1. Introduction

Agricultural productivity has seen a significant increase since the mid-twentieth century, due to the existence of new technologies in agriculture [

1]. However, there are numerous environmental impacts as a result of intensive agricultural practices and agricultural mechanisation. These include soil erosion and loss of soil organic matter [

2,

3,

4,

5]; excessive nitrogen use [

6,

7]; reduction of water reserves above ground and in the aquifer [

8]; and excessive pesticide use that causes numerous environmental problems (eutrophication, ecotoxicity, soil degradation and acidification) [

9]. In addition, human exposure to low-dose pesticide mixtures by interacting with pesticide-mistreated products produces a long-lasting negative health impact [

10]. The agricultural sector significantly affects climate change, accounting for nearly 13.5% of the total global anthropogenic greenhouse gas (GHG) production [

11]. The major GHGs produced in this sector are methane (CH

4), nitrous oxide (N

2O), and carbon dioxide (CO

2). The main agricultural source of CH

4 is the anaerobic decomposition of organic matter during enteric fermentation, manure management, and paddy rice cultivation, while N

2O is mainly synthesised from the microbial transformation of soil nitrogen during the application of manure and synthetic fertilisers in agricultural land and via urine and dung deposited by grazing animals. Finally, CO

2 arises directly from energy use in the farm (fuels, electricity) and from changes in above- and below-ground carbon stocks induced by land use and land use change [

12].

The United Nations Framework Convention on Climate Change (UNFCC) and the Intergovernmental Panel on Climate Change (IPCC) have developed concrete methodologies for GHG calculations [

13], where life cycle assessment (LCA) is the most well-known method, which attempts to cover all attributes or aspects of natural environment, human health, and resources [

14,

15]. LCA is a method used to measure the overall environmental impact caused by the product or process under study from the very beginning to the end [

16,

17]. In the primary sector and especially in agriculture, some of the principles arising from LCA modelling are the environmental, technological, and socioeconomic factors that influence the existence of numerous inconsistencies from the “average” farm practices. Machinery production and maintenance has an impact on GHG emissions and energy consumption, while irrigation, fertilization, and nutrient management (especially nitrogen) are important variables in the environmental performance index of crop production [

18].

Viticulture is a very important agricultural sector for either wine (principally) or table grape production. Christ and Burritt (2013) pointed out that the critical environmental impacts of wine production are the water, land, and energy use, the management of organic and inorganic solid waste streams, the generation of GHG emissions, and the use of chemicals [

19]. As viticulture contributes about 12 MT of CO

2eq per year to the product carbon footprint (PCF) of wine [

20,

21,

22], wine-producing stakeholders are very much interested in increasing the environmental sustainability of the vineyard system. The sources of GHG emissions in viticulture come from fertilizer and pesticide production and transportation, soil emissions, crop residue management, energy use for irrigation, pruning, tillage, fertilizer and pesticide application, compiling the total PCF of wine grapes [

23]. Bosco et al. (2011) concluded that the planting of vine trees and trellis systems contributed significantly to the GHG emissions when the system starts from scratch. Additionally, intensive production practices tend to produce larger amounts of GHG [

22,

24,

25]. Mitigation strategies for GHG emissions from viticulture production can be identified by inventorying and reporting the PCF through LCA, taking into consideration emissions, material, and energy inputs [

24,

26,

27]. Previous research has established that organic fertilization leads to substantial savings in GHG emissions [

28,

29,

30]. Another key point to mitigate viticulture GHG emissions is the use of cultivars already adapted to local conditions that require less inputs [

24,

31] and the reduction of energy requirements in a vineyard that are affected by size, topography, degree of mechanisation, and end-use of the grapes [

31,

32]. Currently, viticulture is gradually shifting to more sustainable production patterns [

33], with an increase of 230% of organic vineyards in Europe between 2007 and 2011 [

34]. A number of studies have been carried out comparing different types of viticulture techniques (i.e., organic, biodynamic, and conventional) in order to assess their environmental impacts through the life assessment approach [

25,

34,

35].

Vázquez-Rowe et al. (2012) [

36] implemented a combined LCA with data envelopment analysis (DEA), which is a suitable tool for assessing multiple input/output data in agrifood systems to determine the level of operational efficiency for grape production. They analysed 40 vineyards and found average reductions in input consumption levels ranging from 8% to 30%, average environmental gains from 28% to 39% for a set of six impact categories, and 10% average increase in economic benefits for inefficient units turning efficient. Rugani et al. (2013) [

25] carried out an extensive review on product carbon footprint (PCF) analyses of wine production, and observed methodological and conceptual limits and challenges behind wine PCF, but pointed out that indicating wine PCF may provide large benefits both to winemakers and consumers. Villanueva-Rey et al. (2014) [

35] performed a comparative LCA in biodynamic and conventional viticulture activities in North-western Spain and concluded that biodynamic production implies the lowest environmental burdens, while the highest environmental impacts were linked to conventional agricultural practices, mainly due to an 80% decrease in diesel inputs related to lower pesticide and fertilisers application and the introduction of manual work rather than mechanised activities in the vineyards. Rouault et al. (2016) [

34] compared organic and integrated viticultural technical management routes using LCA techniques, with the result that the studied organic route had higher impact scores than the integrated for all the chosen impact categories except eutrophication.

Venkat (2012) [

37] compared GHG emissions for 12 crop products, including wine grapes grown in organic and conventional farming systems. Results showed that converting to organic production may offer significant GHG reduction by increasing the soil organic carbon stocks during the transition phase and that conventional systems could improve their environmental performance by adopting management practices that increase soil organic carbon stocks. Aguilera et al. (2015) [

38] conducted research on a LCA of conventional and organic fruit tree orchards including vineyards in Spain, and concluded that machinery use in vineyards accounted for more than 60% of the total global warming potential. Litskas et al. (2017) [

23] determined the PCF of indigenous and introduced grape cultivars through LCA in Cyprus. They concluded that fertilizers and field energy use were the major carbon sources for viticulture. The application of animal manure instead of synthetic fertilizers and the reduction of tillage frequency could potentially reduce the PCF by 40–67%. They also concluded that PCF is affected mostly by the harvest yield (3–8% potential PCF change) [

21].

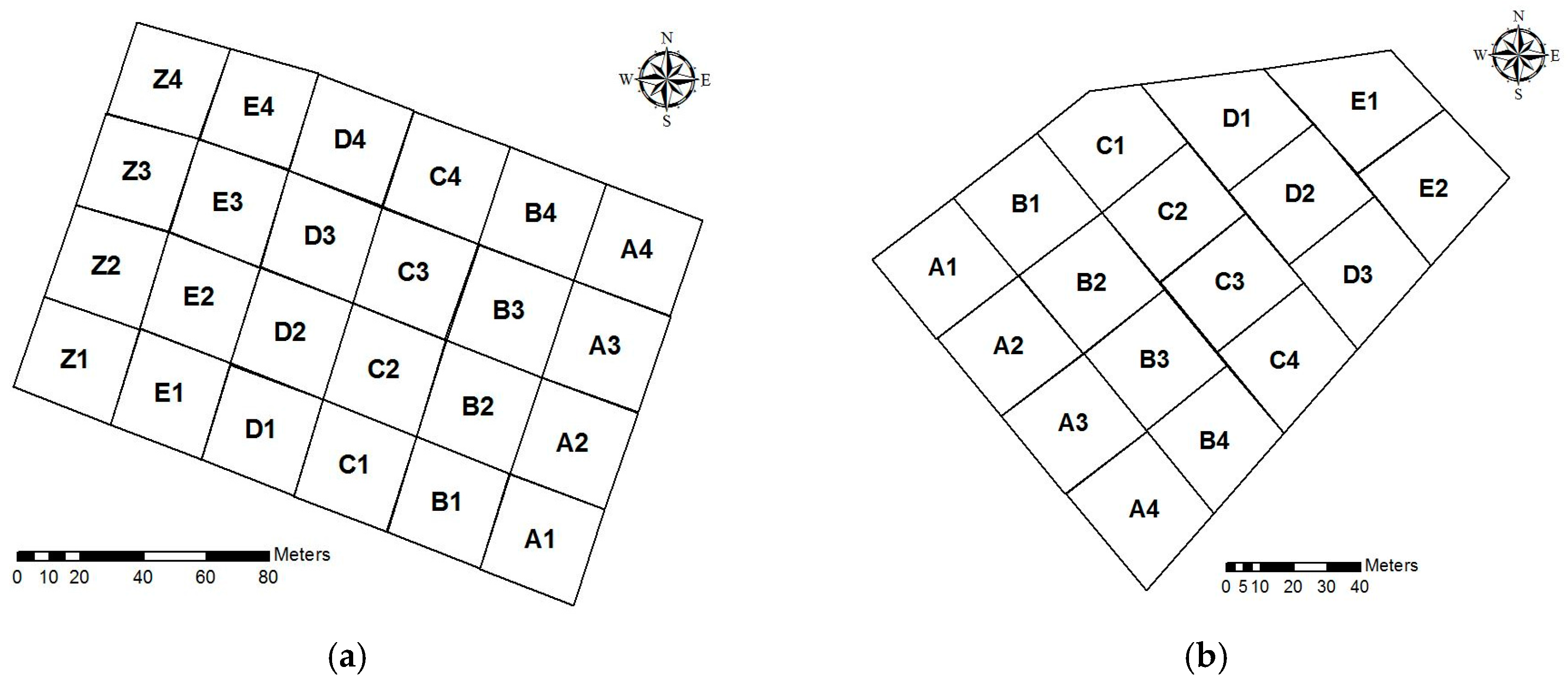

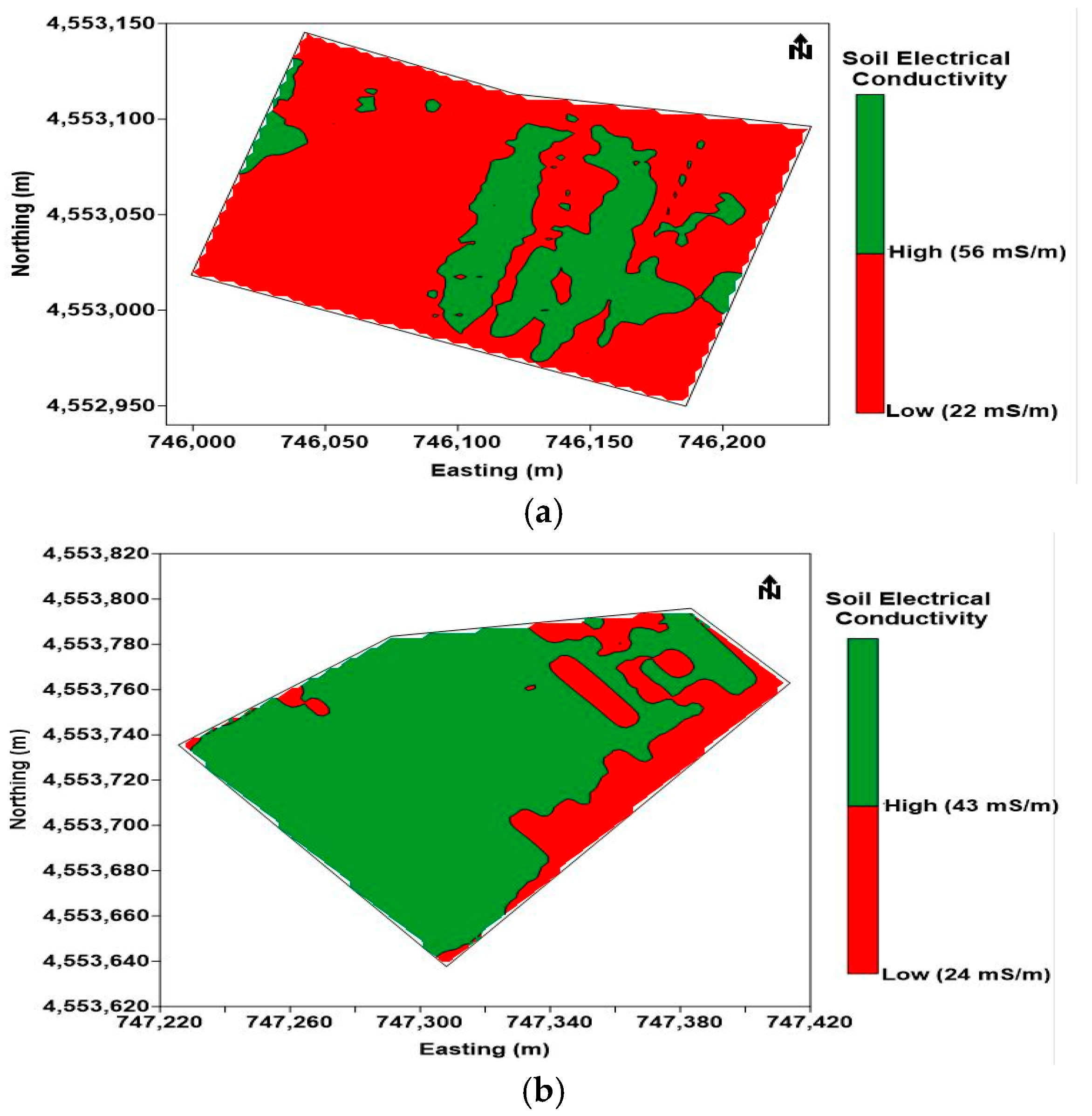

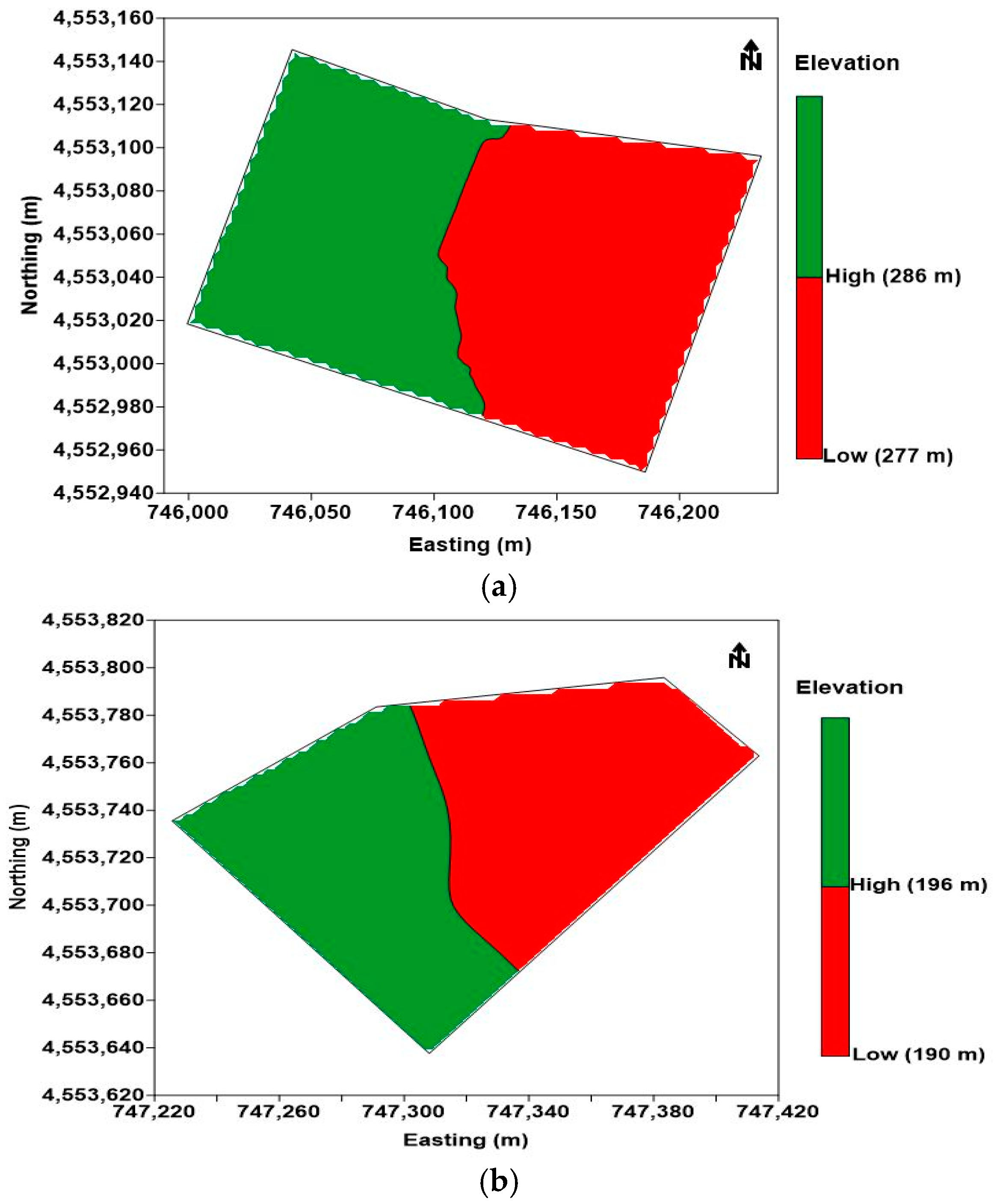

The environmental behaviour of viticultural systems could also be improved by the application of precision viticulture (PV) techniques. PV is a circular process which entails data collection, data analysis, decision-making about management, and evaluation of these decisions [

39]. In this way, the advantages of the vineyard variability in favour of the producer are fully exploited and the application of agricultural inputs (fuel, fertilisers, pesticides, water) is minimised for the maximum yield and quality of produced grapes [

40,

41]. However, the impact of PV on the environment and especially in GHG emissions has not received the attention deserved, with limited results in literature. Hence, in this study a comparative analysis between conventional and PV agricultural practices of two commercial vineyards planted with two different cultivars regarding GHG emissions was carried out in order to quantify in a deterministic basis the environmental benefits of PV in terms of GHG emissions. The structure of this work starts with the description of the vineyards’ input and output of conventional practices and continues with the methodology of delineating management zones that is accompanied with the inventory of PV practices. Subsequently, the methodology of LCA using the selected tool (Cool Farm Tool) is described and the results in product carbon footprint of both the conventional and PV vineyards is presented and discussed, ending with the final conclusions.

3. Results

3.1. Product Carbon Footprint of Sauvignon Blanc Vineyard

The PCF of the SB vineyard with conventional practices in the 2013 vintage reached 452.6 kg CO

2/t grapes. After PV practices for three consecutive growing seasons, the average PCF was 339.3 kg CO

2/t grapes, leading to a reduction of 113.3 kg CO

2eq/t grapes (25%), as shown in

Figure 7.

The paired sample

t-tests showed that PCF values were lower for all consecutive years in comparison to 2013, with

p < 0.05 statistical significance (95% confidence interval of the difference). As for the Q-tests, it was shown that the frequency of PCF values in the three consecutive seasons that were lower than the respective values in 2013 (shown as 0) was trending to significant over the three PV seasons (

Table 6).

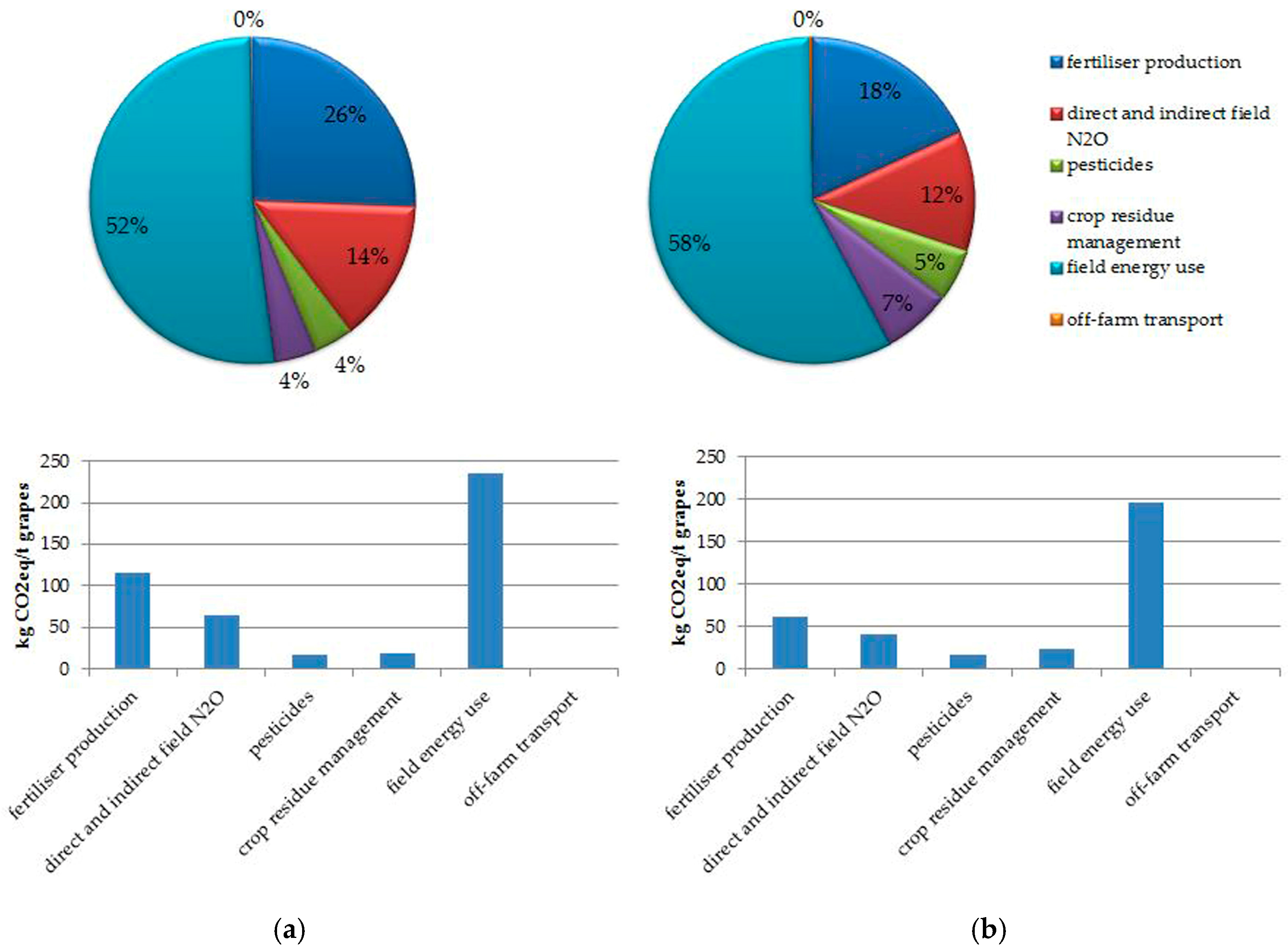

The distribution of emissions among the agricultural practices followed in both conventional viticulture of 2013 and PV as an average of three consecutive seasons using PV practices (2014–2016) are given in

Figure 8. The most significant activity regarding GHG emissions was field energy, which combines fuel for tractor use and electricity for irrigation in both conventional and PV practices, counting for 235.1 and 195.2 kg CO

2eq/t grapes, respectively (52% and 58% of the total GHG emissions). In 2013, the SB vineyard received numerous irrigation applications that contributed 212.9 kg CO

2eq/t grapes to GHG emissions and the average reduction of irrigated water by 16.7% after PV practices in the next three years reduced these emissions to 173.4 kg CO

2eq/t grapes, affecting total vineyard GHGs by 8.8%. Fuel use was almost unaffected, counting for 22.9 kg CO

2eq/t grapes (5% of total GHGs) in the 2013 vintage and 21.79 kg CO

2eq/t grapes (6.4% of total GHGs). This minor difference was due to yield increase.

Fertilizer production and distribution followed in importance in both conventional and the PV practices, reaching 115.8 (26%) and 61.5 kg CO2eq/t grapes (18%), respectively. The decrease of GHGs from this activity between conventional and PV practices was 46.9%. Direct and indirect N2O produced by nitrogen fertilizers and manure application was 64.2 kg CO2eq/t grapes (14.2%) and 40.5 kg CO2eq/t grapes (12%) of the GHG emissions in conventional and PV practices, respectively. Therefore, fertilization as a total (production and application) counted for 180 (40%) and 102 kg CO2eq/t grapes (30%) of the emissions in the SB vineyard following the two practices under study. It can be observed that even if fertilizer production and use was ranked second in importance after within-farm energy use, the reduction after PV techniques had an impact on the total GHG emissions of 17.2%—higher than energy use, showing the importance of precise fertilization in reducing direct and indirect GHG emissions.

Crop residues management emissions (soil incorporation of trimmed canes) was increased from 18.7 to 23.7 kg CO2eq/t grapes when moving from conventional to PV practices, counting for 4% and 7% of the total GHG emissions for each vintage. This result is due to the production of 29.8% more canes on average in the three PV vintages due to better use of nutrients and water after PV application. Pesticide application emissions were reduced minimally from 17.8 to 17.4 kg CO2eq/t grapes (6% for both practices), due to yield increase after PV practices. Finally, off-farm transportation was very low in both vintages, covering 0.2–0.3% of the total GHG emissions of the SB vineyard, because the vineyard under study is within the premises of the winery and transportation is limited to yield transport.

3.2. Product Carbon Footprint of Syrah Vineyard

The SY vineyard showed a different profile than the SB vineyard regarding PCF. In the 2013 vintage, the total GHG emissions were much lower in surface basis in comparison to the SB vineyard (3443.3 vs. 5744.1 kg CO

2/ha) due to less-intensive practices, but the yield was also significantly less (7 vs. 12.7 t/ha), leading to a higher final PCF for SY that reached 491.1 kg CO

2/t grapes in comparison to SB (452.6 kg CO

2/t grapes). After PV practices in the three consecutive vintages, the PCF was 351.9 kg CO

2/t grapes, which reduced emissions by 139.16 kg CO

2eq/t grapes (28.3%) as shown in

Figure 9.

The paired sample

t-tests showed that PCF values were lower for all consecutive years in comparison to 2013, with

p < 0.05 statistical significance (95% confidence interval of the difference). As for the Q-tests, it was shown that the frequency of PCF values in the three consecutive seasons that were lower than the respective values in 2013 (shown as 0) was not significantly different from the conventional method over the three PV seasons (

Table 7).

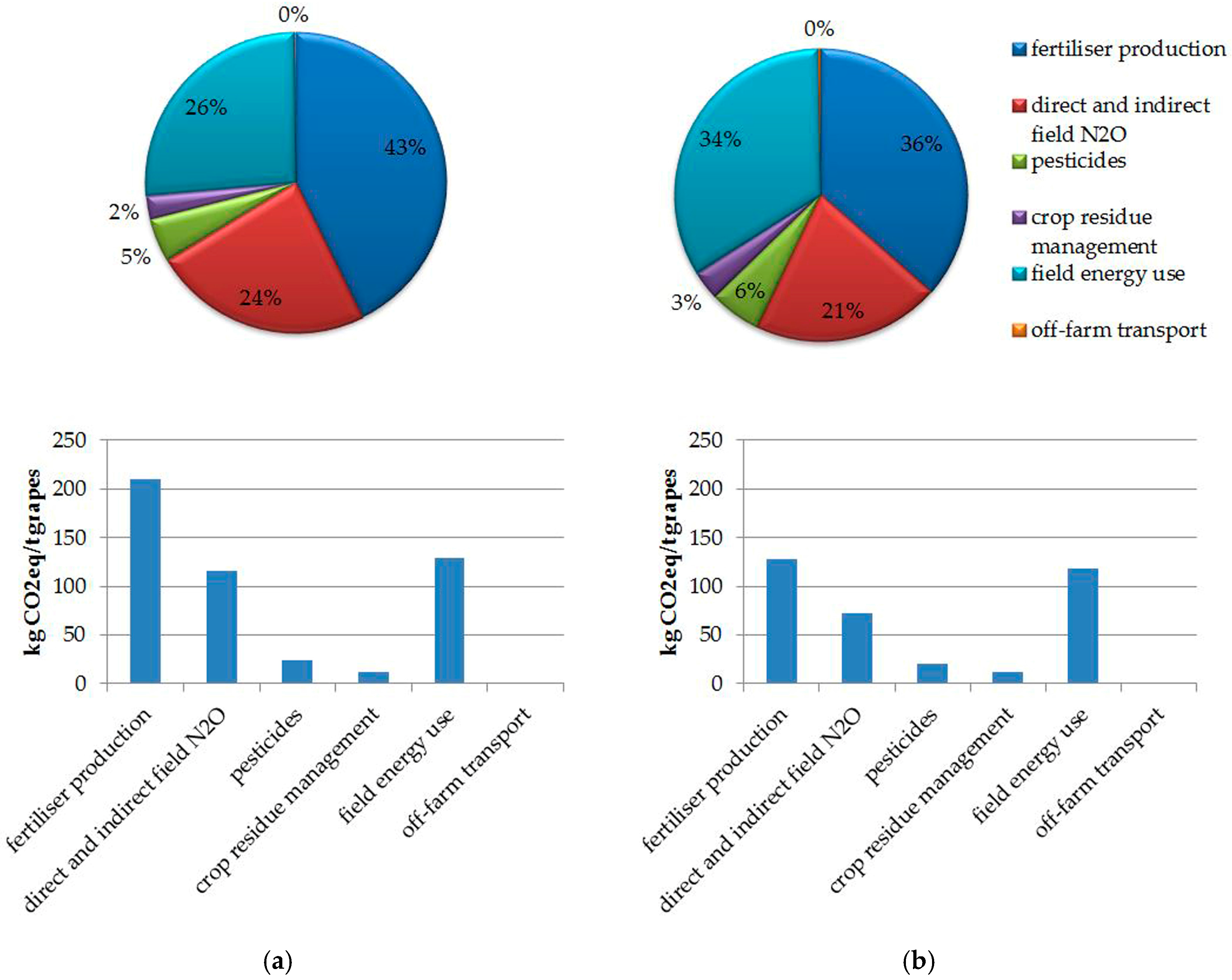

The distribution of emissions among the agricultural practices in the SY vineyard followed a different trend than the SB vineyard (

Figure 10). The reason was that SY received less tillage, pesticide application, and irrigation than SB, which decreased the impact of energy use (electricity and fuel) within the vineyard. Therefore, the most significant activity regarding GHG emissions was fertilizer production and distribution in both conventional and PV practices, reaching 209.5 kg CO

2eq/t grapes (42.7%) and 128.3 kg CO

2eq/t grapes (36.5%), respectively. The decrease of GHGs of this activity between conventional and PV practices was 38.7%.

Nitrogen fertilizers and manure application were also responsible for direct and indirect N2O emissions of 116.2 (23.7%) and 72.8 kg CO2eq/t grapes (20.7%) of the GHG emissions in conventional and PV practices. Hence, fertilization as a total (production and application) counted for 325.7 (66.3%) and 201.2 kg CO2eq/t grapes (57.2%) of the emissions in the SY vineyard following the two practices under study. The PV application reduced the impact of fertilizer use on the total GHG emissions by 25.4%, showing that in less-intensive vineyards precise fertilization can make an even greater difference in potential global warming mitigation.

Even if field energy is less important in terms of GHG emissions, it still plays a significant role in both conventional and PV practices, counting for 128.7 and 118.4 kg CO2eq/t grapes, respectively (26.2% and 33.6% of the total GHG emissions). It was observed that the increase in irrigation (8.3%) after PV techniques did not have a negative impact on the PCF, as the increase of yield (16%) compensated electricity augmentation for water pumping. As in SB, fuel use stayed almost unaffected, counting for 25.9 kg CO2eq/t grapes (5.3% of total GHGs) in 2013 vintage and 22.4 kg CO2eq/t grapes (6.5% of total GHGs).

Crop residues management emissions (soil incorporation of trimmed canes) decreased from 12.2 to 11.3 kg CO2eq/t grapes when moving from conventional to PV practices, counting for 2.5% and 3.2% of the total GHG emissions for each vintage. PV practices increased canes by 6.6% due to better use of nutrients and water, but yield increase (16%) reversed the situation. Pesticide application emissions were reduced from 23.4 to 20.2 kg CO2eq/t grapes (4.8% and 5.7% for each practice, respectively), due to yield increase during the PV practices. Similarly to SB, off-farm transportation covered 0.2–0.3% of the total GHG emissions of the SY vineyard, as it is only attributed to 5-km transport of grapes within the premises of the winery.

4. Discussion

This study compares the conventional practices that were carried out in one vintage period (2013) with PV practices that followed in the next three consecutive vintages (2014–2016). Differences in the average rainfall and temperatures between the vintages under study caused discrepancies in critical stages that were responsible for variations in the final yield, impacting the LCA calculations among the years. The fact that multiple growing seasons are examined—where the year effect cannot impact as a major factor in the LCA analysis—makes this work provide stable results based on average values of multi-seasonal variable rate application of nutrients and irrigation water. The importance of this study was to show the influence on the reduction of GHG emissions both from different vineyard cultivars in the same region that receive different numbers of operations, and also the effect of different management zones, which is the cornerstone of precision agriculture.

From the two vineyard cultivars under study applying variable rate fertilizers and irrigation water, it is evident that the main GHG reduction came from fertilizers and energy use. SB contribution to GHG emissions was significantly higher than SY on a surface basis (40%) using conventional practices (5744 kg CO

2eq/ha vs. 3443 kg CO

2eq/ha), because a larger number of practices was carried out in comparison to SY. This is an indication that presents the effect of a higher number of practices per vineyard cultivar in the reduction of GHGs. The decrease of the GHG emissions from both vineyards after PV practices on a surface basis (where the impact of yield is not included) was higher in SB (23%) than in SY (17%), reflecting the higher impact of less agricultural inputs in more intensive cultivation systems. Literature does not provide information on the global warming potential of precision viticulture practices. However, similar statements have been given by studies focusing on organic viticulture that is again a comparison between existing agricultural practices and a new production system, and could enforce the results of this paper. Rouault et al. (2016) pointed out that some emission models need to be improved to better assess the environmental impacts of viticulture and that soil quality should also be integrated in the analysis, as its absence may be a disadvantage for organic viticulture [

34]. This comes in accordance with Kavargiris et al. (2009), who found that GHGs were significantly higher in all cultivation practices except pruning in conventional viticulture compared to organic viticulture [

53]. Moreover, according to their study, pruning presented significantly higher GHG emissions in the organic viticulture. Rugani (2013) concluded that a wide range of issues related to wine PCF remain unexplored [

25]. In addition, Venkat (2012) indicated that vineyard machinery use accounted for more than 60% of the total global warming potential [

37]. The latter comes in accordance with Longbottom and Petrie (2015), who stated that fuel and electricity use are responsible for almost 98% of the total GHG emissions in viticulture [

54]. The average net global warming potential was 158 g CO

2eq/kg for conventional grapes and was reduced to 113 g CO

2eq/kg under organic management [

37]. Moreover, viticulture has the largest environmental impact in the whole wine value chain according to Neto et al. (2013) [

55].

This experimental work showed that applying variable rate application of fertilizers and water in a vineyard based on the actual requirements of different in-field zones can reduce significantly GHG emissions derived from viticulture. Such practices can show a potential for environmental benefits in combination with the positive results on quantitative and qualitative parameters. Therefore, research in PV should not only look at the effect in yield and optimization of resources, but also in the reduction of emissions, which is a vital part of the field variability. As stated above, studies focusing on the environmental impact of precision agriculture are very scarce, and future work should also look at this aspect apart from the agronomic and economic effects [

56].

5. Conclusions

Precision viticulture has evolved significantly in recent years, and it has indications of increasing the production quality and quantity, with a positive impact on vineyard economics as well. However, the environmental impact, and more specifically the potential effect on global warming from the application of such practices, was not analysed thoroughly in literature.

In this work, a life cycle assessment of the production system of two vineyards in Northern Greece planted with different cultivars of wine vines (Sauvignon Blanc and Syrah) was executed for two production systems during four growing seasons, where in 2013 conventional practices were applied and in the consecutive years (2014, 2015, and 2016) it was selected to regulate irrigation and fertilizer application according to precision viticulture techniques. Two management zones were delineated for each vineyard, and different water and fertilizer quantities were applied to each zone according to vigour analysis of the vines canopy. After assembling a detailed inventory of inputs and outputs of the vineyards for both conventional and PV practices, a deterministic analysis of the emitted GHG emissions from each agricultural practice was carried out, and suggested that PV application can significantly reduce GHG emission derived by wine grape production.