1. Introduction

After the first deployment of the EU emission trading system (EU-ETS), emission trading systems to tackle climate change have spread across the world and covered 35 countries in 2015 by International Carbon Action Partnership(ICAP) [

1]. Emission trading systems have effectively encouraged regulated polluters to make much effort towards managing and reducing carbon emissions. In line with the worldwide efforts to cut carbon emissions, business and industry have taken decarbonization into consideration in their logistics operations because a significant amount of carbon is emitted from freight transport and warehousing. According to World Economic Forum(WEF) [

2], logistics contributes approximately 5.5% of the 50,000 megatons of carbon emissions generated by all human activity annually. Even more problematic is that the amount of carbon emitted by each tonne-km of freight movement also appears to be rising by Intergovernmental Panel on Climate Change(IPCC) [

3], and freight traffic is predicted to grow at 2.3% annually from 2000 to 2050 in World Business Council for Sustainable Development(WBCSD) [

4].

Lowering carbon emissions requires enormous changes in the operation of logistics, but shifting to low carbon logistics produces a concern about the classical models that have been widely used for designing and operating a logistics system. Although the traditional models have provided a solid theoretical foundation, we have doubts about whether the operational decisions (e.g., shipment size) developed based on the classical models are feasible when carbon costs are newly introduced.

Some research has recently addressed the question and extended the classical EOQ (Economic Order Quantity) model to include carbon emissions and its costs in developing an optimal decision. Hua et al. [

5] and Chen et al. [

6] used the classical framework of the EOQ model and analytically evaluated the impacts of carbon emissions on order decisions and costs. They also provided numerical results describing a condition under which carbon reduction is possible by modifying an order quantity. Bouchery et al. [

7] proposed a multi-objective formulation of the EOQ model in which cost and carbon minimization constructs an efficient frontier and analytically find a Pareto optimum. Benjaafar et al. [

8] considered a multi-period lot-sizing problem with a cap on carbon emissions and suggested the possibility of reducing carbon emissions by making an operational adjustment in an efficient manner. Bouchery et al. [

9] extended the EOQ model into a two-echelon EOQ model and showed that coordination possibly enables lowering both cost and emissions. Konur [

10] and Konur and Schaefer [

11] integrated the EOQ model with transportation costs and considered different emission factors for various characteristics of a truck.

There is another direction of research incorporating carbon emissions into the classical Newsvendor model, which is effective in finding a single-period optimal production quantity under various carbon emission regulations; see [

12,

13,

14]. Song and Leng [

13] provided a basic idea on the use of the Newsvendor model and find an optimal production quantity with the consideration of carbon emissions. Zhang and Xu [

14] extended the single-item Newsvendor model to the multi-item case and investigate the effects of carbon price and carbon cap on production quantity, profit, and carbon emissions.

Despite their wide use, there is a potential drawback in the literature based on the classical inventory models. According to Piecyk and McKinnon [

15], carbon emissions are highly affected by the structure of a distribution system. For example, Ballot and Fontane [

16] reveal that pooling inventory across locations reduces carbon emissions by increasing the chance to travel at full capacity and reducing travel distance. However, the classical inventory models fail to consider how the characteristics of distribution systems such as travel distance and customer density affect the amount of carbon emissions.

The joint decision on carbon reduction investment and operation is a new stream of research. An empirical study of Lai and Wong [

17] suggests that improving productivity and operational performance is worth the costs of investment in implementation of green logistics management. In the context of a supply chain coordination, customer demand is formulated as a function of greening efforts that require upfront investment in [

18,

19]. They found a condition on the optimal greening effort to achieve better supply chain performance. Toptal et al. [

20] extended the EOQ model to study joint decisions on order quantity and carbon reduction investment, and presented the possibility of reducing carbon emissions while reducing the cost. Similarly, Jiang and Klabjan [

12] reformulated the Newsvendor model to study joint decision on production quantity and carbon reduction under carbon emission regulations. The current literature such as [

12,

18,

19,

20,

21] has only dealt with the gross emissions in spite of the difference in technologies for managing carbon emissions from transportation and warehousing. Carbon emissions from energy use in the operation of logistics are broken down into two types: emissions from freight transport and emissions from storage by McKinnon [

22]. While carbon emission in transportation is a function of travel distance and fuel efficiency, the inventory holding period and energy efficiency determine emissions at storage.

In this paper, we attempt to contribute to the literature on the joint decision on shipment size and carbon reduction by developing novel models for distribution systems under direct shipment and peddling distribution strategies. Unlike the literature that has simply investigated the effects of carbon costs on operational decisions, we address how to reduce carbon emissions and logistics costs by adjusting shipment size and making a decision on carbon reduction investment. Instead of using the framework of classical inventory models, we consider two different distribution systems so as to fully investigate the effects of the distribution structure (e.g., distribution strategy, travel distance, customer density, etc.) on carbon emissions and their costs. In particular, one of our research interests is coming up with a model covering the difference in managing carbon emissions from transportation and storage. To the best of our knowledge, no research has explicitly considered two sources of carbon emissions separately. This paper divides the gross emission into two components by separately determining emission factors (a.k.a. carbon intensity and emission intensity) from freight transportation and storage in the proposed model.

Based on our proposed models, the purpose of this paper is twofold. First, we find optimal shipment size and emission factors in order to minimize the total cost for delivering an item under direct shipment and peddling distribution strategies. The second is to show that a well-designed decision on shipment size and emission factors can reduce distribution costs as well as carbon emissions under direct shipment and peddling distribution strategies.

The rest of this paper is organized as follows.

Section 2 begins with describing optimization models that formulate the cost for delivering items under direct shipment and peddling strategies.

Section 3 and

Section 4 present an optimal solution of both shipment size and emission factors for direct shipment and peddling strategy, respectively. Furthermore, we analytically show the possibility of carbon and cost reduction by adjusting shipment size and/or emission factors. In

Section 6, we conduct numerical analysis to illustrate the results of our study.

Section 7 concludes the paper with suggestions about a direction for future research.

2. Mathematical Model

Burns et al. [

23] formulate the long-run average distribution cost for delivering an item from a depot (e.g., a manufacturing plant or a warehouse) to many customers under direct shipment and peddling distribution strategies. They find an optimal shipment size that minimizes the unit distribution cost including the transportation and inventory cost. We extend the model proposed by Burns et al. [

23] to include the cost incurred by carbon emissions. The cost of carbon emissions considered in this paper is two-fold; the cost for trading carbon emissions under cap-and-trade regulation, which has been commonly considered in the literature, and the cost associated with the investment on carbon emissions.

The models are formulated with the notations that are summarized in

Table 1. Throughout the paper, the superscript

D and

P represent direct shipment strategy and peddling strategy, respectively.

2.1. Modeling of the Direct Shipment Strategy

The direct shipment strategy allows each capacitated truck to visit only one customer in every delivery. The long-run average transportation cost per load is proportional to the total traveling distance and represented as

. Customer demand is assumed to be known and arrive at a constant rate. We also assume that the production at the depot is perfectly coordinated with the customer demand. Under these assumptions, the average total time spent by a unit from production to consumption is given as

(see Burns et al. [

23]) and the long-run average inventory cost per unit becomes

. Combining the transportation and inventory cost provides the unit logistics cost,

, as similarly found in [

23,

24].

To formulate the cost for trading carbon emissions, we first propose the amount of carbon emission denoted by

. Carbon emissions are mainly from energy consumed in transportation and storage. Let

c and

h denote carbon emission factors in transportation and warehousing, respectively (see WRI [

25] for a detailed description on emission factors). A few papers in the literature formulated emission factors as a function of load factors or vehicle types [

10,

11,

26]. For example, the emissions from an empty truck were defined independently from the emission from delivering items. In this paper, the emissions from an empty truck is assumed to be a part of the emission factor in warehousing because of their structural similarity as defined in [

10,

11]. For simplicity, an average load factor is assumed to be a part of the emission factors, which means we consider homogeneous trucks similar to [

27]. Furthermore, the weight of a load is ignored when calculating the amount of carbon emission. For carbon emission factors

c and

h, we have that

. For a given carbon cap

K, we have to determine the amount of carbon trading

x such that

. If

x is negative (i.e.,

), then it costs

to buy emission permits. On the contrary, a positive value of

x adds profit

into the model.

McKinnon et al. [

28] emphasized the importance of improving energy efficiency and lowering carbon emission factors of energy used in transportation and warehousing operations. Lowering emission factors can be achieved by introducing low carbon technologies for vehicles (e.g., aerodynamic fairings, hybrid and electronic vehicles, replacing diesel with environmental friendly fuels, low-rolling resistance tires and anti-idling devices, etc.) and designing energy efficient warehouses (e.g., energy efficient lightning systems and material handling equipment, etc.). For example, FedEx operates hybrid-electric vehicles and LPG (Liquefied Petroleum Gas)-powered ground support equipment at its hub and other warehousing facilities across the world. FedEx reported that the hybrid trucks reduced carbon emissions by 30% in the U.S. [

29]. For reference, low carbon technologies for logistics operations are presented in Dey et al. [

30] and McKinnon [

22].

These technology-driven efforts to improve emission factors should be accompanied by additional costs. Some literature argues that the cost is convex and increasing as lowering emission factors [

18,

19]. However, we use a linear cost function similar to Jiang and Klabjan [

12], and convex cost functions are numerically evaluated in

Section 6. The costs for lowering emission factors from their initial values

and

to

c and

h are given as

. Keeping the initial values

and

incurs no cost, but it costs more by lowering

c and

h. The emission factors are assumed to be bounded below and not allowed to be less than

and

.

By combining theses cost components, we obtain the distribution cost denoted by

for the direct shipment strategy (This section is based on our previous work in [

31], and we redescribe the model to help readers easily understand further analysis.):

Let

and

so that

F and

H imply the transportation and inventory holding cost considering carbon emissions. Replacing

x with

yields the following simpler model:

2.2. Modeling of the Peddling Strategy

In each delivery, the peddling strategy allows a vehicle to visit several customers within a defined delivery region. Thus, the total travel distance includes not only the round trip distance

L but also local delivery distance. Let

n and

m denote the number of customers within the delivery region and the number of customer stops per delivery, respectively. For given

n and

m, Stein [

32] shows that the local delivery distance becomes

, where

is customer density and

k is a constant of which its value is approximately 0.6. Readers are recommended to see Burns et al. [

23] that provides detailed description on how to determine

n and

m.

In this paper, we consider a situation in which a vehicle should visit all customers within a delivery region in each delivery. This is generally found when the vehicle capacity is substantially larger than the demand in a delivery region and would likely fit the case where a depot delivers items via fixed routes. Based on this consideration, we can now assume that and provide closed form expressions for decision variables and analytical results. Finally, the long-run average transportation cost per unit for peddling strategy is given as , where .

The inventory holding cost for a peddling strategy is similar to that in a direct shipment model except for the customer demand. Unlike the direct shipment strategy, it needs to take account of several customers within a delivery region. When assuming all customers are identical, the total demand from n customers is . Thus, the long-run average inventory holding cost per unit becomes .

Combining carbon emissions in transportation and warehousing provides the amount of carbon emissions

when emission factors are

c and

h. Then, the problem for peddling distribution strategy is formulated as follows:

Let

which represents the unit transportation cost for local delivery and

(i.e.,

). Reorganizing the model by replacing

x with

provides the model for peddling distribution strategy:

4. Reducing Carbon Emissions and Distribution Cost

4.1. Direct Shipment Strategy

This section investigates whether it is possible to reduce carbon emissions as well as the distribution cost by adjusting shipment size and carbon emission factors to the optimal values as found in Proposition 2. Recall that the optimal shipment size is , where and are the transportation and inventory holding costs with the optimal emission factors and . Let denote an optimal shipment size when and . Then, . We now show that the following Theorem 1 on carbon emissions holds.

Theorem 1. . It means that adjusting the shipment size and emission factors to their optimal levels (, and ) reduces carbon emissions.

Proof. and let .

- (i)

If , then

- (ii)

If , then and .

and by the definitions of and . Thus, .

- (iii)

If , then and .

and by the definitions of and . Thus, .

- (iv)

If , then and .

- (a)

If , then .

- (b)

If , then it needs to show .

.

Because , we conclude and .

- (c)

When , it can be similarly shown that .

From (i)–(iv), we conclude . ☐

From Theorem 1, we see that reducing emission factors leads to an emission reduction. Now, we investigate the effect of including cost associated with carbon emissions in determining the shipment size on the reduction in carbon emissions. In particular, we show that adjusting the shipment size, when considering the carbon costs lowers the carbon emissions. Let denote an optimal shipment size when ignoring carbon costs, and . That is, the inequality holds as shown in the following Theorem 2.

Theorem 2. Carbon reduction is possible by including the cost associated with carbon emissions in determining the shipment size if .

Proof. and

.

- (i)

If (i.e., ), then there is no difference between and .

- (ii)

If (i.e., ), then it is easy to show by applying and into the inequality. Thus, .

- (iii)

Similarly, (i.e., ) leads to and .

From (i)–(iii), it concludes the proof. ☐

We have a similar analytical result in Theorem 2 with the finding proposed by Chen et al. [

6]. By using the EOQ framework, Chen et al. [

6] argue that modifying order quantities possibly reduces carbon emissions only if

, where

A and

h are ordering and inventory holding cost and

and

are emissions associated with placing an order and holding an item in inventory, respectively. In the case of

, carbon emissions are at their minimum regardless of how to adjust the shipment size considering carbon costs.

Corollary 1. A carbon emission reduction is possible by adjusting the shipment size and emission factors considering carbon costs if .

Proof. From the previous two theorems, we conclude that . ☐

Corollary 1 indicates the possibility of carbon emission reductions by adjusting the shipment size or emission factors. Now, we investigate cost reduction.

Theorem 3. Reducing the distribution cost is possible by adjusting the shipment size and emission factors if .

Proof. We prove .

and

.

- (i)

If

, then

if and if .

- (ii)

If

, then

where the inequality holds because

.

According to the result of (i), we conclude .

- (iii)

If

, then

where the inequality holds because

.

According to the result of (i), we conclude .

- (iv)

If

, then

where the inequality holds because

and

.

From (i)–(iv), we conclude if . ☐

In addition to an emission reduction, Theorem 3 shows that cost reduction can be achieved by adjusting the shipment size or the emission factors. Because we determine an emission factor at which it minimizes the distribution cost by evaluating the trade-off between the cost for lowering the emission factor and the gains from an operational cost reduction, it is easy to understand why a distribution cost reduction is possible. However, even if we make no change in the emission factors from their initial levels and , cost reduction is attainable by modifying the shipment size if . An interesting finding is that is the only condition required for simultaneously reducing both carbon emission and distribution cost.

4.2. Peddling Strategy

We analytically investigate the possibility of carbon and cost reduction under the peddling strategy by using the amount of carbon emissions given as . As shown in Proposition 3, the distribution cost is minimized when the shipment size is U. Thus, unlike the case of the direct shipment strategy, adjusting shipment size is not a significant means of reducing carbon emissions and cost. Thus, we mainly consider the effects of adjusting emission factors to their optimal levels on carbon emissions and distribution cost.

Theorem 4. Adjusting emission factors reduces carbon emissions.

Proof. We need to show .

- (i)

If , then

- (ii)

If , then .

Since , it is trivial to show the inequality holds. Thus, because and .

- (iii)

If , then .

When considering , it is easy to show . Thus, because .

- (iv)

If , then .

Applying and yields and , and it supports .

From (i)–(iv), we conclude . ☐

Corollary 2. Adjusting emission factors reduces the distribution cost.

Proof. We need to show , but the proof is trivial because is the point that minimizes . An explicit proof is also shown below.

- (i)

If , then

- (ii)

If , then .

Because when , .

- (iii)

If , then .

Because when , .

- (iv)

If , then .

Because and , .

The conclusion from (i)–(iv) completes the proof of . ☐

There is no required condition to satisfy for reducing emissions and cost. The condition that is found under the direct shipment strategy is mainly due to the shipment size, but no modification is allowed under the peddling strategy. Thus, we observe that lowering at least one of carbon emission factors leads to a reduction in emissions and distribution cost.

5. Direct Shipment vs. Peddling

Comparing peddling and direct shipment allows us to identify conditions when peddling is advantageous over direct shipment and vice versa. We compare the carbon emission factors, amount of carbon emissions and distribution cost of peddling to those of direct shipment. The comparison highlights the sensitivity of the differences in carbon emissions and distribution cost with respect to F, V and H (cost for line-haul transportation, local delivery and carrying inventory, respectively).

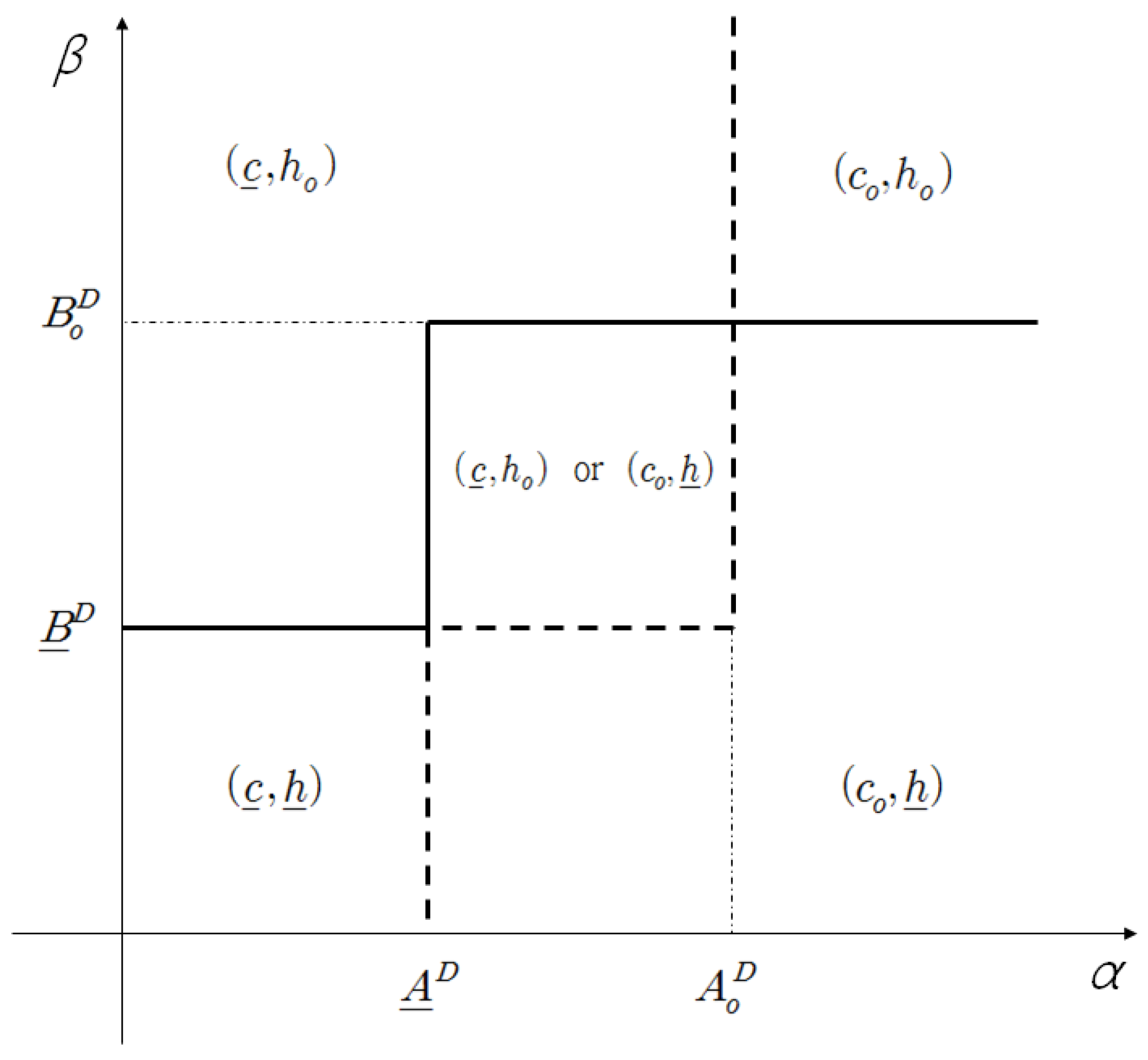

5.1. Carbon Emission Factors

Comparing Proposition 5 with Proposition 2 shows that the policies for determining c and h are almost similar. The policy for the peddling strategy is also of the control-limit type, and we observe an inter-dependency between c and h when and are at an intermediate level. Despite their similarity, there are some interesting differences found in designing the control limits. In terms of lowering carbon emission factors, the comparison of Propositions 5 and 2 reveals that warehousing is relatively more important under the direct shipment strategy. In this regard, we derive the following proposition.

Proposition 6. It is less likely to lower the emission factor at storage under the peddling strategy than under the direct shipment strategy.

Proof. We have that

and

This implies that the control limit for lowering emission factor

h under the direct shipment strategy is higher than that under the peddling strategy. Thus, for a given

, it is less likely to lower the emission factor for storage under the peddling strategy than under the direct shipment strategy. ☐

In the determination of h under the peddling strategy, the cost for local delivery V is only involved and the line-haul/back-haul travel distance can be ignored. Thus, () should be less than () because normally we expect that the local travel distance is shorter than the line-haul/back-haul distance (i.e., ). When assuming no difference in other conditions, this implies that it is less likely to lower the emission factor in warehousing under the peddling strategy than under the direct shipment strategy.

Compared with the direct shipment strategy, the peddling strategy requires a longer travel distance because a local delivery distance should be additionally considered. That is, () consists of two parts: the first part shows cost reduction in line-haul/back-haul transportation, and the latter part is cost reduction in local delivery. The longer travel distance may increase the necessity of reducing carbon emissions and the corresponding cost in transportation; therefore, it is more likely to lower the transportation emission factor under the peddling strategy. However, unlike Proposition 6, the result of comparing control limits for lowering the transportation emission factor is situational.

Investigating the difference between

and

indicates under which conditions the peddling strategy is more likely to lower the emission factor in transportation than the direct shipment strategy:

By increasing demand D and decreasing vehicle capacity U, is more likely to be larger than . Thus, it indicates that the peddling strategy is more likely to lower the transportation emission factor than the direct shipment strategy.

5.2. Carbon Emissions and Distribution Cost

There are several common factors involved in determining F, V and H. For example, a change in affects F, V and H, simultaneously. The effects of change in these common factors are, however, difficult to be analytically tractable. We assume that F, V and H are independent of each other with aims to understand how the change in F, V or H affects the difference in carbon emissions and distribution costs of direct shipment and peddling strategies. In addition, let assume c and h are the same for both direct shipment and peddling strategies to simplify the analysis.

and

are the amount of carbon emissions under direct shipment strategy and peddling strategy, respectively. According to

and

shown in

Section 4, we obtain the difference between

and

as follows:

Since the shipment size q is less than or equal to the vehicle capacity U (i.e., ), it is reasonable to assume that . Thus, is highly likely to be positive, meaning the direct shipment strategy emits more amount of carbon than the peddling strategy.

In addition, we find how much the distribution cost of direct shipment strategy is different from that of peddling strategy:

Now, we take the partial derivative of

and

with respect to

F,

V and

H, respectively:

It shows that is convex with respect to F and H and minimized at and . Thus, is minimized at , and then . is concave with respect to V and maximized at .

is non-decreasing with respect to F because , which means that peddling strategy lowers the distribution cost when line-haul transportation cost is large enough. On the contrary, since , it implies that direct shipment strategy is more preferred as V increases. Direct shipment strategy outperforms the peddling strategy in terms of reducing distribution cost if local delivery cost is larger than the line-haul transportation cost.

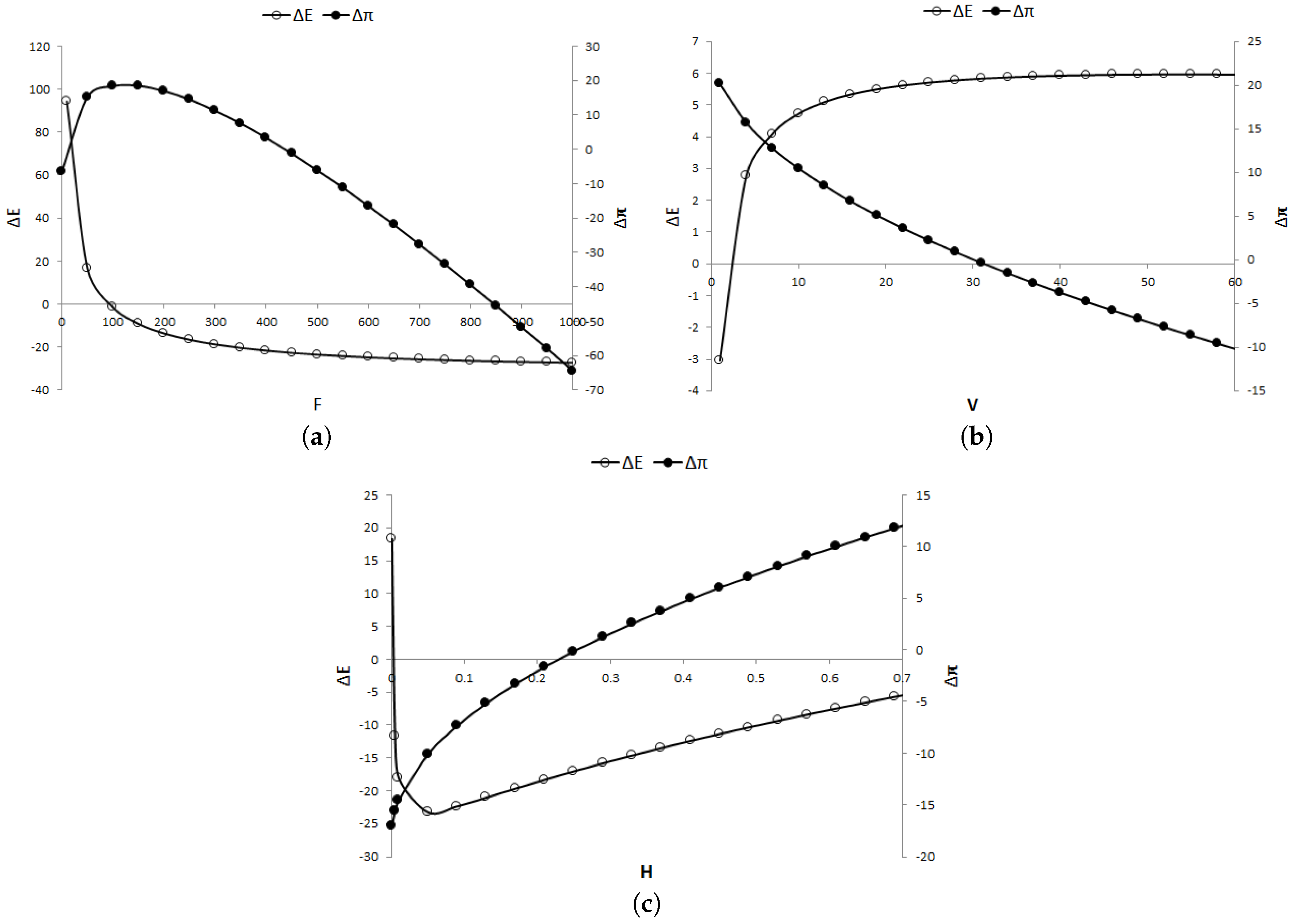

We conduct a brief numerical analysis to validate the findings and summarize the results in

Figure 2, showing the changes in

and

as increasing

F,

V and

H.

Figure 2 indicates which one of the distribution strategies performs better under different conditions. For example, if the line-haul transportation cost

F is in the range of 100 and 850 (

$/tonne-km),

while

, which means that direct shipment emits a lesser amount of carbon while peddling incurs less distribution costs. Furthermore, peddling outperforms direct shipments in both distribution cost and carbon emissions if

F is 850 or more. Here, we remind readers that the correlations among

F,

V and

H are ignored in the analysis.

and move in an opposite direction with respect to F and V, but both and tend to increase as H increases. Hence, determining F and V should be based on the trade-off between distribution cost and carbon emissions. Unlike the effects of F and V, the increase in H consistently supports the use of peddling.

6. Numerical Analysis

In this section, we conduct numerical analysis to validate the analytical results and provide some interesting findings. A test problem is developed by mainly referring to the data obtained from Kwon and Seo [

33] that reports the estimation of logistics costs consisting of transportation, storage and others in South Korea. We use the following values for numerical analysis:

,

,

,

,

,

,

,

and

.

To estimate the range of carbon emission factors, we collect and analyze actual data adapted from a regional logistics service provider in 2014. We use a fuel-based method and convert the emission factor for the fuel (kgCO

/TJ) given by IPCC into the emission factor for distance (kgCO

/km) by reflecting the actual travel distance and fuel consumption of each truck. The emission factor at storage is estimated based on electricity consumption and annual sales data. The carbon emission factors in transportation ranges from 0.5 to 2.0 across trucks and that in warehousing is approximately 1.5. Furthermore, the Korea Exchange [

34] reports that the carbon price in Korea has been around

$ 0.1 per kgCO

in 2015 (i.e.,

).

6.1. Concavity of the Distribution Cost Function

First of all, we validate the concavity of the distribution cost

that is shown in Proposition 1 and the basis of determining optimal emission factors and shipment size. In

Section 2, we formulate the cost for lowering emission factors as a linear function

.

Figure 3a illustrates the change of

when employing a linear cost function for lowering emission factors. This supports the result that the distribution cost is jointly concave in

c and

h. However, the concavity does not hold when taking account of a quadratic cost function

, and thus

is structurally indefinite.

Figure 3b shows that

with the quadratic cost function is almost convex in

c and

h. While we can numerically find the optimal emission factors for a quadratic cost function, we leave it for further research.

Figure 3a also shows that the distribution cost is minimized at

, and it verifies that an optimal solution for

and

is determined at the vertex of the boundary of

c and

h. However, the minimizer is not necessarily a vertex of the boundary when considering a quadratic cost function for lowering emission factors. According to our numerical experiments, an optimal point (

) is generally a vertex, but we also see that

(or

) lies in between

(

) and

(

) because

seems to be close to a convex function.

6.2. Decisions on Lowering Emission Factors

Table 2 summarizes the control limits obtained for the test problem. This numerical analysis provides an insight as to what levels of

and

should be to initiate lowering carbon emission factors. For example, when

under the direct shipment strategy, it is better not to make an investment on lowering emission factors if it costs more than

$ 2.07 in transportation and

$ 0.85 in warehousing to reduce 1 kgCO

per each unit. Here, the values of

and

in

Table 2 are arbitrarily given for testing purposes.

Table 2 also shows the effects of demand, carbon price, and initial emission factors on the control limits. We first see that the control limits decrease as customer demand

D increases, which implies that it is less likely to lower the emission factors. It is well known that large customer demand contributes to reducing the unit distribution cost by exploiting the economies of scale. This kind of cost reduction is because large customer demand weakens the necessity of making an additional investment on reducing carbon emissions. Second, it is easy to expect that a higher carbon price increases the control limits so as to increase the chance of lowering emission factors. The control limits are interestingly less sensitive to the change of the initial emission factors

and

. This suggests that making a decision on lowering emission factors is almost independent of the current levels of emission factors and mainly relies on the cost for lowering them.

By comparing the two distribution strategies in

Table 2, we see that

and

tend to be less than

and

, which implies that more cost reduction is expected under the direct shipment strategy by lowering emission factors, if the other conditions are the same. For example, when

and

, we have

and

under the peddling strategy, whereas

under the direct shipment strategy.

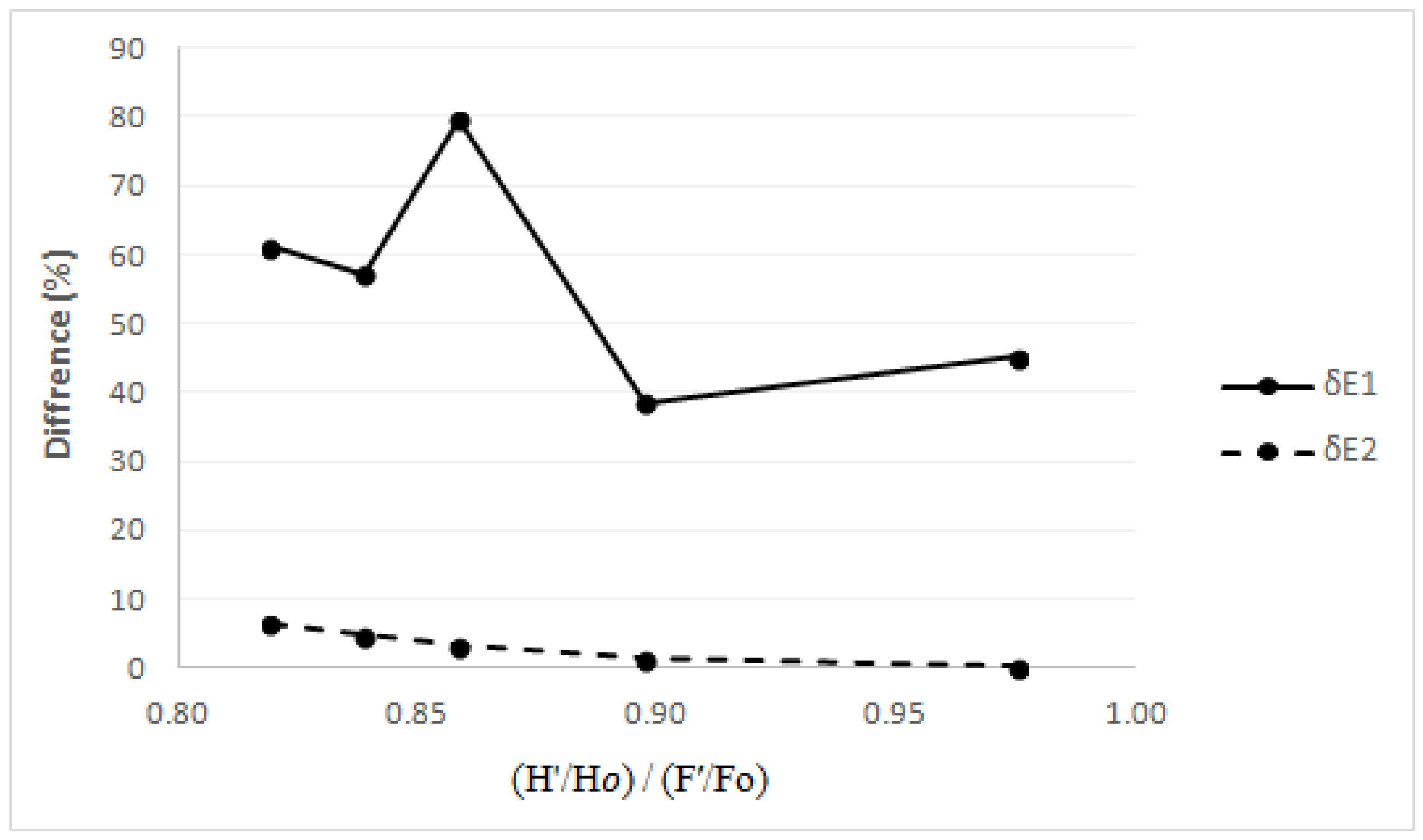

6.3. Sensitivity Analysis on Cost and Carbon Reduction

Corollary 1 and Theorem 3 provide a condition (

) required to reduce carbon emissions and distribution cost. We conduct a sensitivity analysis to validate this condition and summarize numerical results of

and

by varying the ratios

in

Table 3. We increase the value of

by decreasing

so that the shipment size

q also increases. The results of

Table 3 support the analytical results obtained in

Section 4.2. It is possible to reduce both carbon emissions and distribution cost at the same time if satisfying the condition

. When the ratio

is almost close to 1 (i.e.,

), there is no difference in the distribution cost

, which means that no cost reduction is possible by adjusting the shipment size and emission factors.

Figure 4 shows the difference in carbon emissions, where

and

denote the ratio of emissions reduced by adjusting emission factors and by adjusting shipment size without any modifications of emission factors, respectively. Here, we define

and

The values of

represented by the dotted line is monotonically decreasing in

and converges to zero as the ratio approaches to 1. There is no difference between

and

when

. The convergence of

is consistent with the findings in Chen et al. [

6], which claims that we can reduce emissions by adjusting the shipment size only if

.

There is, however, no monotonicity of

(solid line) with respect to the ratio

. As shown in

Table 3, the difference between

and

is not necessarily to be zero when satisfying

because reducing carbon emissions is possible if it contributes to the distribution cost reduction, which is decided based on the trade-off between the cost for lowering emission factors and the benefits from reducing carbon emissions. For example, in

Table 3, the cost for achieving optimal emission factors (

) is 5.71 when the ratio is 0.86, whereas the cost becomes 1.96 with optimal emission factors (

) when the ratio is 0.9. Changing the ratio from 0.86 to 0.90 reduces the cost for lowering emission factors from 5.71 to 1.96 because no reduction in

is done when the ratio is 0.90. In this example, reducing carbon emissions saves 3.19, but it costs 3.95 more, and thus it is better not to reduce carbon emissions in terms of minimizing the distribution cost. After all, adjusting emission factors to their optimal values makes the difference between

and

.

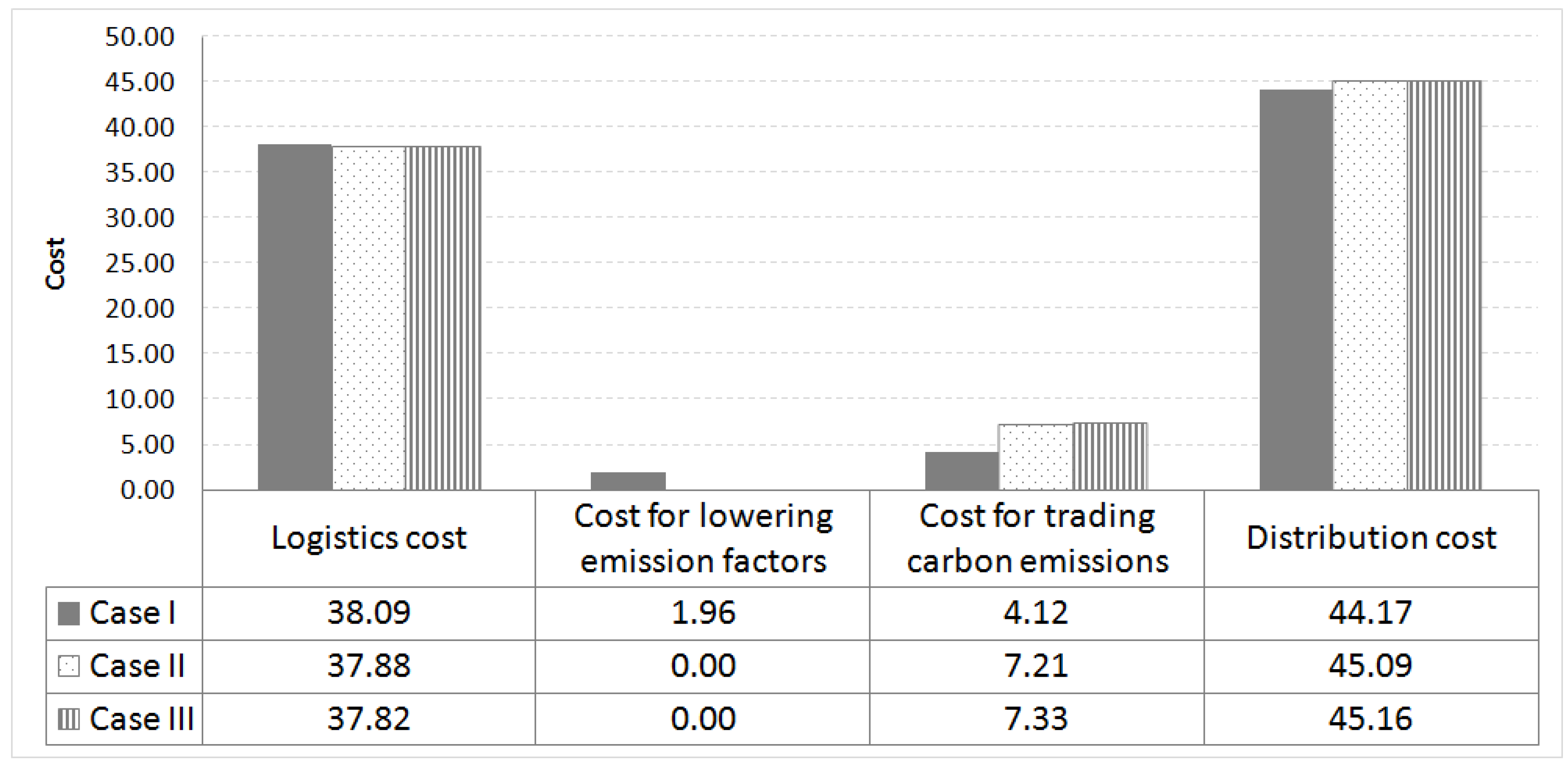

The detailed investigation of the distribution cost explains the effects of adjusting emission factors on reducing the distribution cost that is the sum of the logistics cost (i.e., traditional transportation and inventory holding cost), cost for lowering carbon emission factors and cost for trading carbon emissions.

Figure 5 divides the distribution cost into three cost components so as to show which one of them mainly affects the reduction of the distribution cost. In

Figure 5, Case I describes a situation where emission factors are adjusted to their optimal levels. Unlike Case I, we keep the initial values of emission factors and make no change in

and

in both Case II and Case III. Case II shows an optimal shipment size with the cost associated with carbon emissions, whereas Case III totally ignores carbon costs when determining an optimal shipment size. Thus, Case I, Case II and Case III result in an optimal shipment size as

,

, and

, respectively.

While Case I has a higher logistics cost compared with two other cases, it successfully minimizes the distribution cost by significantly saving costs for trading carbon emissions. Case I has an additional cost for lowering emission factors, but the adjustment of emission factors helps save more in costs for trading carbon emissions, and the distribution cost becomes less than the other cases (see Theorem 3). Thus, we believe that this result supports the feasibility of making an investment in lowering carbon emission factors.

We further investigate the amount of carbon and cost reduction under the peddling strategy and summarize the results in

Table 4, where

and

represent carbon and cost reductions, respectively. Recall that the optimal shipment size is fixed as

U, and there is no condition on reducing carbon emissions and distribution cost. The effects of the vehicle capacity

U are now investigated rather than evaluating the sensitivity of the ratio

.

It should be noted that the carbon emission with optimal emission factors dramatically goes up to 31.73 from 9.05 when U moves from 8 to 9. This change in U switches optimal emission factors from to , which leads to a significant increase of carbon emissions. As aforementioned, reducing the carbon emission is allowed only when the cost for lowering emission factors is less than the benefit from reducing carbon emissions. In this numerical example, a sufficiently large vehicle capacity reduces the benefits from reducing relevant cost than lowering carbon emissions. Thus, a large shipment size is better in terms of lowering carbon emissions, but the shipment size should be limited as above to pursue lowering carbon emissions and minimizing the distribution cost.

7. Conclusions

This paper proposes a model for a joint decision on the shipment size and emission factors under two distribution strategies: direct shipment and peddling strategies. Analytical and numerical investigation provides some interesting findings. First, the policy for determining emission factors is of a control limit-type with respect to the unit cost for lowering emission factors. In particular, the optimal emission factors in transportation and warehousing are interdependent with each other. Comparing the two distribution strategies indicates that peddling strategy should give relatively more focus to transportation than warehousing in terms of lowering the emission factors. On the contrary, the chance of lowering the emission factor in warehousing is higher under the direct shipment strategy. A sufficient reduction in the distribution cost enables lower emission factors, whereas it incurs additional investment cost. Further analysis shows the possibility of reducing the carbon emissions and distribution costs by adjusting the shipment size along with lowering the emission factors. Finally, the numerical analysis validates the analytical results.

The results give us some interesting directions for future research. First, we consider that the cost for lowering carbon emissions is a linear function of carbon reduction; however, some papers in the literature formulate the cost as a quadratic function. It is arguable whether one should use a linear or convex function to formulate the cost incurred by reducing carbon emissions. Nevertheless, it is interesting to extend the current linear cost function for lowering carbon emission factors to a convex cost function. As aforementioned, considering a convex function removes the concavity of the distribution cost, and optimal emission factors should be numerically identified. For that purpose, investigating structural properties is required to design and improve an effective procedure for identifying the optimal emission factors.

This paper considers two types of distribution systems and briefly describes the similarities and differences in how to adjust the shipment size and emission factors to minimize the distribution cost. It is of interest to compare the two distribution strategies in terms of carbon and cost reductions. This comparison will provide insights on designing a cost-effective distribution system.

References