Development of the CO2 Emission Evaluation Tool for the Life Cycle Assessment of Concrete

Abstract

:1. Introduction

2. Previous Studies

3. GHG Emissions LCA of Concrete

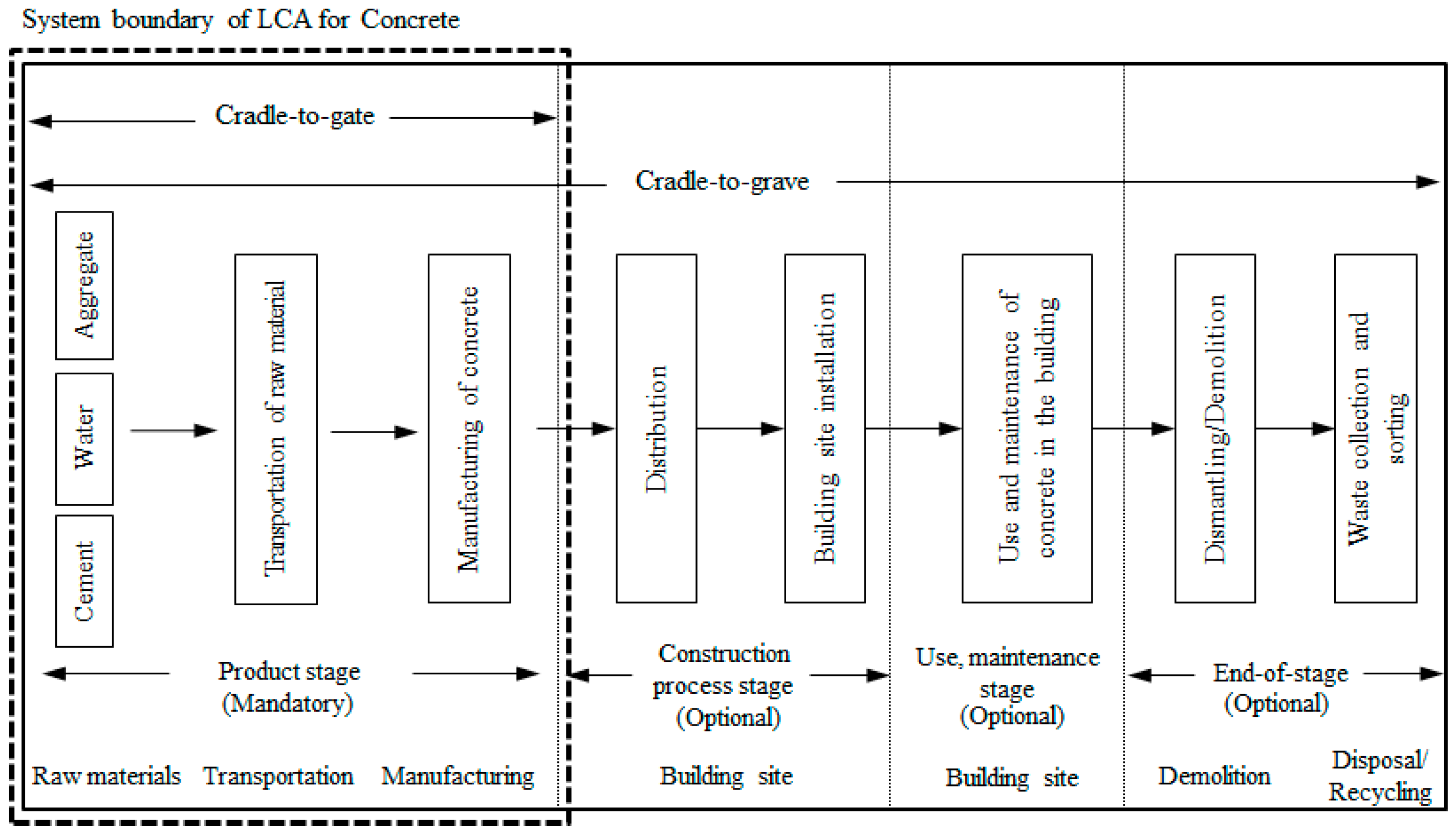

3.1. Overview

3.2. Aim and Scope

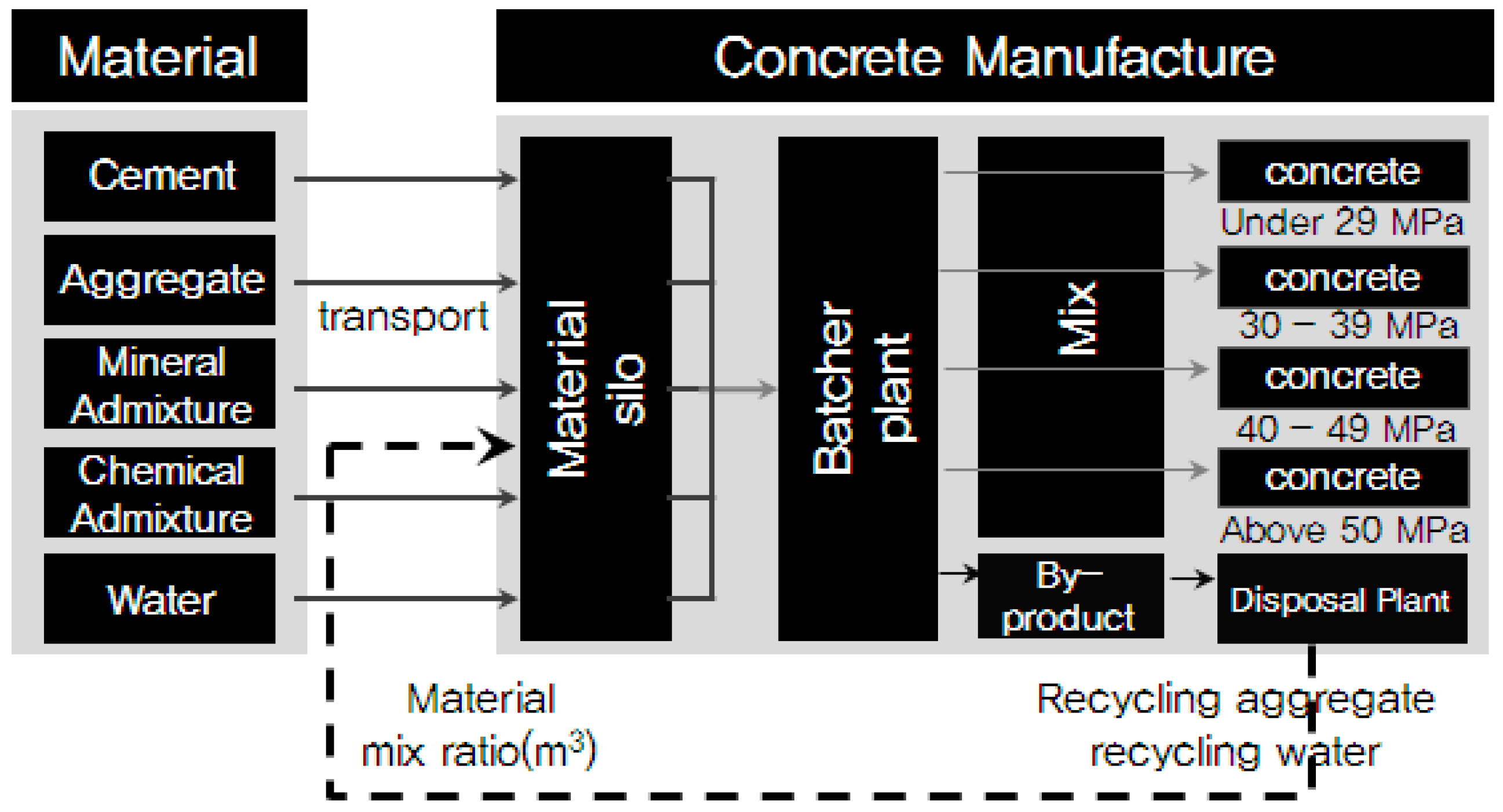

3.3. Inventory Analysis

3.4. Impact Assessment

3.4.1. Raw Materials Stage

3.4.2. Transportation Stage

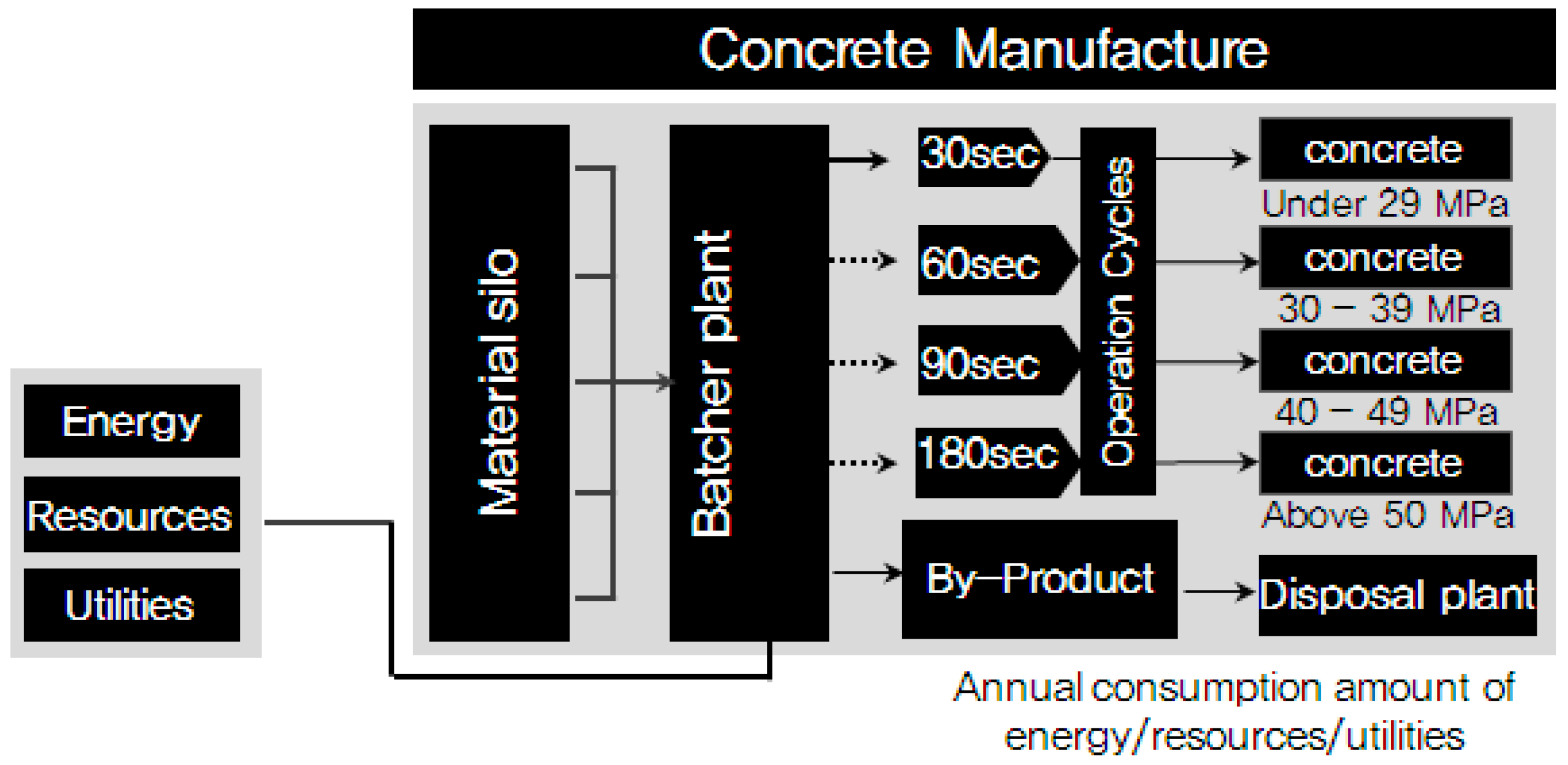

3.4.3. Manufacturing Stage

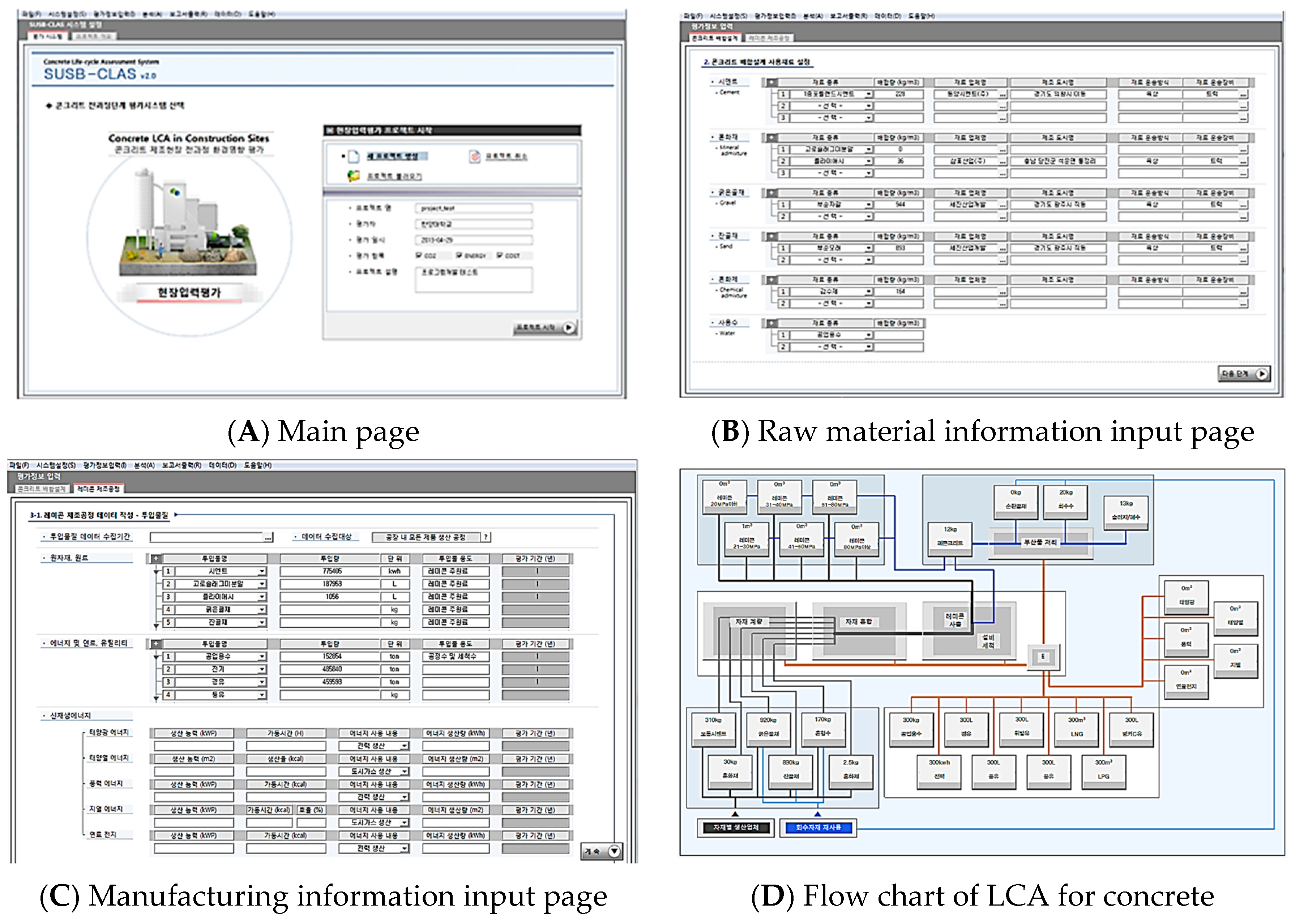

4. Assessment Software Development

4.1. Overview

4.2. Concrete GHG Emissions LCA Software

4.2.1. Project Overview Input Stage

4.2.2. Combined Material Information Input Stage

4.2.3. Manufacturing Process Information Input Stage

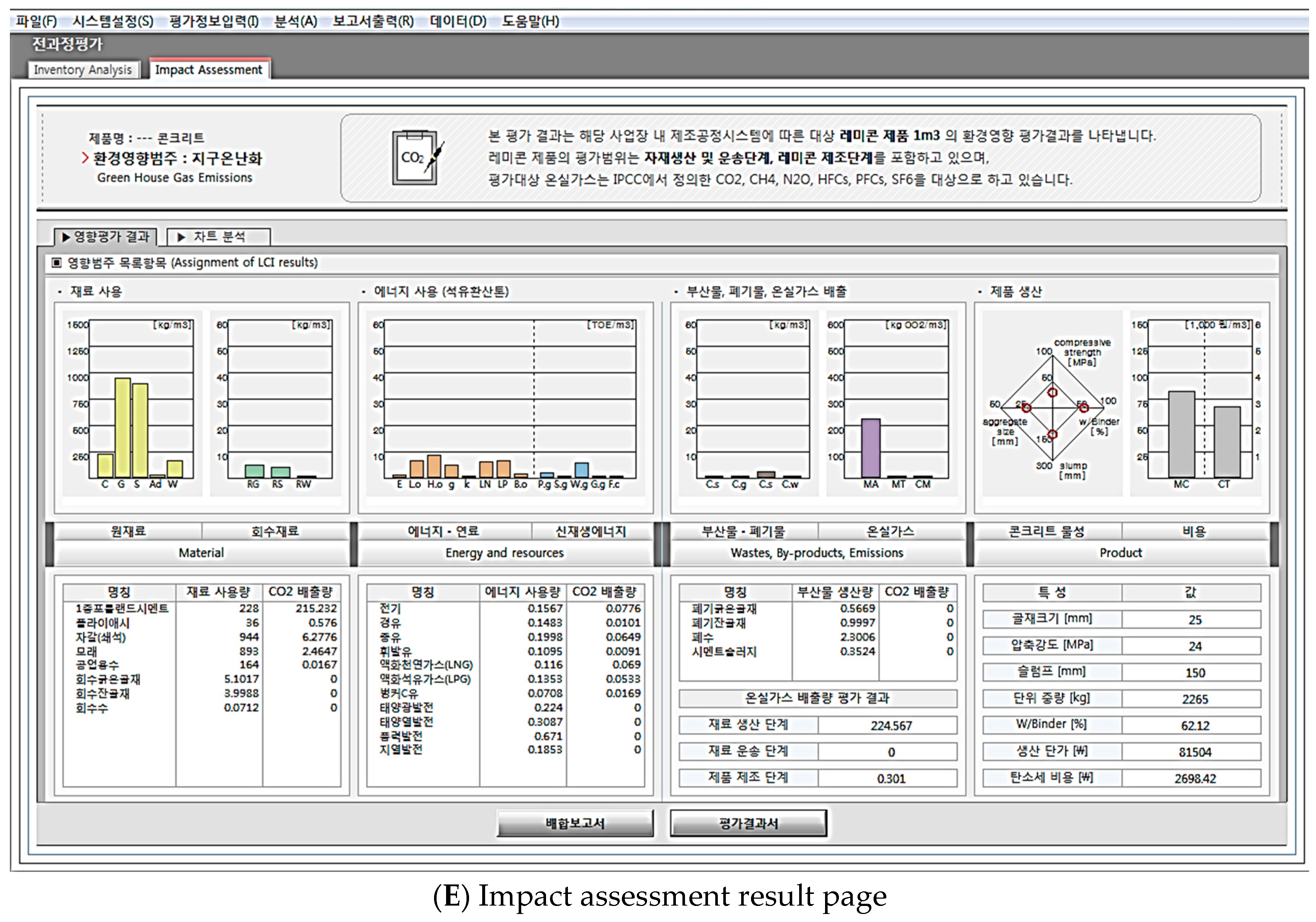

4.2.4. LCA Performance Stage

5. Case Analysis

5.1. Overview

5.2. Analysis Target

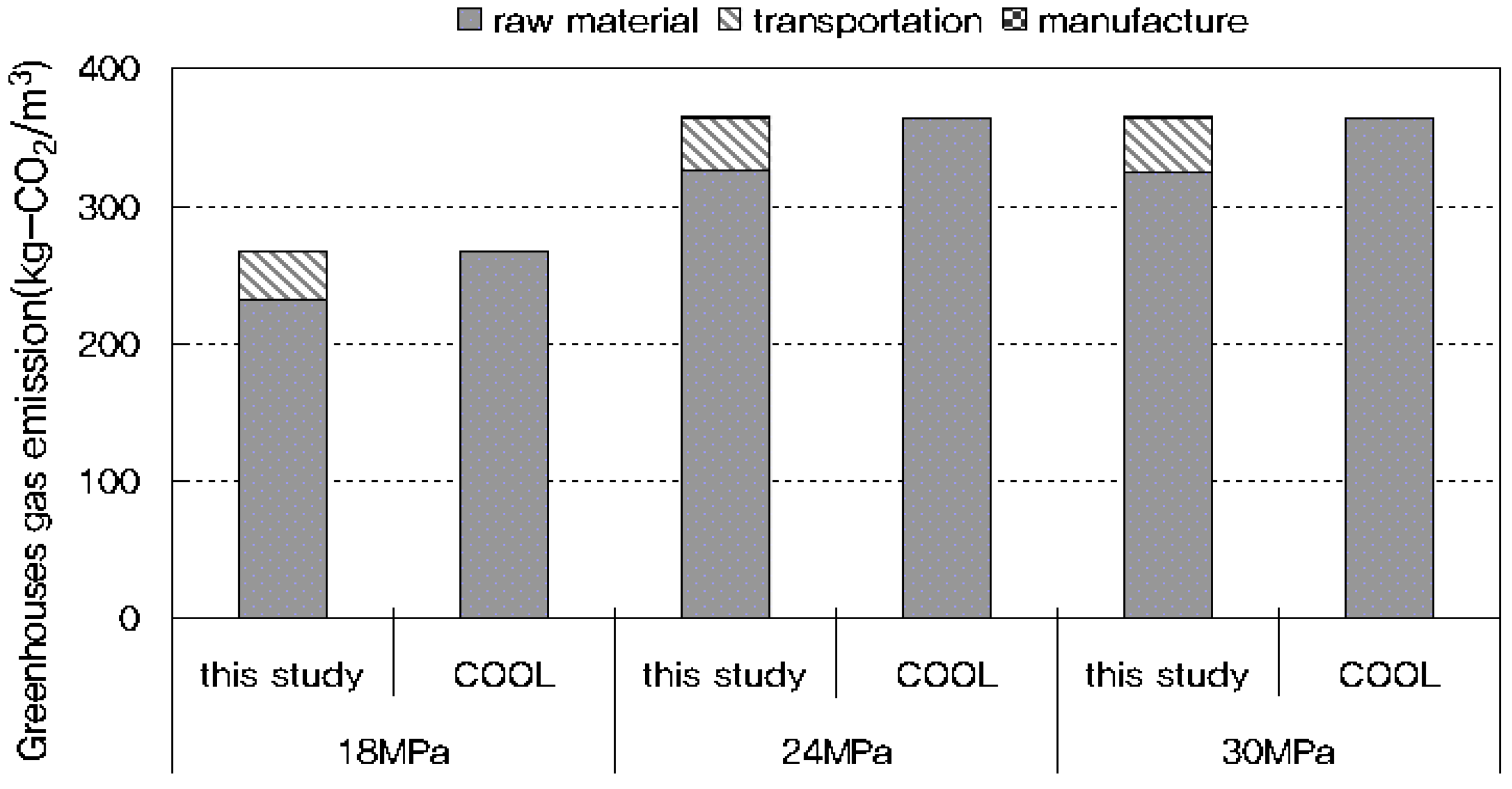

5.3. Assessment Results

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Leggett, J. A guide to the Kyoto protocol a treaty with potentially vital strategic implications for the renewables industry. Renew. Sustain. Energy Rev. 2008, 12, 345–351. [Google Scholar] [CrossRef]

- National Life Cycle Index Database Information Network. Available online: http://www.edp.or.kr (accessed on 15 October 2017).

- Ministry of Land, Transport and Maritime Affairs of the Korean Government. National Database for Environmental Information of Building Products; Ministry of Land, Transport and Maritime Affairs of the Korean Government: Sejong City, Korea, 2008.

- Ecoinvent, Swiss Centre for Life Cycle Inventories. Available online: http://www.ecoinvent.org/database (accessed on 15 October 2017).

- ISO 14044. Life Cycle Assessment (Requirements and Guidelines); International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- ISO/DIS 13315-2. Environmental Management for Concrete and Concrete Structures-Part 2: System Boundary and Inventory Data; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- Korea Environmental Industry & Technology Institute. Carbon Labeling Guidelines; Korea Environmental Industry & Technology Institute: Seoul, Korea, 2009. [Google Scholar]

- Korea Environmental Industry & Technology Institute. Environmental Declaration of Product. Available online: http://www.edp.or.kr/edp/edp_intro.asp (accessed on 15 October 2017).

- Korea National Cleaner Production Center. Environmental Declaration of Product. Available online: http://www.kncpc.or.kr/main/main.asp (accessed on 15 October 2017).

- European thematic network on practical recommendations for sustainable construction (PRESCO WP2). Inter-Comparison and Benchmarking of LCA-Based Environmental Assessment and Design Tool, Final Report; PRESCO: Paris, France, 2005. [Google Scholar]

- Available online: http://www.athenasmi.org (accessed on 15 October 2017).

- Available online: http://www.gabi-software.com/ (accessed on 15 October 2017).

- Available online: http://ecoquantum.com.au/ (accessed on 15 October 2017).

- Available online: https://envest2.bre.co.uk/ (accessed on 15 October 2017).

- Available online: http://www.vtt.fi/vtt/index.jsp (accessed on 15 October 2017).

- Available online: http://www.lisa.au.com/ (accessed on 15 October 2017).

- Marinković, S. On the selection of the functional unit in LCA of structural concrete. Int. J. Life Cycle Assess. 2017, 22, 1634–1636. [Google Scholar] [CrossRef]

- Mohammadi, J.; South, W. Life cycle assessment (LCA) of benchmark concrete products in Australia. Int. J. Life Cycle Assess. 2017, 22, 1588–1608. [Google Scholar] [CrossRef]

- Yazdanbakhsh, A.; Bank, L.C.; Baez, T.; Wernick, I. Comparative LCA of concrete with natural and recycled coarse aggregate in the New York City area. Int. J. Life Cycle Assess. 2017, 1–11. [Google Scholar] [CrossRef]

- Vieira, D.R.; Calmon, J.L.; Coelho, F.Z. Life cycle assessment (LCA) applied to the manufacturing of common and ecological concrete: A review. Constr. Build. Mater. 2016, 124, 656–666. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Cabeza, L.F.; Labrincha, J.; De Magalhaes, A.G. Eco-Efficient Construction and Building Materials: Life Cycle Assessment (LCA), Eco-Labelling and Case Studies; Elsevier: Cambridge, MA, USA, 2014. [Google Scholar]

- ISO 21930. Environmental Declaration of Building Products; International Organization for Standardization: Geneva, Switzerland, 2007. [Google Scholar]

- Jung, J.S.; Lee, J.S.; An, Y.J.; Lee, K.H.; Bae, K.S.; Jun, M.H. Analysis of Emission of Carbon Dioxide from Recycling of Waste Concrete. Arch. Inst. Korea 2008, 24, 109–116. [Google Scholar]

- Van den Heede, P.; De Belie, N. Environmental impact and life cycle assessment (LCA) of traditional and “green” concretes: Literature review and theoretical calculations. Cem. Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- Kim, T.H.; Tae, S.H. Proposal of Environmental Impact Assessment Method for Concrete in South Korea: An Application in LCA (Life Cycle Assessment). Int. J. Environ. Res. Public Health 2016, 13, 1074. [Google Scholar] [CrossRef] [PubMed]

- Jesus, G.M.; Justo, G.N. Assessment of the decrease of CO2 emissions in the construction field through the selection of materials: Practical case study of three houses of low environmental impact. Build. Environ. 2006, 41, 902–909. [Google Scholar]

- Kim, T.H.; Tae, S.H.; Chae, C.U. Analysis of Environmental Impact for Concrete Using LCA by Varying the Recycling Components, the Compressive Strength and the Admixture Material Mixing. Sustainability 2016, 8, 389. [Google Scholar] [CrossRef]

- Kim, S.H.; Chae, C.W. LCA Study on Concrete and Environmental Evaluation Method by Concrete Strength; Korea Concrete Institute: Seoul, Korea, 2012. [Google Scholar]

- Korea Concrete Institute. Environmental Impact and CO2 Assessment of Concrete Structures; Korea Concrete Institute: Seoul, Korea, 2013. [Google Scholar]

| Content | |

|---|---|

| Name | concrete |

| Function | concrete structures formation |

| Function unit | 1 m3 production of concrete |

| Division | Reference | Nation | |

|---|---|---|---|

| Raw material | Cement | National LCI | Korea |

| Coarse aggregate | National LCI | Korea | |

| Fine aggregate | National LCI | Korea | |

| recycled fine aggregate | Ecoinvent | Switzerland | |

| recycled coarse aggregate | Ecoinvent | Switzerland | |

| Blast furnace slag | Ecoinvent | Switzerland | |

| Fly ash | Ecoinvent | Switzerland | |

| Water | National LCI | Korea | |

| Chemical admixture | Ecoinvent | Switzerland | |

| Energy | Electric | National LCI | Korea |

| Diesel | National LCI | Korea | |

| Kerosene | National LCI | Korea | |

| Transportation | Truck | National LCI | Korea |

| Train | National LCI | Korea | |

| Detailed Assessment Items | |

|---|---|

| Project overview | - basic information: manufacturer, product specifications |

| Input of the combined material information | - material information: type of material, mix proportion, area of production, transport mode |

| - supplier information: material suppliers, location | |

| - transport details: material transport, transportation routes/destinations | |

| Input of manufacturing process information | - annual input material date: materials, energy, fuel, renewable energy |

| - annual output material date: concrete, by-product/waste, recycling materials | |

| LCA | - system boundaries, functional units - environmental impact categories: global warming |

| - material flow analysis and review

- applying assignment, material balance review - derived materials and resources list | |

| - applying emission factors of list items

- emission factors (classification, characterization) | |

| - GHG emissions, resource/energy usage | |

| Assessment result | - LCA results of GHG |

| - project assessment database storage |

| Division | Contents | |

|---|---|---|

| Energy and resource consumption (per year) | electronic (kwh) | 1,708,481 |

| diesel (L) | 842,582 | |

| kerosene (L) | 57,475 | |

| water (L) | 93,274 | |

| Production (per year) | 1–20 MPa | 68,962 |

| 21–30 MPa | 490,041 | |

| 31–40 MPa | 20,542 | |

| By-products emissions and disposal | by-products | All material inputs 2% (assumed) |

| recycling rate (aggregate) | 100% recovery of aggregate remaining (assumed) | |

| recycling rate (water) | 60% | |

| Materials/products during transportation | utility | Truck (limited to the same fuel vehicles) |

| Distance (km) | Specific materials transport route | |

| Mix Design of Concrete (kg/m3) | ||||||||

|---|---|---|---|---|---|---|---|---|

| OPC | FA | G | S | R/S | AE | W | R/W | |

| 18 MPa | 236 | 35 | 958 | 454 | 455 | 1.22 | 97 | 64 |

| 24 MPa | 336 | 0 | 936 | 453 | 443 | 3.05 | 131 | 0 |

| 30 MPa | 334 | 59 | 954 | 393 | 394 | 2.95 | 103 | 68 |

| Division | Greenhouse Gas Emissions [kg-CO2 eq/m3] | |||

|---|---|---|---|---|

| Concrete Standard | Method | This Study | COOL Program | |

| Stage | ||||

| case 1 (18 MPa) | raw material | 232.18 | 266.62 | |

| transportation | 34.61 | |||

| manufacturing | 0.67 | 0.12 | ||

| total | 267.46 | 266.74 | ||

| case 2 (24 MPa) | raw material | 325.74 | 364.15 | |

| transportation | 38.57 | |||

| manufacturing | 0.67 | 0.12 | ||

| total | 364.99 | 364.27 | ||

| case 3 (30 MPa) | raw material | 324.81 | 363.85 | |

| transportation | 39.21 | |||

| manufacturing | 1.34 | 0.12 | ||

| total | 365.36 | 363.97 | ||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, T.; Lee, S.; Chae, C.U.; Jang, H.; Lee, K. Development of the CO2 Emission Evaluation Tool for the Life Cycle Assessment of Concrete. Sustainability 2017, 9, 2116. https://doi.org/10.3390/su9112116

Kim T, Lee S, Chae CU, Jang H, Lee K. Development of the CO2 Emission Evaluation Tool for the Life Cycle Assessment of Concrete. Sustainability. 2017; 9(11):2116. https://doi.org/10.3390/su9112116

Chicago/Turabian StyleKim, Taehyoung, Sanghyo Lee, Chang U. Chae, Hyoungjae Jang, and Kanghee Lee. 2017. "Development of the CO2 Emission Evaluation Tool for the Life Cycle Assessment of Concrete" Sustainability 9, no. 11: 2116. https://doi.org/10.3390/su9112116