1. Introduction

Firms can increase their competitiveness by improving their supply chain (SC) activities, which encompasses procurement of raw materials, manufacturing of products, and forward/reverse logistics of the manufactured goods [

1]. This revolutionary concept has changed the way managers perceive business. Close coordination among upstream and downstream SC members is critical to business success as competition arises among SCs, not among individual companies [

2]. Previously in the business arena, there was a time that efficient SC strategies were the trend. These include efficient consumer response (ECR), vendor managed inventory (VMI), collaborative planning, forecasting, and replenishment (CPFR), and lean SCs [

3,

4,

5,

6]. The primary objective of these strategies is to reduce work-in-process inventory while increasing customer service. Toyota’s just-in-time strategy and Walmart’s VMI practices show that efficient strategies could be effective methods for reducing costs. Thus, it is not surprising that firms benchmarked efficient SCs rigorously.

Maximizing efficiency, however, is not always the best strategy. Efficient SCs are susceptible to critical damage from sudden market changes and unexpected disruptions because they are established in a specific manufacturing context seeking zero inventories, leaving little flexibility to accommodate disruptions in their operation [

7]. Currently, business is more exposed to risks as a result of globalization, outsourcing, and increased terrorist attacks [

8,

9]. Lack of preparation for such disruptions can be detrimental to firms in the following two areas: First, firms can lose profitability. For example, the terrorist attacks on 11 September 2001 caused significant losses for Ford and Toyota [

10]. Factories for both companies were forced to wait for long periods of time to receive components, for the initiating new airport security measures and, more critically, had little safety stock as a result of their just-in-time inventory policy. Second, firms can lose market share or are forced to exit the market when their responses to disruptions are ineffective compared to their competitors. This is well illustrated in Ericsson’s painful experience [

10]. When its semiconductor supplier, Philips NV, was disrupted due to lightning in 2000, Ericsson failed to take immediate action to find alternative supply sources. In contrast, Nokia secured all remaining supplies of semiconductors from various sources swiftly. Consequently, Ericsson experienced a $400 million loss in the phone market and eventually discontinued business. At this juncture, it is clear that firms’ ability to respond to disruptions is not only imperative but also valuable for strategic competitive advantage.

From this backdrop, supply chain resilience (SCR) has gained recent recognition among researchers. SCR can be defined as the ability to prepare for, respond to, and recover from potential disruptions, and increase market share [

11]. The main difference between efficient and resilient SCs is that the latter pursue redundant capacity or inventory intentionally when business is normal, in order to manage possible disruptions effectively. Numerous contributions have been made to understand resilience, and there are two distinct streams of research. The first constructs a conceptual framework to define and schematize resilience [

12,

13,

14]. These studies define several key factors of resilience and identified their relationship with resilience performance measures, e.g., the number of disruptions in an SC. The second group of studies uses quantitative models [

15,

16]. These studies have drawn managerial insights through simulation and complex network theory.

While both approaches have their own merits, measuring resilience has received relatively less attention [

11]. Some authors have used individual indicators, such as customer service level and order fulfillment rate, to evaluate resilience in a simulation framework [

16,

17,

18]. Additional researchers have used either topological measures, such as the number of nodes and supply distance in complex network theory [

19,

20,

21], or developed resilience indices based on survey scales [

14,

22,

23]. In analyzing resilience, most of these studies considered a single factor at a time, e.g., the number of nodes and supply distance, but did not include all influential factors in a single analysis framework. In other fields of research, two previous studies examined resilience considering various factors [

22,

23]. These studies analyzed resilience in petrochemical plants using the data envelopment analysis (DEA). The two studies, however, are different from the current one in two aspects. First, their research scope is centered on petrochemical plants—not an SC. Moreover, their resilience performance measures are based on survey scales, which can be exposed to criticism of biased evaluation of SCR as opinions from study respondents are subjective.

To address this gap in the literature, the present study evaluates a set of configurations of a supply chain network (SCN) and estimates the relative resilience potential using DEA models. DEA is employed to assess performance among decision-making units (DMUs) [

24], and in this study, the DMUs are different SCN configurations. The main purpose of DEA is to measure the efficiency of the DMUs. The resulting efficiency score is interpreted as the extent to which a firm can improve its output (input) in relation with the SCN configurations that show the best-practice. One purpose of DEA modeling is to minimize input usage while maintaining outputs, known as the “input orientation DEA model”, which is grounded in engineering and production theory. In traditional DEA models with input orientation, spare labor and capacity for a given output level is always undesirable. From a resilience viewpoint, however, such an input inefficiency can be considered beneficial in that the resilience of SCs can be “bolstered by either building in redundancy or building in flexibility” [

9]. Therefore, variables should be redefined to identify resilient and non-resilient SCN configurations. Hence, this paper considers three types of variables: positive, negative, and external factors. Positive factors are the set of variables that improve resilience when the factor values are increased. In contrast, the negative factors are the variables that weaken resilience when the factor values are increased. There are also factors that do not affect resilience per se, but can exert detrimental influence when an SC is facing turbulence. The factors with an indirect effect on SCR are termed external factors. In summary, the resiliency of an SC increases when positive factors increase, and negative or external factors decrease.

This paper contributes to SCR literature in three ways. First, SCR is measured using a more objective peer-evaluation approach using DEA models. Previous work on measuring resilience featured a narrow approach by focusing on single factors, such as order fill rate and lead time ratio, among others (see

Table 1). The present study employs a more holistic approach which considers additional influential factors. Previous research results may include bias resulting from the subjective measurements in magnitude of the resilience arising from survey-based research [

23]. In contrast, this study provides more objective measurements using DEA models and covers the entire SC as its scope. Second, measures used in this paper encompasses several topological and operational indicators of SCN, rarely used in previous works. Topological characteristics in this study is based on more scientific information-measuring tools such as ArcGIS, which is more advantageous and objective than measures based on survey scales used in previous research. Third, the treatment of capacity in this paper is unique in the literature. Specifically, existing studies that applied the DEA treated “capacity” as input; assuming that output level remains unchanged, less usage of capacity is preferred. On the other hand, the DEA analysis in the present study suggests that higher capacity is better, whenever possible. SCR increases in spare capacity, so an SCN deserves higher credit if more capacity is available in the network.

The remainder of this paper is organized as follows.

Section 2 reviews relevant literature on the conceptual framework and measurement issues of resilience.

Section 3 explains the DEA model and selected variables used in the model.

Section 4 presents the application of the model to the SC of a case study of the LPG company in Korea and details the data collection and analysis results. Finally,

Section 5 concludes the paper.

5. Results and Discussion

Table 4 presents the resiliency scores, where the scores are given in the form of decimal numbers between zero and one. The “zero” score indicates the worst-performing network configuration relative to others (in terms of resilience), while the best-practices are given a score of 1. The second and fourth columns report the resulting score before and after factoring population density into the analysis, respectively. Looking at the plain resilience score, the discriminatory power is rather high, i.e., only four SCN configurations 19–22, are resilient. This indicates that the DEA results in the present study are dependable [

52]. This can also be interpreted as a signal to stop inclusion of new configurations to the analysis, which requires addition of more supply nodes and capacity to the SCN. Note that resilient scores vary widely across different configurations. SCN configurations, such as 1–7, receive very low resilience scores, meaning that they are most vulnerable to disruptions. Considering the fourth column, however, some of the SCN configurations considered to be vulnerable become resilient when population risk is taken into account. For example, the resilience scores in SCN numbers 1, 2, 6, 18 increase dramatically when population risk is considered. This is due to the relatively lower population density in the mentioned configurations, resulting in negligible impacts on the people around the supply nodes when serious accidents occur. In other words, the SCR is sufficient and features little need for improvement with respect to population concerns.

Table 5 lists slacks in the DEA model not including the population factor. They indicate that the degree of each resilience factor (positive and negative) of the SCN at the current norm (Configuration No. 1) should improve to enhance SCR to a certain point. For instance, SCN 1 should increase its available capacity by 143,116 and its average node degree by 3 to achieve the highest resilience. This way, it is observed that network configurations of the alternative SCs lacking in resilience tend to require additional efforts for increasing resilience, even if they offer a better level of resiliency comparing to the current norms. However, the total distance is an exception to this claim. In other words, it can be concluded that total distance (negative factor) is not a significant determinant of resiliency based on these results.

Table 6 displays the slack results after incorporating population density into the analysis. Interestingly, the pattern of slacks in

Table 6 is different from those in

Table 5. Current average node degree is sufficient, but total distance requires additional reduction. This may be because more residents are exposed to the danger of accidents when supply routes are longer (longer total distance). Moreover, increasing node degree may expose more people to supply chain disruption. However, though this study did not intend to restrict population density value, model results are more realistic in that population density has zero slacks. Otherwise, having positive slack values for this variable can be considered unrealistic, since the population density cannot be changed to solve the resilience problem in practice.

The SCN rankings of both models with and without the population factor and the slack measures provide SC managers with useful decision-making guidelines for examining to what extent resiliency of the current network should be improved. On the other hand, it should be noted that some of the systems lacking in resilience under the first model (no population factor model), such as SC 1, 2, 5 and 18, resulted in being resilient when the population factor was considered. This is in contrast with the results of previous studies [

21,

48,

49], which claim that an increase in each of the positive factors of clustering coefficient and average node degree (as individual factor), or considering additional capacity [

9,

14,

29] leads to redundancy, and in turn improves resiliency of the SCN. The results of the present study, however, show that this is not always true as shown in

Table 6, especially when more comprehensive factors such as population exposure risk are considered. Therefore, this indicates that the estimation of resiliency as a relative measure among possible SCN configurations should be conducted with simultaneous consideration of divergent and conflicting factors, as used in this study.

6. Conclusions

This research assesses the SCR using the DEA. Acknowledging resiliency as a strategy for the design of SCN [

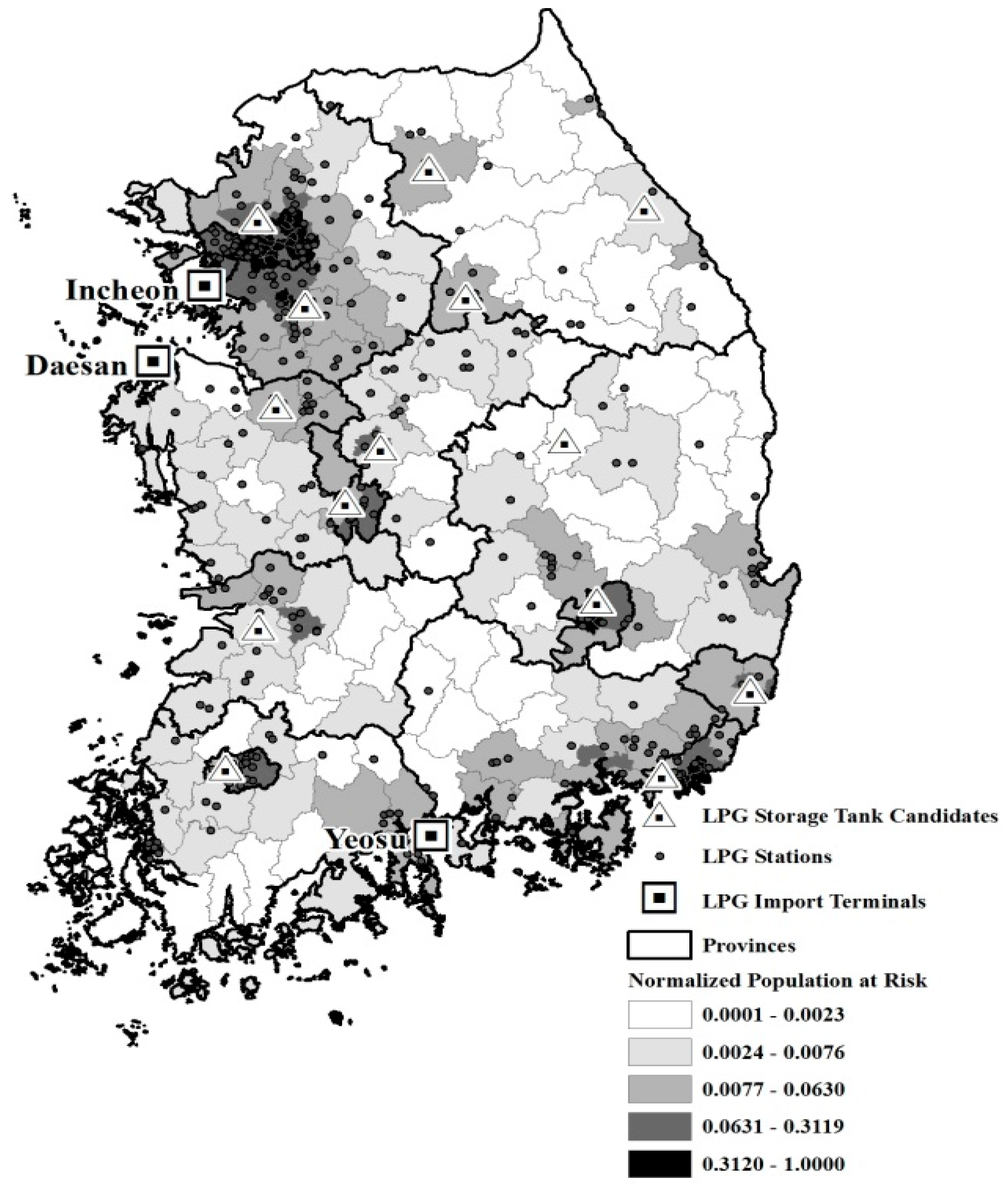

53], the present study attempted to score alternative SCN configurations with respect to different factors. To this end, a number of topological and operational characteristics that affects the resilience of the LPG supply chain are further considered. The developed approach proposes a unique framework of applying DEA to evaluate resiliency. Traditional DEA approaches assume that input redundancy and output shortfalls are “bad”. In contrast, redundancy in this study is a primary requirement for resilient SCs, so SCNs with more inputs, e.g., redundant capacity, should receive more credit from a resiliency viewpoint. From this perspective, variables were classified into three types. First, positive factors are a set of variables that enhance resilience if their values are increased. Available capacity, average node degree, clustering coefficient, and the number of supply nodes were included as positive factors. Conversely, negative factors are variables that deteriorate resiliency when their values increase. In the analysis provided in this research paper, total distance traveled was included in this category. Lastly, external factors represent the variables that do not directly affect resiliency, but can exert significant negative effects, in tandem with other factors, when an SC is disrupted. Population density was used as an external factor.

The resilience model was applied to a case study of an LPG handling company in Korea, E1. The results show that the SCN of the analyzed firm, E1, needs substantial improvement. The low resilience configuration featured small values for all positive factors. When population density was included in the model, the average node degree required no improvement, whereas reduction in total distance was necessary. This implies that average node degree is not necessarily important to mitigate population risk, but reduction in total distance is a critical factor.

The approach used in this study can be used for both academia and industry, as resiliency in an SCN can be measured in relation to the alternative configurations. Moreover, comprehensive factors influencing resiliency are simultaneously considered in the developed approach in the present research. The proposed approach provides a useful decision-making framework for examining investment decisions for the resiliency of SC. The provided ranking and slack measures provide insight for trade-offs between the required investment to change SC system, and consequential benefits by the enhanced SCR. This is the first study to consider population exposure risk together with other relevant factors in SCR.

This paper also provides managerial implications. Three strategies are recommended to enhance the resiliency of the SCN configuration. First, SCR planners should consider both direct shipping to gas stations, as well as shipping to gas stations through intermediate storage tanks. In doing so, alternative supply nodes would be available when a specific node breaks down. Second, interconnection among the supply nodes is suggested for facilitating exchange among suppliers when necessary. Finally, to cope with capacity shortfalls in periods of disruption, managers should consider retaining excess capacity. However, if this option is limited, due to a lack of budget for example, they can discriminate between different demand nodes according to demand elasticity or the other relevant criteria. For example, the demand nodes which are located in the strategic regions should be served as top priority.

Future research can extend results of the present study in several ways. In comparing SCN configurations of LPG, the analysis is confined to a single company. Future studies can broaden data used in analysis by evaluating SCNs covering multiple firms. This analysis identifies the profile of less resilient and resilient firms, which is effective in drawing managerial implications, such as how vulnerable firms can increase their resilience. Moreover, inclusion of more operational measures such as delivery time and total cost incurred for a specific SCN, would improve index reliability. When the proposed method is applied to service logistics and online shopping cases, shortages, and backorder costs can be incorporated to strengthen the analysis. Lastly, this paper assumes that higher capacity is always better to increase resilience, as numerous authors have assumed implicitly, e.g., Pettit et al. [

14], Azadeh and Salehi [

22], and Azadeh et al. [

23]. However, excessive capacity has negative aspects from the managerial viewpoint, as this increases costs associated with maintenance and storage. Therefore, a more desirable approach would determine minimum excess capacity that can ensure swift recovery and reduce costs simultaneously. When additional data on actual damage and recovery are collected, one can assess the extent to which the capacity of DMUs should be enhanced to improve resilience considering the trade-off between increased cost and benefit of reduced damage, and the recovery cost.