Biomass Energy Technological Paradigm (BETP): Trends in This Sector

Abstract

:1. Introduction

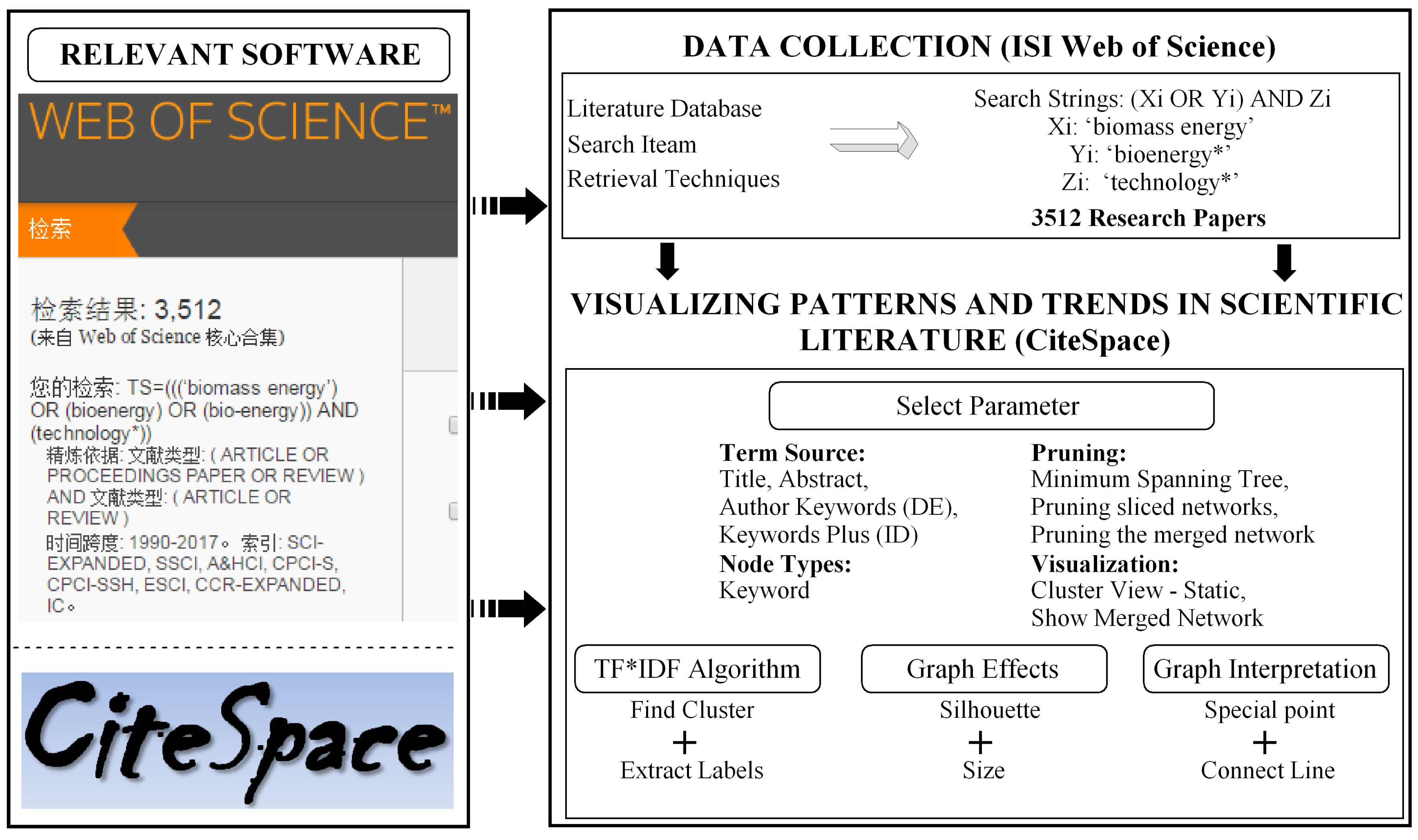

2. Literature Analysis

2.1. The Introduction of the DAS

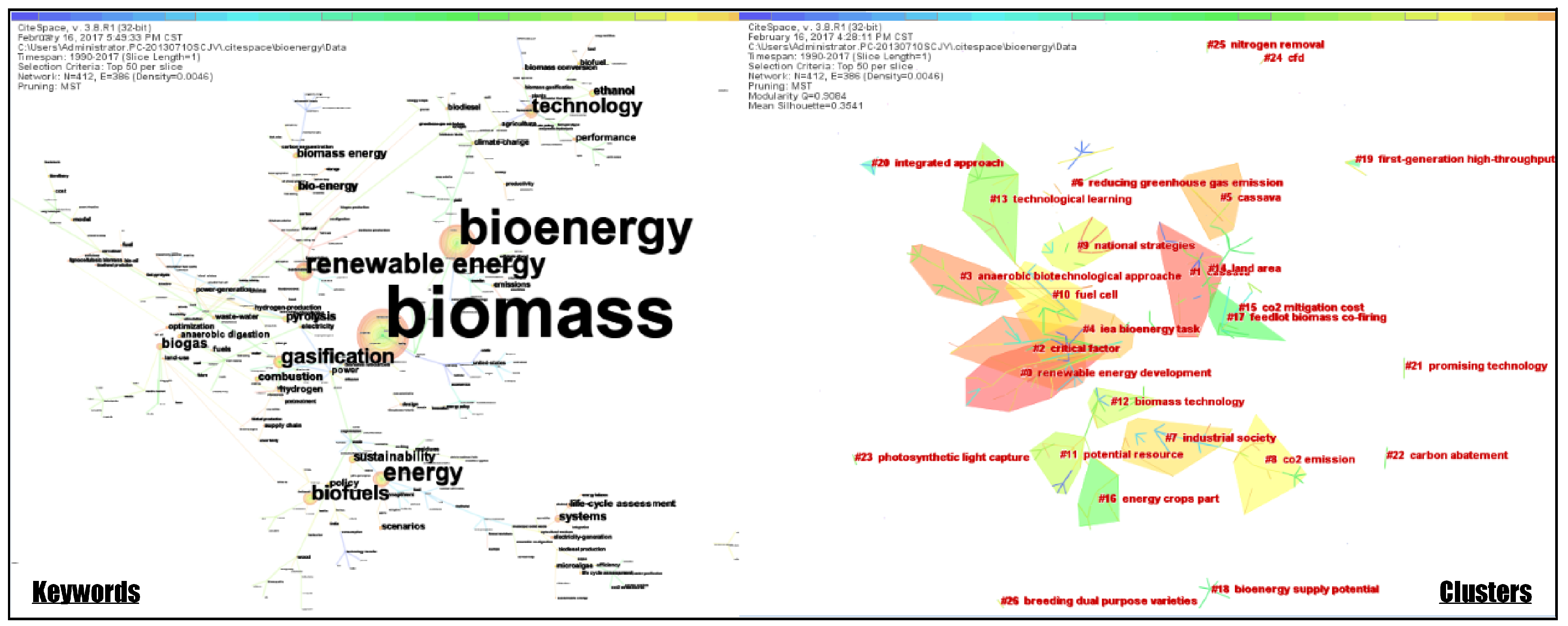

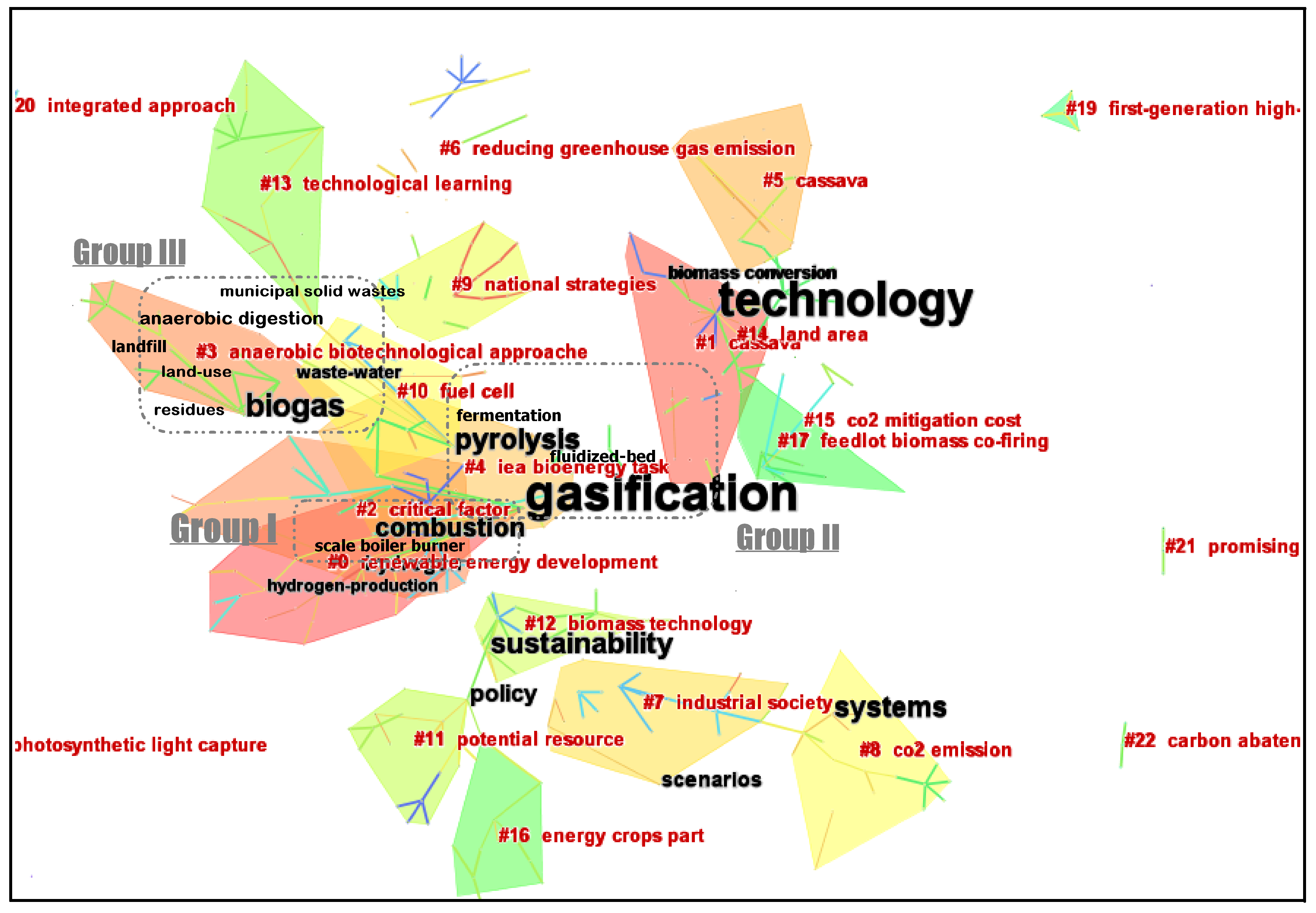

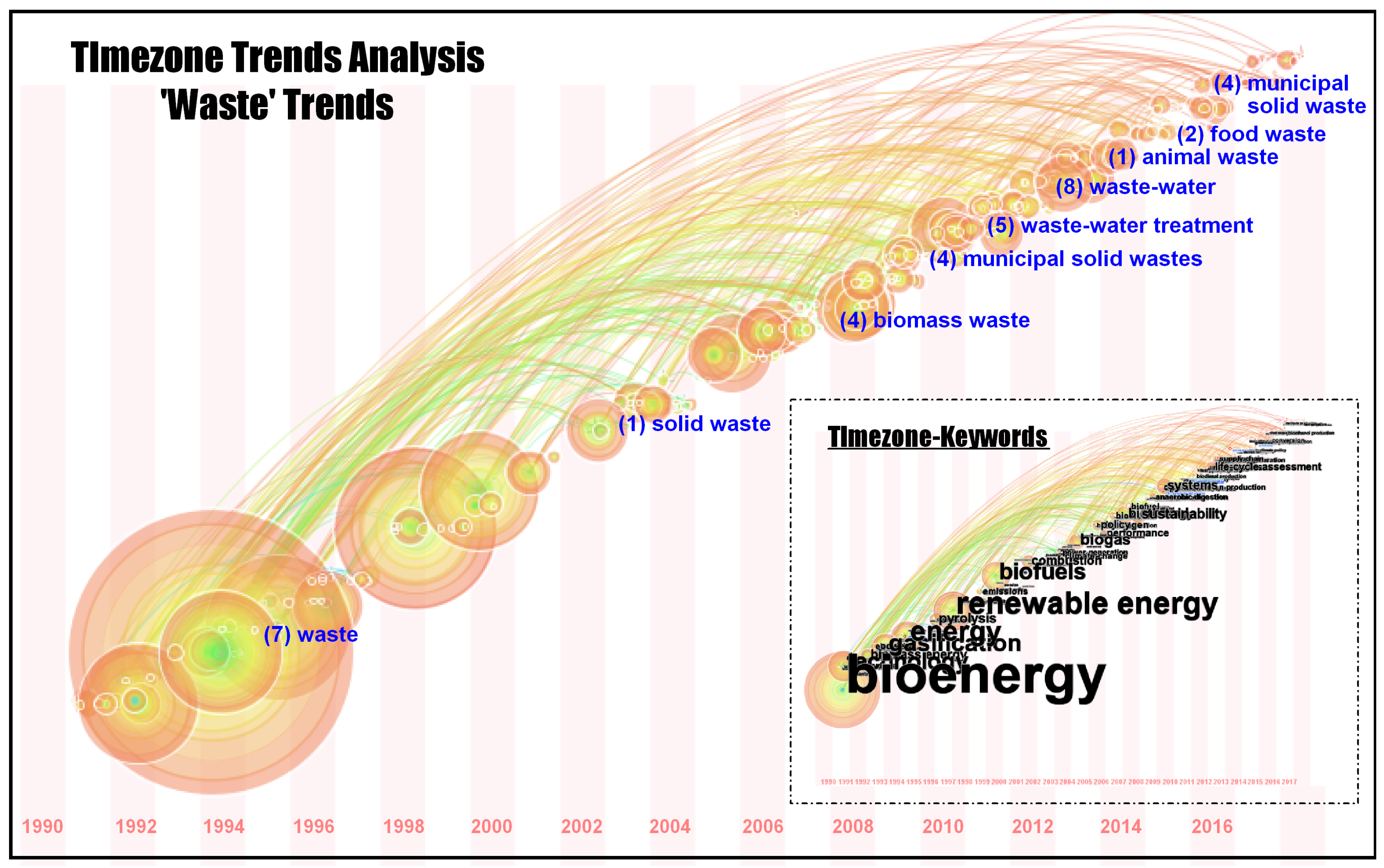

2.2. Keywords Foci Trend Analysis

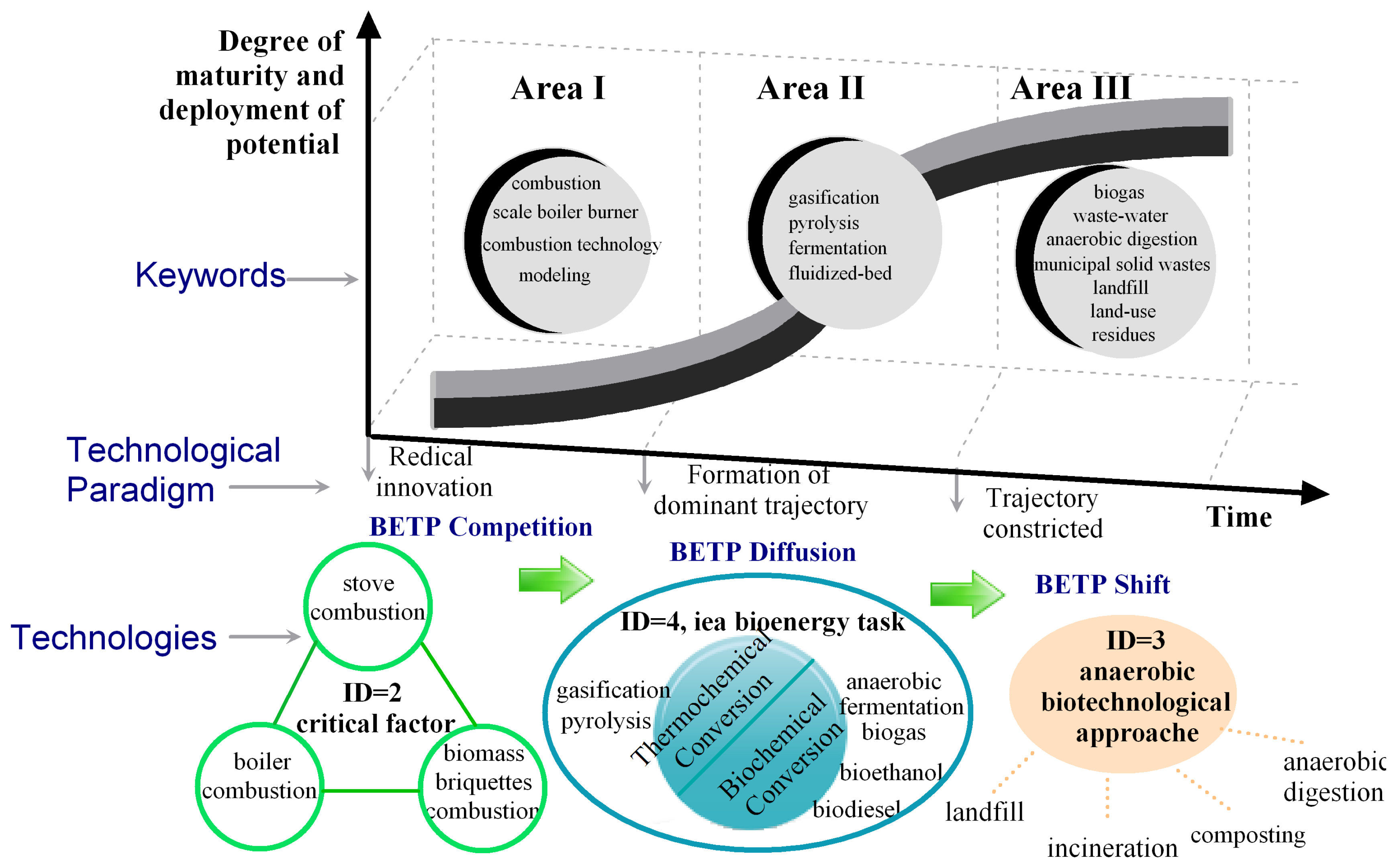

- ID = 2: cluster label is the ‘critical factor’, size = 24 and silhouette = 0.625, mean year = 1998, label (TF*IDF) = 13.23; keywords: combustion, scale boiler burner, combustion technology and modeling (Group I).

- ID = 4: cluster label is ‘iea bioenergy task’, size = 23 and silhouette = 0.643, mean year = 2004, label (TF*IDF) = 9.94; keywords: gasification, pyrolysis, fermentation and fluidized-bed (Group II).

- ID = 3: cluster label is ‘anaerobic biotechnological approach’, size = 23 and silhouette = 0.522, mean year = 2006, label (TF*IDF) = 13.23; keywords: biogas waste-water, anaerobic digestion, municipal solid wastes, landfill, land-use and residues (Group III).

2.3. Analysis Results

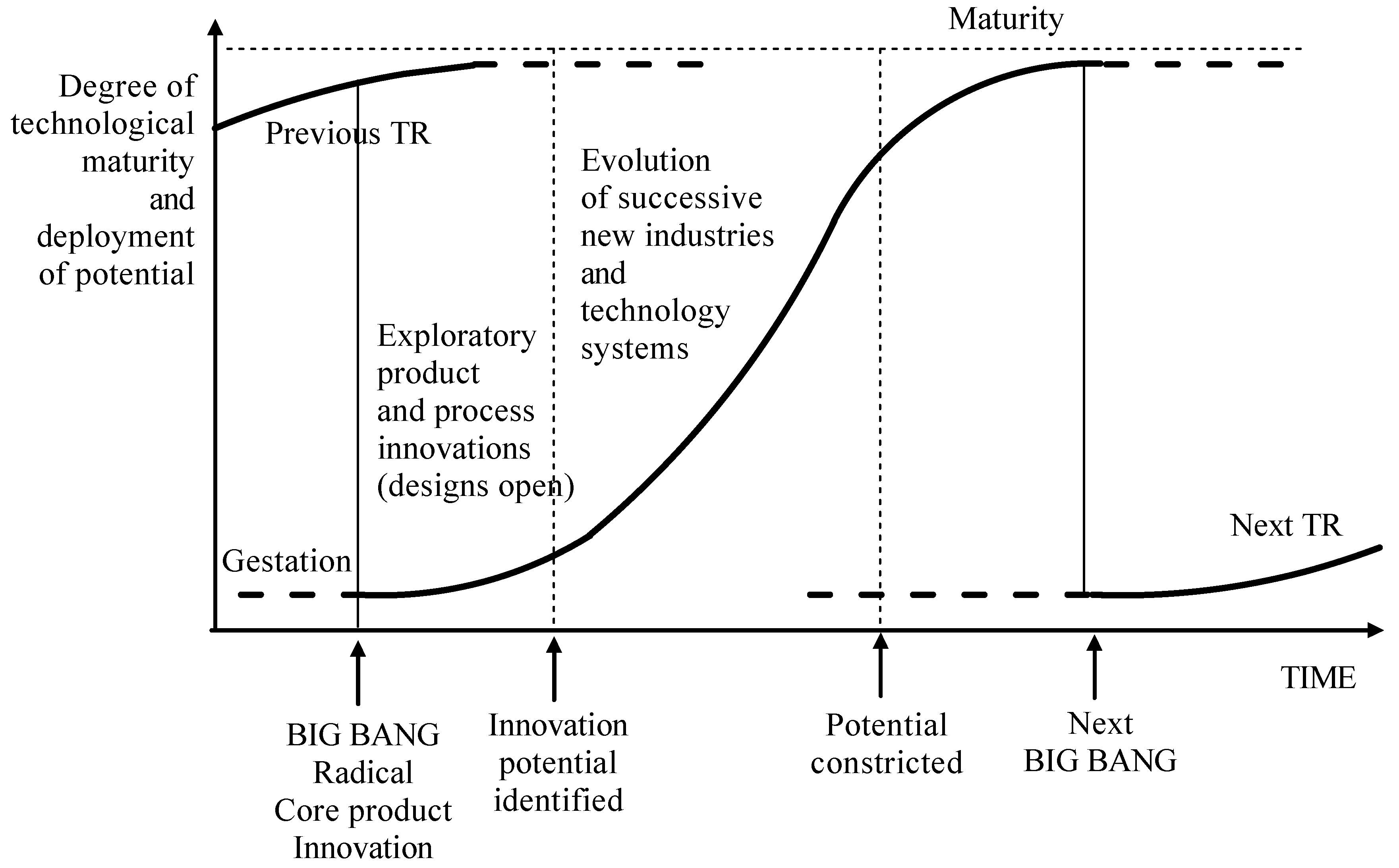

3. The Three Stages of BETP

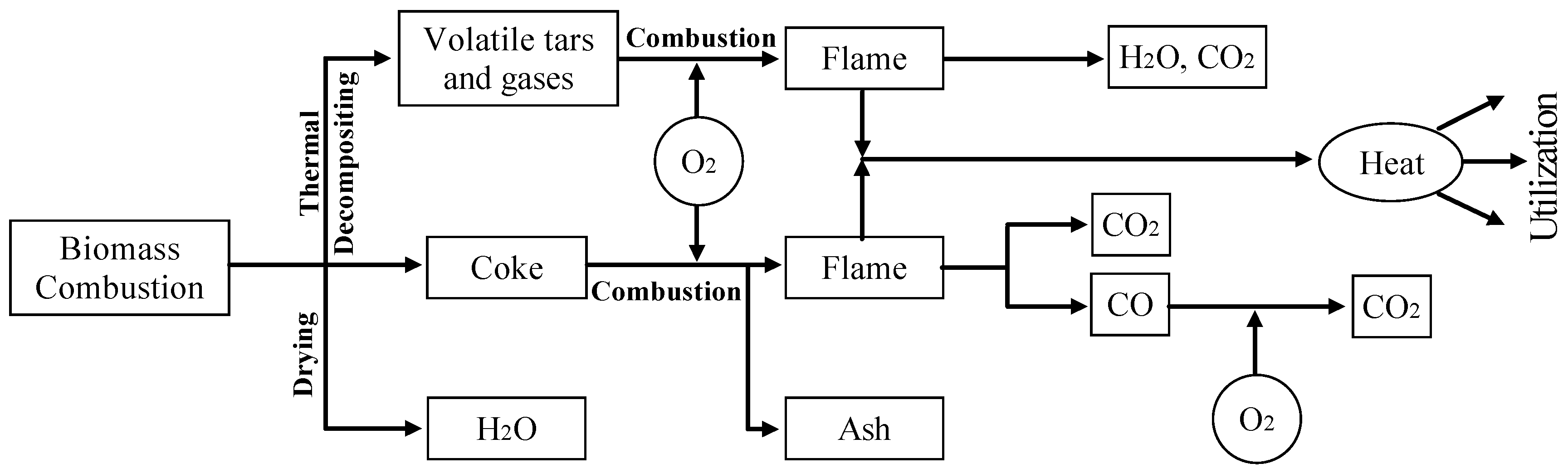

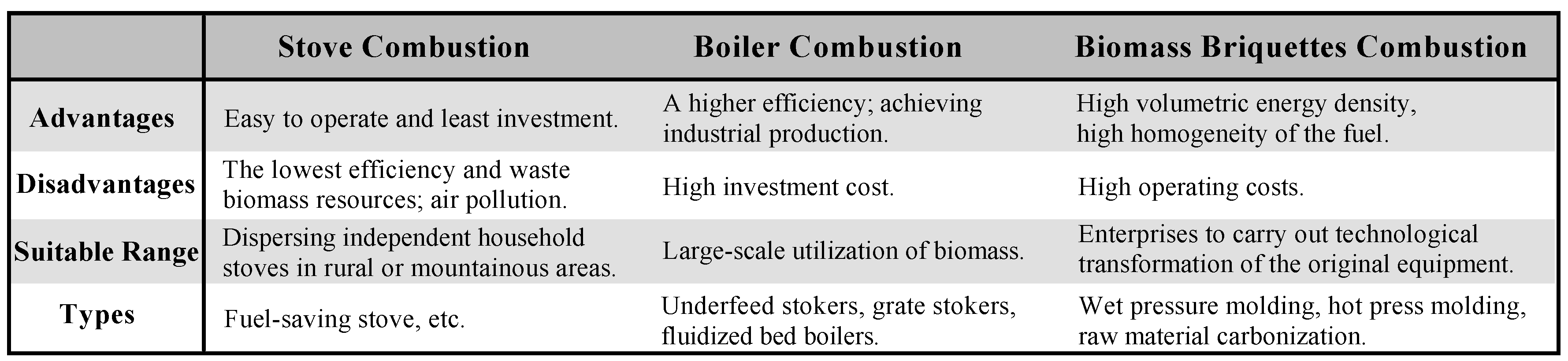

3.1. BETP Competition

3.2. BETP Diffusion

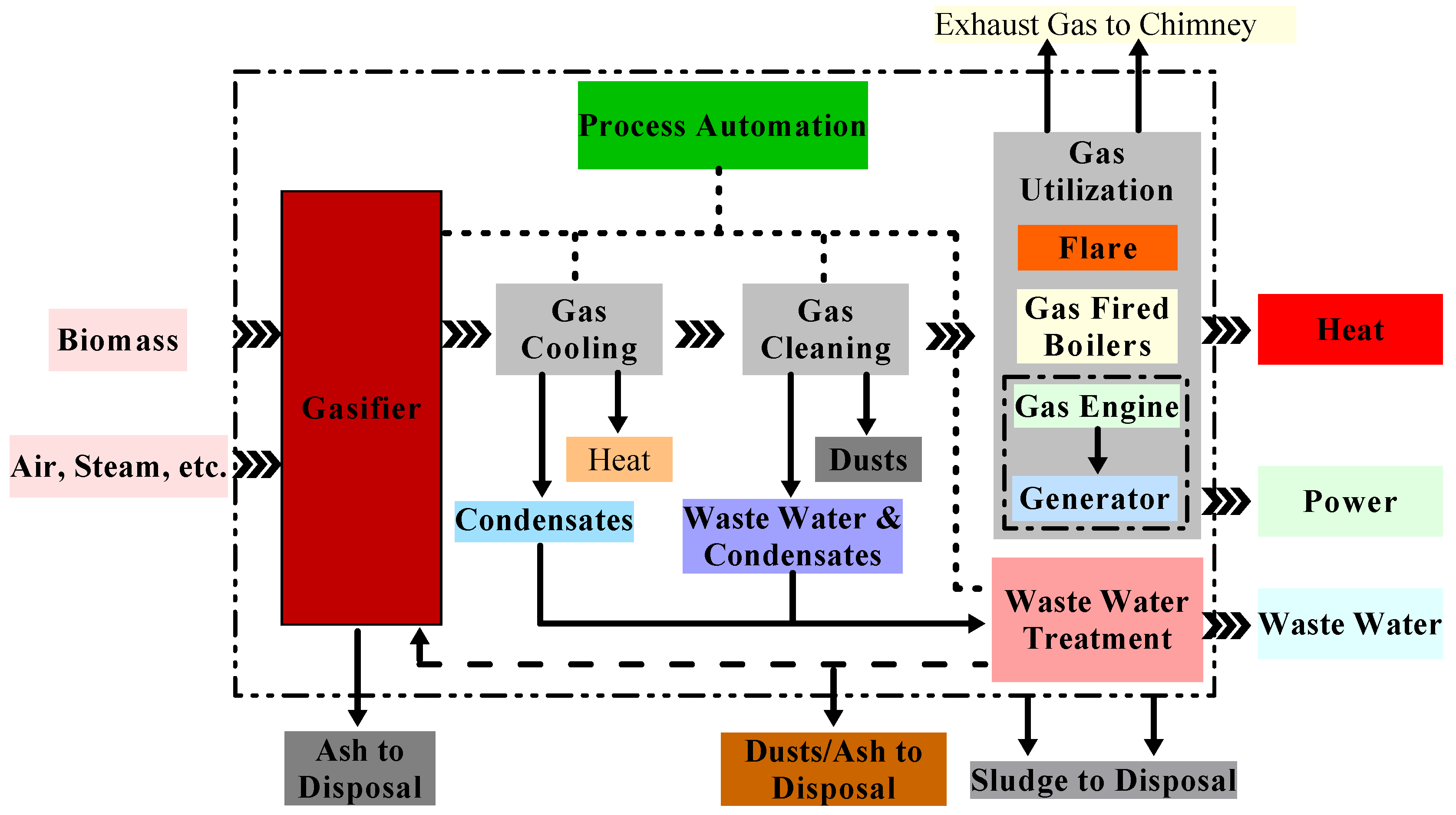

3.2.1. Thermochemical Conversion

3.2.2. Biochemical Conversion

3.3. BETP Shift

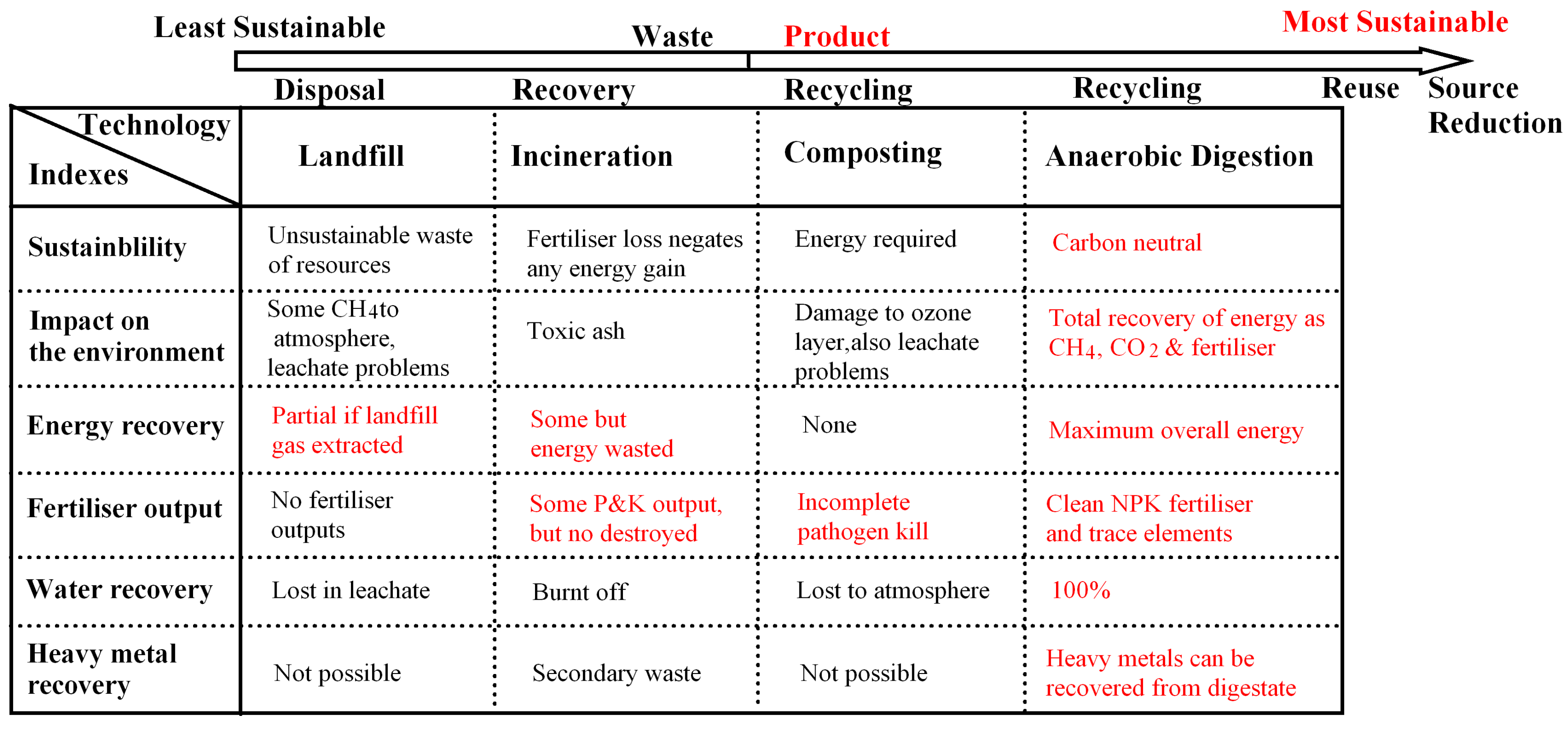

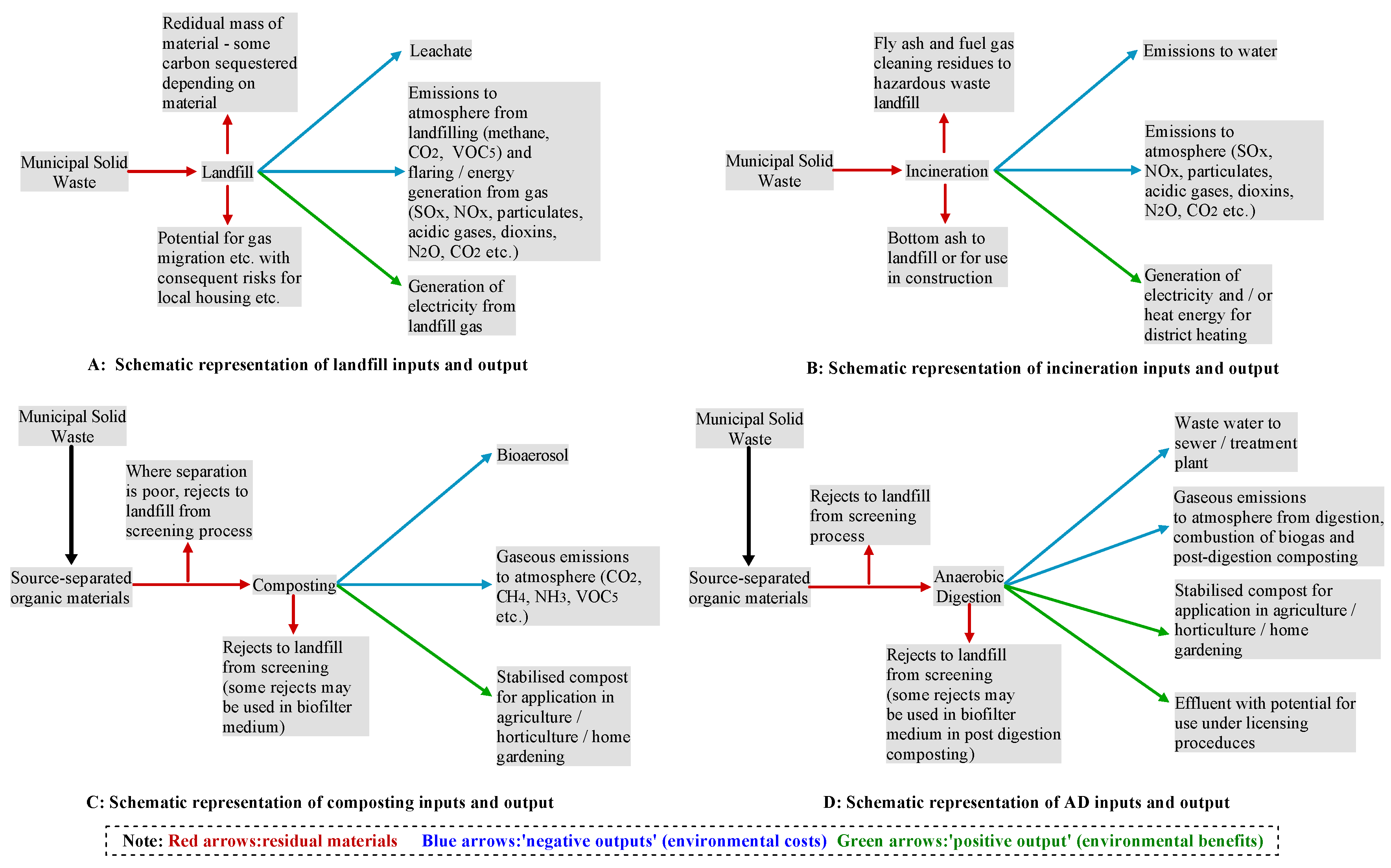

3.3.1. Landfill

3.3.2. Incineration

3.3.3. Composting

3.3.4. Anaerobic Digestion

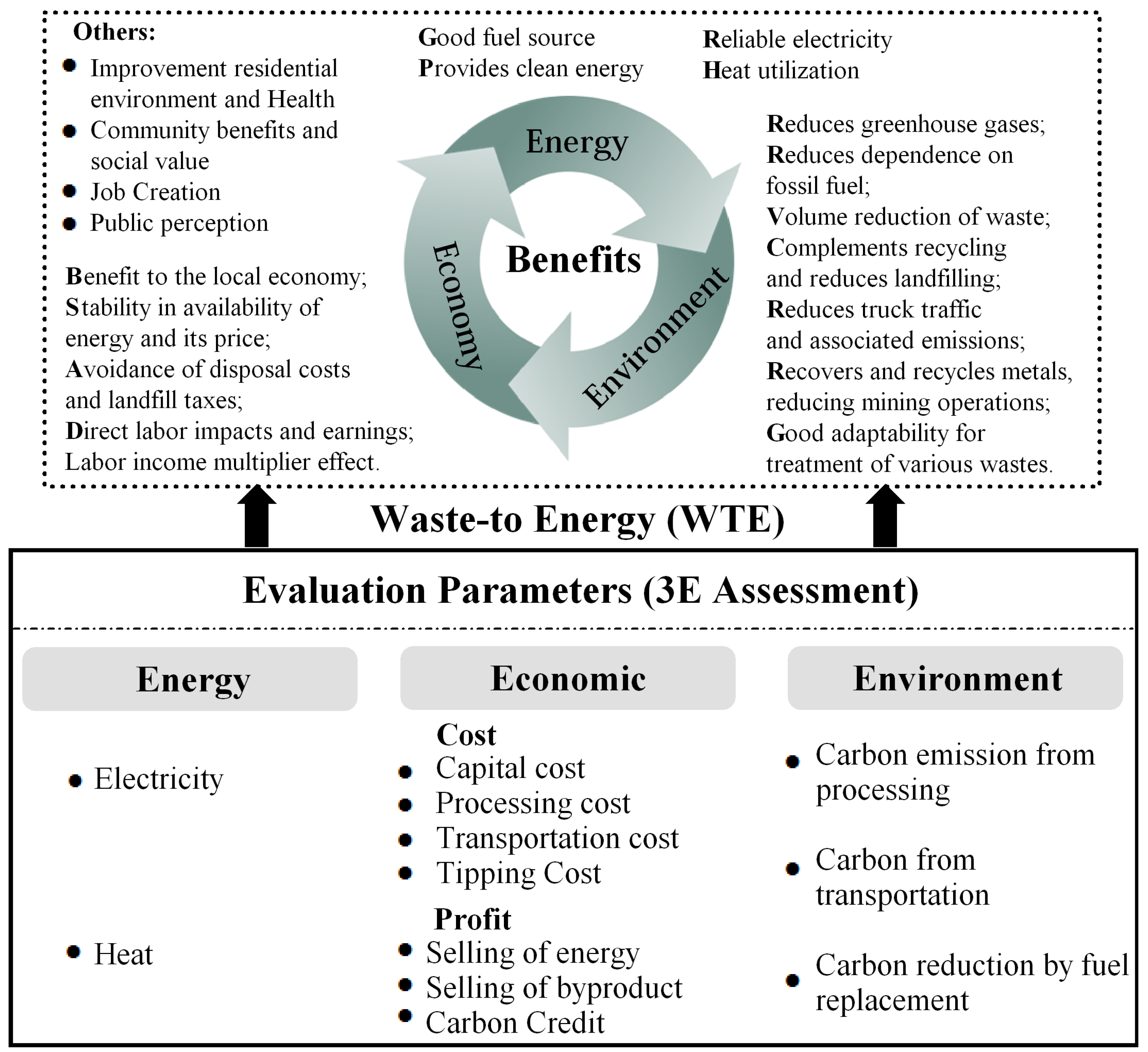

4. Discussion

4.1. Trends from Literature Analysis

4.2. Sustainable MSW Management

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| BETP | Biomass energy technological paradigm |

| MSW | Municipal solid waste |

| WTE | Waste-to-energy |

| DAS | Data analysis system |

| WOS | Web of Science |

| ISI | Institute for Scientific Information |

| SCI-Expanded | Science Citation Index Expanded |

| SSCI | Social Sciences Citation Index |

| A&HCI | Arts & Humanities Citation Index |

| TF*IDF | Term frequency-inverse document frequency |

| AD | Anaerobic digestion |

| LFG | Landfill gas |

| BTU | British Thermal Unit |

| GT | Gas turbines |

| ICE | Internal combustion engine |

| CCP | Combined anaerobic/aerobic Composting Process |

| OFMSW | Organic part of municipal solid waste |

| IEA | International Energy Agency |

| GHG | Greenhouse gas |

| 3E | Energy, economy and environmental |

References

- Conti, J.; Holtberg, P.; Diefenderfer, J.; LaRose, A.; Turnure, J.T.; Westfall, L. International Energy Outlook 2016 with Projections to 2040. Available online: https://www.eia.gov/outlooks/ieo/ (accessed on 24 March 2017).

- Nes, E.H.V.; Scheffer, M.; Brovkin, V.; Lenton, T.M.; Ye, H.; Deyle, E.; Sugihara, G. Causal feedbacks in climate change. Nat. Clim. Chang. 2015, 5, 445–448. [Google Scholar]

- Demirbaş, A. Biomass resource facilities and biomass conversion processing for fuels and chemicals. Energy Convers. Manag. 2001, 42, 1357–1378. [Google Scholar] [CrossRef]

- Rada, E.C.; Ragazzi, M.; Cioca, L.I.; Ionescu, G.; Ranieri, E.; Trulli, E. Renewable energy in the Alps: A case study. Calitatea 2017, 18, 151. [Google Scholar]

- Capuano, D.; Costa, M.; Di Fraia, S.; Massarotti, N.; Vanoli, L. Direct use of waste vegetable oil in internal combustion engines. Renew. Sustain. Energy Rev. 2017, 69, 759–770. [Google Scholar] [CrossRef]

- Chaliki, P.; Psomopoulos, C.S.; Themelis, N.J. WTE plants installed in European cities: A review of success stories. Manag. Environ. Qual. Int. J. 2016, 27, 606–620. [Google Scholar] [CrossRef]

- Marculescu, C.; Alexe, F.; Bacalum, F.; Doncea, S. Alternative fuels production and properties characterization using food industry waste to energy conversion. In Proceedings of the IEEE International Conference on Emerging Technologies and Innovative Business Practices for the Transformation of Societies (EmergiTech), Port Louis, Mauritius, 3–6 August 2016; pp. 345–350. [Google Scholar]

- Rada, E. Energy from municipal solid waste. WIT Trans. Ecol. Environ. 2014, 190, 945–958. [Google Scholar]

- Stan, C.; Badea, A. Thermo-physico-chemical analyses and calorific value of poultry processing industry waste. UPB Sci. Bull. Ser. C 2013, 75, 277–284. [Google Scholar]

- Hernández-Fernández, F.; De Los Ríos, A.P.; Salar-García, M.; Ortiz-Martínez, V.; Lozano-Blanco, L.; Godínez, C.; Tomás-Alonso, F.; Quesada-Medina, J. Recent progress and perspectives in microbial fuel cells for bioenergy generation and wastewater treatment. Fuel Process. Technol. 2015, 138, 284–297. [Google Scholar] [CrossRef]

- Kurchania, A. Biomass energy. In Biomass Conversion; Springer: Berlin, Germany, 2012; pp. 91–122. [Google Scholar]

- Demirbas, A. Progress and recent trends in biofuels. Progr. Energy Combust. Sci. 2007, 33, 1–18. [Google Scholar] [CrossRef]

- Molino, A.; Chianese, S.; Musmarra, D. Biomass gasification technology: The state of the art overview. J. Energy Chem. 2016, 25, 10–25. [Google Scholar] [CrossRef]

- Chianese, S.; Loipersböck, J.; Malits, M.; Rauch, R.; Hofbauer, H.; Molino, A.; Musmarra, D. Hydrogen from the high temperature water gas shift reaction with an industrial Fe/Cr catalyst using biomass gasification tar rich synthesis gas. Fuel Process. Technol. 2015, 132, 39–48. [Google Scholar] [CrossRef]

- Chianese, S.; Fail, S.; Binder, M.; Rauch, R.; Hofbauer, H.; Molino, A.; Blasi, A.; Musmarra, D. Experimental investigations of hydrogen production from CO catalytic conversion of tar rich syngas by biomass gasification. Catal. Today 2016, 277, 182–191. [Google Scholar] [CrossRef]

- Molino, A.; Nanna, F.; Villone, A. Characterization of biomasses in the southern Italy regions for their use in thermal processes. Appl. Energy 2014, 131, 180–188. [Google Scholar] [CrossRef]

- Bulushev, D.A.; Ross, J.R.H. Catalysis for conversion of biomass to fuels via pyrolysis and gasification: A review. Catal. Today 2011, 171, 1–13. [Google Scholar] [CrossRef]

- Mata-Alvarez, J.; Mace, S.; Llabres, P. Anaerobic digestion of organic solid wastes. An overview of research achievements and perspectives. Bioresour. Technol. 2000, 74, 3–16. [Google Scholar] [CrossRef]

- Chen, C.; Ibekwe-Sanjuan, F.; Hou, J. The structure and dynamics of cocitation clusters: A multiple-perspective cocitation analysis. J. Assoc. Inf. Sci. Technol. 2010, 61, 1386–1409. [Google Scholar] [CrossRef]

- Chen, C. CiteSpace II: Detecting and visualizing emerging trends and transient patterns in scientific literature. J. Assoc. Inf. Sci. Technol. 2006, 57, 359–377. [Google Scholar] [CrossRef]

- Li, X.; Ma, E.; Qu, H. Knowledge mapping of hospitality research? A visual analysis using CiteSpace. Int. J. Hosp. Manag. 2017, 60, 77–93. [Google Scholar] [CrossRef]

- Zheng, B.; Xu, J.; Ni, T.; Li, M. Geothermal energy utilization trends from a technological paradigm perspective. Renew. Energy 2015, 77, 430–441. [Google Scholar] [CrossRef]

- Xu, J.P.; Li, M.H.; Ni, T. Feedstock for Bioethanol Production from a Technological Paradigm Perspective. Bioresources 2015, 10, 6285–6304. [Google Scholar] [CrossRef]

- Xu, J.; Li, M. Innovative technological paradigm-based approach towards biofuel feedstock. Energy Convers. Manag. 2016, 4, 075. [Google Scholar] [CrossRef]

- Kuhn, T. The Structure of Scientific Revolution; University of Chicago Press: Chicago, IL, USA, 1962. [Google Scholar]

- Dosi, G. Technological paradigms and technological trajectories: A suggested interpretation of the determinants and directions of technical change. Res. Policy 1982, 11, 147–162. [Google Scholar] [CrossRef]

- Van den Ende, J.; Dolfsma, W. Technology-push, demand-pull and the shaping of technological paradigms-Patterns in the development of computing technology. J. Evol. Econ. 2005, 15, 83–99. [Google Scholar] [CrossRef]

- Ayres, R.U. Barriers and breakthroughs: An “expanding frontiers” model of the technology-industry life cycle. Technovation 1988, 7, 87–115. [Google Scholar] [CrossRef]

- Kim, J.; Lee, J.; Kim, G.; Park, S.; Jang, D. A Hybrid Method of Analyzing Patents for Sustainable Technology Management in Humanoid Robot Industry. Sustainability 2016, 8, 474. [Google Scholar] [CrossRef]

- Kim, J.; Lee, S.; Shim, W.; Kang, J. A Mapping of Marine Biodiversity Research Trends and Collaboration in the East Asia Region from 1996 to 2015. Sustainability 2016, 8, 1075. [Google Scholar] [CrossRef]

- Pang, H. A knowledge discovery method based on analysis of multiple co-occurrence relationships in collections of journal papers. Chin. J. Libr. Inf. Sci. 2012, 5, 9–20. [Google Scholar]

- Falagas, M.E.; Pitsouni, E.I.; Malietzis, G.A.; Pappas, G. Comparison of PubMed, Scopus, Web of Science, and Google Scholar: Strengths and weakness. FASEB J. 2008, 22, 338–342. [Google Scholar] [CrossRef] [PubMed]

- Aghaei Chadegani, A.; Salehi, H.; Yunus, M.M.; Farhadi, H.; Fooladi, M.; Farhadi, M.; Ale Ebrahim, N. A Comparison between Two Main Academic Literature Collections: Web of Science and Scopus Databases. Asian Soc. Sci. 2013, 9, 18–26. [Google Scholar] [CrossRef]

- Archambault, É.; Campbell, D.; Gingras, Y.; Larivière, V. Comparing bibliometric statistics obtained from the Web of Science and Scopus. J. Assoc. Inf. Sci. Technol. 2009, 60, 1320–1326. [Google Scholar] [CrossRef]

- Leydesdorff, L.; Carley, S.; Rafols, I. Global maps of science based on the new Web-of-Science categories. Scientometrics 2013, 94, 589–593. [Google Scholar] [CrossRef] [PubMed]

- Griffiths, T.L.; Steyvers, M. Colloquium Paper: Mapping Knowledge Domains: Finding scientific topics. Proc. Natl. Acad. Sci. USA 2004, 101, 5228–5235. [Google Scholar] [CrossRef] [PubMed]

- Synnestvedt, M.B.; Chen, C.; Holmes, J.H. CiteSpace II: Visualization and Knowledge Discovery in Bibliographic Databases. Available online: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC1560567/ (accessed on 24 March 2017).

- Wang, G.; Yu, S.; Huang, H.; Hu, Y. Visualization Analysis of Chinese Distance Education Research: Based on the Core Literature, Research Hotspots and Research Frontier. Available online: http://en.cnki.com.cn/Article_en/CJFDTotal-YCJY201501008.htm (accessed on 24 March 2017).

- Liu, D.D.; Liu, S.L.; Zhang, J.H. Visualization analysis of research hotspots based on CiteSpace II: Taking medical devices as an example. Med. Devices Evid. Res. 2014, 7, 357–361. [Google Scholar] [CrossRef] [PubMed]

- Bourianoff, G.; Brewer, J.E.; Cavin, R.; Hutchby, J.A.; Zhirnov, V. Boolean Logic and Alternative Information-Processing Devices. Computer 2008, 41, 38–46. [Google Scholar] [CrossRef]

- Reddy, D.; Register, L.F.; Tutuc, E.; Banerjee, S.K. Bilayer Pseudospin Field-Effect Transistor: Applications to Boolean Logic. IEEE Trans. Electron Devices 2010, 57, 755–764. [Google Scholar] [CrossRef]

- Kuhn, T.S. The Structure of Scientific Revolutions. Isis 1963, 31, 554–555. [Google Scholar]

- Willinger, M.; Zuscovitch, E. Efficience, irréversibilités et constitution des technologies. Rev. Décon. Ind. 1993, 65, 7–22. [Google Scholar] [CrossRef]

- Demirbas, A. Combustion characteristics of different biomass fuels. Prog. Energy Combust. Sci. 2004, 30, 219–230. [Google Scholar] [CrossRef]

- Li, Z. Biomass Direct Combustion Power Generation in China: Present Situation, Problems and Policy Suggestions. Technol. Econ. 2008, 27, 34–37. [Google Scholar]

- Koppejan, J.; Van Loo, S. The Handbook of Biomass Combustion and Co-Firing; Routledge: Abingdon, UK, 2012. [Google Scholar]

- Obernberger, I. State-of-the-art of small-scale biomass combustion in boilers. Available online: http://www.ieabcc.nl/workshops/task32_Dublin_SSC/05%20Obernberger.pdf (accessed on 24 March 2017).

- Li, J.; Xing, Z.; Delaquil, P.; Larson, E.D. Biomass energy in China and its potential. Energy Sustain. Dev. 2001, 5, 66–80. [Google Scholar]

- Roy, M.M.; Corscadden, K.W. An experimental study of combustion and emissions of biomass briquettes in a domestic wood stove. Appl. Energy 2012, 99, 206–212. [Google Scholar] [CrossRef]

- Smith, K.R. Health, energy, and greenhouse-gas impacts of biomass combustion in household stoves. Energy Sustain. Dev. 1994, 1, 23–29. [Google Scholar] [CrossRef]

- Ndiema, C.K.W.; Mpendazoe, F.M.; Williams, A. Emission of pollutants from a biomass stove. Energy Convers. Manag. 1998, 39, 1357–1367. [Google Scholar] [CrossRef]

- Saidur, R.; Abdelaziz, E.A.; Demirbas, A.; Hossain, M.S.; Mekhilef, S. A review on biomass as a fuel for boilers. Renew. Sustain. Energy Rev. 2011, 15, 2262–2289. [Google Scholar] [CrossRef]

- Nussbaumer, T.; Hustad, J.E. Overview of Biomass Combustion; Springer: Dordrecht, The Netherlands, 1997; pp. 1229–1243. [Google Scholar]

- Caldera, M.; Roberto, R.; Flores Brand, F.; Masoero, M.C. Analysis of a Concentrating Solar Power Generation System Integrated with Biomass Boiler. Available online: http://www.etaflorence.it/proceedings/?detail=11488 (accessed on 24 March 2017).

- Kaliyan, N.; Morey, R.V. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Hartmann, H.; Kaltschmitt, M. Energie aus Biomasse: Grundlagen, Techniken und Verfahren; Springer: Berlin, Germany, 2001. [Google Scholar]

- Chen, L.; Xing, L.; Han, L. Renewable energy from agro-residues in China: Solid biofuels and biomass briquetting technology. Renew. Sustain. Energy Rev. 2009, 13, 2689–2695. [Google Scholar] [CrossRef]

- Li, M. Stress Analysis and Determination of Geometry Parameters in Plastic Zone of wheel groove for continuous extrusion. J. Plast. Eng. 1999, 6, 25–30. [Google Scholar]

- Williams, A.; Jones, J.; Ma, L.; Pourkashanian, M. Pollutants from the combustion of solid biomass fuels. Progr. Energy Combust. Sci. 2012, 38, 113–137. [Google Scholar] [CrossRef]

- Tanger, P.; Field, J.L.; Jahn, C.E.; Defoort, M.W.; Leach, J.E. Biomass for thermochemical conversion: Targets and challenges. Front. Plant Sci. 2013, 4, 218. [Google Scholar] [CrossRef] [PubMed]

- Damartzis, T.; Zabaniotou, A. Thermochemical conversion of biomass to second generation biofuels through integrated process design—A review. Renew. Sustain. Energy Rev. 2011, 15, 366–378. [Google Scholar] [CrossRef]

- Kothari, R.; Tyagi, V.V.; Panwar, N.L. Thermo Chemical Conversion of Biomass—Eco Friendly Energy Routes. Renew. Sustain. Energy Rev. 2012, 16, 1801–1816. [Google Scholar]

- McKendry, P. Energy production from biomass (part 2): Conversion technologies. Bioresour. Technol. 2002, 83, 47–54. [Google Scholar] [CrossRef]

- Verkooijen, A.H.M. Fluidized bed gasification as a mature and reliable technology for the production of bio-syngas and applied in the production of liquid transportation fuels—A review. Energies 2011, 4, 389. [Google Scholar]

- Goyal, H.; Seal, D.; Saxena, R. Bio-fuels from thermochemical conversion of renewable resources: A review. Renew. Sustain. Energy Rev. 2008, 12, 504–517. [Google Scholar] [CrossRef]

- Zafar, S. Importance of Biomass Energy. Available online: http://www.bioenergyconsult.com/tag/importance-of-biomass-energy/ (accessed on 24 March 2017).

- Warnecke, R. Gasification of biomass: Comparison of fixed bed and fluidized bed gasifier. Biomass Bioenergy 2000, 18, 489–497. [Google Scholar] [CrossRef]

- Kohl, A.L. Filtering Method and Apparatus Therefor. Available online: http://www.freepatentsonline.com/4360364.html (accessed on 24 March 2017).

- Xiao, G.; Wang, X.; Zhang, J.; Ni, M.; Gao, X.; Luo, Z.; Cen, K. Granular bed filter: A promising technology for hot gas clean-up. Powder Technol. 2013, 244, 93–99. [Google Scholar] [CrossRef]

- Asadullah, M. Barriers of commercial power generation using biomass gasification gas: A review. Renew. Sustain. Energy Rev. 2014, 29, 201–215. [Google Scholar] [CrossRef]

- Cheng, S.; Wei, L.; Zhao, X.; Julson, J. Application, Deactivation, and Regeneration of Heterogeneous Catalysts in Bio-Oil Upgrading. Catalysts 2016, 6, 195. [Google Scholar] [CrossRef]

- Bridgwater, A.V. Review of fast pyrolysis of biomass and product upgrading. Biomass Bioenergy 2012, 38, 68–94. [Google Scholar] [CrossRef]

- Akash, B. Thermochemical Depolymerization of Biomass. Procedia Comput. Sci. 2015, 52, 827–834. [Google Scholar] [CrossRef]

- Li, X.X.; Shu, X.Q.; Li, G.; Zhang, L.; Zhang, L.; Zhang, L.X.; Zhang, Y.; Jia, Y.M. Study on the pyrolysis and kinetics of three agro-forestry biomass. Renew. Energy Resources 2010, 28, 63–70. [Google Scholar]

- Rostek, E.; Biernat, K. Liquid biofuels of the first and second generation—The method of preparation and application. J. Pol. CIMAC 2012, 7, 191–199. [Google Scholar]

- Demirbas, A.; Arin, G. An Overview of Biomass Pyrolysis. Energy Sources 2002, 24, 471–482. [Google Scholar] [CrossRef]

- Pereira, J.; Agblevor, F.A.; Beis, S.H. The Influence of Process Conditions on the Chemical Composition of Pine Wood Catalytic Pyrolysis Oils. Isrn Renew. Energy 2012, 2012, 167629. [Google Scholar] [CrossRef]

- Balat, M.; Balat, M.; Kırtay, E.; Balat, H. Main routes for the thermo-conversion of biomass into fuels and chemicals. Part 1: Pyrolysis systems. Energy Convers. Manag. 2009, 50, 3147–3157. [Google Scholar] [CrossRef]

- Mohan, D.; Pittman, C.U.; Steele, P.H. Pyrolysis of Wood/Biomass for Bio-Oil: A Critical Review. Energy Fuels 2006, 20, 848–889. [Google Scholar] [CrossRef]

- Basu, P.; Basu, P. Biomass Gasification and Pyrolysis: Practical Design and Theory; Academic Press: Cambridge, MC, USA, 2010; Volume 25, pp. 141–158. [Google Scholar]

- Balat, M. Biomass Energy and Biochemical Conversion Processing for Fuels and Chemicals. Energy Sources Part A Recovery Util. Environ. Effects 2006, 28, 517–525. [Google Scholar] [CrossRef]

- Shilton, A.N.; Mara, D.D.; Craggs, R.; Powell, N. Solar-powered aeration and disinfection, anaerobic co-digestion, biological CO2 scrubbing and biofuel production: The energy and carbon management opportunities of waste stabilisation ponds. Water Sci. Technol. 2008, 58, 253–258. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Schanbacher, F.L. Production of Methane Biogas as Fuel through Anaerobic Digestion; Springer: Berlin, Germany, 2009; pp. 105–127. [Google Scholar]

- Gunaseelan, V.N. Anaerobic digestion of biomass for methane production: A review. Biomass Bioenergy 1997, 13, 83–114. [Google Scholar] [CrossRef]

- Cioabla, A.E.; Ionel, I.; Dumitrel, G.A.; Popescu, F. Comparative study on factors affecting anaerobic digestion of agricultural vegetal residues. Biotechnol. Biofuels 2012, 5, 39. [Google Scholar] [CrossRef] [PubMed]

- Ali Shah, F.; Mahmood, Q.; Maroof Shah, M.; Pervez, A.; Ahmad Asad, S. Microbial ecology of anaerobic digesters: The key players of anaerobiosis. Sci. World J. 2014, 2014, 183752. [Google Scholar] [CrossRef] [PubMed]

- Shepard, M.S. Microwave-Based Alkali Pretreatment of Newspaper for Enhanced Methane Production. Ph.D. Thesis, Tennessee Technological University, Cookeville, TN, USA, 2011. [Google Scholar]

- Chynoweth, D.P.; Owens, J.M.; Legrand, R. Renewable methane from anaerobic digestion of biomass. Renew. Energy 2001, 22, 1–8. [Google Scholar] [CrossRef]

- Xuan, T.D.; Phuong, N.T.; Khang, D.T.; Khanh, T.D. Influence of sowing times, densities, and soils to biomass and ethanol yield of sweet sorghum. Sustainability 2015, 7, 11657–11678. [Google Scholar] [CrossRef]

- Hamelinck, C.N.; Hooijdonk, G.V.; Faaij, A.P.C. Prospects for Ethanol from Lignocellulosic Biomass: Techno-Ecnomic Performance as Development Progress. Available online: https://books.google.com.hk/books/about/Prospects_for_Ethanol_from_Lignocellulos.html?id=NNmFGwAACAAJ&redir_esc=y (accessed on 24 March 2017).

- Lynd, L.R.; Laser, M.S.; Bransby, D.; Dale, B.E.; Davison, B.; Hamilton, R.; Himmel, M.; Keller, M.; Mcmillan, J.D.; Sheehan, J. How biotech can transform biofuels. Nat. Biotechnol. 2008, 26, 169–172. [Google Scholar] [CrossRef] [PubMed]

- Cardona, C.A.; Sánchez, Ó.J. Fuel ethanol production: Process design trends and integration opportunities. Bioresour. Technol. 2007, 98, 2415–2457. [Google Scholar] [CrossRef] [PubMed]

- Demirbas, A. Biofuels from Agricultural Biomass. Energy Sources Part A Recovery Util. Environ. Effects 2009, 31, 1573–1582. [Google Scholar] [CrossRef]

- Quintero, J.A.; Cardona, C.A. Ethanol Dehydration by Adsorption with Starchy and Cellulosic Materials. Ind. Eng. Chem. Res. 2009, 48, 6783–6788. [Google Scholar] [CrossRef]

- Vasudevan, P.; Sharma, S.; Kumar, A. Liquid fuel from biomass: An overview. J. Sci. Ind. Res. 2005, 64, 822–831. [Google Scholar]

- Schubert, C. Can biofuels finally take center stage? Nat. Biotechnol. 2006, 24, 777–784. [Google Scholar] [CrossRef] [PubMed]

- Demirbas, A. Use of algae as biofuel sources. Energy Convers. Manag. 2010, 51, 2738–2749. [Google Scholar] [CrossRef]

- Demirbas, A. Biofuels securing the planet’s future energy needs. Energy Convers. Manag. 2009, 50, 2239–2249. [Google Scholar] [CrossRef]

- Pradeep, P.; Reddy, O.V.S. Effect of supplementation of malted cowpea (Vigna Unguiculata L.) flour in the enhancement of yeast cell viability and ethanol production in VHG fermentation. Asian J. Microbiol. Biotechnol. Environ. Sci. 2008, 10, 767–772. [Google Scholar]

- Bisig, C.; Roth, M.; Müller, L.; Comte, P.; Heeb, N.; Mayer, A.; Czerwinski, J.; Petri-Fink, A.; Rothen-Rutishauser, B. Hazard identification of exhausts from gasoline-ethanol fuel blends using a multi-cellular human lung model. Environ. Res. 2016, 151, 789–796. [Google Scholar] [CrossRef] [PubMed]

- Lateef, F.A.; Onukwuli, O.D.; Okoro, U.C.; Ejikeme, P.M.; Jere, P. Some physical properties and oxidative stability of biodiesel produced from oil seed crops. Korean J. Chem. Eng. 2014, 31, 725–731. [Google Scholar] [CrossRef]

- Alsoudy, A.; Thomsen, M.H.; Janajreh, I. Influence on process parameters in transesterification of vegetable and waste oil—A review. Int. J. Res. Rev. Appl. Sci. 2012, 10, 64–77. [Google Scholar]

- Shen, G.Y. Progress in Technology for Biodiesel Production. Available online: http://www.sciencedirect.com/science/book/9780857091178 (accessed on 24 March 2017).

- Bournay, L.; Hillion, G.; Boucot, P.; Chodorge, J.A.; Bronner, C.; Forestiere, A. Process for Producing Alkyl Esters from a Vegetable or Animal Oil and an Aliphatic Monoalcohol. U.S. Patent 6,878,837, 12 April 2005. Available online: https://docs.google.com/viewer?url=patentimages.storage.googleapis.com/pdfs/US6878837.pdf (accessed on 8 April 2017).

- Zhang, T.; Yuan, Y.N. Environmental and Economic Benefit of Biodiesel. Energy Environ. Prot. 2005, 2, 16–19. [Google Scholar]

- Hill, J.; Nelson, E.; Tilman, D.; Polasky, S.; Tiffany, D. Environmental, economic, and energetic costs and benefits of biodiesel and ethanol biofuels. Proc. Natl. Acad. Sci. USA 2006, 103, 11206–11210. [Google Scholar] [CrossRef] [PubMed]

- Stoeglehner, G.; Narodoslawsky, M. How sustainable are biofuels: Answers and further questions arising from an ecological footprint perspective. Bioresour. Technol. 2009, 100, 3825–3830. [Google Scholar] [CrossRef] [PubMed]

- Lianpin, K.; Ghazoul, J. Biofuels, biodiversity, and people: Understanding the conflicts and finding opportunities. Biol. Conserv. 2008, 141, 2450–2460. [Google Scholar]

- Christensen, C.M. The Innovator’s Dilemma: When New Technologies Cause Great Firms to Fail. Soc. Sci. Electron. Publ. 2016, 8, 661–662. [Google Scholar]

- Dalgleish, H.Y.; Foster, I.D.L. 137Cs losses from a loamy surface water gleyed soil (Inceptisol); a laboratory simulation experiment. Catena 1996, 26, 227–245. [Google Scholar] [CrossRef]

- Gug, J.; Cacciola, D.; Sobkowicz, M.J. Processing and properties of a solid energy fuel from municipal solid waste (MSW) and recycled plastics. Waste Manag. 2014, 35, 283–292. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Meng, A.H.; Long, Y.Q.; Li, Q.H.; Zhang, Y.G. ChemInform Abstract: An Overview of Characteristics of Municipal Solid Waste Fuel in China: Physical, Chemical Composition and Heating Value. Renew. Sustain. Energy Rev. 2014, 36, 107–122. [Google Scholar] [CrossRef]

- Udomsri, S.; Petrov, M.P.; Martin, A.R.; Fransson, T.H. Clean energy conversion from municipal solid waste and climate change mitigation in Thailand: Waste management and thermodynamic evaluation. Energy Sustain. Dev. 2011, 15, 355–364. [Google Scholar] [CrossRef]

- Cyranoski, D. Waste management: One man’s trash... Nature 2006, 444, 262–263. [Google Scholar] [CrossRef] [PubMed]

- Kumarappan, S.; Joshi, S.; Maclean, H.L. Biomass supply for biofuel production: Estimates for the United States and Canada. Bioresources 2009, 4, 1070–1087. [Google Scholar]

- Kwon, E.E.; Castaldi, M.J. Urban energy mining from municipal solid waste (MSW) via the enhanced thermo-chemical process by carbon dioxide (CO2) as a reaction medium. Bioresour. Technol. 2012, 124, 23–29. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.D. An integrated biomass production and conversion process for sustainable bioenergy. Sustainability 2015, 7, 522–536. [Google Scholar] [CrossRef]

- Davis, G.; Song, J.H. Biodegradable packaging based on raw materials from crops and their impact on waste management. Ind. Crops Prod. 2006, 23, 147–161. [Google Scholar] [CrossRef]

- Gertsakis, J.; Lewis, H. Sustainability and the Waste Management Hierarchy; Retrieved on January. Available online: http://www.helenlewisresearch.com.au/wp-content/uploads/2014/05/TZW_-_Sustainability_and_the_Waste_Hierarchy_2003.pdf (accessed on 24 March 2017).

- Gharfalkar, M.; Court, R.; Campbell, C.; Ali, Z.; Hillier, G. Analysis of waste hierarchy in the European waste directive 2008/98/EC. Waste Manag. 2015, 39, 305. [Google Scholar] [CrossRef] [PubMed]

- Landfill, Composting, Incineration, Pyrolysis, Gasification, or Anaerobic Digestion. What Is the Best for Organic Waste Management and Usage? 2014. Available online: http://jcgregsolutions.weebly.com/blogs/landfill-composting-incineration-pyrolysis-gasification-or-anaerobic-digestion-what-is-the-best-for-organic-waste-management-and-usage (accessed on 24 March 2017).

- Li, Y.; Park, S.Y.; Zhu, J. Solid-state anaerobic digestion for methane production from organic waste. Renew. Sustain. Energy Rev. 2012, 15, 821–826. [Google Scholar] [CrossRef]

- Halkos, G.; Petrou, K.N. Efficient Waste Management Practices: A Review. Mpra Paper, 2016. Available online: https://mpra.ub.uni-muenchen.de/71518/1/MPRA_paper_71518.pdf(accessed on 8 April 2017).

- Crawford, J.F.; Smith, P.G. Landfill Technology; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- El-Fadel, M.; Khoury, R. Modeling settlement in MSW landfills: A critical review. Crit. Rev. Environ. Sci. Technol. 2000, 30, 327–361. [Google Scholar] [CrossRef]

- Lou, X.; Nair, J. The impact of landfilling and composting on greenhouse gas emissions: A review. Bioresour. Technol. 2009, 100, 3792–3798. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.R.; Park, H.I.; Babu, G.L.S.; Ling, H.I.; Leshchinsky, D.; Mohri, Y.; Kawabata, T. Estimation of Municipal Solid Waste Landfill Settlement. J. Geotech. Geoenviron. Eng. 1998, 125, 21–28. [Google Scholar] [CrossRef]

- Kjeldsen, P.; Barlaz, M.A.; Rooker, A.P.; Baun, A.; Ledin, A.; Christensen, T.H. Present and long-term composition of MSW landfill leachate: A review. Crit. Rev. Environ. Sci. Technol. 2002, 32, 297–336. [Google Scholar] [CrossRef]

- Schiopu, A.M.; Gavrilescu, M. Options for the treatment and management of municipal landfill leachate: Common and specific issues. CLEAN Soil Air Water 2010, 38, 1101–1110. [Google Scholar] [CrossRef]

- Yang, L.; Chen, Z.; Zhang, X.; Liu, Y.; Xie, Y. Comparison study of landfill gas emissions from subtropical landfill with various phases: A case study in Wuhan, China. Air Waste 2015, 65, 980–986. [Google Scholar] [CrossRef] [PubMed]

- Shi, L.; Zhao, Y.C.; Tang, S.J. Review on Landfill Gas Collection, Purification and Utilization. China Biogas 2004, 22, 14–17. [Google Scholar]

- Johari, A.; Ahmed, S.I.; Hashim, H.; Alkali, H.; Ramli, M. Economic and environmental benefits of landfill gas from municipal solid waste in Malaysia. Renew. Sustain. Energy Rev. 2012, 16, 2907–2912. [Google Scholar] [CrossRef]

- Shin, H.C.; Park, J.W.; Kim, H.S.; Shin, E.S. Environmental and economic assessment of landfill gas electricity generation in Korea using LEAP model. Energy Policy 2005, 33, 1261–1270. [Google Scholar] [CrossRef]

- Bove, R.; Lunghi, P. Electric power generation from landfill gas using traditional and innovative technologies. Energy Convers. Manag. 2006, 47, 1391–1401. [Google Scholar] [CrossRef]

- Koerner, R.M.; Soong, T.Y. Stability Assessment of Ten Large Landfill Failures; Geo-Denver: Aurora, CO, USA, 2000; pp. 1–38. [Google Scholar]

- Sabbas, T.; Polettini, A.; Pomi, R.; Astrup, T.; Hjelmar, O.; Mostbauer, P.; Cappai, G.; Magel, G.; Salhofer, S.; Speiser, C.; et al. Management of municipal solid waste incineration residues. Waste Manag. 2003, 23, 61–88. [Google Scholar] [CrossRef]

- Assamoi, B.; Lawryshyn, Y. The environmental comparison of landfilling vs. incineration of MSW accounting for waste diversion. Waste Manag. 2012, 32, 1019–1030. [Google Scholar] [CrossRef] [PubMed]

- Cheng, H.; Hu, Y. Municipal solid waste (MSW) as a renewable source of energy Current and future practices in China. Bioresour. Technol. 2010, 101, 3816–3824. [Google Scholar] [CrossRef] [PubMed]

- Lam, C.H.K.; Ip, A.W.M.; Barford, J.P.; Mckay, G. Use of incineration MSW ash: A review. Sustainability 2010, 2, 1943–1968. [Google Scholar] [CrossRef]

- Gori, M.; Bergfeldt, B.; Reichelt, J.; Sirini, P. Effect of natural ageing on volume stability of MSW and wood waste incineration residues. Waste Manag. 2013, 33, 850–857. [Google Scholar] [CrossRef] [PubMed]

- Jung, C.H.; Matsuto, T.; Tanaka, N.; Okada, T. Metal distribution in incineration residues of municipal solid waste (MSW) in Japan. Waste Manag. 2004, 24, 381–391. [Google Scholar] [CrossRef]

- Lee, V.K.C.; Kwok, K.C.M.; Cheung, W.H.; Mckay, G. Operation of a municipal solid waste co-combustion pilot plant. Asia Pac. J. Chem. Eng. 2007, 2, 631–639. [Google Scholar] [CrossRef]

- Singh, R.; Tyagi, V.; Allen, T.; Ibrahim, M.H.; Kothari, R. An overview for exploring the possibilities of energy generation from municipal solid waste (MSW) in Indian scenario. Renew. Sustain. Energy Rev. 2011, 15, 4797–4808. [Google Scholar] [CrossRef]

- Åberg, A.; Kumpiene, J.; Ecke, H. Evaluation and prediction of emissions from a road built with bottom ash from municipal solid waste incineration (MSWI). Sci. Total Environ. 2006, 355, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Han, W.; Clarke, W.; Pratt, S. Composting of waste algae: A review. Waste Manag. 2014, 34, 1148–1155. [Google Scholar] [CrossRef] [PubMed]

- Sunar, N.M.; Stentiford, E.I.; Stewart, D.I.; Fletcher, L.A. The Process and Pathogen Behavior in Composting: A Review. arXiv, 2014; arXiv:1404.5210. [Google Scholar]

- Xu, S.; He, H.; Luo, L. Status and Prospects of Municipal Solid Waste to Energy Technologies in China; Springer: Singapore, 2016. [Google Scholar]

- Lombardi, F.; Gavasci, R.; Sirini, P.; Lonardo, M.C.D.; Pantini, S.; Verginelli, I.; Costa, G. Assessment and comparison of the leaching behavior of two types of compost materials from aerobic/anaerobic biodegradation processes. J. Solid Waste Technol. Manag. 2016, 42, 336–346. [Google Scholar]

- Bertoldi, M.D.; Sequi, P.; Lemmes, B.; Papi, T. The Science of Composting; Springer: Dordrecht, The Netherlands, 1996; pp. 306–313. [Google Scholar]

- Jain, S.; Jain, S.; Wolf, I.T.; Lee, J.; Tong, Y.W. A comprehensive review on operating parameters and different pretreatment methodologies for anaerobic digestion of municipal solid waste. Renew. Sustain. Energy Rev. 2015, 52, 142–154. [Google Scholar] [CrossRef]

- Bond, T.; Templeton, M.R. History and future of domestic biogas plants in the developing world. Energy Sustain. Dev. 2011, 15, 347–354. [Google Scholar] [CrossRef]

- Kirkeby, J.T.; Birgisdottir, H.; Hansen, T.L.; Christensen, T.H.; Bhander, G.S.; Hauschild, M. Evaluation of environmental impacts from municipal solid waste management in the municipality of Aarhus, Denmark (EASEWASTE). Waste Manag. Res. 2006, 24, 16–26. [Google Scholar] [CrossRef] [PubMed]

- Surroop, D.; Mohee, R. Comparative assessment of anaerobic digestion of municipal solid waste at mesophilic and thermophilic temperatures. Int. J. Environ. Technol. Manag. 2011, 14, 238–251. [Google Scholar] [CrossRef]

- Ren, P.S. Renewables 2016 Global Status Report; REN21 Secretariat: Paris, France, 2016. [Google Scholar]

- Energy, I.R. Medium Term Market Report; International Energy Agency: Paris, France, 2016. [Google Scholar]

- Partidario, M.R.; Vicente, G.; Belchior, C. Can New Perspectives on Sustainability Drive Lifestyles? Sustainability 2010, 2, 2849–2872. [Google Scholar] [CrossRef]

- Mervis, J. Garbology 101: Getting a grip on waste. Science 2012, 337, 668. [Google Scholar] [CrossRef] [PubMed]

- Hoornweg, D.; Bhada-Tata, P.; Kennedy, C. Environment: Waste production must peak this century. Nature 2013, 502, 615–617. [Google Scholar] [CrossRef] [PubMed]

- Tan, S.T.; Ho, W.S.; Hashim, H.; Lee, C.T.; Taib, M.R.; Ho, C.S. Energy, economic and environmental (3E) analysis of waste-to-energy (WTE) strategies for municipal solid waste (MSW) management in Malaysia. Energy Convers. Manag. 2015, 102, 111–120. [Google Scholar] [CrossRef]

- Menikpura, S.N.M.; Sang-Arun, J.; Bengtsson, M. Assessment of environmental and economic performance of Waste-to-Energy facilities in Thai cities. Renew. Energy 2016, 86, 576–584. [Google Scholar] [CrossRef]

- Tan, S.; Hashim, H.; Lee, C.; Taib, M.R.; Yan, J. Economical and Environmental Impact of Waste-to-Energy (WTE) Alternatives for Waste Incineration, Landfill and Anaerobic Digestion. Energy Procedia 2014, 61, 704–708. [Google Scholar] [CrossRef]

- Berenyi, E.B. Nationwide Economic Benefits of the Waste-to-Energy Sector; Governmental Advisory Associate. Available online: https://www.wtienergy.com/sites/default/files/130820-Berenyi-Natl-WTE-Economic-Benefits.pdf (accessed on 24 March 2017).

- Charrette, Y.E. Waste to Energy Background Paper. Available online: http://www.yukonenergy.ca/media/site_documents/charrette/docs/papers/WASTE_TO_ENERGY_YEC_Background_Paper.pdf (accessed on 24 March 2017).

- Johri, R.; Rajeshwari, K.; Mullick, A. Technological options for municipal solid waste management. In Wealth from Waste; The Energy and Resources Institute (TERI): New Delhi, India, 2011; p. 341. [Google Scholar]

- Cantrell, K.B.; Ducey, T.; Ro, K.S.; Hunt, P.G. Livestock waste-to-bioenergy generation opportunities. Bioresour. Technol. 2008, 99, 7941–7953. [Google Scholar] [CrossRef] [PubMed]

- De Baere, L. Will anaerobic digestion of solid waste survive in the future? Water Sci. Technol. 2006, 53, 187–194. [Google Scholar] [CrossRef] [PubMed]

- Molino, A.; Nanna, F.; Ding, Y.; Bikson, B.; Braccio, G. Biomethane production by anaerobic digestion of organic waste. Fuel 2013, 103, 1003–1009. [Google Scholar] [CrossRef]

- Kothari, R.; Tyagi, V.; Pathak, A. Waste-to-energy: A way from renewable energy sources to sustainable development. Renew. Sustain. Energy Rev. 2010, 14, 3164–3170. [Google Scholar] [CrossRef]

- Appels, L.; Baeyens, J.; Degrève, J.; Dewil, R. Principles and potential of the anaerobic digestion of waste-activated sludge. Prog. Energy Combust. Sci. 2008, 34, 755–781. [Google Scholar] [CrossRef]

- Gavala, H.N.; Yenal, U.; Skiadas, I.V.; Westermann, P.; Ahring, B.K. Mesophilic and thermophilic anaerobic digestion of primary and secondary sludge. Effect of pre-treatment at elevated temperature. Water Res. 2003, 37, 4561–4572. [Google Scholar] [CrossRef]

- Tan, Y. Feasibility Study on Solid Waste to Energy Technological Aspects. Available online: https://www.degruyter.com/view/j/pjct.2016.18.issue-4/pjct-2016-0075/pjct-2016-0075.xml (accessed on 24 March 2017).

- Vujic, G.; Stanisavljevic, N.; Batinic, B.; Jurakic, Z.; Ubavin, D. Barriers for implementation of “waste to energy” in developing and transition countries: A case study of Serbia. J. Mater. Cycles Waste Manag. 2017, 19, 55–69. [Google Scholar] [CrossRef]

| Process | Retention | Heating | Maximum | Main |

|---|---|---|---|---|

| Type | Period | Rate | Temperature | Products |

| Slow pyrolysis | ||||

| Carbonization | Few hours∼several days | Extremely low | 400 °C | Charcoal |

| Convention | 5∼30 min | Low | 600 °C | Gas, oil, charcoal |

| Fast pyrolysis | ||||

| Fast | 0.5∼5 s | Relatively high | 650 °C | Oil |

| Flash (oil) | <1 s | High | <650 °C | Oil |

| Flash (gas) | <1 s | High | >650 °C | Gas |

| Extremely fast | <0.5 s | Extremely high | 1000 °C | Gas |

| Vacuum | <2∼30 s | Middle | 400 °C | Oil |

| Reactive thermal cracking | ||||

| Hydrogenation pyrolysis | <10 s | High | 500 °C | Oil |

| Methane pyrolysis | 0.5∼10 s | High | 1050 °C | Chemicals |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Luo, N.; Lu, Y. Biomass Energy Technological Paradigm (BETP): Trends in This Sector. Sustainability 2017, 9, 567. https://doi.org/10.3390/su9040567

Li M, Luo N, Lu Y. Biomass Energy Technological Paradigm (BETP): Trends in This Sector. Sustainability. 2017; 9(4):567. https://doi.org/10.3390/su9040567

Chicago/Turabian StyleLi, Meihui, Na Luo, and Yi Lu. 2017. "Biomass Energy Technological Paradigm (BETP): Trends in This Sector" Sustainability 9, no. 4: 567. https://doi.org/10.3390/su9040567