Sustain. Energy Rev. 2013, 17, 126–146. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, X. Rethinking and reshaping the climate policy: Literature review and proposed guidelines. Renew. Sustain. Energy Rev. 2013, 21, 469–477. [Google Scholar] [CrossRef]

- Raupach, M.R.; Marland, G.; Ciais, P.; Le, Q.C.; Canadell, J.G.; Klepper, G.; Field, C.B. Global and regional drivers of accelerating CO2 emissions. Proc. Natl. Acad. Sci. USA 2007, 104, 10288–10293. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q. Time for commercializing non-food biofuel in China. Renew. Sustain. Energy Rev. 2011, 15, 621–629. [Google Scholar] [CrossRef]

- Wang, Q. China needing a cautious approach to nuclear power strategy. Energy Policy 2009, 37, 2487–2491. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, X. China’s electricity market-oriented reform: From an absolute to a relative monopoly. Energy Policy 2012, 51, 143–148. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, X. Regulatory failures for nuclear safety–the bad example of Japan–implication for the rest of world. Renew. Sustain. Energy Rev. 2012, 16, 2610–2617. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, X. Regulatory transparency—How China can learn from Japan’s nuclear regulatory failures? Renew. Sustain. Energy Rev. 2012, 16, 3574–3578. [Google Scholar] [CrossRef]

- Tapio, P. Disaggregative policy Delphi: Using cluster analysis as a tool for systematic scenario formation. Technol. Forecast. Soc. Chang. 2003, 70, 83–101. [Google Scholar] [CrossRef]

- Tapio, P.; Banister, D.; Luukkanen, J.; Vehmas, J.; Willamo, R.; France, N. Energy and transport in comparison: Immaterialisation, dematerialisation and decarbonisation in the EU15 between 1970 and 2000. Energy Policy 2007, 35, 433–451. [Google Scholar] [CrossRef]

- Rikkonen, P.; Tapio, P. Future prospects of alternative agro-based bioenergy use in Finland—Constructing scenarios with quantitative and qualitative Delphi data. Technol. Forecast. Soc. Chang. 2009, 76, 978–990. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, Y. Barriers and opportunities of using the clean development mechanism to advance renewable energy development in China. Renew. Sustain. Energy Rev. 2010, 14, 1989–1998. [Google Scholar] [CrossRef]

- Qiang, W.; Qiu, H.N.; Kuang, Y. Market-driven energy pricing necessary to ensure China’s power supply. Energy Policy 2009, 37, 2498–2504. [Google Scholar]

- Wang, Q.; Jha, A.N.; Chen, X.; Dong, J.-F.; Wang, X.-M. The future of nuclear safety: Vital role of geoscientists? Renew. Sustain. Energy Rev. 2015, 43, 239–243. [Google Scholar] [CrossRef]

- Andreoni, V.; Galmarini, S. Decoupling economic growth from carbon dioxide emissions: A decomposition analysis of Italian energy consumption. Energy 2012, 44, 682–691. [Google Scholar] [CrossRef]

- Sorrell, S.; Lehtonen, M.; Stapleton, L.; Pujol, J.; Champion, T. Decoupling of road freight energy use from economic growth in the United Kingdom. Energy Policy 2012, 41, 84–97. [Google Scholar] [CrossRef]

- Wang, Q. Nuclear safety lies in greater transparency. Nature 2013, 494, 403. [Google Scholar] [CrossRef] [PubMed]

| Time | Action | Purpose and Specific Content |

|---|---|---|

| September 2005 | “Circular of the general office of the State Council on further promoting the reform and popularization of wall materials” | Further promote the reform of wall materials and promote energy-efficient construction, effective protection of arable land and energy conservation. |

| November 2005 | Civil building energy conservation management regulations | In order to strengthen the administration of energy conservation, improve the efficiency of energy utilization and improve the quality of indoor thermal environment, the Ministry of construction has formulated the regulations in accordance with the relevant laws and regulations. |

| August 2007 | Measures for the administration of green building evaluation marks | These measures are formulated for the purpose of standardizing the work of green building evaluation and marking and guiding the healthy development of green buildings. |

| September 2007 | Green construction guidelines | Green construction refers to the construction of the project, in ensuring the quality, safety and other basic requirements under the premise of scientific management and technological progress, to maximize the resources and reduce the negative impact on the construction activities of the environment to achieve energy saving, land, water, Materials and environmental protection. |

| August 2008 | Civil building energy conservation regulations | This Ordinance is to strengthen the management of civil building energy conservation, reduce energy consumption in the use of civil buildings, improve energy efficiency. |

| October 2008 | Interim Measures for the administration of financial subsidies for renewable energy efficient building materials | To support the Wenchuan earthquake construction waste treatment and recycling, national finance will arrange special funds to support the production of energy-saving building materials and recycling utilization. |

| December 2010 | “National Green Building Innovation Award” and “National Green Building Innovation Award” | To do a good job in the management and evaluation of the National Green Building Innovation Award, and guide the healthy development of green building in China. |

| January 2011 | On further deepening the northern heating area of existing residential building heating metering and energy conservation work notice | During the Twelfth Five-Year Guideline, the Ministry of finance, and department of housing and urban rural development will further intensify efforts to improve the relevant policies to carry out heating metering and energy conservation work. |

| December 2011 | “Housing Ministry of Urban and Rural Construction on the implementation of the” State Council on the issuance of “the Twelfth Five-Year Guideline” energy-saving emission reduction comprehensive work program notice “implementation plan” | This program requires all levels of housing urban and rural construction departments to fully understand the housing urban and rural areas in the field of energy conservation and emission reduction work of the importance and urgency, establish a high degree of political responsibility and sense of mission, strengthen cooperation with relevant departments, solid work to ensure Complete the task of energy-saving emission reduction. |

| January 2013 | Forward the development and reform of the Ministry of Housing and Urban Construction “Green Building Action Program” notice | In order to thoroughly implement the scientific concept of development, effectively transform the urban and rural construction mode and the development of the construction industry, improve the efficiency of resource utilization, achieve energy conservation and emission reduction targets, and actively respond to global climate change, build a resource-saving and environment-friendly society, Civilized level, improve people’s quality of life. |

| Time | Country | Action | Specific Content |

|---|---|---|---|

| April 1989 | China | “Standardization law” | It stipulates development and supervision related to standardization laws. It also specifies the penalties on products, which fail to meet compulsory standards for production, sales, and imports. |

| March 2002 | China | “Management Method of National Supervision and Random Inspection of Product Quality” | National supervision and random in section is one method of maintaining product quality by the State. Regular supervision and random inspections are conducted every quarter, and irregular supervision and inspections are conducted according to the status of the product quality. |

| January 1998 | China | “Energy Conservation Law” | It regulates energy conservation management, energy utilization, improvement of energy conservation technologies, and legal liabilities. |

| 2002 | China | “Management Method of Energy Conservation Product Certification” | Product certifications adopt the principal of voluntarism. The method stipulates certification conditions, procedures, usage of energy conservation marks, and treatment after certification. |

| December 2004 | China | “Medium and Long-term Energy Conservation Plan” | It promotes key energy conservation sectors during the “11th Five-Year Plan”: industry, traffic and transportation, commercial and civil applications. The Plan also puts forward the organization and implementation of key energy conservation projects, such as modification of industrial coal-burning boilers, regional combined heat and power generation, utilization of excessive heat and pressure, saving and replacing oil, energy conservation of buildings, a green lighting project, establishment of energy conservation monitoring and a technical service system, etc. |

| 2005 | China | “China Buildings Program Strategy” | Its main goal is to promote building energy efficiency through appliance energy efficiency standards and building codes. It states that it is possible to do so using the following actions. |

| 2005 | China | “Design Standard for Energy Efficiency of Public Buildings” | More attention is paid to this particular Standard, as this is the only standard focusing on the energy efficiency of commercial buildings. |

| 2010 | China | The Chinese energy codes consist of three options for compliance | First, a prescriptive path which contains detailed specifications for individual components, second, an alternative to the prescriptive approach allowing trade-offs between envelope components, and third, a performance path that requires that the energy consumption of the design features of the proposed new building does not exceed energy consumption of a reference building [36]. |

| 2007 | India | Energy Conservation Building Code (ECBC) | This code is designed to control building energy consumption and applies to commercial buildings with a connected load of 100 kW or 120 kVA. |

| 2010 | US | The building energy codes in the U.S. become more stringent | The U.S. building energy program started to focus on compliance and developed a plan to achieve 90% compliance with the model energy code by 2017, which requires active training and enforcement programs as well as annual measurement of the rate of compliance. |

| 2015 | Italy and Europe | The building energy codes in the U.S. become more stringent | Provide an overview on EPBD implementation in Europe and a Geocluster Italian distribution of BERCs in order to show their geographical distribution and their influence on the construction sector practices, focusing in particular on the region of Lombardy, describe the methodology followed for the definition of BERCs in nine municipalities in the same region and present the practical application of one of the nine BERCs to a NZEB residential case study as an example of what the EBPD recast define as NZEB. |

| Energy | Default Value of Carbon Content | Carbon Oxidation Rate | Average Lower Heating Value | Carbon Coefficient |

|---|---|---|---|---|

| tC/TJ | % | kJ/kg or kJ/m3 | kg CO2/kg or kgCO2/m3 | |

| Raw Coal | 26.37 | 98% | 20,908 | 1.981 |

| Washed coal | 25.41 | 98% | 26,344 | 2.405 |

| Other washed coal | 25.41 | 98% | 10,454 | 0.955 |

| Coal products | 33.6 | 98% | 17,793 | 2.148 |

| #: briquette | 33.6 | 90% | 17,584 | 1.950 |

| coal water slurry | 33.6 | 98% | 19,854 | 2.397 |

| Pulverized coal | 33.6 | 98% | 20,933 | 2.527 |

| Coke | 29.5 | 93% | 28,435 | 2.860 |

| Natural Gas | 15.3 | 99% | 389,310 | 2.1622 |

| Liquefied natural gas | 15.3 | 100% | 51,498 | 2.889 |

| Crude Oil | 20.1 | 98% | 41,816 | 3.020 |

| Gasoline | 18.9 | 98% | 43,070 | 2.925 |

| Kerosene | 19.6 | 98% | 43,070 | 3.033 |

| Diesel Oil | 20.2 | 98% | 42,652 | 3.096 |

| Fuel Oil | 21.1 | 98% | 41,816 | 3.170 |

| Liquefied petroleum gas | 17.2 | 98% | 50,179 | 3.101 |

| Refinery Gas | 18.2 | 98% | 46,055 | 3.012 |

| Other petroleum products | 20.0 | 98% | 35,168 | 2.527 |

| Year | The Ratio of Thermal Power (%) | The Ratio of Other (Water, Nuclear, Wind) (%) | Consumption Standard of Power (kgce/kW·h) | Carbon Coefficient (tCO2/tce) |

|---|---|---|---|---|

| 2005 | 81.89 | 18.11 | 0.343 | 6.264 |

| 2006 | 82.69 | 17.31 | 0.342 | 6.307 |

| 2007 | 82.98 | 17.02 | 0.332 | 6.144 |

| 2008 | 80.48 | 19.52 | 0.322 | 5.780 |

| 2009 | 80.3 | 19.7 | 0.32 | 5.731 |

| 2010 | 79.2 | 20.8 | 0.312 | 5.511 |

| 2011 | 81.34 | 18.66 | 0.308 | 5.588 |

| 2012 | 78.05 | 21.95 | 0.305 | 5.309 |

| 2013 | 78.19 | 21.81 | 0.302 | 5.262 |

| Building Material | Carbon Coefficient (kgCO2/kg or Kg/m3) |

|---|---|

| Cement | 0.815 |

| Steel | 1.789 |

| Glass | 0.966 |

| Wood | 842.8 |

| Aluminum | 2.6 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, R.; Li, R. Decomposition and Decoupling Analysis of Life-Cycle Carbon Emission in China’s Building Sector. Sustainability 2017, 9, 793. https://doi.org/10.3390/su9050793

Jiang R, Li R. Decomposition and Decoupling Analysis of Life-Cycle Carbon Emission in China’s Building Sector. Sustainability. 2017; 9(5):793. https://doi.org/10.3390/su9050793

Chicago/Turabian StyleJiang, Rui, and Rongrong Li. 2017. "Decomposition and Decoupling Analysis of Life-Cycle Carbon Emission in China’s Building Sector" Sustainability 9, no. 5: 793. https://doi.org/10.3390/su9050793