Life Cycle Assessment of Lubricant Oil Plastic Containers in Brazil

Abstract

:1. Introduction

2. Materials and Methods

2.1. Goal and Scope

2.1.1. Functional Unit

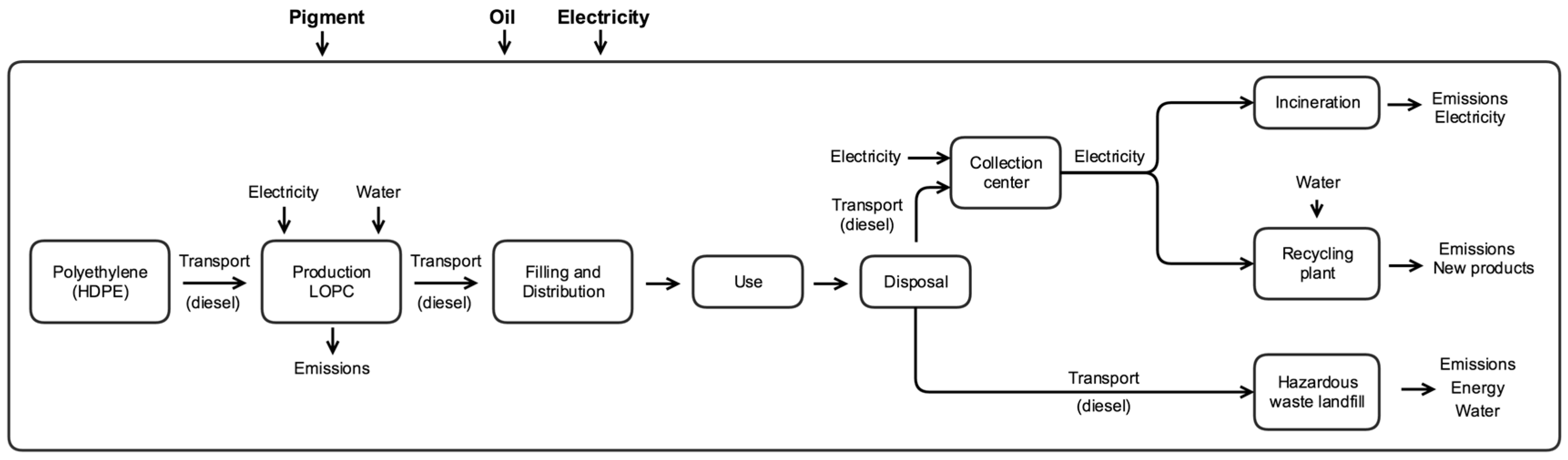

2.1.2. Description of Scenarios and System Boundaries

- Scenario 0: Recycling 16%, industrial landfill 84% (current situation)

- Scenario 1: Recycling 50%, industrial landfill 50%

- Scenario 2: Recycling 16%, incineration 16%, industrial landfill 68%

- Scenario 3: Recycling 50%, incineration 50%

2.2. Life Cycle Inventory

Life Cycle Impact Assessment

2.3. Sensitivity Analysis

3. Results

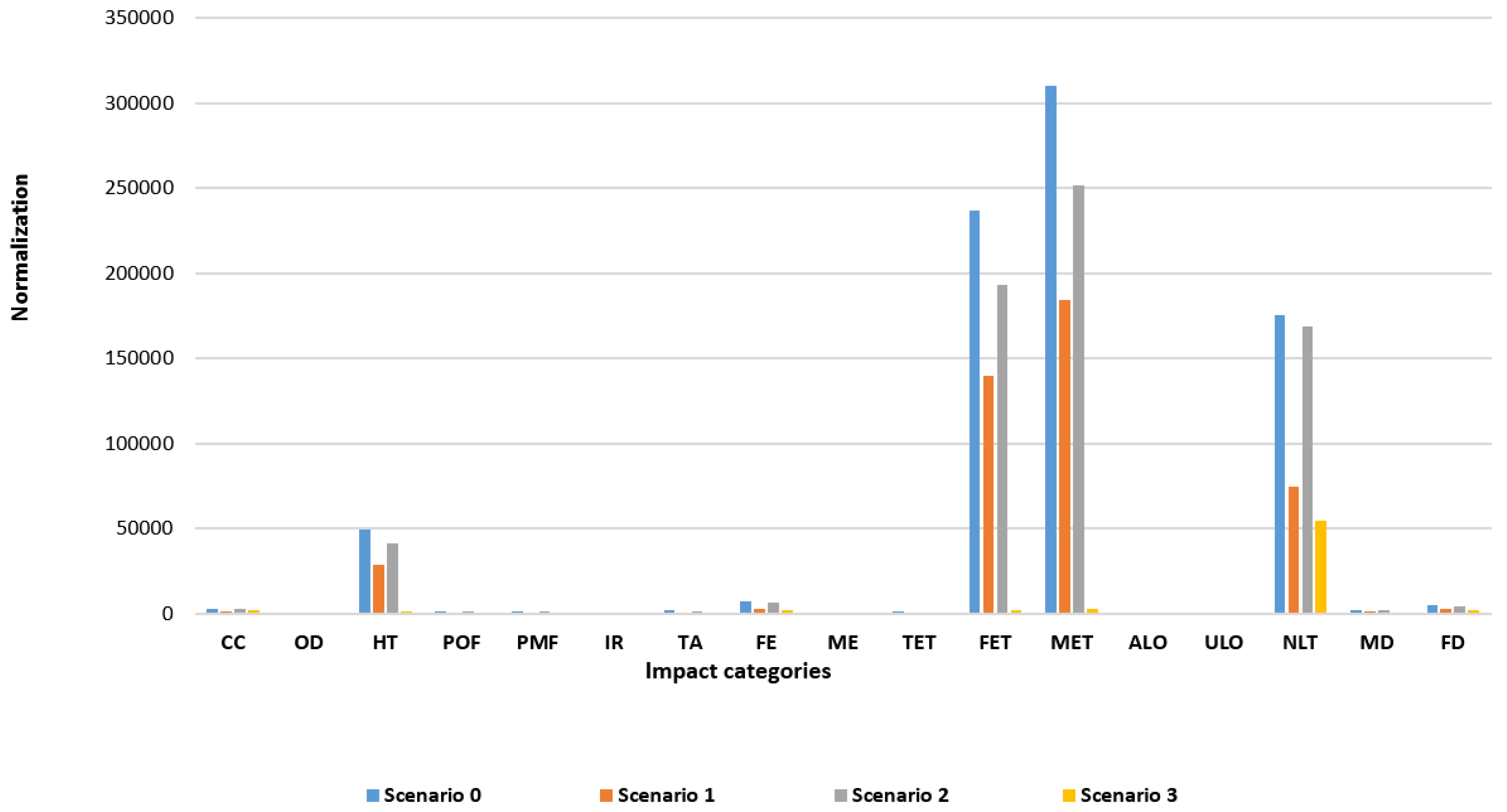

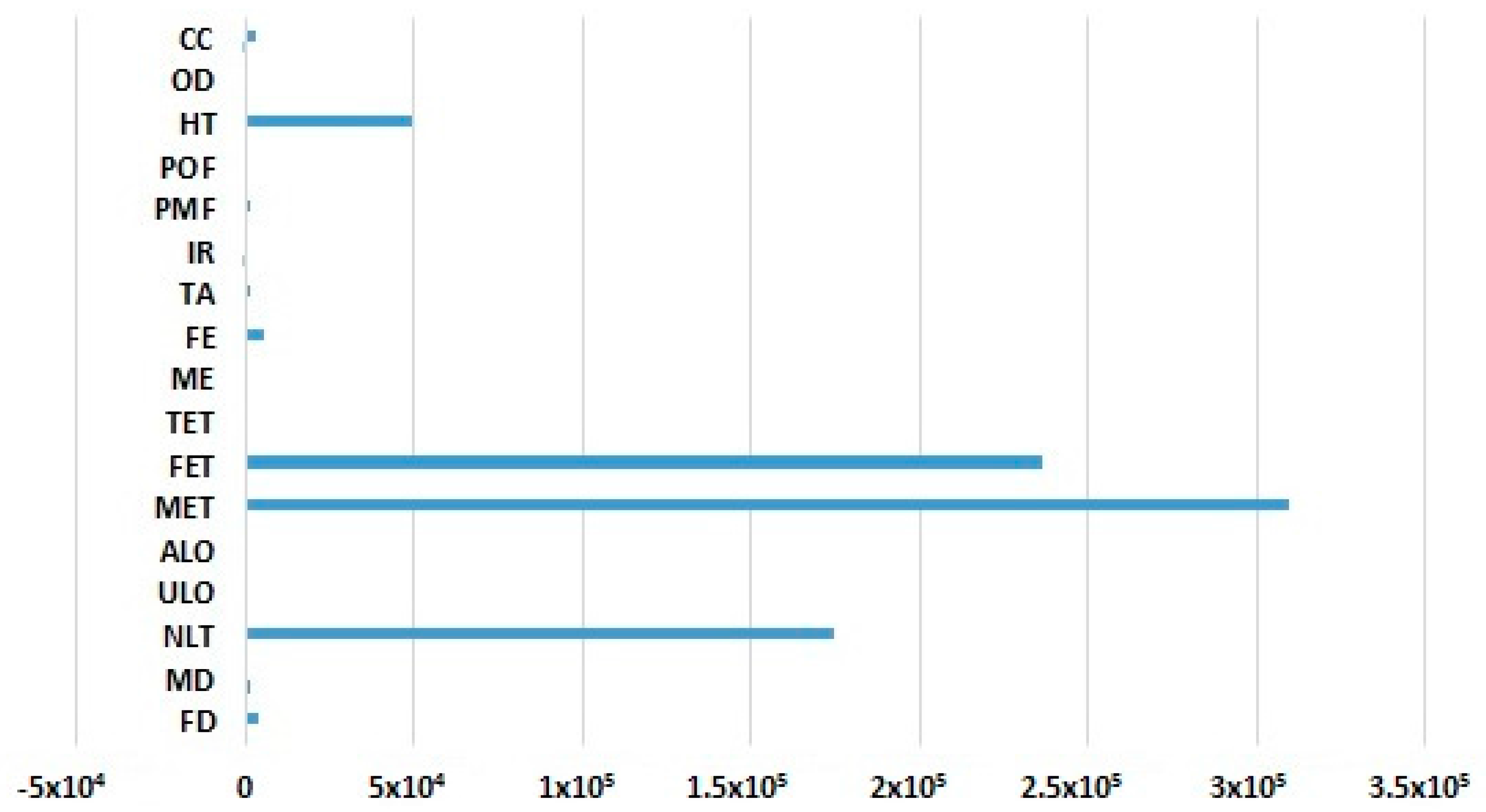

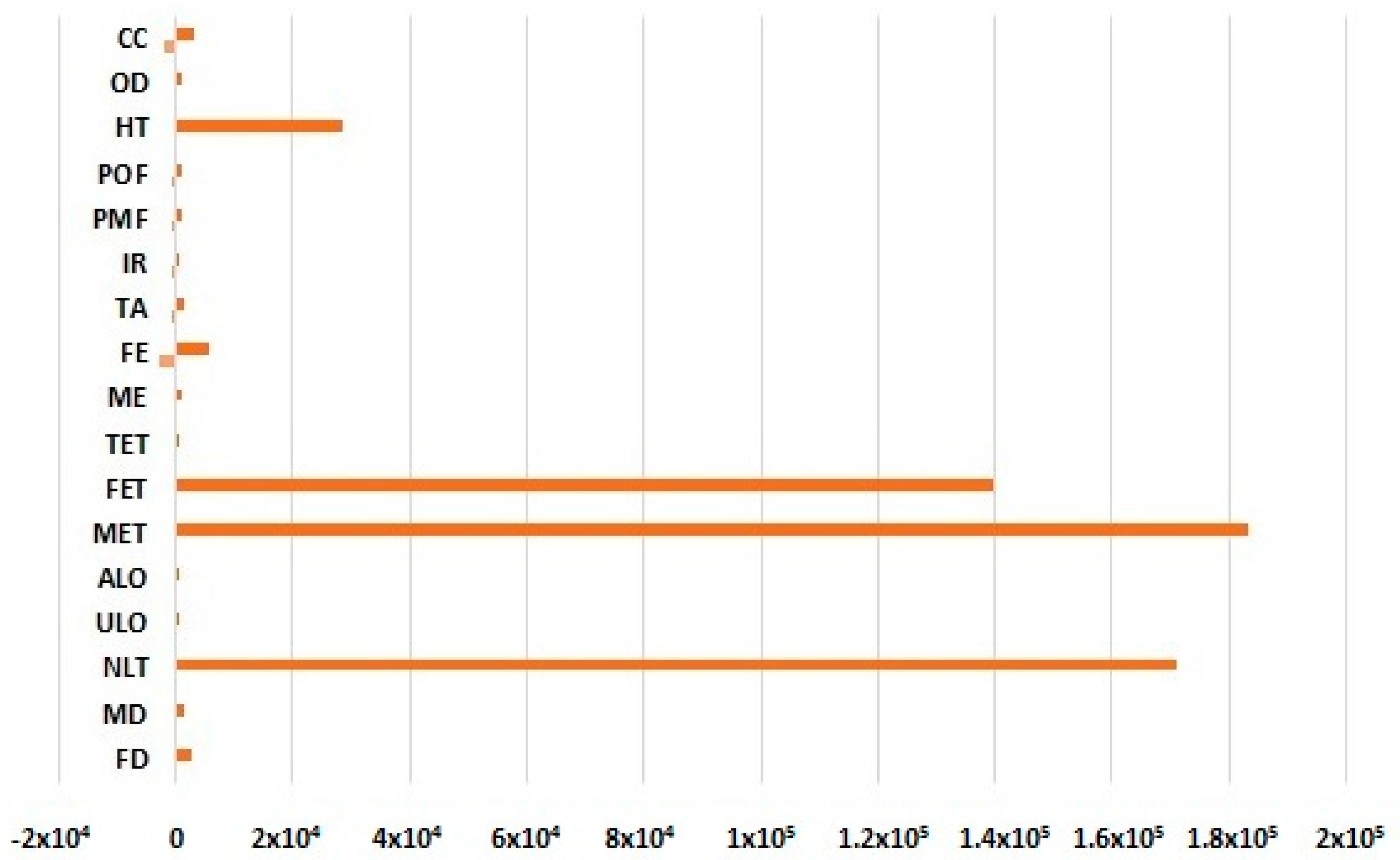

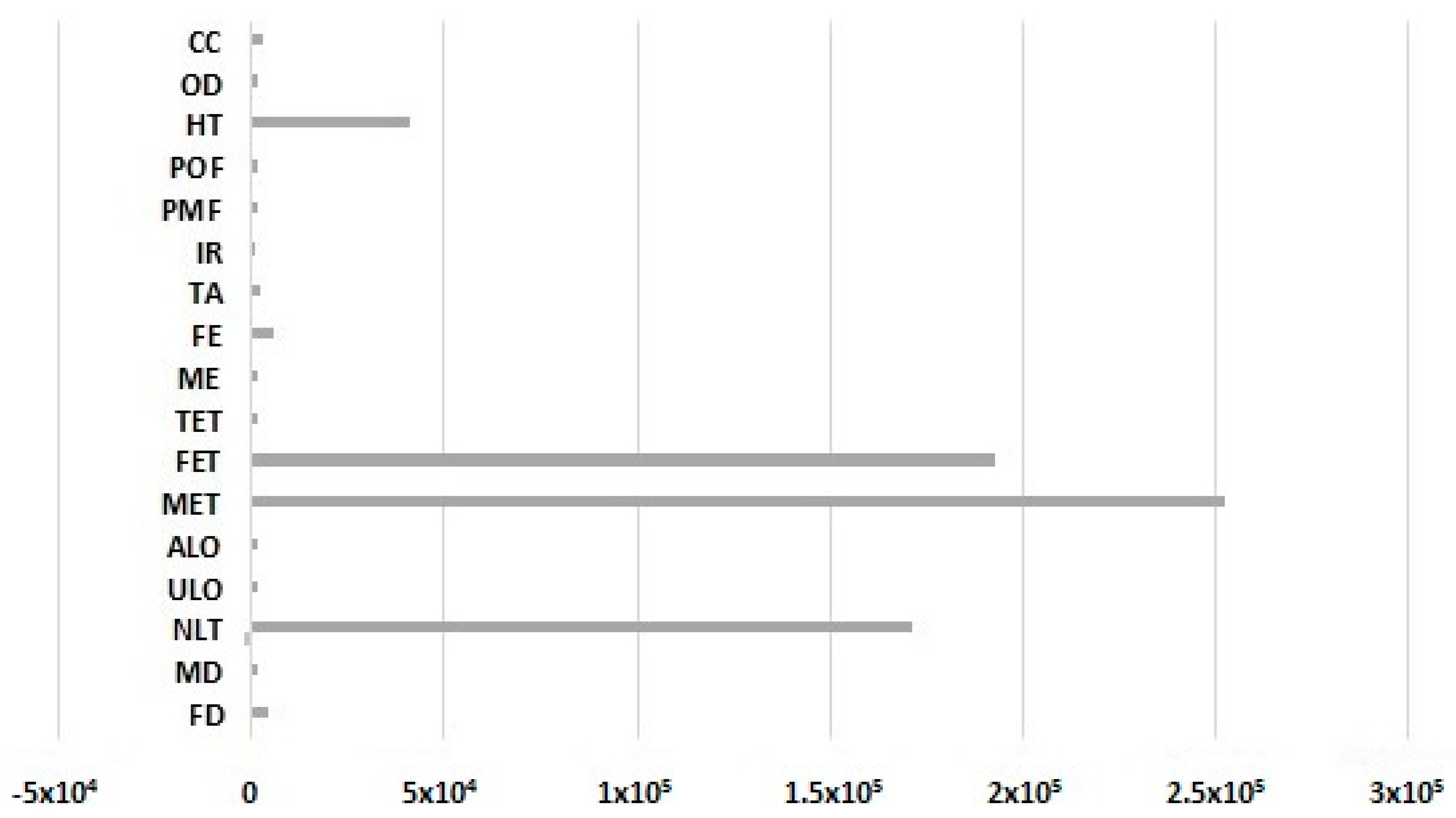

3.1. Environmental Impacts of the Four Scenarios

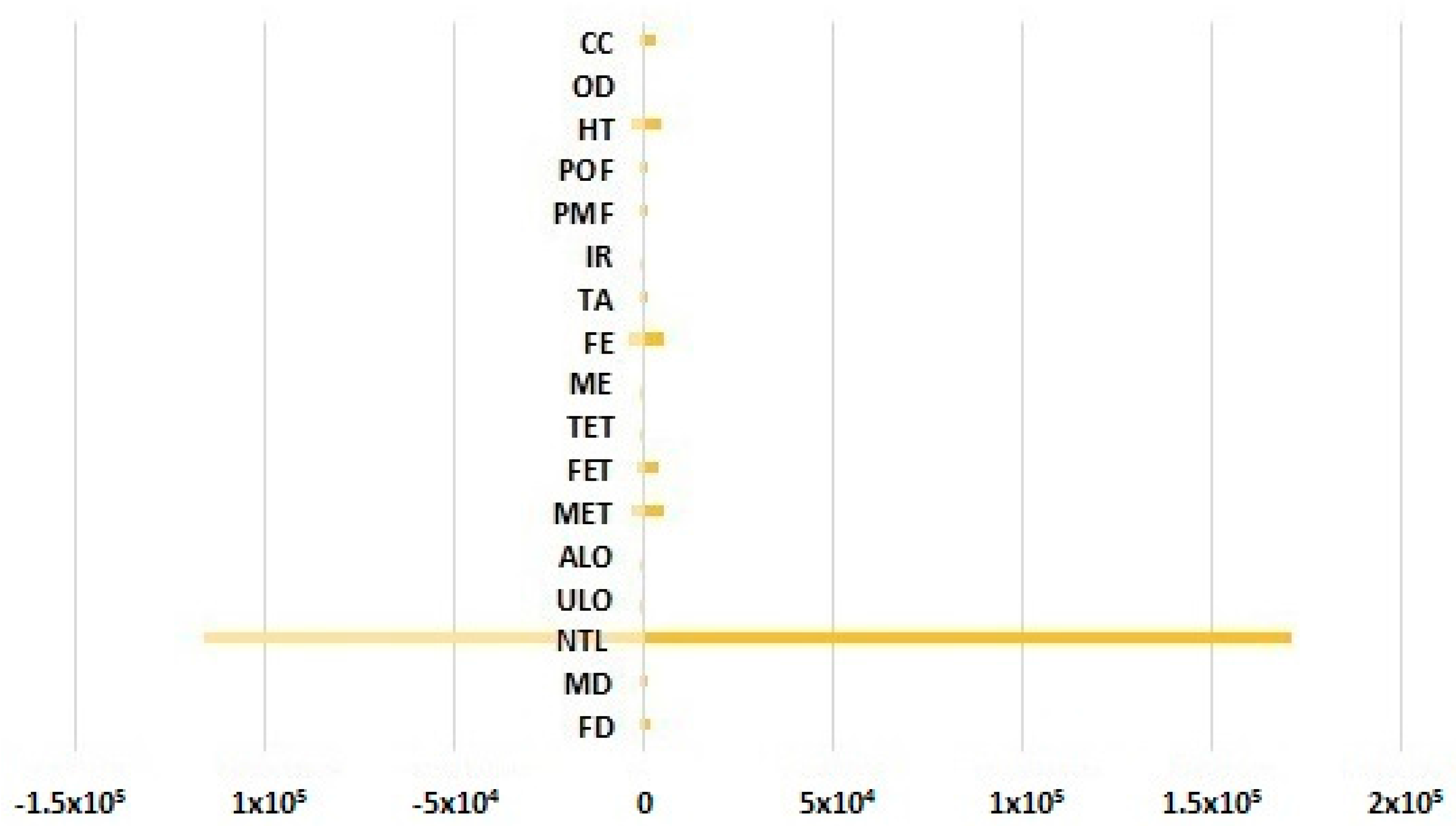

3.2. Sensitivity Analysis Results

4. Discussion and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Denatran. Departamento Nacional de Trânsito. Available online: http://www.denatran.gov.br/index.php/estatistica/253-frota-2014 (accessed on 4 April 2016).

- Aguiar, A.O.; Joaquim Filho, J. Veículos em Fim de Vida Como Resíduos: Panorama, Fragilidades e Perspectivas do Gerenciamento No Brasil. Simpoi. 15. 2012. Available online: http://www.simpoi.fgvsp.br/arquivo/2012/artigos/E2012_T00377_PCN71573.pdf (accessed on 12 September 2016).

- United States Environmental Protection Agency (EPA). Plastic Oil Bottle Recycling. Final Report. 2006. Available online: https://cfpub.epa.gov/ncer_abstracts/index.cfm/fuseaction/display.highlight/abstract/7974/report/F (accessed on 10 December 2016).

- Monier, V.; Labouze, E.; Sofres, T.N. Critical Review of Existing Studies and Life Cycle Analysis on the Regeneration and Incineration of Waste Oils. European Commission. Available online: http://ec.europa.eu/environment/waste/studies/oil/waste_oil.htm (accessed on 10 July 2016).

- United Nations Environment Programme (UNEP). Compendium of Recycling and Destruction Technologies for Waste Oils; IETC: Osaka, Japan, 2012. [Google Scholar]

- Associação Brasileira de Normas Técnicas (ABNT). NBR 10004: Classificação de Resíduos Sólidos; ABNT: Rio de Janeiro, Brazil, 2004. [Google Scholar]

- Intergovernmental Panel on Climate Change (IPCC). Good Practice Guidance and Uncertainty Management in National Greenhouse Gas Inventories. Report. 2001. Available online: http://www.ipcc-nggip.iges.or.jp/public/gp/bgp/5_3_Waste_Incineration.pdf (accessed on 10 December 2016).

- Willing, A. Lubricants based on renewable resources—An environmentally compatible alternative to mineral oil products. Chemosphere 2001, 43, 89–98. [Google Scholar] [CrossRef]

- PlasticsEurope. Plastics—The Facts 2014/2015—An Analysis on European Plastics Production, Demand and Waste Data; PlasticsEurope: Brussels, Belgium, 2015; Available online: http://issuu.com/plasticseuropeebook/docs/final_plastics_the_facts_2014_19122 (accessed on 15 July 2016).

- Plastivida. Monitoramento dos Índices de Reciclagem Mecânica de Plástico No Brasil (IRmP). 2011. Available online: http://www.plastivida.org.br/images/temas/Apresentacao_IRMP2011.pdf (accessed on 25 November 2015).

- Sindicom. Data for the Lubricant Oil Sector. 2016. Available online: http://www.sindicom.com.br/#conteudo.asp?conteudo=72&id_pai=60&targetElement=leftpart (accessed on 9 December 2016).

- Freitas, E. Embalagens Plásticas de Óleo Lubrificante. Programa Jogue Limpo. Congresso Nacional Simepetro. 4. 2011. Available online: http://www.simepetro.com.br/wp-content/uploads/SINDICOM1.pdf (accessed on 12 May 2015).

- Demertzi, M.; Dias, A.C.; Matos, A.; Arroja, L.M. Evaluation of different end-of-life management alternatives for used natural cork stoppers through life cycle assessment. Waste Manag. 2015, 46, 668–680. [Google Scholar] [CrossRef]

- Sistema Firjan. Manual de Gerenciamento de Resíduos: Guia de Procedimento Passo a Passo, 2nd Edição. Available online: http://www.firjan.com.br/lumis/portal/file/fileDownload.jsp?fileId=2C908A8F4EBC426A014ED041F0FB576E&inline=1 (accessed on 10 August 2015).

- Lovón-Canchumani, G.A. Óleos Lubrificantes Usados: Um Estudo de Caso de Avaliação de Ciclo de Vida do Sistema de Rerrefino no Brasil; Tese de Doutorado, Universidade Federal do Rio de Janeiro, Programa de Planejamento Energético PPE/COPPE/UFRJ: Rio de Janeiro, Brazil, 2013. [Google Scholar]

- European Commission. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives; Publications Office of the European Union: Luxemburg, 2008. [Google Scholar]

- Pires, A.; Martinho, G.; Chang, N.-B. Solid waste management in European countries: A review of systems analysis techniques. J. Environ. Manag. 2011, 92, 1033–1050. [Google Scholar] [CrossRef] [PubMed]

- Kanokkantapong, V.; Kiatkittipong, W.; Panyapinyopol, B.; Wongsuchoto, P.; Pavasant, P. Used lubricating oil management options based on life cycle thinking. Resour. Conserv. Recycl. 2009, 53, 294–299. [Google Scholar] [CrossRef]

- Boughton, B.; Horvath, A. Environmental assessment of used oil management methods. Environ. Sci. Technol. 2004, 38, 353–358. [Google Scholar] [CrossRef]

- European Comission. Plastic and Packaging Waste Directive (94/62/EC): European Parliament and Council Directive 94/62/EC of 20 December 1994 on Plastic and Packaging Waste. Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:01994L0062-20150526 (accessed on 20 October 2016).

- Resource Conservation and Recovery Act of 1976, Pub. L. No. 94-580, Oct. 21, 1976, 90 Stat. 2795 (to Be Codified as 42 U.S.C §§ 6901-87). Available online: https://www.epa.gov/laws-regulations/summary-resource-conservation-and-recovery-act (accessed on 15 December 2016).

- Brasil. Lei Federal Nº 12.305, “Institui a Política Nacional de Resíduos Sólidos; Altera a lei n° 9.605, de 12 de Fevereiro de 1998; e dá Outras Providências”, Brasil, 2 de Agosto de 2010. Available online: http://www.planalto.gov.br/ccivil_03/_ato2007-2010/2010/lei/l12305.htm (accessed on 3 March 2017).

- Murphy, P.R.; Poist, R.P. Managing of logistics retro movements: An empirical analysis of literature suggestions. Transp. Res. Forum 1989, 29, 177–184. [Google Scholar]

- Carter, C.R.; Ellram, L.M. Reverse logistics: A review of the literature and framework for future investigation. J. Bus. Logist. 1998, 19, 85–102. [Google Scholar]

- Stock, J.R. Development and Implementation of Reverse Logistics Program; Council of Logistics Management: Oak Brook, IL, USA, 1998. [Google Scholar]

- Dowlatshahi, S. Developing a theory of reverse logistics. Interfaces 2000, 30, 143–155. [Google Scholar] [CrossRef]

- Srivastava, S. Network design for reverse logistics. Omega 2008, 36, 535–548. [Google Scholar] [CrossRef]

- Rogers, D.S.; Tibben-Lembke, R. Going Backwards: Reverse Logistics Trends and Practices; Full Report; Reverse Logistics Executive Council: Reno, NV, USA, 1998. [Google Scholar]

- Pokharel, S.; Mutha, A. Perspectives in reverse logistics: A review. Resour. Conserv. Recycl. 2009, 53, 175–182. [Google Scholar] [CrossRef]

- Agrawal, S.; Singh, R.K.; Murtaza, Q. A literature review and perspectives in reverse logistics. Resour. Recycl. Conserv. 2015, 97, 76–92. [Google Scholar] [CrossRef]

- Jogue Limpo. Available online: www.joguelimpo.org.br (accessed on 12 July 2016).

- Veiga, M.M. Analysis of efficiency of waste reverse logistics for recycling. Waste Manag. Res. 2013, 31, 26–34. [Google Scholar] [CrossRef] [PubMed]

- Friege, H.; Fendel, A. Competition of different methods for recovering energy from waste. Waste Manag. Res. 2011, 29, 30–38. [Google Scholar] [CrossRef] [PubMed]

- Meneses, M.; Schuhmachera, M.; Domingo, J.L. Health risk assessment of emissions of dioxins and furans from a municipal waste incinerator: Comparison with other emission sources. Environ. Int. 2004, 30, 481–489. [Google Scholar] [CrossRef] [PubMed]

- Morselli, L.; Passarini, F.; Piccari, L.; Vassura, I.; Bernardi, E. Risk assessment applied to air emissions from a medium-sized Italian MSW incinerator. Waste Manag. Res. 2011, 29, 48–56. [Google Scholar] [CrossRef] [PubMed]

- Finkbeiner, M.; Schau, E.M.; Lehmann, A.; Traverso, M. Towards life cycle sustainability assessment. Sustainability 2010, 2, 3309–3322. [Google Scholar] [CrossRef]

- Guinée, J.B.; Heijungs, H.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Ekvall, T.; Rydberg, T. Life cycle assessment: Past, present, and future. Environ. Sci. Technol. 2011, 45, 90–96. [Google Scholar] [CrossRef] [PubMed]

- Lorenz, E. Life-cycle assessment in US codes and standards. PCI J. 2014, 59, 49–54. [Google Scholar]

- Rigamonti, L.; Grosso, M.; Giugliano, M. Life cycle assessment of sub-units composing a MSW management system. J. Clean. Prod. 2010, 18, 1652–1662. [Google Scholar] [CrossRef]

- International Standards Organization. ISO 14040 Environmental Management Life Cycle Assessment Principles and Framework; International Standards Organization: Brussels, Belgium, 2006. [Google Scholar]

- ISO 14044 Environmental Management Life Cycle Assessment Requirements and Guidelines; International Stardard Organization: Brussels, Belgium, 2006.

- Guinée, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; de Koning, A.; van Oers, L.; Wegener Sleeswijk, A.; Suh, S.; Udo de Haes, H.A.; et al. Handbook on Life Cycle Assessment: Operational Guide to the ISO Standards, 1st ed.; Springer: Dordrecht, The Netherlands, 2002; 692p. [Google Scholar]

- European Comission. International Reference Life Cycle Data System (ILCD) Handbook—General Guide for Life Cycle Assessment—Detailed Guidance, 1st ed.; Publications Office of the European Union, Joint Research Centre, Institute for Environment and Sustainability: Ispra, Italy, 2010; 417p. [Google Scholar]

- Bousted Consulting and Associates Ltd. Life Cycle Assessment for Three Types of Grocery Bags—Recyclable Plastic. Compostable, Biodegradable Plastic, and Recycled, Recyclable Paper. 2007. Available online: https://plastics.americanchemistry.com/Life-Cycle-Assessment-for-Three-Types-of-Grocery-Bags.pdf (accessed on 10 January 2016).

- Siracusa, V.; Ingrao, C.; Giudice, A.L.; Mbohwa, C.; Dalla Rosa, M. Environmental assessment of a multilayer polymer bag for food packaging and preservation: An LCA approach. Food Res. Int. 2014, 62, 151–161. [Google Scholar] [CrossRef]

- Accorsi, R.; Versari, L.; Manzini, R. Glass vs. plastic: Life cycle assessment of extra-virgin olive oil bottles across global supply chains. Sustainability 2015, 7, 2818–2840. [Google Scholar] [CrossRef]

- Baitz, M.; Kreißig, J.; Byrne, E.; Makishi, C.; Kupfer, T.; Frees, N.; Bey, N.; Hansen, M.S.; Hansen, A.; Bosch, T.; et al. Life Cycle Assessment of PVC and of Principal Competing Materials. 2004. Available online: http://www.pvc.org/upload/documents/PVC-final-report-lca.pdf (accessed on 4 November 2015).

- PE Americas. Comparative Life Cycle Assessment Ingeo™ Biopolymer, PET, and PP Drinking Cups for Starbucks Coffee Company and Nature Works LLC. Full Report. 2009. Available online: http://www.natureworksllc.com/~/media/The_Ingeo_Journey/EcoProfile_LCA/LCA/PEA_Cup_Lid_LCA_FullReport_ReviewStatement_121209_pdf.pdf (accessed on 14 June 2016).

- Lehmann, B.; Vilaplana, F.; Strömberg, E.; Suliman, W.; Cerrato, L.R. Comparative LCA on Plastic Packaging; Report. 2005. Available online: http://www.lcm2007.org/paper/168.pdf (accessed on 4 April 2016).

- LCA of Management Options for Mixed Waste Plastics. 2008. Available online: http://www.wrap.org.uk/sites/files/wrap/LCA%20of%20Management%20Options%20for%20Mixed%20Waste%20Plastics.pdf (accessed on 18 November 2016).

- Perugini, F.; Mastellone, M.L.; Arena, U. A life Cycle assessment of mechanical and feedstock recycling options for management of plastic packaging wastes. Environ. Prog. 2005, 24, 137–154. [Google Scholar] [CrossRef]

- Ferreira, S.; Cabral, M.; da Cruz, N.F.; Simões, P.; Marques, R.C. Life cycle assessment of a packaging waste recycling system in Portugal. Waste Manag. 2014, 34, 1725–1735. [Google Scholar] [CrossRef] [PubMed]

- Instituto Brasileiro de Geografia e Estatística (IBGE). 2016. Available online: http://cod.ibge.gov.br/7DM (accessed on 17 October 2016).

- Becker, H.S. Métodos de Pesquisa em Ciências Sociais; HUCITEC: São Paulo, Brazil, 1997. [Google Scholar]

- Willers, C.D.; Rodrigues, L.B. A critical evaluation of Brazilian life cycle assessment studies. Int. J. Life Cycle Assess. 2014, 19, 144–152. [Google Scholar] [CrossRef]

- Zanghelini, G.M.; de Souza, H.R.A., Jr.; Kulay, L.; Cherubini, E.; Ribeiro, P.T.; Soares, S.R. A bibliometric overview of Brazilian LCA research. Int. J. Life Cycle Assess. 2016, 21, 1759–1775. [Google Scholar] [CrossRef]

- Syke. Reducing Greenhouse Gas Emissions by Recycling Plastics or Textile Waste? Finnish Environment Institute: Helsinki, Finland, 2007; Available online: http://www.iswa.org/uploads/tx_iswaknowledgebase/620121_Paper.pdf (accessed on 16 December 2016).

- Instituto Brasileiro de Informação em Ciência e Tecnologia (IBICT). Banco nacional de Inventários de Ciclo de Vida. 2016. Available online: http://sicv.acv.ibict.br/Node/ (accessed on 16 September 2016).

- Indaver. Sustainability Report. 2014. Available online: http://www.indaver.nl/fileadmin/indaver/Publications/Sust%20report/SR_2014_EN_FINAL.pdf (accessed on 7 March 2017).

- Ecoinvent Center. Ecoinvent Data v3.0. Swiss Centre for Life Cycle Inventories, St. Gallen. Available online: www.ecoinvent.org (accessed on 15 September 2016).

- Ministério do Meio Ambiente (MMA). 1° Inventário Nacional de Emissões Atmosféricas por Veículos Automotores Rodoviários. Relatório Final. 2011. Available online: http://www.mma.gov.br/estruturas/163/_publicacao/163_publicacao27072011055200.pdf (accessed on 17 October 2016).

- Petro-Canada. Petro-Canada Lubricants Handbook. 2016. Available online: http://lubricants.petro-canada.ca/en-CA/ (accessed on 7 October 2016).

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; Schryver, A.D.; Struijs, J.; van Zelm, R. ReCiPe 2008—A Life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level. Available online: http://www.leidenuniv.nl/cml/ssp/publications/recipe_characterisation.pdf (accessed on 15 April 2016).

- Prè-Sustainability. Simapro. Available online: http://www.pre-sustainability.com/simapro-lca-software (accessed on 1 March 2017).

- European Comission. International Reference Life Cycle Data System (ILCD) Analysis of Existing Environmental Impact Assessment Methodologies for Use in Life Cycle Assessment, 1st ed.; Publications Office of the European Union, Joint Research Centre, Institute for Environment and Sustainability: Ispra, Italy, 2010; 417p. [Google Scholar]

- Sleeswijk, A.W.; van Oers, L.F.; Guinèe, J.B.; Struijs, J.; Huijbregts, M.A. Normalization in product life cycle assessment: An LCA of the global and European economic systems in the year 2000. Sci. Total Environ. 2008, 390, 227–270. [Google Scholar] [CrossRef] [PubMed]

| Type of Emission | Light Weight Lorry, 3.5–7.5 Tonnes | Medium Weight Lorry, 7.5–16 Tonnes | Heavy Weight Truck, >28 Tonnes |

|---|---|---|---|

| CO2 | 2.7 | 2.7 | 2.7 |

| CO | 0.42 | 0.58 | 1.01 |

| NOx | 0.08 | 0.11 | 0.19 |

| PM | 0.04 | 0.054 | 0.095 |

| NMVOC | 2.37 | 3.25 | 5.68 |

| Input | Output | ||||

|---|---|---|---|---|---|

| Production LOPC | |||||

| Material | Amount | Units | Material | Amount | Units |

| HDPE | 1 | tonne | LOPC | 1 | tonne |

| Diesel (transport) | 63.75 | L | Heat | 6.14 × 103 | MJ |

| Energy | 52,500 | kWh | CO2 | 172,125 | kg |

| Water (cooling) | 2.99 | m3 | CO | 0.023562 | kg |

| PM | 2.244 | kg | |||

| NOx | 4.488 × 103 | kg | |||

| NMVOC | 132.957 | kg | |||

| Distribution | |||||

| LOPC | 1 | tonne | CO2 | 6.102 × 103 | kg |

| Diesel (transport) | 2.26 | L | CO | 1.15 × 10−6 | kg |

| Lubricant oil * | 43 | tonnes | PM | 1.074 × 10−4 | kg |

| NOx | 2.19 × 10−1 | kg | |||

| NMVOC | 6.46 × 10−3 | kg | |||

| Collection LOPC (Instituto Jogue Limpo) | |||||

| LOPC | 1 | tonne | HDPE | 1 | tonne |

| Diesel (transport) | 69.92 | L | CO2 | 1.88 × 102 | kg |

| Energy | 1.080 × 103 | kWh | CO | 2.58 × 10−2 | kg |

| Lubricant oil * | 1.935 | tonnes | PM | 2.46 × 10−3 | kg |

| NOx | 4.92 × 10−3 | kg | |||

| NMVOC | 1.46 × 10−1 | kg | |||

| Recycling LOPC | |||||

| HDPE | 1 | tonne | Product | 1 | tonne |

| Diesel (transport) | 0.387 | L | Heat | 1.83 × 103 | MJ |

| Energy | 13,305 | kWh | CO2 | 1.045 × 104 | kg |

| Water (cooling) | 19.7 | m3 | CO | 3.44 × 10−4 | kg |

| PM | 3.24 × 10−5 | kg | |||

| NOx | 6.47 × 10−5 | kg | |||

| NMVOC | 1.93 × 10−3 | Kg | |||

| Incineration | |||||

| HDPE | 1 | tonne | Ash | 0.01 | tonne |

| Diesel (transport) | 21.8 | L | Heat | 1087 × 103 | MJ |

| Energy | 500 | kWh | CO2 | 58.86 | kg |

| Heating oil | 0.008095 | tonne | CO | 1.94 × 10−2 | kg |

| Natural gas | 0.963657 | GJ | PM | 1.82 × 10−3 | kg |

| Water | 3581 | L | NOx | 3.64 × 10−3 | kg |

| NMVOC | 1.09 × 10−1 | kg | |||

| Water | 1098 | L | |||

| Industrial Landfill | |||||

| HDPE | 1 | tonne | CO2 | 187.866 | kg |

| Diesel (transport) | 69.58 | L | CO | 3.45 × 10−2 | kg |

| Energy | 0.367 | kWh | PM | 3.66 × 10−3 | kg |

| Lubricant oil | 1.935 | tonnes | NOx | 7.01 × 10−3 | kg |

| NMVOC | 2.08 × 10−1 | kg | |||

| Heat | 32.9 | GJ | |||

| Impact Category | Abbr. | Scenario 0 | Scenario 1 | Scenario 2 | Scenario 3 |

|---|---|---|---|---|---|

| Climate change | CC | 2.61 × 103 | 9.11 × 102 | 2.95 × 103 | 1.98 × 103 |

| Ozone depletion | OD | 1.16 × 102 | 5.90 × 101 | 1.16 × 102 | 5.80 × 102 |

| Human toxicity | HT | 4.97 × 104 | 2.87 × 104 | 4.10 × 104 | 1.47 × 103 |

| Photochemical oxidant formation | POF | 1.04 × 103 | 3.94 × 102 | 1.08 × 103 | 5.20 × 102 |

| Particulate matter formation | PMF | 1.48 × 103 | 6.21 × 102 | 1.47 × 103 | 5.96 × 102 |

| Ionizing radiation | IR | 5.71 × 102 | 2.16 × 102 | 5.91 × 102 | 2.78 × 102 |

| Terrestrial acidification | TA | 1.65 × 103 | 6.67 × 102 | 1.62 × 103 | 5.99 × 102 |

| Freshwater eutrophication | FE | 6.93 × 103 | 3.00 × 103 | 6.54 × 103 | 1.81 × 103 |

| Marine eutrophication | ME | 7.18 × 102 | 3.82 × 102 | 6.25 × 102 | 9.10 × 101 |

| Terrestrial ecotoxicity | TET | 9.22 × 102 | 4.15 × 102 | 8.46 × 102 | 1.75 × 102 |

| Freshwater ecotoxicity | FET | 2.37 × 105 | 1.40 × 105 | 1.93 × 105 | 2.19 × 103 |

| Marine ecotoxicity | MET | 3.10 × 105 | 1.84 × 105 | 2.52 × 105 | 2.65 × 103 |

| Agricultural land occupation | ALO | 3.37 × 102 | 1.68 × 102 | 2.99 × 102 | 5.1 × 100 |

| Urban land occupation | ULO | 1.69 × 102 | 8.20 × 101 | 1.55 × 102 | 4.00 × 100 |

| Natural land transformation | NLT | 1.75 × 105 | 7.44 × 104 | 1.69 × 105 | 5.48 × 104 |

| Metal depletion | MD | 2.15 × 103 | 1.12 × 103 | 1.87 × 103 | 2.65 × 102 |

| Fossil depletion | FD | 4.65 × 103 | 2.40 × 103 | 4.42 × 103 | 1.67 × 103 |

| Impact Categories | Abbr. | Scenario 0 | Scenario 1 | Scenario 2 | Scenario 3 |

|---|---|---|---|---|---|

| Climate change | CC | 2–3% | 16–33% | 1–2% | 8–15% |

| Ozone Depletion | OD | 2% | 4–9% | 0–1% | 5–9% |

| Human Toxicity | HT | 0% | 1–2% | 0% | 16–31% |

| Photochemical Oxidant Formation | POF | 1–3% | 12–24% | 1–3% | 9–18% |

| Particulate Matter Formation | PMF | 1–3% | 9–18% | 1–3% | 9–18% |

| Ionizing Radiation | IR | 2–4% | 16–31% | 2–4% | 12–24% |

| Terrestrial Acidification | TA | 1–2% | 10–20% | 2–3% | 11–22% |

| Freshwater Eutrophication | FE | 1–3% | 9–19% | 1–3% | 15–31% |

| Marine Eutrophication | ME | 1% | 3–5% | 0–1% | 10–21% |

| Terrestrial Ecotoxicity | TET | 1–2% | 8–15% | 1–2% | 19–37% |

| Freshwater Ecotoxicity | FET | 0% | 0–1% | 0% | 10–19% |

| Marine Ecotoxicity | MET | 0% | 0% | 0% | 10–20% |

| Agricultural Land Occupation | ALO | 1% | 5–10% | 1–2% | 17–34% |

| Urban Land Occupation | ULO | 1–2% | 6–12% | 1–3% | 13–25% |

| Natural Land Transformation | NLT | 1–3% | 11–23% | 1–3% | 16–31% |

| Metal Depletion | MD | 1% | 4–8% | 2–3% | 16–32% |

| Fossil Depletion | FD | 1–2% | 5–9% | 1% | 6–13% |

| Impact Categories | Abbr. | Scenario 0 | Scenario 1 | Scenario 2 | Scenario 3 |

|---|---|---|---|---|---|

| Climate change | CC | ±3% | 0–2% | ±2% | ±0% |

| Ozone depletion | OD | ±19% | ±13% | ±16% | ±0% |

| Human toxicity | HT | 0% | ±0% | 0% | ±0% |

| Photochemical oxidant formation | POF | ±9% | ±4% | ±5% | ±0% |

| Particulate matter formation | PMF | ±8% | ±4% | ±5% | ±0% |

| Ionising radiation | IR | ±2% | ±1% | ±1% | ±0% |

| Terrestrial acidification | TA | ±12% | ±6% | ±8% | ±0% |

| Freshwater eutrophication | FE | ±4% | ±2% | ±2% | ±0% |

| Marine eutrophication | ME | ±2% | ±1% | ±1% | ±1% |

| Terrestrial ecotoxicity | TET | ±5% | ±3% | ±3% | ±0% |

| Freshwater ecotoxicity | FET | 0–1% | ±0% | 0% | ±0% |

| Marine ecotoxicity | MET | ±0% | ±0% | 0% | ±0% |

| Agricultural land occupation | ALO | ±1% | ±0% | 0% | ±1% |

| Urban land occupation | ULO | ±8% | ±5% | ±6% | ±0% |

| Natural land transformation | NLT | ±9% | ±5% | ±6% | ±1% |

| Metal depletion | MD | ±1% | ±1% | ±1% | ±0% |

| Fossil depletion | FD | ±18% | ±12% | ±15% | ±1% |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, M.C.; Magrini, A. Life Cycle Assessment of Lubricant Oil Plastic Containers in Brazil. Sustainability 2017, 9, 576. https://doi.org/10.3390/su9040576

Oliveira MC, Magrini A. Life Cycle Assessment of Lubricant Oil Plastic Containers in Brazil. Sustainability. 2017; 9(4):576. https://doi.org/10.3390/su9040576

Chicago/Turabian StyleOliveira, Maria Clara, and Alessandra Magrini. 2017. "Life Cycle Assessment of Lubricant Oil Plastic Containers in Brazil" Sustainability 9, no. 4: 576. https://doi.org/10.3390/su9040576