1. Introduction

The construction industry is infamous for the highest accident rates compared to any other industry in many parts of the world [

1]. The amount of work accidents and injuries has been increasing drastically for years in construction industry. This occurs because the construction industry comprises higher percentage of self-employed workers, and large number of seasonal and migrant workers [

2]. Hence, the importance of accident and injury prevention, which requires a knowledge of accidents’ causal factors and how the factors increase the probability of risks that can cause accidents, has arisen [

3,

4].

The literature on occupational risk assessment reveals that accidents are caused from a wide range of factors such as unsafe tools, conditions related with the work site, the industry specific problems, unsafe methods related with the work, human factors and management issues [

5]. Physical hazards on construction sites occur because of continuing exposure to mechanical process or work activity. As a result, physical hazards can cause various types of injuries, from minor and requiring first aid only, to disabling and/or fatal.

Physical hazards involve conditions such as working at height, falling objects, exposure to electricity, etc. Falls from height have been regarded as the most frequent cause of injury or death among the accidents on construction sites [

6]. Slips and trips that cause fall are also assumed as the most prevalent occupational hazards and lead to one third of all serious injuries. Being struck and crushed by equipment, fires and explosions related with the ignition of flammable materials are other common occupational risks on construction sites. For example, Pipitsupaphol and Watanabe [

7] represented that falling, workers being struck by falling objects, stepping on or striking against objects are the three most frequently occurring type of accidents in Thailand. In addition, OSHA (Occupational Safety and Health Administration) and Huang and Hinze [

8] informed that falls and struck by falling objects also have been the cause of the highest number of injuries and fatalities in the U.S. construction industry.

As for occupation type, particularly, falling off machines and machines overturning when travelling up or down slopes are commonly encountered major hazards for construction site workers [

9]. In addition, electrical devices such as cables, circuit breaker panels and cords present a high risk for workers in areas exposed to electricity. Common sources of these physical injuries on construction sites occur due to technical or human errors [

10]. Dumrak and Mostafa [

11] and Jackson and Loomis [

12] claimed that truck drivers, plant operators, electricians are highly susceptible to fatal accidents.

These may arise from lack of safety knowledge, training, supervision, uncontrolled working environment, inability to carry out a task safely, and error of judgments, carelessness, apathy or reckless operations. Unsafe behaviors, which are the results of a poor safety culture, are other significant factors in the cause of site accidents [

13]. In addition, safety is considered as part of Total Quality Management (TQM); poor safety practices are also accepted as the cause of accidents and subsequent injuries [

2].

According to Toole’s [

14] study in the USA, the causes of accidents include: unsafe methods or sequencing; deficient enforcement of safety; lack of proper training; safety equipment not provided; unsafe site conditions; poor attitude toward safety; not using provided safety equipment; and remote and deviation from regular behavior. Similarly, in their study, Tam et al. [

15] addressed that the main factors affecting safety performance are reckless operations, lack of training, and poor safety awareness of supervisors and top management.

Tam et al. [

15] represented that trained or skilled workers ensure improvement of the site safety. However, high mobility of workers on construction sites and frequent move from one construction site to another makes it difficult to train workers. Dester and Blockley [

16] and Zhou et al. [

17] pointed that the poor safety in the construction industry occurs because of poor safety culture rather than the inherent (nature) hazards of the industry. In addition, Agvu and Olele [

18] represented that poor safety culture cause increased rate of unsafe acts/fatalities in the Nigerian construction industry. Barofsky and Legro [

19] and Folkard and Tucker [

20] concluded that fatigue is a versatile and complex occurrence, including physical, mental and emotional stress and other behavioral points, all of which require additional examination. The importance of management commitment to safety and safety regulations, which influence organizational safety performance in a good way, are indicated by Ismail et al. [

21]. In addition, they represented that there is a relationship between safe behavior, safety rules, and legalization, and management commitment.

Causes of accidents in construction industry are obtained in many ways using variety of ORA (Occupational Risk Assessment) methods.

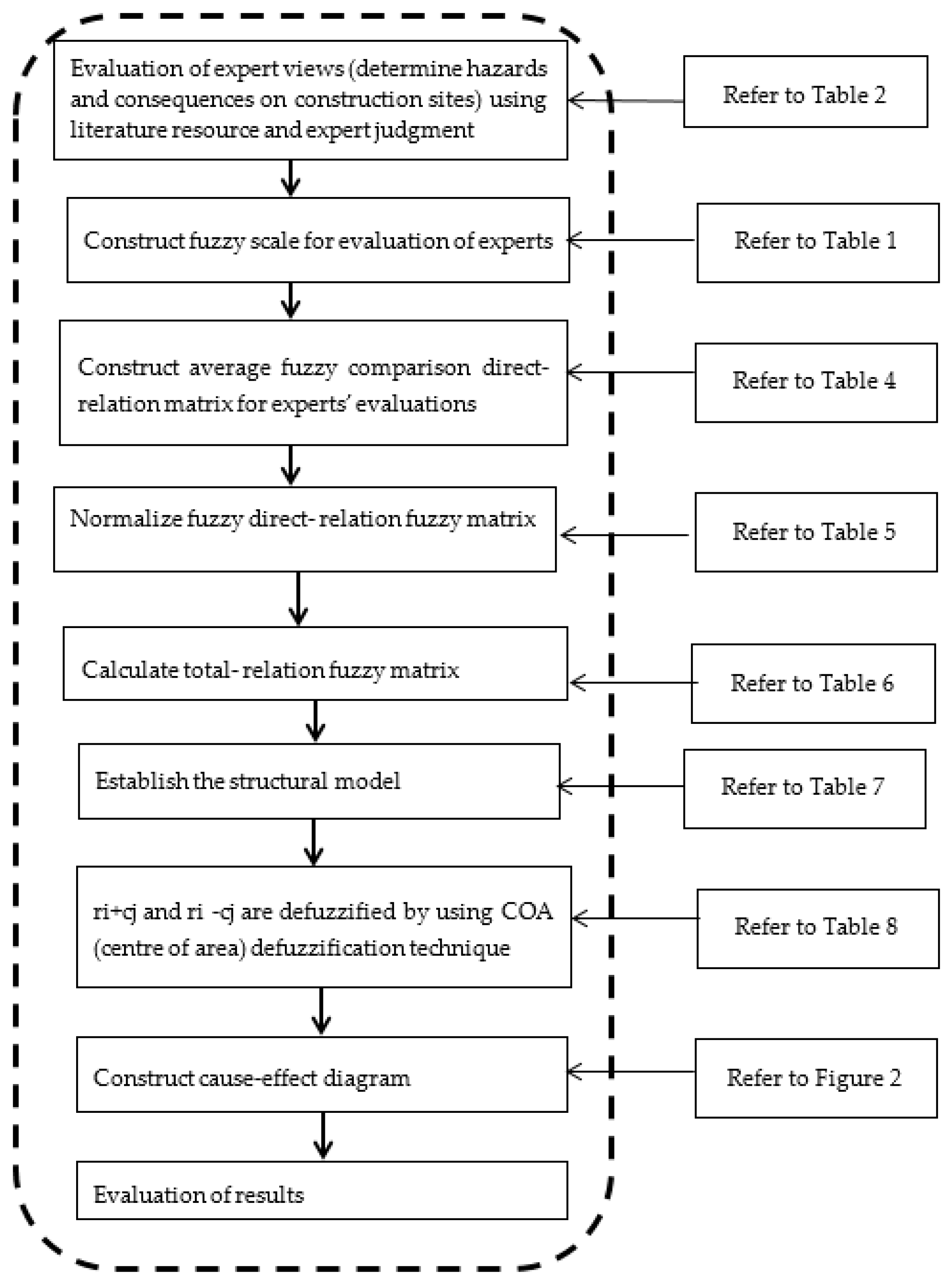

In this study, a better and more practical approach is recommended to simplify the risk assessment process for construction industry. The DEMATEL method is commonly used to obtain a cause–effect diagram of interdependent factors. This method is superior to conventional techniques due to exposing the relationships between criteria, ranking the criteria relating to the type of relationships and revealing intensity of their effects on each criterion. Since a single method is not sufficient to identify occupational risks under uncertainty and vagueness, there exists a need to apply an integrated approach to solve the problem considered. Therefore, fuzzy linguistic modeling is utilized to represent and handle flexible information [

22].

Accordingly, the DEMATEL method is used to reveal the effect and cause criteria, and to increase the model applicability in terms of linguistic variables combined with triangular fuzzy numbers. As a multi criteria decision making method, DEMATEL contributes to risk assessment literature a different point of view by providing an evaluation that enables modeling cause and effect relationships among the risk factors and exposing the degree of relation or the strength of influence analytically [

23].

The proposed approach presents the following advantages compared to traditional methods for ORA:

- (1)

The proposed method illustrates the interrelationships among critical occupational hazards by constructing causal relationship among construction activities.

- (2)

Identifying each hazard using triangular fuzzy numbers gives better and more reliable results, as the uncertainty and vagueness of the data can be managed with a fuzzy approach.

- (3)

The proposed method offers highly accurate and effective material to support the risk assessment procedure because occupational hazards can be better ranked and well evaluated to prevent critical hazards in construction industry.

The remainder of the paper is organized as follows:

Section 2 discusses the limitations of traditional methods for ORA in construction industry and common Multi Criteria Decision Making (MCDM) methods used for risk assessment under fuzzy environment.

Section 3 formally describes proposed framework steps and applied techniques, and presents the analysis of the proposed approach for risk assessment on construction sites.

Section 4 reports the results of aspects, criteria and data analysis, which are based on the proposed steps. In addition, a sensitivity analysis has been carried out to indicate the verification of the results. Finally,

Section 5 concludes the paper by summarizing obtained results and discussing strategic decisions.

2. Literature Review: Risk Analysis on Construction Sites

There is comprehensive literature about occupational risk assessment in the construction industry. In addition, there are many approaches for risk analysis in construction industry and other operating facilities [

24,

25,

26,

27]. In common, the application procedure is presented as follows:

- (1)

Project managers prepare a corporate safety program, which includes performance standards in a number of classes, and then they compare these classes due to their importance and propose a new safety profile [

28].

- (2)

Decision is made about the strengths and weaknesses of a recent safety program using a safety audit, which is part of the company’s safety program [

29].

- (3)

Injury rate of recurrence, which is the number of lost-time injuries per million hours worked and assumed as a method of evaluating safety performance, is computed [

30,

31].

However, many authors [

32,

33,

34,

35,

36,

37] presented the shortcomings of traditional methods for ORA because these methods are formed from incomplete information, which is based on uncertainty, vagueness and imprecision. On the other hand, sources of imprecision usually require data obtained from expert judgment, which cannot be evaluated easily by traditional (probabilistic) methods [

38]. In addition, Pinto et al. [

39] investigated traditional methods for occupational risk assessment in the construction industry pointing out limitations and benefits of using fuzzy sets approaches to cope with imprecise situations. Thus, several methods have been presented using fuzzy principles for analyzing risks [

40,

41,

42,

43,

44].

However, in recent years, numerous studies have been carried out using MCDM methods to analyze risks in construction industry [

45]. Dejus and Antucheviciene [

46] proposed MCDM technique for assessment and selection of appropriate solutions for occupational safety. Furthermore, in construction industry, Efe et al. [

47] suggested an integrated intuitionistic fuzzy multi-criteria decision making method and a linear programming for risk evaluation in three firms. The paper aimed to overcome the limitations of traditional Failure Mode and Effects Analysis (FMEA) for risk evaluation. Tamošaitienė and Zavadskas [

41] proposed risk assessment method using the Technique for Order of Preference by Similarity to Ideal Solution with fuzzy information (TOPSIS-F) method for project of commercial center. Basahel and Taylan [

48] suggested a model that can be used to evaluate the most important factors of SMS (safety management system). The significance of these factors and their sub-factors was obtained using the fuzzy Analytic Hierarchy Process (AHP) technique, and the effectiveness of the four construction companies’ SMSs was obtained using fuzzy TOPSIS. Liu and Tsai [

49] proposed a fuzzy risk assessment method to decrease or prevent occupational hazards. The method includes two-stage quality function deployment (QFD) tables to represent the relationships among construction items, hazard types and causes and a fuzzy Analytic Network Process (ANP) method to classify important hazard types and hazard causes and Failure Modes and Effect Analysis (FMEA) to evaluate the risk value of hazard causes based on the fuzzy inference approach. Janackovic et al. [

50] proposed the expert evaluation method and the fuzzy AHP to represent the factors, performance, and indicators of occupational safety with ranking at a Serbian road construction company in Serbia. Kim et al. [

51] presented a decision support model, which is based on fuzzy AHP, to quantify the failure risk and to show experts’ and practitioners’ subjectivities. Using results as an input for fuzzy comprehensive operations, the quantitative failure risks were found. Wu and Shen [

52] suggested an assessment model based on the fuzzy grey relational analysis theory for the factors influencing highway construction safety. In addition, the construction safety evaluation index system was built and the weight of each index was found using AHP. Li et al. [

53] proposed an improved AHP Method (IAHP) for risk identification. It was conducted to open-cut subway construction to show performance of the proposed approach. The application results show that IAHP is predominant to AHP in terms of comparison matrix (CM) consistency. Yuan et al. [

54] improved and employed an effective method to evaluate safety risks on construction projects using the Fuzzy Analytic Network Process (FANP). Zamri et al. [

55] proposed a Fuzzy TOPSIS (FTOPSIS) with Z-numbers to handle uncertainty in the construction problems. The proposed approach was used to determine the causes of workers’ accident at the construction sites.

In addition, Leonavičiūtė and Dėjus [

56] introduced a new MCDM method of the Weighted Aggregated Sum Product Assessment with Grey numbers (WASPAS-G) to determine the best alternative in safety measures to prevent accidents on construction sites. Mohsen and Fereshteh [

57] used Z numbers to overcome uncertainty in the experts’ judgments for risk assessment in a geothermal power plant. In addition, they used the fuzzy VIseKriterijumska Optimizacija I Kompromisno Resenje (VIKOR) technique to rank and prioritize the failure modes based on the minimum individual regret and the maxi group utility.

The goal of this paper is to depict how Fuzzy DEMATEL can be used as a valuable managerial tool for managers of construction sites to develop effective precautions strategies to avoid construction accidents, and to evaluate causal factors of accidents for construction site of buildings.

4. Results

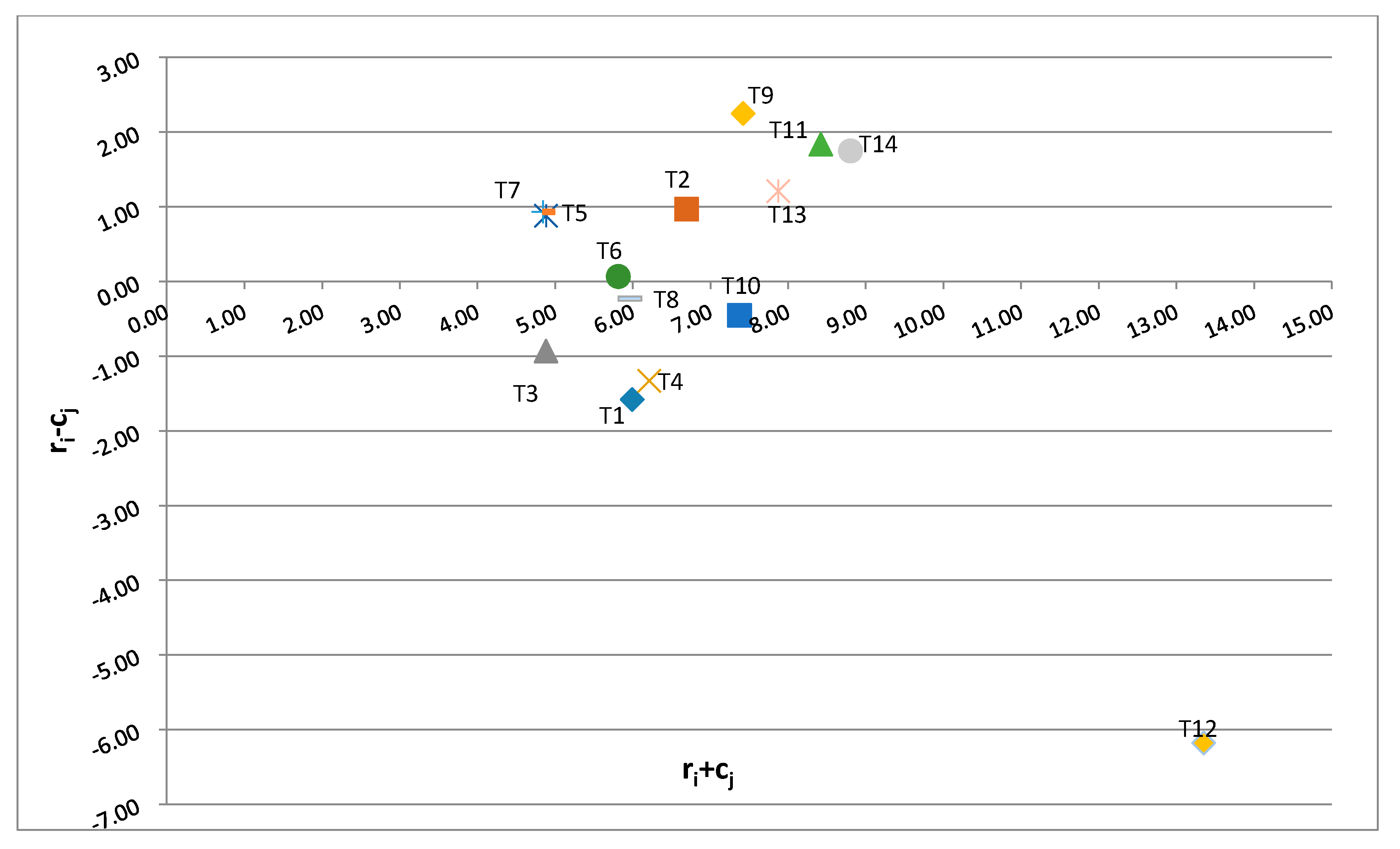

This study combines Fuzzy System Theory and DEMATEL method to develop a systematic risk assessment methodology for potential occupational hazards on construction sites. The results are summarized based on the causal diagram as follows. The assessment criteria Worker capabilities (knowledge, skills) (T2), Site conditions (excluding equipment, weather, materials) (T5), Work scheduling (T6), Unsuitability of materials (T7) Safety culture (T9), Shortage of safety management (T11), Poor safety conscientiousness of laborers (T13), and Poor site management (T14) are classified into the cause criteria group, while effect criteria group includes Worker actions/behavior (T1), Communication (T3), Worker health/fatigue (T4), Unsuitability of equipment (T8), Construction process (T10), and Poor of education of laborers (T12) , which need to be improved. Since cause factors influence the effect group criteria, they should be the focus. The cause group criteria refer to the implication of the influencing criteria, while the effect group criteria refer to the implication of the influenced criteria. Considering the interdependence among factors, much attention should be paid to the cause group criteria related to their influence on the effect group criteria [

65]. Therefore, by improving cause factors, effect factors are developed simultaneously. Therefore, T9, T11, T14, T12 and T10 are critical occupational factors of accidents to be considered in construction industry based on evaluators’ wide experiences and knowledge.

The most significant causal factor of occupational hazards that cause accident is “Safety culture (T9)” has the highest (

ri −

cj) value with 2.25, which means (T9) should be given more consideration on the overall system of critical occupational hazards on construction sites. Besides,

Table 7 shows that influential impact degree of (T9) is 4.83, which is ranked the third highest degree among all causal factors. In common, (T9) is a main factor that requires more consideration in the construction industry process. “Shortage of safety management (T11)” has significant impact on other cause group factors with the second highest (

ri −

cj) degree. Furthermore, (T11) has the second highest ri value (5.13) among the causal factors in terms of prominent impact degree. Likewise, “Poor site management (T14)” is another significant factor because the

ri −

cj value is in the third place (1.75). Besides, T14 has the highest

ri value (5.27).

If the value of (ri − cj) is negative, such perspective is classified in the effect group (hazards), and is largely influenced by others. In this study, “Poor education of laborers (T12)” has the highest (ri + cj) value among the whole process. However, their (ri − cj) values are very high when compared to other factors in effect group (−6.18). This means that it has a significant impact on the other factors. However, its (ri + cj) score is the second highest in the other effect group criteria. “Construction process (T10)” has impact to improve the system as its ri − cj value is very low (−0.45). It is easily affected by the other factors. “Worker health/fatigue (T4)” has the third highest (ri + cj) in the whole process. The remaining factors have moderate (ri + cj) values. Their (ri − cj) values are comparatively low, which point as a strong influenced degree.

Considering the results, managers are able to define regular precautions that must be taken for critical causal factors of occupational hazards. The precautions against the most critical causal factors in construction industry are given in

Table 9.

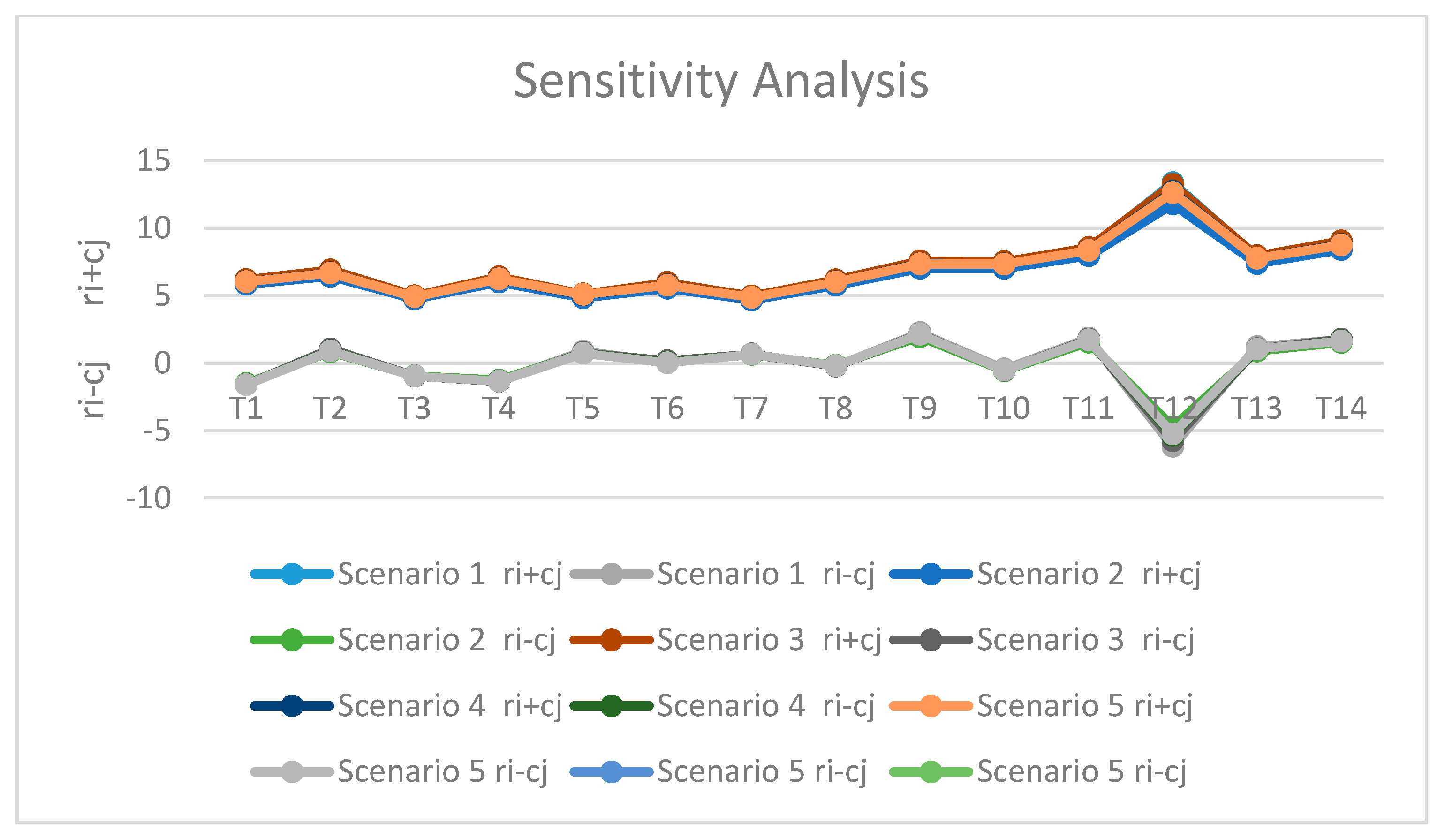

Sensitivity Analysis of Results

Sensitivity analysis is performed to test the reliability of decisions made by evaluators. To understand the effects of using various combinations of decision criteria weight (keeping equal weightings and adjust more weight to any evaluator), sensitivity analysis is conducted [

66]. To verify the results, sensitivity analysis is presented in this study. Initially, equal weights are assigned to each evaluator (Scenario 1). Then, weights of each evaluator are changed according to their years of experience and job responsibilities to analyze how much the cause–effect relations vary. Accordingly, considering that Evaluator 2, Evaluator 3 and Evaluator 1, respectively, faced more occupational accidents during their job experiences, their weights are assigned higher than other evaluators. Scenarios based on evaluator weights are given in

Table 10.

The results show that the ranking of cause and effect factors remain unchanged in all scenarios. The sensitivity analysis has shown robust and valid results that are close to real preferences of the consulted evaluators. As a result, the understanding of evaluators about the causes of accidents in construction industry is adequate for this study.

5. Conclusions

This study aims to improve Fuzzy DEMATEL approach to causal factors of critical occupational hazards, which are implemented through 14 criteria, for construction industry. Thus, this study presents a novel occupational risk assessment approach for evaluating critical casual factors of accidents for construction industry, which can help managers of construction industry to make proper precautionary strategies for accidents. The proposed method is superior to conventional techniques because of exposing the relationships between factors and ranking the criteria relating to the type of relationships and intensity of their effects on each criterion. In addition, by using fuzzy linguistic scale, imprecise and inaccurate information has been handled. Due to these advantages, DEMATEL is used to reveal a better knowledge of the influences of the analysis of cause and effect criteria, and to increase the model applicability. Thus, the proposed method has capability to represent the causal relationship of criteria and is favorable to handle group decision making in fuzzy environment.

According to the findings, several precautions can be suggested for potential occupational hazards. Firstly, it can be proposed to concentrate on the cause group criteria because of their influences on the effect group criteria. Arrangement of cause group criteria are much more difficult than the effect group criteria.

Moreover, managers should focus on critical causal factors in construction industry, which are Worker capabilities (knowledge, skills) (T2), Site conditions (excluding equipment, weather, materials) (T5), Work scheduling (T6), Unsuitability of materials (T7) Safety culture (T9), Shortage of safety management (T11), Poor safety conscientiousness of laborers (T13), Poor site management (T14). Worker actions/behavior (T1), Communication (T3), Worker health/fatigue (T4), Unsuitability of equipment (T8), Construction process (T10), and Poor of education of laborers (T12).

The sensitivity analysis is also introduced to reveal robust and valid results that are close to real preferences of evaluators. The Fuzzy DEMATEL method is a useful tool and widely used in all industry sectors to handle problems that need group decision-making in a fuzzy environment. Therefore, the proposed framework can be enhanced in further studies to test the research findings presented in this study by applying them to a real construction site. In addition, in future research, more evaluator opinions can be evaluated.