Improvement of Certified Artisan Cheese Production through Systemic Analysis—Serra da Estrela PDO

Abstract

:1. Introduction

1.1. The Case for a Systemic Perspective in Food Production Improvement

1.2. The Systemic Design Methodology

- Man at the centre of the design project: products have become the fulcrum of a paradigm of values and actions, as economical wellness, the quantity of monetary resources, the desire to achieve social status, negatively shape consumption choices. This approach, instead, questions the present industrial setting and proposes a new paradigm where at the centre of each productive process there are social, cultural, ethical and biological values that every person shares.

- Output as input: as in Nature, what is not used by a system becomes raw material for the development and survival of someone or something else; in production processes waste (output) of a system becomes an opportunity (input) for another one, creating new economic opportunities.

- Relationship: considering, broadly, all the networks of components in a production system, including materials (resources) and energy, which are used, captured and stored through different stages of the product life cycle. Understanding the pattern of material and energy flow and investigating where it can be improved enables identification of entry-points for designing a more sustainable system.

- Towards autopoiesis: in Nature, self-maintaining systems sustain themselves by reproducing automatically, defining their own paths of action. The system naturally seeks balance and preserves independence. If a production system were to aim autopoiesis, it would be possible to efficiently allocate and distribute material and energy flows.

- Act locally: just as an ecosystem is deeply influenced and shaped by its habitat, the same applies to any type of system. Based on local context, new opportunities can be created by reducing the problems of adaptability inherent to ‘general’ solutions and increasing people’s participation.

2. Materials and Methods

2.1. Ethnographic Approach

2.2. Design Methodology

3. Results

3.1. Identified Critical Points

- The lock mechanism for milking systems in use in the region is designed for hornless sheep breeds. This can lead to injuries in ewes with horns. Ewe’s milk for Serra da Estrela PDO cheese production can only originate from “Bordaleira Serra da Estrela” breed with helical, elongated, strong, rough horns with a triangular section, and “Churra Mondegueira” breed with thin horns of an open spiral shape, elongated in the horizontal plane, and with a slightly elliptical profile. Thus, this anatomical detail turns a procedure that would otherwise be simple in something considerably difficult. Redesign of the lock systems to accommodate the anatomy of the ewe’s horns is hence a potential process improvement.

- A producer of cheese may depend on dozens of small ewe’s milk producers scattered in a mountainous area, where gathering and transporting milk becomes an obstacle to overcome, translating as increased production cost. Moreover, ewe’s milk does not undergo any kind of conservation procedure, milk has to be transformed raw, as a requirement of the specification, contributing to a health risk to the consumer. Contributing to mitigate the potential risks to human health in the cheese making process, may involve improvements in self refrigerating containers for raw milk transportation for added consumer health and safety.

- Postures that place dairy workers at risk of injuries at work and cause productivity loss. The design of the “francela”, which acts as a table to support the process of whey draining, forming the resulting mass in molds called “cinchos” and other minor tasks, has a slope in relation to the horizontal plane, which makes it useful for an uninterrupted fluid flow of the whey but at the same time contributes to erosion of the task’s ergonomic qualities. This task hence places cheese makers at risk of injuries associated with task repetition at the level of the upper limbs and vertebral spine. Process improvement by equipment redesign is hence desirable to safeguard workers health.

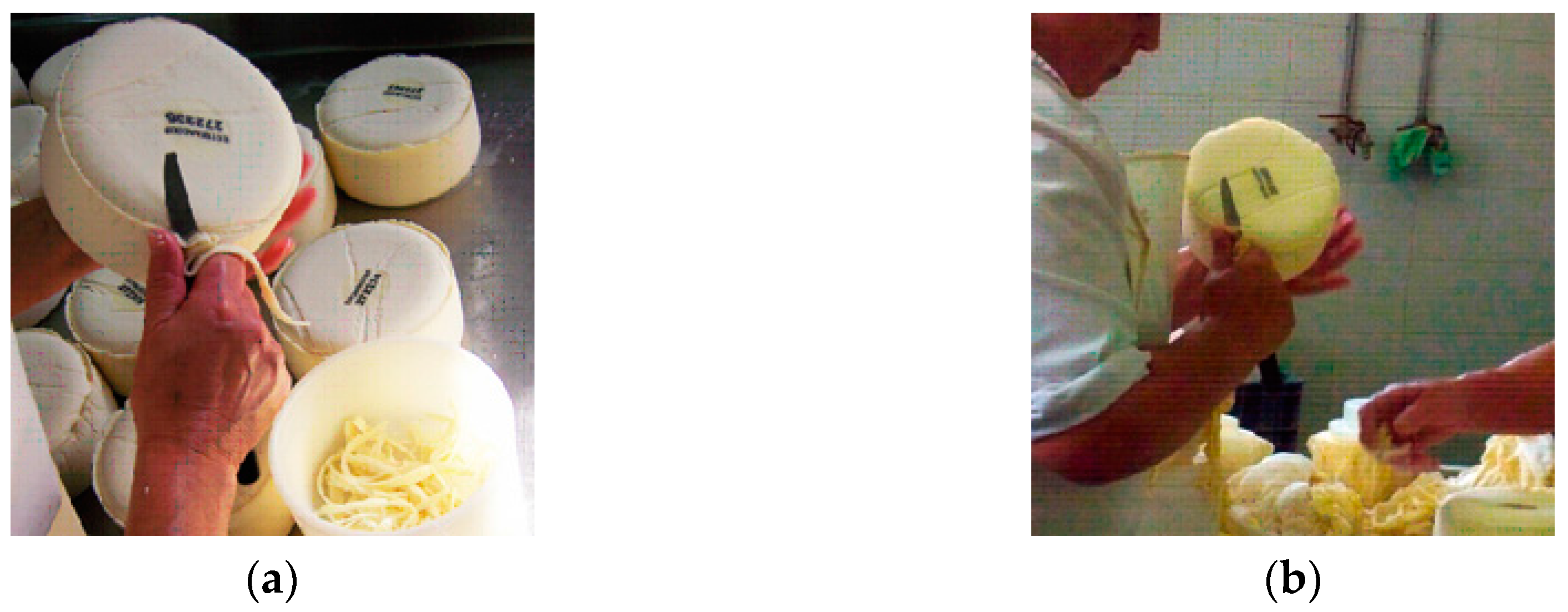

- After removal of the cheese molds from the mechanical press, the resulting cheese cylinders present a barb, which manifests itself in the top edge, as a result of the contact area between the “cincho” and its lid. For the surface of the cheese cylinder to coincide with the description contained in the Serra da Estrela PDO cheese specification rules, regarding the characteristics of the outer shell, it is necessary to trim excess material. Currently this activity is done manually using a cutting tool, an ordinary kitchen knife, requiring skill for it to be done in a short time, while single handedly bearing the load of 0.5–2 kg cheeses. This places workers at the risk of developing musculoskeletal injuries of the hand and forearm during the cheese chip or barb trimming process. Tool redesign hence represents an opportunity for improvement overcoming this criticality.

- The equipment that is used to store and support cheese during its entire ripening process should be composed of stainless steel or plastic that is suitable for food use, and may be alternatively made of unspecified wood. This being an option, each producer’s decisions are based on what is deemed best. Hence, there are different kinds of equipment in use, some of these can facilitate incubation of preferred microorganisms but also unwanted ones. A technical study setting preferred standards for cheese support and storage equipment is desirable for improvement in this regard.

- During the entire ripening time, various microorganisms, fungi and bacteria contribute to and are also essential to the success of the cheese ripening process. Although tests and quality control analysis for screening of pathogenic microorganisms are regularly performed, the type of microorganisms responsible for the ideal characteristics that are wanted in the Serra da Estrela PDO cheese is not known with accuracy. This allows for variation in the product, taking into account variables such as the dairy where the cheese is produced, the season it is produced, as well as slight variations in humidity and temperature. Inconsistency of the organoleptic characteristics of the cheese and propensity for contamination by harmful microorganisms ripples across multiple dimensions, including product recognition and consumer safety. Further microbiological research is deemed necessary to create additional standards regarding cultures of microorganisms for the cheese curing process and microbiological control of the ripening.

- There is no uniformity in some of the features of the label (Figure 3) that identifies the product as a Serra da Estrela PDO cheese. This prevents consumers from developing stronger recognition. Competition from similar looking but uncertified products, which in the eyes of the consumer is considered a product of the same category and quality as the SE PDO cheese, and the fact that those alternatives are more affordable, is the result of an inability to provide a communications strategy to underline and emphasize the Serra da Estrela PDO cheese as unique. Due to reduced visibility and distorted consumer perception of the Serra da Estrela PDO cheese, the consumer accepts similar products for the genuine product. A communication and logotype redesign work extending to all stakeholders is deemed as an important step towards overcoming this problem.

- One of the problems encountered by producers focuses exactly on the number of orders that are returned from retailers due to issues in which the structural integrity of the product is called into question, as well as the appearance of mildew, which appear naturally in the cheese, an issue seen as a consumer deterrent at points of sale. Packaging that enables safety and ventilation of the cheese, preventing the appearance of molds (additionally, while it is transported some cracks may appear in its surface due to its fragility, resulting in retailer returns) is hence a desirable design development.

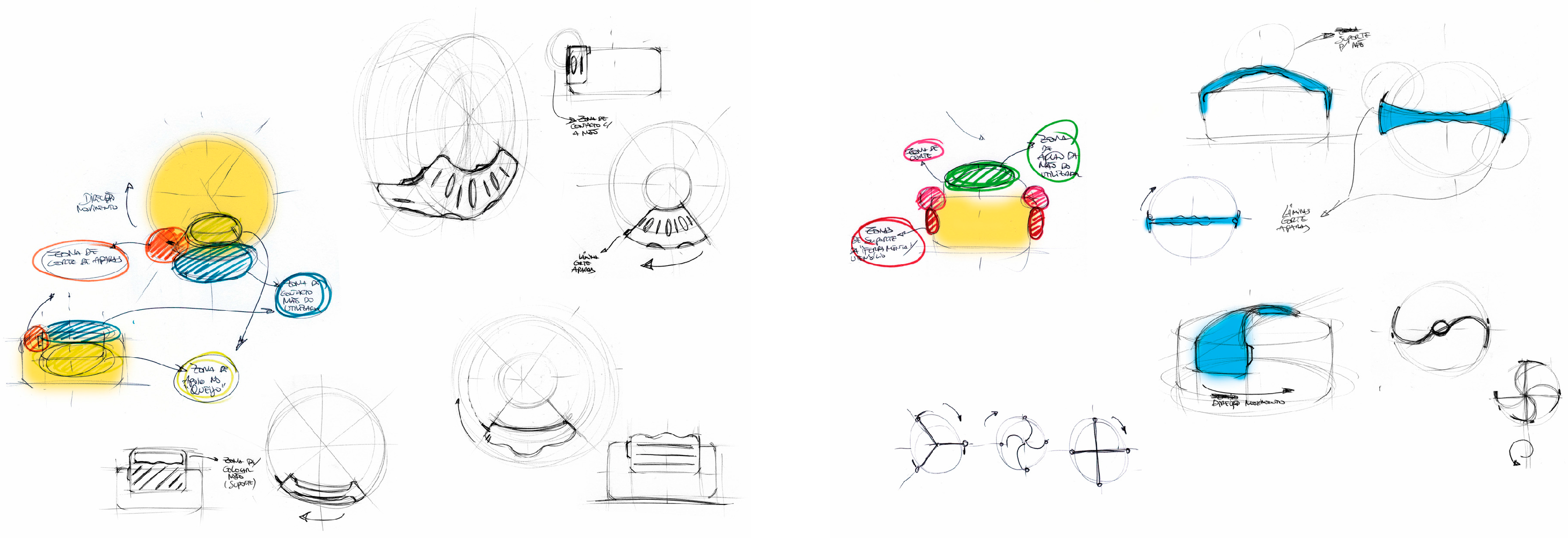

3.2. Design Requirements of a New Chip Cutting Hand Tool

3.3. Alternative Concepts and User Trials of Prototype

4. Discussion and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Guerrero, L.; Guàrdia, M.D.; Xicola, J.; Verbeke, W.; Vanhonacker, F.; Zakowska-Biemans, S.; Sajdakowskac, M.; Sulmont-Rossé, C.; Issanchoud, S.; Contele, M.; et al. Consumer-driven definition of traditional food products and innovation in traditional foods. A qualitative cross-cultural study. Appetite 2009, 52, 345–354. [Google Scholar] [CrossRef] [PubMed]

- Carrola, T.E.P. Análise Sistémica da Manufatura e Discursiva da Imagem do Queijo Serra da Estrela DOP: Aplicação de Metodologias Projetuais à Solução de Pontos Críticos. Master’s Thesis, Universidade da Beira Interior, Covilhã, Portugal, 2013. [Google Scholar]

- Casabianca, F.; de Sainte Marie, C. Concevoir des innovations pour les produits typiques. Quelques enseignements des charcuteries sèches corses. In Proceedings of the 52nd EAAE Seminar, Parma, Italy, 19–21 June 1997.

- Lamas, M. Evolução dos Produtos Tradicionais Qualificados. Direção-Geral de Agricultura e Desenvolvimento Rural. 2014, pp. 62–64. Available online: http://ptqc.drapc.min-agricultura.pt/documentos/evolucao_prod_trad_2002_2009.pdf (accessed on 18 November 2016).

- International Organization for Standardization. Environmental Management—Life Cycle Assessment—Principles and Framework (ISO 14040:2006); ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Ekvall, T.; Weidema, B.P. System boundaries and input data in consequential life cycle inventory analysis. Int. J. Life Cycle Assess. 2004, 9, 161–171. [Google Scholar] [CrossRef]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Tillman, A.-M. Significance of decision-making for LCA methodology. Environ. Impact Assess. Rev. 2000, 20, 113–123. [Google Scholar] [CrossRef]

- Zamagni, A.; Guinee, J.; Heijungs, R.; Masoni, P.; Raggi, A. Lights and shadows in consequential LCA. Int. J. Life Cycle Assess. 2012, 17, 904–918. [Google Scholar] [CrossRef]

- Clift, R.; Doig, A.; Finnveden, G. The application of Life Cycle Assessment to Integrated Solid Waste Management—Part 1—Methodology. Process Saf. Environ. Prot. 2000, 78, 279–287. [Google Scholar] [CrossRef]

- Laurenti, R.; Lazarevic, D.; Poulikidou, S.; Montrucchio, V.; Frostell, B.; Bistagnino, L.; Wennersten, R. Using causal maps to identify potential sources of environmental impact outside the scope of LCA studies: Preliminary findings from case studies on washing machines and road vehicles. In Proceedings of the 18th Annual International Sustainable Development Research Conference, Hull, UK, 24–26 June 2012.

- Field, F.; Kirchain, R.; Clark, J. Life-cycle assessment and temporal distributions of emissions: Developing a fleet-based analysis. J. Ind. Ecol. 2000, 4, 71–92. [Google Scholar] [CrossRef]

- Levine, S.H.; Gloria, T.P.; Romanoff, E. A dynamic model for determining the temporal distribution of environmental burden. J. Ind. Ecol. 2007, 11, 39–49. [Google Scholar] [CrossRef]

- Stasinopoulos, P.; Compston, P.; Newell, B.; Jones, H. A system dynamics approach in LCA to account for temporal effects—A consequential energy LCI of car body-in-whites. Int. J. Life Cycle Assess. 2012, 17, 199–207. [Google Scholar] [CrossRef]

- Chester, M.V.; Horvath, A. Environmental assessment of passenger transportation should include infrastructure and supply chains. Environ. Res. Lett. 2009, 4, 024008. [Google Scholar] [CrossRef]

- Laurenti, R.; Lazarevic, D.; Poulikidou, S.; Montrucchio, V.; Bistagnino, L.; Frostell, B. Group Model-Building to identify potential sources of environmental impacts outside the scope of LCA studies. J. Clean. Prod. 2014, 72, 96–109. [Google Scholar] [CrossRef]

- Spirn, A.W. Ecological Urbanism: A Framework for the Design of Resilient Cities (2014). In The Ecological Design and Planning Reader; Island Press/Center for Resource Economicsm: Washington, DC, USA, 2014; pp. 557–571. [Google Scholar]

- Cadenasso, M.L.; Pickett, S.T.; Weathers, K.C.; Bell, S.S.; Benning, T.L.; Carreiro, M.M.; Dawson, T.E. An interdisciplinary and synthetic approach to ecological boundaries. BioScience 2003, 53, 717–722. [Google Scholar] [CrossRef]

- Furlan, C.; De Meulder, B. Leftover as a resource. A systemic design approach to re-cycle a diffuse territory. In Proceedings of the AA. VV., Atti della XVII Conferenza Nazionale SIU, L’urbanistica Italiana nel Mondo, Milan, Italy, 15–16 May 2014.

- Berger, A. Systemic Design Can Change the World; Sun Publishers: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Barbero, S.; Tamborrini, P.M. Systemic Design goes between disciplines for the sustainability in food processes and cultures. In Proceedings of the 7th International Aesop Sustainable Food Planning Conference, Torino, Italy, 7–9 October 2015; pp. 517–525.

- Spirn, A.W. The poetics of city and nature: Towards a new aesthetic for urban design. Landsc. J. 1988, 7, 108–126. [Google Scholar] [CrossRef]

- Vennix, J.A.M. Group Model Building: Facilitating Team Learning Using System Dynamics; John Wiley & Sons: New York, NY, USA, 1996. [Google Scholar]

- Pisek, P.E.; Wilson, T. Complexity, Leadership, and Management in Healthcare Organizations. Br. Med. J. 2001, 323, 746–749. [Google Scholar]

- Porter, M.E. Competitive Advantage of Nations; Free Press: New York, NY, USA, 1990. [Google Scholar]

- Frosh, R.A.; Gallopoulos, N.E. Strategies for Manufacturing. Sci. Am. 1989, 3, 94–102. [Google Scholar] [CrossRef]

- Chertow, M.R. Industrial Symbiosis: Literature and Taxonomy. Annu. Rev. Energy Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef]

- Buchanan, R. Wicked problems in design thinking. Des. Issues 1992, 8, 5–21. [Google Scholar] [CrossRef]

- Fuller, R.B. Critical Path; St. Martin’s Press: New York, NY, USA, 1981. [Google Scholar]

- Chertow, M.R.; Ashton, W.; Kuppali, R. The Industrial Symbiosis Research Symposium at Yale: Advancing the Study of Industry and Environment; Yale School of Forestry & Environmental Studies: New Haven, CT, USA, 2004. [Google Scholar]

- Jones, P.H. Learning the lessons of systems thinking: Exploring the gap between Thinking and Leadership. Integral Leadersh. Rev. 2009, 9, 1–30. [Google Scholar]

- Pauli, G. The Blue Economy: 10 Years, 100 Innovations, 100 Million Jobs; Paradigm Pubblications: Taos, NM, USA, 2010. [Google Scholar]

- Gaiardo, A.; Tamborrini, P. Systemic Innovation design methodology: The comparison of two cases studies. In Proceedings of the 11th European Academy of Design Research, Paris, France, 22–24 April 2015.

- The Organisation for Economic Co-operation and Development. Data-Driven Innovation for Growth and Well-Being; OECD: Paris, France, 2014. [Google Scholar]

- Filippetti, A. Innovation modes and design as a source of innovation: A firm-level analysis. Eur. J. Innov. Manag. 2011, 14, 5–26. [Google Scholar] [CrossRef]

- Bistagnino, L. Systemic Design, Designing Environmental and Productive Sustainability; Slow Food Editore: Bra, Italy, 2011. [Google Scholar]

- Barbero, S.; Pereno, A.; Tamborrini, P.M. Qualitative/quantitative cross analysis to design eco-pack. In Proceedings of the International Symposium on Sustainable Design, Recife, Brazil, 29–30 September 2011.

- Barbero, S.; Tamborrini, P. Systemic Design in AgroFood Sector: EN.FA.SI Project. In Proceedings of the International Conference on Designing Food and Designing For Food, London, UK, 28–29 June 2012; pp. 285–296.

- Bartis, P. Folklife and Fieldwork: A Layman’s Introduction to Field Techniques, 3rd ed.; Library of Congress: Washington, DC, USA, 2002; Volume 3, p. 38. [Google Scholar]

- Bistagnino, L.; De Morais, D. Design Sistêmico: Uma abordagem interdisciplinar para a inovação. Cadernos de Estudos Avançados em Design Sustentabilidade 2009, 2, 79. [Google Scholar]

- Principia Cybernetica Web. Available online: http://pespmc1.vub.ac.be (accessed on 7 March 2012).

- Lovelock, J. The Ages of Gaia: A Biography of our Living Earth; Norton: New York, NY, USA, 1988. [Google Scholar]

- Fiksel, J. Design resilient, sustainable systems. Environ. Sci. Technol. 2003, 37, 5330–5339. [Google Scholar] [CrossRef] [PubMed]

- Couvinhas, A.F.; Ferrara, P.R.; Coelho, D.A.; Jorge, S.; Walter, J.K. Ergonomic considerations for a systemic approach: The millennium maize mills project in northern Mozambique. Work 2012, 41, 568–575. [Google Scholar] [PubMed]

- Bistagnino, L. Design Sistemico. Progettare la Sostenibilità Produttiva e Ambientale; Slow Food Editore: Bra, Italy, 2009. [Google Scholar]

- Coelho, D.A.; Ferrara, P.R.; Couvinhas, A.F.; Lima, T.M.; Walter, J.K. Macroergonomic aspects in the design of development programs in IDCs. Work 2012, 41, 2651–2655. [Google Scholar] [PubMed]

- Lighthall, F.F. Disastrous High-Tech Decision Making: From Disasters to Safety; Dog Ear Publishing, Kilburn Sackett Press: Indianapolis, Indiana, 2015. [Google Scholar]

- Maffei, S. Foodplexity and Design. Planning the Food Experience. In Arts & Foods. Rituals Since 1851; Celant, G., Ed.; Electa: Milano, Italy, 2015. [Google Scholar]

- Fetterman, D.M. Ethnography: Step-by-Step, 3rd ed.; Sage: Thousand Oaks, CA, USA, 2010; p. 173. [Google Scholar]

- Vieira, M.F. O Impacto da Dinâmica de Grupos na Criatividade. Master’s Thesis, Universidade da Beira Interior, Covilhã, Portugal, 2013. [Google Scholar]

- Coelho, D.A. A Method for User Centering Systematic Product Development Aimed at Industrial Design Students. Des. Technol. Educ. Int. J. 2010, 15, 44–54. [Google Scholar]

- Figueiredo, J.F.; Coelho, D.A. Semiotic Analysis in Perspective: A Frame of Reference to Inform Industrial Design Practice. Des. Princ. Pract. Int. J. 2010, 4, 333–346. [Google Scholar]

- Lewis, W.P.; Bonollo, E.E. An analysis of professional skills in design: Implications for education and research. Des. Stud. 2002, 23, 385–406. [Google Scholar] [CrossRef]

- Hales, C. Analysis of the Engineering Design Process in an Industrial Context; Gants Hill Publications: Eastleigh, UK, 1991. [Google Scholar]

- Carrola, T.E.; Couvinhas, A.F.; Coelho, D.A. Manufacturing Analysis of the Serra da Estrela PDO cheese under the Perspective of Systemic Design. In Proceedings of the ODAM2014—Human Factors in Organizational Design and Management–XI & Nordic Ergonomics Society Annual Conference—46, Copenhagen, Denmark, 17–20 August 2014.

- Carrola, T.E.; Vieira, F.L.; Couvinhas, A.F.; Coelho, D.A. Redesign of the logo and design of a new ergonomic hand tool enabled by systemic analysis of the Serra da Estrela PDO cheese universe. In Proceedings of the ODAM2014—Human Factors in Organizational Design and Management–XI & Nordic Ergonomics Society Annual Conference—46, Copenhagen, Denmark, 17–20 August 2014.

| Year | Cheese Production 1 | Price 2 |

|---|---|---|

| 2002 | 90.10 | 14.96 |

| 2003 | 98.80 | 15.75 |

| 2004 | 93.60 | 15.75 |

| 2005 | 74.80 | 15.75 |

| 2006 | 81.00 | 14.70 |

| 2007 | 98.60 | 14.70 |

| 2008 | 101.10 | 14.70 |

| 2009 | 134.70 | 14.70 |

| Date | Fieldwork Events and Field Observations |

|---|---|

| 2 February 2013 | Participation in the regional Serra da Estrela Cheese Fair in Fornos de Algodres; visit to a traditional cheese dairy owned by Joaquim Albuquerque de Sousa, in Vila Ruiva (Fornos de Algodres). |

| 12 April 2013 | First meeting with ESTRELACOOP’s certifying authority chief executive officer in Celorico da Beira; visit to the museum hall of the Cheese Manor in Celorico da Beira. |

| 23 April 2013 | Visit to the agriculture society of Vale do Seia, observation and registration of the cheese manufacturing processes, interviews and contact with shepherds in Santiago, Seia; visit to the Fernandes Pessoa dairy in Carragozela (Seia); Visit to “Casa Matias” to meet the company’s CEO and discuss market challenges. |

| 7 May 2013 | Observation of manual milking in a herd owned by Joaquim Nunes in Monte do Bispo, Belmonte. |

| 20 May 2013 | Second meeting with the CEO of ESTRELACOOP in Celorico da Beira. |

| Subordinate Process | Nature of Process | Output from Process |

|---|---|---|

| 1. Task clarification | A set of tasks including negotiating a design brief with the client, setting objectives, planning and scheduling subsequent tasks, preparing time and cost estimates | Design brief, including design specification, project plan with time line and cost estimates |

| 2. Concept generation | A set of creative tasks aimed at generating a wide range of concepts as potential solutions to the design problem specified in the brief | A folio of concept sketches, supported by simple models or mock ups, providing a visual representation of design ideas |

| 3. Evaluation and refinement | A set of analytical tasks in which the concepts in (2) are evaluated and reduced to a small number of refined solutions, usually only one or two candidate solutions | A folio of refined concept sketches, supported by models and technical information as required and illustrating the preferred concepts |

| 4. Detailed design of preferred concept | A set of tasks aimed at developing and validating the preferred concept, including layout drawings, dimensional specifications, selection of materials, finishes, indicative tolerances | A folio of layout and detailed component drawings, supported by a technical report giving preliminary manufacturing information |

| 5. Communication of results | A set of tasks whereby the concept detailed in (4) is communicated to the client via appropriate two- and three-dimensional media and written report. | A folio of presentation drawings, including technical drawings from (4) and supported by a refined three dimensional model and/or prototype |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coelho, D.A.; Carrola, T.E.P.; Couvinhas, A.F. Improvement of Certified Artisan Cheese Production through Systemic Analysis—Serra da Estrela PDO. Sustainability 2017, 9, 468. https://doi.org/10.3390/su9030468

Coelho DA, Carrola TEP, Couvinhas AF. Improvement of Certified Artisan Cheese Production through Systemic Analysis—Serra da Estrela PDO. Sustainability. 2017; 9(3):468. https://doi.org/10.3390/su9030468

Chicago/Turabian StyleCoelho, Denis A., Tiago E. P. Carrola, and Ana F. Couvinhas. 2017. "Improvement of Certified Artisan Cheese Production through Systemic Analysis—Serra da Estrela PDO" Sustainability 9, no. 3: 468. https://doi.org/10.3390/su9030468