Decomposition and Attribution Analysis of Industrial Carbon Intensity Changes in Xinjiang, China

Abstract

:1. Introduction

2. Empirical Analysis

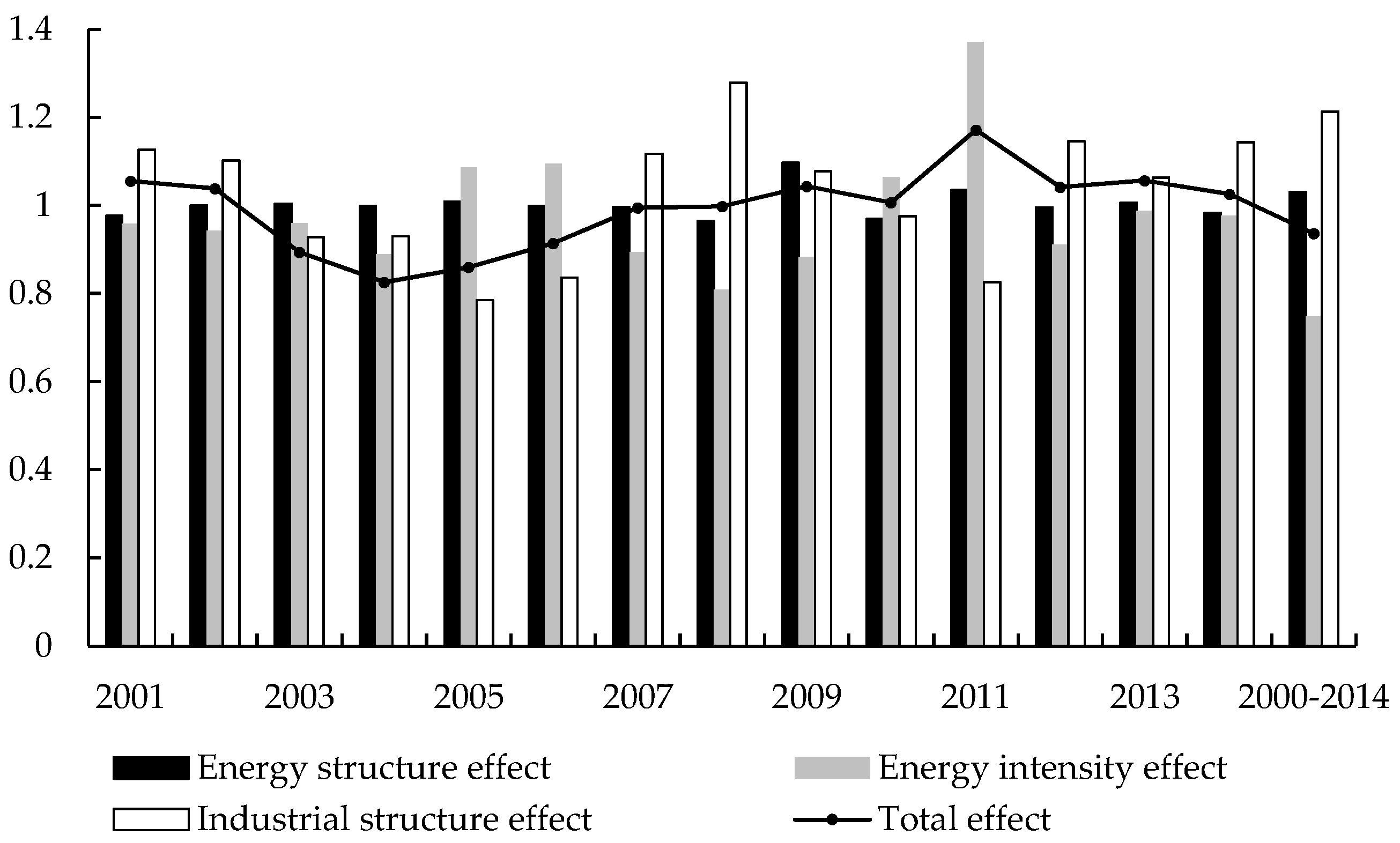

2.1. Sato-Vartia Index Decomposition Analysis

2.2. Attribution Analysis

3. Discussion

4. Conclusions and Policy Implications

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

| Fuels | Conversion Factors (t ce/t or tce/103 m3) a | LCV (MJ/t or MJ/Mm3) b | Carbon Emission Factors (TC/TJ) c | Oxidation Rate c |

|---|---|---|---|---|

| Raw coal | 0.714 | 20.908 | 25.8 | 0.918 |

| Cleaned coal | 0.900 | 26.344 | 27.680 | 0.918 |

| Other washed coal | 0.286 | 8.363 | 25.800 | 0.918 |

| Coke | 0.971 | 28.435 | 29.410 | 0.928 |

| Crude oil | 1.429 | 41.816 | 20.80 | 0.979 |

| Gasoline | 1.471 | 43.070 | 18.900 | 0.986 |

| Kerosene | 1.471 | 43.070 | 19.600 | 0.980 |

| Diesel oil | 1.457 | 42.652 | 20.170 | 0.982 |

| Fuel oil | 1.429 | 41.816 | 20.000 | 0.980 |

| LPG | 1.714 | 50.179 | 17.200 | 0.990 |

| Refinery gas | 1.571 | 46.055 | 18.200 | 0.989 |

| Other petroleum products | 1.429 | 41.816 | 20.000 | 0.980 |

| gas | 1.330 | 38.931 | 17.200 | 0.990 |

| 15 Sub-Sectors | |

|---|---|

| Mining and quarrying | Mining and Washing of Coal; Extraction of Petroleum and Natural Gas; Mining and Processing of Ferrous Metals Ores; Mining and Processing of Nonferrous Metals Ores; Mining and Processing of Nonmetal Ores; Mining Activities |

| Foods and tobacco | Manufacture of Food; Manufacture of Beverage; Manufacture of Tobacco |

| Textile | Manufacture of Textile; Manufacture of Textile Wearing Apparel, Footwear and Caps; Leather, Fur, Feather and Related Products Manufacturing |

| Timber and furniture | Processing of Timber, Wood, Bamboo, Cane, Grass Products; Manufacture of Furniture |

| Pulp and paper | Manufacture of Paper and Paper Products; Printing and Copying of Medium for Record; Manufacture of Articles for Culture, Education, Sports and Entertainment |

| Fuel processing | Oil Processing, Coking and Nuclear Fuel Processing |

| Chemicals | Raw Chemical Material and Chemical Products; Manufacture of Medicine; Manufacture of Chemical Fiber; Manufacture of Rubber Products |

| Non-metallic mineral products | Manufacture of Nonmetal Mineral Products |

| Smelting and pressing of metals | Smelting and Pressing of Ferrous Metals; Smelting and Pressing of Nonferrous Metals |

| Metal products | Manufacture of Metal Products |

| General and special purpose machinery | Manufacture of General Purpose Machinery; Manufacture of Special Purpose Machinery |

| Transport equipment | Manufacture of Automobile; Manufacture of Railroads, Ships, Aerospace and Other Transportation |

| Electrical machinery and equipment | Manufacture of Electric Equipment and Machinery |

| Production and supply | Production and Supply of Electricity and Thermal; Production and Supply of Gas; Production and Supply of Water |

| Other manufactures | Others |

References

- Intergovernmental Panel on Climate Change (IPCC). Climate Change 2007: The Fourth Assessment Report of the Inter-Governmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- You, C.F.; Xu, X.C. Coal combustion and its pollution control in China. Energy 2010, 35, 4467–4472. [Google Scholar] [CrossRef]

- Wang, J.; Feng, L.; Davidsson, S.; Höök, M. Chinese coal supply and future production outlooks. Energy 2013, 60, 204–214. [Google Scholar] [CrossRef]

- Wang, C.; Wang, F.; Zhang, H.; Ye, Y.; Wu, Q. China’s carbon trading scheme is a priority. Environ. Sci. Technol. 2014, 48, 13559. [Google Scholar] [CrossRef] [PubMed]

- Zeng, N.; Ding, Y.; Pan, J.; Wang, H.; Gregg, J. Climate change—The Chinese challenge. Science 2008, 319, 730–731. [Google Scholar] [CrossRef] [PubMed]

- Qiu, J. China’s climate target: Is it achievable? Nature 2009, 462, 550–551. [Google Scholar] [CrossRef] [PubMed]

- David, M. China’s peak carbon pledge raises pointed questions. Science 2014, 346, 903. [Google Scholar]

- Mi, Z.; Wei, Y.M.; Wang, B.; Meng, J.; Liu, Z.; Shan, Y.; Liu, J.; Guan, D. Socioeconomic impact assessment of China’s CO2 emissions peak prior to 2030. J. Clean. Prod. 2017, 142, 2227–2236. [Google Scholar] [CrossRef]

- Guan, D.; Liu, Z.; Geng, Y.; Lindner, S.; Hubacek, K. The gigatonne gap in China’s carbon dioxide inventories. Nat. Clim. Chang. 2012, 2, 672–675. [Google Scholar] [CrossRef]

- Gu, M.S.; Wang, L.M. Petroleum terminal utilization carbon emissions in China based on regional differences. Resour. Sci. 2016, 38, 255–264. (In Chinese) [Google Scholar]

- Zhang, C.; Lin, Y. Panel estimation for urbanization, energy consumption and CO2 emissions: A regional analysis in China. Energy Policy 2012, 49, 488–498. [Google Scholar] [CrossRef]

- Fan, Y.; Liu, L.C.; Wu, G.; Tsai, H.T.; Wei, Y.M. Changes in carbon intensity in China: Empirical findings from 1980–2003. Ecol. Econ. 2007, 62, 683–691. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Da, Y.B. The decomposition of energy-related carbon emission and its decoupling with economic growth in China. Renew. Sustain. Energy Rev. 2015, 41, 1255–1266. [Google Scholar] [CrossRef]

- Mahony, T.O. Decomposition of Ireland's carbon emissions from 1990 to 2010: An extended Kaya identity. Energy Policy 2013, 59, 573–581. [Google Scholar] [CrossRef]

- Wang, W.; Liu, R.; Zhang, M.; Li, H. Decomposing the decoupling of energy-related CO2 emissions and economic growth in Jiangsu Province. Energy Sustain. Dev. 2013, 17, 62–71. [Google Scholar] [CrossRef]

- Mi, Z.; Zhang, Y.; Guan, D.; Shan, Y.; Liu, Z.; Cong, R.; Yuan, X.C.; Wei, Y.-M. Consumption-based emission accounting for Chinese cities. Appl. Energy 2016, 184, 1073–1081. [Google Scholar] [CrossRef]

- Mi, Z.F.; Pan, S.Y.; Yu, H.; Wei, Y.M. Potential impacts of industrial structure on energy consumption and CO2 emission: A case study of Beijing. J. Clean. Prod. 2015, 103, 455–462. [Google Scholar] [CrossRef]

- Huang, R.; Wang, Z.; Ding, G.Q.; Gong, Y.R.; Liu, C.X. Trend prediction and analysis of influencing factors of carbon emissions from energy consumption in Jiangsu province based on STIRPAT model. Geogr. Res. 2016, 35, 781–789. (In Chinese) [Google Scholar]

- Wang, Z.X.; Ye, D.J. Forecasting Chinese carbon emissions from fossil energy consumption using non-linear grey multivariable models. J. Clean. Prod. 2017, 142, 600–612. [Google Scholar] [CrossRef]

- Wang, T.; Watson, J. Scenario analysis of China’s emissions pathways in the 21st century for low carbon transition. Energy Policy 2010, 38, 3537–3546. [Google Scholar] [CrossRef]

- Schipper, L.; Murtishaw, S.; Khrushch, M.; Ting, M.; Karbuz, S.; Unander, F. Carbon emissions from manufacturing energy use in 13 IEA countries: Long-term trends through 1995. Energy Policy 2001, 29, 667–668. [Google Scholar] [CrossRef]

- Dhakal, S. Urban energy use and carbon emissions from cities in China and policy implications. Energy Policy 2009, 37, 4208–4219. [Google Scholar] [CrossRef]

- Qi, T.; Winchester, N.; Karplus, V.J.; Zhang, X. Will economic restructuring in China reduce trade-embodied CO2 emissions? Energy Econ. 2014, 42, 204–212. [Google Scholar] [CrossRef]

- Cheng, J.H. Decomposition of carbon cap target at provincial level in China: A case study of Zhejiang. China Popul. Resour. Environ. 2016, 26, 23–30. (In Chinese) [Google Scholar]

- Wang, C.; Wang, F.; Zhang, X.; Yang, Y.; Su, Y.; Ye, Y.; Zhang, H. Examining the driving factors of energy related carbon emissions using the extended STIRPAT model based on IPAT identity in Xinjiang. Renew. Sustain. Energy Rev. 2017, 67, 51–61. [Google Scholar] [CrossRef]

- Xie, S.H.; Wang, L.X.; Shao, Z.L. Review on carbon emissions researches at home and abroad. Arid Land Geogr. 2014, 37, 720–730. (In Chinese) [Google Scholar]

- Ang, B.W. Decomposition analysis for policymaking in energy: Which is the preferred method? Energy Policy 2004, 32, 1131–1139. [Google Scholar] [CrossRef]

- Su, B.; Ang, B.W. Structural decomposition analysis applied to energy and emissions: Some methodological developments. Energy Econ. 2012, 34, 177–188. [Google Scholar] [CrossRef]

- Sun, J.W. Changes in energy consumption and energy intensity: A complete decomposition model. Ecol. Econ. 1998, 20, 85–100. [Google Scholar] [CrossRef]

- Wang, L.; Ma, D.; Chen, W. A new improved decomposition model base Laspeyres index: A case of CO2 emission in China from 1996–2011. Adv. Mater. Rese. 2013, 734–737, 1797–1803. [Google Scholar] [CrossRef]

- Sinton, J.E.; Levine, M.D. Changing energy intensity in Chinese industry: The relatively importance of structural shift and intensity change. Energy Policy 1994, 22, 239–255. [Google Scholar] [CrossRef]

- Shang, W.; Pei, G.; Walsh, C.; Meng, M.; Meng, X. Have Market-oriented Reforms Decoupled China’s CO2 Emissions from Total Electricity Generation? An Empirical Analysis. Sustainability 2016, 8, 468. [Google Scholar] [CrossRef]

- Li, D.; Wang, D. Decomposition analysis of energy consumption for an freeway during its operation period: A case study for Guangdong, China. Energy 2016, 97, 296–305. [Google Scholar] [CrossRef]

- Wang, W.; Liu, X.; Zhang, M.; Song, X. Using a new generalized LMDI (logarithmic mean Divisia index) method to analyze China’s energy consumption. Energy 2014, 67, 617–622. [Google Scholar] [CrossRef]

- Xie, X.; Shao, S.; Lin, B. Exploring the driving forces and mitigation pathways of CO2 emissions in China’s petroleum refining and coking industry: 1995–2031. Appl. Energy 2016, 184, 1004–1015. [Google Scholar] [CrossRef]

- Li, H.; Wei, Y.M. Is it possible for China to reduce its total CO2 emissions? Energy 2015, 83, 438–446. [Google Scholar] [CrossRef]

- Wu, R.; Zhang, J.; Bao, Y.; Zhang, F. Geographical Detector Model for Influencing Factors of Industrial Sector Carbon Dioxide Emissions in Inner Mongolia, China. Sustainability 2016, 8, 149. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, Y. Features and influencing factors of carbon emissions indicators in the perspective of residential consumption: Evidence from Beijing, China. Ecol. Indic. 2016, 61, 634–645. [Google Scholar] [CrossRef]

- Zhang, X.P.; Zhang, Y.X.; Rao, R.; Shi, Z.P. Exploring the drivers to energy-related carbon emissions changes at China’s provincial levels. Energy Effic. 2014, 8, 699–712. [Google Scholar] [CrossRef]

- Zhang, X.P.; Tan, Y.K.; Tan, Q.L.; Yuan, J.H. Decomposition of aggregate CO2 emissions within a joint production framework. Energy Econ. 2012, 34, 1088–1097. [Google Scholar] [CrossRef]

- Li, A.; Zhang, A.; Zhou, Y.; Yao, X. Decomposition analysis of factors affecting carbon dioxide emissions across provinces in China. J. Clean. Prod. 2017, 141, 1428–1444. [Google Scholar] [CrossRef]

- Liu, L.C.; Fan, Y.; Wu, G.; Wei, Y.M. Using LMDI method to analyze the change of China’s industrial CO2 emissions from final fuel use: An empirical analysis. Energy Policy 2007, 35, 5892–5900. [Google Scholar] [CrossRef]

- Yan, X.; Fang, Y.P. CO2 emissions and mitigation potential of the Chinese manufacturing industry. J. Clean. Prod. 2015, 103, 759–773. [Google Scholar] [CrossRef]

- Choi, K.H.; Ang, B.W. Attribution of changes in Divisia real energy intensity index—An extension to index decomposition analysis. Energy Econ. 2012, 34, 171–176. [Google Scholar] [CrossRef]

- Wang, Q.; Hang, Y.; Zhou, P.; Wang, Y. Decoupling and attribution analysis of industrial carbon emissions in Taiwan. Energy 2016, 113, 728–738. [Google Scholar] [CrossRef]

- Liu, N.; Ma, Z.; Kang, J. Changes in carbon intensity in China’s industrial sector: Decomposition and attribution analysis. Energy Policy 2015, 87, 28–38. [Google Scholar] [CrossRef]

- Su, B.; Ang, B.W. Attribution of changes in the generalized Fisher index with application to embodied emission studies. Energy 2014, 69, 778–786. [Google Scholar] [CrossRef]

- Fernández González, P.; Landajo, M.; Presno, M.J. The Divisia real energy intensity indices: Evolution and attribution of percent changes in 20 European countries from 1995 to 2010. Energy 2013, 58, 340–349. [Google Scholar] [CrossRef]

- Choi, K.H.; Oh, W. Extended Divisia index decomposition of changes in energy intensity: A case of Korean manufacturing industry. Energy Policy 2014, 65, 275–283. [Google Scholar] [CrossRef]

- Fernández González, P.; Presno, M.J.; Landajo, M. Regional and sectoral attribution to percentage changes in the European Divisia carbonization index. Renew. Sustain. Energy Rev. 2015, 52, 1437–1452. [Google Scholar] [CrossRef]

- González, D.; Martínez, M. Changes in CO2 emission intensities in the Mexican industry. Energy Policy 2012, 51, 149–163. [Google Scholar] [CrossRef]

- Su, B.; Ang, B.W. Multi-region comparisons of emission performance: The structural decomposition analysis approach. Ecol. Indic. 2016, 67, 78–87. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, H.; Liang, S.; Xu, M.; Liu, W.; Li, S.; Zhang, R.; Nielsen, C.P.; Bi, J. Temporal and spatial variations in consumption-based carbon dioxide emissions in China. Renew. Sustain. Energy Rev. 2014, 40, 60–68. [Google Scholar] [CrossRef]

- Wang, C.; Wang, F.; Zhang, H.; Ye, Y.; Wu, Q.; Su, Y. Carbon Emissions Decomposition and Environmental Mitigation Policy Recommendations for Sustainable Development in Shandong Province. Sustainability 2014, 6, 8164–8179. [Google Scholar] [CrossRef]

- Mi, Z.F.; Wei, Y.M.; He, C.Q.; Li, H.N.; Yuan, X.C.; Liao, H. Regional efforts to mitigate climate change in China: A multi-criteria assessment approach. Mitig. Adapt. Strateg. Glob. Chang. 2015, 22, 45–66. [Google Scholar] [CrossRef]

- Wang, C.; Wang, F. Structural Decomposition Analysis of Carbon Emissions and Policy Recommendations for Energy Sustainability in Xinjiang. Sustainability 2015, 7, 7548–7567. [Google Scholar] [CrossRef]

- Zhang, X.L.; Wang, Q.; Wang, C.J.; Lu, J.R. Analyses of development and industry relevancy of energy industries in Xinjiang. J. Univ. Chin. Acad. Sci. 2013, 30, 504–509. (In Chinese) [Google Scholar]

- Hasanbeigi, A.; Price, L.; Fino-Chen, C.; Lu, H.; Ke, J. Retrospective and prospective decomposition analysis of Chinese manufacturing energy use and policy implications. Energy Policy 2013, 63, 562–574. [Google Scholar] [CrossRef]

- Ang, B.W.; Choi, K.H. Decomposition of aggregate energy and gas emission intensities for industry: A refined Divisia index method. Energy J. 1997, 18, 59–73. [Google Scholar] [CrossRef]

- Tan, Z.; Li, L.; Wang, J.; Wang, J. Examining the driving forces for improving China’s CO2 emission intensity using the decomposing method. Applied Energy 2011, 88, 4496–4504. [Google Scholar] [CrossRef]

- Statistic Bureau of Xinjiang Uygur Autonomous Region. Xinjiang Statistical Yearbook 2001; Statistic Bureau of Xinjiang Uygur Autonomous Region: Xinjiang, China, 2001. (In Chinese) [Google Scholar]

- Statistic Bureau of Xinjiang Uygur Autonomous Region. Xinjiang Statistical Yearbook 2002; Statistic Bureau of Xinjiang Uygur Autonomous Region: Xinjiang, China, 2002. (In Chinese) [Google Scholar]

- Statistic Bureau of Xinjiang Uygur Autonomous Region. Xinjiang Statistical Yearbook 2003; Statistic Bureau of Xinjiang Uygur Autonomous Region: Xinjiang, China, 2003. (In Chinese) [Google Scholar]

- Statistic Bureau of Xinjiang Uygur Autonomous Region. Xinjiang Statistical Yearbook 2004; Statistic Bureau of Xinjiang Uygur Autonomous Region: Xinjiang, China, 2004. (In Chinese) [Google Scholar]

- Statistic Bureau of Xinjiang Uygur Autonomous Region. Xinjiang Statistical Yearbook 2005; Statistic Bureau of Xinjiang Uygur Autonomous Region: Xinjiang, China, 2005. (In Chinese) [Google Scholar]

- Statistic Bureau of Xinjiang Uygur Autonomous Region. Xinjiang Statistical Yearbook 2006; Statistic Bureau of Xinjiang Uygur Autonomous Region: Xinjiang, China, 2006. (In Chinese) [Google Scholar]

- Statistic Bureau of Xinjiang Uygur Autonomous Region. Xinjiang Statistical Yearbook 2007; Statistic Bureau of Xinjiang Uygur Autonomous Region: Xinjiang, China, 2007. (In Chinese) [Google Scholar]

- Statistic Bureau of Xinjiang Uygur Autonomous Region. Xinjiang Statistical Yearbook 2008; Statistic Bureau of Xinjiang Uygur Autonomous Region: Xinjiang, China, 2008. (In Chinese) [Google Scholar]

- Statistic Bureau of Xinjiang Uygur Autonomous Region. Xinjiang Statistical Yearbook 2009; Statistic Bureau of Xinjiang Uygur Autonomous Region: Xinjiang, China, 2009. (In Chinese) [Google Scholar]

- Statistic Bureau of Xinjiang Uygur Autonomous Region. Xinjiang Statistical Yearbook 2010; Statistic Bureau of Xinjiang Uygur Autonomous Region: Xinjiang, China, 2010. (In Chinese) [Google Scholar]

- Statistic Bureau of Xinjiang Uygur Autonomous Region. Xinjiang Statistical Yearbook 2011; Statistic Bureau of Xinjiang Uygur Autonomous Region: Xinjiang, China, 2011. (In Chinese) [Google Scholar]

- Statistic Bureau of Xinjiang Uygur Autonomous Region. Xinjiang Statistical Yearbook 2012; Statistic Bureau of Xinjiang Uygur Autonomous Region: Xinjiang, China, 2012. (In Chinese) [Google Scholar]

- Statistic Bureau of Xinjiang Uygur Autonomous Region. Xinjiang Statistical Yearbook 2013; Statistic Bureau of Xinjiang Uygur Autonomous Region: Xinjiang, China, 2013. (In Chinese) [Google Scholar]

- Statistic Bureau of Xinjiang Uygur Autonomous Region. Xinjiang Statistical Yearbook 2014; Statistic Bureau of Xinjiang Uygur Autonomous Region: Xinjiang, China, 2014. (In Chinese) [Google Scholar]

- Statistic Bureau of Xinjiang Uygur Autonomous Region. Xinjiang Statistical Yearbook 2015; Statistic Bureau of Xinjiang Uygur Autonomous Region: Xinjiang, China, 2015. (In Chinese) [Google Scholar]

- Liang, S.; Zhang, T. What is driving CO2 emissions in a typical manufacturing center of South China? The case of Jiangsu Province. Energy Policy 2011, 39, 7078–7083. [Google Scholar] [CrossRef]

- Xi, F.; Geng, Y.; Chen, X.; Zhang, Y.; Wang, X.; Xue, B.; Dong, H.; Liu, Z.; Ren, W.; Fujita, T.; et al. Contributing to local policy making on GHG emission reduction through inventorying and attribution: A case study of Shenyang, China. Energy Policy 2011, 39, 5999–6010. [Google Scholar] [CrossRef]

- Geng, Y.; Zhao, H.; Liu, Z.; Xue, B.; Fujita, T.; Xi, F. Exploring driving factors of energy-related CO2 emissions in Chinese provinces: A case of Liaoning. Energy Policy 2013, 60, 820–826. [Google Scholar] [CrossRef]

- Lv, K.W.; Miao, C.H.; Shang, W.Y. Sectoral difference in carbon emission of industrial energy consumption: A case study of Henan province. Econ. Geogr. 2012, 32, 15–20. (In Chinese) [Google Scholar]

| 2001 | 2002 | 2003 | 2004 | 2005 | 2006 | 2007 | 2008 | 2009 | 2010 | 2011 | 2012 | 2013 | 2014 | Mean | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | −0.76 | 0.00 | −0.43 | −0.05 | −8.82 | 0.07 | −0.02 | −1.10 | 5.93 | 0.85 | −1.44 | −0.09 | 0.60 | 0.06 | −0.37 |

| 2 | 0.22 | 0.00 | −0.19 | −0.01 | −1.06 | −0.02 | −0.01 | −0.09 | −2.82 | 0.10 | 0.28 | 0.04 | −0.15 | −0.09 | −0.27 |

| 3 | −0.19 | 0.00 | −0.03 | 0.00 | −1.79 | 0.00 | −0.05 | −0.35 | 7.74 | −0.86 | 0.36 | 0.02 | 0.05 | 0.26 | 0.37 |

| 4 | −0.99 | 0.00 | 1.31 | 0.04 | −0.49 | −0.02 | −0.02 | 0.45 | 0.19 | −0.87 | 3.13 | −0.14 | 0.51 | 0.26 | 0.24 |

| 5 | −0.16 | 0.00 | −0.29 | 0.00 | 2.87 | 0.00 | −0.01 | −0.42 | −0.20 | 0.10 | 0.30 | 0.08 | 0.01 | −0.10 | 0.16 |

| 6 | 0.26 | 0.00 | −0.04 | 0.00 | 2.52 | −0.02 | −0.01 | −1.71 | 0.06 | −0.19 | 10.29 | 0.01 | −0.22 | 0.03 | 0.78 |

| 7 | 0.05 | 0.00 | −0.08 | −0.01 | 2.13 | 0.01 | −0.01 | 1.90 | −1.89 | 0.95 | −0.68 | 0.04 | 0.07 | −0.27 | 0.16 |

| 8 | 0.48 | 0.00 | −0.03 | 0.01 | −0.89 | 0.00 | −0.01 | −0.79 | −0.69 | 0.00 | −0.64 | −0.08 | −0.13 | 0.01 | −0.20 |

| 9 | 0.18 | 0.00 | 0.50 | −0.01 | 5.96 | −0.04 | −0.04 | 1.37 | −0.87 | 0.67 | −0.78 | 0.04 | 0.06 | 0.01 | 0.50 |

| 10 | 1.25 | 0.00 | −0.30 | 0.00 | 5.43 | −0.05 | −0.03 | −0.11 | −0.03 | −0.94 | −0.20 | −0.06 | −0.18 | 0.39 | 0.37 |

| 11 | −1.52 | 0.00 | 0.62 | −0.03 | −1.70 | 0.00 | 0.00 | −1.02 | −0.63 | −1.18 | −2.55 | 0.11 | −0.36 | 0.03 | −0.59 |

| 12 | 0.16 | 0.00 | 0.16 | −0.02 | 0.16 | −0.05 | −0.02 | −0.29 | 4.55 | −0.58 | −2.65 | 0.05 | −0.10 | −2.73 | −0.10 |

| 13 | 0.05 | 0.00 | −0.45 | 0.01 | −2.44 | 0.03 | −0.03 | −0.26 | −0.77 | −0.40 | −0.96 | −0.40 | 0.12 | 0.05 | −0.39 |

| 14 | −1.24 | 0.00 | −0.38 | −0.01 | −1.35 | −0.01 | −0.02 | −0.54 | −0.62 | −0.69 | −1.06 | −0.03 | 0.10 | 0.05 | −0.41 |

| 15 | −0.09 | 0.00 | 0.07 | 0.00 | 0.31 | −0.01 | 0.00 | −0.63 | −0.24 | −0.02 | 0.10 | 0.04 | 0.23 | 0.12 | −0.01 |

| total | −2.29 | 0.00 | 0.44 | −0.10 | 0.84 | −0.11 | −0.28 | −3.59 | 9.71 | −3.06 | 3.51 | −0.37 | 0.62 | −1.92 |

| 2001 | 2002 | 2003 | 2004 | 2005 | 2006 | 2007 | 2008 | 2009 | 2010 | 2011 | 2012 | 2013 | 2014 | Mean | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | −4.67 | −1.25 | −0.95 | −3.66 | −5.38 | −3.66 | −1.22 | 0.38 | −3.90 | 0.69 | −1.66 | 0.41 | 0.88 | −0.51 | −1.75 |

| 2 | −0.20 | 0.17 | −0.44 | −0.63 | −0.38 | 0.54 | −0.26 | −0.03 | −5.62 | 0.07 | 0.10 | −0.26 | −0.16 | 0.19 | −0.49 |

| 3 | 0.08 | −0.07 | −0.02 | −0.08 | −0.18 | −0.02 | −0.29 | −0.01 | 1.17 | −0.12 | 0.02 | −0.01 | 0.00 | −0.05 | 0.03 |

| 4 | 0.01 | −0.03 | 0.03 | 0.06 | −0.01 | 0.03 | −0.03 | 0.00 | 0.01 | −0.04 | 0.04 | 0.03 | 0.02 | −0.03 | 0.01 |

| 5 | 0.03 | −0.04 | −0.12 | −0.02 | 0.21 | 0.01 | −0.08 | −0.02 | −0.06 | 0.01 | 0.02 | −0.07 | 0.00 | 0.03 | −0.01 |

| 6 | 0.85 | −1.72 | −4.42 | −3.18 | 9.76 | 5.93 | −3.04 | −18.66 | 16.86 | −1.30 | 36.98 | −2.28 | −7.03 | −1.28 | 1.96 |

| 7 | −0.04 | 0.53 | −0.12 | −0.72 | 0.89 | 0.14 | −0.45 | 0.63 | −8.12 | 3.29 | −1.90 | −1.42 | 0.48 | 4.06 | −0.20 |

| 8 | −0.99 | 0.39 | −0.14 | 1.29 | −0.80 | 0.30 | −0.69 | −0.49 | −2.45 | −0.01 | −0.65 | 1.16 | −0.44 | −0.06 | −0.25 |

| 9 | −0.10 | −0.26 | 1.61 | −2.25 | 4.54 | 3.43 | −5.19 | 1.20 | −8.28 | 4.57 | −3.47 | −2.63 | 0.54 | 0.31 | −0.43 |

| 10 | −0.06 | 0.00 | −0.01 | 0.00 | 0.04 | 0.06 | −0.05 | 0.00 | −0.02 | −0.05 | 0.00 | 0.01 | −0.01 | −0.03 | −0.01 |

| 11 | 0.12 | −0.04 | 0.10 | −0.21 | −0.04 | 0.00 | 0.00 | −0.01 | −0.04 | −0.03 | −0.01 | −0.01 | 0.00 | 0.00 | −0.01 |

| 12 | −0.01 | −0.05 | 0.01 | −0.03 | 0.00 | 0.01 | 0.00 | 0.00 | 0.06 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| 13 | 0.00 | −0.01 | −0.02 | 0.01 | −0.02 | −0.01 | −0.01 | 0.00 | −0.02 | −0.01 | −0.01 | 0.03 | 0.00 | 0.00 | 0.00 |

| 14 | 0.02 | −0.04 | 0.00 | −0.02 | −0.02 | 0.01 | −0.02 | 0.00 | −0.03 | −0.02 | −0.01 | 0.00 | 0.00 | 0.00 | −0.01 |

| 15 | 0.78 | −3.38 | 0.50 | −1.62 | −0.15 | 2.32 | 0.52 | −2.09 | −1.36 | −0.84 | 1.34 | −3.90 | 4.29 | −5.27 | −0.63 |

| Total | −4.17 | −5.81 | −4.00 | −11.07 | 8.48 | 9.08 | −10.82 | −19.10 | −11.81 | 6.22 | 30.78 | −8.93 | −1.41 | −2.64 |

| 2001 | 2002 | 2003 | 2004 | 2005 | 2006 | 2007 | 2008 | 2009 | 2010 | 2011 | 2012 | 2013 | 2014 | Mean | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | −1.13 | −0.69 | 0.92 | 0.43 | 1.12 | 0.89 | −0.89 | −0.67 | −0.36 | −0.33 | 1.03 | −0.29 | −0.59 | −0.75 | −0.09 |

| 2 | 0.35 | 0.88 | −0.53 | −0.27 | −0.36 | −0.21 | 0.35 | −0.08 | 0.59 | −0.26 | −0.06 | 0.22 | 0.20 | 0.23 | 0.07 |

| 3 | −0.46 | −0.08 | −0.21 | −0.32 | −0.05 | −0.11 | 0.24 | −0.03 | −0.01 | −0.08 | −0.04 | −0.02 | 0.00 | −0.01 | −0.08 |

| 4 | −0.03 | 0.03 | −0.01 | −0.01 | −0.02 | −0.03 | 0.01 | −0.02 | 0.01 | 0.01 | −0.02 | −0.03 | −0.01 | 0.00 | −0.01 |

| 5 | −0.05 | 0.04 | 0.01 | −0.05 | −0.20 | −0.10 | −0.02 | −0.02 | 0.04 | −0.15 | −0.03 | 0.04 | 0.03 | 0.00 | −0.03 |

| 6 | 10.01 | 4.82 | −2.76 | −6.29 | −13.20 | −11.24 | 3.09 | 17.33 | −0.05 | −1.23 | −23.38 | −0.19 | 10.88 | 5.79 | −0.46 |

| 7 | 0.29 | 0.24 | −0.26 | 0.09 | −0.36 | 0.10 | 0.90 | −0.11 | 2.23 | 0.96 | 0.87 | 2.88 | −0.31 | −0.96 | 0.47 |

| 8 | 1.27 | −0.58 | −0.48 | −2.07 | −0.94 | −0.41 | 0.53 | 0.71 | 0.78 | −0.14 | 0.40 | −0.23 | 0.49 | 0.38 | −0.02 |

| 9 | 1.78 | 1.43 | −1.61 | 1.37 | −3.48 | −2.56 | 4.75 | −0.49 | 2.58 | 0.09 | 0.70 | 1.97 | −0.41 | 3.31 | 0.67 |

| 10 | 0.02 | −0.04 | −0.01 | 0.02 | −0.03 | −0.02 | 0.02 | 0.01 | 0.04 | 0.00 | 0.00 | −0.01 | 0.02 | 0.00 | 0.00 |

| 11 | −0.01 | 0.00 | −0.14 | 0.10 | −0.04 | −0.04 | 0.01 | 0.01 | 0.01 | −0.03 | 0.00 | 0.00 | 0.00 | 0.00 | −0.01 |

| 12 | 0.04 | −0.04 | −0.01 | 0.00 | −0.01 | −0.03 | 0.00 | 0.00 | −0.01 | 0.00 | −0.01 | 0.00 | 0.00 | −0.01 | 0.00 |

| 13 | 0.01 | 0.01 | 0.00 | −0.03 | 0.00 | 0.01 | 0.01 | 0.00 | 0.01 | 0.02 | −0.01 | 0.00 | 0.00 | 0.01 | 0.00 |

| 14 | −0.01 | 0.06 | 0.01 | 0.00 | 0.00 | −0.02 | 0.03 | 0.00 | 0.01 | 0.00 | 0.00 | −0.02 | 0.00 | 0.00 | 0.00 |

| 15 | 0.19 | 4.04 | −2.19 | −0.13 | −4.15 | −2.84 | 2.55 | 2.93 | 2.70 | −2.02 | 1.30 | 9.93 | −4.64 | 6.34 | 1.00 |

| total | 12.29 | 10.12 | −7.26 | −7.16 | −21.72 | −16.60 | 11.58 | 19.57 | 8.56 | −3.18 | −19.24 | 14.26 | 5.66 | 14.34 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Zhao, Y.; Sun, Q.; Wang, C. Decomposition and Attribution Analysis of Industrial Carbon Intensity Changes in Xinjiang, China. Sustainability 2017, 9, 459. https://doi.org/10.3390/su9030459

Zhang X, Zhao Y, Sun Q, Wang C. Decomposition and Attribution Analysis of Industrial Carbon Intensity Changes in Xinjiang, China. Sustainability. 2017; 9(3):459. https://doi.org/10.3390/su9030459

Chicago/Turabian StyleZhang, Xinlin, Yuan Zhao, Qi Sun, and Changjian Wang. 2017. "Decomposition and Attribution Analysis of Industrial Carbon Intensity Changes in Xinjiang, China" Sustainability 9, no. 3: 459. https://doi.org/10.3390/su9030459