China’s Carbon Footprint Based on Input-Output Table Series: 1992–2020

Abstract

:1. Introduction

2. Methodology

2.1. The Methodology of Calculating Emissions

2.2. Updating Input-Ouput Table Series

- (1)

- Transform the benchmark IO matrix into an unconstrained matrix in which the elements can be freely forecasted. We divide the IO matrix into four quadrants. The first quadrant is the intermediate input and output part, the second quadrant is the final demand part, the third quadrant is the value added part and the fourth quadrant is GDP. Then the unconstrained matrix also can be divided into four quadrants. This unconstrained matrix is actually a coefficient matrix. The elements in the first quadrant of this matrix represent the proportion of the monetary value of the transactions between a pair of sectors (from Sector i to Sector j) to the total final demand of Sector i. Moreover, the elements in the third quadrant represent the ratio of each sector’s value added to the last sector’s value added;

- (2)

- Establish the Autoregressive Integrated Moving Average (ARIMA) model for each element (the coefficient) in the unconstrained matrix to forecast the corresponding element in the target years’ unconstrained matrix;

- (3)

- Back-transform the unconstrained matrix into the input-output matrix of target years by inverse computation. The back-transformation process involves three steps. First, since the sum of all sectors’ value added is equal to GDP, the first step is to use the target year’s GDP data and the third quadrant of unconstrained matrix to compute each sector’s value added. The forecast of GDP is based on China’s 13th Five Year Plan and Bai et al. [36] which use the sum of labor production growth rate and population growth rate as the GDP growth rate. Second, use the value added data of each sector and unconstrained matrix to calculate the final demand of each sector. Third, use the final demand data and unconstrained matrix to calculate every element in the IO matrix. The specific process can refer to Zheng et al. [35] and Wang et al. [34]. The prominent advantage of MTT is that it takes into account that the transaction coefficients are changing over time while almost all of the existing methods, including the RAS method, rely heavily on the assumption that they will not dramatically change [34].

3. Measurement of Embodied Carbon Emission

- Step 1:

- calculate the direct carbon emissions of 29 industries with Equation (1).

- Step 2:

- compute the direct carbon emissions intensity of 1992–2014 with Equation (2). When it comes to year 2015 and later, we do not have access to acquire energy consumption data, and the National Bureau of statistics did not publish the input-output table data after 2012. This is also the reason why the current studies on China’s carbon footprint are still in place before 2014. However, how China’s carbon footprint will change in the future (after 2015) under the current energy consumption structure is a more important point we should focus on. In order to calculate the total embodied carbon emissions and multipliers after 2014, we only need to obtain the direct carbon emission intensities of 2015–2020 since the input-output table series updated by Zheng et al. [35] contain the tables of 2013–2020. Thus, we have made an assumption here that the direct carbon emission intensities of 2015–2020 will remain the same as that of 2014.

- Step 3:

- measure the 29 industries’ embodied carbon emission multipliers and total embodied carbon emissions of 29 sectors from 1992 to 2020 with Equation (3).

4. Results and Discussion

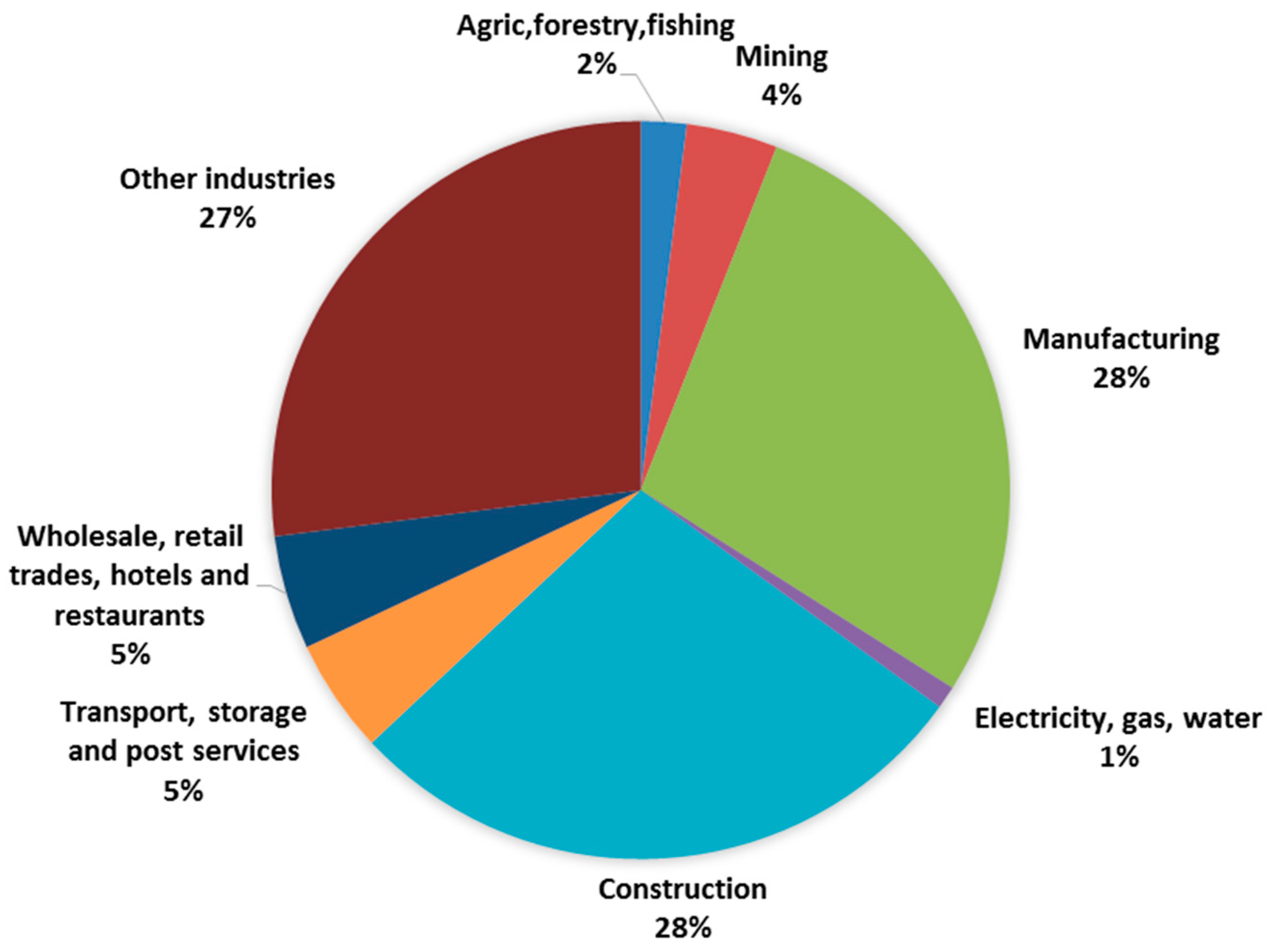

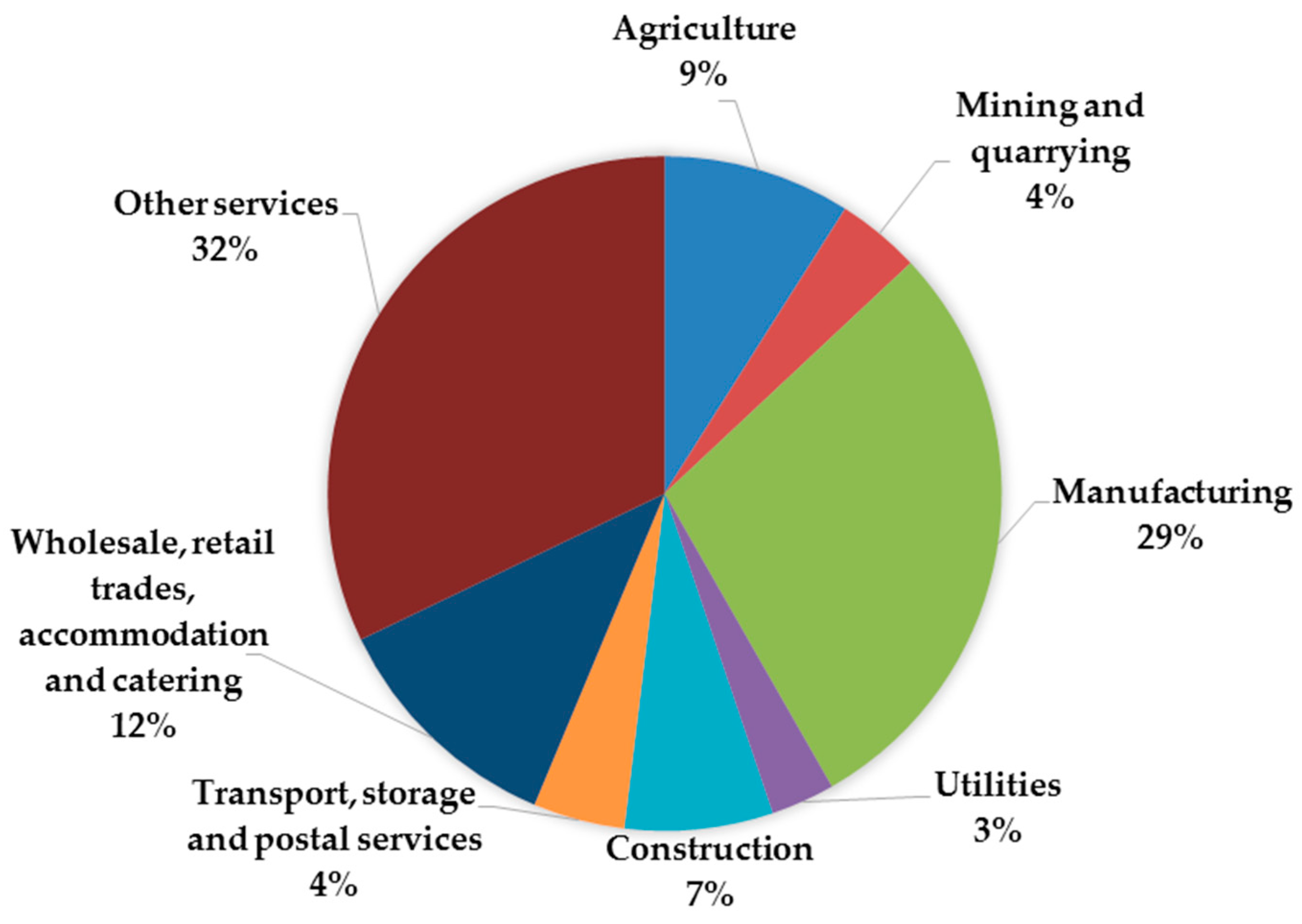

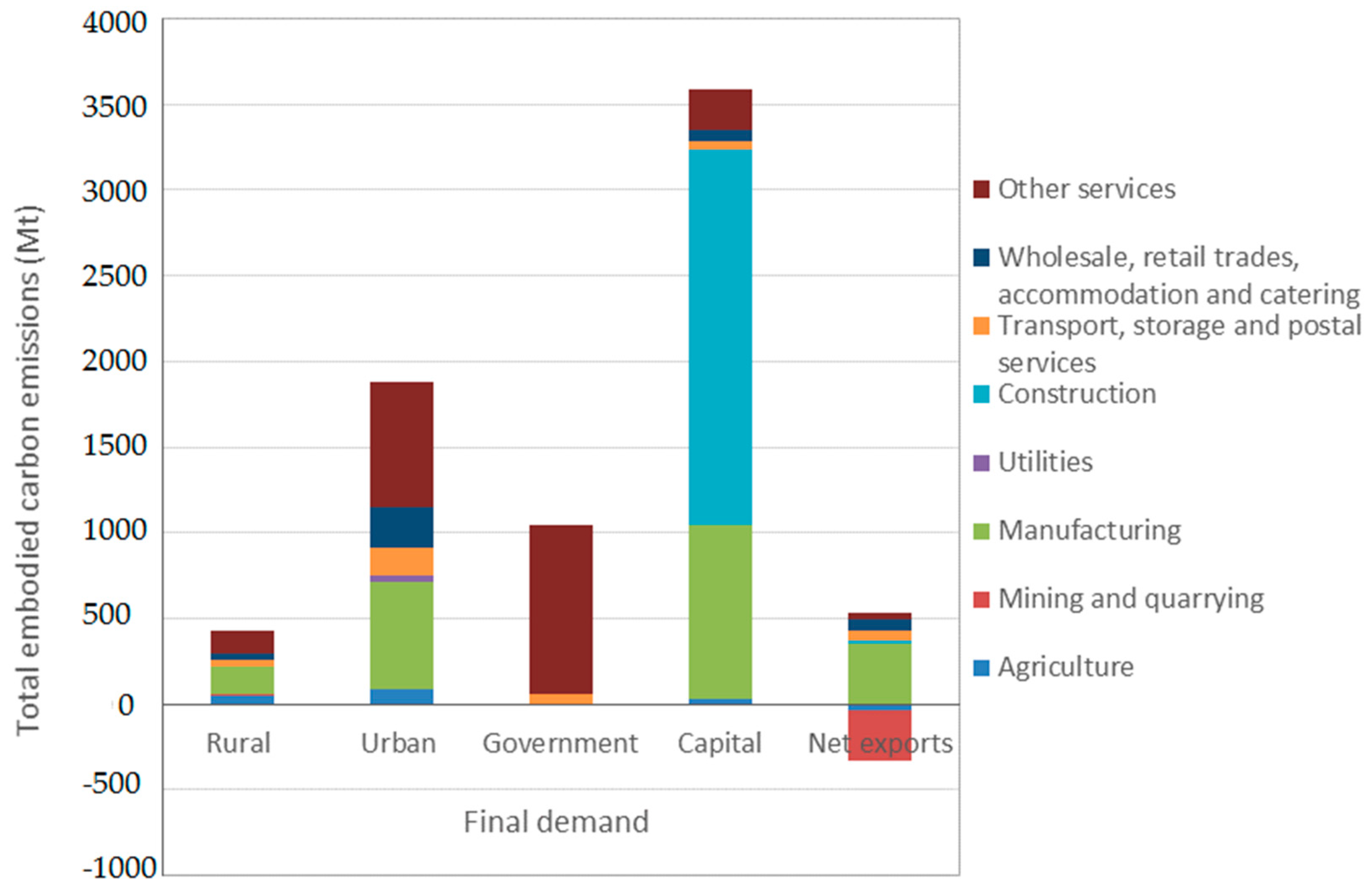

4.1. Emissions in 2016

4.2. Carbon Emission Multipliers from 1992 to 2020

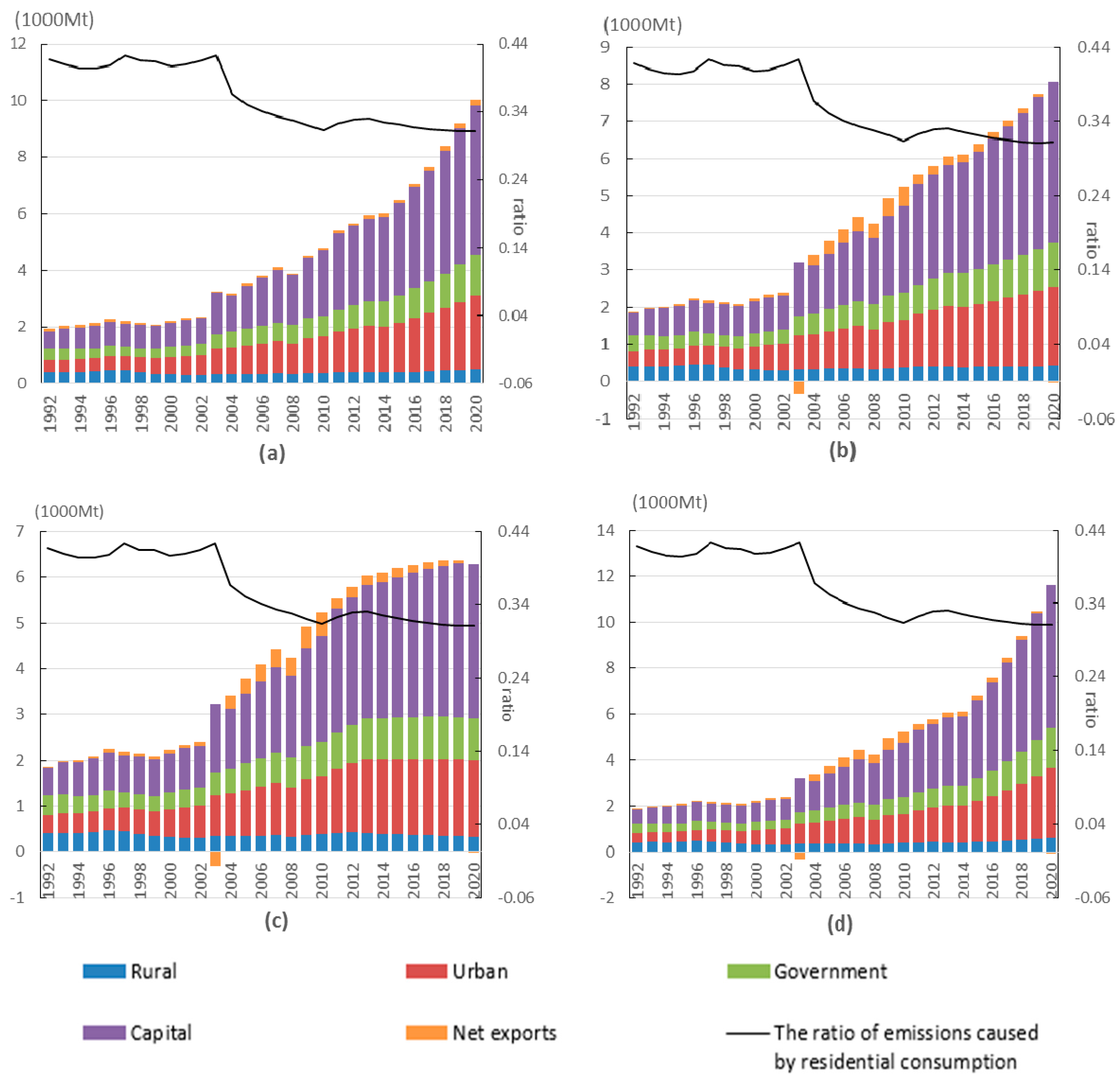

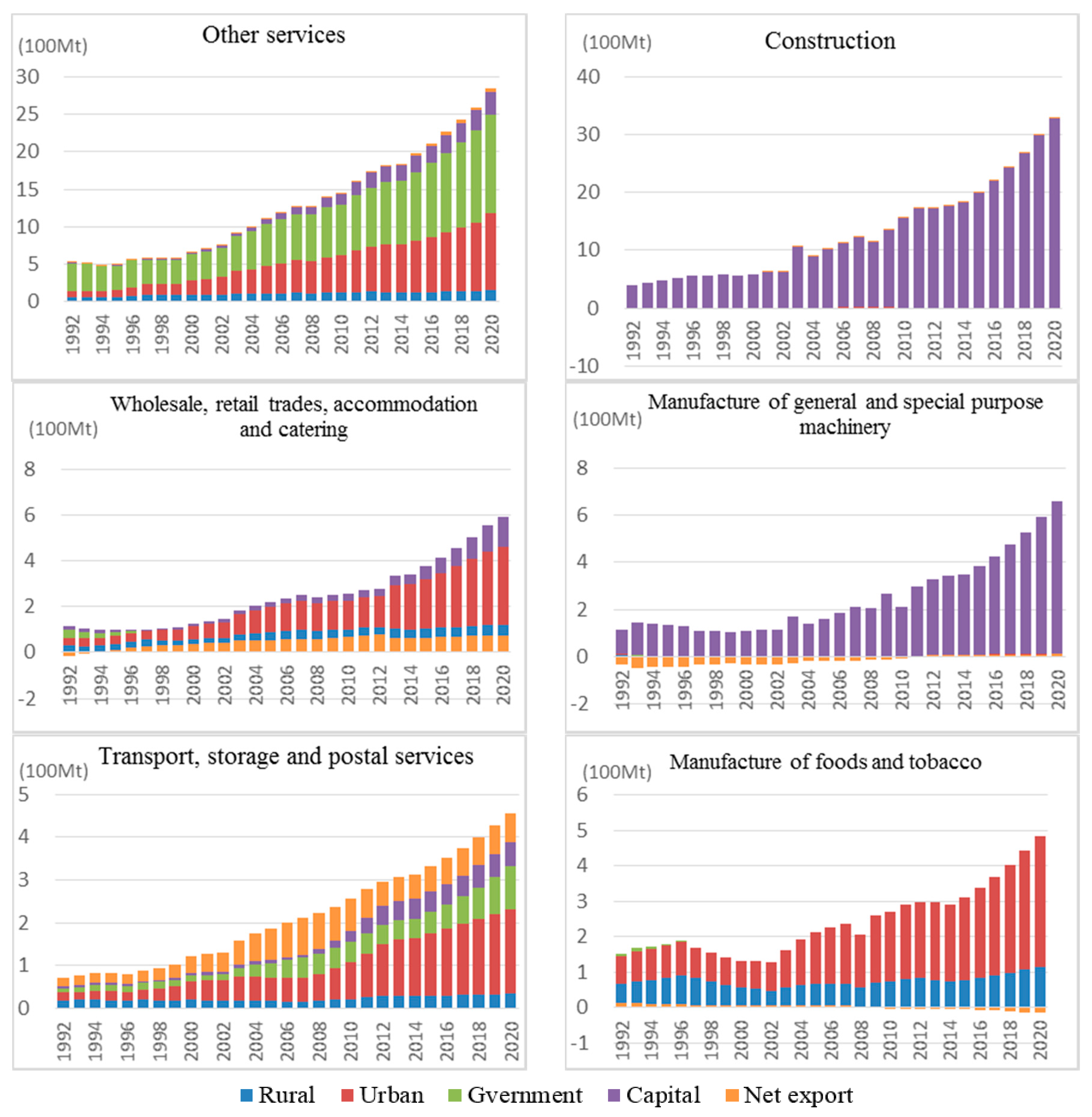

4.3. Embodied Carbon Emissions from 1992 to 2020

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Finkbeiner, M. Carbon Footprinting—Opportunities and Threats; Springer: Berlin, Germany, 2009. [Google Scholar]

- Weidema, B.P.; Thrane, M.; Christensen, P.; Schmidt, J.; Løkke, S. Carbon footprint. J. Ind. Ecol. 2008, 12, 3–6. [Google Scholar] [CrossRef]

- Weber, C.L.; Matthews, H.S. Quantifying the global and distributional aspects of American household carbon footprint. Ecol. Econ. 2008, 66, 379–391. [Google Scholar] [CrossRef]

- Hertwich, E.G.; Peters, G.P. Carbon footprint of nations: A global, trade-linked analysis. Environ. Sci. Technol. 2009, 43, 6414–6420. [Google Scholar] [CrossRef] [PubMed]

- Minx, J.C.; Wiedmann, T.; Wood, R.; Peters, G.P.; Lenzen, M.; Owen, A.; Scott, K.; Barrett, J.; Hubacek, K.; Baiocchi, G. INPUT–OUTPUT ANALYSIS AND CARBON FOOTPRINTING: AN OVERVIEW OF APPLICATIONS. Econ. Syst. Res. 2009, 21, 187–216. [Google Scholar] [CrossRef]

- Park, H.C.; Heo, E. The direct and indirect household energy requirements in the Republic of Korea from 1980 to 2000—An input–output analysis. Energy Policy 2007, 35, 2839–2851. [Google Scholar] [CrossRef]

- Cohen, C.; Lenzen, M.; Schaeffer, R. Energy requirements of households in Brazil. Energy Policy 2005, 33, 555–562. [Google Scholar] [CrossRef]

- Cellura, M. Application of the Structural Decomposition Analysis to assess the indirect energy consumption and air emission changes related to Italian households consumption. Renew. Sustain. Energy Rev. 2012, 16, 199–214. [Google Scholar] [CrossRef]

- Das, A.; Paul, S.K. CO2 emissions from household consumption in India between 1993–94 and 2006–07: A decomposition analysis. Energy Econ. 2014, 41, 90–105. [Google Scholar] [CrossRef]

- Giljum, S.; Hubacek, K. Alternative approaches of physical input–output analysis to estimate primary material inputs of production and consumption activities. Econ. Syst. Res. 2004, 16, 301–310. [Google Scholar] [CrossRef]

- Wood, R.; Dey, C.J. Australia’s carbon footprint. Econ. Syst. Res. 2009, 21, 243–266. [Google Scholar] [CrossRef]

- Lenzen, M. Primary energy and greenhouse gases embodied in Australian final consumption: An input–output analysis. Energy Policy 1998, 26, 495–506. [Google Scholar] [CrossRef]

- Biesiot, W.; Noorman, K.J. Energy requirements of household consumption: A case study of The Netherlands. Ecol. Econ. 1999, 28, 367–383. [Google Scholar] [CrossRef]

- Wier, M.; Lenzen, M.; Munksgaard, J.; Smed, S. Effects of household consumption patterns on CO2 requirements. Econ. Syst. Res. 2001, 13, 259–274. [Google Scholar] [CrossRef]

- Lenzen, M.; Dey, C.; Foran, B. Energy requirements of Sydney households. Ecol. Econ. 2004, 49, 375–399. [Google Scholar] [CrossRef]

- Lenzen, M.; Wood, R.; Foran, B. Direct versus Embodied Energy. The Need for Urban Lifestyle Transitions; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Druckman, A.; Jackson, T. The carbon footprint of UK households 1990–2004: A socio-economically disaggregated, quasi-multi-regional input–output model. Ecol. Econ. 2009, 68, 2066–2077. [Google Scholar] [CrossRef] [Green Version]

- Kerkhof, A.C.; Nonhebel, S.; Moll, H.C. Relating the environmental impact of consumption to household expenditures: An input–output analysis. Ecol. Econ. 2009, 68, 1160–1170. [Google Scholar] [CrossRef]

- Wiedenhofer, D.; Lenzen, M.; Steinberger, J.K. Spatial and Socioeconomic Drivers of Direct and Indirect Household Energy Consumption in Australia; CSIRO Publishing: Collingwood, Australia, 2011. [Google Scholar]

- Lenzen, M.; Wier, M.; Cohen, C.; Hayami, H.; Pachauri, S.; Schaeffer, R. A comparative multivariate analysis of household energy requirements in Australia, Brazil, Denmark, India and Japan. Energy 2006, 31, 181–207. [Google Scholar] [CrossRef]

- Zhu, Q.; Peng, X.; Wu, K. Calculation and decomposition of indirect carbon emissions from residential consumption in China based on the input–output model. Energy Policy 2012, 48, 618–626. [Google Scholar] [CrossRef]

- Zhang, Y. IMPACT OF URBAN AND RURAL HOUSEHOLD CONSUMPTION ON CARBON EMISSIONS IN CHINA. Econ. Syst. Res. 2013, 25, 287–299. [Google Scholar] [CrossRef]

- Liu, L.C.; Wu, G.; Wang, J.N.; Wei, Y.M. China’s carbon emissions from urban and rural households during 1992–2007. J. Clean. Prod. 2011, 19, 1754–1762. [Google Scholar] [CrossRef]

- Fan, J.; Guo, X.; Marinova, D.; Wu, Y.; Zhao, D. Embedded carbon footprint of Chinese urban households: Structure and changes. J. Clean. Prod. 2012, 33, 50–59. [Google Scholar] [CrossRef]

- Chen, G.Q.; Guo, S.; Shao, L.; Li, J.S.; Chen, Z.M. Three-scale input–output modeling for urban economy: Carbon emission by Beijing 2007. Commun. Nonlinear Sci. Numer. Simul. 2013, 18, 2493–2506. [Google Scholar] [CrossRef]

- Zhang, G.; Liu, M.; Gao, X. Dynamic Characteristic Analysis of Indirect Carbon Emissions Caused by Chinese Urban and Rural Residential Consumption Based on Time Series Input-Output Tables from 2002 to 2011. Math. Probl. Eng. 2014, 2014, 297637. [Google Scholar] [CrossRef]

- Södersten, C.J.; Wood, R.; Hertwich, E.G. Environmental Impacts of Capital Formation. J. Ind. Ecol. 2017. [Google Scholar] [CrossRef]

- Weisz, H.; Suh, S.; Graedel, T. Industrial Ecology: The role of manufactured capital in sustainability. Proc. Natl. Acad. Sci. USA 2015, 112, 6260–6264. [Google Scholar] [CrossRef] [PubMed]

- Müller, D.B.; Wang, T.; Duval, B.; Graedel, T.E. Exploring the engine of anthropogenic iron cycles. Proc. Natl. Acad. Sci. USA 2006, 103, 16111–16116. [Google Scholar] [CrossRef] [PubMed]

- Pauliuk, S.; Müller, D.B. The role of in-use stocks in the social metabolism and in climate change mitigation. Glob. Environ. Chang. 2014, 24, 132–142. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.-Q.; Graedel, T. In-use product stocks link manufactured capital to natural capital. Proc. Natl. Acad. Sci. USA 2015, 112, 6265–6270. [Google Scholar] [CrossRef] [PubMed]

- Peters, G.P.; Weber, C.L.; Guan, D.; Hubacek, K. China’s Growing CO2 Emissions a Race between Increasing Consumption and Efficiency Gains. Environ. Sci. Technol. 2007, 41, 5939–5944. [Google Scholar] [CrossRef] [PubMed]

- Xie, S.-C. The driving forces of China’s energy use from 1992 to 2010: An empirical study of input–output and structural decomposition analysis. Energy Policy 2014, 73, 401–415. [Google Scholar] [CrossRef]

- Wang, H.; Wang, C.; Zheng, H.; Feng, H.; Guan, R.; Long, W. Updating Input–Output Tables with Benchmark Table Series. Econ. Syst. Res. 2015, 27, 1–19. [Google Scholar] [CrossRef]

- Zheng, H.; Fang, Q.; Wang, H.; Wang, C.; Ren, R. Input-output serial table’s updating and the analysis of industrial structure change in China: 1992–2020. In Proceedings of the China Economics 2016 Annual Conference, Wuhan, China, 3–4 December 2016.

- Bai, C.; Zhang, Q. China’s economic growth prospects. New Financ. Rev. 2014, 1, 135–151. (In Chinese) [Google Scholar]

- Department of Energy Statistics, National Bureau of Statistics. China Energy Statistical Yearbook 2007; China Statistics Press: Beijing, China, 2008.

- Department of Energy Statistics, National Bureau of Statistics. China Energy Statistical Yearbook 2008; China Statistics Press: Beijing, China, 2009.

- Department of Energy Statistics, National Bureau of Statistics. China Energy Statistical Yearbook 2009; China Statistics Press: Beijing, China, 2010.

- Department of Energy Statistics, National Bureau of Statistics. China Energy Statistical Yearbook 2010; China Statistics Press: Beijing, China, 2011.

- Department of Energy Statistics, National Bureau of Statistics. China Energy Statistical Yearbook 2011; China Statistics Press: Beijing, China, 2012.

- Department of Energy Statistics, National Bureau of Statistics. China Energy Statistical Yearbook 2012; China Statistics Press: Beijing, China, 2013.

- Department of Energy Statistics, National Bureau of Statistics. China Energy Statistical Yearbook 2013; China Statistics Press: Beijing, China, 2014.

- Department of Energy Statistics, National Bureau of Statistics. China Energy Statistical Yearbook 2014; China Statistics Press: Beijing, China, 2015.

- 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Institute for Global Environmental Strategies: Kanagawa, Japan, 2006.

| Industry a | Intensity b | Embodied Carbon Emission Multiplier | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 2014 | 1992 | 2000 | 2010 | 2014 | 2015 | 2016 | 2017 | 2020 | |

| 1 | 0.21 | 3.84 | 1.37 | 0.78 | 0.58 | 0.60 | 0.62 | 0.64 | 0.74 |

| 2 | 0.51 | 10.82 | 3.02 | 1.51 | 1.12 | 1.13 | 1.15 | 1.17 | 1.21 |

| 3 | 0.19 | 5.61 | 2.22 | 0.84 | 0.61 | 0.62 | 0.64 | 0.65 | 0.70 |

| 4 | 0.15 | 7.22 | 2.08 | 0.98 | 0.82 | 0.84 | 0.86 | 0.88 | 0.94 |

| 5 | 0.25 | 8.01 | 2.40 | 1.33 | 0.95 | 0.98 | 1.00 | 1.02 | 1.09 |

| 6 | 0.10 | 5.81 | 1.71 | 1.00 | 0.67 | 0.67 | 0.68 | 0.69 | 0.74 |

| 7 | 0.09 | 6.87 | 1.91 | 1.14 | 0.81 | 0.83 | 0.85 | 0.86 | 0.91 |

| 8 | 0.03 | 6.01 | 1.59 | 1.02 | 0.70 | 0.70 | 0.71 | 0.72 | 0.74 |

| 9 | 0.07 | 7.24 | 1.92 | 1.14 | 0.79 | 0.79 | 0.79 | 0.81 | 0.86 |

| 10 | 0.13 | 7.27 | 2.23 | 1.46 | 0.87 | 0.85 | 0.84 | 0.82 | 0.78 |

| 11 | 0.57 | 7.54 | 4.55 | 1.61 | 1.23 | 1.24 | 1.26 | 1.28 | 1.33 |

| 12 | 0.46 | 10.52 | 3.28 | 1.94 | 1.47 | 1.48 | 1.47 | 1.47 | 1.42 |

| 13 | 1.25 | 15.02 | 4.96 | 3.40 | 2.33 | 2.35 | 2.37 | 2.39 | 2.44 |

| 14 | 0.44 | 10.07 | 3.75 | 1.77 | 1.39 | 1.41 | 1.43 | 1.45 | 1.54 |

| 15 | 0.04 | 7.63 | 2.60 | 1.09 | 1.02 | 1.06 | 1.10 | 1.15 | 1.25 |

| 16 | 0.03 | 6.11 | 2.16 | 1.01 | 0.91 | 0.92 | 0.93 | 0.95 | 1.00 |

| 17 | 0.02 | 5.65 | 2.14 | 1.09 | 0.87 | 0.89 | 0.91 | 0.93 | 0.99 |

| 18 | 0.01 | 11.41 | 2.38 | 1.13 | 1.03 | 1.04 | 1.06 | 1.08 | 1.14 |

| 19 | 0.01 | 6.04 | 1.90 | 0.97 | 0.80 | 0.82 | 0.83 | 0.85 | 0.90 |

| 20 | 0.01 | 5.81 | 2.06 | 1.05 | 0.86 | 0.87 | 0.88 | 0.90 | 0.94 |

| 21 | 0.04 | 10.55 | 2.24 | 0.88 | 0.56 | 0.59 | 0.61 | 0.63 | 0.68 |

| 22 | 0.03 | 5.37 | 0.00 | 0.33 | 0.31 | 0.33 | 0.33 | 0.34 | 0.37 |

| 23 | 0.05 | 5.35 | 2.60 | 1.04 | 0.71 | 0.70 | 0.69 | 0.69 | 0.73 |

| 24 | 0.09 | 8.90 | 5.21 | 0.88 | 0.67 | 0.68 | 0.68 | 0.68 | 0.69 |

| 25 | 0.02 | 4.47 | 1.51 | 0.69 | 0.56 | 0.56 | 0.56 | 0.56 | 0.56 |

| 26 | 0.13 | 7.70 | 2.69 | 1.63 | 1.20 | 1.22 | 1.24 | 1.26 | 1.33 |

| 27 | 1.36 | 7.06 | 4.25 | 2.51 | 2.13 | 2.15 | 2.18 | 2.20 | 2.29 |

| 28 | 0.25 | 4.95 | 1.59 | 0.80 | 0.62 | 0.63 | 0.65 | 0.68 | 0.74 |

| 29 | 0.52 | 12.33 | 2.68 | 1.27 | 0.98 | 0.99 | 1.00 | 1.01 | 1.05 |

| Industry No. a | 1992 | 1993 | 1994 | 1995 | 1996 | 1997 | 1998 | 1999 | 2000 | 2001 |

| 1 | 0.26 | 0.28 | 0.28 | 0.28 | 0.27 | 0.25 | 0.26 | 0.26 | 0.23 | 0.22 |

| 6 | 0.13 | 0.15 | 0.16 | 0.17 | 0.18 | 0.17 | 0.17 | 0.16 | 0.15 | 0.15 |

| 27 | 0.05 | 0.05 | 0.05 | 0.05 | 0.04 | 0.05 | 0.05 | 0.06 | 0.06 | 0.06 |

| 28 | 0.07 | 0.07 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.07 | 0.07 |

| 29 | 0.13 | 0.13 | 0.13 | 0.14 | 0.17 | 0.22 | 0.24 | 0.26 | 0.29 | 0.31 |

| Total b | 0.65 | 0.67 | 0.69 | 0.71 | 0.72 | 0.75 | 0.78 | 0.80 | 0.80 | 0.81 |

| TE (Mt) c | 409.8 | 421.8 | 419.9 | 432.0 | 464.7 | 462.3 | 394.9 | 344.1 | 323.5 | 312.4 |

| Industry No. a | 2002 | 2003 | 2004 | 2005 | 2006 | 2007 | 2008 | 2009 | 2010 | 2011 |

| 1 | 0.22 | 0.21 | 0.20 | 0.19 | 0.17 | 0.16 | 0.15 | 0.14 | 0.14 | 0.13 |

| 6 | 0.14 | 0.15 | 0.17 | 0.17 | 0.17 | 0.17 | 0.16 | 0.19 | 0.19 | 0.19 |

| 27 | 0.06 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.06 | 0.06 |

| 28 | 0.07 | 0.08 | 0.09 | 0.10 | 0.11 | 0.12 | 0.11 | 0.10 | 0.09 | 0.08 |

| 29 | 0.33 | 0.31 | 0.31 | 0.31 | 0.32 | 0.33 | 0.33 | 0.32 | 0.32 | 0.32 |

| Total b | 0.81 | 0.80 | 0.82 | 0.82 | 0.82 | 0.81 | 0.81 | 0.80 | 0.79 | 0.78 |

| TE (Mt) c | 299.6 | 345.3 | 344.0 | 350.5 | 357.0 | 365.7 | 333.1 | 372.2 | 383.9 | 414.6 |

| Industry No. a | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | |

| 1 | 0.12 | 0.13 | 0.13 | 0.13 | 0.12 | 0.12 | 0.13 | 0.13 | 0.13 | |

| 6 | 0.19 | 0.19 | 0.19 | 0.19 | 0.20 | 0.20 | 0.21 | 0.22 | 0.22 | |

| 27 | 0.07 | 0.07 | 0.07 | 0.07 | 0.07 | 0.07 | 0.07 | 0.07 | 0.07 | |

| 28 | 0.08 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.09 | 0.09 | |

| 29 | 0.34 | 0.32 | 0.32 | 0.31 | 0.31 | 0.30 | 0.30 | 0.29 | 0.30 | |

| Total b | 0.80 | 0.80 | 0.80 | 0.80 | 0.80 | 0.80 | 0.80 | 0.80 | 0.80 | |

| TE (Mt) c | 423.8 | 416.5 | 397.8 | 410.7 | 426.1 | 444.8 | 466.8 | 492.8 | 519.3 |

| Industry No. a | 1992 | 1993 | 1994 | 1995 | 1996 | 1997 | 1998 | 1999 | 2000 | 2001 |

| 1 | 0.13 | 0.14 | 0.14 | 0.14 | 0.14 | 0.13 | 0.13 | 0.13 | 0.11 | 0.11 |

| 6 | 0.19 | 0.20 | 0.20 | 0.20 | 0.19 | 0.17 | 0.16 | 0.14 | 0.13 | 0.12 |

| 27 | 0.04 | 0.04 | 0.05 | 0.05 | 0.04 | 0.04 | 0.05 | 0.06 | 0.07 | 0.07 |

| 28 | 0.09 | 0.08 | 0.08 | 0.08 | 0.07 | 0.07 | 0.08 | 0.09 | 0.09 | 0.10 |

| 29 | 0.23 | 0.21 | 0.21 | 0.21 | 0.23 | 0.27 | 0.27 | 0.28 | 0.31 | 0.32 |

| Total | 0.69 | 0.68 | 0.68 | 0.67 | 0.67 | 0.68 | 0.69 | 0.70 | 0.71 | 0.71 |

| TE (Mt) | 409.8 | 421.8 | 419.9 | 432.0 | 464.7 | 462.3 | 394.9 | 344.1 | 323.5 | 312.4 |

| Industry No. a | 2002 | 2003 | 2004 | 2005 | 2006 | 2007 | 2008 | 2009 | 2010 | 2011 |

| 1 | 0.10 | 0.09 | 0.08 | 0.08 | 0.07 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 |

| 6 | 0.11 | 0.12 | 0.14 | 0.15 | 0.15 | 0.15 | 0.14 | 0.15 | 0.15 | 0.15 |

| 27 | 0.07 | 0.06 | 0.06 | 0.05 | 0.05 | 0.05 | 0.06 | 0.06 | 0.07 | 0.07 |

| 28 | 0.10 | 0.10 | 0.11 | 0.11 | 0.11 | 0.11 | 0.11 | 0.10 | 0.10 | 0.10 |

| 29 | 0.33 | 0.33 | 0.35 | 0.37 | 0.38 | 0.39 | 0.40 | 0.39 | 0.39 | 0.39 |

| Total | 0.72 | 0.70 | 0.74 | 0.75 | 0.76 | 0.76 | 0.77 | 0.76 | 0.77 | 0.77 |

| TE (Mt) | 299.6 | 345.3 | 344.0 | 350.5 | 357.0 | 365.7 | 333.1 | 372.2 | 383.9 | 414.6 |

| Industry No. a | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | |

| 1 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | |

| 6 | 0.14 | 0.14 | 0.13 | 0.13 | 0.14 | 0.14 | 0.14 | 0.14 | 0.14 | |

| 27 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | |

| 28 | 0.09 | 0.12 | 0.12 | 0.12 | 0.13 | 0.13 | 0.13 | 0.13 | 0.13 | |

| 29 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | 0.38 | 0.39 | |

| Total | 0.76 | 0.77 | 0.78 | 0.78 | 0.78 | 0.78 | 0.78 | 0.78 | 0.79 | |

| TE (Mt) | 423.8 | 416.5 | 397.8 | 410.7 | 426.1 | 444.8 | 466.8 | 492.8 | 519.3 |

| Industry No. a | 1992 | 1993 | 1994 | 1995 | 1996 | 1997 | 1998 | 1999 | 2000 | 2001 |

| 1 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.01 | 0.01 | 0.00 | 0.01 |

| 27 | 0.02 | 0.03 | 0.04 | 0.04 | 0.04 | 0.05 | 0.05 | 0.04 | 0.04 | 0.03 |

| 29 | 0.86 | 0.87 | 0.88 | 0.90 | 0.93 | 0.95 | 0.95 | 0.95 | 0.96 | 0.96 |

| Total | 0.88 | 0.90 | 0.92 | 0.94 | 0.97 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| TE(Mt) | 409.8 | 421.8 | 419.9 | 432.0 | 464.7 | 462.3 | 394.9 | 344.1 | 323.5 | 312.4 |

| Industry No. a | 2002 | 2003 | 2004 | 2005 | 2006 | 2007 | 2008 | 2009 | 2010 | 2011 |

| 1 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.00 |

| 27 | 0.03 | 0.04 | 0.05 | 0.06 | 0.07 | 0.07 | 0.07 | 0.07 | 0.07 | 0.06 |

| 29 | 0.97 | 0.95 | 0.94 | 0.94 | 0.93 | 0.92 | 0.92 | 0.93 | 0.93 | 0.93 |

| Total | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| TE(Mt) | 299.6 | 345.3 | 344.0 | 350.5 | 357.0 | 365.7 | 333.1 | 372.2 | 383.9 | 414.6 |

| Industry No. a | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | |

| 1 | 0.00 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | |

| 27 | 0.06 | 0.05 | 0.05 | 0.05 | 0.05 | 0.06 | 0.06 | 0.07 | 0.07 | |

| 29 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.93 | 0.93 | 0.92 | |

| Total | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | |

| TE(Mt) | 423.8 | 416.5 | 397.8 | 410.7 | 426.1 | 444.8 | 466.8 | 492.8 | 519.3 |

| Industry No. a | 1992 | 1993 | 1994 | 1995 | 1996 | 1997 | 1998 | 1999 | 2000 | 2001 |

| 16 | 0.17 | 0.20 | 0.18 | 0.16 | 0.15 | 0.13 | 0.13 | 0.13 | 0.13 | 0.12 |

| 17 | 0.06 | 0.07 | 0.07 | 0.07 | 0.07 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 |

| 18 | 0.03 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| 26 | 0.64 | 0.62 | 0.65 | 0.67 | 0.68 | 0.71 | 0.70 | 0.69 | 0.69 | 0.68 |

| 29 | 0.00 | 0.00 | 0.01 | 0.01 | 0.01 | 0.02 | 0.02 | 0.02 | 0.02 | 0.03 |

| Total | 0.91 | 0.92 | 0.92 | 0.93 | 0.93 | 0.93 | 0.93 | 0.92 | 0.91 | 0.91 |

| TE(Mt) | 409.8 | 421.8 | 419.9 | 432.0 | 464.7 | 462.3 | 394.9 | 344.1 | 323.5 | 312.4 |

| Industry No. a | 2002 | 2003 | 2004 | 2005 | 2006 | 2007 | 2008 | 2009 | 2010 | 2011 |

| 16 | 0.12 | 0.11 | 0.11 | 0.11 | 0.11 | 0.11 | 0.11 | 0.12 | 0.09 | 0.11 |

| 17 | 0.06 | 0.06 | 0.06 | 0.06 | 0.07 | 0.07 | 0.08 | 0.08 | 0.09 | 0.09 |

| 18 | 0.01 | 0.01 | 0.03 | 0.03 | 0.03 | 0.04 | 0.04 | 0.04 | 0.02 | 0.03 |

| 26 | 0.68 | 0.71 | 0.67 | 0.67 | 0.66 | 0.65 | 0.63 | 0.62 | 0.67 | 0.63 |

| 29 | 0.03 | 0.03 | 0.04 | 0.04 | 0.05 | 0.05 | 0.06 | 0.06 | 0.06 | 0.07 |

| Total | 0.90 | 0.92 | 0.91 | 0.91 | 0.91 | 0.92 | 0.92 | 0.92 | 0.93 | 0.93 |

| TE(Mt) | 299.6 | 345.3 | 344.0 | 350.5 | 357.0 | 365.7 | 333.1 | 372.2 | 383.9 | 414.6 |

| Industry No. a | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | |

| 16 | 0.11 | 0.11 | 0.11 | 0.11 | 0.12 | 0.12 | 0.12 | 0.12 | 0.12 | |

| 17 | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 | 0.08 | 0.08 | 0.08 | 0.07 | |

| 18 | 0.03 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | |

| 26 | 0.61 | 0.61 | 0.61 | 0.61 | 0.61 | 0.62 | 0.62 | 0.62 | 0.62 | |

| 29 | 0.07 | 0.07 | 0.07 | 0.07 | 0.06 | 0.06 | 0.06 | 0.05 | 0.06 | |

| Total | 0.93 | 0.92 | 0.92 | 0.92 | 0.92 | 0.92 | 0.92 | 0.91 | 0.91 | |

| TE(Mt) | 423.8 | 416.5 | 397.8 | 410.7 | 426.1 | 444.8 | 466.8 | 492.8 | 519.3 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, H.; Fang, Q.; Wang, C.; Wang, H.; Ren, R. China’s Carbon Footprint Based on Input-Output Table Series: 1992–2020. Sustainability 2017, 9, 387. https://doi.org/10.3390/su9030387

Zheng H, Fang Q, Wang C, Wang H, Ren R. China’s Carbon Footprint Based on Input-Output Table Series: 1992–2020. Sustainability. 2017; 9(3):387. https://doi.org/10.3390/su9030387

Chicago/Turabian StyleZheng, Haitao, Qi Fang, Cheng Wang, Huiwen Wang, and Ruoen Ren. 2017. "China’s Carbon Footprint Based on Input-Output Table Series: 1992–2020" Sustainability 9, no. 3: 387. https://doi.org/10.3390/su9030387